德国费亚泰克泵综合样本

- 格式:pdf

- 大小:2.42 MB

- 文档页数:12

Applications:Wastewater transportWastewater treatmentSludge treatmentStormwater transportFlood controlMore information:Type K-maxType E-max Type DType F-maxOur technology. Y our success.Pumps Valves ServiceAmarex KRT – Compact Wastewater Pumpwith Cooling JacketImpeller optionsAlso available with lifting lugsAdditional KRT Series Pumps:Compact Jacket-Cooled Motor10hp to 87hpMotor withconvection cooling5hp to 10hpFull-size Jacket-Cooled Motorup to 1,005hp2553.023-01-U S / 10.20 / © 2020 K S B , I n c . · S u b j e c t t o t e c h n i c a l m o d i f i c a t i o n w i t h o u t p r i o r n o t i c eAmarex KRT –Compact Wastewater Pump with Cooling Jacket1 ReliabilityNon-clogging impellers with large free passages, optimized for every type of wastewaterWatertight, resin-sealed cable entry system, even in the event the cable is damagedMonitoring sensors:motor temperature and leakagemechanical seal leakage (float switch) vibration sensor (optional)bearing temperature at pump and motor end (optional) Explosion-proof, meeting FM and CSA requirements Wear rings in hard metal to ensure continued high effi ciencies and long impeller life2 Energy-savingOptimized hydraulic system yields high efficiency Energy-saving motors meeting IE3 requirements* VFD compatible3 DependabilityMotor cooling via a closed cooling circuit – hence no contact between cooling liquid and fluid handled; no external cooling requiredDouble mechanical seal for added protection Dependable operation even at high ambient temperatures Ease of maintenanceCartridge mechanical seal with integrated impeller for cooling liquid circulationOptimized for digital monitoring* I EC 60034-30 standard not binding for submersible motors. Effi ciencies calculated/determined according to the measurement method specifi ed in IEC 60034-2. The marking is used for submersible motors that achieve effi ciency levels similar to those of standardized motors to the IEC 60034-30 standard.KSB, Inc.4415 Sarellen Road Henrico, VA Wet installation guide wire Wet installation guide rail Dry installation horizontal dry installationverticalMultiple options for installationAmaslide optionSlide mount for convenient, one-person maintenance and inspectionTechnical dataDischarge diameter sizes Up to 12 inches Flow rate Up to 8,800 gpm HeadUp to 160 feet Horsepower rangeUp to 87hp Fluid handling termperature Up to 104o FAutomation optionsAvailable upon requestCost efficiencyThe right material combinations for a long service life, including: grey cast iron, wear resistant high chromium white iron, duplex stainless steel, white cast iron Rolling element bearings lubricated for life to reduce maintenanceOptimized spare parts inventories: Standardizedcomponents are interchangeable within this type series and with wastewater pumps of the Sewatec type series。

Pulsafeeder ExpertiseTechnology is the key to delivering responsible products to the markets that we serve. Leading the way in the development of metering technologies, Pulsafeeder continues to set the standard for accuracy, reliability and safety.Innovation is another hallmark of Pulsafeeder. Helping customers find a new approach to an old problem is what we do best.PULSAtron Series PumpsFor over 20 years, the PULSAtron product line has evolved into philosophy of design that continues to set the standards for the entire industry. Our engineers have developed a guided check valve system with a proven ‘seat and ball’ design that ensures reliable and accurate metering year after year.Our fin cooled Solenoid enclosure dissipates heat ensuring that the pressure handling capability of the pump can be maintained. The thermally protected Solenoid protects the pump from seizing up in extreme heat conditions with an automatic reset feature allowing the pump to resume operation upon cool-down. All PULSAtrons are tested and rated under hot conditions guaranteeing that the flow and pressure ratings meet the specifications.Materials of Construction • Housing - PBT• Head materials - GFPPL, PVC, PVDF, Viton, 316SS • Seats materials - CSPE, TFE, Viton• Ball materials - Alloy C, Ceramic, TFE, 316SS • Diaphragm - PTFE faced CSPEFlow (GPD)P r e s s u r e (P S I )Pulsatron Performance RangeP r e s s u r e (B A R )Flow (LPH)3710141720240235681624324048566496100150200250300MP , E+, EHVA+C+, C50350TypicalApplications• Water Treatment • Water Conditioning • Ware Wash •Car WashCSPE is generic formulation of Hypalon, a registered trademark of E.I. DuPont Company. Viton is a registered trademark of E.I. DuPont Company .ProductSpecifications• Flows to 600 gpd ( 94.6 lph) on specific series• Pressures to 300 psi (21 Bar) on specific models• Accuracy +/- 2% at max capacity on E Plus, HV and MP Series. +/- 3% at max capacity on A Plus, C, C Plus,and E Series.The Pulsatron is available in several different series.Shown here are the Pulsatron MP Series, E Plus Series, HV Series, A Plus, and C Series.PULSAtron ConfigurationsShaftCoil(Solenoid)ArmatureSpringsSuction ValveDiaphragmDischarge ValveDiaphragm Metering Pump TechnologyThe PULSAtron family are solenoid powered diaphragm metering pumps. The key element which differentiates these pumps from other types is the TFE lined elastomer diaphragm. This diaphragm is sealed against the reagent head forming a seal-less, leak free pumping chamber. The solenoid driver is connected to the diaphragm to create the pumping motion. As the diaphragm moves away from the face of the reagent head, it creates a vacuum which closes the discharge check valve and opens the suction check valve, drawing the pumped fluid into the pumping chamber. As the solenoid forces the diaphragm toward the face of the reagent head, the suction check valve closes and the discharge check valve opens allowing the liquid to flow out the discharge valve.Model Specific QR CodePulsafeeder assistseveryonein the field with information for THAT SPECIFIC PRODUCT , quickly and easily. No dedicated app needed. Simply use your QR Reader on your smart phone or tablet and scan the QR Code located on the Pulsafeeder product label, either Pump or Controller.• Identify - Model Number, Serial number, KOPkit (Repair Kit)• View - Quickly find product information such as parts list, IOM, tech sheet and more • Contact - Call or email Tech Support immediately to assist you•Email - Send this information to yourself or someone else, to save or even view laterFeatures & BenefitsMP Series• Automatic control, fully scalable 4-20mADC, 20-4mADC orexternal pacing• Manual control allows for a combined 1000:1 turndown• Flow verification option is available on select sizes• 16 character LCD display and indicator lights• Relay and stop outputs• Simple prompts in plain language and programmable in fourlanguagesE Plus Series• 100:1 turn down ratio• Optional 4-20mA with stop function• Optional external pacing with stop function• Auto-Off-Manual selection switch with indicator lights• Built in circuit protection with easy access panel mounted fuse• Clear hinged cover over controls for water resistanceHV Series• Automatic control, available with 4-20mADC direct or externalpacing, with stop function• Manual control by on-line adjustable stroke rate & stroke length• Viscosities to 20,000 CPS• Auto-Off-Manual switch• Highly reliable timing circuitA Plus, C Plus, E Series• 100:1 turn down ratio; 1000:1 on some models• Water resistant for outdoor installation• Manual control by on-line adjustable stroke length and stroke rate• Optional external pacing with Auto/Manual switch on A Plus• Internally dampened to reduce noise• Optional: External pace, external stop or bothC Series• 10:1 turn down ratio• Optional automatic control by external pacing with prime switch• Manual control by on-line adjustable stroke length• Liquid low level option available to prevent loss of prime• Internally dampened to reduce noiseFeatures & BenefitsPremium Construction• Few moving parts• Optional wet-endmaterials• High Viscosity handling• Long life diaphragm• Leak free designGuided Ball CheckValve System• Dual ball check withTFE seats• Reduce back flow• Outstanding primingcharacteristicsBleed ValveAssembly Standard• Safe & easy priming• Durable and leak freeHighly ReliableElectronics• Timing circuit• Rated hot forcontinuous duty• Thermal overloadAutomatic DegassingTechnologyThe unique degas valve system is designedto allow air to be vented from the pump headwhile minimizing the return fluid volume. Thisallows the pump to be totally self-primingwhich eliminates the need for a bleed valve.The degassing head also prevents the pumpfrom losing its prime due to gas build up,especially in applications where the pump isrun intermittently with long off times betweenruns.Proportional ProcessControlThe PULSAtron series metering pumps offera wide variety of process control inputs.• 4-20mA inputs for metering control withWater meters and PLC’s.• Dry contact pulse inputs for use withPLC’s and dry contact water meters.• External remote stop input that can beused with a level wand for low chemicallevel control.Controls, Options and SystemsValve OptionsIntegrated Tank SystemAvailable on all PULSAtron models • 15 gallon tank• Bulk head assembly • Flow indicator • Float assembly• Pump mounting plateFive Function & Five Function De-Gas Valve• De-Gas - Bypass gasses and fluid with Five Function De-Gas Valve • Back pressure • Anti-Siphon • Air bleed• Discharge drain•Pressure Relief with Five Function ValveValvesOptional Valves available• Double ball standard with TFE seats • Spring loaded • NPT connections • Metric connections• Ceramic, Stainless and TFE balls • CSPE, Viton, and TFE seatsPre-Engineered System and Panel Mounted SystemsAvailable on all PULSAtron models • Pre-Configured system • Easy to install and operate • Mounting flexibility • Quick delivery• Designed for harsh environmentsAutomatic Control• External/remote pacing, with stop available on E Plus, HV, MP Series• External pace with auto/manual selection available on A Plus and C Series• Flow Verification available on MP pumps100 psi or lessTypical Installation Typical Installation Includes:• Tank• Calibration Column• Pulsation Dampeners• Pressure Relief Valve• Pressure GaugeAll Available through Pulsafeeder!Parts & AccessoriesEMP001 B17Corporation StopPulsafeeder’s high quality brass corporation stop and nozzle assembly disperses chemical into the center of a line for even mixing.Pressure Relief Valves prevent an over pressurization situation from ever damaging your pumps or pipes. Over pressurization can occur when a valve is closed or a blockage occurs. They are always recommended equipment for any pump or skid system.Pulsation Dampeners improve pump system efficiency by removing pulsating flows from positive displacement pumps.Solution TanksAvailable in sizes from 15 to 500 gallon.Contact your local Pulsafeeder Distributor or Pulsafeeder Technical Servicesat 800-333-6677Solenoid Valves are used to permit and shut off fluid flow.Pump ShelfDesigned to safely and securely mount your metering pumps on a wall or level surface and contain any potential spills.Calibration KitCalibration columns are used on the supply side of the pump to permit flow calibration.KOPkitsWhen you need a part, you’ve got it. A KOPkit can help you cut downtime and put you back in business fast.。

