GM1927全球供应商质量手册(中文)

- 格式:pdf

- 大小:788.83 KB

- 文档页数:125

全球供应商质量管理手册(doc 64页)全球供应商质量手册第一版0 绪论组织绩效主要因素之一,就是其产品或服务的品质。

顾客对质量的期望日趋严苟,已蔚为全球性之趋势。

伴随这一趋势,已形成一种共识,即为达成并维持良好经济绩效就必需不断改进质量。

多数组织(工商界或政府机构)生产一产品或服务,著意于满足顾客之需求。

该项需求常转化成“规格”。

如果规格上有所缺失或设计及制造产品或服务之组织系统有所不当,则技术性规格本身就难以保证可满足顾客一贯之要求。

因此,势必开发品质系统标准及各项准则,以完成技术规格中所订定相关产品或服务之要求。

此一系列国际标准(含ISO 9000至ISO 9004)即是将这方面众多且不同国家的方法合理化的一项具体表现。

一个组织之质量系统深受组织目标、产品或服务以及组织特有之实务等所影响,因此,质量系统亦随组织不同而有所不同。

附件中列有质量系统要项对照表以供参考。

1.适用范围本国际标准之目的为a)澄清主要质量观念彼此间的区别与相互关系(参阅条款4),以及b)提供一系列质量系统国际标准的选用指南,俾可用于内部质量管理(ISO 9004),以及用于外部质量保证(ISO 9001,ISO 9002,与ISO 9003)(参阅条款5至8)。

备注:本系列国际标准(ISO 9000至ISO 9004)的目的不在于将组织所实施的质量系统予以标准化。

2.参考资料ISO 8402质量—词汇ISO 9001质量系统—设计/发展,生产,安装与售后服务的质量保证模式(注1)ISO 9002质量系统—生产与安装的质量保险模式(注1)ISO 9003质量系统—最终检验与测试的质量保证模式(注1)ISO 9004质量管理与品质系统要项—指导纲要3.定义本国际标准适用ISO 8402中所列各项定义。

由于适切引用词汇至为重要,特自ISO 8402中采用五项重要用语及定义,纳入本国际标准中。

3.1 质量政策由一个组织高层管理者所正式宣示的该组织整体品质之意图及方针。

全球供应商质量手册目录版次履历仅为了轻松阅读,所有确定的术语(例如:供应商,买家,产品,等)在整篇手册中将或可能以小写字体印刷。

术语定义Page1Page21.0 与我们合作1.1我们公司在特灵科技(Trane Technologies) 我们大胆挑战实现可持续发展世界的一切可能性。

全球大趋势的发展已经将气候问题推到了世界关注的最前沿。

作为全球温控系统的创新者,特灵科技展示了我们采取行动的承诺。

凭借旗下两大战略品牌特灵(Trane®)和冷王(Thermo King®)及其对环境负责的产品组合与服务,我们致力于为楼宇建筑、民用住宅和交通运输领域提供高效、可持续发展的温控系统解决方案。

我们也充分认可与提供优质零件和原材料的供应商建立牢固合作伙伴关系的重要性,以确保满足客户的期望, 并为可持续发展解决方案铺就一条更好的发展之路。

供应商请访问我们的网站(), 点击链接了解更多内容:https:///en/index/company/doing-business-with-us.html1.2 目标全球供应商质量手册详述了对所有特灵科技(Trane Technologies)直接物料供应商的期望。

