Auburn, IN

Three Rivers, MI

Jackson AMD, Ms

Gainsboro, TN

To TPM

六种损失对设备可生产时间的影响

8 小时

总机器可用时间

设备可用性角 度衡量

总可操作时间

6小时

停机损失

剩余操作时间

4.8小时

生产效率角度衡 量

速度损失

最终可操作时间 不良损失

3.2 小时

2. Observe proper "Lockout/Tagout" procedures when shutting down your equipment

for cleaning.

3. Systematically clean each part of the equipment using the checklist on the next

TPM Services

美国工厂 平均水平

30-45% OEE

55-70%

损失

隐藏的工厂

最大产

85% OEE 15%

损失

能

世界级

TPM Services

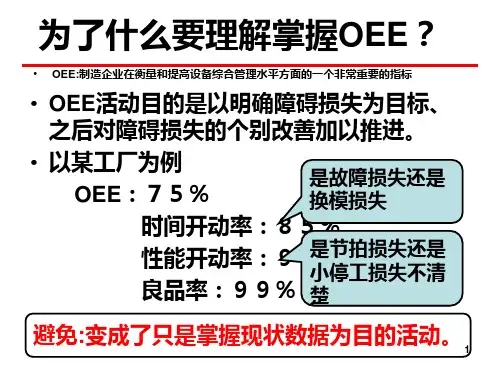

OEE

如何计算OEE

设备有效性 X 生产效率 X 质量结果

停机 换型 & 调整 其他

等待 & 微小停机 速度减缓

制程不良 开机或换型不良

提醒: OEE 衡量制造过程中的六种损失

page.

Note: An "abnormal condition" is defined as any condition within, or around the machine that affects the appearance and performance of the machine or production cell. a "normal condition" is defined as a condition in which the machine's appearance and performance is in "like new" condition and no waste is generated in time, resources, or materials. An abnormal condition can be a broken bolt, a leak, a worn or damaged part, it can also be a dirty part. As you document these conditions on your "Abnormality Summary Sheet" try and discover the reasons for them. Ask yourself the following questions: