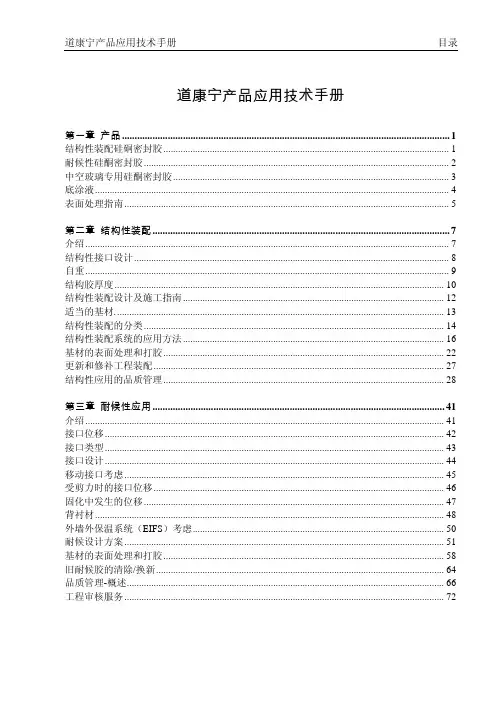

道康宁灌封材料技术文档TDS

- 格式:pdf

- 大小:740.27 KB

- 文档页数:10

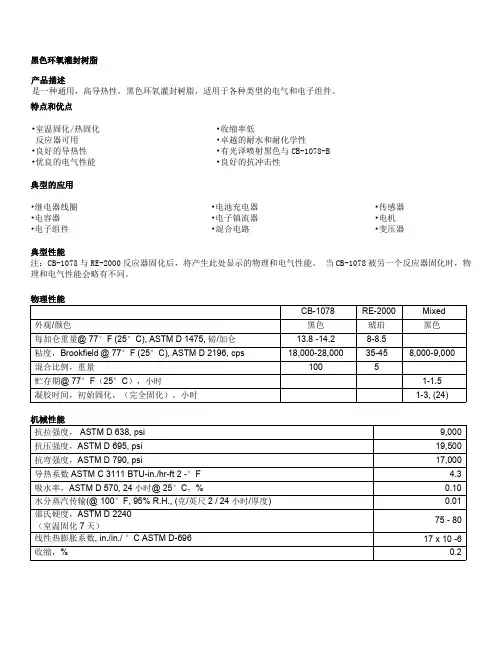

黑色环氧灌封树脂产品描述是一种通用,高导热性,黑色环氧灌封树脂,适用于各种类型的电气和电子组件。

特点和优点•室温固化/热固化•收缩率低反应器可用•卓越的耐水和耐化学性•良好的导热性•有光泽喷射黑色与CB-1078-B•优良的电气性能•良好的抗冲击性典型的应用•继电器线圈•电池充电器•传感器•电容器•电子镇流器•电机•电子组件•混合电路•变压器典型性能注:CB-1078与RE-2000反应器固化后,将产生此处显示的物理和电气性能。

当CB-1078被另一个反应器固化时,物理和电气性能会略有不同。

物理性能CB-1078RE-2000Mixed外观/颜色黑色琥珀黑色每加仑重量@77°F(25°C),ASTM D1475,磅/加仑13.8-14.28-8.5粘度,Brookfield@77°F(25°C),ASTM D2196,cps18,000-28,00035-458,000-9,000混合比例,重量1005贮存期@77°F(25°C),小时1-1.5凝胶时间,初始固化,(完全固化),小时1-3,(24)机械性能抗拉强度,ASTM D638,psi9,000抗压强度,ASTM D695,psi19,500抗弯强度,ASTM D790,psi17,000导热系数ASTM C3111BTU-in./hr-ft2-°F 4.3吸水率,ASTM D570,24小时@25°C,%0.10水分蒸汽传输(@100°F,95%R.H.,(克/英尺2/24小时/厚度)0.01邵氏硬度,ASTM D224075-80(室温固化7天)线性热膨胀系数,in./in./°C ASTM D-69617x10-6收缩,%0.2电动介电强度,1/8"样品,伏特/密耳,ASTM d-149400表面电阻率,欧姆7.5x1014体积电阻率,欧姆-厘米8.0x1015介电常数@23°C,60赫兹,ASTM D-150 4.596耗散因数@23°C,60赫兹,ASTM d-1500.0207注:当与其他反应器一起被固化时,该机械和电气性能会略有不同。