只要提供了相关产品给特灵科技(Trane Technologies)及顾客,供应商需要满足或超过本手册的要求和规定。

秉承本手册的既定方针,对于供货给特灵科技(Trane Technologies)的产品,供应商应不断改善其设计和生产工艺。

本手册中:本手册中的“应”(shall)或“必须”(must)是表示要求,“应当”(should)仅起指导或推荐作用。

本手册的英文版本为正式版本。

如果发生因为翻译造成不同版本之间的差异,以英文版本为准。

Page31.3 业务伙伴行为准则供应商应接受和遵守买家的业务伙伴行业准则(BPCOC)。

供应商应采取必要的措施确保下级供应商和分包商遵守BPCOC的要求。

在供应商的要求下,买家将邮寄复印件给供应商。

GM Advance Product Quality Planning ManualTable of ContentsGM ADVANCE PRODUCT QUALITY PLANNING (1)WORK INSTRUCTIONS (2)VALVE A (3)G ENERAL R EQUIREMENTS (3)D ESIGN R EVIEW (3)C OMMERCIAL I SSUES (4)P LANT L AYOUT AND P ROCESS F LOW (4)DFMEA (4)L ESSONS L EARNED AND W ARRANTY (5)G AGE AND T OOLING E QUIPMENT R EVIEW (7)V ALIDATION AND ADVP & R (8)PFMEA AND E RROR P ROOFING (8)P ROCESS C ONTROL P LAN (8)D IMENSIONAL P LAN (9)M ATERIALS/DCS F ILE L OGS (10)D ESIGN A PPEARANCE Q UALITY (10)C ONTAINERIZATION (10)T IERED S UPPLYBASE (11)PPAP (11)R@R (12)GP-12 (12)QSB (12)VALVE B (14)G ENERAL R EQUIREMENTS (14)D ESIGN R EVIEW (14)C OMMERCIAL I SSUES (15)P LANT L AYOUT AND P ROCESS F LOW (15)DFMEA (15)L ESSONS L EARNED AND W ARRANTY (16)G AGE AND T OOLING E QUIPMENT R EVIEW (16)V ALIDATION AND ADVP & R (16)PFMEA AND E RROR P ROOFING (17)P ROCESS C ONTROL P LAN (17)D IMENSIONAL P LAN (17)M ATERIALS/DCS F ILE L OGS (17)D ESIGN A PPEARANCE R EQUIREMENTS (18)C ONTAINERIZATION (18)T IERED S UPPLY-B ASE (18)PPAP (19)R@R (19)GP-12 (19)QSB (19)PPAP (21)G ENERAL R EQUIREMENTS (21)C OMMERCIAL/O PEN I SSUES (21)PFMEA & E RROR P ROOFING (21)D ESIGN A PPEARANCE R EQUIREMENTS (21)T IERED S UPPLY-B ASE (22)R@R (22)GM 1927-04 Advance Product Quality Planning Manual May 2011GP-12 (22)R@R (23)G ENERAL R EQUIREMENTS (23)D ESIGN R EVIEWS, M ATH, AND GD&T (23)PFMEA & E RROR P ROOFING (23)T IERED S UPPLY-B ASE (23)GP-12 (23)APPENDICES (24)A PPENDIX A - APQP G ENERAL T IMING (25)A PPENDIX B – A SSESSMENT R ASIC (26)A PPENDIX C – G LOBAL APQP RASIC (27)A PPENDIX D – R EQUIRED D OCUMENTS, R EFERENCES, & R ESOURCES (28)Design Review (28)Commercial Issues (28)Plant Layout and Process Flow (28)DFMEA (28)GM SQE (28)Lesson Learned and Warranty (28)Gage and Tooling Equipment Review (28)Validation and ADVP&R (28)PFMEA and Error Proofing (28)Process Control Plan (28)Dimensional Plan (28)Material & DCS Logs (29)GM DE & Materials Eng (29)Appearance/Grain/Cloth (29)Containerization (29)Tiered Supplybase (29)PPAP (29)R@R (29)GP 12 (29)QSB (29)A PPENDIX E – G LOSSARY (30)GM 1927-04 Advance Product Quality Planning Manual May 2011GM Advance Product Quality PlanningGM’s vision is to Design, Build, and Sell the World’s Best Vehicles, in order to do that we must have a robust plan. That plan must include great designs, great manufacturing processes and great quality systems.We have learned that the critical components to a successful quality system are communication and standardized work. The purpose of this manual is to communicate GM’s expectations and provide standardized work during the product development cycle.This manual is intended as a supplement to the AIAG Advance Product Quality Manual, which provides the framework and detail for good advance quality planning. The manual is designed to help GMpersonnel and suppliers understand the expectations specifically related to GM launches.In order to help support GM’s vision, the planning process has been split into four reviews, Valve A, Valve B, PPAP and R@R. In the following sections there are four procedures d efining ‘who, what, and when’ for each of the review. Each procedure includes standardized work showing the requirements,escalation options, reference documents, and methodology behind each task.GM 1927-04 Advance Product Quality Planning Manual May 2011Work InstructionsThe following are the work instructions for the task requiring a status of Red, Yellow, or Green. They are intended to show the SQE and Supplier what the ‘ideal’ state for each task is. The ultimate goal is to reach the ‘ideal’ state for each task in order to support program timing for delivering a quality part by the required PPAP date. Deviations from the ‘ideal’ state are listed in the work instructions. The appropriate category shall be selected and loaded into GQTS by the supplier regardless if the part(s) are statused as Supplier or Customer Monitored. If the parts(s) are statused as Customer-Monitored, the SQE will approve the supplier’s submission. A worksheet (GM 1927-34) has been provided for the SQE and supplier to use as a summary sheet. Also, included in the work instructions are Resources and References, regional documentation requirements, and suggested methodologies to help the team achieve the required content.GM 1927-04 Advance Product Quality Planning Manual May 2011Valve AGeneral RequirementsTiming:•Valve A is targeted to be completed three (3) weeks prior to Tool Kick-Off (TKO). TKO is commodity specific and is based on the official program timing template generated through theProgram Timing Office.•The individual tasks shall be cadenced appropriately from sourcing to the Valve A event. See Appendix A for recommended cadence of events.Ownership:•All events (Valve A, Valve B, PPAP and R@R) shall be coordinated by the supplier with input from SQE.•Valve A shall be attended at a minimum by:o Supplier: Program Management, Quality, Manufacturing, and Engineeringo GM: SQE, Design Release Engineer, and Purchasingo Optional attendees: Dimensional Engineering, GD&T group, and Appearance Engineer Deliverables:• A supplier kick-off meeting shall be conducted at award of the business. The GM 1927- 14 should be used as reference and best practice for the meeting agenda and content discussion.GM SQE shall communicate program timing deliverables at that time. The supplier shallmaintain a contact list for each program over the life of the program. The list shall include at aminimum: Name, Position, Cell Phone, email, 24-hour contact, and escalation priority (i.e. whoshould be called 1st, 2nd, etc) for all necessary supplier personnel.•Each program shall have one open issues list that includes all program issues; this would include, but is not limited to, all commercial, design, engineering, quality and manufacturingissues.•APQP specific timing items shall be maintained on one overall program management timeline with additional program critical information such as timing for tooling, testing etc.•Red, Yellow, or Green status shall be identified for each item listed per Appendix A and documented according to GM1927-34 in the APQP module.Design Review•Engineering has confirmed that math data is released and is accessible to supplier.•Math data and related files include all appropriate notes on other necessary items such as materials, test specifications, software requirements, etc.•Released engineering data has been compared to the SOR/SSTS and CTS; all discrepancies have an adequate action plan for resolution.•Supplier to confirm availability of the math data and notes and has confirmed feasibility for production.•Key Characteristic Designation System (KCDS) meeting is scheduled or has been completed•Supplier to review GD&T documentation for the following:o The datum schemes are consistent with both product use and process intent.o Plans for gage development are consistent with the datum scheme.o Tolerances are understood and verified achievable by the supplier.o In cases of new technology or tighter tolerances than historically achieved, an action plan is needed to monitor the progress of capability performance throughout the process developmentphase.•Escalation Drop DownsGM 1927-04 Advance Product Quality Planning Manual May 2011o G – Adequate math data and GD&T released – Supplier has confirmed feasibilityo Y – Adequate design data not available – recovery plan in placeo Y – Datums or tolerances not agreed to – recovery plan in placeo Y – Feasibility not confirmed – recovery plan in placeo Y – KCDS not completed but scheduledo R – Adequate design data not available – recovery plan not in placeo R – Datums or tolerances not agreed to – recovery plan not in placeo R – Feasibility not confirmed – recovery plan not in placeCommercial Issues•Supplier received piece price and tooling contract to the latest available level of Math Data•Supplier has received tooling PO•SQE to verify that supplier has no additional commercial issues, i.e. issues with directed-buy suppliers pricing, etc.