道康宁有机硅

- 格式:pdf

- 大小:53.32 KB

- 文档页数:10

道康宁314058元/支道康宁3140 敷形涂料是一种高粘度、自流平、现成可用、室温硬化的硅酮弹性体。

固化时产生的副产品是非腐蚀性的。

因此,道康宁3140 敷形涂料可用于易于腐蚀的电气/电子设备。

本产品供货时是一种高粘度的液体,固化后成为坚韧、耐磨的弹性体,主要用于改善引出端与焊料结合处的覆盖性能和薄层密封。

康宁DC-OE6550AB高折配粉胶牌号:美国道康宁产商:3500-4000元/KG类别:高温型有机硅树脂含量≥:0(%)用途:大功率LED配粉硅胶C AS:1000产品特性:颜色无色透明外观半流动性品牌道康宁粒度大功率LED荧光粉胶耐温250(℃)粘度LED配粉胶脱色率LED固粉胶(%)(%)水份0(%)主要用途大功率LED荧光粉胶产品优势:一、特性及說明:OE6550有机硅为A、B部分、双组份加成型产品,无溶剂,高纯度;固化物具有很好的电绝缘性、防水密封性、抗黃化抗老化及抗冷热交替性能;固化物与金属粘接附和性良好,经严格测试不硬化、不硅裂;高品质的耐高溫有机硅材料,折射率高。

产品说明: OE-6550 大功率LED封装配粉硅胶●品牌:Dow Corning●品名:OE-6550 A/B(封装胶)●产品描述(物料编号∕型号∕规格∕包装方式): OE-6550 A,BOT,500G OE-6550 B,BOT,500G●制程应用参数:(仅供参考,建议客户在不同制程工艺下微调) 1.双组分,A:B配比1:1,冷暗环境下保存,无需放置冰箱,保质期12个月。

2.固化温度与时间:150℃下1H. 3.粘滞度:4 Pa.s. 4.折射率:1.543.(高折射率) 5.硬度:52(JIS A)。

6.透光率:98%。

(高透光率)技术指标:固化前外观 A组份………………………无色透明液体B组份………………………无色透明液体密度(g/cm3)A组份………………………0.96~0.99B组份………………………0.96~0.99粘度(25℃/ mpa.s)A组份…………………11000-11200B组份…………………1400-1600AB混合比例(重量比)……………………………1:1粘度(混合后)@25℃/mpa.s………………………4500-5000强度(邵氏A) (20)可操作时间(常温25℃)……………………140分钟固化方式................. 150℃)60分钟固化后外观……………………………透明粘弹性体体积电阻Ω.㎝……………………………>1.0×1015介电常数(1.2MHz) ………………………………≤3击穿电压强度(Kv/mm) …………………………>25扯断伸长率(﹪) ………………………………≥200耐温范围(℃)....................................-60~200折射率(ND25)..........................................1.51透光率(%) 450nm 1mm thick (98)道康宁CN-8760混合粘度:3200mPa.s产品特性:A:B=1:1,流动性好,少气泡,灌封电源模块。

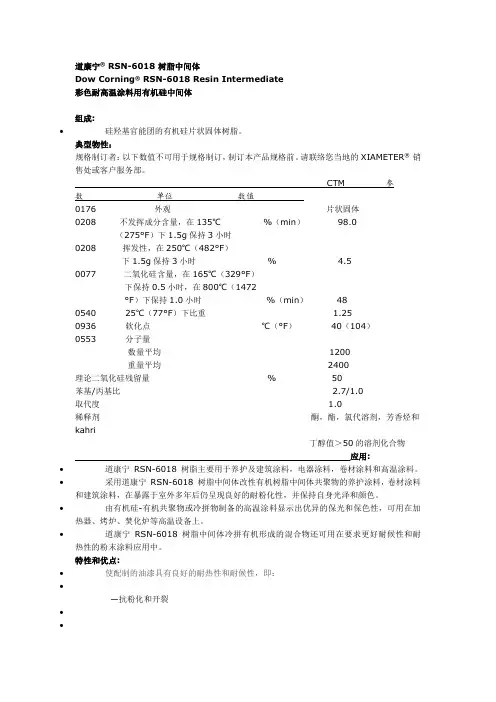

道康宁® RSN-6018 树脂中间体Dow Corning® RSN-6018 Resin Intermediate彩色耐高温涂料用有机硅中间体组成:•硅羟基官能团的有机硅片状固体树脂。