以上固化前性能数据均在25℃,相对湿度55%条件下所测,机械性能及电性能数据均在试样完全固化后所测。

本公司对测试条件不同或产品改进造成的数据不同不承担相关责任。

四、使用工艺1、混合前:首先把A组分和B组分在各自的容器内充分搅拌均匀。

2、混合时:应遵守A组分:B组分=1:1的重量比,并搅拌均匀。

3、排泡:胶料混合后应真空排泡1-3分钟。

4、灌封:混合好的胶料应尽快灌注到被灌产品中,以免后期胶料增稠而流动性不好5、固化:加温固化。

温度越高,固化速度越快。

五、注意事项1、胶料应在干燥室温环境下密封贮存,混合好的胶料应尽快用完,避免造成浪费。

2、本品属非危险品,但勿入口和眼。

3、本品无毒,具有良好的生理惰性,对皮肤无刺激和伤害。

产品不含有易燃易爆成份,不会引发火灾及爆炸事故,对运输无特殊要求。

4、存放一段时间后,胶会有所分层。

请搅拌均匀后使用,不影响性能。

5、以下物质可能会阻碍本产品的固化,或发生不固化现象,所以,最好在进行简易实验验证后应用,必要时需要清洗应用部位。

a、不完全固化的缩合型硅酮胶。

b、胺固化型环氧树脂。

c、白蜡焊接处或松香焊点。

六、包装规格及贮存及运输1、A剂 25kg/桶;B剂 25kg/桶。

2、本产品的贮存期为1年(25℃以下),超过保存期限的产品应确认无异常后方可使用。

3、此类产品属于非危险品,可按一般化学品运输。

七、建议和声明建议用户在正式使用本产品之前先做适用性试验。

由于实际应用的多样性,我公司不担保特定条件下使用我司产品出现的问题,不承担任何直接、间接或意外损失的责任,用户在使用过程遇到什么问题,可联系我公司售后服务部,我们将竭力为您提供帮助。

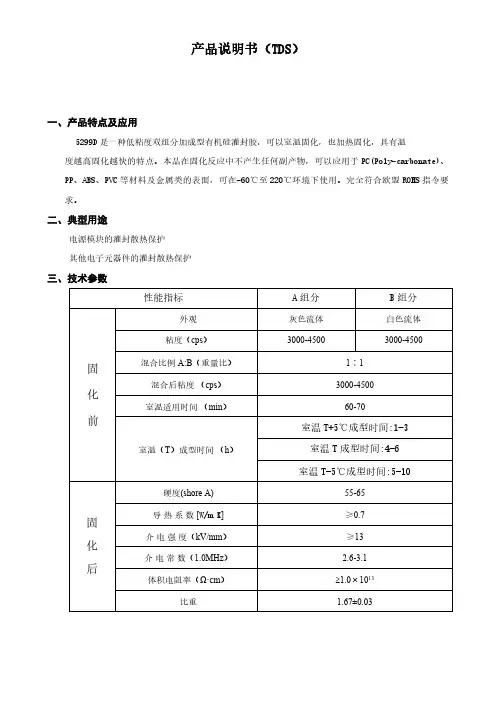

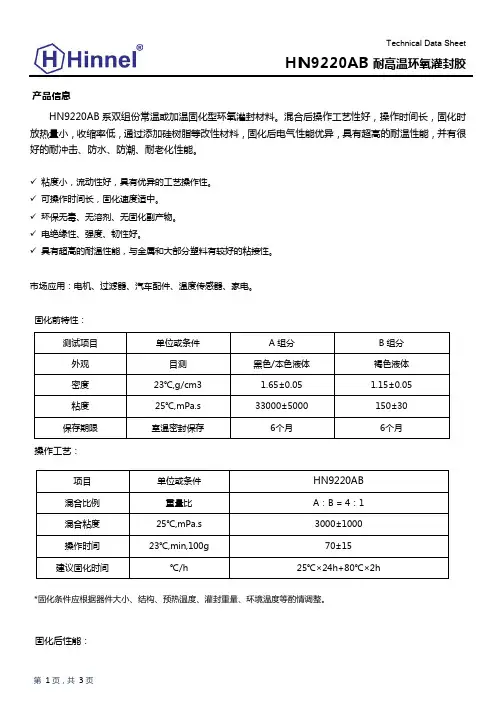

Technical Data SheetHN9220AB 耐高温环氧灌封胶产品信息HN9220AB 系双组份常温或加温固化型环氧灌封材料。

混合后操作工艺性好,操作时间长,固化时放热量小,收缩率低,通过添加硅树脂等改性材料,固化后电气性能优异,具有超高的耐温性能,并有很好的耐冲击、防水、防潮、耐老化性能。

