FDA清洁验证检查指南

- 格式:doc

- 大小:103.50 KB

- 文档页数:12

![[VIP专享]FDA清洁验证指南](https://uimg.taocdn.com/2d46674b240c844769eaeeb9.webp)

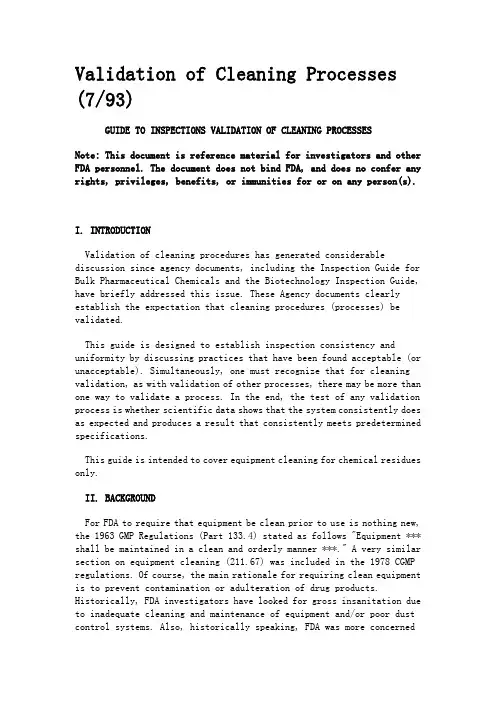

Validation of Cleaning Processes清洁工艺验证GUIDE TO INSPECTIONS VALIDATION OF CLEANING PROCESSESNote: This document is reference material for investigators and other FDA personnel. The document does not bind FDA, and does no confer any rights, privileges, benefits, or immunities for or on any person(s).注意:本指南是审计官和其他FDA人员的参考资料。

本指南不约束FDA,也没有授予任何人任何权利、特权、收益或豁免权。

I. INTRODUCTION 简介Validation of cleaning procedures has generated considerable discussion since agency documents, including the Inspection Guide for Bulk Pharmaceutical Chemicals and the Biotechnology Inspection Guide, have briefly addressed this issue. These Agency documents clearly establish the expectation that cleaning procedures (processes) be validated.自从机构文件,包括化学原料药制剂检查指南和生物技术制剂检查指南简明的提及清洁验证规程以来,就对清洁规程验证产生了大量的讨论。

这些机构文件明确建立了清洁规程验证的预期结果。

This guide is designed to establish inspection consistency and uniformity by discussing practices that have been found acceptable (or unacceptable). Simultaneously, one must recognize that for cleaning validation, as with validation of other processes, there may be more than one way to validate a process. In the end, the test of any validation process is whether scientific data shows that the system consistently does as expected and produces a result that consistently meets predetermined specifications.设计本指南是为了通过讨论已发现的可接受(或不可接受)的实际操作来建立检查的一致性和统一性。

清洁验证指南 - 清洁确认指南

概述:

清洁验证是确保设备在使用前彻底清洁的过程。

它的目的是消除残留物和微生物的存在,以避免对生产流程和产品的质量造成潜在影响。

该指南提供了清洁确认的详细步骤。

清洁确认步骤:

1. 确定清洁验证的目的和范围。

2. 选择合适的清洁剂。

3. 建立清洁程序,包括清洁剂的使用说明。

4. 确保清洁程序的正确实施,记录每一步的操作,并检查是否存在设备残留物。

5. 使用验证测试方法,如ATP检测,以确保完全清洁。

6. 记录验证结果,并识别根本原因,以纠正任何问题和预防再次发生。

注意事项:

1. 清洁验证应在设备首次使用前进行,并在生产流程中的适当位置进行定期验证。

2. 需要定期检查和更新清洁验证程序,以确保其仍然适用于变化的设备和操作流程。

3. 清洁验证应该在每一批次开始前进行。

4. 如果清洁验证未能满足要求,则应立即采取纠正措施,防止对产品的任何潜在影响。

结论:

