组合机床毕业设计说明书样本

- 格式:doc

- 大小:293.50 KB

- 文档页数:23

毕业设计说明书末端传动壳体底面加工组合机床设计摘要组合机床是以系列化、标准化的通用部件为基础,配以少量专用部件组成的专用机床。

组合机床加工大批量零件快捷方便,生产效率高,其应用是机械加工的发展方向。

本次毕业设计的题目是“末端传动壳体平面组合机床设计”,要求所设计组合机床实现零件底面的铣削加工,底面精度要求达到粗糙度为3.2,平面度为0.2。

此次设计要完成的主要内容包括:编写零件的机械加工工序,确定铣削底面时的定位基准与定位方式,并计算出铣削底面这一工序的切削用量。

进行机床总体布局设计,选择合理的机床配置形式,决定加工使用的刀具及其结构,并设计出机床总体的结构。

对机床的主要运动和各传动部分进行设计,选择合适的运动部件,如滑台、动力头等。

结合实际,设计出机床专用的夹具。

通过完成此设计,本机床完全可以满足所要求的加工要求,而且与传统的机床相比,本机床具有高自动化程度,高生产率高,高精度等优点。

关键词:组合机床设计;总体布局;传动部件;专用夹具;生产率高AbstractThe modular machine tool is the special machine tool based on the serialized and standardized common components,together with a small amount of dedicated components . The modular machine tool processes large quantities of components fastly and conveniently, and it has high production efficiency. Its application is the development direction of the machining.The task of my graduation project is " the modular machine tool design for the end of the transmission housing plane". It requires that the modular machine tool I design can mill the underside of the component .And the required accuracy of the underside is to achieve roughness of 3.2, the flatness of 0.2. The main contents the design to finish include: formulate its machining process of the component, confirm the locating datum and positioning way of milling the underside , and calculate the cutting specifications when mill the underside . General layout design for machinetools .C hoose the machine configurations form and design the overall structure of the machine . Ensure the tools of processing and its structure .Design the main movement and the transmission part of the machine , and then make the choice of moving parts, such as the slide unit and dynamic head. .Design the machine special fixtures c ombined with the e xamples.Through the completion of this design, the machine is fully capable to meet the processing requirements .Compared to traditional machine, this machine has a high degree of automation, high productivity and high precision.Keywords: the modular machine tool design; general layout; transmission part; special fixtures; high productivity目录摘要........................................................................................................................... I I Abstract (II)目录 (III)第一章引言 (1)1.1 课题背景与意义 (1)1.2 本课题国内外研究概况 (2)第二章组合机床的总体设计 (4)2.1 组合机床方案的拟定 (4)2.1.1 制定工艺方案 (4)2.1.2 确定组合机床的配置形式和结构方案 (4)2.2 确定切削用量及选择刀具 (6)2.2.1 确定工序间余量 (6)2.2.2 选择切削用量 (6)2.2.3 确定切削力、切削功率 (6)2.2.4 选择刀具结构 (7)2.3 铣削组合机床总设计方案图纸的编制 (7)2.3.1 被加工零件工序图 (7)2.3.2 加工示意图 (8)2.3.3 机床联系尺寸图 (9)2.3.4 生产率计算卡 (11)第三章多轴箱的设计 (13)3.1铣削头概述 (13)3.1.1 铣削头的组成 (13)3.1.2 铣削头的分类 (13)3.2 铣削头的选用 (14)3.2.1 机床分析 (14)3.2.2 铣削头选用 (14)第四章夹具设计 (16)4.1 组合机床夹具概述 (16)4.1.1 机床夹具的组成 (16)4.1.2 机床夹具的类型 (16)4.2 工件结构特点分析 (16)4.3 工件定位方案及定位元件的设计 (17)4.4 夹紧方案及夹紧元件的设计 (17)4.4.1 夹紧机构的组成 (17)4.4.2 夹紧力确定 (18)4.5 夹具体的设计 (19)4.6 夹具的性能及优点 (19)4.7 误差的分析与计算 (19)4.8 夹具总装配图技术要求制定 (20)4.8.1.精度等级 (20)4.8.2.定位精度要求 (20)4.8.3.总装配图绘制要求 (20)4.9 夹具操作的简要说明 (20)第一章引言1.1 课题背景与意义快速发展的现代化工业技术,特别是自动化领域,促使组合机床的研究成为当今机器制造界的一个重要方向。

第一章概述第一节组合机床多轴箱简介组合机床是针对被加工零件的特点及工艺要求,按高度集中工序原则设计的一种高效率专用机床。

它由大量的通用部件和少量的专用部件组成的,能够对一种(或几种)零件进行多刀,多轴,多面,多工位加工,在组合机床上可以完成钻孔,扩孔,铰孔,钻孔,攻丝,车削,铣削及滚压等工序,生产率高,加工精度稳定。