✓ 粘度小,流动性好,具有优异的工艺操作性。

✓ 可操作时间长,固化速度适中。

✓ 环保无毒、无溶剂、无固化副产物。

✓ 电绝缘性、强度、韧性好。

✓ 具有超高的耐温性能,与金属和大部分塑料有较好的粘接性。

市场应用:电机、过滤器、汽车配件、温度传感器、家电。

固化前特性:操作工艺:*固化条件应根据器件大小、结构、预热温度、灌封重量、环境温度等酌情调整。

固化后性能:测试项目 单位或条件 A 组分 B 组分 外观 目测 黑色/本色液体 褐色液体 密度 23℃,g/cm3 1.65±0.05 1.15±0.05 粘度 25℃,mPa.s 33000±5000150±30 保存期限室温密封保存6个月6个月项目 单位或条件 HN9220AB混合比例 重量比 A :B = 4:1 混合粘度 25℃,mPa.s 3000±1000 操作时间 23℃,min,100g70±15建议固化时间℃/h25℃×24h+80℃×2h测试项目单位或条件HN9220AB固化后状态- 黑色/本色固体硬度Shore D,25℃90±5体积电阻率Ω.cm,25℃>1.0×1015绝缘强度KV/mm,25℃≥20吸水率25℃,24h,% <0.03剪切强度25℃,Mpa ≥10线膨胀系数μm/(m,℃)44阻燃等级UL-94 V-0应用温度范围℃-40~230* 表格中的数据是依据特定标准测试所得,仅可用于指导,并不可用于作为产品规范。

