Honeywell传感器规格书

- 格式:pdf

- 大小:438.94 KB

- 文档页数:4

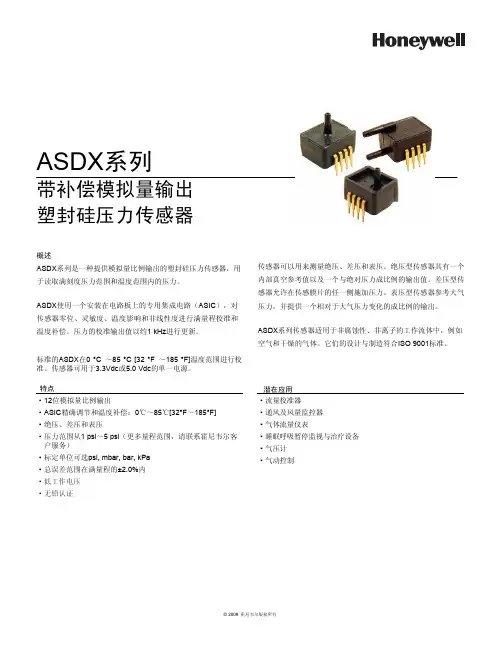

·低工作电压·无铅认证ASDX ㋏߫ᏺ㸹ٓᢳ䞣䕧ߎลᇕ⸙य़Ӵᛳ఼ὖ䗄ASDX ㋏߫ᰃϔ⾡ᦤկᢳ䞣↨՟䕧ߎⱘลᇕ⸙य़Ӵᛳ఼ˈ⫼Ѣ䇏প⒵ࠏᑺय़㣗ೈ⏽ᑺ㣗ೈݙⱘय़DŽASDX Փ⫼ϔϾᅝ㺙⬉䏃ᵓϞⱘϧ⫼䲚៤⬉䏃˄ASIC ˅ˈᇍӴᛳ఼䳊ԡǃ♉ᬣᑺǃ⏽ᑺᕅડ䴲㒓ᗻᑺ䖯㸠⒵䞣᷵ޚ⏽ᑺ㸹ٓDŽय़ⱘ᷵ޚ䕧ߎؐҹ㑺1 kHz 䖯㸠ᮄDŽᷛޚⱘASDX 0 °C ̚85 °C [32 °F ̚185 °F]⏽ᑺ㣗ೈ䖯㸠᷵ޚDŽӴᛳ఼ৃ⫼Ѣ3.3Vdc 5.0 Vdc ⱘऩϔ⬉⑤DŽӴᛳ఼ৃҹ⫼ᴹ⌟䞣㒱य़ǃᏂय़㸼य़DŽ㒱य़ൟӴᛳ఼᳝ϔϾݙ䚼ⳳぎখ㗗ؐҹঞϔϾϢ㒱ᇍय़៤↨՟ⱘ䕧ߎؐDŽᏂय़ൟӴᛳ఼ܕ䆌Ӵᛳ㝰⠛ⱘӏϔջᮑࡴय़DŽ㸼य़ൟӴᛳ఼খ㗗⇨य़ˈᑊᦤկϔϾⳌᇍѢ⇨य़ব࣪ⱘ៤↨՟ⱘ䕧ߎDŽASDX ㋏߫Ӵᛳ఼䗖⫼Ѣ䴲㜤㱔ᗻǃ䴲⾏ᄤⱘᎹ⌕ԧЁˈ՟བぎ⇨ᑆ➹ⱘ⇨ԧDŽᅗӀⱘ䆒䅵Ϣࠊ䗴ヺড়ISO 9001ᷛޚDŽ⡍⚍g 12ԡᢳ䞣↨՟䕧ߎg ASIC ㊒⹂䇗㡖⏽ᑺ㸹ٓ˖0ć̚85ć[32°F ̚185°F] g 㒱य़ǃᏂय़㸼य़g य़㣗ೈҢ1 psi ̚5 psi ˄䞣㣗ೈˈ䇋㘨㋏䳡ሐ䶺ᇨᅶ᠋᳡ࡵ˅g ᷛᅮऩԡৃ䗝psi, mbar, bar, kPa g ᘏ䇃Ꮒ㣗ೈ⒵䞣ⱘ±2.0%ݙ┰ᑨ⫼g ⌕䞣᷵ޚ఼g 䗮亢ঞ亢䞣ⲥ఼g ⇨ԧ⌕䞣Ҿ㸼g ⴵ᱖ذⲥ㾚Ϣ⊏⭫䆒g ⇨य़䅵g ⇨ࡼࠊ© 2009 䳡ሐ䶺ᇨ⠜ᴗ᠔᳝© 2009 霍尼韦尔版权所有2 霍尼韦尔传感与控制部ASDX 系列塑封硅压力传感器表1. 绝压最大额定值1参数最小最大单位供电电压(V 电源)-0.3 6.0V 任意引脚上的电压-0.3V 电源+0.3V ESD 感应(人体模式)3-kV 储存温度-50[-58]125[257]℃ [O F]焊接温度(2s 至4s)-250[482]℃ [O F]V 供电和接地之间的外部电容2100470nF表2. 操作规格参数最小典型最大单位供电电压(V 电源)33.3V 5.0V根据按订货指南选定的型传感器可以是3.3V ,也可以是5.0V(见图1) 3.04.753.345.043.65.25Vdc 供电电流 2.5mA补偿温度范围50[32]-85[185]℃ [O F]工作温度范围6-20[-4]-105[221]℃ [O F]过压72倍工作压力范围以上爆裂压力83倍工作压力范围以上启动时间(电源供应直至数据就绪)--5ms 响应时间-1.0-ms 最高输出限制97.5--%V 电源最低输出限制-- 2.5%V 电源最小负载电阻 5.0--k Ω总误差带9-- 2.0%FSS(满量程)10输出分辨率12--bits表3. 环境规格参数特性湿度0%至95%RH(相对湿度),无凝露振动20Hz 至2000Hz, 10G 冲击100G 持续11ms 寿命最少1百万次压力循环表4. 湿材料11参数端口1(压力端口)端口2(压力端口)密封盖玻璃充填PBT 玻璃充填PBT 粘合剂硅树脂RTV 硅树脂RTV 和环氧电气部件硅树脂和玻璃硅树脂、玻璃和金制品注:1. 绝对最大额定值是装置可以承受而不引起装置损坏的极限。