1.组合机床上的通用部件和标准零件约占全部机床零、部件总量的70%-80%,因此设计和制造的周期短,投资少,经济效果好。

2.由于组合机床采用多刀加工,并且自动化程度高,因此通用机床生产效率高,产品质量稳定,劳动强度低。

3.组合机床的通用部件是经过周密设计和长期生产实践考验的,又有专门厂成批制造,因此结构稳定、工作可靠,使用和维修方便。

4.在组合机床上加工零件时,由于采用专用夹具、刀具和导向装置等,加工质量靠工艺装备保证,对操作工人的技术水平要求不高。

5.当被加工产品更新时,采用其他类型的专用机床时,其大部分部件要报废。

用组合机床时,其通用部件和标准零件可以重复使用,而不必另行设计和制造。

6.组合机床易于联成组合机床自动线,以适应大规模的生产需要。

通过分析,采用组合机床加工。

多轴箱是组合机床的主要部件之一,它关系到整台组合机床质量的好坏。

按专用需求进行设计,由通用零件组成,按加工工件和工艺要求进行专门设计。

其主要作用是,根据被加工零件的加工要求,将动力和运动由电动机或动力部件传给各工作主轴,使主轴得到所要求的转速和转向。

多轴箱的设计主要包括多轴箱箱体的设计和传动系统的设计。

第二节本设计简介本设计来源于实际生产中的问题,当零件有多孔或者相同特征的多个部位需要加工时,如果用传统的机床逐个加工,势必会造成生产效率低下以及定位精度低的问题,这个时候,组合机床的优势就会凸现出来。

如果采用专用钻床加工,一次进刀只能加工一个孔,生产效率就会跟不上整体的节奏,而且也不容易保持三个孔之间的位置精度,如果采用留空同时加工的组合机床,情况就会大大改观,正是基于此,才提出了《基于UG的多轴箱设计及虚拟装配》的课题。

目录摘要 (I)Abstract (II)第一章绪论 (1)1.1 设计的目的 (1)1.2 设计的内容 (1)1.3 设计的要求 (1)第二章组合机床的总体设计 (2)2.1 工序图 (2)2.2 加工示意图 (2)2.3 机床尺寸联系总图 (5)第三章多轴箱的设计 (9)3.1 多轴箱的组成 (9)3.2多轴箱装配图的绘制 (9)(1)驱动轴位置的确定 (9)(2)主轴位置的的确定 (9)(3)驱动轴齿轮的确定 (9)(4)各传动轴位置的确定 (11)(5)手柄轴的安置 (11)(6)润滑油泵的安置 (11)3.3选择加工基准坐标系XOY,计算主轴、驱动轴的坐标 (11)总结 (13)参考文献(References) (14)致谢 (15)卧式双面24轴组合钻床总体设计及左主轴箱设计(双级圆锥-圆柱齿轮减速器箱体底座)专业:机械设计制造及其自动化学号:7011210138 学生姓名:徐伟龙指导老师:冯永平摘要:组合钻床是根据工件加工的需要,以通用部件为基础,配之以少量的专用部件和按工件形状与加工工艺设计的专用部件和夹具,组成的专用钻床。

组合机床同时具有生产效率高、加工精度高、配置较为灵活等优点,是机械一线生产中不可获缺的机器,也是高校大学生毕业设计研究的一个重要课题之一。

作为一名机械专业的学生,我有幸选择了这一个课题的研究,得到了这次了解组合机床的机会。

现在我就来简述这次课程设计的过程:根据零件(双级圆锥-圆柱齿轮减速器箱体底座左端面12孔)的类型和加工的要求我选择了卧式组合钻床;在动力部件选择方面,由于液压滑台导向性好、使用寿命长、液压缸活塞和后盖上分别装有双向单向阀和缓冲装置所以我选择了液压滑台;动力箱方面则采用三相异步电动机作为动力源,动力头选用了钻削头;辅助部件包括定位、夹紧、润滑、冷却、排屑以及自动线的清洗机等各种辅助装置,当然还有其他支承部件、控制部件、辅助部件等等我将在说明书中详述。

四川理工学院毕业设计(论文)1 / 40第一章 概述组合机床的组成和特点:组合机床是根据工件加工需要,以大量通用部件为基础,配以少量专用部件组成的一种高效专用机床。