建议使用工艺本规格环氧灌封料,广泛应用于自动化生产线,也可用于手工灌封。

胶水tds说明书胶水TDS(Technical Data Sheet)说明书是对胶水产品的详细介绍和技术参数的文档。

本文将从胶水的成分、性能特点、使用方法以及安全注意事项等方面进行介绍。

一、胶水的成分胶水通常由以下几类成分组成:基体树脂、添加剂、填料和溶剂。

基体树脂是胶水的主要成分,常见的有丙烯酸酯、聚氨酯、环氧树脂等。

添加剂可以改善胶水的黏附性、流动性等性能,常见的有固化剂、稳定剂等。

填料可以增加胶水的粘度和强度,常见的有硅酸盐、碳酸钙等。

溶剂则用于调节胶水的粘度和干燥速度,常见的有丙酮、甲苯等。

二、胶水的性能特点1. 黏附性:胶水具有良好的黏附性,能够将不同材料粘合在一起。

2. 强度:胶水能够提供一定的强度,使粘合的材料具有一定的抗拉、抗剪和抗剥离能力。

3. 耐候性:胶水具有一定的耐候性,能够在不同环境条件下保持稳定的性能。

4. 耐温性:胶水能够在一定温度范围内保持稳定的性能,一些特殊胶水甚至具有耐高温或耐低温的特点。

5. 耐化学性:胶水对一些化学物质具有一定的耐受性,能够在接触一些化学物质时仍然保持良好的性能。

三、胶水的使用方法1. 表面处理:在使用胶水之前,需要将粘合表面进行处理,确保表面干净、干燥、光滑。

可以使用去油剂、砂纸等工具进行处理。

2. 胶水的涂布:将胶水均匀地涂布在粘合表面上,可以使用刷子、滚筒等工具进行涂布。

3. 压合:将需要粘合的材料紧密地压合在一起,确保胶水能够充分接触到粘合表面,并保持一定的压力,促使胶水快速固化。

4. 固化时间:胶水在涂布后需要一定的时间进行固化,具体时间根据胶水的种类和环境条件而定。

四、安全注意事项1. 使用胶水时,应保持通风良好的工作环境,避免吸入胶水挥发出的有害气体。

2. 避免胶水接触皮肤和眼睛,如不慎接触,请立即用清水冲洗,并寻求医生帮助。

3. 使用胶水时应避免接触明火,以免引起火灾。

4. 存放胶水时,应密封保存在阴凉、干燥的地方,远离火源和高温。

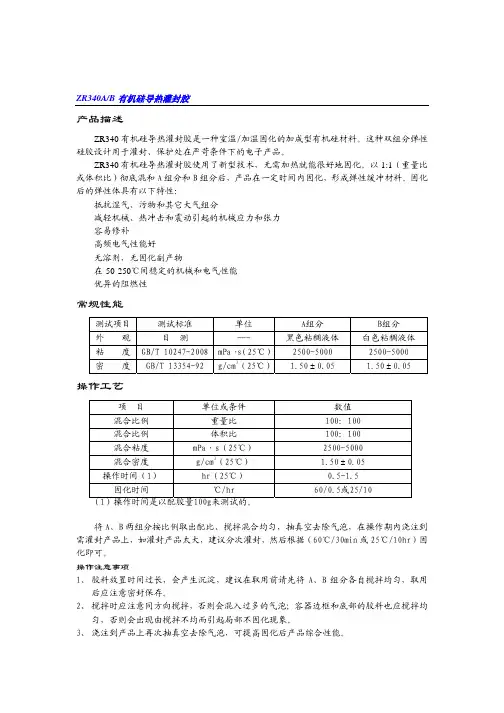

ZR340A/B有机硅导热灌封胶产品描述ZR340有机硅导热灌封胶是一种室温/加温固化的加成型有机硅材料。

这种双组分弹性硅胶设计用于灌封、保护处在严苛条件下的电子产品。

ZR340有机硅导热灌封胶使用了新型技术,无需加热就能很好地固化。

以1:1(重量比或体积比)彻底混和A组分和B组分后,产品在一定时间内固化,形成弹性缓冲材料。

固化后的弹性体具有以下特性:抵抗湿气、污物和其它大气组分减轻机械、热冲击和震动引起的机械应力和张力容易修补高频电气性能好无溶剂,无固化副产物在-50-250℃间稳定的机械和电气性能优异的阻燃性常规性能测试项目 测试标准 单位 A组分 B组分外 观 目 测 --- 黑色粘稠液体 白色粘稠液体 粘 度 GB/T 10247-2008mPa·s(25℃)2500-5000 2500-5000 密 度 GB/T 13354-92 g/cm3(25℃) 1.50±0.05 1.50±0.05操作工艺项 目 单位或条件 数值混合比例 重量比 100:100混合比例 体积比 100:100混合粘度 mPa·s(25℃) 2500-5000混合密度 g/cm3(25℃) 1.50±0.05 操作时间(1) hr(25℃) 0.5-1.5固化时间 ℃/hr 60/0.5或25/10 (1)操作时间是以配胶量100g来测试的。

将A、B两组分按比例取出配比、搅拌混合均匀,抽真空去除气泡,在操作期内浇注到需灌封产品上,如灌封产品太大,建议分次灌封,然后根据(60℃/30min或25℃/10hr)固化即可。

