Data Requirements

Capacity cost structure (alternatives?) Expected demand (multiple scenarios?)

EVA

Product and service requirements (e.g. time standards)

Chapter 8, Slide 16

Alternate Demand Scenarios

Current Level Demand 2,000 5,000 7,000 Revenue $2,400,000 $3,600,000 $3,600,000 Fixed Expenses $1,600,000 $1,600,000 $1,600,000 Expanded Revenue $2,400,000 $6,000,000 $6,000,000 Fixed Expenses $2,800,000 $2,800,000 $2,800,000 New Site Revenue $2,400,000 $6,000,000 $8,400,000 Fixed Expenses $3,800,000 $3,800,000 $3,800,000

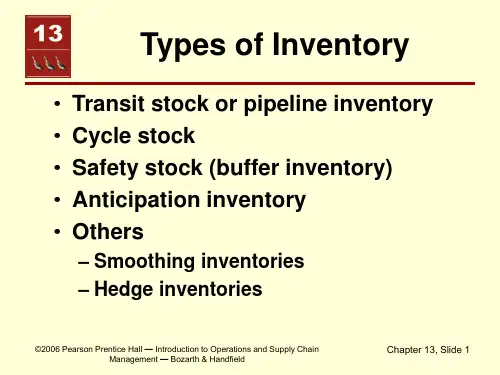

Capacity

•Limited ability to adjust capacity •Detailed planning •Lowest risk

• Workforce, inventory, subcontracting decisions • Intermediate-level planning •Moderate risk

ch08capacitydecisions运营管理英文版版英文版运营管理经营管理运营管理部

Capacity Decisions