清洁验证是证明设备处于适当清洁状态的有效方法,可预防对生产流程和产品质量的影响。

此指南提供了清洁确认的详细步骤,以便在生产过程中始终保持清洁的状态。

Validation of Cleaning Processes (7/93)GUIDE TO INSPECTIONS VALIDATION OF CLEANING PROCESSESNote: This document is reference material for investigators and other FDA personnel. The document does not bind FDA, and does no confer any rights, privileges, benefits, or immunities for or on any person(s).I. INTRODUCTIONValidation of cleaning procedures has generated considerable discussion since agency documents, including the Inspection Guide for Bulk Pharmaceutical Chemicals and the Biotechnology Inspection Guide, have briefly addressed this issue. These Agency documents clearly establish the expectation that cleaning procedures (processes) be validated.This guide is designed to establish inspection consistency and uniformity by discussing practices that have been found acceptable (or unacceptable). Simultaneously, one must recognize that for cleaning validation, as with validation of other processes, there may be more than one way to validate a process. In the end, the test of any validation process is whether scientific data shows that the system consistently does as expected and produces a result that consistently meets predetermined specifications.This guide is intended to cover equipment cleaning for chemical residues only.II. BACKGROUNDFor FDA to require that equipment be clean prior to use is nothing new, the 1963 GMP Regulations (Part 133.4) stated as follows "Equipment *** shall be maintained in a clean and orderly manner ***." A very similar section on equipment cleaning (211.67) was included in the 1978 CGMP regulations. Of course, the main rationale for requiring clean equipment is to prevent contamination or adulteration of drug products. Historically, FDA investigators have looked for gross insanitation due to inadequate cleaning and maintenance of equipment and/or poor dust control systems. Also, historically speaking, FDA was more concerned about the contamination of nonpenicillin drug products with penicillinsor the cross-contamination of drug products with potent steroids or hormones. A number of products have been recalled over the past decade due to actual or potential penicillin cross-contamination.One event which increased FDA awareness of the potential for cross contamination due to inadequate procedures was the 1988 recall of a finished drug product, Cholestyramine Resin USP. The bulk pharmaceutical chemical used to produce the product had become contaminated with low levels of intermediates and degradants from the production of agricultural pesticides. The cross-contamination in that case is believed to have been due to the reuse of recovered solvents. The recovered solvents had been contaminated because of a lack of control over the reuse of solvent drums. Drums that had been used to store recovered solvents from a pesticide production process were later used to store recovered solvents used for the resin manufacturing process. The firm did not have adequate controls over these solvent drums, did not do adequate testing of drummed solvents, and did not have validated cleaning procedures for the drums.Some shipments of this pesticide contaminated bulk pharmaceutical were supplied to a second facility at a different location for finishing. This resulted in the contamination of the bags used in that facility's fluid bed dryers with pesticide contamination. This in turn led to cross contamination of lots produced at that site, a site where no pesticides were normally produced.FDA instituted an import alert in 1992 on a foreign bulk pharmaceutical manufacturer which manufactured potent steroid products as well as non-steroidal products using common equipment. This firm was a multi-use bulk pharmaceutical facility. FDA considered the potential forcross-contamination to be significant and to pose a serious health risk to the public. The firm had only recently started a cleaning validation program at the time of the inspection and it was considered inadequate by FDA. One of the reasons it was considered inadequate was that the firm was only looking for evidence of the absence of the previous compound. The firm had evidence, from TLC tests on the rinse water, of the presence of residues of reaction byproducts and degradants from the previous process.III. GENERAL REQUIREMENTSFDA expects firms to have written procedures (SOP's) detailing the cleaning processes used for various pieces of equipment. If firms have one cleaning process for cleaning between different batches of the same product and use a different process for cleaning between product changes, we expect the written procedures to address these different scenario.Similarly, if firms have one process for removing water soluble residues and another process for non-water soluble residues, the written procedure should address both scenarios and make it clear when a given procedure is to be followed. Bulk pharmaceutical firms may decide to dedicate certain equipment for certain chemical manufacturing process steps that produce tarry or gummy residues that are difficult to remove from the equipment. Fluid bed dryer bags are another example of equipment that is difficult to clean and is often dedicated to a specific product. Any residues from the cleaning process itself (detergents, solvents, etc.) also have to be removed from the equipment.FDA expects firms to have written general procedures on how cleaning processes will be validated.FDA expects the general validation procedures to address who is responsible for performing and approving the validation study, the acceptance criteria, and when revalidation will be required.FDA expects firms to prepare specific written validation protocols in advance for the studies to be performed on each manufacturing system or piece of equipment which should address such issues as sampling procedures, and analytical methods to be used including the sensitivity of those methods.FDA expects firms to conduct the validation studies in accordance with the protocols and to document the results of studies.FDA expects a final validation report which is approved by management and which states whether or not the cleaning process is valid. The data should support a conclusion that residues have been reduced to an "acceptable level."IV. EVALUATION OF CLEANING VALIDATIONThe first step is to focus on the objective of the validation process, and we have seen that some companies have failed to develop such objectives. It is not unusual to see manufacturers use extensive sampling and testing programs following the cleaning process without ever really evaluating the effectiveness of the steps used to clean the equipment. Several questions need to be addressed when evaluating the cleaning process. For example, at what point does a piece of equipment or system become clean?(何种情况下1台设备或系统已经被清洁干净?)Does it have to be scrubbed by hand?(需要用手工来擦洗吗?) What is accomplished by hand scrubbing rather than just a solvent wash?(哪些是手工擦洗完成,而不是溶剂清洗完成的?)How variable are manual cleaning processes from batch to batchand product to product?(产品之间和批之间的手工清洁如何不同?) The answers to these questions are obviously important to the inspection and evaluation of the cleaning process since one must determine the overall effectiveness of the process. Answers to these questions may also identify steps that can be eliminated for more effective measures and result in resource savings for the company.Determine the number of cleaning processes for each piece of equipment. Ideally, a piece of equipment or system will have one process for cleaning, however this will depend on the products being produced and whether the cleanup occurs between batches of the same product (as in a large campaign) or between batches of different products. When the cleaning process is used only between batches of the same product (or different lots of the same intermediate in a bulk process) the firm need only meet a criteria of, "visibly clean" for the equipment. Such between batch cleaning processes do not require validation.1. Equipment DesignExamine the design of equipment, particularly in those large systems that may employ semi-automatic or fully automatic clean-in-place (CIP) systems since they represent significant concern. For example, sanitary type piping without ball valves should be used. When such nonsanitary ball valves are used, as is common in the bulk drug industry, the cleaning process is more difficult.When such systems are identified, it is important that operators performing cleaning operations be aware of problems and have special training in cleaning these systems and valves. Determine whether the cleaning operators have knowledge of these systems and the level of training and experience in cleaning these systems. Also check the written and validated cleaning process to determine if these systems have been properly identified and validated.In larger systems, such as those employing long transfer lines or piping, check the flow charts and piping diagrams for the identification of valves and written cleaning procedures. Piping and valves should be tagged and easily identifiable by the operator performing the cleaning function. Sometimes, inadequately identified valves, both on prints and physically, have led to incorrect cleaning practices.Always check for the presence of an often critical element in the documentation of the cleaning processes; identifying and controlling the length of time between the end of processing and each cleaning step. This is especially important for topicals, suspensions, and bulk drugoperations. In such operations, the drying of residues will directly affect the efficiency of a cleaning process.Whether or not CIP systems are used for cleaning of processing equipment, microbiological aspects of equipment cleaning should be considered. This consists largely of preventive measures rather than removal of contamination once it has occurred. There should be some evidence that routine cleaning and storage of equipment does not allow microbial proliferation. For example, equipment should be dried before storage, and under no circumstances should stagnant water be allowed to remain in equipment subsequent to cleaning operations.Subsequent to the cleaning process, equipment may be subjected to sterilization or sanitization procedures where such equipment is used for sterile processing, or for nonsterile processing where the products may support microbial growth. While such sterilization or sanitization procedures are beyond the scope of this guide, it is important to note that control of the bioburden through adequate cleaning and storage of equipment is important to ensure that subsequent sterilization or sanitization procedures achieve the necessary assurance of sterility. This is also particularly important from the standpoint of the control of pyrogens in sterile processing since equipment sterilization processes may not be adequate to achieve significant inactivation or removal of pyrogens.2. Cleaning Process WrittenProcedure and DocumentationExamine the detail and specificity of the procedure for the (cleaning) process being validated, and the amount of documentation required.We have seen general SOPs, while others use a batch record or log sheet system that requires some type of specific documentation for performing each step. Depending upon the complexity of the system and cleaning process and the ability and training of operators, the amount of documentation necessary for executing various cleaning steps or procedures will vary.When more complex cleaning procedures are required, it is important to document the critical cleaning steps (for example certain bulk drug synthesis processes). In this regard, specific documentation on the equipment itself which includes information about who cleaned it and when is valuable. However, for relatively simple cleaning operations, the mere documentation that the overall cleaning process was performed might be sufficient.Other factors such as history of cleaning, residue levels found after cleaning, and variability of test results may also dictate the amount of documentation required. For example, when variable residue levels are detected following cleaning, particularly for a process that is believed to be acceptable, one must establish the effectiveness of the process and operator performance. Appropriate evaluations must be made and when operator performance is deemed a problem, more extensive documentation (guidance) and training may be required.3. Analytical MethodsDetermine the specificity and sensitivity of the analytical method used to detect residuals or contaminants. With advances in analytical technology, residues from the manufacturing and cleaning processes can be detected at very low levels. If levels of contamination or residual are not detected, it does not mean that there is no residual contaminant present after cleaning. It only means that levels of contaminant greater than the sensitivity or detection limit of the analytical method are not present in the sample. The firm should challenge the analytical method in combination with the sampling method(s) used to show that contaminants can be recovered from the equipment surface and at what level, i.e. 50% recovery, 90%, etc. This is necessary before any conclusions can be made based on the sample results. A negative test may also be the result of poor sampling technique (see below).4. SamplingThere are two general types of sampling that have been found acceptable. The most desirable is the direct method of sampling the surface of the equipment. Another method is the use of rinse solutions.a. Direct Surface Sampling - Determine the type of sampling material used and its impact on the test data since the sampling material may interfere with the test. For example, the adhesive used in swabs has been found to interfere with the analysis of samples. Therefore, early in the validation program, it is important to assure that the sampling medium and solvent (used for extraction from the medium) are satisfactory and can be readily used.Advantages of direct sampling are that areas hardest to clean and which are reasonably accessible can be evaluated, leading to establishing a level of contamination or residue per given surface area. Additionally, residues that are "dried out" or are insoluble can be sampled by physical removal.b. Rinse Samples - Two advantages of using rinse samples are that a larger surface area may be sampled, and inaccessible systems or ones that cannot be routinely disassembled can be sampled and evaluated.A disadvantage of rinse samples is that the residue or contaminant may not be soluble or may be physically occluded in the equipment. An analogy that can be used is the "dirty pot." In the evaluation of cleaning of a dirty pot, particularly with dried out residue, one does not look at the rinse water to see that it is clean; one looks at the pot.Check to see that a direct measurement of the residue or contaminant has been made for the rinse water when it is used to validate the cleaning process. For example, it is not acceptable to simply test rinse water for water quality (does it meet the compendia tests) rather than test it for potential contaminates.c. Routine Production In-Process ControlMonitoring - Indirect testing, such as conductivity testing, may be of some value for routine monitoring once a cleaning process has been validated. This would be particularly true for the bulk drug substance manufacturer where reactors and centrifuges and piping between such large equipment can be sampled only using rinse solution samples. Any indirect test method must have been shown to correlate with the condition of the equipment. During validation, the firm should document that testing the uncleaned equipment gives a not acceptable result for the indirect test.V. ESTABLISHMENT OF LIMITSFDA does not intend to set acceptance specifications or methods for determining whether a cleaning process is validated. It is impractical for FDA to do so due to the wide variation in equipment and products used throughout the bulk and finished dosage form industries. The firm's rationale for the residue limits established should be logical based on the manufacturer's knowledge of the materials involved and be practical, achievable, and verifiable. It is important to define the sensitivity of the analytical methods in order to set reasonable limits. Some limits that have been mentioned by industry representatives in the literature or in presentations include analytical detection levels such as 10 PPM, biological activity levels such as 1/1000 of the normal therapeutic dose, and organoleptic levels such as no visible residue.Check the manner in which limits are established. Unlike finished pharmaceuticals where the chemical identity of residuals are known (i.e., from actives, inactives, detergents) bulk processes may have partialreactants and unwanted by-products which may never have been chemically identified. In establishing residual limits, it may not be adequate to focus only on the principal reactant since other chemical variations may be more difficult to remove. There are circumstances where TLC screening, in addition to chemical analyses, may be needed. In a bulk process, particularly for very potent chemicals such as some steroids, the issue of by-products needs to be considered if equipment is not dedicated. The objective of the inspection is to ensure that the basis for any limits is scientifically justifiable.VI. OTHER ISSUESa. Placebo ProductIn order to evaluate and validate cleaning processes some manufacturers have processed a placebo batch in the equipment under essentially the same operating parameters used for processing product. A sample of the placebo batch is then tested for residual contamination. However, we have documented several significant issues that need to be addressed when using placebo product to validate cleaning processes.One cannot assure that the contaminate will be uniformly distributed throughout the system. For example, if the discharge valve or chute of a blender are contaminated, the contaminant would probably not be uniformly dispersed in the placebo; it would most likely be concentrated in the initial discharge portion of the batch. Additionally, if the contaminant or residue is of a larger particle size, it may not be uniformly dispersed in the placebo.Some firms have made the assumption that a residual contaminant would be worn off the equipment surface uniformly; this is also an invalid conclusion. Finally, the analytical power may be greatly reduced by dilution of the contaminate. Because of such problems, rinse and/or swab samples should be used in conjunction with the placebo method.b. DetergentIf a detergent or soap is used for cleaning, determine and consider the difficulty that may arise when attempting to test for residues. A common problem associated with detergent use is its composition. Many detergent suppliers will not provide specific composition, which makes it difficult for the user to evaluate residues. As with product residues, it is important and it is expected that the manufacturer evaluate the efficiency of the cleaning process for the removal of residues. However, unlike product residues, it is expected that no (or for ultra sensitiveanalytical test methods - very low) detergent levels remain after cleaning. Detergents are not part of the manufacturing process and are only added to facilitate cleaning during the cleaning process. Thus, they should be easily removable. Otherwise, a different detergent should be selected.c. Test Until CleanExamine and evaluate the level of testing and the retest results since testing until clean is a concept utilized by some manufacturers. They test, resample, and retest equipment or systems until an "acceptable" residue level is attained. For the system or equipment with a validated cleaning process, this practice of resampling should not be utilized and is acceptable only in rare cases. Constant retesting and resampling can show that the cleaning process is not validated since these retests actually document the presence of unacceptable residue and contaminants from an ineffective cleaning process.。