操作注意事项1、胶料放置时间过长,会产生沉淀,建议在取用前请先将A、B组分各自搅拌均匀,取用后应注意密封保存。

2、搅拌时应注意同方向搅拌,否则会混入过多的气泡;容器边框和底部的胶料也应搅拌均匀,否则会出现由搅拌不均而引起局部不固化现象。

3、浇注到产品上再次抽真空去除气泡,可提高固化后产品综合性能。

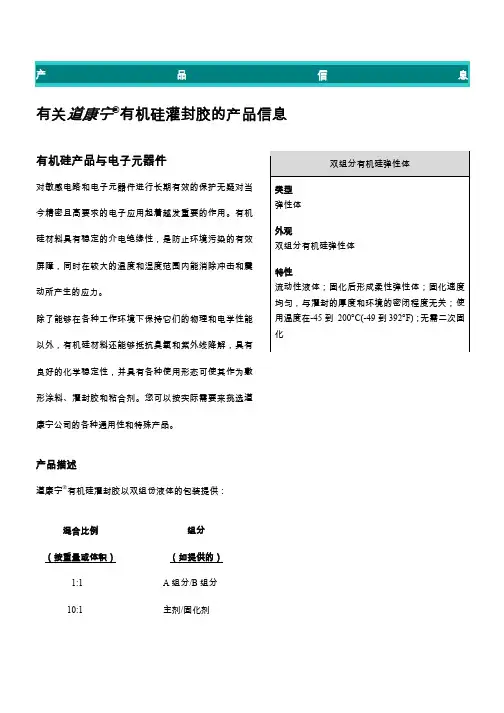

Information about Dow Corning ® BrandSilicone EncapsulantsSilicones and ElectronicsLong-term, reliable protection of sensitive circuits and compo -nents is becoming more important in many of today’s delicate and demanding electronic applications. Silicone encapsulants provide unparalleled protection for electronic modules and devices ranging from relatively simple to highly complex archi -tectures and geometries. Silicones function as durable dielectric insulation, as barriers against environmental contaminants, and as stress-relieving shock and vibration absorbers over a wide temperature and humidity range.In addition to sustaining their physical and electrical properties over a broad range of operating conditions, silicones are resistant to ozone and ultraviolet degradation and have good chemical stability. The Dow Corning encapsulant family offers many choices to customize or tune product usage and performance for your specific application.DESCRIPTIONDow Corning ® silicone encapsulants or pottants are supplied as two-part liquid component kits comprised of:Mix RatioComponents (by weight or volume)(as supplied) 1:1 Part A/Part B10:1Base/Curing agentWhen liquid components are thoroughly mixed, the mixture cures to a flexible elastomer, which is suited for the protec-tion of electrical/electronic applications. Dow Corning silicone encapsulants cure without exotherm at a constant rate regardless of sectional thickness or degree of confine-ment. Dow Corning silicone elastomers require no post cure and can be placed in service immediately following the completion of the cure schedule with an operating temper-ature range of -45 to 200°C (-49 to 392°F). Several products enable easy rework and repair. Select materials have been classified by Underwriters Laboratories and/or meet military specifications. Standard silicone encapsulants require a sur -face treatment with a primer in addition to good cleaning for adhesion while primerless silicone encapsulants require only good cleaning.PRODUCT INFORMATION1These data were collected on 50-100 gram samples of a lot believed to be typical and should be used as initial estimates of cure times. Times will vary slightly from batch to batch and can be longer or shorter due to thermal mass of your parts and your heating ramp rate. Pretesting is recommended to confirm adequate cure for your application.For primerless adhesion products, cure time is based on time to reach durometer. Full adhesion may take more time at the cure temperature.341These data were collected on 50-100 gram samples of a lot believed to be typical and should be used as initial estimates of cure times. Times will vary slightly from batch to batch and can be longer or shorter due to thermal mass of your parts and your heating ramp rate. Pretesting is recommended to confirm adequate cure for your application.For primerless adhesion products, cure time is based on time to reach durometer. Full adhesion may take more time at the cure temperature.5TYPICAL PROPERTIESSpecification Writers: Please contact your local Dow Corning sales office or your Global Dow Corning Connection before writing specifications on this product.67MixinG – 1:1/ParT a:ParT BDow Corning silicone 1:1 encapsulants are supplied in two parts that do not require lot matching. The 1:1 mix ratio, by weight or volume, simplifies the proportioning process. To ensure uniform distribution of filler, Parts A and B must each be thoroughly mixed prior to their combination in a 1:1 ratio. When thoroughly blended, the Part A and B liquid mixture should have a uniform appearance. The presence of light-colored streaks or marbling indicates inadequate mix-ing and will result in incomplete cure.Due to the fast-curing characteristics of some encapsulants included in this data sheet, automated mix and dispense equipment should be utilized. In applications sensitive to air entrapment, deairing with 28 to 30 inches Hg vacuum is required.MixinG – 10:1/BaSe:CurinG aGenTDow Corning silicone 10:1 encapsulants are supplied in two parts as lot-matched base and curing agent that are mixed in a ratio of 10 parts base to one part curing agent, by weight. After thoroughly mixing base and curing agent, agitate gently to reduce the amount of air introduced. Allowing the mixture to set for 30 minutes before pouring may be adequate for removal of the air introduced during mixing. If air bubbles are still present, vacuum deairing may be required. Deair in a container with at least four times the liquid volume to allow for expansion of material. Air entrapped in the mixture can be removed by using a vacuum of 28 to 30 inches Hg. Continue the vacuum until the liquid expands and settles to its original volume and bubbling subsides. This may take 15 minutes to 2 hours depending on the amount of air introduced during stirring. For best curing results, glassware and glass or metal stirring implements should be used. Mix with a smooth action that does not introduce excess air.PoT Life/WorkinG TiMeCure reaction begins with the mixing process. Initially, cure is evidenced by a gradual increase in viscosity, followedby gelation and conversion to a solid elastomer. Pot life is defined as the time required for viscosity to double after Parts A and B (base and curing agent) are mixed. Please refer to individual pot life for each silicone encapsulant.PRIMER SELECTION GUIDESpecification Writers: Please contact your local Dow Corning sales office or your Global Dow Corning Connection before writing specifications on these products.Product Special Properties Substrates Compatible SiliconesDow Corning®P5 00 Adhesion Promoter – Clear The most versatile of all Dow Corning primers for thewidest range of silicones and electronics applications.This clear primer is similar to Dow Corning® 1 00 OSPrimer but uses a slightly different adhesion promotercombination. It enhances the adhesion of many RTVand heat-cure silicones to a wide variety of surfaces. Notregistered for use in European Union.Wide variety of surfaces includingFR-4, ceramics, and many metalsand plasticsAllDow Corning®1 00 OS Primer Clear The most versatile of all Dow Corning primers for thewidest range of silicone types and electronics applications.This clear primer is supplied in a low-VOC diluent forlower environmental impact and exhibits low odor forconvenient handling. It enhances the adhesion of manyRTV and heat-cure silicones to a variety of surfaces. Thisprimer is very similar to Dow Corning P5 00 AdhesionPromoter and is registered for use in the European Union.Wide variety of surfaces includingFR-4, ceramics, and many metalsand plasticsAllDow Corning®P5 04 Adhesion Promoter This clear primer is supplied in a low-VOC diluent forlower environmental impact and exhibits low odor forconvenient use. It is specially formulated to enhanceadhesion of many moisture-cure RTV silicones to a widevariety of surfaces.Wide variety of surfaces includingFR-4, ceramics, and metals. Notrecommended for plastics.AllDow Corning®1 01 RTV Prime Coat This transparent primer with yellow tint is supplied in amixture of acetone and toluene solvents. It is specificallyformulated to enhance the adhesion of Dow Corning®3110 and 31 0 RTV Silicone Rubber to a wide variety ofsurfaces, especially FR-4 and metals.Wide variety of surfaces, especiallyFR-4 and metalsDow Corning® 3110, 311 , 31 0RTV Silicone RubberDow Corning®1 05 Prime Coat Specially formulated to increase adhesion of a wide rangeof silicones to plastics including more difficult types, suchas acrylic and polycarbonate. This clear primer is suppliedin a mixture of organic solvents.Most plastics, ceramics, andcompositesNot recommended for use withaddition-cure silicones, such asSylgard® 170, 184, 186 SiliconeElastomer Kit, etc.Dow Corning®9 -0 3 Primer Specially formulated for use with addition-cure silicones tomitigate surface cure poisoning. This clear primer is dilutedin heptane solvent and enhances the adhesion of manyaddition-cure silicones to a wide variety of surfaces.FR-4, most metals, and ceramics Non-pigmented, two-part addition-cure silicones8ProCeSSinG and CurinGThoroughly mixed Dow Corning