组合机床中各种部件都是具有一定独立功能的部件,并且大都是已经标准化、系列化和通用化的通用部件。

只有多轴箱和夹具是根据工件的尺寸形状和工艺要求设计的专用部件,但其中绝大多数零件如夹压元件、传动件等也是标准件和通用件。

通用部件是组合机床的基础。

用以实现机床切削和进给运动的通用部件,如各种工艺切削头、动力箱、动力滑台等动力部件。

用以安装动力部件的通用部件,如底座等。

组合机床的特点:⒈ 主要用于箱体零件和复杂的孔面加工。

⒉ 生产率高。

因为工序集中,可多面、多工位、多轴、多刀同时自动加工。

⒊ 加工精度稳定。

因为工序固定,可选用成熟的通用部件、精密夹具和自动工作循环来保证加工精度的一致性。

⒋ 研制周期短,便于设计、制造和使用维护,成本低。

因为通用化、系列化、标准化程度高,通用零部件占70-90%,通用部件可组织批量生产,进行预制或外购。

⒌ 自动化程度较高,劳动强度低。

⒍ 配置灵活。

因为结构模块化、组合化。

可按工件或工序要求,用大量通用部件和少量专用部件灵活组成各种类型的组合机床及自动线;机床易于改装,产品及工艺变化时,通用部件一般可以重复利用。

组合机床常用的通用部件有:床身(侧底座)、底座(包括中间底座和立柱底座)、立柱、动力箱、动力滑台、各种工艺切削头等。

对于一些按顺序加工的多工位组合机床,还有移动工作台或回转工作台。

动力箱、各种工艺切削头和动力滑台是组合机床完成切削主运动和进给运动的动力部件,其中还有可能同时完成切削主运动和进给运动动力头。

床身、立柱、中间底座等是组合机床的支承部件,起着机床的基础骨架作用。

组合机床的刚度和部件之间的精度保持性,主要由这些部件保证。

除了上述主要部件之外,组合机床还有各种控制部件,主要指挥机床按顺序动作,以保证机床按规定的程序进行工作。

:

科学技术学院

毕业设计任务书

(工科及部分理科专业使用)

题目:卧式双面24轴组合钻床总体设计及左主轴箱

设计(双级圆锥-圆柱齿轮减速器箱体)

学科部:理工

专业:机械设计制造及其自动化

班级:机制103 班

学号:7011210138

学生姓名:徐伟龙

起讫日期:2014年1月—2014年5月

指导教师:冯永平职称:讲师

学科部主任:王德友

审核日期:2014年5月

说明

1.毕业设计任务书由指导教师填写,并经系或专业学科组审定,下达到学

生。

2.进度表由学生填写,每两周交指导教师签署审查意见,并作为毕业设计

工作检查的主要依据。

3.学生根据指导教师下达的任务书独立完成开题报告,1个月内提交给指

导教师批阅。

4.本任务书在毕业设计完成后,与论文一起交指导教师,作为论文评阅和

毕业设计答辩的主要档案资料,是学士学位论文成册的主要内容之一。

9。

毕业设计说明书卧式组合机床设计系部:机械系学生姓名:指导教师:职称副教授专业:机械设计制造及其自动化班级:机本完成时间:5月25在组合机床的设计中,主轴箱加工工艺是关键。

“三图一卡”包括加工零件工序图,加工示意图, 机床总图,生产效率计算卡。

其中加工零件工序图是表示一台组合机床对被加工零件应完成的工艺内容的示意图。

它包括加工部位尺寸精度,表面粗糙度及技术要求等内容。

加工示意图表明被加工零件在机床的加工过程,刀具,辅具的位置状况,工件与夹具,刀具等机床各零部件间的位置关系,以及机床的工作行程和工作循环等。

机床总图表示机床各组成部件相互配合关系及各零件、部件、标准件、通用件等名称、代号、数量及运动关系。

以及检验各部件的相对位置及尺寸之间联系是否满足加工要求,通用部件是否合适等内容。

关键词:组合机床、主轴箱、“三图一卡”In transfer and unit machine design, the head stock processing craft is a key. "A three charts card" including processing components working procedure chart, processing schematic drawing,engine bed assembly drawing, production efficiency computation card. Processing components working procedure chart is expressed a aggre gate machine-tool to is processed the craft content schematic drawing which the components should complete. It including processing spot sizeprecision, content and so on surface roughness and specification. The processing schematic drawing indicated is processed the components in the engine bed processing process, the cutting tool, auxiliary position condition, work piece and jig, position relations engine bed various spare parts and so on between cutting tool, as well as engine bed power stroke and operating cycle and so on. The engine bed assembly drawing expressed the engine bed each composition part mutually coordinates the relations and various components, the part, the standard letter, General Work piece and so on the name, the code number, the quantity and the movement relations. Examines various parts between the relative position and the size relates whether satisfies the processing request, the general part is whether appropriate and so on the content.Key words: transfer;unit machine Head stock;"a three charts card"目录1组合机床设计内容 (1)1.1 组合机床的特点: (1)1 主要用于箱体其零件和杂件的孔面加工。