典型物性:规格制订者:以下数值不可用于规格制订,制订本产品规格前。

请联络您当地的XIAMETER®销售处或客户服务部。

CTM 参数单位数值0176 外观片状固体0208 不发挥成分含量,在135℃%(min)98.0(275°F)下1.5g保持3小时0208 挥发性,在250℃(482°F)下1.5g保持3小时% 4.5 0077 二氧化硅含量,在165℃(329°F)下保持0.5小时,在800℃(1472°F)下保持1.0小时 %(min) 480540 25℃(77°F)下比重 1.250936 软化点℃(°F) 40(104)0553 分子量数量平均1200重量平均 2400理论二氧化硅残留量 % 50苯基/丙基比 2.7/1.0取代度 1.0稀释剂酮,酯,氯代溶剂,芳香烃和kahri丁醇值>50的溶剂化合物应用:•道康宁RSN-6018 树脂主要用于养护及建筑涂料,电器涂料,卷材涂料和高温涂料。

•采用道康宁RSN-6018 树脂中间体改性有机树脂中间体共聚物的养护涂料,卷材涂料和建筑涂料,在暴露于室外多年后仍呈现良好的耐粉化性,并保持自身光泽和颜色。

•由有机硅-有机共聚物或冷拼物制备的高温涂料显示出优异的保光和保色性,可用在加热器、烤炉、焚化炉等高温设备上。

•道康宁RSN-6018 树脂中间体冷拼有机形成的混合物还可用在要求更好耐候性和耐热性的粉末涂料应用中。

特性和优点:•使配制的油漆具有良好的耐热性和耐候性,即:•—抗粉化和开裂••—保持光泽和颜色••含 30%道康宁®RSN-6018 树脂的铝颜料保护涂料,工作温度可达 425°C (797°F)。

道康宁反应型有机硅油道康宁反应型有机硅油是一种具有优异性能的有机硅化合物,广泛应用于各个领域。

它以其独特的化学结构和物理特性,为众多工业和科学领域带来了革命性的变化和进展。

道康宁反应型有机硅油具有良好的热稳定性和耐高温性。

在高温环境下,它能够保持稳定的物理和化学性质,不发生分解或氧化反应。

这使得道康宁反应型有机硅油在高温工艺和设备中得到广泛应用,例如润滑油、导热介质和高温涂层等领域。

道康宁反应型有机硅油具有良好的电绝缘性能。

它具有较高的绝缘强度和体积电阻率,能够有效隔离电流,防止电流泄漏和电弧放电。

这使得道康宁反应型有机硅油在电子电气领域得到广泛应用,例如变压器、电容器和电缆绝缘等设备中。

道康宁反应型有机硅油还具有优异的化学稳定性和耐腐蚀性。

它能够抵抗酸碱、溶剂、氧化剂和腐蚀性气体的侵蚀,不发生化学反应或腐蚀。

这使得道康宁反应型有机硅油在化工和材料处理领域得到广泛应用,例如防腐涂料、密封材料和化学反应媒介等。

道康宁反应型有机硅油还具有良好的润滑性和附着性。

它能够有效减少机械设备的摩擦和磨损,提高设备的工作效率和使用寿命。

同时,道康宁反应型有机硅油还能够附着在物体表面,形成润滑膜,保护材料不受磨损和腐蚀。

这使得道康宁反应型有机硅油在机械制造和润滑领域得到广泛应用,例如汽车发动机油、润滑脂和润滑油等。

道康宁反应型有机硅油还具有良好的抗氧化性和抗老化性。

在长时间的使用和暴露于外界环境的情况下,它能够保持稳定的物理和化学性质,不发生氧化或降解。

这使得道康宁反应型有机硅油在化妆品、医药和食品工业中得到广泛应用,例如护肤品、药物载体和食品添加剂等。

道康宁反应型有机硅油以其独特的性能和广泛的应用领域,为各个行业带来了巨大的发展机遇和创新空间。

它不仅提升了产品的性能和品质,还推动了工业和科学技术的进步与发展。

随着科学技术的不断发展,道康宁反应型有机硅油将继续发挥重要作用,为人类创造更加美好的生活和未来。

纺织品与皮革解决方案有机硅皮革整理剂道康宁有机硅皮革整理剂皮革由于其外观漂亮,手感良好,已经成为时尚的一部分;同时它舒适且容易打理,在日常生活中也非常实用。

因此皮革制品在汽车内饰,衣饰和家用时尚饰品市场中的份额迅速增长。

有机硅能够为天然皮革带来真实自然的触感和外观,并使其具备重要的疏水和耐摩性能。

有机硅可以使合成革更软,透气、透湿性更好。

本手册提供了全球范围内经销的道康宁有机硅皮革整理剂产品的相关信息。

其全球产品家族包括一系列在皮革整理中,经验证具有高性能、实用的有机硅产品。

而且道康宁还提供其他一些特别适用于您当地特殊需求的有机硅产品。

如需更多信息,请联系当地道康宁代表处。

产品描述(天然皮革整理)道康宁 产品特性/优点涂饰Q2-3238 分散性有机硅添加剂高分子量有机硅系统;特别适用于汽车革涂层的添加剂,改善手感,提高耐湿磨性能,并提供消光效果;与聚氨酯和丙烯酸树脂相容性良好;可用于溶剂和水性体系。