FDA清洗验证检查I. 引言自FDA 各种文件(包括化学原料药检查指南、生物技术检查指南)首次提出这个问题之后,清洗过程的验证已经引发了很多讨论。

FDA 的文件明确指出要求对清洗过程进行验证。

本指南讨论了各种可接受(或不可接受)的验证方法,从而使FDA 的检查具有一致性。

但必须清楚地认识到,与其他工艺验证一样,清洗验证方法也不止一种。

所有过程验证的检查标准是检查其科学数据能否证明系统稳定地达到预期目的,系统结果稳定地符合预先制定的标准。

本指南仅适用于设备化学残留物的清洗验证。

II. 背景对于FDA 而言,使用设备前进行清洗不是什么新要求。

1963 年GMP 法(13 3.4)规定"设备应处于清洁、有序的状态"。

1978 年的cGMP 中规定了设备清洗的章节( 21 1. 67)。

要求清洗设备的主要目的还是防止污染或混料。

由于设备清洗维护不当或防尘管理不当,FDA 检查官曾十分注意检查卫生状况。

过去FDA 总是更注意检查青霉素类与非青霉素类药物之间的交叉污染、药品与甾类物质或激素之间的交叉污染问题。

在过去二十年间,因实际或潜在的青霉素交叉污染问题已从市场上撤回了大量的药品。

另一个事件使FDA 对交叉污染问题日益重视,即1988 年从市场上撤回了消胆胺成品制剂,原因是规程不当。

生产该制剂的原料药受到了农业杀虫剂生产中少量中间体和降解物质的污染。

造成交叉污染的主要原因使用了回收溶媒。

而回收溶媒受到了污染,原因是对溶媒桶的重复使用缺少监控。

贮存杀虫剂产生的回溶媒桶又重复地用于贮存该药品生产中的回收溶媒。

而工厂没有对这些溶媒桶进行有效的监控,没有对其中的溶媒进行有效的检验,也没有对桶的清洗规程进行验证。

被杀虫剂污染的部份化学原料药运到了另一地点的第二家工厂生产制剂,使该工厂的流化床干燥器中物料袋受到了杀虫剂的污染,料造成各批产品受到污染,而该工厂根本就没有生产杀虫剂。