HoneywellHoneywell/Commercial Switch-Sensor 霍尼韦尔开关与传感器1 上海:Tel************* 北京:Tel************* 深圳:Tel************* 广州: Tel:020-********e-mail:******************************:///sensing参考与应用数据 压力传感器配管与安装考虑事项-注释#9有许多型号和规格尺寸的管道可用于安装MICRO SWITCH 压力传感器将管道连接至塑料压力端口的方法有好几种MICRO SWITCH 提供下列资料作为对客户的服务然而用户是评判每一个应用场合所使用的管道与连接方法是否合适的最佳评判者软管/管道乙烯管可用在室温低压<50 psig 的应用场合乙烯成本低廉并应在使用时配上软管夹硅管非常柔软并能耐极端温度硅管应当用在低压<50 psig 应用场合中建议配上软管夹聚乙烯管非常柔软建议用于室温和压力低于50 psig 的应用场合建议配上软管夹聚氨脂管价格最高不柔软但能承受较高的温度和压力建议配上软管夹但可能不需要软管夹泰顿公司供应两类被称为管扣的软管夹建议在大多数气温不超过200℉或水温不超过180℉的应用场合使用天然乙酰型软管夹热稳定的玻璃纤维混合型软管夹适用于400℉持续使用的场合管扣在各种各样的化学品包括盐碱醇醚洗涤剂汽油润滑油和润滑脂等中也能呈稳定状态可按要求提供各种规格尺寸的软管夹从当地五金商店的管件部购得的管夹和从电气产品销售商那儿购买的电缆扣也可以用来连接管道和塑料端口Mazzer Industries 供应各种Mazzer-Loc JG 变速配件这些配件可与20PC 系列大流量传感器非常协调地工作 附件 添加端口Imperial Eastman 公司供应各种型号和规格的黄铜添加端口可用于连接铜管安装五金件ITW FasTex 供应品种繁多的安装连接器尼龙螺钉铆钉和推针这些五金件可用于固定压力传感器的安装托架添加端口软管/管道软管夹3/16"外径的管子至1/8"外螺纹管-外螺纹接头表2添加端口68-FL-03X02 69-FL-03X02 3/16"外径的管子至1/8"外螺纹管-外螺纹弯头 70-FL-03X02 3/16"外径的管子至1/8"内螺纹管-内螺纹弯头 KF03-02PS 3/16"内径的软管至1/8"外螺纹管-有倒钩的端口 KF04-02PS 1/4"内径的软管至1/8"外螺纹管-有倒钩的端口 66-FL-03X02 3/16"外径的管子至1/8"内螺纹管-内螺纹接头内螺纹接头与有倒钩的端口配套使用软管夹/附件 Hoses/TubingNorton Performance PlasticsCorporationP.O. Box 3660Akron, OH 44309-3660 USA (330) 798-9240United States Plastics Corporation 1390 Neubrecht Road Lima, Ohio 45801USA (419) 228-2242Clippard Instrument Laboratory, Inc.7390 Colerain Road Cincinnati, Ohio 45239 USA (513) 521-4261Hose Clamps/Accessories Tyton Corporation 7930 North Faulkner Road P.O. Box 23055Milwaukee, WI 53223 USA (414) 355-1130Imperial Eastman Acquisition Corporation1151Bryn MawrItasca, IL 60143 USA (630) 285-6100Clippard Instrument Laboratory, Inc.7390 Colerain RoadCincinnati, Ohio 45239 USA (513) 521-4261Mazzer Industries, Inc.125 Elmgrove Park Rochester, NY 14624(716) 247-0311ITW Fastex195 Algonquin RoadDes Plaines, IL 60016-6197 USA(847) 299-2222。