2-9147 LF 分散液分散于溶剂(即乙二醇单乙醚)中的高分子量有机硅,使使用更方便;特别适用于汽车革涂层的添加剂,改善手感,提高耐湿磨性能,并提供消光效果;与聚氨酯和丙烯酸树脂相容性良好;可用于溶剂和水性体系。

3289分散于水中的高分子量有机硅系统;特别适用于汽车革涂层的添加剂,改善手感,提高耐湿磨性能,并提供消光效果;与聚氨酯和丙烯酸树脂相容性良好;可用于溶剂和水性体系。

5-7033 LF 悬浮液有机硅弹性体颗粒的水分散悬浮液;作为聚氨酯和丙烯酸树脂涂层的手感剂,可用于所有种类皮革的处理,特别是汽车革和家具革;涂层手感天然,并具有自然的消光效果。

5-7031 LF 乳液氨基硅油的大颗粒乳液用于改善手感,且能适度增强耐湿磨性能。

5-7194 LF乳液高分子量氨基硅油的微乳液用于改善皮革涂层触感。

5-7222 LF乳液超高分子量特殊聚二甲基硅氧烷的大颗粒乳液;用于皮革涂层,提高耐磨和耐湿擦性能,同时有助于改善触感。

道康宁部分树脂参数道康宁® RSN-6018 树脂中间体Dow Corning® RSN-6018 Resin Intermediate彩色耐高温涂料用有机硅中间体组成:∙硅羟基官能团的有机硅片状固体树脂。

典型物性:规格制订者:以下数值不可用于规格制订,制订本产品规格前。

请联络您当地的XIAMETER®销售处或客户服务部。

CTM 参数单位数值0176 外观片状固体0208 不发挥成分含量,在135℃%(min)98.0(275°F)下1.5g保持3小时0208 挥发性,在250℃(482°F)下1.5g保持3小时% 4.50077 二氧化硅含量,在165℃(329°F)下保持0.5小时,在800℃(1472°F)下保持1.0小时 %(min) 480540 25℃(77°F)下比重 1.250936 软化点℃(°F) 40(104)0553 分子量数量平均1200重量平均 2400理论二氧化硅残留量 % 50苯基/丙基比 2.7/1.0取代度 1.0稀释剂酮,酯,氯代溶剂,芳香烃和kahri丁醇值>50的溶剂化合物应用:∙道康宁RSN-6018 树脂主要用于养护及建筑涂料,电器涂料,卷材涂料和高温涂料。

∙采用道康宁RSN-6018 树脂中间体改性有机树脂中间体共聚物的养护涂料,卷材涂料和建筑涂料,在暴露于室外多年后仍呈现良好的耐粉化性,并保持自身光泽和颜色。

∙由有机硅-有机共聚物或冷拼物制备的高温涂料显示出优异的保光和保色性,可用在加热器、烤炉、焚化炉等高温设备上。

∙道康宁RSN-6018 树脂中间体冷拼有机形成的混合物还可用在要求更好耐候性和耐热性的粉末涂料应用中。

特性和优点:∙使配制的油漆具有良好的耐热性和耐候性,即:∙—抗粉化和开裂∙∙—保持光泽和颜色∙∙含 30%道康宁®RSN-6018 树脂的铝颜料保护涂料,工作温度可达 425°C (797°F)。

道康宁给我们带来了什么?David Tao随着道康宁(张家港)19万吨/年硅氧烷装置的全面投料生产,国内有机硅行业被期待、兴奋、恐慌、沮丧等诸多纷繁复杂的情绪所笼罩。

不久前在上海参加一个会展时,我与几位业内人士谈论过道康宁(张家港)项目,从技术的先进性到环境保护水平,从对国内有机硅单体企业的冲击到促进产业结构调整,话题不一而足。

那么,道康宁究竟给国内有机硅行业带来了什么呢?毋容置疑的是,道康宁(张家港)给中国有机硅行业带来的不仅是新一轮的产业结构重整和升级,而且更将是一场新思维、新方法和新观念的革命。