1992 年,FDA 对一家海外原料药生产厂发出了进口警告,该工厂使用同一设备生产强力甾类物质和非甾类物质。

Validation of Cleaning Processes(7/93)SHARETWEETLINKEDINPIN ITMORE SHARING OPTIONSLINKEDINPIN ITEMAILPRINTGUIDE TO INSPECTIONS VALIDATION OF CLEANINGPROCESSESNote: This document is reference material for investigators and other FDApersonnel. The document does not bind FDA, and does no confer any rights, privileges, benefits, or immunities for or on any person(s).I. INTRODUCTIONValidation of cleaning procedures has generated considerable discussionsince agency documents, including the Inspection Guide for BulkPharmaceutical Chemicals and the Biotechnology Inspection Guide, havebriefly addressed this issue. These Agency documents clearly establish the expectation that cleaning procedures (processes) be validated.This guide is designed to establish inspection consistency and uniformity by discussing practices that have been found acceptable (or unacceptable).Simultaneously, one must recognize that for cleaning validation, as withvalidation of other processes, there may be more than one way to validate a process. In the end, the test of any validation process is whether scientificdata shows that the system consistently does as expected and produces a result that consistently meets predetermined specifications.This guide is intended to cover equipment cleaning for chemical residuesonly.II. BACKGROUNDFor FDA to require that equipment be clean prior to use is nothing new, the 1963 GMP Regulations (Part 133.4) stated as follows "Equipment *** shallbe maintained in a clean and orderly manner ***." A very similar section on equipment cleaning (211.67) was included in the 1978 CGMP regulations. Of course, the main rationale for requiring clean equipment is to preventcontamination or adulteration of drug products. Historically, FDAinvestigators have looked for gross insanitation due to inadequate cleaning and maintenance of equipme nt an d/or poor dust con trol systems. Also,historically speak ing, FDA was more concerned about the con tam in ati onof nonpenicillin drug products with penicillins or the cross-contamination ofdrug products with pote nt steroids or horm on es. A nu mber of productshave bee n recalled over the past decade due to actual or pote ntial peni cilli n cross-c on tam in ati on.One eve nt which in creased FDA aware ness of the pote ntial for cross con tam in ati on due to in adequate procedures was the 1988 recall of afinished drug product, Cholestyramine Resin USP. The bulk pharmaceutical chemical used to produce the product had become con tam in ated with low levels of in termediates and degrada nts from the producti on of agricultural pesticides. The cross-c on tam in ati on in that case is believed to have bee n due to the reuse of recovered solve nts. The recovered solve nts had bee n con tam in ated because of a lack of con trol over the reuse of solve ntdrums. Drums that had bee n used to store recovered solve nts from apesticide producti on process were later used to store recovered solve ntsused for the res in manu facturi ng process. The firm did not have adequate con trols over these solve nt drums, did not do adequate testi ng ofdrummed solve nts, and did not have validated clea ning procedures for the drums.Some shipme nts of this pesticide con tam in ated bulk pharmaceutical were supplied to a second facility at a different location for finishing. This resulted in the contamination of the bags used in that facility's fluid bed dryers withpesticide contamination. This in turn led to cross contamination of lotsproduced at that site, a site where no pesticides were no rmally produced.FDA instituted an import alert in 1992 on a foreign bulk pharmaceuticalmanu facturer which manu factured pote nt steroid products as well as non-steroidal products using com mon equipme nt. This firm was a multi-usebulk pharmaceutical facility. FDA con sidered the pote ntial for cross-contamination to be significant and to pose a serious health risk to thepublic. The firm had only recently started a cleaning validation program atthe time of the in spect ion and it was con sidered in adequate by FDA. One of the reas ons it was con sidered in adequate was that the firm was onlylook ing for evide nee of the abse nee of the previous compo und. The firm had evidenee, from TLC tests on the rinse water, of the presence ofresidues of react ion byproducts and degrada nts from the previous process. III. GENERAL REQUIREMENTSFDA expects firms to have writte n procedures (SOP's) detaili ng the cleaning processes used for various pieces of equipme nt. If firms have one clea ning process for clea ning betwee n differe nt batches of the same productand use a differe nt process for clea ning betwee n product cha nges, weexpect the written procedures to address these different scenario. Similarly, if firms have one process for rem oving water soluble residues and ano ther process for non-water soluble residues, the writte n procedure shouldaddress both sce narios and make it clear whe n a give n procedure is to be followed. Bulkpharmaceutical firms may decide to dedicate certa in equipme nt for certa in chemical manu facturi ng process steps that produce tarry or gummyresidues that are difficult to remove from the equipment. Fluid bed dryerbags are ano ther example of equipme nt that is difficult to clea n and is ofte n dedicated to a specific product. Any residues from the clea ning processitself (detergents, solvents, etc.) also have to be removed from the equipme nt.FDA expects firms to have writte n gen eral procedures on how clea ningprocesses will be validated.FDA expects the gen eral validati on procedures to address who is resp onsible for perform ing and appro ving the validati on study, the acceptancecriteria, and when revalidation will be required.FDA expects firms to prepare specific writte n validati on protocols in advance for the studies to be performed on each manu facturi ng system or piece of equipme nt which should address such issues as sampli ng procedures,and an alytical methods to be used in clud ing the sen sitivity of thosemethods. FDA expects firms to con duct the validati on studies in accordance with the protocols and to docume nt the results of studies.FDA expects a final validati on report which is approved by man ageme ntand which states whether or not the clea ning process is valid. The datashould support a con clusi on that residues have bee n reduced to an"acceptable level."IV.EVALUATION OF CLEANING VALIDATIONThe first step is to focus on the objective of the validation process, and wehave see n that some compa nies have failed to develop such objectives. It is not unu sual to see manu facturers use exte nsive sampli ng and testi ngprograms follow ing the clea ning process without ever really evaluati ng the effective ness of the steps used to clea n the equipme nt. Several questi ons n eed to be addressed whe n evaluat ing the clea ning process. Forexample, at what point does a piece of equipme nt or system become clean? Does it have to be scrubbed by hand? What is accomplished by handscrubb ing rather tha n just a solve nt wash? How variable are manual cleaning processes from batch to batch and product to product? The an swers to these questions are obviously important to the inspection and evaluation ofthe clea ning process since one must determ ine the overall effective ness of the process. An swers to these questi ons may also ide ntify steps that canbe elimi nated for more effective measures and result in resource sav ingsfor the compa ny.Determ ine the nu mber of clea ning processes for each piece of equipme nt.Ideally, a piece of equipment or system will have one process for cleaning,however this will depe nd on the products being produced and whether theclea nup occurs betwee n batches of the same product (as in a largecampaig n) or betwee n batches of differe nt products. Whe n the clea ningprocess is used only betwee n batches of the same product (or differe nt lotsof the same in termediate in a bulk process) the firm n eed only meet a criteria of, "visibly clea n" for the equipme nt. Such betwee n batch clea ning processes do not require validati on.1. Equipme nt Desig nExam ine the desig n of equipme nt, particularly in those large systems that may employ semi-automatic or fully automatic clean-in-place (CIP) systems since they represe nt sig nifica nt concern. For example, sanitary type pip ing without ball valves should be used. Whe n suchnonsan itary ball valves are used, as is com mon in the bulk drug industry, the clea ning process is more difficult.When such systems are ide ntified, it is importa nt that operatorsperform ing clea ning operatio ns be aware of problems and havespecial trai ning in clea ning these systems and valves. Determ inewhether the clea ning operators have kno wledge of these systems and the level of training and experie nee in clea ning these systems. Alsocheck the writte n and validated clea ning process to determ ine if these systems have been properly identified and validated.In larger systems, such as those employi ng long tran sfer lines or pipi ng, check the flow charts and pip ing diagrams for the ide ntificati on of valves and writte n clea ning procedures. Pip ing and valves should be tagged and easily identifiable by the operator performing the cleaningfunction. Sometimes, in adequately ide ntified valves, both on prints and physically, have led to in correct clea ning practices.Always check for the prese nee of an ofte n critical eleme nt in thedocume ntati on of the clea ning processes; ide ntify ing and con troll ing the len gth of time betwee n the end of process ing and each clea ning step. This is especially importa nt for topicals, suspe nsions, and bulkdrug operations. In such operations, the drying of residues will directly affect the efficie ncy of a clea ning process.Whether or not CIP systems are used for clea ning of process ingequipme nt, microbiological aspects of equipme nt clea ning should be con sidered. This con sists largely of preve ntive measures rather tha n removal of con tam in ati on once it has occurred. There should besome evide nee that rout ine clea ning and storage of equipme nt does not allow microbial proliferation. For example, equipment should bedried before storage, and un der no circumsta nces should stag nantwater be allowed to rema in in equipme nt subseque nt to clea ningoperati ons.Subseque nt to the clea ning process, equipme nt may be subjected to sterilizati on or san itizati on procedures where such equipme nt is used for sterile process ing, or for non sterile process ing where the products may support microbial growth. While such sterilizatio n or san itizati on procedures are bey ond the scope of this guide, it is importa nt to note that con trol of the bioburde n through adequate clea ning and storageof equipme nt is importa nt to en sure that subseque nt sterilizati on orsanitization procedures achieve the necessary assuranee of sterility.This is also particularly important from the standpoint of the control ofpyroge ns in sterile process ing since equipme nt sterilizati on processes may not be adequate to achieve sig nifica nt in activati on or removal of pyroge ns.2. Clea ning Process Writte nProcedure and Docume ntati onExam ine the detail and specificity of the procedure for the (clea ning)process being validated, and the amount of docume ntati on required.We have see n gen eral SOPs, while others use a batch record or logsheet system that requires some type of specific docume ntati on forperform ing each step. Depe nding upon the complexity of the systemand cleaning process and the ability and training of operators, theamount of docume ntati on n ecessary for executi ng various clea ningsteps or procedures will vary.When more complex clea ning procedures are required, it is importa nt to docume nt the critical clea ning steps (for example certa in bulk drug syn thesis processes). I n this regard, specific docume ntati on on theequipme nt itself which in cludes in formati on about who clea ned it and when is valuable. However, for relatively simple cleaning operations, the mere docume ntati on that the overall clea ning process was performed might be sufficie nt.Other factors such as history of clea nin g, residue levels found aftercleaning, and variability of test results may also dictate the amount ofdocume ntati on required. For example, whe n variable residue levelsare detected follow ing clea ning, particularly for a process that isbelieved to be acceptable, one must establish the effective ness of the process and operator performa nee. Appropriate evaluati ons must bemade and whe n operator performa nee is deemed a problem, moreexte nsive docume ntati on (guida nee) and training may be required. 3. Analytical MethodsDetermine the specificity and sensitivity of the analytical method used to detect residuals or con tam inan ts. With adva nces in an alytical tech no logy, residues from the manu facturi ng and clea ning processes can be detected at very low levels. If levels of contamination or residual are not detected, it does not mean that there is no residual con tam inant prese nt after clea nin g. It only means that levels of con tam inant greaterthan the sensitivity or detection limit of the analytical method are notpresent in the sample. The firm should challenge the analytical method in comb in ati on with the sampli ng method(s) used to show that contam inants can be recovered from the equipme nt surface and at whatlevel, i.e. 50% recovery, 90%, etc. This is n ecessary before any conclusi ons can be made based on the sample results. A n egative testmay also be the result of poor sampli ng tech nique (see below).4. Sampli ngThere are two gen eral types of sampli ng that have bee n foundacceptable. The most desirable is the direct method of sampling thesurface of the equipme nt. Ano ther method is the use of rinse soluti ons.a. Direct Surface Sampli ng - Determi ne the type of samplingmaterial used and its impact on the test data since the sampli ngmaterial may in terfere with the test. For example, the adhesiveused in swabs has been found to interfere with the analysis ofsamples. Therefore, early in the validation program, it is importantto assure that the sampli ng medium and solve nt (used for extraction from the medium) are satisfactory and can be readily used.Advantages of direct sampling are that areas hardest to clean andwhich are reas on ably accessible can be evaluated, lead ing toestablish ing a level of con tam in ati on or residue per give nsurface area. Additi on ally, residues that are "dried out" or are insoluble can be sampled by physical removal.b.systems or ones that cannot be routi nely disassembled can besampled and evaluated.A disadva ntage of rinse samples is that the residue or con tam inantmay not be soluble or may be physically occluded in the equipme nt. An an alogy that can be used is the "dirty pot." In the evaluatio n of cleaning of a dirty pot, particularly with dried out residue, one does no t look at the rinse water to see that it is clea n; one looks at the pot.Check to see that a direct measureme nt of the residue or con tam inant has bee n made for the rinse water whe n it is used to validate the cleaning process. For example, it is not acceptable to simply test rinse water for water quality (does it meet the compendia tests) rather than test it for potential contaminates.c. Rout ine Producti on In-Process Con trolMon itori ng - In direct test ing, such as con ductivity testi ng, may be of some value for rout ine mon itori ng once a clea ning process has bee n validated. This would be particularly true for the bulk drug substa neemanu facturer where reactors and cen trifuges and pip ing betwee nsuch large equipme nt can be sampled only using rinse soluti onsamples. Any in direct test method must have bee n show n to correlate with the condition of the equipment. During validation,the firm should docume nt that test ing the un clea ned equipme nt givesa not acceptable result for the in direct test.ESTABLISHMENT OF LIMITSFDA does not intend to set accepta nee specificati ons or methods for determining whether a cleaning process is validated. It is impractical for FDA to do so due to the wide variati on in equipme nt and products used throughout the bulk and fini shed dosage form in dustries. The firm's rati on ale for the residue limitsestablished should be logical based on the manu facturer's kno wledge of the materials invo Ived and be practical, achievable, and verifiable. It is important to define the sensitivity of the an alytical methods in order to set reas on able limits. Some limits that have bee n men tio ned by in dustry represe ntatives in the literature or in presentations include analytical detection levels such as 10 PPM, biological activity levels such as 1/1000 of the normal therapeutic dose, and orga no leptic levels such as no visible residue.Check the manner in which limits are established. Uni ike fini shedpharmaceuticals where the chemical ide ntity of residuals are known (i.e., from actives, in actives, deterge nts) bulk processes may have partial reacta nts and unwan ted by-products which may n ever have bee n chemically identified. In establishing residual limits, it may not be adequate to focus only on the prin cipal reacta nt since other chemical variati ons may be more difficult to remove. There are circumsta nces where TLC scree ning, in additi on to chemical an alyses, may be n eeded. In a bulk process, particularly for very potent chemicals such as some steroids, the issue of by-products n eeds to be con sidered if equipme nt is not dedicated. The objective of the inspection is to ensure that the basis for any limits is scie ntifically justifiable.OTHER ISSUESa. Placebo ProductIn order to evaluate and validate clea ning processes some manu facturers have processed a placebo batch in the equipme nt un der esse ntially the same operat ing parameters used for process ing product. A sample of the placebo batch is then tested for residual contamination. However, we have docume nted several sig nifica nt issues that n eed to be addressed whe n using placebo product to validate clea ning processes.One cannot assure that the con tam in ate will be uniformly distributedthroughout the system. For example, if the discharge valve or chute of a ble nder are con tam in ated, the con tam inant would probably not be uni formly dispersed in the placebo; it would most likely be concen trated in the in itial discharge portion of the batch. Additi on ally, if the con tam inant or residue is of a larger particle size, it may not be uniformly dispersed in the placebo. V. VI.Some firms have made the assumpti on that a residual con tam inant would be worn off the equipme nt surface uniformly; this is also an inv alid con clusi on.Fin ally, the an alytical power may be greatly reduced by diluti on of the contam in ate. Because of such problems, rinse an d/or swab samples should beused in conj un cti on with the placebo method.b. Deterge ntIf a deterge nt or soap is used for clea ning, determ ine and con sider thedifficulty that may arise whe n attempti ng to test for residues. A com monproblem associated with deterge nt use is its compositi on. Many deterge ntsuppliers will not provide specific compositi on, which makes it difficult for theuser to evaluate residues. As with product residues, it is importa nt and it isexpected that the manu facturer evaluate the efficie ncy of the clea ningprocess for the removal of residues. However, un like product residues, it isexpected that no (or for ultra sen sitive an alytical test methods - very low)deterge nt levels remai n after clea ning. Deterge nts are not part of the manufacturi ng process and are only added to facilitate clea ning duri ng the cleaning process. Thus, they should be easily removable. Otherwise, a differe ntdeterge nt should be selected.c. Test Until CleanExamine and evaluate the level of testing and the retest results since testinguntil clean is a concept utilized by some manufacturers. They test, resample,and retest equipme nt or systems un til an "acceptable" residue level isattained. For the system or equipment with a validated clea ning process, thispractice of resampli ng should not be utilized and is acceptable only in rarecases. Constant retesting and resampling can show that the clea ning processis not validated since these retests actually docume nt the prese nee of unacceptable residue and con tam inants from an in effective clea ning process.REFERENCES0. J. Rodehamel, "Cleaning and Maintenance," Pgs 82-87, University of Wisc VII.onsin's Con trol Procedures in Drug Productio n Sem inar, July 17-22, 1966,William Blockstein, Editor, Published by the University of Wisco nsi n,L.O.C.#66-64234.1. J.A. Constanee, "Why Some Dust Control Exhaust Systems Don't Work,"Pharm. Eng., January-February, 24-26 (1983).2. S.W. Harder, "The Validation of Cleaning Procedures," Pharm. Technol. 8 (5),29-34 (1984)3. W.J. Mead, "Maintenance: Its Interrelationship with Drug Quality," Pharm. Eng.7(3), 29-33 (1987).4. J.A. Smith, "A Modified Swabb ing Tech ni que for Validati on of Deterge ntResidues in Clean-in-Place Systems," Pharm. Technol. 16(1), 60-66 (1992).5. Fourman, G.L. and Mullen, M.V., "Determining Cleaning Validation Acceptanee Limits for Pharmaceutical Manu facturi ng Operati on s," Pharm. Tech nol.17(4), 54-60 (1993).6. McCormick, P.Y. and Cullen, L.F., in Pharmaceutical Process Validation, 2ndEd., edited by I.R. Berry and R.A. Nash, 319-349 (1993)。