摘要组合机床是以通用部件为基础,配以工件特定外形和加工工艺设计的专用部件和夹具,组成的半自动或自动专用机床。

它一般采用多轴、多刀、多工序、多面或多工位同时加工的方式,生产效率比通用机床高几倍至几十倍。

由于通用部件已经标准化和系列化,可根据需要灵活配置,能缩短设计和制造周期。

因此,组合机床兼有低成本和高效率的优点,在大批、大量生产中得到广泛应用,并可用以组成自动生产线。

本课题是针对汽车减速器壳体侧端面上6×Φ8孔钻削这一特定工序而设计的一台专用卧式组合机床。

本设计中,在充分数据计算的基础上对标准通用零件做了仔细选择。

并依据被加工零件的结构特点、加工部位的尺寸精度、表面粗糙度要求,以及定位夹紧方式、工艺方法和加工过程所采用的刀具、生产率、切削用量情况等,设计了结构合理的多轴箱。

关键词:组合机床、多轴箱、工艺流程、生产率ABSTRACTWith the general components as the basic structure,the combined machine tool is a kind of semi-automatic or automatic specific machine composed by the specific components and clamps for the specific workpiece shape and processing technology design. It generally applies stamulous processing from the aspects of multi-axis, multi-cutter, multi-procedure, multi-surface or multi-station so that the production efficiency is several times and even more higher than the general machine tool. Owing to the standardization and serialization of the general components, the configuration can be made flexibly to shorten the circle of design and manufacture. Therefore, with the advantages of low cost and high efficiency, the combined machine tool is applied to the production in a large quantity and to form the automatic production line.On the specific procedure of 6×Φ8 hole drilling of the auto s peed reducer shell side-end, the horizontal combined machine tool is designed specifically.On the basis of the complete data calculation, the standard general parts is chosen. The multi-axis box with reasonable structure is designed based on the structural features of the processed parts, the dimension precision of the processing sites, the surface roughness, the locating and clamping ways, the technological approach as well as the cutter, production efficiency, cutting parameter in the manufacturing process.Keyword:Combined machine tool, production efficiency, clamp, multi-axis开题报告一、课题介绍本课题是针对汽车减速器壳体侧端面上6个孔钻削这一特定工序而设计的一台专用卧式组合机床。