迄今为止,道康宁已经在中国完成“技术服务-生产-销售”、“从初级原料-中间体-下游产品开发”的完整产业链建设。

当我们穿越道康宁在中国市场的开拓历程,便能深深地感受到新思维、新观念给我们带来的冲击,而最令我们无法抗拒的是道康宁营销理念所形成的那种超自然的魔力。

自1943年至今,道康宁经过近70年的研发、生产和市场开拓,已经构建成为基于营销职能的企业组织,这正是国内有机硅行业最欠缺、最值得借鉴的企业组织形式,也是本文要重点阐述和讨论的命题。

那么,我们怎样才能认识这种企业组织形式?在阐述这种企业组织形式之前,让我们回答以下命题:n 产品卖不出去是销售部门的责任; n 产品研发项目由技术研发人员自己确定;n 产品质量指标由生产管理部门自己确定。

你认为上述命题正确吗?答案是否定的。

事实上,随着全球经济一体化进程的加速,企业已不是传统意义上纯生产组织,而是集资本、技术、管理、装备、研发、市场等多项职能综合而成的整体。

那么,如何促使这个整体高效运作,就成为了所有企业家所孜孜以求的现实命题,而实现高效运作的基点,则是企业要构建基于什么的企业组织。

当我们踏着道康宁在中国市场开拓的脉搏寻求这个答案时,感受最强烈的是其对营销职能的理解,以及在实践中强化其职能,使其能够成为带动企业全方位高效运作的引擎。

U n R e g i s t e r e d现在,让我们回顾道康宁在中国市场开拓和发展的路线图。

硅基热塑性硫化胶TPSiV的特性及应用硅基热塑性硫化胶(TPSiV)是道康宁公司开发的世界上第一个以硫化硅橡胶颗粒在热塑性基材上形成的热塑性有机硅弹性体,该系列有机硅弹性体拥有13项专利技术。

通过有机硅的表面富集性和憎水性,不仅拓展了热塑性弹性体和热塑性硫化胶的性能,使得其具有优良的抗高温性能,高温时的低拉伸性和压缩性以及良好的耐磨性、抗水解性和耐化学(包括燃料和油性),同时,相对于普通热塑性弹性体而言,有机硅弹性体TPSiV具有更加优异的包覆性和独特的人体美学触感,并且可以回收使用、绿色环保,目前广泛应用于消费电子、化妆品、食品、汽车、运动休闲等各个行业。

起源及结构特点TPSiV是热塑性有机硅弹性体(Thermo Plastic Silicone Vulcanizate)的简称及注册商标。

它是应用道康宁所独有的具有13项专利的动态硫化交联技术将充分硫化的硅橡胶微粒,均匀分散在热塑性材料的连续相中所形成的一种稳定的TPV高分子合金。

与高分子合成方法制备的热塑性弹性体TPE相比,TPSiV具有以下特点:(1)具有特殊的海—岛相态结构,其中微小的硅橡胶粒子呈分散相存在,而热塑性基体则以连续相包覆在硅橡胶粒子周围,如图1和图2所示;(2)整个有机硅橡胶的硫化过程是清洁化学反应:无副产物、无气味、无挥发物。

TPSiV独特的结构赋予了其优良的物理机械性能和热塑加工性。

海相/连续相——热塑性基体岛相/分散相——硅橡胶粒子图1 TPSiV的海—岛结构图2 电镜扫描照片应用具有专利的动态硫化技术研发而成的TPSiV,与通常的热塑性弹性体相比,具有如下特性:(1)配方中不含有溶剂油和增塑剂等易导致黄变的添加剂,可以根据需求染成各种颜色,如图3;(2)表面不易吸附灰尘;(3)抗油性和抗化学性好,不易污染;(4)与许多热塑性工程塑料如PC、PC/ABS、ABS、PA、PVC等具有优异的粘接性,可用于共挤和双色注塑成型;(5)150℃热空气或150℃高温老化后依然可以保持较高的机械强度;(6)可用于丝印、移印、喷漆等二次加工。

硅基热塑性硫化胶TPSiV的特性及应用硅基热塑性硫化胶(TPSiV)是道康宁公司开发的世界上第一个以硫化硅橡胶颗粒在热塑性基材上形成的热塑性有机硅弹性体,该系列有机硅弹性体拥有13项专利技术。

通过有机硅的表面富集性和憎水性,不仅拓展了热塑性弹性体和热塑性硫化胶的性能,使得其具有优良的抗高温性能,高温时的低拉伸性和压缩性以及良好的耐磨性、抗水解性和耐化学(包括燃料和油性),同时,相对于普通热塑性弹性体而言,有机硅弹性体TPSiV 具有更加优异的包覆性和独特的人体美学触感,并且可以回收使用、绿色环保,目前广泛应用于消费电子、化妆品、食品、汽车、运动休闲等各个行业。