Datasheet2What makes our sensors better:• Robust IC design with ESD Class 2, reversepolarity protection and 150 °C [302 °F] capability • Package and sensitivity options to bettermatch application needs • Dependable performance – similar Honeywellsensor ICs have been tested to over 100 million operations • Honeywell legacy and expertise – 45 yearsof engineering excellence and Hall effect technology experienceUnipolar Digital Hall-Effect Sensor ICsThe SS340RT/SS440R sensor ICs are small, versatile digital Hall-effect devices that are operated by the magnetic field from a permanent magnet or an electromagnet. They are designed to respond to a single pole: North (SS340RT) or South (SS440R).These unipolar Hall ICs are supplied in three different magnetic sensitivities to meet a wide range of potential applications:• SS341RT and SS441R offer the highest sensitivity, with a typical operating point of 75 G at 25 °C [77 °F]. • SS343RT and SS443R offer medium sensitivity, with a typical operating point of 135 G at 25 °C [77 °F]. • SS349RT and SS449R offer the lowest sensitivity, with a typical operating point of 305 G at 25 °C [77 °F].These sensors are available in two package styles:• The SS340RT is available in the miniature SOT-23 surface mount package. • SS440R is available in the leaded, flat TO-92-style package.The SS340RT’s small size requires less PC board space, allowing it to be used in smaller assemblies. Its 3 Vdc capability allows for use in low voltage applications, promoting energy efficiency.The SS340RT Series is available on tape and reel (3000 units per reel); the SS440R Series is available in a bulk package (1000 units per bag).SMALL • VERSATILESS340RTSS440R3 SubminiaTuRe package Size (SS340RT) Supplied on Tape and ReelAllows for a compact design with automated component placement, helping to reduce manufacturing costsSimple acTivaTion fRom a Single pole and mulTiple magneTic SenSiTiviTieS (high, medium and low)Make this product suitable in a variety of potential motion control, lid closure detection, and displacement sensing applicationslow volTage 3 v capabiliTyHelps reduce power consumptionbuilT -in ReveRSe polaRiTy pRoTecTionProtects the device from potential damage during installationTheRmally balanced inTegRaTed ciRcuiTProvides for stable operation over a wide temperature range of -40 °C to 150 °C [-40 °F to 302 °F]RohS-complianT maTeRialSMeet Directive 2002/95/ECFeatures and BenefitsHigh, medium and low magnetic sensitivities.Enhances application flexibility.4induSTRialdooR oR lid cloSuRe deTecTion in applianceS oR elecTRonically conTRolled conTaineRSMay be used recessed in the door frame with a magnet embedded in the door. The magnet activates the sensor to indicate door open or close.Simple Speed and Rpm (RevoluTionS peR minuTe) SenSing in fiTneSS and induSTRial equipmenTMay be mounted on the motor shaft of a treadmill such that the rotating magnet pole, which rotates with the motor, activates the sensor with each revolution, producing a single digital pulse for each revolution.flow RaTe SenSing in waTeR SofTeneRS, induSTRial pRoceSSeS, and applianceSMay be used used with one or more magnets mounted on a paddle to measure the flow rate.dampeR oR valve poSiTion conTRol in induSTRial, hvac and ReSidenTial oR commeRcial applicaTionSMay be used to determine if a valve or damper is fully open or fully closed.RoboTic conTRol (cylindeR poSiTion moniToRing)May be used to detect the piston’s position by detecting a magnet mounted on the piston ring located inside a non-ferromagnetic cylinder.level/TilT meaSuRemenTMay be installed in the base of a machine with a magnet mounted pendulum fashion over the sensor. A change in state of the output as the magnet swings away from the sensor indicates that the machine is not level.RemoTe conveyoR SenSingMay be mounted to the frame of the conveyor, with a magnet mounted on the tail pulley. When the magnet revolves past the sensor, it produces one output per revolution, providing an intermittent visual or audible signal at a remote location to assure stability. Any interruption of the conveyor motion will interfere with the normal signal and alert the operators.puSh buTTon conTRolS medicalpoSiTion SenSoR in hoSpiTal bedS and medical equipmenTMay be used