摘要组合机床,是由大量的通用部件和少量专用部件组成的工序集中的高效率机床。

其特点有:结构紧凑、工作质量可靠、设计和制造周期短、投资少、经济效果好、生产率高等。

本次设计的题目是铣削组合机床及主轴组件。

首先针对所要加工的零件入手,对机床进行总体方案设计,进而确定机床的总体布局,随后,对主轴组件进行设计。

在设计主轴组件时,以主轴为线索,在满足刚度、精度等要求下,完成其它(如轴承、轴向调节机构、锁紧机构等)所有零件的设计。

设计机械加工工艺规程遵循如下原则:1)保证零件图样上所有技术要求的实现。

2)必须能满足生产纲领的要求。

3)在满足技术要求和生产纲领要求的前提下,要求工艺成本最低,低耗节能。

4)尽量减轻工人的劳动强度,保障生产安全。

维护环境卫生。

本产品是按用户要求而设计的,用户讨论合格后,投入生产,希望指导、鉴定。

关键词:组合机床,主轴组件,主轴,轴承,轴向调节机构AbstractModular Machine, by the large number of common parts and a small number of specialized components of the process focused efficient machine. Its features include compact, reliable quality, design and manufacturing cycle shorter, less investment and economic effects, and higher productivity.The design is the subject of combined milling machine spindle components. First of all, for the processing of parts to start with a general program of machine design, machine tool and then determine the overall layout, then the design of the main components. Components in the design of the spindle to spindle for clues, to meet the stiffness and precision required to complete the other (such as bearings, axial adjustment agencies, locking, etc.) the design of all parts.Design mechanical processing order to follow the following principles1) To ensure that all parts drawings on the realization of the technical requirements.2) Program must be able to meet production requirements.3) To meet the technical requirements and requirements of the production program, under the premise of the minimum requirements of cost, low energy.4) Minimize the labor intensity of workers, protection of production safety.This product is based on user requirements and design, the user discussion after passing the production, hope the guide, identified.Keywords:Modular Machine, spindle components, spindle, bearings, axial adjustment目录绪论 (1)第1章机床总体设计 (1)1.1 机床总体方案设计的依据 (1)1.2工艺分析 (1)1.3机床主要技术参数的确定 (3)1.4进给驱动电动机功率的确定 (5)第2章主轴组件要求与设计计算 (6)2.1主轴的基本要求 (6)2.2主轴组件的布局 (9)2.3主轴结构的初步拟定 (12)2.4主轴的材料与热处理 (13)2.5主轴的技术要求 (13)2.6主轴直径的选择 (14)2.7主轴前后支承轴承的选择 (15)2.8主轴内孔直径 (16)2.9主轴前端悬伸量 (17)2.10主轴支承跨距 (18)2.11主轴结构图 (18)2.12主轴组件的验算 (18)第3章主轴组件相关部件 (23)3.1主轴轴承的润滑 (21)3.2主轴组件的密封 (21)3.3轴肩挡圈 (23)3.4挡圈 (23)3.5圆螺母 (23)3.6套筒 (24)3.7前、后支承的轴承盖 (25)3.8主轴用套筒及其锁紧部分 (26)3.9主轴尾部的内花键 (27)3.10主轴组件轴向调节机构 (28)3.11箱体设计 (30)第4章结论 (31)参考文献 (32)致谢 (33)1 绪论机械制造业在国民经济中占有重要的地位,是国民经济各部门赖以发展的基础,是国民经济的重要支柱,是生产力的重要组成部分。

第1章绪论1.1 本课题的研究背景及意义随着现代化工业技术的快速发展,特别是随着它在自动化领域内的快速发展,组合机床的研究已经成为当今机器制造界的一个重要方向,在现代工业运用中,大多数机器的设计和制造都是用机床大批量完成的。

现代大型工业技术的飞速发展,降低了组合机床的实现成本,软件支持机制也使得实现变得更为简单,因此,研究组合机床的设计具有十分重要的理论意义和现实意义。

在工业高速发展的现代化浪潮中,各种机械设计和制造业中,组合机床的应用越来越广泛,越来越转化为生产力,从这个意义上讲,对组合机床的研究具有重要的现实意义。

组合机床是根据工件加工需要,以通用部件为基础,配以少量专用部件组成的一种高效专用机床。

组合机床是按系列化标准化设计的通用部件和按被加工零件的形状及加工工艺要求设计的专用部件组成的专用机床。

由于通用部件已经标准化和系列化,可根据需要灵活配置,从而缩短了设计和制造的周期,因此,组合机床兼有低成本和高效率的优点,在大批、大量生产中得到了广泛的应用,并可用以组成自动生产线。

总体方案的设计主要包括制定工艺方案(确定零件在组合机床上完成工艺内容及加工方法,选择定位基准和夹紧部位,决定工步和刀具种类及其结构形式,选择切削用量等)、确定机床配置形式、制订影响机床总体布局和技术性能的主要部件的结构方案。

总体方案的拟定是设计组合机床最关键的一步。

方案制定得正确与否,将直接影响机床能否达到合同要求,保证加工精度和生产率,并且结构简单、成本较低和使用方便。

对于同一加工内容,有各种不同的工艺方案和机床配置方案,在最后决定采用哪种方案时,必须对各种可行的方案作全面分析比较,根据工件的加工要求和特点,按一定的原则、结合组合机床常用工艺方法、充分考虑各种影响因素,并经技术经济分析后拟订出先进、合理、经济、可靠的工艺方案。

在组合机床诸多零件中,多轴箱和夹具与组合机床密切相关,是组合机床的重要组成部件。

它是选用通用零件"按专用要求设计的,所以是组合机床设计过程中工作量较大的零部件,就多轴箱设计来说,工作量主要集中在传动系统的设计上,轴的设计必须保证各轴的转速、旋向、强度和刚度,而且应当考虑有无让刀,有无调位机构等。