?起源及结构特点?TPSiV是热塑性有机硅弹性体(ThermoPlasticSiliconeVulcanizate)的简称及注册商标。

它是应用道康宁所独有的具有13项专利的动态硫化交联技术将充分硫化的硅橡胶微粒,均匀分散在热塑性材料的连续相中所形成的一种稳定的TPV高分子合金。

与高分子合成方法制备的热塑性弹性体TPE相比,TPSiV具有以下特点:(1)具有特殊的海—岛相态结构,其中微小的硅橡胶粒子呈分散相存在,而热塑性基体则以连续相包覆在硅橡胶粒子周围,如图1和图2所示;(2)整个有机硅橡胶的硫化过程是清洁化学反应:无副产物、无气味、无挥发物。

TPSiV独特的结构赋予了其优良的物理机械性能和热塑加工性。

海相/连续相——热塑性基体?岛相/分散相——硅橡胶粒子图1TPSiV的海—岛结构图2电镜扫描照片应用具有专利的动态硫化技术研发而成的TPSiV,与通常的热塑性弹性体相比,具有如下特性:(1)配方中不含有溶剂油和增塑剂等易导致黄变的添加剂,可以根据需求染成各种颜色,如图3;(2)表面不易吸附灰尘;(3)抗油性和抗化学性好,不易污染;(4)与许多热塑性工程塑料如PC、PC/ABS、ABS、PA、PVC等具有优异的粘接性,可用于共挤和双色注塑成型;(5)150℃热空气或150℃高温老化后依然可以保持较高的机械强度;(6)可用于丝印、移印、喷漆等二次加工。