•Escalation Drop Downso R – No tooling POo R – Additional commercial issueso Y – Contracts need to be updatedo G – No commercial issuesPlant Layout and Process Flow•Plant Layouto Supplier to provide current plant layout for the entire facility including planned area where new program will be housed, the shipping, receiving, inventory, suspect/scrap material holdareas, etc.o Supplier to provide detailed view of area where program will be housed, if applicable should include cell configuration, in-process & finished goods inventory area, scrap area, etc.o GM SQE should review layout to make sure there are no concerns, i.e. over lapping rework and finished goods storage, if there are issues supplier needs to provide a plan to address/control •Process Flowo Supplier to provide a diagram for production and pre-production process both should include shipping , receiving , and rework , and should coordinate with the PFMEA and Control Plan;preliminary diagram should include GP-12o Process flow should include every operation within the process of making this part in accordance with the AIAG APQP and Control Plan Manual•Escalation Drop Downo R – Supplier does not have a plan/space to house the new p rogramo Y – Supplier has to move existing programs to house new programo G – Supplier has no issues with housing new programDFMEA•General Requirementso Supplier has done all necessary design analysis for part and tool manufacturability, i.e. mold flow analysis, tool material hardness, etc, for the particular commodityGM 1927-04 Advance Product Quality Planning Manual May 2011o Supplier has applied the DFMEA to all relevant areaso Supplier & GM have reviewed all warranty issues and incorporated all corrective actions into the DFMEAo Supplier has evaluated the design to determine if potential failures will be addressed via process control or the assembly equipment•GM – Design Responsibleo Supplier has worked with GM DRE to build DFMEAo Supplier has reviewed the DFMEA corresponding to the current design from the GM DRE •Supplier – Design Responsibleo Supplier has reviewed the SOR/SSTS and CTS for all design, governmental, reliability, appearance, serviceability, and any other applicable requirements and incorporated intoDMFEAo Supplier has reviewed the latest AIAG FMEA Edition and applied all applicable requirementso Supplier has considered all influences the awarded part has on mating parts and the influence of mating parts on the awarded part and incorporated into DFMEAo Supplier has provided the DFMEA corresponding to the current design to the GM DRE and the DFMEA is approved by the GM DRE•Escalation Drop Downo G – DFMEA Complete to current EWO GM responsibleo G – DFMEA Complete to current EWO Supplier responsibleo R – DFMEA Not Complete to current EWO GM responsibleo R – DFMEA Not Complete to current EWO Supplier responsibleLessons Learned and Warranty•Supplier has reviewed all similar products across all vehicles, OEMs, and manufacturing facilities and incorporated all information into Lessons Learned document or database; information cancome from customer complaints, in-house quality reviews, GP-12, warranty complaints, GM SORs,GM Process Specific Audits, etc.•Supplier has used information from Lessons Learned and incorporated into the control plan, PFMEA, DFMEA, operator instructions, and all other applicable areas; if supplier is not designresponsible they should inform product engineering of any important information •Supplier has a procedure to address warranty issues, should include how warranty returns are handled, contact info for key personnel, protocol for how potential warranty issues arecommunicated to the customer, steps as to how corrective action is fed back to lessons learneddatabase, control plan, PFMEA, etc.•Escalation Drop Downso R – Supplier has no Lessons Learned database or Warranty Issues procedure and has no plan for oneo Y – Supplier has no Lessons Learned database or Warranty Issues procedure and has plan for oneo Y – Supplier has Lessons Learned database and Warranty Issues procedure and has not incorporated informationGM 1927-04 Advance Product Quality Planning Manual May 2011o G – Supplier has Lessons Learned database and Warranty Issues procedure and has incorporated informationGM 1927-04 Advance Product Quality Planning Manual May 2011Gage and Tooling Equipment Review•General Requirementso Supplier has received toolable P-released, or at a minimum T-released, math data; if T-released there should be a recovery plan for P-released matho Supplier has received final contracted part GD&T and reviewed tolerances with GM SQE, DE, and Dimensional Engineer and is in agreemento If assembling, supplier has component part GD&To Supplier has reviewed and agreed to all SQ Part Specific SORs for gage and tooling requirements, should have been done prior to sourcingo Supplier has done all necessary design analysis for part and tool manufacturability, i.e. mold flow analysis, tool material hardness, etc, for the particular commodity•Tooling Review Requirementso Supplier has ensured that all Part or SQ SOR tooling requirements are comprehended in the tooling equipment plan and has clearly defined all tooling equipment function and verified thatall SOR requirements are satisfiedo Supplier has comprehended all component and assembly GD&T into assembly equipmento Supplier has provided error proofing plan for equipment, process flow, PFMEA, and PCP and documents are approved by SQE; For VAA suppliers, approval needed from SQE andManufacturing Engineero Supplier has provided timing chart detailing equipment build, shipment, set-up timing, expected date of first shots, PPAP, and R@R; equipment timing is to include all line itemsrequired for the part to meet all fit, finish, and function requirementso Supplier has completed and returned all relevant process specific audits, answers are to be based on what will be incorporated in the tooling equipment•Gage Review Requirementso Supplier has set-up and conducted an initial design review with the gage source, meeting attendees should at minimum include the GM DE, SQE, and craftsmanship engineer; for VAAsthe manufacturing engineer should be invited as wello Discussion for meeting should include points where any KPCs or PQCs ports will be placed on the gageo Supplier will set-up and conduct a 90% complete design review at the gage source, at a minimum meeting attendees should include the GM DE, SQE, and craftsmanship engineer; forVAAs the manufacturing engineer should be invited as well; SQE to approve gage design o Supplier has ensured that all GD&T requirements are capable of being checked on gage by some feature, and where not being checked by a feature supplier shall provide a plan as to howthe requirement will be verifiedo Supplier has provided timing for gage completion and level if gage build is staged •Escalation Drop Downso G – Tooling Design completeo G – Gage design completeo Y – Tooling design not complete; no impact to PPAP targeto Y – Gage design not complete; no impact to PPAP targetGM 1927-04 Advance Product Quality Planning Manual May 2011o R – Tooling design not complete; impact to PPAP targeto R – Gage design not complete; impact to PPAP targetValidation and ADVP & R•Requirements for supplier-responsible validation are clearly communicated by GM to the supplier.Normally these are located in Statement of Requirements Appendix G1 GMW3600 and AppendixG2. Additional requirements may be documented on drawing or in math data (DCS file log).•Supplier understands and is in agreement as represented by ADVP&R submission.•ADVP&R is approved by GM Validation Engineer and Lead Engineer.•Supplier to ensure the materials used for ADVP&R correspond to the DCS File Log•Testing and final report, GM1829, will be complete in time for PPAP approval.•ADVP&R should include plan to validate the maximum allowable regrind percentage per the material spec•Escalation Drop Downso G – SOR and design record requirements completeo G – SOR and design record requirements accepted by suppliero G – ADVP&R approvedo R – SOR and design record requirements not completeo R – SOR and design record requirements not accepted by suppliero R – ADVP&R not approvedPFMEA and Error Proofing•The supplier has adequate design information to conduct PFMEA activities•The supplier has a Pre-production PFMEA based on the design release and historical Best Practices information of similar products/processes•The supplier has identified unique aspects of the current design not covered by historical Best Practices, and prepared initial PFMEA activities on those new items•PFMEAs are a cross-functional activity•PFMEAs have been reviewed by the appropriate authority for reasonableness•PFMEA information is included in the packages to the potential tooling sources for effected processes.•The supplier has reviewed assembly PFMEAs and identified relevant issues to communicate to the various Tier 2 component suppliers•Potential tooling sources and Tier 2 Suppliers have previously demonstrated an understanding of the potential failure modes and how to compensate for them in the process design •Escalation Drop Downso G – PFMEA cross functional activities in placeo Y – PFMEAs need additional GM input to proceedo Y – PFMEAs need additional supplier worko Y – PFMEAs need communication to Tier 2s or Tooling Supplierso R – PFMEAs not complete or communicated – recovery plan not in placeo R – PFMEA not being usedProcess Control Plan•Supplier should base Pre-production Process Control Plan (PCP) on Pre-production PFMEAGM 1927-04 Advance Product Quality Planning Manual May 2011•Supplier to insure that PCP includes all requirements from the AIAG APQP & Process Control Manual•Pre-production PCP to be reviewed and approved by cross-functional team, team should include a minimum of GM SQE and DE•Supplier ensure that all Key Product Characteristics (KPCs) and Product Quality Characteristics (PQC) are treated appropriately•Supplier should include error proofing plan to be incorporated into Pre-production PCP•Supplier ensures gages are referenced as needed in Pre-production PCP•Supplier should include all applicable GM or Supplier required Lot Acceptance Testing, Part Specific SQ SORs, and Process Specific Audits requirements or recommendations in Pre-production PCP•Supplier should ensure all learnings from internal read-across activities are included in Pre- production PCP•Supplier should ensure all process testing from Part SOR, SSTS/CTS, GMW specs and DSC File Logs are included in Pre-production PCP•Escalation Drop Downso G – Pre-production Process Control Plan competed and risk appropriatelyo Y – Pre-production Process Control Plan competed and not risk appropriatelyo R – Pre-production Process Control Plan not competedo R – Supplier new to commodityDimensional Plan•Supplier completely understands GM requirements for dimensional data submissions throughout program, i.e. Prototype, Matching, PPV, NS, etc.