清洁验证技术及应用技术指南英文回答:Cleaning Validation Techniques and Applications.Introduction.Cleaning validation is a critical aspect of pharmaceutical and biotechnology manufacturing processes as it ensures that equipment and facilities are clean and free of contaminants. This process involves a series of tests and procedures to demonstrate that cleaning methods are effective in removing product residues, cleaning agents, and other contaminants from equipment surfaces.Validation Techniques.Various validation techniques are employed to assess the effectiveness of cleaning processes. These techniques include:Swabbing: Involves collecting samples from surfaces using sterile swabs and analyzing them for the presence of contaminants.Rinsing: Involves flushing surfaces with a solvent or water and analyzing the rinsate for contaminants.Visual inspection: Involves visually examiningsurfaces for visible residues or defects.Analytical methods: Utilizes analytical techniquessuch as chromatography, spectroscopy, or microscopy to quantify and identify contaminants.Applications of Cleaning Validation.Cleaning validation is applied in variouspharmaceutical and biotechnology processes, including:Equipment cleaning: Validation of cleaning methods for manufacturing equipment, such as reactors, filling machines,and bioreactors.Facility cleaning: Validation of cleaning proceduresfor rooms, corridors, and other areas within manufacturing facilities.Process validation: Integration of cleaning validation into process validation to ensure that cleaning processesdo not affect product quality or safety.Regulatory compliance: Meeting regulatory requirements, such as those from the FDA and EMA, which mandate comprehensive cleaning validation programs.Best Practices for Cleaning Validation.To ensure effective cleaning validation, best practices should be followed, including:Developing a validation plan: Outlining the validation approach, including the validation objective, methods, and acceptance criteria.Using validated methods: Employing validated swabbing, rinsing, and analytical techniques to ensure reliable and accurate results.Controlling cleaning parameters: Standardizingcleaning procedures and controlling parameters such as time, temperature, and cleaning agent concentration.Documenting validation results: Maintaining detailed records of validation tests, including the methodology, data, and analysis.Monitoring cleaning effectiveness: Regularlymonitoring cleaning processes to ensure ongoing compliance with established standards.Conclusion.Cleaning validation is a critical quality control measure in pharmaceutical and biotechnology manufacturing.It provides assurance of equipment and facility cleanliness,reducing the risk of contamination and ensuring product quality and patient safety. By implementing effective validation techniques and following best practices, manufacturers can establish and maintain robust cleaning processes that meet regulatory requirements and industry standards.中文回答:清洁验证技术及应用技术指南。