silicone encapsulant may be poured/dispensed directly into the container in which it is to be cured. Care should be taken to minimize air entrap-ment. When practical, pouring/dispensing should be done under vacuum, particularly if the component being potted or encapsulated has many small voids. If this technique can-not be used, the unit should be evacuated after the silicone encapsulant has been poured/dispensed.Dow Corning silicone encapsulants may be either room tem-perature (25°C/77°F) or heat cured. Room temperature cure encapsulants may also be heat accelerated for faster cure. Ideal cure conditions for each product are given in the prod-uct selection table. Two-part condensation cure encapsulants should not be heat accelerated above 60°C (140°F).Dow Corning® 255 Curing Agent should be stirred prior to use because some settling may occur during shipping and storage. The curing agent is reactive with atmospheric mois-ture so care should be exercised to limit exposure to air prior to use.PreParinG SurfaCeSIn applications requiring adhesion, priming will be required for the silicone encapsulants. See the Primer Selection Guide for the correct primer to use with a given product. For best results, the primer should be applied in a very thin, uniform coating and then wiped off after application. After application, it should be thoroughly air dried prior to application of the silicone elastomer. Additional instructions for primer usage can be found in the Dow Corning litera-ture, “How To Use Dow Corning Primers and Adhesion Promoters” (Form No. 10-366) and in the information sheets specific to the individual primers.uSefuL TeMPeraTure ranGeSFor most uses, silicone elastomers should be operational over a temperature range of -45 to 200°C (-49 to 392°F) for long periods of time. However, at both the low and high temperature ends of the spectrum, behavior of the materials and performance in particular applications can become more complex and require additional considerations.For low-temperature performance, thermal cycling to conditions such as -55°C (-67°F) may be possible, but per-formance should be verified for your parts or assemblies. Factors that may influence performance are configuration and stress sensitivity of components, cooling rates and hold times, and prior temperature history. There are specialized products including Dow Corning® 3-6121 Low Temperature Elastomer that can perform at -65°C (-85°F) and below.At the high-temperature end, the durability of the cured silicone elastomer is time and temperature dependent. As expected, the higher the temperature, the shorter the time the material will remain usable.CoMPaTiBiLiTYCertain materials, chemicals, curing agents and plasticizers can inhibit the cure of Dow Corning silicone encapsulants. Most notable of these include:• Organotin and other organometallic compounds• Silicone rubber containing organotin catalyst• Sulfur, polysulfides, polysulfones or other sulfur-containing materials• Amines, urethanes or amine-containing materials• Unsaturated hydrocarbon plasticizers• Some solder flux residuesIf a substrate or material is questionable with respect to potentially causing inhibition of cure, it is recommended that a small scale compatibility test be run to ascertain suitability in a given application. The presence of liquid or uncured product at the interface between the questionable substrate and the cured gel indicates incompatibility and inhibition of cure.Dow Corning 255 Elastomer is not subject to these inhibi-tion concerns but may experience reversion in sealed appli-cations at high temperature and pressure. rePairaBiLiTYIn the manufacture of electrical/electronic devices it is often desirable to salvage or reclaim damaged or defective units. With most non-silicone rigid potting/encapsulating materials, removal or entry is difficult or impossible without causing excessive damage to internal circuitry. Dow Corning silicone encapsulants can be selectively removed with relative ease, any repairs or changes accomplished, and the repaired area repotted in place with additional product.To remove silicone elastomers, simply cut with a sharp blade or knife and tear and remove unwanted material from the area to be repaired. Sections of the adhered elastomer are best removed from substrates and circuitry by mechani-cal action such as scraping or rubbing and can be assisted by applying Dow Corning®brand OS Fluids.Before applying additional encapsulant to a repaired device, roughen the exposed surfaces of the cured encapsulant with an abrasive paper and rinse with a suitable solvent. This will enhance adhesion and permit the repaired material to become an integral matrix with the existing encapsulant. Silicone prime coats are not recommended for adhering products to themselves.HandLinG PreCauTionSDow Corning 255 Elastomer curing agent and uncured catalyzed material will burn skin and eyes upon prolonged contact. In case of eye contact, flush with copious amounts of water for at least 15 minutes and seek medical attention at once. Skin contact areas should be washed with soap and water. Persistent irritation should receive medical attention.9Dow Corning and Sylgard are registered trademarks of Dow Corning Corporation.©2000-2008 Dow Corning Corporation. All rights reserved.Printed in USAAGP9336Form No. 10-898H -01Use only with adequate ventilation; if not available, use respiratory protection.PRODUCT SAFETY INFORMATION REQUIRED FOR SAFE USE IS NOT INCLUDED IN THIS DOCUMENT. BEFORE HANDLING, READ PRODUCT AND MATERI -AL SAFETY DATA SHEETS AND CONTAINER LABELS FOR SAFE USE, PHYSICAL AND HEALTH HAZARD INFORMATION. THE MATERIAL SAFETY DATA SHEET IS A V AILABLE ON THE DOW CORNINGWEBSITE AT , OR FROM YOUR DOW CORNING REPRESENTATIVE, OR DIS -TRIBUTOR, OR BY CALLING YOUR GLOBAL DOW CORNING CONNECTION.uSaBLe Life and SToraGeShelf life is indicated by the “Use By” date found on the product label.For best results, Dow Corning silicone encapsulants should be stored at or below 25°C (77°F). Special precautions must be taken to prevent moisture from contacting these materi-als. Containers should be kept tightly closed and head or air space minimized. Partially filled containers should be purged with dry air or other gases, such as nitrogen. Dow Corning 255 Elastomer should be kept refrigerated (10°C/50°F) until use. Any special storage and handling in-structions will be printed on the product containers.PaCkaGinGIn general, Dow Corning silicone 1:1 mix ratio encapsulants are supplied in nominal 0.45-, 3.6-, 18- and 200-kg (1-, 8-, 40- and 440-lb) containers, net weight. Dow Corning silicone 10:1 mix ratio encapsulants are supplied in nominal 0.5-, 5-, 25- and 225-kg (1.1-, 11-, 55- and 495-lb) containers, net weight. Packaging options may vary by product. Consult Dow Corning Customer Service at (989) 496-6000 for addi-tional packaging options.LIMITATIONSThese products are neither tested nor represented as suitable for medical or pharmaceutical uses.HEALTH AND ENVIRONMENTAL INFORMATIONTo support customers in their product safety needs, Dow Corning has an extensive Product Stewardshiporganization and a team of Product Safety and Regulatory Compliance (PS&RC) specialists available in each area.For further information, please see our website, , or consult your local Dow Corning representative.LiMiTed WarranTY inforMaTion – PLeaSe read CarefuLLYThe information contained herein is offered in good faith and is believed to be accurate. However, because conditions and methods of use of our products are beyond our control, this information should not be used in substitution forcustomer’s tests to ensure that Dow Corning’s products are safe, effective, and fully satisfactory for the intended end use. Suggestions of use shall not be taken as inducements to infringe any patent.Dow Corning’s sole warranty is that the product will meet the Dow Corning sales specifications in effect at the time of shipment.Your exclusive remedy for breach of such warranty is limited to refund of purchase price or replacement of any product shown to be other than as warranted.DOW CORNING SPECIFICALL Y DISCLAIMSANY OTHER EXPRESS OR IMPLIED W ARRANTY OF FITNESS FOR A P ARTICULAR PURPOSE OR MERCHANTABILITY.DOW CORNING DISCLAIMS LIABILITY FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.。