•Key Characteristic Designation System (KCDS) meeting is scheduled or has been completed•Supplier Dimensional Plan should include:o All Key Product Characteristics (KPCs), Product Quality Characteristics (PQCs), or critical manufacturing dimensions from the GD&T and statistical capability requirements for KPCs orPQCso Critical manufacturing dimensions should include all DTS pointso A plan to support dimensional measurements for first required parts, plan to include staffing, variable measurement data collection method, i.e. CMM, Laser or White Light Scan, etc.o Part Road Map for what areas/points are required for variable data collection above any KPC or PQCs and what points/areas are attribute data collectiono Plan to repair/rework out-of-spec conditions exists (if possible)o All dimensional measurement requirements from applicable SQ Part Specific SOR •If required, dimensional status of prototypes is known•Escalation Drop Downso G – Dimensional Plan complete, no issueso G – Supplier understands requirements and has successfully done in the pasto Y – Supplier has not supported GM dimensional plan requirements in the past, possibly needs trainingo Y – KCDS not completed but scheduledo R – Supplier has no plans/resources to support dimensional submission requirementsGM 1927-04 Advance Product Quality Planning Manual May 2011Materials/DCS File Logs•Supplier has verified that all SOR and GD&T requirements are reflected in the design record•All stakeholders completely understand materials requirements and callouts in the design record •Supplier should plan to validate the maximum regrind amount per the material spec for PPAP approval•Supplier has contracted all materials and identified GM-approved sources where required•Supplier has resources to PPAP material suppliers•Escalation Drop Downso G – Material requirements are called out in the design record(s) and understoodo Y – Material callouts are present in the design record, but approved source not identified yeto R – Material callouts are required, but not present in the design record yeto R – GM-approved source does not yet exist for required materialDesign Appearance Quality•Supplier has received and clearly understands the latest level Design Appearance Requirements (DAR) document for grain and material specifications•Supplier has received and understands all required testing for appearance related validation, such as APOPS, Solar testing, MatSpec, etc., and has developed a plan to complete all testing on time forPPAP•Supplier has received and understands Grain Instruction Form / Process•Supplier has reviewed the design to understand how the design and supplier’s proces s will affect the final appearance in respects to the GM requirements listed in the DAR and has raised anyconcerns (For example, a plastics parts supplier has reviewed mold flow to understand where knitlines will be and if that is acceptable to GM requirements)•Escalation Drop Downso G – DAR Latest Level Receivedo G – Appearance related validation testing completeo G – Tooling Design complete proper Draft Identified for Graino Y – Tooling design not complete proper draft Identified; no impact to PPAP targeto Y – Test identification has not been completed; no impact to PPAP targeto R – DAR not received at latest levelo R – Tooling design not complete; impact to PPAP targeto R – Test identification has not been completed; impact to PPAP targeto R – Appearance Related Validation testing not complete for required full PPAP date Containerization•Supplier has been in contact with the GM Containerization engineer and GM DRE and working on incoming and outgoing packaging design, including footprint and dunnage where applicable, if thecontainers are returnables or expendables for both incoming and outgoing containers •Supplier has been in contact with the GM Containerization engineer and has plan and timing for when the outgoing shipping containers will be available and the amounts for each build; timingplan should include when all containers will be available, how many containers will be available ateach build, how many containers will be available at R@R and if the quantity is sufficient •Supplier shall provide production parts for all shipping trials as part of container validation, should be included in timing & build planGM 1927-04 Advance Product Quality Planning Manual May 2011•Supplier should have a design for expendable packs and timing for all validation testing of packs, design should be approved by the GM DRE and Containerization Engineer•Supplier has maintenance plan which includes storage, handling, and cleaning for containers to ensure racks are properly maintained throughout the life of the program•Escalation Drop Downso G – No Container Issues, design on tracko R – Prototype Container – No designo Y – Prototype Container - Design issueso Y – Preliminary design in processo R – GM Container Engineer not identifiedo R – Containers not in processTiered Supplybase•The supplier has confirmed lead time for all Tiered supplier requirements; Plans are adequate to support program timing•The supplier has adequate Supplier Quality procedures and resources in place, in accordance with their commodity requirements•The supplier has cascaded Run @ Rate planning activities to its Tiered supplybase•Tiered supplier items that are either Directed-Buy or Approved Source List items have a clear agreement between the supplier and GM as to APQP coverage responsibilities•Tier 1 has verified Tiered Supplier manufacturing feasibility and received documentation stating so •Tier 1 has reviewed and approved the Tiered Supplier’s preliminary PMFEA , assembly equipment error proofing, and all applicable GM part specific audits•KCDS/Pass Thru Characteristics must be reviewed by GM DRE/SQE to verify control method at tiered suppliers and incoming inspection at Tier1•Escalation Drop Downso G –Tiered Supplier’s plans are in place and adequateo Y –Tiered Supplier’s plans are not adequate, but recovery plans that support program timing are in placeo R –Tiered Supplier’s plans are not adequate, and recovery plans that support program timing are not in placePPAP•PPAP plans have been discussed by the supplier and the individual SQE responsible for approving the PPAP. Both parties have an understanding and a documented agreement of expectations forboth content and timing.•The plans should target Full PPAP Approval prior to the Vehicle MVBS MRD.•If this supplier is a Tiered Supplier (such as in Directed-Buy arrangements), adequate timing is in the plan to allow the Tier 1 supplier to complete PPAP prior to the Vehicle MVBS MRD.•Open issues affecting the completion of PPAP on time are documented and have an action plan.•Issues that do not have a clear plan for success of on-time PPAP have already been escalated for management assistance.•Escalation Drop Downso G – Plans in place for on time PPAPo Y – Plans in place, but need close monitoring to ensure on time PPAPo R – No plans for PPAP in placeo R – Plans in place, but PPAP timing at serious riskGM 1927-04 Advance Product Quality Planning Manual May 2011•Supplier clearly understands expectations regarding the purpose of the 1411 in the PPAP process •Supplier clearly understands all program deliverables for PPAP (validation, dimensional, etc.) and is aware that all issues must be documented on the 1411 at the time of the first PPAP submission •Supplier has access to AIAG manual and forms for PPAP•Escalation Drop Downso G – Supplier understands requirements and has successfully completed 1411 in the pasto Y – Supplier has not completed 1411 forms before, but understands requiremento Y – Supplier does not have access to AIAG documents, but has plano R – Supplier has no understanding of 1411 requirements & requires training R@R•GM Purchasing has provided Contracted Daily Capacity (LCR) demand data to the supplier for each awarded part•GM Purchasing and the supplier have agreed on daily operating hours that will be used to meet Contracted Daily Capacity requirements•The supplier has prepared capacity planning files showing expected process cycle times, number of tooling sets, and machine capacity loads, and any shared capacity with other program regardless of OEM•The capacity planning data shows adequate coverage of Contracted Daily Capacity requirements •If multiple tool sets or machines will be phased in over time for staged increases in capacity, the plans and timing requirements are documented•The supplier and the individual SQE responsible for approving PPAP have documented the agreed upon expectations for the Run @ Rate event, per GP-9 requirements•Escalation Drop Downso G – Contracted Daily Capacity, operating hours, and capacity plans are documented and show adequate coverageo Y – Contracted Daily Capacity requirements are not adequately covered, but a recovery plan is in place to ensure coverageo Y – Run @ Rate event plans are not documentedo R – Contracted Daily Capacity requirements are not documentedo R – Contracted Daily Capacity requirements are not covered by current plans, and an adequate recovery plan is not in placeo R – The supplier has not performed capacity planning for these partsGP-12•The supplier is knowledgeable about GP-12 activities and requirements.•The supplier has identified whether these GP-12 activities are to be developed off similar products that have been previously launched, or whether new GP-12 activities need to be developed.•Appropriate timelines have been established.•Escalation Drop Downso G – Supplier knowledgeable about GP-12o Y – Supplier needs training on GP-12 – plan in placeo R – Supplier not committed to GP-12QSB•If Supplier is QSB compliant and GM has verified then no further action required•If supplier is not compliant, theno Supplier should have QSB materials and completely understands GM requirementsGM 1927-04 Advance Product Quality Planning Manual May 2011。