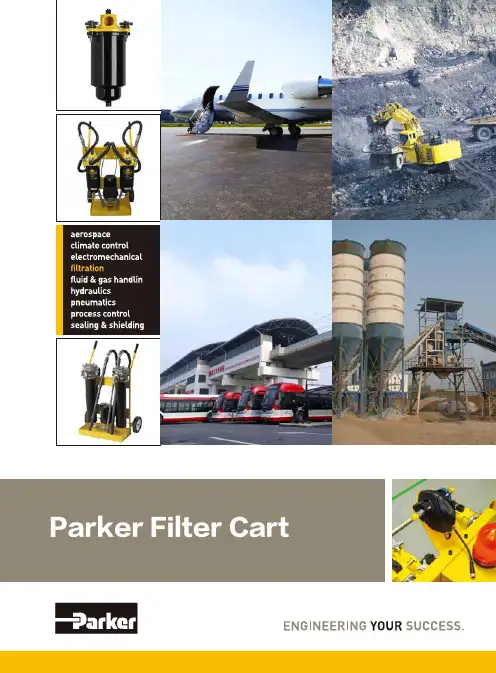

Large Tank Truck Storage TankMobile Mechanical DevicesRefineryFuelIndustrialOil /HydraulicOilAviationFuelLubeHydr LargeStorageCentreMediumStorageCentrePipeStorage TankMedium Tank TruckMedium Tank TruckOil Station Storage CentreRefuelerFactoryStorageCentreFactoryStorageCentreRef FBO Filter CartFuels and lubeoils usually need long-distancetransportation and long-time storage beforere-entering mechanical devices, during whichprocess millions of contaminations will be brought toyour system and will have serious effect on theworking life and reliability of your facilities, engines,pumps and valves. Consequently, great economicloss will be caused: loss of working time,replacement cost for precise components,maintenance fee, etc.Parker portable filtration provides efficient filtering solution. FBO filter cart meets your needs for high-quality fuels, provides protection to engines - the heart of your mechanical devices and transportvehicles; MF series filter cart provides high-qualityhydraulic, gear and lube oils to better protect thecylinder, valves, gear pumps, improve the devicereliability, save maintenance fee, and enhanceeconomic efficiency. e Oil /raulic OilLarge Tank TruckStorage Tank Portable Tank Mobile Mechanical DevicesMobile Mechanical Devices RefuelerRefueler AircraftAircraftfuelerFBO Filter CartApplicationsProduct Overview Filtering new fluid before putting into serviceTransferring fluid from drums or storage tanks to system reservoirsPurifying fluid that is already in usePurifying fluid produced by small and medium sized refineryFor use with fluids such as diesel and aviation fuelModel FBO Filter CartFlow 10 gallons/min (37.9 l/m)Weight 60kgDimension 674mm×525mm×1135mmIndicator Delta P IndicatorBypass Valve Settings Inlet - 2.5 psid (0.2 bar)(Integral to Element) Outlet - 15 psid (1 bar)Maximum Operating Pressure 150 psid (10bar)Maximum Operating Temperature 240°F (115°C)Electrical Motor 220V/50Hz 0.75kw@1450rpm, IP55Fluid Type diesel, aviation fuelConstructions Cart frame :steel, Hoses: PVC, Wand Assembly:PVC, Seat: aluminum, Bowl Assembly: steelMicron Rating 1/5/10/25 micronElement Changeouts Split-typeA fluid quality test that Parker has conducted toward regular gas stations in various regions of China shows that contaminants of most new fluid surpass the standard requirements to construction mechanical devices and vehicle's engine fuel injection system. Parker's FBO filter cart, which applies dual-stage aviation technology, is a filter system integrating functions of filtering, monitoring and alarm. Racor's coalescing technology, global unique and patented, can synchronize the filtration of water and impurity. FBO filter cart can equip the on-line, monitoring and pre-alarm system to monitor the filtered fluid quality in real time.Specifications:Box 1 Box 2 Box 3 Box 4 Box 5 Box 6 Box 7 Box 810FBO 14 25M 10S B VP I 1Select the desired symbol (in the correct position) to construct a model code. Example: Replacement Element How to Order Please note the bolded options reflect standard options, and IcountPD is a high-level product newly launched by Parker – online particle detector. FBO two-stage filter can synchronize thefiltration of water and impurities, which makesthe working life longer. It solves the problemthat impurities and water might bring toengines and precision accessories.Drain Valve – Filter is fitted with lockablemanual drain valve to drain out filtered watereasily.Pre-Alarm System – Light on top of thesystem reminds user to make appropriateactions according to the signals.1. If the cleanliness of fluid has achieved theset point, the alarm light will be turned on,meaning that the fluid doesn’t need to becleaned anymore.2. If the separated water is out of the warninglevel, the sensor will display signal to meanthat the filter needs to drain water.IcountPD Online Particle Detector – optional.IcountPD is Parker’s patented product,which detects fluid quality in real time,monitors and displays the fluid cleanlinesslevel, to meet customers’ demand ofhigh-valued equipments (aircraft, laboratory,etc) protection.It is applicable in the new fluid detection forlarge scale group companies, such asconstruction sites, fleet, mining, etc. Model Symbol Description Box 1: Basic Assembly 10FBO 37.9LPM (maximum 35Cst)Box 2: Length 14 20.5 in(52.1cm) 10 16.5in(41.9cm)Box 3: Inlet Filter Element 25M Particle Removal, 25micron 25S Water Separator, 25 micron Box 4: Outlet Filter Element 01M Particle Removal, 1 micron 05M Particle Removal, 5 micron 10M Particle Removal, 10 micron 01S Water Separator, 1 micron 05S Water Separator, 5 micron 10S Water Separator, 10 micron Box 5: Seals B Nitrile (NBR)Box 6: Indicator VP Visual indicator (mounted on Outlet Filter only)Box 7: Power Supply I 220V 50Hz O 110V 50Hz / 110V 60Hz Box 8: Options 1 None PD With IcountPD WD With IcountPD and water level alarm Particle Removal Water Separator Media FBO10 FBO14 Media FBO10 FBO14 01M088003PS 088011PS 01S 088007PS 088015PS 05M088004PS 088012PS 05S 088008PS 088016PS 10M088005PS 088013PS 10S 088009PS 088017PS 25M 088006PS 088014PS 25S 088010PS 088018PSApplications:Product OverviewMF Series OverviewParker's 5/10MF filter cart is an ideal way to prefilter andtransfer fluids into reservoirs or to clean up existing systems.Most new fluids (right out of the drum) are unfit for use due tohigh initial contamination levels. Contamination, bothparticulate and water, may be added to a new fluid duringprocessing, mixing, storage and transportation. The Parkerportable filter cart uses two high capacity ModuFlow TM Plusfilters and Par-Gel TM element for long element life and bettersystem protection.Filtering new fluid before putting into serviceTransferring fluid from drums or storage tanks to systemreservoirsPurifying fluid that is already in useImproving existing system filtrationRemoving free water from a systemFor use with fluids such as hydraulic, gear and lube oilsMF Series Performance:Fluid cleanliness levels are a function of initialcontamination levels, contamination ingression rates,reservoir size and filter element efficiency. The chartbelow lists approximate time requirements to achievecertain cleanliness levels based on the assumptionsnoted.MF Series Element Performance:Reservoir Capacity (Gallons)Time Required (Hours)Projected Cleanliness Level (ISO) 500.5 20/18/15 501.0 17/15/12 502.5 16/14/111001.5 18/16/131002.5 17/15/121004.0 16/14/112002.5 19/17/142003.5 18/16/132005.0 17/15/12Media Code Filter Media Capacity (Grams)40W Woven Wire *40SA Synthetic *20Q MicroglassⅢ 14010Q MicroglassⅢ 13505Q MicroglassⅢ 13002QMicroglassⅢ 110Notes:The results in the chart are based on the followingassumption:1.Initial contamination level is 500,000 particles greaterthan 10 micrometers per 100 ml of fluid (10MFP cart).2.Inlet filter fitted with 40SA element; outlet with 20Qelement.3.System ingression rate equal to 1×106 particles greaterthan 