Page: 1 of 10Version: 1.5Revision Date: 2010/04/12DOW CORNING(R) 9-6346 SILANE1. PRODUCT AND COMPANY IDENTIFICATIONDow Corning Corporation South Saginaw Road Midland, Michigan 48686 24 Hour Emergency Telephone:Customer Service:Product Disposal Information:CHEMTREC:(989) 496-5900(989) 496-6000(989) 496-6315(800) 424-9300MSDS No.: 04021703 Revision Date: 2010/04/12 Generic Description: Organosilane.Physical Form: LiquidColor: Colorless to pale yellowOdor: Alcoholic odorNFPA Profile: Health3Flammability3Instability/Reactivity0Note: NFPA = National Fire Protection Association2. HAZARDS IDENTIFICATIONPOTENTIAL HEALTH EFFECTSAcute EffectsEye: May cause irreversible damage and burns to the eyes.Skin: May cause moderate irritation.Inhalation: Vapor and/or mist may irritate nose and throat. Overexposure by inhalation may causedrowsiness, dizziness, confusion or loss of coordination.Oral: Overexposure by ingestion may cause effects similar to those listed under repeatedexposure.Prolonged/Repeated Exposure EffectsSkin: Repeated or prolonged exposure may irritate seriously. Overexposure may injure internally if absorbed.Inhalation: Overexposure to vapor may cause blindness and nervous system effects due to methylalcohol poisoning. Overexposure by inhalation may injure the following organ(s): Bladder.Kidneys. Liver. Adrenals.Oral: If swallowed, blindness, even death may result due to methyl alcohol poisoning.Other Health EffectsThis product contains a chemical(s) that has the following effect(s):MutagenicityPage: 2 of 10Version: 1.5Revision Date: 2010/04/12DOW CORNING(R) 9-6346 SILANESee Section 11 for specific details.Signs and Symptoms of OverexposureNo known applicable information.Medical Conditions Aggravated by ExposureNo known applicable information.The above listed potential effects of overexposure are based on actual data, results of studies performed upon similar compositions, component data and/or expert review of the product. Please refer to Section 11 for the detailed toxicology information.3. COMPOSITION/INFORMATION ON INGREDIENTSName% ComponentCAS Number Wt27668-52-6 > 60.0 Octadecyldimethyl trimethoxysilylpropyl ammonium chloride2530-87-2 10.0 - 30.0 Chloropropyltrimethoxysilane67-56-1 10.0 - 30.0 Methyl alcohol<1.0 Propyltrimethoxysilane1067-25-0The above components are hazardous as defined in 29 CFR 1910.1200.4. FIRST AID MEASURESEye: Immediately flush the contaminated eye(s) with lukewarm, gently flowing water for 30 minutes while holding the eyelid(s) open. If contact lens is present, DO NOT delay irrigation orattempt to remove the lens. Neutral saline solution may be used as soon as available. Do notinterrupt flushing. If necessary, continue flushing during transport to emergency care facility.Take care not to rinse contaminated water into the unaffected eye or onto the face.Immediately obtain medical attention.Skin: As quickly as possible remove contaminated clothing, shoes and leather goods (e.g.watchbands, belts). Quickly and gently blot or brush away excess chemical. Immediatelyflush with lukewarm gently flowing water for 15 minutes. Completely decontaminate clothing,shoes and leather goods before reuse or discard. Obtain medical attention.Inhalation: Remove from the source of contamination or move to fresh air If breathing is difficult, trained personnel should administer emergency oxygen. If irritation persists, obtain medical advice.Page: 3 of 10Version: 1.5Revision Date: 2010/04/12DOW CORNING(R) 9-6346 SILANEOral: Never give anything by mouth if victim is rapidly losing consciousness or convulsing. Have victim rinse mouth thoroughly with water DO NOT INDUCE VOMITING. Have victim drink 2to 8 oz. (60 to 240 mL) of water. If vomiting occurs naturally, have victim lean forward toreduce the risk of aspiration. Have victim rinse mouth with water again. Immediately obtainmedical attention.Notes to Physician: Treat according to person's condition and specifics of exposure.5. FIRE FIGHTING MEASURESFlash Point: 71.6 °F / 22 °C (Pensky-Martens Closed Cup)Autoignition Temperature: 496.4 °F / 258 °CFlammability Limits in Air: Not determined.Extinguishing Media: On large fires use dry chemical, foam or water spray. On small fires use carbon dioxide(CO2), dry chemical or water spray. Water can be used to cool fire exposed containers. Fire Fighting Measures: Self-contained breathing apparatus and protective clothing should be worn in fighting large fires involving chemicals. Determine the need to evacuate or isolate the area according toyour local emergency plan. Use water spray to keep fire exposed containers cool. Unusual Fire Hazards: Vapors are heavier than air and may travel to a source of ignition and flash back. Staticelectricity will accumulate and may ignite vapors. Prevent a possible fire hazard by bondingand grounding or inert gas purge.6. ACCIDENTAL RELEASE MEASURESContainment/Clean up: Remove possible ignition sources. Determine whether to evacuate or isolate the areaaccording to your local emergency plan. Observe all personal protection equipmentrecommendations described in Sections 5 and 8. For large spills, provide diking or otherappropriate containment to keep material from spreading. If diked material can be pumped,store recovered material in appropriate container. Clean up remaining materials from spillwith suitable absorbant. Clean area as appropriate since spilled materials, even in smallquantities, may present a slip hazard. Final cleaning may require use of steam, solvents ordetergents. Dispose of saturated absorbant or cleaning