with a magnet mounted on the activator arm to determine the home or end-of-travel position of the equipment.medicaTion bin moniToR on poRTable dRug caRTSMay be used to detect if a drug dispensing drawer is open or closed.Potential Applications5Unipolar Digital Hall-Effect Sensor ICsTable 2. SS340RT/SS440R magnetic Specifications (v = 3 vdc to 24 vdc, 20 ma load, T = -40 ºc to 150 ºc [-40 ºf to 302 ºf].)Table 1. SS340RT/SS440R performance Specifications (v supply = 3 vdc to 24 vdc, 20 ma load, T a = -40 ºc to 150 ºc [-40 ºf to 302 ºf] except where otherwise specified.)Table 3. SS340RT/SS440R absolute maximum Ratings NOTICEAbsolute maximum ratings are the extreme limits that the device will withstand without damage to the device. However, the electrical and mechanical characteristics are not guaranteed as the maximum limits (above recommended operating conditions) are approached, nor will the device necessarily operate at absolute maximum ratings.NOTICEThe magnetic field strength (Gauss) required to cause the switch to change state (operate and release) will be as specified in the magnetic characteristics. To test the switch against the specified magnetic characteristics,the switch must be placed in a uniform magnetic field.SS340RT/SS440R Seriesfigure 1. Typical magnetic vs Temperature performance curves SS341RT/SS441RSS343RT/SS443R SS349RT/SS449ROperate PointVcc = 12 VRelease Point20406080100-40-20020406080100120140 MagneticSwitchPoint(Gauss)Temperature (C)Magnetic Performance vs TemperatureOperate PointVcc = 12 VRelease Point50100150200250300350-40-20020406080100120140 MagneticSwitchPoint(Gauss)Temperature (C)Magnetic Performance vs Temperature20406080100-40-20020406080100120140 MagneticSwitchPoint(Gauss)Temperature (C)120140160180Unipolar Digital Hall-Effect Sensor ICsfigure 2. SS340RT Series maximum Rated Supply voltage vs Temperaturefigure 3. current Sinking output block diagramfigure 4. wiring diagrams7SS340RT/SS440R Seriesfigure 5. SS340RT mounting and Tape/Reel dimensions (for reference only. mm/[in].)MEASUREDA T HUB9Unipolar Digital Hall-Effect Sensor ICsorder guide figure 6. SS440R mounting dimensions (for reference only. mm/[in].)Sensing and Control Honeywell1985 Douglas Drive North Golden Valley, MN 55422 Find out moreHoneywell serves its customers through a worldwide network of sales offices, representatives and distributors. For application assistance, current specifications, pricing or name of the nearest Authorized Distributor, contact your local sales office.To learn more about Honeywell’s sensing and control products, call +1-815-235-6847 or 1-800-537-6945,visit , or e-mail inquiries to *********************addiTional infoRmaTionThe following associated literature is available at : • Product line guide• Product range guide: Position Sensors • Product range guide: Speed Sensors• Product range guide: Sensors and Switches for Potential Medical Applications• Product installation instructionswaRRanTy/RemedyHoneywell warrants goods of its manufacture as being free of defective materials and faulty workmanship. Honeywell’s standard product warranty applies unless agreed to otherwise by Honeywell in writing; please refer to your order acknowledgement or consult your local sales office for specific warranty details. If warranted goods are returned to Honeywell during the period of coverage, Honeywell will repair or replace, at its option, without charge those items it finds defective. The foregoing is buyer’s sole remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and fitness for a particular purpose. in no event shall honeywell be liable for consequential, special, or indirect damages.While we provide application assistance personally, through our literature and the Honeywell website, it is up to the customer to determine the suitability of the product in the application.Specifications may change without notice. The information we supply is believed to be accurate and reliable as of this printing. However, we assume no responsibility for its use.005909-4-EN IL50October 2014© 2014 Honeywell International Inc. All rights reserved.Mouser ElectronicsAuthorized DistributorClick to View Pricing, Inventory, Delivery & Lifecycle Information:H oneywell:SS441R SS449R SS443R SS343RT SS341RT SS349RT。