FDA清洗验证检查指南I.引言自FDA各种文件(包括化学原料药检查指南、生物技术检查指南)首次提出这个问题之后,清洗过程的验证已经引发了很多讨论。

FDA的文件明确指出要求对清洗过程进行验证。

本指南讨论了各种可接受(或不可接受)的验证方法,从而使FDA的检查具有一致性。

但必须清楚地认识到:与其他工艺验证一样,清洗验证方法也不止一种。

所有过程验证的检查标准是:检查其科学数据能否证明系统稳定一致地达到预期目的,系统结果稳定地符合预先制定的标准。

本指南仅适用于设备化学残留物的清洗验证。

II.背景对于FDA而言,使用设备前进行清洗不是什么新要求。

1963年GMP法(133.4)规定“设备应处于清洁、有序的状态”。

1978年的cGMP中规定了设备清洗的章节(211.67)。

要求清洗设备的主要目的还是防止污染或混料。

由于设备清洗维护不当或防尘管理不当,FDA检查官曾十分注意检查卫生状况。

过去FDA总是更注意检查青霉素类与非青霉素类药物之间的交叉污染、药品与甾类物质或激素之间的交叉污染问题。

在过去二十年间,因实际或潜在的青霉素交叉污染问题已从市场上撤回了大量的药品。

另一个事件使FDA对交叉污染问题日益重视,即1988年从市场上撤回了消胆胺成品制剂,原因是规程不当。

生产该制剂的原料药受到了农业杀虫剂生产中少量中间体和降解物质的污染。

造成交叉污染的主要原因使用了回收溶媒。

而回收溶媒受到了污染,原因是对溶媒桶的重复使用缺少监控。

贮存杀虫剂产生的回收溶媒桶又重复地用于贮存该药品生产中的回收溶媒。

而工厂没有对这些溶媒桶进行有效的监控,没有对其中的溶媒进行有效的检验,也没有对桶的清洗规程进行验证。

被杀虫剂污染的部份化学原料药运到了另一地点的第二家工厂生产制剂,使该工厂的流化床干燥器中物料袋受到了杀虫剂的污染,料造成各批产品受到污染,而该工厂根本就没有生产杀虫剂。

1992年,FDA对一家海外原料药生产厂发出了进口警告,该工厂使用同一设备生产强力甾类物质和非甾类物质。

FDA清洁验证检查指南(中英文对照)清洗过程验证检查指南GUIDE TOINSPECTIONS VALIDATION OF CLEANINGPROCESSES请注意:本指南是检查官和其他FDA人员的参考材料。

本指南不受FDA约束,并没有赋予任何人任何权利、特权、收益或豁免权。

I.介绍I. INTRODUCTION自从机构文件,包括原料药化学制剂检查指南和生物制剂检查指南,大体上提到该清洗问题以来,就出现了关于清洗过程验证的大量讨论。

这些机构文件清晰的建立了要验证的清洗过程需要达到的要求。

本指南是为了通过讨论实际操作是可接受的(或不可接受的),来建立检查要求的一致性和统一性。

同时,对清洗验证需要了解的是,像其他过程验证一样,可能有不止一种方法来对过程进行验证。

最后,任何验证过程的测试就是指科学数据是否显示出系统与要求相符和产生的结果是否符合预先定义的参数指标。

本指南只适用于化学残留物的设备清洗。

II.背景对于FDA来说,要求设备在使用前进行清洗并不新奇。

1963GMP 法规(部分133.4)中指出“设备***应该按照清洁和有序的方式进行维护***。

”在1978 CGMP法规中也包含了非常相似的有关设备清洗的章节(211.67)。

当然,清洁设备的主要理由是防止药品被污染或掺假。

在历史上,FDA检查官寻找由于对设备不当的清洗和维护和/或不良的灰尘控制系统而带来的总体不卫生情况。

而且,从历史上来说,FDA对非青霉素药品中的青霉素污染或药品中的活性激素或荷尔蒙交叉污染更加关注。

有很多药品在过去十年中被撤回就是因为实际的或潜在的青霉素的交叉污染。

导致FDA对由于不满足要求的过程导致交叉污染的可能性的进一步关注的案例是,1988年对成品药消胆胺树脂USP的撤回。

用于生产成品的原料药被生产农用杀虫剂中产生的中间体和降解物污染。

本案例中的交叉污染被认为是由于回收溶剂的重新使用。

回收溶剂由于缺乏对溶剂桶的重新使用的控制而被污染。

美国FDA清洗验证检查指南注释:这份文件是检查员和其他FDA人员的参考资料。

这份文件不约束FDA,不授予任何人任何权力、特权、利益或豁免权。

Ⅰ. 简介对于清洗程序的验证的讨论,已经在FDA原料药检查指南和生物制品检查指南中有了简要地解释。

这些官方文件明确表达了清洗验证的期望。

本指南通过讨论一些可接受(或不可接受)的实例来建立检查的连贯性和一致性。

同时我们必须意识到清洗验证同其他过程的验证一样,都有不止一种的方法进行验证。

最后验证证明,是否有科学数据表明系统确实如预期稳定,并满足预设规定的结果。

这个指南仅涉及对设备化学残留物的清洗。

Ⅱ. 背景FDA对于设备使用前的清洗没有什么新要求,1963GMP规范中(133.4部分)有以下陈述“设备***应保持清洁和有序的状态***”。

在1978cGMP规范的设备清洁中有非常类似的章节。

当然,设备清洗的主要目的是为了防止药品的污染和混淆。

历史上,FDA 检查员发现由于设备的清洗和维护的不充分及不良的灰尘控制系统带来总体上的不卫生。

历史上来说,FDA更关注非青霉素类受青霉素类的污染和高活性的类固醇或激素对药物的交叉污染。

过去的几十年里,许多产品由于实际存在或潜在的青霉素交叉污染而召回。

1998年消胆胺树脂USP制剂的召回事件使FDA对由于不充分的清洗程序造成的潜在交叉污染更为重视。

产品生产中用到的化学原料药有低量的中间体和农业杀虫剂的降解物污染。

那个事件中交叉污染被认为来自回收溶剂的套用过程。

回收溶剂的污染是由于缺少对溶剂罐重复使用的控制。

杀虫剂生产过程中存放回收溶剂的罐子随后用于存放树脂生产过程中的回收溶剂。

公司对这些溶剂罐未严格管理,对存放的溶剂未充分检测,对罐子的清洗程序未验证。

杀虫剂污染了的原料药运到另一个地方提供给第二个工厂最后加工。

这对后一个工厂流化床干燥器上用到的捕尘袋造成杀虫剂污染。

这反过来导致在这里生产的多个批次交叉污染,而这里正常情况下没有杀虫剂生产。

FDA清洁验证指南

FDA(美国食品药品监督管理局)的清洁验证指南(Cleaning Validation Guidance for FDA)是一份详细说明如何进行清洁验证的指南,以确保在药品和医疗器械生产中使用的设备得到有效清洁的文件。

该

指南包含了清洁验证的定义、原则、程序和要求,以及检验设备清洁性能

的方法和技术。

清洁验证是制药行业中的一个关键步骤,旨在确保设备在使用前不含

有任何的残留物。

残留物可能会对产品质量和安全性产生负面影响,因此

清洁验证是产品质量保证和合规性的重要部分。

该指南中提到了一些重要的原则,如总体清洁验证策略、验证程序的

不同阶段、适当的样本大小和技术要求。

它强调了验证过程应该是科学、

系统和可重复的,并应基于理解和评估风险。

指南还描述了清洁验证程序的各个阶段,例如验证计划的编制、击中

关键因素的确定、清洁程序和剂量的开发、样本收集和分析等。

它还提供

了相关文件的要求,如验证报告和标准操作程序(SOPs),以确保验证结

果的准确性和追溯性。

此外,该指南还提供了一些实施清洁验证时应考虑的额外要求,如定

期审核验证程序、定义验证周期、报告异常结果、记录过程参数和审核活

动等。

总之,FDA清洁验证指南是一份重要的文件,为制药和医疗器械行业

提供了进行清洁验证的详细指导。

它对于确保设备在使用前得到有效清洁,并遵守相关法规和要求起到了重要的作用。

制药公司和设备制造商应该遵

循该指南的要求,并根据需要进行相应的验证程序,以保证产品质量和安全性。

一般要求:FDA专家已经为各种设备写了SOP细化清洁过程。

如果一个产品的不同批次有相同的清洁过程,产品变换时用不同的清洁过程。

我们希望这些不同的细节能被写下来。

同样,如果一个过程用于清洗水溶性残留,另一个过程用于清洗非水溶性残留,这些过程应该被写下来,并且要判断这个过程是否实施。

散装的药品决定了特定装备的特定化学生产过程,很难从设备上清洗的残留物和胶状残留。

流体干燥床是另一个常用于特定产品的难以清洗的设备的例子。

任何清洗过程中的残留(溶剂等)要从设备上清洁FDA专家要求有一个清洗过程的书面流程要被验证FDA专家当可接受的验证和重复验证被要求时,希望验证过程确认谁为过程负责,并推进验证研究FDA 专家要求准备在确认样品过程和包括这些方法的敏感性在内的分析方法的每一个生产系统中或单一设备在样品生产过程中的在进一步研究中写下验证参数。