10 micrometers entering the system per minute. Two filters instead of one, 2.5 times of standardproduct in lengthHeavy duty frame“Par-Gel TM ” water removalelements availableHeavy duty frameLightweight and portableTwo flow rates available: 18.9 liter/min and37.9 liter/min 3.6m suction pipe (hose and connections included)Pump protection and long element life Capable of getting fluid to a desired cleanliness level Removes free water from a system Rugged and durable Easy to move from place to place Enables use in low or high viscosity applications Unnecessary for additional hardwareElement cost saving and trouble-free service Extends fluid life and system performance Gets dirt and water out of system with one process Built to last for many hours of use One person operation Matched to your needsReady to use as received Features Advantages Benefits Efficiency%Efficiency 50.095.099.099.599.9100001000200100202048121620βSize (C)Model 5MFP/10MFP portable filter cartFlow 5 gallons/min - 10 gallons/min (18.9 l/m – 37.9 l/m)Weight 110 lbs. (45.4 kg)Dimension 648mm×503mm×1034mmMaximum Recommended 5MFP: 3000 SUS (627 cSt), 0.85 specific gravityFluid Viscosity 10MFP: 500 SUS (108 cSt), 0.85 specific gravityVisual Indicator (outlet filter) Visual differential type, 3-band(clean, change, bypass)Bypass Valve Settings Inlet – 3 psid (0.2bar)(Integral to Element) Outlet - 35psid (2.4bar)Material Synthetic, Stainless steel mesh, Microglass Ⅲ, Par-Gel TM Water Removal Operating Temperature Seal option (standard),NBR: -40°F to 150°F(-40°C to 66°C)Seal option (high temp option) FKM: -15°F to 200°F(-26°C to 93°C)Power Supply 5MFP: 110/220v, 60/50Hz, 8/4A10MFP: 110/220V, 60/50Hz, 10/5AElectrical Moter 5MFP: 0.75kw @ 1725rpm,10MFP: 0.75kw @ 3450rpm, thermal overload protectionTypical Fluid Cleanliness Level Requirements Many manufacturers of hydraulic components have established fluid cleanliness levels for their components. Using a portable filter cart can be a very effective way to reach and maintain these cleanliness levels. Component ISO Cleanliness Level Servo control valves 16/14/11Proportional valves 17/15/12Vane and gear pumps/motors 18/16/13Direction and pressure control valve 18/16/13Gear pumps/motors 19/17/14Flow control valves20/18/15Cylinders 20/18/15New fluid 20/18/15Par-Gel TM MediaWater Capacity Specifications:ModelFluid Viscosity Capacity 5MFP75 SUS 600ml200SUS 420ml 10MFP 75 SUS 500ml200SUS 300ml Notes:1.Par-Gel TM elements are designed to remove system's free water.2.Capacity is very dependent on flow rate andviscosity. Not recommended with fluids in excess of 500 SUS.Box 1 Box 2Box 3 Box 4 Box 5 Box 6 Box 7 Box 810MFP 2 40SA 10Q B VP I 1ModelSymbol Description Box 1: Basic Assembly 5MFP 18.9 l/m (fluid viscosity no larger than 627 cSt ) 10MFP 37.9 l/m (fluid viscosity no larger than 108 cSt)Box 2: Length2 Double Box 3: Inlet Filter Element 40SA Synthetic, 40 micron40W Stainless Steel Mesh, 40 micron nominal20Q Microglass Ⅲ, 20 micron Box 4: Outlet Filter Element 02Q Microglass Ⅲ, 2 micron05Q Microglass Ⅲ, 5 micron10Q Microglass Ⅲ, 10 micron20Q Microglass Ⅲ, 20 micronWR Par-Gel TM Water Removal Box 5: Seals B Nitrile (NBR) V High temperature option (FKM/EPDM)Box 6: Indicator VP Visual indicator (mounted on Outlet Filter only)Box 7: Bypass I 35PSID (2.4 bar) (outlet filter element)Box 8: Options 1None PD Icount PD Please note the bolded options reflect standard options with a reduced lead-time.Inlet Filter (3psid bypass)Outlet Filter (35psid bypass)MediaSeals 02QN/A 937397Q 05QN/A 937398Q 10QN/A 937399Q 20Q940971Q 937400Q 40SA940802 N/A 40W940803 N/A WRN/A 94073402QN/A 937405Q 05QN/A 937406Q 10QN/A 937407Q 20Q940974Q 937408Q 40SA940972 N/A 40W940973 N/A WR N/A 940736NBR FKM Replacement ElementsHow to OrderSelect the desired symbol (in the correct position) to construct a model code. Example:FC-2-10B 12/05W o r l d w i d e M a n u f a c t u r i n g L o c a t i o n s Parker Hannifin Motion & Control (Shanghai) Co., Ltd.280 Yunqiao Road, Jin Qiao Export Processing Zone, Shanghai, China Tel: (86) 21-28995000Fax: (86) 21-64459717Parker Hannifin Filtration Products and Systems(Shanghai) Co., Ltd.No. 2 Workshop, 786 Wangqiao Road, Jinqiao Processing Southern Zone, Shanghai, China Tel: (86) 21-58383030Fax: (86) 21-58382428Europe Engine FiltrationParker Hannifin Corporation Filte Division EuropeShaw Cross Business Park Churwell ValeDewsbury, WF 127RD England /eurofilt North AmericaEngine Filtration Parker Hannifin Corporation Racor Division 3400 Finch Road P .O.Box 3208Modesto, CA /racor Parker Hannifin Corporation Racor Division P .O.Box 6030Holly Springs, MS /racor Parker Hannifin Corporation Racor Division 302 Parker Drive Beautort, SC /baltson Compressed Air Treatment Parker Hannifin Corporation Filtration and Separation Balston Operation 242 Neck Road Haverhill, MA /balston Parker Hannifin CorporationFiltration and Separation Finite Filter Operation500 Glaspie StreetP .O.Box 599Oxford, MI 48371-5132/finitefilter Parker Hannifin Corporation Airtek Division4087 Walden AvenueLancaster, NY 14086 Hydraulic Filtration Parker Hannifin Corporation Hydraulic Filter Division 16810 Fulton County Road #2Metamora, OH /hydraulicfilterProcess FiltrationParker Hannifin Corporation Process Advanced Filtration 2340 Eastman AvenueOxnard, CA 93030/processfiltration Compressed Air Treatment Parker Hannifin Corporation domnick hunter industrial operations Dukesway, Team Valley Trading Estate Gateshead, Tyne & Wear England NE 11 OPZ Parker Hannifin Corporation Parker Hiross S.p.A Strada Zona Industriale, 435020, S. Angelo Piove(PD), Italy Parker Hannifin Corporation ZANDER Aufbereitungstechnik GmbH Stammhaus Essen/Headquarter Germany, Essen Im Teelbruch 11845219 Essenwww.zander.de Hydraulic Filtration Parker Hannifin Corporation Hydraulic Filtration Division Europe Stieltjesweg 8, 6827 BV Amhem P .O.Box 5008 6802 EA, Amhen Amhem, Holland /eurofilt Parker Hannifin Corporation Finn Filter OperationSalmentie 260FI-31700 Urjala as Finland /fiParker Hannifin Corporation CMC OperationBrunel WayThetford, Norfolk IP 24 1HP England /cmc Process Filtration Parker Hannifin Corporation domnick hunter process division Durham Road, Birtley Co. Durham, DH3 2SF England Asia Pacific Parker Hannifin Corporation Shanghai Co.Ltd.280 YunQiao Road JinQiao Export Processing Zone Shanghai 101206 China /china Parker Hannifin CorporationSingapore Pte Ltd.Lot 558A, Jalan Subang 3Off Persiaran SubangSungal Penaga Industrial Park 47610 Subang JayaSelangor Darul Ehsan, Malaysia /malaysia Parker Hannifin Corporation Thailand Co.Ltd.1023 3rd Floor. TPS Building Pattanakam RoadSuanluang, Bangkod 10250 Thailand /thailand Parker Hannifin Corporation Korea Ltd.777 Jung-RiDongtan-Myeon, Hwaseong-City Kyunggi-Do, 445-813 Korea /korea Latin America Parker Hannifin Corporation Comercio Ltda. Filtration Division Estrada Municipal Joel de Paula, 900Eugenio de Melo, Sao Jose dos Campos CEP 12225-390 SP Brazil /br。