(casing and cementing) are vital oil and gas processes that utilize pressure sensors for measurement and monitoring functions.APPLICATIONSHoneywell Wing Union pressure sensors (also known as Hammer Union pressure sensors outside of the United States) are widely used by oil and gas companies to measure pressure level changes in media circulation systems.Oil Mud LoggingFor example, oil mud loggingapplications (see Figure 1) require a series of pressure sensors to be connected to the drilling apparatus and installed in specialized equipment to monitor or “log” the drill’s activity. Logging While Drilling (LWD) and Measurement While Drilling (MWD)pump into the well), mud pumps (for pressure monitoring of incoming and outgoing media to protect the mudpump and drill bit), and return line choke manifold (for pressure monitoring of the return line carrying the mud plus cuttings).During the mud logging process, pumps send drilling media throughout the circulation system, down to the drilling bit, and then return the bit’s cuttings to the surface for analysis and disposal. Honeywell’s wing union/hammer union pressure sensors help detect pressure level changes in the media circulation system, which can indicate changing conditions being encountered downhole by the drill bit, thus allowing the operator to quickly make adjustments to the drilling mixture pressure or drilling process as needed.today’s oil and gas industry, used for many types Models 434, 435, 437 Wing Union/ Hammer Union Pressure TransducerPRESSURE SENSORS FOROIL & GASApplication NoteFracturing, Acidizing, and Cementing Honeywell’s Wing Union/Hammer Union pressure sensors are also used during fracturing, acidizing, and cementing applications for similar pressure monitoring and control purposes.SOLUTIONSHoneywell Wing Union/Hammer Union Pressure Sensors are built ruggedand oilfield tough to stand up to the rigorous demands of oil and gas drilling applications and environments. They have the sensitivity to ensure precise, reliable measurements every time, optimize drilling operation, reduce downtime, and maximize productivity. Durable ConstructionModels 434, 435, and 437 are constructed on Honeywell’s time proven all-welded, one-piece design, with the sensor diaphragm and Weco® 1502, 2202 Wing Union compatible fitting form factor machined as one part. This one-piece design provides a hermetically sealed unit, reducing the chanceof media leakage into the sensitive electronic components, and increasing overall reliability. The isolated, pressure sensing diaphragm minimizes zero-shift during hammer up and also eliminates long term, signal drift in the field, making it easier to install and providing reliable pressure readings over time.The sensor diaphragm is machined from Inconel® 718, which provides additional durability with highly abrasive and corrosive media, and is weldedto the main stainless steel body. The stainless steel electrical connection provides enhanced secondary pressure containment, with multiple electricalconnector options from which to choose.Optional 1-Wire or 2-Wire ShuntCalibrationModels 434, 435, and 437 providean optional 1-wire or 2-wire shuntcalibration. When a customer sends asignal to the wing union/hammer unionfrom their instrumentation, anothersignal will be returned to validate thefunctionality of the unit. This providesconfidence in the pressure readingsduring normal operation.Optional Protective CageModels 434, 435, and 437 are alsoavailable with an optional protectivecage which provides extra electricalconnection protection and durability.Various Accuracy Levels• Model 434: 0.2 %FSS BFSL• Model 435: High accuracy±0.1 %FSS BFSL orstandard accuracy ±0.2 %FSS BFSL• Model 437: Standard accuracy±0.2 %FSS BFSLModel 437 feature a wider aperturedesign than the other models that isuseful for customers utilizing moreviscous media in certain applications,enabling uniform flow of differentviscous media through the criticalsensing area and helping to maintainconsistent accuracy.*Best Fit Straight LineBENEFITS• Higher ±0.1 %FSS BFSL Accuracy(Model 435): Provides additionalconfidence in the actual measuredpressure value, particularly forsmaller changes in pressure, thusallowing the operator to makequicker adjustments to drillingoperations for more precise controland increased efficiency duringextraction• Wider Aperture Design (Model 437):Wider than Models 434 and 435,helping to prevent media cloggingwhen using more viscous mediablends• Reliability/Durability: All-welded,hermetically sealed, stainless steelconstruction with Inconel® 718wetted parts isolate corrosive orabrasive drilling media from sensitiveinternal electronics; materials retainstrength in higher temperatures toprovide reliable performance underdemanding conditions; shock andvibration tested, intrinsically saferating• Easy Installation/Serviceability:Designed for quick field installation,including horizontal or verticalmounting; field-repairableconnectors; zero and spanadjustments can be accessed byremoving the electrical connector,thus preventing ingress failures anddeterring tampering; 1-wire or 2-wireshunt calibration allow the user todetermine if the wing union/hammerunion is still functional in the field,or if it has to be removed for service/calibration.2 APPLICATION NOTE | Wing Union/Hammer Union Pressure Transducers | /astAPPLICATION NOTE | Wing Union/Hammer Union Pressure Transducers | /ast 3SELECTION GUIDEHoneywell offers three models from which to choose:üüü üüü üüü* Note: See Wing Union pressure sensor datasheet for more agency approval classifications.For more information about Wing Union/Hammer Union pressure sensors, including nomenclature and dimensional drawings, see our datasheet.008875-6-EN | 6 | 10/21© 2021 Honeywell International Inc. All rights reserved.HoneywellAdvanced Sensing Technologies 830 East Arapaho Road Richardson, TX 75081WARRANTY/REMEDYHoneywell warrants goods of its manufacture as being free of defective materials and faulty workmanship during the applicablewarranty period. Honeywell’s standard product warranty applies unless agreed to otherwise by Honeywell in writing; please refer to your order acknowledgement or consult your local sales office for specific warranty details. If warranted goods are returned to Honeywell during the period of coverage, Honeywell will repair or replace, at its option, without charge those items that Honeywell, in its sole discretion, finds defective. The foregoing is buyer’s sole remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and fitness for a particular purpose. In no event shall Honeywell be liable for consequential, special, or indirect damages.While Honeywell may provide application assistance personally, through our literature and the Honeywell web site, it is buyer’s sole responsibility to determine the suitability of the product in the application.Specifications may change without notice. The information we supply is believed to be accurate and reliable as of this writing.However, Honeywell assumes no responsibilityfor its use.FOR MORE INFORMATIONHoneywell Advanced Sensing Technolo-gies services its customers through a worldwide network of sales offices and distributors. For application assistance, current specifications, pricing, or the nearest Authorized Distributor, visit /ast or call:USA/Canada +302 327 8920Latin America +1 305 805 8188Europe +1 302 327 8920Japan +81 (0) 3-6730-7152Singapore +65 6355 2828Greater China+86 4006396841。