materials appropriately, sincespontaneous heating may occur. Local, state and federal laws and regulations may apply toreleases and disposal of this material, as well as those materials and items employed in thecleanup of releases. You will need to determine which federal, state and local laws andregulations are applicable. Sections 13 and 15 of this MSDS provide information regardingcertain federal and state requirements.Note: See section 8 for Personal Protective Equipment for Spills. Call (989) 496-5900, if additional information is required.Page: 4 of 10Version: 1.5Revision Date: 2010/04/12DOW CORNING(R) 9-6346 SILANE7. HANDLING AND STORAGEUse with adequate ventilation. Product evolves flammable methyl alcohol when exposed to water or humid air. Provide ventilation during use to control exposure within Section 8 guidelines or use air-supplied or self-contained breathing apparatus. Do not get in eyes. Avoid skin contact. Do not breathe vapor. Keep container closed. Do not take internally. Static electricity will accumulate and may ignite vapors. Prevent a possible fire hazard by bonding and grounding or inert gas purge. Keep container closed and away from heat, sparks, and flame. Keep container closed and store away from water or moisture.8. EXPOSURE CONTROLS / PERSONAL PROTECTIONComponent Exposure LimitsName Exposure LimitsCAS Number ComponentSee methyl alcohol comments.trimethoxysilylpropyl27668-52-6 Octadecyldimethylammonium chloride2530-87-2 Chloropropyltrimethoxysilane Dow Corning guide: TWA 0.1 ppm. Also see methyl alcoholcomments.alcohol OSHA PEL (final rule): TWA 200 ppm, 260 mg/m3 and 67-56-1 MethylACGIH TLV-skin: TWA 200 ppm, STEL 250 ppm.Methyl alcohol forms on contact with water or humid air. Provide adequate ventilation to control exposures within guidelines of OSHA PEL: TWA 200 ppm and ACGIH TLV-skin: TWA 200 ppm, STEL 250 ppm.Engineering ControlsLocal Ventilation: Recommended.General Ventilation: Recommended.Personal Protective Equipment for Routine HandlingEyes: Use chemical worker's goggles.Skin: Wash at mealtime and end of shift. If skin contact occurs, change contaminated clothing as soon as possible and thoroughly flush affected areas with cool water. Chemical protectivegloves are recommended.Suitable Gloves: Avoid skin contact by implementing good industrial hygiene practices and procedures. Select and use gloves and/or protective clothing to further minimize the potential for skin contact.Consult with your glove and/or personnel protective equipment manufacturer for selection ofappropriate compatible materials.Page: 5 of 10Version: 1.5Revision Date: 2010/04/12DOW CORNING(R) 9-6346 SILANEInhalation: Use respiratory protection unless adequate local exhaust ventilation is provided or exposure assessment demonstrates that exposures are within recommended exposure guidelines. IHpersonnel can assist in judging the adequacy of existing engineering controls.Suitable Respirator: General and local exhaust ventilation is recommended to maintain vapor exposures belowrecommended limits. Where concentrations are above recommended limits or are unknown,appropriate respiratory protection should be worn. Follow OSHA respirator regulations (29CFR 1910.134) and use NIOSH/MSHA approved respirators.Personal Protective Equipment for SpillsEyes: Use full face respirator.Skin: Wash at mealtime and end of shift. If skin contact occurs, change contaminated clothing as soon as possible and thoroughly flush affected areas with cool water. Chemical protectivegloves are recommended.Inhalation/Suitable Respirator: Respiratory protection recommended. Follow OSHA Respirator Regulations (29 CFR 1910.134) and use NIOSH/MHSA approved respirators. Protection provided by air purifying respirators against exposure to any hazardous chemical is limited. Use a positive pressure air supplied respirator if there is any potential for uncontrolled release, exposure levels are unknown, or any other circumstance where air purifying respirators may not provide adequate protection.Precautionary Measures: Do not get in eyes. Avoid skin contact. Do not breathe vapor. Keep container closed. Do not take internally. Use reasonable care.Comments: Product evolves flammable methyl alcohol when exposed to water or humid air. Provideventilation during use to control exposure within Section 8 guidelines or use air-supplied orself-contained breathing apparatus.Note: These precautions are for room temperature handling. Use at elevated temperature or aerosol/spray applications may require added precautions. For further information regarding aerosol inhalation toxicity, please refer to the guidance document regarding the use of silicone-based materials in aerosol applications that has been developed by the silicone industry () or contact the Dow Corning customer service group.9. PHYSICAL AND CHEMICAL PROPERTIESPhysical Form: LiquidColor: Colorless to pale yellowOdor: Alcoholic odorSpecific Gravity @ 25°C: 0.96Viscosity: 5 cStFreezing/Melting Point: 28 °FBoiling Point: 64 °CVapor Pressure @ 25°C: 100 mm HgVapor Density: > 1Page: 6 of 10Version: 1.5Revision Date: 2010/04/12DOW CORNING(R) 9-6346 SILANESolubility in Water: Not determined.pH: Not determined.Volatile Content: 12 %Flash Point: 71.6 °F / 22 °C (Pensky-Martens Closed Cup)Autoignition Temperature: 496.4 °F / 258 °CFlammability Limits in Air: Not determined.Note: The above information is not intended for use in preparing product specifications. Contact Dow Corning before writing specifications.10. STABILITY AND REACTIVITYChemical