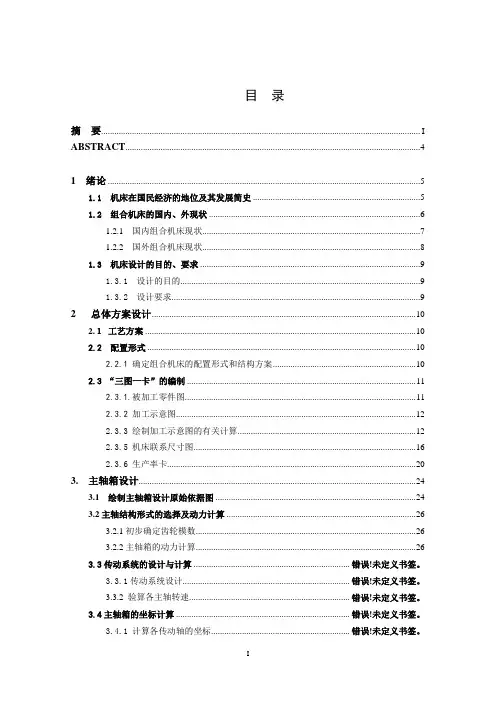

目录摘要 (I)ABSTRACT (4)1 绪论 (5)1.1 机床在国民经济的地位及其发展简史 (5)1.2 组合机床的国内、外现状 (6)1.2.1 国内组合机床现状 (7)1.2.2 国外组合机床现状 (8)1.3 机床设计的目的、要求 (9)1.3.1 设计的目的 (9)1.3.2 设计要求 (9)2 总体方案设计 (10)2.1工艺方案 (10)2.2 配置形式 (10)2.2.1确定组合机床的配置形式和结构方案 (10)2.3 “三图一卡”的编制 (11)2.3.1.被加工零件图 (11)2.3.2 加工示意图 (12)2.3.3 绘制加工示意图的有关计算 (12)2.3.5 机床联系尺寸图 (16)2.3.6 生产率卡 (20)3. 主轴箱设计 (24)3.1 绘制主轴箱设计原始依据图 (24)3.2主轴结构形式的选择及动力计算 (26)3.2.1初步确定齿轮模数 (26)3.2.2主轴箱的动力计算 (26)3.3传动系统的设计与计算 ....................................................................... 错误!未定义书签。

3.3.1传动系统设计............................................................................ 错误!未定义书签。

3.3.2 验算各主轴转速......................................................................... 错误!未定义书签。

3.4主轴箱的坐标计算 ............................................................................... 错误!未定义书签。

3.4.1 计算各传动轴的坐标............................................................... 错误!未定义书签。

目录1. 前言 (1)1.1 组合机床概述 (1)1.2 组合机床的优点 (1)1.3毕业设计的目的 (2)1.4 组合机床的设计步骤 (2)1.5 本次设计方案与技术路线 (4)2.拟订组合机床总体方案 (5)2.1 零件分析 (5)2.2 影响组合机床方案的因素 (7)2.3 确定机床的配置形式 (7)2.4 确定切削用量及刀具的选择 (7)3.组合机床总体设计—三图一卡 (9)3.1 被加工零件工序图的绘制 (9)3.2 加工示意图的绘制 (9)3.3 机床联系尺寸图的绘制 (13)3.4 编制生产率计算卡 (16)4.夹具设计 (19)4.1 定位元件 (19)4.2 夹具机构 (20)5.主轴箱设计 (23)5.1 绘制主轴箱原始依据图 (23)5.2 主轴结构型式的选择与动力计算 (24)5.3 传动系统的设计与计算 (25)6.其它 (26)6.2 机床精度及检测 (27)6.3 机床调整 (27)6.4 机床的维护和保养 (27)参考文献 (28)1. 前言1.1 组合机床概述随着加工工件的复杂化,批量化,以及在生产中所追求的高经济效益。

在单独的机床上已不能完成所有加工,这就要考虑到加工的专业化,即在加工一个工件的某些面孔等时配置一套专门的刀具夹具等。

组合机床就是根据工件需要,以大量通用部件为基础,配以少量专用部件组成的一种高效专用机床。

通用部件是组成组合机床的基础,用来实现机床切削运动的通用件。

如单轴工艺切削头,传动装置,动力箱,进给滑台等为动力部件。

用以安装动力部件的通用部件如侧底座,立柱,立柱底座为支撑部件。

目前组合机床主要用于平面加工和孔加工两类工序,平面加工包括铣平面,车端面。

孔加工包括钻.扩.铰孔以及倒角,切槽,攻螺纹滚压孔等。

随着综合自动化的发展,其工艺范围正在扩大到车外圆,行星铣削,拉削,推削,磨削,研磨及抛光,冲压等工序,此外还可以完成焊接热处理,自动装配和检测,清洗和零件分类以及打印等非切削工艺。

绪论组合机床是由已经系列化、标准化的通用部件和少量的专用部件组成的,它能从多面,多工位,多轴对一个或几个工件同时进行加工,和一般万能机床相比,具有设计制造周期短,成本低,自动化程度高,加工效率高,加工质量稳定,减轻工人劳动强度等优点。