1. Supplier Quality Base Requirements: 供应商质量基本要求•This document is intended to be used in conjunction with and is in addition to the GM General Standard Terms and Conditions。

该文件被视为GM的一般标准条款,以及标准条款的额外补充。

•All suppliers are expected to supply parts to General Motors with zero defects. Parts shall meet all engineering specifications and function with no abnormalities according tointent。

所有供应商的供货应当是零缺陷的。

零件必需符合工程以及性能要求。

•Funding is to be identified in the initial quote and subsequent quotes to reflect error occurrence detection (poka yoke, error proofing devices, etc) and defect outflowprevention to customers. Controls implemented at a later date are the financialresponsibility of the supplier。

为了阻止缺陷外流给客户或因需要防错而产生了额外费用,该费用应当在最开始的报价或之后的几轮报价中反映出来。

后续控制所产生的费用应当由供应商自己承担.2. ISO/TS 16949 — Quality System Requirements:质量体系要求:•All providers of a) production materials, b) production or service parts, or c) heat treating, plating, painting or other finishing services directly to General Motors must be certified to ISO/TS 16949 by a Certification Body (CB) recognized by the International Automotive Task Force (IATF) and have a current certificate available demonstratingcompliance to GM supplements.所有与GM有关的原料,配件以及热熔焊,电镀,喷漆或其他加工服务,必须获得认证机构所颁发的TS16949认证并在有效期内.•Effectiveness of the heat treating processes, the plating processes and the coating processes shall be demonstrated using the CQI—9 Heat Treat System Assessment, the CQI-11 Plating System Assessment, and the CQI—12 Coating System Assessment published by theAIAG and as required in the GM Customer Specifics。

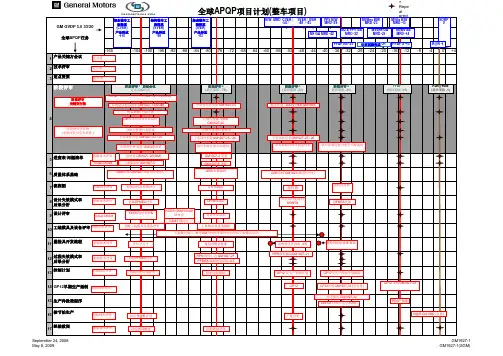

通用汽车公司GM全球性GM 全球性APQP产品质量先期策划全球性采购2000年11月第一版序言本参考手册详述/阐述了致力于开发GM(通用汽车公司)APQP(产品质量先期策划)统一的流程之全球GM团队的共同努力。

在此之前,通用汽车公司的供应商质量系统均采纳各自的部门或区域性之一套具体的方法使得APQP流程更为简捷从而便于实施。

全球性团队使得各部门和区域间的APQP流程更为和谐统一而又标准从而制定了本GM APQP手册〔GM1927〕。

本手册制定了通用汽车公司开发并实施一系列的产品或服务的APQP流程所必需的一致统一的环球产品质量策划要求。

旨在将其作为一个标准将一个统一的格式提供给供应商的质量工程师以及供应商。

通过统一的形式来进行APQP的所有步骤。

本文件是第一修订版,首次发行并差不多过更新以反映由通用汽车公司为所有的全球供应商设定的最新标准。

作为修订的部分,即在模块组装的支持业务的基础上重又增加了一部分。

专门多的工作也差不多更新,包括模块部件和系统的专门业务。

专门多模块的APQP业务都用一个专门的上标M来表示以突出任务。

参加«产品质量先期策划»的审核〔人员〕如下:K. Williams R. Gasper W. Kraatz全球采购动力列车北美卡车经营部供应商质量供应商质量供应商质量J. Graff M. Morretti M. Aldea北美轿车经营部拉丁美洲经营部亚太经营部供应商质量供应商质量供应商质量M. Schoenleber欧洲经营部供应商质量名目名目手册内容说明APQP过程模式流程图监控的用户及供应商矩阵图APQP任务定义任务1:要紧股本持有人会议任务2:技术评审任务3:风险评估及其起源任务4:供应商程序评审任务5:进度表以及公布项目任务6:可制造性评估函任务7:流程图任务8:DFMEA—设计失效模式和后果分析任务9:设计评审任务10:量具、工具以及设备评审任务11:GP—11预制模型和原形材料任务12:PFMEA—设计过程的分析开发任务13:操纵方案/打算任务14:GP—12早期生产范畴/规模任务15:PPAP—生产部件审核过程/流程任务16:运行@速率〔GP—9〕任务17:所汲取的教训附件:附件1—GM区域性文件要求模型以及GM1927文件GM1927-1 APQP项目打算/安排GM1927-2 APQP进度表GM1927-3 供应商质量要求表〔SOR〕GM1927-4 所要求的质量情形函GM1927-5 APQP公布项目表GM1927-6 要紧股本持有人会议检查清单GM1927-7 早期风险评估GM1927-8 进度安排及可行性表格GM1927-9 系列工具及检验设备检查清单GM1927-10 所学课程流程总览GM1927-11 所学课程及实施流程图GM1927-12 所学课程规范检查清单GM1927-13 技术评审检查清单GM1927-14 APQP启动〔试生产〕会议检查清单GM1927-15 APQP启动会议说明GM1927-16 过程操纵打算审计工作单GM1927-17 GM以及供应商程序联系单GM1927-18 典型的股本持有人会议时刻安排GM1927-19 可制造性信函GM1927-20 随时刻而变的过程能力GM1927-21 RPN削减小结模块供应商的专用文件MGM1927—22M 程序治理RASICGM1927—23M 直截了当购买检查清单GM1927—24M 供应商程序审查GM1927—25M 转包的程序状态矩阵图GM1927—26M 转包的详细状态矩阵图附件2:M模块APQP补充及定义附件3:术语—名词说明手册内容说明每一部分都用任务号注明有出处,包括下属内容:•任务名称•任务所有人• 任务完成时刻〔大约〕• 任务说明• 依照具体任务完成情形移交• 具体的可交付物品的用户• 完成具体任务,包括每一投入资源的必要投入• 资源明细---包括从事完成这一任务的组织人员• 一套方法---需要采取措施的简要说明• 参考〔资料〕以及附加信息附件附件中包括所有GM〔通用汽车公司〕贯穿于履行APQP流程的APQP〔先期产品质量策划〕所使用的专有表格和文件。