ITT flygt飞力泵ITT goulds泵ITT Lowara罗瓦拉泵ITT Bell & Gossett泵ITT Robot罗伯特泵SEEPEX西派克泵ALLDOS安度实泵Silverson高剪切混合器Ebara荏原泵Grundfos格兰富泵弗尔德VERDER 泵ABEL 泵易威奇iwaki(イワキ) 泵GSD川源泵WANNER万纳尔Hydra-cell多柱塞高压隔膜泵DAB德宝泵WILO威乐泵CALPEDA科沛达泵CA T高压泵ESPA亚士霸泵TSURUMI鹤见泵walrus华乐士泵Wilden威尔顿泵ARO英格索兰泵Ingersoll-Rand 英格索兰空气压缩机Giant巨人泵胜达因MASO SINE泵米顿罗milton roy泵胜达因sundyne 泵普罗名特Prominent泵seko计量泵普旭BUSCH真空泵固瑞克Graco HUSKY气动隔膜泵马拉松Marathon气动隔膜泵马拉松Marathon气动隔膜泵胜佰德Sandpiper泵日机装NIKKISO 泵德国Lutz插桶泵斯坦德STANDARD桶泵博格BORGER凸轮泵威马Versa-Matic气动隔膜泵阿法拉伐Toftejorg BLABO罐清洗系统帕斯菲达Pulsafeeder计量泵威肯Viking齿轮泵华伦力Warren Rupp气动隔膜泵Johnson凸轮泵可肯Corken滑片泵, 压缩机Bladgon气动隔膜泵LC流量计Magnus齿轮泵Wright圆周柱塞泵BLOV AC ClEANER气动真空吸尘器莫依诺MOYNO泵和顺hoelschertechnic粉碎机LITTLE-GIANT小巨人泵lewa里瓦泵OBL计量泵Masoneilan梅索尼兰调节阀Burkert宝帝阀Nash纳士真空泵压缩机里其乐托玛斯Rietschle Thomassmith-blair管路连接系统瓦诺Vano泵爱德华EDW ARDS 泵莱克勒Lechler喷嘴ALCO 阀门SPECK泵CASHCO阀SOR索尔压力开关HOKE仪表阀门及管件Orbit球阀TESCOM阀门AUTOCLA VE阀门Apollo球阀Circle Seal Controls阀O'BRIEN伴热管线CIRCOR阀门COOPER CAMERON V ALVES(CCV)阀门Goodwin双板止回阀GRAYLOC管道系统装置贝克BECKER真空泵费亚泰克Friatec阀门泵FELUWA软管隔膜柱塞泵CCI THERMAL西西阿尔电加热费戈斯ferguson泵Bornemann鲍诺曼泵福力德Fluid-o-Tech泵磨锐ensival-moret泵NETZSCH耐驰NEMO奈莫螺杆泵凯士比KSB泵阀福斯flowserve泵阀Richter磁力泵ROTAN内啮合齿轮泵泵泰克尼姆tecnium泵艾格尔argal化工泵DOSEURO道茨计量泵Sulzer苏尔寿工业泵SA VINO BARBERA泵埃理奥特ELLIOTT压缩机威顿vanton泵Durameter计量泵金子KANEKO电磁阀ASCO通用电磁阀罗斯蒙特ROSEMOUNT测量仪表SAAB雷达液位计凯泰克K-TEK测量仪表阿牛巴Annubar流量计阿特拉斯·科普柯ATLAS COPCO压缩机JOHNSON泵马格maag泵斯可金格SCHERZINGER泵ALLWEILER阿尔维勒泵houttuin泵IMO泵warren泵ZENITH泵ZENITH泵Tushaco泵约翰克兰johncrane密封海密梯克hermetic屏蔽泵豪顿howden压缩机BAND-IT紧固产品美卓自动化metsoautomation阀门阿法拉伐Alfa Laval春鼎TRUNDEAN机械弗鲁克FLUKO实验室搅拌机|高剪切分散乳化机|分散机|乳化机|均质机|粉碎机|混合机|捷流分散混合机|固液混合系统莱宝LEYBOLD真空泵埃杜尔edur溶气泵莫诺MONO泵HIHCHINE气液混合泵|气浮泵|溶气泵|混气泵|加气泵|臭氧添加泵|曝气泵威仕VSE流量计百利beinlich齿轮泵/柱塞泵多尔DST永磁联轴器系统罗迪ROTELMANN罗德曼球阀沃森马洛-布雷德尔watson marlow-bredel泵布朗卢比BRAN+LUEBBE泵NOV国民油井Mission砂泵莱宁LIGHTNIN搅拌机DUCHTING浆液泵CERA SYSTEM陶瓷阀PLENTY泵COPES-VULCAN阀威普克液压WEPUKO HYDRAULIK航特阀门HUNT V ALVE千世KEMPION计量泵哈莫尔曼HAMMELMANN泵特夫洛tapflo泵凯恩孚KNF泵福禄flow帝国teikoku屏蔽泵百马blackmer泵WOMA沃马高压柱塞泵Mahr测量仪器海捷hijet真空压缩系统kmt-mccartney 泵科尔庭koerting喷射泵PCM泵frymakoruma弗科玛研磨设备|在线均质机|脱气机刮片式热交换机|连续型生产设备wangen王恩泵克隆巴赫KROMBACH阀门伯马Boehmer球阀Dresser Wayne阀门VPS干式螺杆真空泵法尔珂FAK阀门柏勒夫Bellofram阀门盖米GEMUE阀门日立HITACHI泵寿力sullair压缩机爱发科ULV AC真空泵Yoshitake耀希达凯蒸汽减压阀、气体减压阀、水用减压阀、安全阀、过滤器、疏水阀、汽水分离器、背压阀、排空气阀、电磁阀、电动阀格林韦德glynwed管道系统甲南电机konan气动液压诺亚NOACH电动执行机构德恩杰Z&J阀门伯纳德bernard电动执行器松河sonho电机Chemquip泵阀克瑞crane阀门dickow泵femyers泵gormanrupp戈尔曼.鲁普泵gusher泵haywardgordon泵工装koso常压控制阀ruthmann泵smith泵summit泵塔海尔tuthill泰悉尔真空|风机|泵pomac泵康普艾compair压缩机龙铁longtech鼓风机阿尔泰克Alltech计量泵PROCON高压旋转叶片泵神钢kobelco压缩机super塑宝泵MALHATY 丸八泵albany泵斯普瑞SPRAY喷雾奥丽文OLIVER阀门DKLOK阀门SAFELOK阀门STAUBLI快速接头TECSIS仪器仪表TECO-Westinghouse东元西屋电机积水sekisui塑胶管材HACH哈希水质分析仪KAMAT泵OSAW A大泽气动吸尘器RUHRPUMPEN鲁尔泵依爱EXAIRPROTEGO保特高TODO-GAS干式快速接头美国penguin(企鹅泵)KNOLL科诺尔泵Brinkmann泵barmag巴马格泵EV A艾瓦泵SEIM赛姆泵TECOFI阀Love is not a maybe thing. You know when you love someone.。

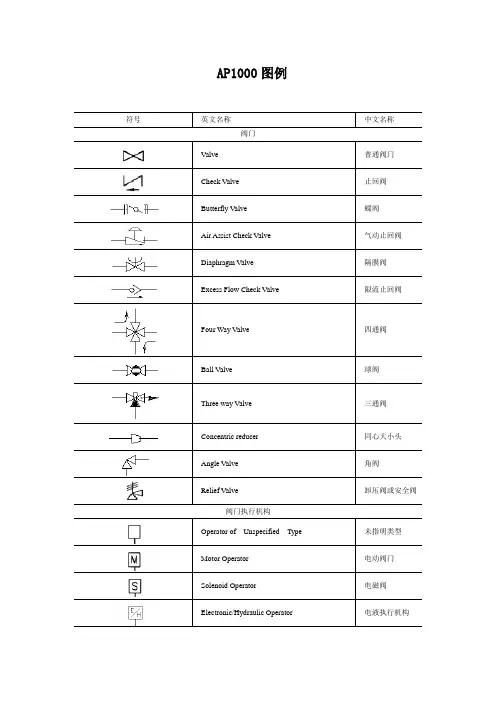

AP1000图例

阀门

阀门执行机构

机械设备

隔断装置

电气设备

其他

1.1 其他

1) 图纸之间的连接:

或

2) 仪表

测量仪表多种多样,主要有测量压力、流量、温度等的各种元件。

3) 智能阀

智能阀可以数字传输过程仪表的信号,如入口压力,出口压力,温度,流量。

在上面的例子中,阀门V117提供出入口压力,温度,流量指示信息,控制算法的计算在FICA100中进行。

来源设备或指向设备

方向 设备坐标 图纸号 来源或去向 来源或去向

在上例中,阀门V117提供出入口压力,温度,流量的指示,阀门利用通道FICA065的其他输入信息进行控制算法的计算。

4)控制逻辑块

说明:上面的表格为控制逻辑块,能够指示出仪表通道与相关设备之间的关系。

其中,1为接口部件的位号,2为信号或第一格中产生的动作,3为信号或相关设备的动作。

以下举例说明两种常见的指示方式:

