约克空调末端电子样本

- 格式:pdf

- 大小:737.69 KB

- 文档页数:2

YGCC-0F 系列风管送风式空调风管送风式空调((热泵热泵))机组 维修手册V1.0YGCC-0F 风管送风式空调风管送风式空调((热泵热泵))机组维修手册 SERVICE MANUAL约克广州空调冷冻设备有限公司1目录1产品介绍2电加热配置表 3机组性能参数表 4机组特点 5样机式样 6技术规格参数 7系统原理图 8电气原理图 9配线图10主要部件的技术资料 11空调运行环境温度 12线控及遥控功能13室内机主板机组风量静压的调节 14热水盘管的安装 15控制软件功能 16故障判断与排除17 YGCC 电气部分零件 18选配件19机组主要零部件清单21 产品介绍YORK 公司推出的YGCC 系列卧式暗装分体空调器严格遵循GB/T18836《风管送风式空调(热泵)机组》,确保该机提供高质量的运行状态,高度的可靠性以及优良的适应性。

机组的安装及现场布线要严格按照现行的国家标准及当地规范。

1.1 产品命名方式 室内机第1码:Y 表示约克第2码: 室内机用途:D - 数码涡旋系列;G - 一拖一系列第3码: 室内机形式:CC - 暗装卧式;HW - 壁挂式;CK - 卡式天花;CP - 暗装整体式第4码: 冷量代号,单位KBTU 第5码: 产品标识码 第6码: 机组应用:H - 热泵;C - 单冷第7码: 回风箱配置: N - 无回风箱;B - 带后回风箱;D - 带下回风箱,F - 带过滤网 第8码: 风压:S - 标准风压 第9码: 接管方式:L - 左式;R - 右式;N - 不分左右式第10码: 辅助电加热: 0 - 无电加热;2 - 带2号标准功率电加热;4 - 带4号功率电加热 第11码: 制造厂:G - 约克广州工厂制造 第12码: 短横线,与前面的功能要求分隔第13码: 工厂内部的识别代码:0 - 没发生过更改;1 - 第一次更改;以此类推 第14码:设计序列号:A 表示原始设计,B 表示第一次设计改进,室外机第2码: 机组类型:D - 表示数码涡旋;G - 表示一拖一;M - 表示 第3码: O 表示室外机组第4码: 机组应用模式: H - 热泵;C - 单冷 第5码: 表示制冷量,单位KBTU 第6码: 产品标识码第7码: 电源供给方式: A - 220V/1/50Hz ; E - 380V/3Ph/50Hz第8码: 内外机连接:0 - 单联,2 - 一拖二,3 - 一拖三 第9码: 制造厂:G - 约克广州工厂制造 第10码: 短横线,与前面的功能要求分隔第11码: 工厂内部的识别代码:0 表示没有发生过更改;第12码: 设计序列号:A 表示原始设计,B 表示第一次设计改进,31.2 产品型号YGCC-0F 系列暗装卧式分体空调机组提供单冷和热泵机型,产品的配置型号见下表。