在机械制造工业中,装备新企业或者对老企业进行技术制造,采用组合机床及自动线,是发展生产,提高质量的有效途径之一。

机械部分着重介绍组合机床的设计原理,设计步骤和方法,以及组合机床及其自动线工艺方案的拟定原则。

为了更好的了解组合机床的优越性,有必要将其设计制造的情况和专用机床进行一下对比。

由于组合机床是由70%~90%的通用零件和部件组成的,在需要的时候,它可以部分或全部改装,以组成适应新的加工要求的新设备。

组合机床有重新改装的优越性,其通用零部件可以多次重复使用。

组合机床是按具体的加工对象专门设计的,因而可以按量合理的工艺过程进行加工。

在组合机床上可以同时从几个方向采用多把刀具对几个工件进行加工。

它是实现集中工序的最好途径,是提高生产率的有效设备。

组合机床常常是用多轴对多箱体零件一个面上的许多孔同时进行加工。

这样就能保证各孔之间的精度要求,提高产品的质量;减少了工件工序间的搬运改善劳动条件,也减少了占地面积。

由于组合机床大多数零部件是同类的零部件,这就简化了机床的维护和修理。

必要时可以更换整个部件,以提高机床的维修速度,组合机床的通用部件可以组织专门工厂集中生产。

这样可以采用专用高效设备进行加工,有利于提高通用部件的性能,降低制造成本。

组合机床的优点虽然很多,但是也存在不足。

组合机床的可变性较万能机床低,重新改装的有10%~20%的零件不能重复使用,而且改装的劳动量比较大。

组合机床的通用部件不是为某一种机床而设计的,而是具有较广的适用性。

这样,就使组合机床的结构比专用机床复杂些。

1被加工零件的工艺分析制定组合机床的工艺方案是设计组合机床的重要步骤之一。

工艺方案制定的正确与否,将决定机床能否达到重量轻,体积小,机构简单,使用方便,效率高,质量好的要求。

目录摘要 .................................................................................................................................................... Abstract ............................................................................................................................................... 第一章绪论.. 01.1 设计目 01.2 设计内容 01.3 设计规定 0第二章组合机床总体设计 (1)2.1 工序图 (1)2.2 加工示意图 (2)2.3 机床尺寸联系总图 (5)第三章多轴箱设计 (9)3.1 多轴箱构成 (10)3.2多轴箱装配图绘制 (9)(1)驱动轴位置拟定 (9)(2)主轴位置拟定 (9)(3)驱动轴齿轮拟定 (9)(4)各传动轴位置拟定 (11)(5)手柄轴安顿 (11)(6)润滑油泵安顿 (11)3.3选取加工基准坐标系XOY,计算主轴、驱动轴坐标 (13)总结 (14)参照文献(References) (15)致谢 (17)卧式双面24轴组合钻床总体设计及左主轴箱设计(双级圆锥-圆柱齿轮减速器箱体底座)专业:机械设计制造及其自动化学号:学生姓名:徐伟龙指引教师:冯永平摘要:组合钻床是依照工件加工需要,以通用部件为基本,配之以少量专用部件和按工件形状与加工工艺设计专用部件和夹具,构成专用钻床。

组合机床同步具备生产效率高、加工精度高、配备较为灵活等长处,是机械一线生产中不可获缺机器,也是高校大学生毕业设计研究一种重要课题之一。

作为一名机械专业学生,我有幸选取了这一种课题研究,得到了这次理解组合机床机会。

当前我就来简述这次课程设计过程:依照零件(双级圆锥-圆柱齿轮减速器箱体底座左端面12孔)类型和加工规定我选取了卧式组合钻床;在动力部件选取方面,由于液压滑台导向性好、使用寿命长、液压缸活塞和后盖上分别装有双向单向阀和缓冲装置因此我选取了液压滑台;动力箱方面则采用三相异步电动机作为动力源,动力头选用了钻削头;辅助部件涉及定位、夹紧、润滑、冷却、排屑以及自动线清洗机等各种辅助装置,固然尚有其她支承部件、控制部件、辅助部件等等我将在阐明书中详述。

核心词:组合机床,动力部件,辅助部件,支承部件Abstract:The combination machine the workpiece is required,in order based on common components,combined with a small amount of special components and process according to the workpiece shape and design of special parts and fixtures,special machines composed. Combination machine also has high production efficiency,high precision,more flexible configuration,etc.,is indispensable actual production machines,also graduated from college students is an important topic of study design,as a mechanical engineering student,I fortunate to have chosen a subject of this study,has been the opportunity to understand the combination of machine tools. Now I come to brief the curriculum design process:According parts - Requirements (two-stage tapered cylindrical gear reducer base cabinet left side 12 holes) the type and processing I chose a combination of horizontal drilling;in the power unit,since the hydraulic slide guiding good,long life hydraulic cylinder piston and the back cover are equipped with two-way check valve and buffer device so I chose a hydraulic sliding table;power box area is used in three-phase asynchronous motor as a power source,power head chose the drilling head;accessories including positioning,clamping,lubrication,cooling,chip washing machines and automatic lines and other auxiliary devices,and other supporting components,control components,accessories,etc. will be described in the specification.Keywords:Combination machine,Power unit,Accessories,Supporting member第一章绪论1.1 设计目对于本次组合机床毕业设计,其目重要是通过对组合机床设计,对咱们大学四年所学理论知识总结,以及与在这四年中所接触实践知识两者相结合,锻炼学生自己动手能力、设计能力,为此后咱们在机械生产岗位工作做铺垫。