全球供应商质量手册第一版0 绪论组织绩效重要因素之一,就是其产品或服务的品质。

顾客对质量的盼望日趋严苟,已蔚为全球性之趋势。

随着这一趋势,已形成一种共识,即为达成并维持良好经济绩效就必需不断改善质量。

多数组织(工商界或政府机构)生产一产品或服务,著意于满足顾客之需求。

该项需求常转化成“规格”。

假如规格上有所缺失或设计及制造产品或服务之组织系统有所不妥,则技术性规格自身就难以保证可满足顾客一贯之规定。

因此,势必开发品质系统标准及各项准则,以完毕技术规格中所订定相关产品或服务之规定。

此一系列国际标准(含ISO 9000至ISO 9004)即是将这方面众多且不同国家的方法合理化的一项具体表现。

一个组织之质量系统深受组织目的、产品或服务以及组织特有之实务等所影响,因此,质量系统亦随组织不同而有所不同。

附件中列有质量系统要项对照表以供参考。

1.合用范围本国际标准之目的为a)澄清重要质量观念彼此间的区别与互相关系(参阅条款4),以及b)提供一系列质量系统国际标准的选用指南,俾可用于内部质量管理(ISO 9004),以及用于外部质量保证(ISO 9001,ISO 9002,与ISO 9003)(参阅条款5至8)。

备注:本系列国际标准(ISO 9000至ISO 9004)的目的不在于将组织所实行的质量系统予以标准化。

2.参考资料ISO 8402质量—词汇ISO 9001质量系统—设计/发展,生产,安装与售后服务的质量保证模式(注1)ISO 9002质量系统—生产与安装的质量保险模式(注1)ISO 9003质量系统—最终检查与测试的质量保证模式(注1)ISO 9004质量管理与品质系统要项—指导纲要3.定义本国际标准合用ISO 8402中所列各项定义。

由于适切引用词汇至为重要,特自ISO 8402中采用五项重要用语及定义,纳入本国际标准中。

3.1 质量政策由一个组织高层管理者所正式宣示的该组织整体品质之意图及方针。

页码1 /41 文件作者:供应商质量工程小组生效日期: 2003年10月08日修订号 4本文件除原始电子文档以外的任何形式,将不受控制,除非本文件被压印、启动并注明日期。

本文件包含属纳科物料装卸设备集团有限公司所有的绝密资料。

因此,借阅者必须同意本文件将不会用于其他目的。

供应商质量手册(SQM)用于购买零部件及组件该文件为受控文件, 可从NMHG 网页的主索引上获得其电子只读文本.任何人持有该文件或其中所引用部分的打印件, 均视为非受控文件,且应参考NMHG 的主索引或被批准的网址以获得最新的版本号.纳科物料装卸设备集团有限公司(NMHG)2002年7月页码2 /41 文件作者:供应商质量工程小组生效日期: 2003年10月08日修订号 4本文件除原始电子文档以外的任何形式,将不受控制,除非本文件被压印、启动并注明日期。

本文件包含属纳科物料装卸设备集团有限公司所有的绝密资料。

因此,借阅者必须同意本文件将不会用于其他目的。

亲爱的供应商,纳科物料装卸设备集团有限公司 (NMHG) 非常高兴能够提供我们的第一本“供应商质量手册”(SQM)。

所有生产用零部件及组件的供应商必须立即满足该手册中的新要求。

我们希望该手册能用作畅通交流和持续改进的一个工具。

本公司(NMHG)希望我们的供应商能领会该手册的所有内容,并将其融入到每天的运行及产品开发活动中去以确保最可能优良的高品质。

一本关于SQM的循序渐进的使用指南已准备就绪,望能帮助理解该手册所讲的范围和每个系统的详细内容。

该指南和手册装在同一张CD盘里,希望每一个供应商都能仔细阅读并领会。

阅读完里面的内容后,如果你还有疑问,请与以下任何地点的你地区的供应商质量工程师(SQE)联系:肯塔基州比雷亚(Berea)克里斯•考克斯(Chris Cox)总监 –供应商质量工程查里•弗兰德(Charlie Friend)供应商质量工程师查德•汀德尔(Chad Tindall)供应商质量工程师巴里•斯图尔特(Barry Stewart) 供应商质量工程师北卡罗莱纳州格林威尔(Greenville)史蒂夫•埃伦(Steve Allen)供应商质量工程师凯利•诺维尔(Kelly Nowell)供应商质量工程师德望•派特儿(Devang Patel)供应商质量工程师苏格兰欧文(Irvine)阿兰•劳森(Alan Lawson)供应商质量工程师北爱尔兰克雷戈万(Craigavon)伊恩•巴恩斯(Ian Barnes)供应商质量工程师斯蒂芬•麦拉夫林(Stephen Mclaughlin)供应商质量工程师意大利马萨特(Masate)安德利亚•莫拉(Andrea Molla)供应商质量工程师中国上海 (Shanghai) 郑虹雯 (Shirley Zheng) 供应商质量工程师查看该手册章节1第3和第4页的地点、电话号码和电子邮件地址,或参见包括在CD内的该手册指南以与SQE联系人进行联系。

注: GP-12“早期生产控制” (GM-1920)已经并入GM PPAP程序,参考全球供应商质量手册(GM1927) – APQP Task 14.1.0范围: GP-12用于所有试生产和正式生产,服务和附加产品的要求;•要求生产件批准程序 (PPAP)•陈述对顾客造成的重大风险2.0 DEFINITION AND PURPOSE定义和目的:GP-12早期生产控制要求制定一个能加强供应商的正式生产控制计划和提高可信度的试生产控制计划以确信所有产品的发运满足GM的要求,试生产控制计划也应适用于验证正式生产控制计划,试生产控制计划应考虑产品的所有已知的关键条件,以及在PPAP中确定的潜在的有问题部分。