在上面的例子中,阀V022在TICA-100发出“高”信号时打开。

在上面的例子中,阀V022在TICA-100发出“高”信号时打开。

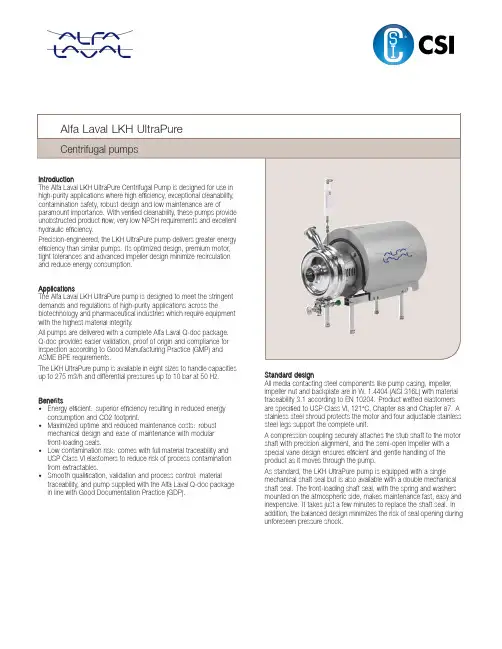

The LKH UltraPure pump is available in eight sizes to handle capacities up to275m3/h and differential pressures up to10bar at50Hz.B e n e t s•Energy ef cient:superior ef ciency resulting in reduced energy consumption and CO2footprint.•Maximized uptime and reduced maintenance costs:robust mechanical design and ease of maintenance with modularfront-loading seals.•Low contamination risk:comes with full material traceability and USP Class VI elastomers to reduce risk of process contamination from extractables.•Smooth quali cation,validation and process control:material traceability,and pump supplied with the Alfa Laval Q-doc package in line with Good Documentation Practice(GDP).S t a n d a r d d e s i g nAll media contacting steel components like pump casing,impeller, impeller nut and backplate are in W.1.4404(AISI316L)with material traceability3.1according to EN10204.Product wetted elastomers are speci ed to USP Class VI,121°C,Chapter88and Chapter87.A stainless steel shroud protects the motor and four adjustable stainless steel legs support the complete unit.A compression coupling securely attaches the stub shaft to the motor shaft with precision alignment,and the semi-open impeller with a special vane design ensures ef cient and gentle handling of the product as it moves through the pump.As standard,the LKH UltraPure pump is equipped with a single mechanical shaft seal but is also available with a double mechanical shaft seal.The front-loading shaft seal,with the spring and washers mounted on the atmospheric side,makes maintenance fast,easy and inexpensive.It takes just a few minutes to replace the shaft seal.In addition,the balanced design minimizes the risk of seal opening during unforeseen pressure shock.T E C H N I C A L D A T AM a t e r i a l sProduct wetted steel parts:W.1.4404(316L)with material traceability3.1according to EN10204 Other steel parts:Stainless steel Inside surface nish:Mech Ra≤0.5 External nish:Fiber brushed Product wetted elastomers:EPDM-USP Class VI,121°C.Chapter88,and Chapter87 Rotary seal face:Silicon Carbide Stationary seal face:Silicon CarbideM o t o rFoot- anged motor according to the IEC metric standard,2poles=3000/3600rpm at50/60Hz,4poles=1500/1800rpm at50/60Hz,IP55 (with drain hole with labyrinth plug),insulation class F.M o t o r s i z e s50Hz: 1.5-75kW 60Hz: 1.2-80kW M i n/m a x m o t o r s p e e d2poles:1.2-45kW:900-4000rpm 2poles:55-80kW:900-3600rpm 4poles:1.6-75kW:900-2200rpm W a r r a n t yExtended3-years warranty on LKH pumps.The warranty covers all non wear parts on the condition that genuine Alfa Laval Spare Parts are used.O P E R A T I N G D A T AM a x i n l e t p r e s s u r eLKH UltraPure10-70:500kPa(5bar)T e m p e r a t u r eTemperature range:-10°C to+140°C(EPDM) Flush media:Max70°C Flush housing sterilization(pump not in operation):Max125°C D o u b l e m e c h a n i c a l s h a f t s e a lWater pressure inlet,LKH UltraPure10-60:Max.500kPa(5bar) Water pressure inlet,LKH UltraPure70:Max.300kPa(3bar) Water consumption:0.25-0.5l/min C o n n e c t i o n s f o r d o u b l e m e c h a n i c a l s h a f t s e a lLKH UltraPure10-70:1/8"GD i m e n s i o nP u m p s p e c i c m e a s u r e sP u m p M o d e l L K H U l t r a P u r e-10L K H U l t r a P u r e-20L K H U l t r a P u r e-25L K H U l t r a P u r e-35L K H U l t r a P u r e-40L K H U l t r a P u r e-45L K H U l t r a P u r e-60L K H U l t r a P u r e-70 A142180193193212193261254 B878810611912697102147 C2327322328416225 D247253303303329329329408 E51636954646410676 P1123129153153166153165206 T12323242624284711M o t o r s p e c i c m e a s u r e sM o t o r I E C I E C90I E C100I E C112I E C132I E C160I E C180I E C200I E C250 M o t o r k W1.5/2.23.04.05.5/7.511/15/18.52230/3755/75 F(max)*316336339358386406372500 G157185198196262286399394H288325359383485533670738 I(LKH-10to LKH-60)434516497597791842980-I(LKH-70)----8048559931051*Possible to reduce dimension F by min.59mm for all pump models.For smaller models it will be possible to reduce dimension F even further.F r a m e o v e r v i e wP u m p M o d e l L K H U l t r a P u r e-10L K H U l t r a P u r e-20L K H U l t r a P u r e-25L K H U l t r a P u r e-35L K H U l t r a P u r e-40L K H U l t r a P u r e-45L K H U l t r a P u r e-60L K H U l t r a P u r e-70 M o t o r r a n g e(I E C)I E C90-I E C160I E C90-I E C160I E C90-I E C200I E C90-I E C180I E C90-I E C200I E C100-I E C180I E C112-I E C200I E C160-I E C250 Moter range(kW) 1.5-11 1.5-18.5 1.5-30 1.5-22 1.5-303-224-4511-75 Dimensional data are based on2pole,ABB motors.D r a i n d i a m e t e rI S O1127T CC l a m p C l a m p1/2"13.512.73/4"17.219Dimensions are for guidance only.For exact measures of speci c pump speci cations,please refer to Anytime Con gurator.C o n n e c t i o n sL K H U l t r a P u r e-10L K H U l t r a P u r e-25L K H U l t r a P u r e-40L K H U l t r a P u r e-45L K H U l t r a P u r e-60 P u m p M o d e l L K H U l t r a P u r e-20L K H U l t r a P u r e-70L K H U l t r a P u r e-35Clamp ISO1127M136********M23636364892 Clamp ASME BPE M12929292929M22929292929 Clamp ISO2037M12121212121M22121212121 Clamp DIN32676M16464649292M22164216492 Flange Asept.A for DIN M16496966060M24764479660 Flange Asept.A for ASME M156********M24756475860 Union Asept.A for DIN M11001001006464M2481004810064 Union Asept.A for ASME M16054546464M24860485464J1*63.5/2.5"76.1/3"76.1/3"101.6/4"101.6/4"J2*51/2"63.5/2.5"51/2"76.1/3"101.6/4"*Other dimensions might be available upon request.ESE00269/9F l o w c h a r t –F r e q u e n c y :50H z -S p e e d (s y n c h r ):3000r p m12010080604020020*******150100503007-0080LKH UP-70LKH UP-40LKH UP-35LKH UP-45LKH UP-10LKH UP-60LKH UP-20LKH UP-25H (m)Q (m3/h)Q -d o cStandard documentation package:•Declaration of compliance with Regulation (EC)No.:1935/2004•Declaration of compliance to EN 10204type 3.1(MTR)•Declaration of compliance to the U.S.Food &Drug Administration CFR 21(non-metallic parts)•Declaration of compliance to the U.S.Pharmacopeia (Elastomers and polymers)•TSE (Transmissible Spongiform Encephalopathy)/ADI (Animal Derivative Ingredient)declaration •Declaration of surface nish compliance•Declaration of passivation and electro polishing (if speci ed)• 3.1certi cation in accordance to EN10204•Pump performance test certi cateOptional documentation:•Hydrostatic test certi cate •Surface measurement report •Delta ferrite report (impeller)O p t i o n sA.Impeller with reduced diameter.B.Impeller with delta ferrite max.1%.C.Motor for other voltage and/or frequency.D.Half speed motor.E.Motor with increased safety/ ame proof motor.F.ATEX approved execution(LKHex UltraPure)G.Double mechanical shaft seal.H.Adjustable pads.I.Horizontal drain connection,see illustration below.J.Drain with1/2"Alfa Laval Unique DVST UltraPure valve welded directly to casing,see illustration below.K.Special ush arrangement with1/2"Alfa Laval Unique DVST UltraPure diaphragm valve,needle valve and ow meter,see illustration below. L.No drain.M.Product wetted surface nish mechanically polished to Ra≤0.8μm.N.Product wetted surface nish electropolished to Ra≤0.4μm.O.Passivated surface.P.Product wetted elastomers FPM or FEP to USP Class VI,121°C Chapter88,and Chapter87.Q.Hydrostatic testing with certi cate.R.Surface nish measurement with certi cate.S.0°,90°or270°outlet,see illustration below.A v a i l a b l e o u t l e t p o s i t i o n s1/2"A l f a L a v a l U n i q u e D V S T U l t r a P u r e v a l v e -Welded directly to casing-Inside nish electropolished to Ra≤0.4μm -PTFE diaphragm conforming to USP Class VI- ISO1127- DIN11850- ASME-BPE- ISO2037F l u s h a r r a n g e m e n tWith the ush kit arrangement some process uid is passing through the ush housing of the double mechanical seal,creating a barrier from the atmosphere to avoid potential process contamination across the seal face.Flow meterFlush housingA v a i l a b l e d r a i n c o n n e c t i o n s½”or¾”-Tri-clamp for ASME-Clamp for ISO1127½”or¾”-Tri-clamp for ASME-Clamp for ISO1127-Clamp for DIN11864-3O r d e r i n gPlease state the following when ordering:•Pump size.•Connections.•Impeller diameter.•Motor size.•Voltage and frequency.•Flow,pressure and temperature.•Density and viscosity of the product.•Options.N o t e!For further details,see also Instruction manual ESE01703.This product has EHEDG certi cateAlfa Laval reserves the right to change specifications without prior notification.H o w t o c o n t a c t A l f a L a v a l Contact details for all countriesare continually updated on our website.Please visit to access the information direct.A l f a L a v a l i s a t r a d e m a r k r e g i s t e r e d a n d o w n e d b y A l f a L a v a l C o r p o r a t e AB .。