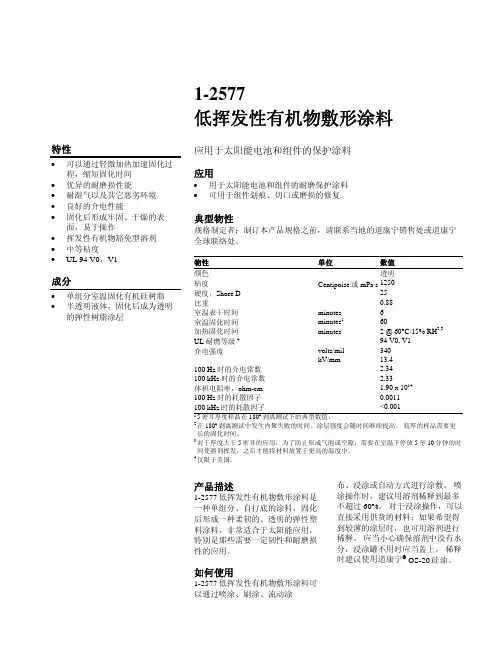

特性∙可以通过轻微加热加速固化过程,缩短固化时间∙优异的耐磨损性能∙耐湿气以及其它恶劣环境∙良好的介电性能∙固化后形成牢固、干燥的表面,易于操作∙挥发性有机物豁免型溶剂∙中等粘度∙UL 94 V0,V1成分∙单组分室温固化有机硅树脂∙半透明液体,固化后成为透明的弹性树脂涂层产品描述1-2577低挥发性有机物敷形涂料是一种单组分、自打底的涂料,固化后形成一种柔韧的、透明的弹性塑料涂料,非常适合于太阳能应用,特别是那些需要一定韧性和耐磨损性的应用。