water-cooled screw chiller YEWS-DOn the coverIntegrated professional services designed for your unique business needs.We care about your business and understand that every organization has its unique requirements. Our comprehensive maintenance package is tailor-made to fit all financial and technical needs.It covers everything from planned routine equipment inspections and predictive maintenance routines to system performance checks andannual shutdowns.3Water-cooled Screw Chiller - YEWS SeriesYEWS-D Series is newly developed water-cooled screw chillers using HFC-134a refrigerant. Its industrial semi-hermetic twin-screw compressor ensures high energy efficiency and long service life.With high efficiency flooded evaporator, its COP value leads the industry. Besides, its high-efficiency compressor starts at the minimum load position and provides a 12.5%-100% capacity control range through a continuous function slide valve, maximizing load efficiency and energy savings.Equipped with advanced fuzzy logic controls, the microprocessor control system is allowed to monitor key variables andaccurately anticipate the chiller operation, thus provide tight and precise control. The control system is the most advanced of all competing models. The microprocessor can be connected to Building Automation System via MODBUS Protocol. Ensuring operator safety, its power panel is separated from its control panel and is armed with an emergency stop. The packaged chiller is designed with a compact footprint which greatly reduces installation costs. The chillers compact footprint makes it ideal for retrofit.AHRI Certification ProgramThe performance of YORK YEWS200 andYEWS250 chillers has been certified to the Air Conditioning and Refrigerant Institute (AHRI)as complying with the certification sections of the latest issue of ARI Standard 550/590.Under this Certification Program, chillers are regularly tested in strict compliance with this Standard. This provides an independent, third-partyverification of chiller performance.12.5% 4510 67fouling factor 0.04403m².°C/kW.2. Star Delta open starting.3. Two passes for all mode heat exchangers, but four passes for YEWS100 evaporator.4. “XX“ in model is power supply code, and it can be 50,53 or 55.2. The above A/C condition: Chilled water ebtering/leaving temperature 7/12°C Condenser cooling water entering/leaving temperature 30/35°C.3. The concentration of ethylene glycol (EG) in the evaporator is 25%, fouling factor is 0.01761m².°C/kW; Condenser cooling water fouling factor 0.04403m².°C/kW.4. Three passed for all model evaporators, and two passes for all model condensers, but four passes for YEWS100 evaporator and 2 passes YEWS250 evaporator.5. “XX“ in model is power supply code, and it can be 50,53 or 55.Operation Range I based on 5°C water temperature approach for both chilled and cooling water.I ----AC unit standard full load operation II ----Extra full load operation range after equiped with three-way valve to maintain the required condenser pressure.Operation Range I based on 5°C water temperature approach for both chilled and cooling water under AC mode.I ----ITS unit standard full load operation II ----Extra full load operation range after equiped with three-way valve to maintain the required condenser pressure.520518304025304020101015-6.525159I II157373501015C o o l i n g W a t e r T e m p I N -°CC o o l i n g W a t e r T e m p I N -°CC o o l i n g W a t e r T e m p I N -°CC o o l i n g W a t e r T e m p I N -°CChilled Water Temp OUT-°CChilled Water Temp OUT-°CAC chiller operation RangeITS unit operation Range8Electric DataWater Pressure DropFlow Rate (L/S)Flow Rate (L/S)E v a p o r a t o r W a t e r P r e s s u r e D r o p (k P a )C o n d e n s e r W a t e r P r e s s u r eD r o p (k P a )9DimensionsYEWS100/130/170/200SA-D , YEWS100DA-DYEWS130/170/200DA-DYEWS250SA/DA10Sketch Map11© 2009 Johnson Controls, PUBL-5211(1109)Johnson Controls is the global leader that creates smart environments – bringing ingenuity to the places where people live, work and travel.Johnson Controls Building Efficiency business enables safe, comfortable, energy efficient and sustainable facilities.We are a single source of integrated heating/cooling, controls, lighting, fire, security and wireless infrastructure products for buildings and industrial plants. And our comprehensive life-cycle approach to in-building technology and operations includes planning and design, installation and integration optimization and maintenance as well as integrated real estate and facility management services. To us, sustainability matters at every level. Our triple bottom line - Economic Prosperity, Environmental Stewardship and Social Responsibility - and every facet of our operations and community involvement are geared to the efficient use of resources to benefit the planet and people all over the world.For example, in conjunction with the US Energy Association, Johnson Controls helped to launch the Annual Energy Efficiency Forum. We are also a lead technology and energy-efficiency partner for the Clinton Climate Initiative and its ambitious C40 Large Buildings Retrofit Program. And, building on our unparalleled expertise in LEED (Leadership in Energy Environment Design) rating and certification, Johnson Controls is supporting a growing number of green building projects across Asia.Today Johnson Controls’ solutions are playing a key role in the region’s LEED-certified buildings, including India’s ITC Green Centre and Nokia’s Greater China headquarters complex in Beijing. They can also be found in some of the world’s tallest buildings - Taipei 101, Shanghai World Finance Center and Petronas Towers, Kuala Lumpur.Our network of more than 150 sales and support centers with more than 10,000 dedicated professionals located in 15 countries and regions has made us the partner of choice for some of the most recognizable structures in Asia and the Pacific, including many of the iconic stadiums used in the 2008 Beijing Olympics. Asia Factories: Guangzhou & Wuxi, China · Pune, IndiaAsia Engineering Centre: Wuxi, ChinaAsia Centre of Excellence in Engineering (CoEE): Beijing, China · Mumbai & Pune, IndiaAsia Centre of Engineering & Technology (CET): Hong KongAsia Parts & Product Hub: Shanghai, ChinaTaiwan Tel : +886 (2) 2657 5568Fax: +886 (2) 2657 6388Malaysia Tel : +60 (3) 7628 4300Fax: +60 (3) 7874 1180Indonesia Tel : +62 (21) 626 3535Fax: +62 (21) 659 8875Australia Tel : +61 (2) 9805 8300Fax: +61 (2) 9247 7750Asia Headquarters20/F, Tower 1, 2 & 3, Enterprise Square1, 9 Sheung Yuet Road, Kowloon Bay,Kowloon, Hong KongTel : +852 2590 0012Fax: +852 2516 5648Thailand Tel : +66 (2) 717 0751Fax: +66 (2) 717 0750New Zealand Tel : +64 (9) 444 6434Fax: +64 (9) 444 2092Japan Tel : +81 (3) 5738 6100Fax: +81 (3) 5738 6298China (Shanghai)Tel : +86 (21) 6276 6509Fax: +86 (21) 6277 3543VietnamTel : +84 (8) 526 1205Fax: +84 (8) 526 1206 PhilippinesTel : +63 (2) 706 1420-22Fax: +63 (2) 706 1486KoreaTel : +82 (2) 554 5935Fax: +82 (2) 554 5739Hong KongTel : +852 2590 0012Fax: +852 2516 5648Singapore Tel : +65 6748 0202Fax: +65 6283 3015Macau Tel : +853 2875 1820Fax: +853 2875 1821India Tel : +91 (22) 3082 0391Fax: +91 (22) 3088 1592。