The pump system consists of a centrifugal pump and a separator, which enables air to be separated from the liquid and be sucked by a vacuum pump - making automatic priming possible. Even with suction heights of several meters the machine rapidly evacuates the air from the suction pipe and starts to pump. Additionally, thanks to the semi-open impeller, the PAS HF range is also suitable for pumping liquids with solids in suspension.Both Atlas Copco and Varisco have decades of experience in designing and producing pumps. We have put those years of expertize into providing a solutions portfolio that works across multiple applications. The PAS HF (high flow) range is packed with features that not only meet, but exceed the needs of the market. We are focused on an efficient, extremely versatile pump that is suitable for many industries, including construction, general dewatering and emergency applications, such as flood clean up.ApplicationsBenefitsDiesel - Qmax 510 m³/h (2,250 USgpm) - Hmax 51 m (167 ft)Indicative picture of the productPAS HF - Vacuum prime centrifugal pumpsPumpHigh efficiency: 70% (B.E.P .)Rapid “dry” primingUp to a height of 7,5 m (24.6 ft)High resistanceTo abrasive liquids and turbid sandy waters Semi-open impellerSolids handling up to 76 mm (3”)Diaphragm vacuum pumpOil free suitable for dry running: no contamination of the environmentMechanical shaft seal in oil bathIt allows the “dry running” operation of the pump Wear plateCast iron wear plate that is easily replaceable Easy maintenanceHinged cover for direct access to the impeller (without lifting devices). Link belt quick to replace on the field.Test according to UNI EN ISO 9906 standard - level 2 Test liquid: clean water, density 1,000 kg/m³Spherical solids handling: D.76 mm (3”)Priming time: 30 s from 1,5 m (4.9 ft)Max absorbed power: 51,0 kW - 68.4 HP (2.200 rpm)Performance curvesTechnical dataArrangementSpecification is subject to change without prior notice. Please check with your local Atlas Copco representative for the latest specifications.。

Tubing, Filter, Valves and Other Accessories SuppliedCANADA www.omega.ca Laval(Quebec) 1-800-TC-OMEGA UNITED KINGDOM www. Manchester, England0800-488-488GERMANY www.omega.deDeckenpfronn, Germany************FRANCE www.omega.frGuyancourt, France088-466-342BENELUX www.omega.nl Amstelveen, NL 0800-099-33-44UNITED STATES 1-800-TC-OMEGA Stamford, CT.CZECH REPUBLIC www.omegaeng.cz Karviná, Czech Republic596-311-899TemperatureCalibrators, Connectors, General Test and MeasurementInstruments, Glass Bulb Thermometers, Handheld Instruments for Temperature Measurement, Ice Point References,Indicating Labels, Crayons, Cements and Lacquers, Infrared Temperature Measurement Instruments, Recorders Relative Humidity Measurement Instruments, RTD Probes, Elements and Assemblies, Temperature & Process Meters, Timers and Counters, Temperature and Process Controllers and Power Switching Devices, Thermistor Elements, Probes andAssemblies,Thermocouples Thermowells and Head and Well Assemblies, Transmitters, WirePressure, Strain and ForceDisplacement Transducers, Dynamic Measurement Force Sensors, Instrumentation for Pressure and Strain Measurements, Load Cells, Pressure Gauges, PressureReference Section, Pressure Switches, Pressure Transducers, Proximity Transducers, Regulators,Strain Gages, Torque Transducers, ValvespH and ConductivityConductivity Instrumentation, Dissolved OxygenInstrumentation, Environmental Instrumentation, pH Electrodes and Instruments, Water and Soil Analysis InstrumentationHeatersBand Heaters, Cartridge Heaters, Circulation Heaters, Comfort Heaters, Controllers, Meters and SwitchingDevices, Flexible Heaters, General Test and Measurement Instruments, Heater Hook-up Wire, Heating Cable Systems, Immersion Heaters, Process Air and Duct, Heaters, Radiant Heaters, Strip Heaters, Tubular HeatersFlow and LevelAir Velocity Indicators, Doppler Flowmeters, LevelMeasurement, Magnetic Flowmeters, Mass Flowmeters,Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area Flowmeters, Vortex Shedding FlowmetersData AcquisitionAuto-Dialers and Alarm Monitoring Systems, Communication Products and Converters, Data Acquisition and Analysis Software, Data LoggersPlug-in Cards, Signal Conditioners, USB, RS232, RS485 and Parallel Port Data Acquisition Systems, Wireless Transmitters and Receivers。

A4 SeriesEnergy-efficient dry multi-stage Roots process pumps for all semiconductor and coating applications.2Semi wafer Solar cellsDisplayFull range of greendry process pumps forharsh duty applicationsfrom 100 to 3,000 m3/hHarsh duty processes in semiconductor production always pro-vide new challenges for vacuum pumps. Based on the provenand energy efficient multi-stage Roots technology, the A4series offers a wide range of dry pump solutions, with differentpumping speeds from 100 to 3,000 m3/h.The new A 3004 pump extends the range as the high capacitysolution for emerging deposition or etch applications.New XN models feature Pfeiffer Vacuum’ advanced materialsfor full corrosion resistance. Additionally, new integratedoptions are available, increasing pump health monitoring capa-bilities or extending pump service intervals. With an extendedprocess lifetime – associated with a low power consumption –the A4 series pumps are counted among those with the lowestcost of ownership in the market.A 3004: The energy saverHighest performance atthe lowest operating costof its classThe A 3004 pump sets a new standard in the 3,000 m3/hpumping speed category. Its optimized construction providesthe best compression ratio under process flow operation,resulting in the lowest power consumption on the market.Additionally, the A 3004 features the highest pumpingcapacity above 30 slm inlet flow, providing a wider processwindow and margin even on the most advanced CVDapplications.Extended operatingtemperature rangeThe pumps are equipped with an extended temperaturemanagement covering low and high operating temperature toprevent by-product deposition or cracking within the pumpingstages. Associated with high temperature precision bearings,this results in enhanced process reliability.Applications3Customer benefits■High energy efficiency thanks to multi-stage Roots technology, high efficiency motors and limited use of electrical heaters■Wide operating temperature range protects the pump against precursor cracking or condensable deposition ■Full corrosion resistant materials for increased lifetime ■High MTBF and low cost of ownership■High particle tolerance increases tool uptime■Extended monitoring functionalities provide better control of pump conditions (water sensor, vibration box)■Integrated hot N 2 injection prevents exhaust clogging■IP33, Semi S2 and UL compliantFull corrosion resistance Launched several years ago, the A4X models use specialmaterials to protect the rotors of the primary pumps fromcorrosion. This solution has already proven its efficiency inthe field, greatly increasing pump lifetime.However, some applications such as conductor etch requirehigh temperature operation to prevent deposition inside thepumps, further increasing the corrosion rate. For these mostdemanding applications, the XN coating technology has beendeveloped, protecting all parts in contact with corrosive gas.Using XN technology, the pump lifetime has drastically impro-ved – up to a factor 5 on some processes. This makes thesedry pumps the optimum choice for the most corrosive CVDand etch processes.Intelligent Equipped with a sophisticated monitoring system,the A4 series includes new functionalities to improve troubleshooting and monitor pump health in real time.A new optional water sensor detects the presence of water inthe pump enclosure that may occur during pump lifetime,increasing safety of sub Fab operations.The new optional V-Box features dry pump vibration monito-ring in real time. Correlated with other pump parameters,V-Box allows the detection of abnormal pump behavior.We can reduce the risk of exhaust line clogging and increasedilution below LEL on applications using flammable gas withour new I-HN option that features an integrated hot N2 injec-tion at the pump exhaust. Compared to conventional externalsystems installed on exhaust lines, I-HN is a zero footprintsolution at lower operating costs.Idle modes is also available, reducing N2 purge and/or powerconsumption up to 35 % meaning operating costs are drama-tically reduced.Low maintenance Through the improved particle tolerance, corrosion andcondensation resistance, lifetime of the pumps is extended.Additionally, the XN technology drastically increases main-tenance intervals, which means an additional reduction ofoperating costs. There is no required on-site routinemaintenance.4567891011VACUUM SOLUTIONS FROM A SINGLE SOURCEPfeiffer Vacuum stands for innovative and custom vacuum solutions worldwide, technological perfection, competent advice and reliable service.COMPLETE RANGE OF PRODUCTSFrom a single component to complex systems:We are the only supplier of vacuum technology that provides a complete product portfolio.COMPETENCE IN THEORY AND PRACTICEBenefit from our know-how and our portfolio of training opportunities!We support you with your plant layout and provide first-class on-site service worldwide.。