Stability: Stable.Hazardous polymerization will not occur.HazardousPolymerization:Conditions to Avoid: None.Materials to Avoid: Oxidizing material can cause a reaction. Water, moisture, or humid air can cause hazardous vapors to form as described in Section 8.Hazardous Decomposition ProductsThermal breakdown of this product during fire or very high heat conditions may evolve the following decomposition products: Silicon dioxide. Carbon oxides and traces of incompletely burned carbon compounds. Chlorine compounds. Nitrogen oxides. Formaldehyde.11. TOXICOLOGICAL INFORMATIONComponent Toxicology InformationThis material may liberate methanol upon exposure to moisture or humid air. Overexposure to methanol can result in blindness and nervous system effects.Chloropropyltrimethoxysilane was found to be genetically active via inhalation in a bone marrow micronucleus assay (female rats exposed to 200 ppm/day for 28 days). In the same assay, no evidence of genetic activity was found in mice exposed to 500, 1000 or 1625 mg/kg by I.P. injection. The potential relevance of this to humans has not yet been determined.Special Hazard Information on ComponentsMutagensCAS Number Wt % Component NamePage: 7 of 10Version: 1.5Revision Date: 2010/04/12DOW CORNING(R) 9-6346 SILANE2530-87-2 10.0 - 30.0 Chloropropyltrimethoxysilane Genetically active in IN VITRO and INVIVO assay(s).12. ECOLOGICAL INFORMATIONEnvironmental Fate and DistributionComplete information is not yet available.Environmental EffectsComplete information is not yet available.Fate and Effects in Waste Water Treatment PlantsComplete information is not yet available.Ecotoxicity Classification CriteriaHazard Parameters (LC50 or EC50) High Medium LowAcute Aquatic Toxicity (mg/L) <=1 >1 and <=100 >100Acute Terrestrial Toxicity <=100 >100 and <= 2000 >2000This table is adapted from "Environmental Toxicology and Risk Assessment", ASTM STP 1179, p.34, 1993.This table can be used to classify the ecotoxicity of this product when ecotoxicity data is listed above. Please read the other information presented in the section concerning the overall ecological safety of this material.13. DISPOSAL CONSIDERATIONSRCRA Hazard Class (40 CFR 261)When a decision is made to discard this material, as received, is it classified as a hazardous waste? Yes Characteristic Waste:Ignitable: D001State or local laws may impose additional regulatory requirements regarding disposal.Call (989) 496-6315, if additional information is required.14. TRANSPORT INFORMATIONDOT Road Shipment Information (49 CFR 172.101)Proper Shipping Name: Flammable liquids, n.o.s.Hazard Technical Name: Methoxysilane / MethanolHazard Class: 3Page: 8 of 10Version: 1.5Revision Date: 2010/04/12DOW CORNING(R) 9-6346 SILANEUN/NA Number: UN 1993Packing Group: IIHazard Label(s): Flammable LiquidOcean Shipment (IMDG)Proper Shipping Name: FLAMMABLE LIQUID, N.O.S.Hazard Technical Name: Methoxysilane / MethanolHazard Class: 3UN/NA Number: UN 1993Packing Group: IIHazard Label(s): flammable liquidMarine Pollutant: Organosilylammonium ChlorideAir Shipment (IATA)Proper Shipping Name: Flammable liquid, n.o.s.Hazard Technical Name: Methoxysilane / MethanolHazard Class: 3UN/NA Number: UN 1993Packing Group: IIHazard Label(s): Flammable LiquidCall Dow Corning Transportation, (989) 496-8577, if additional information is required.15. REGULATORY INFORMATIONContents of this MSDS comply with the OSHA Hazard Communication Standard 29 CFR 1910.1200.TSCA Status: All chemical substances in this material are included on or exempted from listing on the TSCA Inventory of Chemical Substances.EPA SARA Title III Chemical ListingsSection 302 Extremely Hazardous Substances (40 CFR 355):Page: 9 of 10Version: 1.5Revision Date: 2010/04/12DOW CORNING(R) 9-6346 SILANENone.Section 304 CERCLA Hazardous Substances (40 CFR 302):CAS Number Wt % Component Name67-56-1 12.0 MethylalcoholSection 311/312 Hazard Class (40 CFR 370):Acute: YesChronic: YesFire: YesPressure: NoReactive: NoSection 313 Toxic Chemicals (40 CFR 372):CAS Number Wt % Component Namealcohol67-56-1 12.0 MethylNote: Chemicals are listed under the 313 Toxic Chemicals section only if they meet or exceed a reporting threshold.Supplemental State Compliance InformationCaliforniaWarning: This product contains the following chemical(s) listed by the State of California under the Safe Drinking Water and Toxic Enforcement Act of 1986 (Proposition 65) as being known to cause cancer, birth defects or other reproductive harm.None known.MassachusettsCAS Number Wt % Component Name67-56-1 10.0 - 30.0 Methyl alcoholNew JerseyCAS Number Wt % Component Name27668-52-6 > 60.0 Octadecyldimethyl trimethoxysilylpropyl ammonium chloride2530-87-2 10.0 - 30.0 ChloropropyltrimethoxysilanePage: 10 of 10Version: 1.5Revision Date: 2010/04/12DOW CORNING(R) 9-6346 SILANE67-56-1 10.0 - 30.0 Methyl alcoholPennsylvaniaCAS Number Wt % Component Name27668-52-6 > 60.0 Octadecyldimethyl trimethoxysilylpropyl ammonium chloride2530-87-2 10.0 - 30.0 Chloropropyltrimethoxysilane67-56-1 10.0 - 30.0 Methyl alcohol16. OTHER INFORMATIONPrepared by: Dow Corning CorporationThese data are offered in good faith as typical values and not as product specifications. No warranty, either expressed or implied, is hereby made. The recommended industrial hygiene and safe handling procedures are believed to be generally applicable. However, each user should review these recommendations in the specific context of the intended use and determine whether they are appropriate.(R) indicates Registered Trademark。