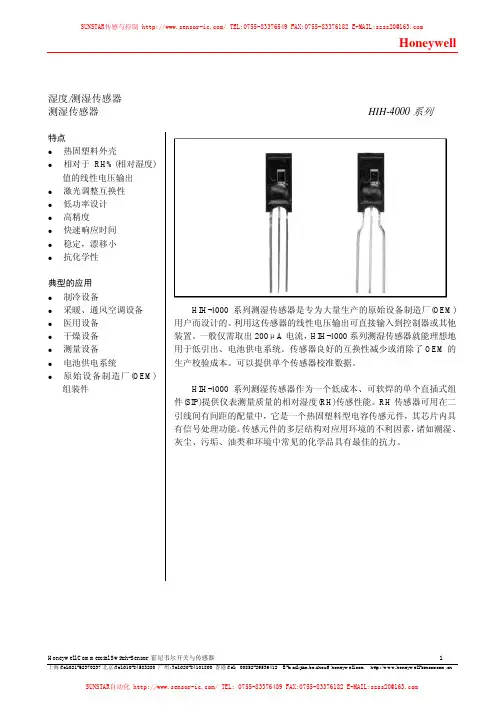

湿度/测湿传感器测湿传感器HIH-4000系列特点热固塑料外壳相对于RH%(相对湿度)值的线性电压输出激光调整互换性低功率设计高精度快速响应时间稳定,漂移小抗化学性典型的应用制冷设备采暖、通风空调设备医用设备干燥设备测量设备电池供电系统原始设备制造厂(OEM)组装件HIH-4000系列测湿传感器是专为大量生产的原始设备制造厂(OEM)用户而设计的。

利用这传感器的线性电压输出可直接输入到控制器或其他装置。

一般仅需取出200μA电流,HIH-4000系列测湿传感器就能理想地用于低引出、电池供电系统。

传感器良好的互换性减少或消除了OEM的生产校验成本。

可以提供单个传感器校准数据。

HIH-4000系列测湿传感器作为一个低成本、可软焊的单个直插式组件(SIP)提供仪表测量质量的相对湿度(RH)传感性能。

RH传感器可用在二引线间有间距的配量中,它是一个热固塑料型电容传感元件,其芯片内具有信号处理功能。

传感元件的多层结构对应用环境的不利因素,诸如潮湿、灰尘、污垢、油类和环境中常见的化学品具有最佳的抗力。

表1:性能规格在5.0 VDC供电电压和25°C时,除非另有规定%RH性能规格包括试验系统测量误差(±0.5%的典型值)参数最小值典型值最大值单位互换性(最佳配合直线)%RH0至60%RH-5 5%RH60%至100%-8 8互换性(二阶曲线)%RH±3.5%RH*精度(最佳配合直线)±3.5%RH**精度电压输出(二阶曲线)±2.5%RH 滞后性 3%RH重复精度±0.5整定时间70mSSec响应时间l/e指在缓慢流动的空气中15***稳定性(在1年内50%RH 的条件下)%RH±1.2****稳定性(50%RH条件下 ) %RH供电要求TBDVDC5.8供电电压 4μA供电电流500电压输出(一阶配合) V输出=V供电(0.0062(传感器RH)+0.16)电压输出(二阶曲线配合) V输出= 0.00003 (传感器RH)2 + 0.0281 (传感器RH) +0.820,在25°C时的典型数据温度补偿V输出=(0.0305+0.000044T-0.0000011T2) (传感器RH)+ (0.9237-0.0041T+0.000040T2)T=温度单位为°C工作温度-40 见图1 85 °C°F-40 185工作湿度 0见图1 100 %RH储存温度°C-40 125°F-40 257储存湿度见图2 %RH* 仅对HIH-400-003和-004型号而言。

电子罗盘模块按照NMEA格式,通过RS232/485串口提供航向输出(横滚、俯仰、偏航)采用Honeywell公司的固态磁阻传感器,具有快速的响应时间至20Hz,航向精度为0.5˚ ,分辨率为0.1˚。