CHEMICALLY RESISTANT, OIL-FREE AND SAFEATEX CHEMISTRY DIAPHRAGM PUMPSATEX chemistry diaphragm pumps offer all ad-vantages of oil-free chemistry diaphragm pumps. Typical applications are rotary evaporators and drying ovens with potentially explosive atmo-spheres. The ATEX approval includes the interior of the pump (in contact with pumped gases) as well as the surrounding area of the pump. All wetted parts of the pumps have excellent chemi-cal resistance and are mainly made of antistatic materials. Included in delivery is a separate gas ballast connection port for use of inert gas. ATEX chemistry vacuum systems are equipped with separator and condenser. The separator at the inlet (AK) retains particles and liquid droplets. The waste vapor condenser at the outlet (EK) is highly efficient and compact. The condenser enables near-100-percent solvent recovery.ATEX VARIO® CHEMISTRY DIAPHRAGM PUMPS With the new ATEX VARIO® chemistry diaphragm pumps and vacuum systems, the vacuum can be precisely controlled by the motor speed. The VARIO®pump is driven by an additional control signal line. The optional vacuum controller CVC 3000 with system accessories (I/O-Module, sup-ply / isolation amplifier) and ATEX vacuum sensor enable fully automatic evaporations without the need for parameter settings or user program-ming. With the adaptive control it finds the boiling pressure independently and adjusts the vacuum continuously and optimally according to the va-por pressure. The vacuum controller and system accessories are installed in a non-hazardous area.ATEX CHEMISTRY DIAPHRAGM PUMPS.ATEX VARIO® CHEMISTRY DIAPHRAGM PUMPS.Chemistry diaphragm pumps, vacuum systems and gaugesfor use in areas with potentially explosive atmospheresWhen intended for use in areas with potentially explosive atmospheres, European Community Directive 94/9/EC (ATEX) requires equipment in conformity with ATEX standards. VACUUBRAND offers Category 2 chemistry diaphragm pumps and vacuum systems in conformity with ATEX (for use in zones where an explosive atmosphere is likely to occur). These chemistry diaphragm pumps are appropriate for such loca-tions because they are oil-free, have no sliding surfaces, and the expansion chamber is hermetically sealed against the drive zone. ATEX chemistry vacuum systems with solvent recovery provide safe, convenient vacuum while protecting the environment.NEW: ATEX chemistry diaphragm pumps and vacuum systems are now avaible with variable speed motor for vacuum control as VARIO®-version.The VACUUBRAND range of ATEX chemistry diaphragm pumps is supplemented by an ATEX vacuum gauge with excellent corrosion resistance and long-term stability. (Note: Compliance with EC Directive 94/9/EC does not ensure compliance with similar codes in countries outside of the EC. These pumps are not avail-able in every location. Contact your local VACUUBRAND representative for availability.)2.3 ATEX vacuum pumps // /atexPUMPING SPEED DIAGRAM at 50 Hz, without gas ballast4.5ATEX vacuum pumps // /atexAccessoriesPTFE tubing KF DN 16(1000 mm: 20686031)Items suppliedPump completely mounted, ready for use, with manual, 2 m cable without plug. Shatter and shock protection for glass parts must be pro -vided by the customer.ATEX conformity Pumping chamber (pumped gases): II 2G Ex h IIC T3 Gb X Environment with inert purge gas:II 2G Ex h IIB T4 Gb X Environment without inert purge gas: II 3G Ex h IIB T4 Gc X Motor:II 2G Ex d IIB T4 GbMax. pumping speed at 50 Hz1.9 m³/h Ultimate vacuum (abs.)12 mbarUltimate vacuum (abs.) with bas ballast 18 mbarInlet connectionSmall flange KF DN 16Outlet connection Small flange KF DN 16 Outlet connection Hose nozzle DN 8–10 mmDegree of protection IP 54 Degree of protection IP 52Dimensions (L x W x H) 337 x 287 x 251 mm Dimensions (L x W x H) 357 x 308 x 470 mmWeight, approx. 21.6 kg Weight, approx.25.4 kgTechnical data O utstanding chemical resistance and tolerance to condensate by use of fluoro plasticsF lame-proof motor with built-in and self-retaining overcurrent and excess temperature protection, the customer does not need any additional overcurrent protection systemO verpressure safety relief valve at the outletS afety diaphragm design with inert gas purge feature to permit op-tional installation of a diaphragm crack-detection systemS eparator AK and emission con -denser EK for pump protection and solvent recoveryMZ 2C EXMZ 2C EX +AK +EKdown to 12 mbar // 1.9 m 3/hPTFE tubing KF DN 25(1000 mm: 20686033)Pump completely mounted, ready for use, with manual, 2 m cable without plug. Shatter and shock protection for glass parts must be pro -vided by the customer.ATEX conformity Pumping chamber (pumped gases): II 2G Ex h IIC T3 Gb X Environment with inert purge gas:II 2G Ex h IIB T4 Gb X Environment without inert purge gas: II 3G Ex h IIB T4 Gc X Motor:II 2G Ex d IIB T4 GbMax. pumping speed at 50 Hz3.7 m³/h Ultimate vacuum (abs.)3 mbarUltimate vacuum (abs.) with bas ballast 10 mbarInlet connectionSmall flange KF DN 25Outlet connection Small flange KF DN 16 Outlet connection Hose nozzle DN 8-10 mmDegree of protection IP 54Dimensions (L x W x H) 440 x 265 x 305 mm Dimensions (L x W x H) 600 x 365 x 420 mmWeight, approx. 29.3 kg Weight, approx.37.4 kgdown to 3 mbar // 3.7 m 3/h MD 4C EXMD 4C EX +AK +EKAccessoriesItems suppliedTechnical data O utstanding chemical resistance and tolerance to condensate by use of fluoro plasticsF lame-proof motor with built-in and self-retaining overcurrent and excess temperature protection, the customer does not need any additional overcurrent protection systemO verpressure safety relief valve internal and at the outletS afety diaphragm design with inert gas purge feature to permit op-tional installation of a diaphragm crack-detection systemS eparator AK and emission con -denser EK for pump protection and solvent recovery6.7ATEX vacuum pumps // /atexAccessoriesPTFE tubing KF DN 25(1000 mm: 20686033)Items suppliedPump completely mounted, ready for use, with manual, two 2 m cables without plug (two mo -tors).ATEX conformity Pumping chamber (pumped gases): II 2G Ex h IIC T3 Gb X Environment with inert purge gas:II 2G Ex h IIB T4 Gb X Environment without inert purge gas: II 3G Ex h IIB T4 Gc X Motor:II 2G Ex d IIB T4 GbMax. pumping speed at 50 Hz8.1 m³/h Ultimate vacuum (abs.)2 mbarUltimate vacuum (abs.) with bas ballast 10 mbarInlet connectionSmall flange KF DN 25Outlet connection Small flange KF DN 16 Outlet connection Hose nozzle DN 8–10 mmDegree of protection IP 54Dimensions (L x W x H) 560 x 430 x 410 mm Dimensions (L x W x H) 649 x 525 x 452 mmWeight, approx. 63.2 kg Weight, approx.64.0 kgTechnical data MV 10C EXMV 10C EX +AK +EKdown to 2 mbar // 8.1 m 3/h O utstanding chemical resistance and tolerance to condensate by use of fluoro plasticsF lame-proof motor with built-in and self-retaining overcurrent and excess temperature protection, the customer does not need any additional overcurrent protection systemO verpressure safety relief valve internal and at the outletS afety diaphragm design with inert gas purge feature to permit op-tional installation of a diaphragm crack-detection systemS eparator AK and emission con -denser EK for pump protection and solvent recoveryATEX conformity Pumping chamber (pumped gases): II 2G Ex h IIC T3 Gb X Environment with inert purge gas:II 2G Ex h IIB T4 Gb X Environment without inert purge gas: II 3G Ex h IIB T4 Gc X Motor:II 2G Ex d IIB T4 GbMax. pumping speed at 50 Hz3.7 m³/h Ultimate vacuum (abs.)3 mbarUltimate vacuum (abs.) with bas ballast 10 mbarInlet connectionSmall flange KF DN 25Outlet connection Small flange KF DN 16 Outlet connection Hose nozzle DN 8–10 mmDegree of protection IP 54Dimensions (L x W x H) 469 x 265 x 305 mm Dimensions (L x W x H) 600 x 365 x 420 mmWeight, approx. 28.0 kg Weight, approx.36.0 kgdown to 3 mbar // 3.7 m 3/h MD 4C EX VARIOMD 4C EX VARIO +AK +EKPTFE tubing KF DN 25(1000 mm: 20686033)Pump completely mounted, ready for use, with manual. Shatter and shock protection for glass parts must be provided by the customer. Speed control via 4-20 mA current loop (4 mA = 0 rpm, 20 mA = 1500 rpm). Control signal line 10 m,mains cable 2 m without plug.AccessoriesItems suppliedTechnical data F ull advantage of ATEX chemistry diaphragm pumpsShort process times due to hystere-sis-free VARIO ® vacuum control V ARIO ®-pump operates on demand only as fast as necessary – minimal power consumption, extendedmaintenance intervals, silent opera -tionV acuum controller CVC 3000 (op -tional) for precise vacuum control and fully automatic processes C omplete system accessories I/O- Module, supply / isolation amplifier and ATEX vacuum sensor8.9ATEX vacuum pumps // /atexAccessoriesPTFE tubing KF DN 25(1000 mm: 20686033)Items suppliedPump completely mounted, ready for use, with manual. Shatter and shock protection for glass parts must be provided by the customer. Speed control via 4-20 mA current loop (4 mA = 0 rpm, 20 mA = 1500 rpm). Control signal line 10 m,mains cable 2 m each without plug.ATEX conformity Pumping chamber (pumped gases): II 2G Ex h IIC T3 Gb X Environment with inert purge gas:II 2G Ex h IIB T4 Gb X Environment without inert purge gas: II 3G Ex h IIB T4 Gc X Motor:II 2G Ex d IIB T4 GbMax. pumping speed at 50 Hz8.1 m³/h Ultimate vacuum (abs.)2 mbarUltimate vacuum (abs.) with bas ballast 10 mbarInlet connectionSmall flange KF DN 25Outlet connection Small flange KF DN 16 Outlet connection Hose nozzle DN 8–10 mmDegree of protection IP 54Dimensions (L x W x H) 560 x 457 x 410 mm Dimensions (L x W x H) 651 x 555 x 452 mmWeight, approx. 61.0 kg Weight, approx.63.0 kgTechnical data MV 10C EX VARIOMV 10C EX VARIO +AK +EKdown to 2 mbar // 8.1 m 3/h F ull advantage of ATEX chemistry diaphragm pumpsS hort process times due to hystere-sis-free VARIO ® vacuum control V ARIO ®-pump operates on demand only as fast as necessary – minimal power consumption, extendedmaintenance intervals, silent opera -tionV acuum controller CVC 3000 (op -tional) for precise vacuum control and fully automatic processes C omplete system accessories I/O- Module, supply / isolation amplifier and ATEX vacuum sensorACCESSORIES FOR VACUUBRAND ATEX VARIO ®-PUMPS14I/O-ModuleControl range (dependent on the sensor) 1080 - 0.1 mbar / 810 – 0.1 torrInterface externalRS 232CInterface to pump / sensor Analog-I/O-Module, connectable via isolation amplifierDimensions (L x W x H) 144 x 124 x 115 mmWeight, approx.0.44 kgCVC 3000 Installation outside of the EX-area, without integrated sensor110.11ATEX vacuum pumps // /atexAccessoriesPTFE tubing KF DN 16 (1000 mm: 20686031)DAkkS calibration with first delivery (20900214)DAkkS recalibration (20900215)Rubber vacuum tubing DN 6 mm (20686000)9 V battery (20612891)Items suppliedVacuum gauge complete with integrated vacuum sensor, including battery, hex key, connectingparts and manual.ATEX-approval II 2G Ex ib IIC T4 Gb Upper measuring limit 1060 / 795 mbar/hPa / torr Lower measuring limit1 / 1 mbar/hPa / torrAccuracyof measurement < +- 1 mbar /hPa /torr / +- 1 digit Temperaturecoefficient< 0.15 mbar/hPa /0.11 torr /KMaterial of Robust plastic outer housing housing with goodchemical resistancePower supply 9 V batteryDegree of protection IP 40Dimensions (L x W x H) 117 x 117 x 91 mmWeight, approx.0.4 kgVacuum connection Small flange KF DN 16, PTFE tubing connection 10/8 mm, hose nozzle DN 6/10 mmTechnical data DVR 3proVacuum GaugeATEX category 2 approval Flexible application range due to mains-inde- pendent operation of the fully electronic vacu- um gauge with ATEX approvalL arge, graphical analog display combined withprecise digital readout allows users to detect and view tendencies easilyI mproved functionality within the navigation menu helps to save energy and to increase the life cycle of the battery; battery easily replace -able; no lithium batteryH igh reliability, low EMI emission level near detection limit, high degree of immunity to electromagnetic interference, suitable for use in industrial environmentsC apacitive ceramic diaphragm vacuum sensor made of aluminum oxide with excellent chemi -cal resistance, accuracy and long-term stabili -ty and long term stabilityVACUUBRAND GMBH + CO KG Alfred-Zippe-Str. 4 97877 Wertheim Germany+49 9342 808-0+49 9342 808-5550+49 9342 808-5660*******************Phone Sales ServiceEN / 06 / 2020© VACUUBRAND GMBH + CO KG。