如何使用1-2577低挥发性有机物敷形涂料可以通过喷涂、刷涂、流动涂布、浸涂或自动方式进行涂敷。

喷涂操作时,建议用溶剂稀释到最多不超过60%。

对于浸涂操作,可以直接采用供货的材料;如果希望得到较薄的涂层时,也可用溶剂进行稀释。

应当小心确保溶剂中没有水分,浸涂罐不用时应当盖上。

稀释时建议使用道康宁® OS-20硅油。

1-2577低挥发性有机物敷形涂料应用于太阳能电池和组件的保护涂料应用∙用于太阳能电池和组件的耐磨保护涂料∙可用于组件划痕、切口或磨损的修复典型物性规格制定者:制订本产品规格之前,请联系当地的道康宁销售处或道康宁全球联络处。

物性单位数值颜色透明粘度Centipoise或mPa.s 1250硬度,Shore D 25比重0.88室温表干时间minutes6室温固化时间minutes160加热固化时间minutes 2 @ 60°C/15% RH2,3UL 耐燃等级494 V0, V1介电强度volts/mil340kV/mm13.4100 Hz时的介电常数 2.34100 kHz 时的介电常数 2.33体积电阻率,ohm-cm 1.90 x 1014100 Hz时的耗散因子0.0011100 kHz时的耗散因子<0.0011 5密耳厚度样品在180º剥离测试下的典型数值。

2 在180º剥离测试中发生内聚失败的时间。

黑色环氧灌封树脂TDS模板产品名称:黑色环氧灌封树脂产品型号:XT-1001产品描述:产品特点:1.高强度:该产品经过特殊处理,具有较高的机械强度,能有效保护电子元件免受外部冲击和振动的影响。

2.耐高温:产品具有良好的耐高温性能,能在高温环境下长时间稳定工作。

3.耐候性好:在极端环境条件下,产品仍然能保持良好的性能稳定性。

4.耐腐蚀性:产品具有良好的耐酸碱和溶剂腐蚀性,能有效防止电子元件受到腐蚀。

技术指标:1.外观:黑色均匀液体2.混合比例:A:B=3:1(重量比)3. 密度:1.1±0.1g/cm³4.固化时间:25°C下24小时5. 硬度:Shore D 856. 弯曲强度:≥65Mpa7.热导率:≥0.6W/m·K8.工作温度范围:-40°C至150°C应用领域:1.电子元件封装:适用于各种电子元件封装,如晶振、电容器、电感器、变压器等。

2.电工器材:适用于电缆终端盒、绝缘子、互感器等电力设备的封装和绝缘保护。

3.仪器仪表:适用于各种仪器仪表的灌封和防护,如传感器、仪表控制器等。

使用方法:1.将A组份和B组份按照规定的比例混合均匀。

2.清洁待密封的表面,确保干净无油无杂质。

3.将混合后的树脂倒入待密封的器件内,确保灌封均匀且完全包覆器件。

4.放置密封的器件在25°C下固化24小时后即可使用。

注意事项:1.使用前请充分搅拌树脂A和B组份,确保混合均匀。

2.本产品只适用于低电压设备的封装和防护,不适用于高压设备的绝缘保护。

3.本产品固化后可产生少许气泡,请确保使用时密封齐全,避免气泡影响使用效果。

4.使用本产品时应戴好防护手套和眼镜,避免接触皮肤和眼睛。

包装规格:1. 1kg/桶2. 5kg/桶3. 20kg/桶以上是黑色环氧灌封树脂TDS模板,详细信息根据实际产品进行调整。

种类:OLED材料LED荧光粉配粉胶道康宁OE6550 大功率LED品牌:其他型号:道康宁OE6550A/B 加工定制:否分辨率:LED调粉胶灰度:LED配粉胶亮度:普通模组尺寸:LED硅胶(mm)屏幕尺寸:LED混粉胶(英寸)显示方式:静态显示显示颜色:全彩像素:LED荧光粉胶像素间距:led(mm)像素直径:Ф5(mm)种类:OLED材料技术指标:固化前外观 A组份………………………无色透明液体B组份………………………无色透明液体密度(g/cm3)A组份………………………0.96~0.99B组份………………………0.96~0.99粘度(25℃/ mpa.s)A组份…………………11000-11200B组份…………………1400-1600AB混合比例(重量比)……………………………1:1粘度(混合后)@25℃/mpa.s………………………4500-5000强度(邵氏A) (20)可操作时间(常温25℃)……………………140分钟固化方式................. 150℃)60分钟固化后外观……………………………透明粘弹性体体积电阻Ω.㎝……………………………>1.0×1015介电常数(1.2MHz) ………………………………≤3击穿电压强度(Kv/mm) …………………………>25扯断伸长率(﹪) ....................................≥200 耐温范围(℃)....................................-60~200 折射率(ND25)..........................................1.54 透光率(%) 450nm 1mm thick (98)。