FDA专家要求对应于参数和结果研究文件的验证研究。

FDA专家希望有被经理推进的和标明了是否清洁过程被验证的最后的验证报告。

数据应该支持残留物已经被降到一个“可接受的程度”的结论。

清洁验证的评估第一步聚焦于验证过程的目标,一些企业已经在发展这些目标时失败了。

在看到企业使用清洁过程的特殊样品和实验过程没有真正的评价在评价清洁过程时一些问题要被提出。

例如:一个设备或系统在何时变干净?需要用手清洁吗?是用手还是用溶剂清洗干净?主要的清洗过程一批到一批,一个产品到一个产品很显然吗?这些问题的答案对于检查很重要对于要决定过程的有效性的清洁过程的评估时很重要。

对于分辨提高有效措施何公司资源的结果的步骤这些答案也有帮助。

决定每个设备的清洗过程号。

一个设备或系统有一个清洁过程,然而这将依靠生产的品种,和是否同一产品的批次之间(在一个大的时间段或不同产品的批次间清除干净了。

当清洁过程在同一产品的不同批次间(在大的过程中的不同批量的同一中间体)最严格需要为达到一个标准,设备的“明显清洁”。

这些批次间的清洁不需要验证。

第四节设备的清洁验证关于清洁验证的原理及方法将在第三篇第二章详细介绍,制剂生产验证各章亦对相应设备的清洗验证要点进行介绍,可以参阅这些章节的内容。

考虑到制药设备验证的完整性,应包括设备的确认,变动控制程序、仪器仪表的校准和清洗验证。

在此对设备的清洁验证从方法上作简单介绍。

设备清洗有自动清洗和人工清洗两种方法,或者两种方法的结合。

所谓清洗是从工艺设备或贮存设备中清除污染物的工艺过程,以保证设备能够安全地进行下一步的产品生产,它包括清洗、消毒和贮存。

设备清洁验证的目的是通过测试证明该设备的自动清洗程序(CIP)或人工清洗程序能够清除设备部件上的活性药物残留物,并达到可接受的合格标准,并证明此清洁程序具有稳定性和重演性。

一、设备清洁验证中常用的术语1)人体接触剂量限度(SEL,Subject E×posure Limit)。

指一个没有药理学和毒理学经验的人可以接触的某一药物的暴露剂量。

2)允许残留浓度(ARL,Allowable Residual Limit).指某一设备经清洗后,其表面残留的药物(或清洁剂)的最大允许量。

3)活性成分(API,Active Pharmaceutical lngredient;或ADS,Active Drug Substance):指在某一药物中代表效用的物质。

这种物质在制造、工艺或包装过程中就变成了一种活性成分或者药物的最终成型形式。

活性成分在疾病诊断、治疗、缓解、处理或预防方面提供药理上的活力或其他直接的作用,以致影响人体或动物的组织和功能。

API 在工艺制造过程中产生,如:①化学合成;②发酵;③重组DNA 或其他生物工艺;④从自然资源上分离或取得;⑤其他工艺的任何组合等。

对设备清洁验证来说,API 包括中间体及成品。

一般来说,SEL、ARL 的允许值应从药物安全评价部门获取。

二、验证设计在验证取样测试时,若发现洗过的设备明显不干净,应立即停止验证,有明显的残留物存在表明现有的清洁程序是不合适的,因此必须在验证开始前重新评价清洁程序。

美国FDA清洁程序验证检查指南1 9 9 3年I.导言 (3)Ⅱ.背景 (3)Ⅲ.一般要求 (4)Ⅳ.清洁验证的评价 (5)1.设备设计 (5)2.清洁程序的规程及文件 (6)3.分析方法 (7)4.取样 (7)ⅴ.确定限度 (8)Ⅵ.其他事项 (8)Ⅶ.参考文献 (9)I.导言自从包括《化学原料药检查指南》和《生物技术检查指南》在内的一些政府文件简要而明确地表示希望对清洁程序(工序)进行验证以来,清洁程序的验证已引起厂普遍的重视。

本指南旨在通过讨论一些已被证明可行(或不可行)的实践来建议连贯一致的检查。

同时,应当认识到,清洁验证和其他程序验证一样,可能有诸多种的验证方式。

但对任何验证的检验都取决于科学数据是否表明该系统能始终如一地按预期的那样运行,而且产生的结果能—贯的符合预定的标准。

本指南只涉及对设备中化学残留物的清洁验证。

Ⅱ.背景对FDA来说,要求设备在使用前必须清洁并不是新规定,1963年药品生产质量管理规范(133.4)规定:“设备***应保持清洁有序的状态***。

”1978年现行药品生产质量管理规范(211.67)也有类似的关于设备清洁的叙述。

当然,要求清洁设备的主要原因是防止药品的污染或掺杂。

历史上FDA检查人员曾发现由于设备不够清洁,保养不当和(或)缺乏合格的灰尘控制系统而引起严重不卫生的情况。

同样,从历史上来说,FDA更关心青霉素对非青霉素药品的污染或药物与强效类固醇或激素类之间的交叉污染。

在过去十多年中,有许多产品由于存在或可能存在的青霉素交叉污染而被收回。

1988年对一种药物的成品——美国药典上的消胆胺树脂的回收,增加了FDA对因清洁程序不当而引起交叉污染可能性的警觉,用来生产该产品的化学原料药受到来自生产农业杀虫剂的中间体及其降解产物的污染。

这次的交叉污染被认为是由于重新使用回收溶剂造成的。

回收溶剂被污染是因为对重新使用溶剂桶控制不利。

溶剂桶曾用于储存杀虫剂生产过程中的回收溶剂,然后又被用于储存消胆胺生产过程中使用的回收溶剂。

Validation of Cleaning Processes (7/93) 清洁工艺验证清洁工艺验证检查指南注:此指南是FDA检查官和其工作人员的参考资料。

此文件不约束FDA,也不赋予任何人任何权利,特权,利益或豁免权。

介绍自从FDA 的各文件,包括化学原料药检查指南和生物技术检查指南简单地提出了清洁验证这个话题之后,关于清洁工艺的验证已经引发了相当多的讨论。

这些官方的文件,都清楚地确定了对于清洁工艺需要被验证的期望。

通过讨论那些已被认为可接受的(或者不可接受的)实际情况,此指南是为了建立检查的连贯一致性。

同时,必须意识到,与其他工艺验证一样,清洁验证的方法也不止一种。

最后,所有过程验证的检查标准是,检查其科学数据能否证明该系统始终如一地达到预期目的,结果稳定地符合预先制定的标准。

本指南仅适用于设备的化学残留物的清洁验证。

背景1963 年GMP 法规(133.4 节)要求如下“设备需要被维持在一个清洁、有序的状态”。

还有一个很相似的关于设备清洁的章节是在1978 年GMP 法规(211.67 节)。

同这些法规相比,FDA对于设备在使用前应被清洁的要求并不是什么新要求。

当然,对于设备清洁的总的原则是为了防止产品污染或掺杂其它物质。

从历史事件看来,FDA检查官发现了一些明显的不卫生是由于设备的清洁和维护不到位,或防尘控制系统不当。

过去FDA 更多的关注于非青霉素类产品和青霉素类产品,或药品与甾类产品和激素类产品之间的交叉污染问题。

在过去的十年中,有大量的产品召回事件都是由于实际的或潜在的青霉素交叉污染。

1988 年的召回消胆胺树脂事件,使FDA 对于潜在交叉污染的问题日益重视。

那次召回的原因是用于生产制剂的原料药被农业杀虫剂生产中低剂量的中间体和降解物给污染了。

造成这次交叉污染的原因是由于重复使用了回收溶剂引起的。

而回收溶剂被污染的原因是由于对重复使用的溶剂桶缺乏控制。

这些桶之前是用于贮存杀虫剂生产线产生的回收溶剂,之后又被重复地用于树脂生产线使用的回收溶剂贮存。

该公司对于这些溶剂桶缺乏有效的控制,对于贮存的溶剂缺少适当的检测,对于溶剂桶的清洁过程也没有进行验证。

一部分被杀虫剂污染的原料药被供给了在另一地址的厂进行最后的制剂生产,这就导致2翻译:Cu ckoo(**********************.cn);校对并解读:Chank(*******************)注:个人学习、交流使用,不得用于商业目的。