德国阿尔泰克计量设备有限公司Alltech柱塞隔膜计量泵工作原理柱塞隔膜计量泵是由驱动齿轮2带动中空柱塞10往复运动,并通过中空柱塞10中的液压油驱动计量膜片6。

中空柱塞10上有一个特殊设计的调节空,使柱塞内外的液压油相同。

柱塞10外面套有一可调节的用来关闭调节空的滑环11。

当调节孔关闭时,柱塞推动里面的液压油来驱动计量膜片6。

在每个行程中,被柱塞推动来驱动计量隔膜的液压油的量,正好等于被计量的介质的量。

柱塞隔膜计量泵剖面结构图计量泵流量的调节,可通过柱塞法兰上的手动旋钮12来实现,也可通过变频器、伺服电机等来实现。

该计量泵的流量不随压力变化的而变化,在静态和工作状态下均可进行0~100%的线性调节,调节精度高(±1%)。

其中空柱塞不是固定在电机偏心轮上,在吸入行程中,柱塞被弹簧9反弹回到零位置,从而有效防止了吸入介质在计量头中形成堵塞时给泵造成的损害。

吸入阀8在介质吸入过程中被打开,使介质流入计量头,在加压时吸入阀则切断。

压力阀5在介质加压过程中被打开,而在吸入过程中关闭以防止压出的介质回流入计量头。

内置过压安全保护阀所有FKM系列计量泵均内置已经设定好的过压安全保护阀4,该阀安装在承压端,和液压系统一起配合使用。

如果泵的承压端堵塞,此安全会自动跳起,从而有效地保护泵及整个管路系统。

注意:为使泵能良好地运行,在吸入阀8和压力阀5之间必须存在至少1巴的正差压。

计量泵在正压的情况吸入端和吸入系统连接时,这一点尤为重要。

管线和接头的尺寸吸入管内的流速不得超过0.3m/s。

隔膜的往复运动会使介质产生一脉冲流动。

在每一次行程中,管道内的介质必须从静态加速至最大流速,以后流速又逐渐减缓。

对于只有一个活塞隔膜的计量泵,其最大的流速是同规格的其它连续介质流泵的流速的3.2倍。

在决定吸入管及接头长度时必须将这一点考虑进去。

在大多数情况下,建议在出口管上安装一台脉动阻尼器。

柱塞隔膜计量泵的特点:柱塞隔膜计量泵克服了隔膜计量泵(压力低、流量小)和活塞计量泵(耐腐蚀性能差、密封性能不好)的缺点,集中了两种泵的优点,可适用于强腐蚀高压力的介质,最高压力可达100bar,流量大(max.3000l/h)、精度高(±1%),且流量不随压力变化,可在0-100%范围内进行线性调节,并可进行各种特殊设计。