GP-12的目的:•验证供应商的正式生产控制计划•避免在关键时期我们的装配和生产中心和服务产品质量不合格•文件化供应商在启动和加速期间,修订生产过程之后,或独立生产运行3个月或更长时的绩效以核实它的过程控制,•确信在供应商处可能发生的任何质量问题都能快速标识,控制和纠正•增强供应商最高管理的可见度3.0供应商职责: l供应商应:A. 验证程序:建立包含以下内容的验证程序:1.确定主要负责人以确保验证程序的开发和实施2.实施由顾客指定的GP-12进入日期,关闭标准和关闭日期3.建立GP-12控制台,且脱离生产线,隔离和独立检验于正式生产过程和场地,另外,为更有效,可以使用过程控制台且必须形成文件由顾客/供应商质量工程师(SQE)批准4.在产品和程序开发期间,基于关键产品特性(KPCs)、产品质量特性(PQCs)、高PRN和/或问题验证,确定GP-12控制台要求的附加检验,试验和尺寸检验。

5.培训员工有关GP-12控制台的标准作业6.针对每种缺陷建立一个反应计划.7.实施GP-12各层管理(包括现场领导)的评审程序(分层审核),以确保符合试生产控制计划8.验证程序中包括分包商(二级供应商)B.计划开发:制定一个能加强正式生产控制计划并包括附加控制,检验,评审和试验的试生产控制计划以确信生产程序的符合性和能力,计划需要考虑:1.在正式生产控制计划中按照规定增加频次/抽检数量2.包装和标签的标识—包括服务和附加产品要求,可以包括产品上原产国标识3.防错的有效性的验证4.在GP-12控制区域或在接收场地发现不合格时的控制快速执行和永久纠正措施C.文件:将试生产控制计划(控制计划格式参考AIAG先期产品质量策划和控制计划参考手册或或其它顾客批准的先期产品质量策划参考手册),试生产控制计划不是正式生产控制计划的代替口品,而是正式生产控制计划的添加并验证它1.在控制计划特殊特性中将GP-12控制台或过程检验台要求的附加检验、功能试验和尺寸检验文件化,格式参考AIAG APQP手册—附录K并在试生产控制计划中的参考文件作为一个特殊工序2..文件化GP-12控制台检验作业指导书以确信标准化作业3.文件化执行证据和控制计划(使用图表I (GM1927-66或其它顾客同意的格式)的验证,顾客/SQE评审时,数据必须易于使用4.文件化内部和顾客质量相关的问题解决(使用顾客接受的格式),包括问题描述,问题根源,永久纠正措施随同断点和适当更新FMEAS和控制计划。

前言本参考手册是通用汽车全球小组集体努力的结晶, 该小组致力于建立通用汽车共同的APQP的过程。

在此之前, 通用汽车的每一个供应商质量组织采用各部门和地区特定的方法, 推动APQP的实施。

全球小组对APQP的过程进行了协调和标准化, 从而建立了此通用汽车 APQP 手册(通用汽车APQP 手册GM 1927)。

此手册定义了通用汽车共同的全球产品质量策划需求, 它们对于建立和实施产品或服务的APQP过程必不可少。

它旨在作为一种标准, 以向SQE 以及供应商提供一种通用的格式,以推进APQP的各个步骤的实施。

本文件是初次发行稿的第2次修订版,并且已加以更新,以反映通用汽车为所有全球供应商所确定的最新要求。

对此修订本的批准如下:全球采购部拉美业务部供应商质量供应商质量M.Wolf M. Morretti动力总成亚太业务部供应商质量供应商质量T.Nejman M. Aldea北美卡车业务部欧洲业务部供应商质量供应商质量W. Kraatz M. Schöenleber注:本APQP中文版由上海通用汽车采购部供应商质量和开发科组织翻译,根据中国实际情况进行了修订。

本程序的解释权归供应商开发小组所有。

本中文版编辑人员:黄斌、宋峥崎、杨金龙、李宁、陆捷、黄皆捷本中文版版权归GM和SGM共有,任何人均不得以电子文本形式外传。

GM Global APQP Highlights(主要的更改和变化)1、强调了GM APQP在全球范围内的统一性和严密性。

2、对APQP各阶段工作明确定义为17项任务,对各项任务的责任人、时间、任务输入输出、实施方法、SQE责任、供应商责任、参考资料等明确定义,以规范项目的开展。

3、在RFQ中增加供应商质量SOR,明确质量要求、体系要求、适用程序、质量策划、分供方要求等。

对PT零件供应商,还对KPC过程能力、PFMEA风险顺序数等明确要求。

4、供应商报价时应同时提交初始DFMEA、PFMEA、控制计划、过程流程图等质量文件,并在定点时作为评审内容之一。

版本Revision: V0 审批Approved: 日期Date: 2023-10-26 页数: 1 of 6编号Doc No.: XX/QC- 编写Prepared: 供给商质量手册SUPPLIER QUALITY MANUAL版本Revision: V0 审批Approved: 日期Date: 2023-10-26 页数: 1 of 6编号Doc No.: XX/QC-编写Prepared:1. 前言为保证供给商所生产的产品符合永刚公司规格及订单要求 ,工厂必需建立有质量把握系统. 该系统须包括工作程序,检验方法,测试方法,测试器具及质量把握记录.供给商之质量系统应承受永刚公司周期性审核.2. 适用范围本手册内容适用于:- 全部目前与本公司有生意来往的供给商;- 欲在将来成为永刚认可的供给商.3. 最低的质量系统要求各供给商应维持有效率的,现代的质量治理系统. 该系统应至少满足供给商自身的质量要求.我们要求供给商承受的质量系统应基于国际公认的品质治理标准比方ISO9001,TS16949等等. 质量治理系统应可以:3.1. 确定自身生产力气及技术水平;3.2. 能把握来料质量;3.3. 查出不合格品;3.4. 进展准时的改善行动;3.5. 防止不合格品运往客户;3.6. 供给商应制订有足够的制作程序,技术指标,工作指导书以维持对品质的把握.3.7. 图纸及图纸改动把握. 供给商应制订有图纸及图纸改动把握程序. 此程序应确保工厂上下使用最的图纸/规格要求, 以及确保全部已失效的图纸/ 规格要求从使用处收回.3.8. 量度测试器具,生产检具和夹具. 生产商应保持有足够的试验仪器,生产检具和夹具以确保产品合符规格要求.全部器具须进展足够频密的校正以确保其准确度的连续性.已过期而未校正的器具应从使用地点移走.3.9. 供给商应制订有制程把握系统以确保各制造工序在受控的环境下进展.版本Revision: V0 审批Approved: 日期Date: 2023-10-26 页数: 1 of 6编号Doc No.: XX/QC-编写Prepared:3.10. 供给商应在生产过程的适宜点设置质量检查点以保证对质量进展连续的把握.3.11. 成品的最终检验与测试. 生产商应制订有成品检验标准以确保能对产品进展足够的测试从而令成品质量符合订单的要求. 该标准可由永刚公司帮助制订并认可. 全部检验记录应予保存.3.12. 进料及生产过程中的不合格品的把握. 供给商应制订有标准程序用以把握,识别及隔离从进料和生产中消灭的不合格品.3.13. 质量问题改善行动程序. 供给商应设有程序以进展快速的内部及外部质量问题改善行动从而令质量得到持续性的改进.3.14. 质量记录. 供给商应保存足够的检验记录以用来核实及证明所供给的产品已到达全部合约上及规格上的要求.4. 预生产要求:4.1样品〔可以是手工制作〕预期的产品将被送给永刚作设计,功能和外观的批准。