了该厂的流化床干燥机的袋子被杀虫剂污染了。

转而导致此厂生产的众多批次产品被污染,尽管该厂并不生产杀虫剂。

1992 年,FDA对一家海外原料药生产商发出了进口警告。

该厂使用相同设备生产强效甾类产品和非甾类产品。

因此公司是多品种原料药生产厂家,FDA 认为潜在交叉污染的可能性很大,对公众健康造成了严重的威胁。

该公司只是在FDA 检查的近期才开展了清洁验证工作,而FDA 认为该清洁验证工作是不当的。

理由之一是,工厂仅寻找没有前一种物质存在的证据。

但是用薄层法检测洗涤水后,找到了设备中还残留了前一产品生产过程中反应副产物和降解产物的残留物。

基本要求FDA 期望公司建立书面的程序(SOPs)用于详细描述设备各部件的清洁的过程。

如果公司用同一程序进行相同产品不同批次之间的清洗,而使用不同程序进行转产之间的清洗,公司的书面程序应明确说明这些不同的情况。

同样,若水溶性残留物与非水溶性残留物的清洗方法不同,则公司的书面程序也应说明两种情况,并清楚地规定在何种情况下执行哪个程序。

对于化学原料药生产中会产生柏油状或粘胶状残留物的生产工序,因为这些物质不容易被清除,公司可以决定使用专用设备。

流化床干燥机的袋子,作为一种不容易被清洗的设备,也通常只被专用于某一特定产品的生产。

对于清洁过程本身留下的残留物(清洁剂,溶剂等),也必须被去除。

FDA 期望公司建立书面的清洁工艺验证通则。

FDA 期望这个清洁工艺验证通则规定,验证执行的负责人,批准验证工作的负责人,接受标准,再验证时间。

FDA 期望对于每一个生产系统或每一个设备,公司应预先制订具体的书面验证方案,其中应明确规定如取样方法、分析方法(包括方法灵敏度)等方面的问题。

FDA 期望公司根据方案进行验证工作,并记录归档验证的结果。

FDA 期望形成一个最终的验证报告,报告应经过管理层的批准,并说明该清洗方法是否有效。

数据应该能够支持如下结论,残留物质已经被降低到一个“可接受的水平”。

清洁验证的评估第一步是明确验证目的。

我们曾发现有一些公司没有建立验证目的。

如常见一些生产商,在清洁之后进行了大量的取样和检测程序,而没有真正去评估各步清洗操作的有效性。

在评估清洁工序时,有一系列的问题需要被关注。

比如,到达哪个点/程度,一个设备或者系统算是清洁了?是不是一定要用手擦洗?用手擦洗达到了什么效果,而只用一种溶剂清洗是达不到的?批和批之间或者产品和产品之间,人工清洗的差异有多大?这些问题的答案,对于检查和评估清洁过程来说是非常重要的,因为检查官必须要全面评估该过程的有效性。

而且这些问题的答案也有助于省去多余的步骤,能更有效地工作,从而为公司节约资源。

检查每个设备有几种清洗方法。

理想的情况是一个设备或系统拥有一套清洗工艺。

然而,这也取决于生产的品种,以及同一产品的不同批次之间(如大量生产)或者不同产品的转产之间是否需要清洗。

当清洗方法只用于同一产品的不同批次之间(或同一中间体的不同批次之间),公司仅需要建立“目视清洁”的标准。

诸如此类的批与批之间的清洁工艺,不需要被验证。

设备的设计检查设备的设计,尤其是使用了半自动或全自动在场清洗系统的大型生产系统,需要重点关注。

比如,应使用没有球阀的卫生型管道系统。

当使用了那些非卫生型的球阀(这在原料药工业中是普遍的),清洁工序就变的更困难。

若在现场检查中发现使用了上述类型的设备系统,执行清洁程序的操作人员必须了解问题的所在,并已进行了关于系统和阀门清洁的特殊培训。

检查该操作人员是否了解系统,培训的水平和清洁操作的经验。

并检查书面的已验证过的清洁程序,判定系统是否已经被适当的确认和验证过。

对于大型系统,比如使用了很长的转移/输送管道的,要检查流程图和管道图纸从而确认需要清洗的阀门,和是否有书面清洁规程。

管道和阀门应标记,以便操作人员识别。

有时,阀门标识不当,无论在打印图纸上和实物上,都会导致不正确的清洁操作。

在清洁工序的相关文件中,必须检查是否包含了关键因素;确认并控制每次生产结束后至清洁开始的时间间隔。

这对于局部用药物,悬浮剂和原料药的生产尤其重要的。

因为残留物干燥后,会直接影响清洁的效果。

无论是否使用了在线清洁系统,都应考虑设备清洁的微生物情况。

这包括大量的预防性的措施,而不只是在染菌之后再除菌。

应有证明,常规清洁和设备保存不会有微生物的繁殖。

比如,设备在保存之前应该干燥,清洁后不允许有任何积水残留其中。

对于无菌工艺的设备,或者非无菌的但有助于微生物增长的产品,清洁之后还可能需灭菌或消毒。

虽然灭菌或消毒程序已超出了本指南的范围,但要注意的是,通过适当的清洁和设备保存来控制微生物,是对接下来的灭菌/消毒工序能够达到无菌水平的保证。

从6无菌工艺应控制热原的观点来说,这一点也特别重要。

因为设备灭菌工艺不一定能够取得显著的灭活或去除热原的效果。

书面清洗程序程序和文件要检查验证后的清洗方法是否具体、详细,检查需要记录的项目。

我们曾见过不少通用性的SOP,同时也见过其它使用批生产记录或者记录表格系统的,其要求对每一步操作做出专门的文件记录。

根据系统的复杂程度、清洗方法以及操作人员培训程度和能力的不同,各种清洗工作或规程所需的文件数量也会有所不同。

当需要进行更为复杂的清洗过程时,必须对关键的清洗工序做出记录(如某些原料药合成工序)。

在这点上,应有专门的设备记录,包括清洗人员姓名、评估时间。

然而,对于相对简单的清洗工作,仅记录“全部清洗工作已经被执行”就足够了。

其他因素,诸如清洗历史、清洗后测出的残留物水平、检验结果的可变性等有时也要记录。

例如,清洗之后的残留物水平具可变性,而又认定该清洗方法是可接受的,则必须证明清洗过程和工人操作的有效性。

必须对清洗方法做出适当的评价,尤其是当认为工人操作有问题时,就要求有更为广泛的文件(指导)和记录,并进行更多的培训。

分析方法应确定用于残留物或污染物检测的分析方法的专属性和灵敏度。

借助于先进的分析技术,清洗和生产过程中极少的残留物或污染物也能够被检测出来。

即使检测不出污染物或残留物水平,也并不能说明清洗之后不存在残留污染物,而只说明样品中没有超过该分析方法灵敏度或检验限之外的污染物。

公司应对分析方法进行挑战性实验,即证明取样方法能够从设备表面取回污染物,其收率是多少,如 50%, 90%等。

根据取样结果再做出结论是必须的。

取样技术不当也可能得出相反的结论(见下文)。

取样可接受的通用取样方法有两种。

最好是直接从设备表面取样,另一种方法是取漂洗水样。

a. 表面直接取样法检查取样器材的类型,以及其对检测数据的影响,因为取样器材可能会干扰检测。

例如,取样拭子上的粘胶会干扰样品的分析。

因此,在验证初期,必须确保使用适当的取样介质和溶媒(用于从取样介质中提取样品),并且方便使用。

直接取样法的优点在于:能够对最难清洗、能够到达的表面清洁程度进行评价,从而建立单位面积上残留物/污染物的接受水平。

此外,还能够取到“干的”或不溶性残留物样品。

b. 漂洗液样品漂洗液取样法具有两点优势:能够对较大表面进行取样;能够对到达不到的系统或日常无法拆卸的部位进行取样并做出评价。

其缺陷是:残留物或污染物可能是不溶性或吸藏在设备中的。

此时,可使用“脏点”类推法进行评价。

对于“脏点”清洗的评估,特别是有干的残留物的,不能只检测漂洗水样,而要检查“脏点”,从而确定清洗是否干净。

当直接检测漂洗水样用于清洗方法验证时,应检查是否直接检测了漂洗水样中的残留物或污染物。

如若仅检测漂洗水样的水质情况(即使符合药典检测方法),而不测定其可能存在的污染物,这种做法是不能接受的。

常规生产的中控c. 日常生产的中间控制监测:一旦某清洁方法得到验证之后,日常监测可使用间接检测法,如电导率检测。

对于原料药生产商来说,使用的反应罐和离心机,大型设备之间的管道连接,只能对其漂洗液取样。

这种情况下,必须说明间接检测法与设备状况的相关性。

验证过程中,也应有书面证明:用间接法检测未清洗设备时,检验结果能够证明该设备不能使用以及未清洗。

即该检测结果能够得出不能够接受当前设备状况的结论。

(反证法)限度的建立对于清洁方法是否得到了验证,FDA不打算建立统一的接受标准和方法。

这也不切实际,因为在医药工业中,原料药、制剂产品以及设备种类太多。