综合的专业化服务,专为您的业务需求量身定制我们关注您的业务需求,了解每个行业有其独特的要求。

我们全方位的维护服务能满足您在经济和技术方面的所有需求,包括日常设备检查和预测性维护常规工作以及系统性能检测和每年的停工检修等。

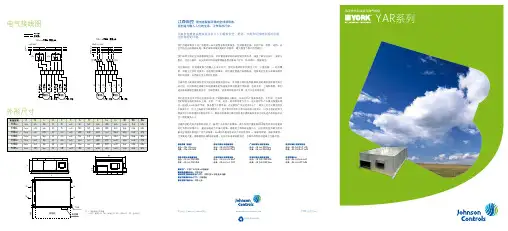

3机组命名 - YAH04 B4LX0D空气处理机组YAH 系列约克YAH 系列吊顶式空气处理机组是中央空调末端装置。

其功能是对空气进行降温冷却,去湿干燥、加热、等焓加湿、过滤净化以及作为新风机组等。

机组将处理过的空气通过风管送到一定距离的地方,特别适用于小型商业办公大楼和工业应用的空调工程。

约克YAH 系列空气处理机组提供10种型号供客户选择,每种型号均有多种排管方式供选择。

冷量从8kW 到252kW ,风量从1500m³/h 到15000m³/h 。

约克YAH1.5到06型号机组采用外转子离心式风机,机组全压范围为146-235Pa ,YAH1.5到06型号机组采用皮带传动的离心式风机,机组全压范围为180-320Pa 。

约克YAH08到15型号采用皮带传动的离心式风机,机组全压范围为275-340Pa 。

本系列机组具有安装方便、使用简单、占用建筑面积小、噪声小、冷量大、送风距离远、价格合理等特点。

机组的结构形式为镀锌钢板箱内贴保温棉,机组的结构形式为镀锌钢板箱内贴保温棉,外挂板式尼龙网过滤器。

冷热盘管均采用铜管套双曲波纹片,盘管翅片间距10~12片/英寸,风机和电机,皮带轮均选用优质产品,性能稳定、高效,风机采用双进风离心前倾多翼风机,外转子电机,防护等级IP54,,F 级绝缘。

闭式三相异步电机,防护等级IP54,F 级绝缘,电源为380V-3-50Hz ,轴承无需润滑。

外挂过滤器既可以从侧面取出,也可以从下面取出。

湿膜加湿器为可选项。

4技术规格1. 湿膜加湿器为等焓加湿过程,仅适用于舒适性空调,不宜用于对湿度有较高精度要求的场合。

2. 当机组配置湿膜加湿器时,机组的机外余压应相应的减去加湿器的风阻。

综合的专业化服务,专为您的业务需求量身定制我们关注您的业务需求,了解每个行业有其独特的要求。

我们全方位的维护服务能满足您在经济和技术方面的所有需求,包括日常设备检查和预测性维护常规工作以及系统性能检测和每年的停工检修等。

3机组命名 - YAH04 B4LX0D空气处理机组YAH 系列约克YAH 系列吊顶式空气处理机组是中央空调末端装置。

其功能是对空气进行降温冷却,去湿干燥、加热、等焓加湿、过滤净化以及作为新风机组等。

机组将处理过的空气通过风管送到一定距离的地方,特别适用于小型商业办公大楼和工业应用的空调工程。

约克YAH 系列空气处理机组提供10种型号供客户选择,每种型号均有多种排管方式供选择。

冷量从8kW 到252kW ,风量从1500m³/h 到15000m³/h 。

约克YAH1.5到06型号机组采用外转子离心式风机,机组全压范围为146-235Pa ,YAH1.5到06型号机组采用皮带传动的离心式风机,机组全压范围为180-320Pa 。

约克YAH08到15型号采用皮带传动的离心式风机,机组全压范围为275-340Pa 。

本系列机组具有安装方便、使用简单、占用建筑面积小、噪声小、冷量大、送风距离远、价格合理等特点。

机组的结构形式为镀锌钢板箱内贴保温棉,机组的结构形式为镀锌钢板箱内贴保温棉,外挂板式尼龙网过滤器。

冷热盘管均采用铜管套双曲波纹片,盘管翅片间距10~12片/英寸,风机和电机,皮带轮均选用优质产品,性能稳定、高效,风机采用双进风离心前倾多翼风机,外转子电机,防护等级IP54,,F 级绝缘。

闭式三相异步电机,防护等级IP54,F 级绝缘,电源为380V-3-50Hz ,轴承无需润滑。

外挂过滤器既可以从侧面取出,也可以从下面取出。

湿膜加湿器为可选项。

4技术规格1. 湿膜加湿器为等焓加湿过程,仅适用于舒适性空调,不宜用于对湿度有较高精度要求的场合。

2. 当机组配置湿膜加湿器时,机组的机外余压应相应的减去加湿器的风阻。