快速响应时间小体积低功耗高精度宽的倾斜角度对铁磁物性金属进行补偿使用固态磁传感器提高了响应速度,和万向架固定式的磁通门传感器相比提高了数据更新速度。

仅为一块线路板,重量小于57克,体积为83x25x22mm,铝外壳封装。

功耗小于25mA,可长时间电池供电0.5˚ 航向精度,分辨率0.1˚ ,可适用于严格定向的应用场合。

倾斜角度为±40˚ ,适合于广泛的要求精确的应用通过对因环境中存在铁磁性金属而对地磁场造成的扭曲的补偿,提高精度。

下表显示,9针插头引脚排列,电源可以为调制的5V ,或不调制6—15V ,只有#9针或#8针中的一个,可由给定连接方法连接。

见以下:接口信号描述通信HMR3000 用简单的ASCII 字符与外部主控制器,通过 RS-232 或 RS-485 通讯。

ASCll 码的发送和接收,使用1个起始位,8个数据位(先是LSB,MSB 总为0) ,无奇偶位,和一个停止位,波特率可设置为1200,2400,4800,9600,19200或38400,HMR3000 对所有收到的带校验码的有效输入作反应。

罗盘输出HMR3000输出三种NMEA 标准格式(HDG,HDT 和XDR),三种专用格式(HPR,RCD 和CCD),及一个 ASCll 码航向输出,用于数据显示。

HDG,HDT 和HPR 是最通用格式。

$HCHDG 航向、偏差角、磁偏角$HCHDG, 85.5, 0.0, E, 0.0, E*77$HCHDT,航向、对(True)$HCHDT,271.1,T*2C$PTNTHPR,航向、俯仰和横滚$PTNTHPR,Heading,Heading Status,Pitch,Pitch Status,Roll,Roll Status*hh<cr><lf>$PTNTHPR,85.9,N,-0.9,N,0.8,N*2C名称TxD/B RxD/A GND 6-15V 5VOper/Calib(2)Run/Stop(2)Ready/Sleep(2)Cont/Reset(2)入/出Out In In In In In In In In引脚235981647描述RS-232 发送/ RS-485RS-232 接收 / RS-485电源/信号地未调理的电源电压输入调理的电源电压输入Operate/Calibrate (3) input (open=Operate)Run/Stop (3) input (open=Run)Ready/Sleep (3) input(open=Ready)Continue/Reset (3) input (open=Continue)(典型值)---6-155 ± 5%0-50-50-50-5(最小值)(1)-18-1800-20-20-20-20单位Vdc VdcVdc Vdc Vdc Vdc Vdc Vdc(最大值)(1)1818307.520202014(1) 绝对最大值(2) 沉电流:200µA (典型值), 400mA(最大值)(3) 开路输入 =高电平HMR3000 连线图——计算机RS232 到 HMR3000订货指南HMR3000-Demo-232*.....RS232HMR3000-D00-232..........RS232.........NoneHMR3000-D21-232..........RS232.........Extended BaseHMR3000-D00-485..........RS485.........NoneHMR3000-D21-485..........RS485.........Extended Base*Development Kit includes one module in alu minum enclosure, cablingwith power supply, demonstration software for PC running Windows™and User’s Manual.数值<0.5˚<1.5˚± 0.3˚0.1˚degrees/mils ±40˚±0.4˚±0.6˚±0.2˚0.1˚degree/mils ±1.0 Gauss (最大值)1 mGauss 5.0 Vdc 调理电压6~15Vdc 未调理电压35 mA@6 Vdc13 mA 2.0 mA RS-232RS-4851200 to 38400 bps NMEA 0183连续滤波0.75 oz (22g)3.25 oz (92g)1.2 x 2.95 x 0.7601.5 x 4.2 x 0.88-20 to 70˚C -35 to 100˚C 30 英寸高落下20~2000Hz Random 2 hrs/axisIPC6012IPC610航向角俯仰和横滚磁场电气接口物理环境制造指标1. 航向精度是假设地球磁体只有硬铁干扰,已通过标定进行补偿2. 标定值3. 由设计参数保证4. 典型5. 迟到或超过*器件方向角不超过75˚在工作或贮存时——可引起短暂的精度损失。