注: GP-12“早期生产控制” (GM-1920)已经并入GM PPAP程序,参考全球供应商质量手册(GM1927) – APQP Task 14.1.0范围: GP-12用于所有试生产和正式生产,服务和附加产品的要求;•要求生产件批准程序 (PPAP)•陈述对顾客造成的重大风险2.0 DEFINITION AND PURPOSE定义和目的:GP-12早期生产控制要求制定一个能加强供应商的正式生产控制计划和提高可信度的试生产控制计划以确信所有产品的发运满足GM的要求,试生产控制计划也应适用于验证正式生产控制计划,试生产控制计划应考虑产品的所有已知的关键条件,以及在PPAP中确定的潜在的有问题部分。

GP-12的目的:•验证供应商的正式生产控制计划•避免在关键时期我们的装配和生产中心和服务产品质量不合格•文件化供应商在启动和加速期间,修订生产过程之后,或独立生产运行3个月或更长时的绩效以核实它的过程控制,•确信在供应商处可能发生的任何质量问题都能快速标识,控制和纠正•增强供应商最高管理的可见度3.0供应商职责: l供应商应:A. 验证程序:建立包含以下内容的验证程序:1.确定主要负责人以确保验证程序的开发和实施2.实施由顾客指定的GP-12进入日期,关闭标准和关闭日期3.建立GP-12控制台,且脱离生产线,隔离和独立检验于正式生产过程和场地,另外,为更有效,可以使用过程控制台且必须形成文件由顾客/供应商质量工程师(SQE)批准4.在产品和程序开发期间,基于关键产品特性(KPCs)、产品质量特性(PQCs)、高PRN和/或问题验证,确定GP-12控制台要求的附加检验,试验和尺寸检验。

5.培训员工有关GP-12控制台的标准作业6.针对每种缺陷建立一个反应计划.7.实施GP-12各层管理(包括现场领导)的评审程序(分层审核),以确保符合试生产控制计划8.验证程序中包括分包商(二级供应商)B.计划开发:制定一个能加强正式生产控制计划并包括附加控制,检验,评审和试验的试生产控制计划以确信生产程序的符合性和能力,计划需要考虑:1.在正式生产控制计划中按照规定增加频次/抽检数量2.包装和标签的标识—包括服务和附加产品要求,可以包括产品上原产国标识3.防错的有效性的验证4.在GP-12控制区域或在接收场地发现不合格时的控制快速执行和永久纠正措施C.文件:将试生产控制计划(控制计划格式参考AIAG先期产品质量策划和控制计划参考手册或或其它顾客批准的先期产品质量策划参考手册),试生产控制计划不是正式生产控制计划的代替口品,而是正式生产控制计划的添加并验证它1.在控制计划特殊特性中将GP-12控制台或过程检验台要求的附加检验、功能试验和尺寸检验文件化,格式参考AIAG APQP手册—附录K并在试生产控制计划中的参考文件作为一个特殊工序2..文件化GP-12控制台检验作业指导书以确信标准化作业3.文件化执行证据和控制计划(使用图表I (GM1927-66或其它顾客同意的格式)的验证,顾客/SQE评审时,数据必须易于使用4.文件化内部和顾客质量相关的问题解决(使用顾客接受的格式),包括问题描述,问题根源,永久纠正措施随同断点和适当更新FMEAS和控制计划。

(完整版)GM1927-06Component/System Name: AP Number:Part Number(s): Program/Vehicle Line:Level of Supplier Integration1. Technical Information YES NO CommentsA. GM Design responsible:Supplier Integration Level I1.1 Design FMEA completed by GM Engineering ?1.2 Have KCDS items been identified by Engineering ?If No, will a KCDS Workshop planned ?1.3 Will drawings/SOR/SSTS/CTS and other technical information be sufficient to ensurecomparable quotes ?B.Supplier Design Responsible: Supplier Integration Level II1.4 Will preliminary KCDS items be identified by Engineering? sufficient?1.5 Will approved SSTS/CTS/SOR and other technical documents be sufficient to ensurecomparable quotes?1.6 Will preliminary A/D/V P&R plans be completed by Engineering (Approved by GM)?C. Supplier System/Design Responsible: Supplier Integration Level III & IV1.7 Will preliminary KCDS items be identified by Engineering?1.8 Will the Statement of Requirements (SOR) be included and sufficient?1.9 Will approved SSTS/CTS and other technical documents be sufficient to ensurecomparable quotes?1.10 Will preliminary A/D/V P&R plans be completed byEngineering (Approved ByGM)?2. Timing2.1Has the Buyer provided Program & sourcing timing (Pre-RFQ throughSourcing decision)?2.2 Has Product Engineer provided development timing (Prototype, drawings, definition ofrequirements etc.)?2.3 Has SQE provided timing for quality requirements (GP-11, GP-12, PPAP, Run @ Rateetc.)?3. Quality Expectations3.1 Has the SQE verified that the Supplier Quality Required Quality Information letter andthe Supplier Quality SOR will be included in the RFQ.3.2 Will tooling and gaging requirements be included in the RFQ?3.3 Have warranty targets been established?3.4 Have functional tests been identified?4. Bidders List4.1 Do all suppliers on bidders list fulfill Quality Criteria?4.2 Is PSA (Potential Supplier Assessment) or STEP (Sourcing Team Evaluation process)required for any supplier?4.4 New business hold list provided by Creativity Team?5. Capacity Requirements5.1 Daily Capacity Requirements (LCR / MCR)established?5.2 Option Penetration identified?5.3 Additional capacity needed for carry-over parts identified?YES NO COMMENTS6. Manufacturing Requirements6.1 Assembly plants identified?6.2 Broadcast window (if required)?7. Bill of Material (BOM)7.1 BOM identified for assemblies?8. Other8.1 Are any components a directed buy?8.2 Has After-Market flexibility capacity and packaging been considered and included inRFQ?8.3 Is warehousing required?8.4 Is special packaging required?8.5 Are parts shipped directly to a GM facility?8.6 Are parts to be sequenced?RECOMMENDATION:Items on previous pages are fulfilled satisfactorily. Information to be included in the RFQ package willbe sufficient to obtain Quality assured and comparable quotations.Items on previous pages are NOT fulfilled satisfactorily. However the information will be sufficient to obtain Quality assured and comparable quotations. Exceptions and corrective actions are to be listed on the APQP Open Issues List GM1927-5 and tracked to closure.Items on previous pages are NOT fulfilled and do not believe Quality assured and comparable quotations will bereceived.The recommendation will be to stop the RFQ package until open items listed on the APQP Open Issues List GM1927-5 areresolved satisfactorily.Date:______________________________________Buyer______________________________________Product Engineer______________________________________SQE______________________________________Manufacturing Engineer。