此外,通过对组合机床主运动和机械传动系统初步设计,使咱们在这些设计过程中,得到设计构思、方案分析、机械构造工艺性、机械绘图、零件强度计算、编写阐明书和查阅数据资料等方面综合训练,掌握了基本设计流程,培养基本设计办法,并培养了咱们具备初步机械构造分析、机械构造设计和数据计算能力。

1.2 设计内容1.2.1 运动设计依照任务书已给定被加工零件材料和被加工孔孔径大小,拟定机床切削用量、切削扭矩、切削力、切削功率等初始数据,通过度析已绘制工序图、加工示意图、尺寸联系图制定初步传动方案和传动系统图,比较初拟定传动方案和传动系统图,拟定每级传动副传动比及齿轮模数和齿数,最后比较主轴实际转速与设计原则转速相对误差。

1.2.2 动力设计依照给定被加工零件,初算拟定各轴直径、齿轮模数;然后初步拟定动力箱尺寸;再计算多轴箱尺寸和初步设计传动路线。

完毕所有图纸后,还需要验算传动轴直径,齿轮模数、齿轮强度与否在容许范畴内。

1.2.3 构造设计进行主运动主轴和传动轴系、主轴齿轮等主件、箱体箱盖、润滑与密封等装置和零件布置和机构设计。

1.2.4 编写组合加床设计阐明书1.3 设计规定通过自己独立对组合机床设计,理解组合机床构造特点和用途范畴,对毕业生四年所学知识总结;最后完毕设计图纸要做到明了简洁,设计方案需要达到既定经济指标,做到物美价廉才会受市场使用和欢迎。

第二章组合机床总体设计2.1 工序图2.1.1 技术分析工件锻造而成后,用清砂机清理铸件,并进行内应力消除。

依照任务书给定被加工零件以及被加工孔孔径工艺规定如下:钻孔:12xΦ17.4mm材料:HT250硬度:HB175-255孔深:L=30mm2.1.2工艺分析依照组合机床特点咱们可以采用一次加工十二个孔办法。

是十二个孔位置精度不一,因此在设计是对主轴位置精度规定较高。

依照工件构造特点,本次加工采用一面两销办法定位,并且对箱盖上顶面进行夹压。

图1 工序图2.2 加工示意图2.2.1 加工示意图作用和内容加工示意图是设计刀具、多轴箱、夹具和电气、液压系统以及选取动力部件、绘制机床联系尺寸图根据;是对机床布局与机床性能原始规定;也是对机床和刀具调节所必须文献。

加工示意图重要绘制机床加工办法、导向装置构造尺寸、切削用量、接杆构造尺寸、工作循环和工作行程、刀具导向套间配合等等。

2.2.2 刀具和导套选取及关于计算(1) 刀具选取铸件壁厚为10mm 在2.5~10之间,因此选硬度HBS 在175~255之间。

依照资料《组合机床设计简要手册》 P134查得:布氏硬度 228HB =175)-255(1/3-255=HBmin)-1/3(HBmax -HBmax =HB 依照资料《组合机床设计简要手册》 P130中表6-11 查得加工材料为铸铁,高速钢钻头D=17.4mm 属于12mm-22mm 区间时切削用量:选用:V=12m/min f=0.2mm/r依照资料《组合机床设计简要手册》 P134中公式得:r/min 5.19214.34.17121000 D 1000V n =**==π m m /m in 9.340.25.192f n f =*=*=Vn —刀具转速 v —切削速度(m/min) f —每转进给量(mm) Vf -进给运动速度 依照资料《组合机床设计简要手册》P134中表6-20公式,切削力: 3244.12N 2820.24.7126HB 26D F 0.60.80.60.8=***==f切削扭矩:mm 56.163162822.04.7110HB f10D T 0.60.81.90.60.81.9•=***==N 切削功率:kW 0.36764.1714.397401216316.569740Tv P =***==D π 式中: HBS —布氏硬度 F —切削力(N ) D —钻头直径(mm ) f —每转进给量(mm) T —切削扭矩(N ·mm ) v —切削速度(m/min ) P —切削功率(kW )依照GB/T 1438.2-查得:图2 锥柄麻花钻依照GBT 1443-1996机床和工具柄用自夹圆锥原则,可得出莫氏二号锥柄各项数据,D=17.5mm ,1L =165mm ,L=263mm 。