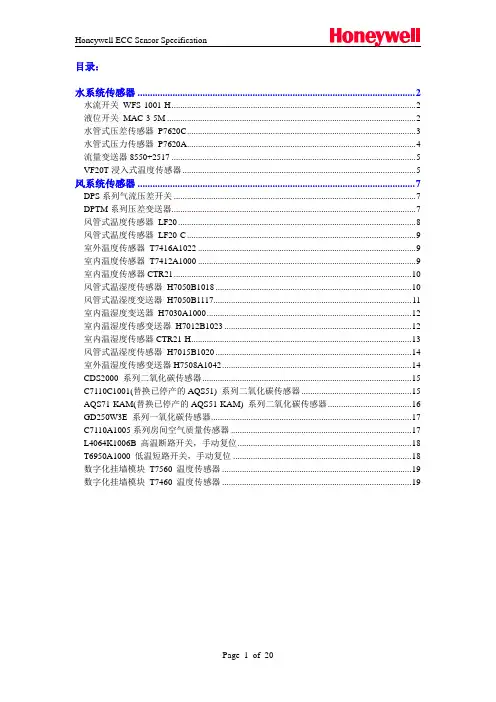

目录:水系统传感器 (2)水流开关WFS-1001-H (2)液位开关MAC-3-5M (2)水管式压差传感器P7620C (3)水管式压力传感器P7620A (4)流量变送器8550+2517 (5)VF20T浸入式温度传感器 (5)风系统传感器 (7)DPS系列气流压差开关 (7)DPTM系列压差变送器 (7)风管式温度传感器LF20 (8)风管式温度传感器LF20-C (9)室外温度传感器T7416A1022 (9)室内温度传感器T7412A1000 (9)室内温度传感器CTR21 (10)风管式温湿度传感器H7050B1018 (10)风管式温湿度变送器H7050B1117 (11)室内温湿度变送器H7030A1000 (12)室内温湿度传感变送器H7012B1023 (12)室内温湿度传感器CTR21-H (13)风管式温湿度传感器H7015B1020 (14)室外温湿度传感变送器H7508A1042 (14)CDS2000 系列二氧化碳传感器 (15)C7110C1001(替换已停产的AQS51) 系列二氧化碳传感器 (15)AQS71-KAM(替换已停产的AQS51-KAM) 系列二氧化碳传感器 (16)GD250W3E 系列一氧化碳传感器 (17)C7110A1005系列房间空气质量传感器 (17)L4064K1006B 高温断路开关,手动复位 (18)T6950A1000 低温短路开关,手动复位 (18)数字化挂墙模块T7560 温度传感器 (19)数字化挂墙模块T7460 温度传感器 (19)水系统传感器水流开关 WFS-1001-H应用∙ WFS 水流开关具有SPDT 输出,性能优异,高精度可靠性,可安装在水管和对铜无腐蚀性液体中,当液体流量达到整定速率时,可不到整定点,其一个回路关闭,另一个回路打开,典型应用于连锁作用或断流保护的场所。

∙ WFS 系列开关仅用0℃以上液体介质,它亦可于高盐或氯气的液体,但是非易燃介质。

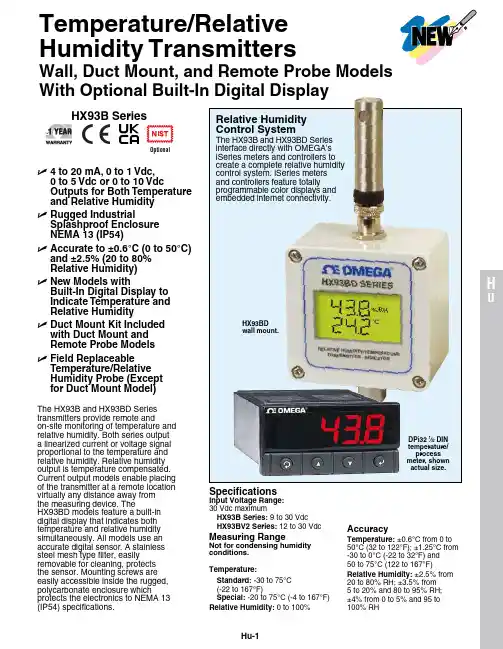

Hu-1HuSpecificationsInput Voltage Range: 30 Vdc maximumHX93B Series: 9 to 30 Vdc HX93BV2 Series: 12 to 30 VdcMeasuring RangeNot for condensing humidity conditions.Temperature:Standard: -30 to 75°C (-22 to 167°F)Special: -20 to 75°C (-4 to 167°F)Relative Humidity: 0 to 100%AccuracyTemperature: ±0.6°C from 0 to 50°C (32 to 122°F); ±1.25°C from -30 to 0°C (-22 to 32°F) and 50 to 75°C (122 to 167°F)Relative Humidity: ±2.5% from 20 to 80% RH; ±3.5% from 5 to 20% and 80 to 95% RH; ±4% from 0 to 5% and 95 to 100% RHThe HX93B and HX93BD Series transmitters provide remote andon-site monitoring of temperature and relative humidity. Both series output a linearized current or voltage signal proportional to the temperature and relative humidity. Relative humidity output is temperature compensated. Current output models enable placing of the transmitter at a remote location virtually any distance away from the measuring device. TheHX93BD models feature a built-in digital display that indicates both temperature and relative humidity simultaneously. All models use an accurate digital sensor. A stainless steel mesh type filter, easily removable for cleaning, protects the sensor. Mounting screws are easily accessible inside the rugged, polycarbonate enclosure whichprotects the electronics to NEMA 13 (IP54) specifications.DPi32 1⁄32 DIN temperature/process U 4 to 20 mA, 0 to 1 Vdc, 0 to 5 Vdc or 0 to 10 VdcOutputs for Both Temperature and Relative Humidity U R ugged IndustrialSplashproof Enclosure NEMA 13 (IP54)UA ccurate to ±0.6°C (0 to 50°C) and ±2.5% (20 to 80% Relative Humidity)U N ew Models withBuilt-In Digital Display to Indicate Temperature and Relative Humidity U D uct Mount Kit Included with Duct Mount and Remote Probe Models U F ield Replaceable Temperature/Relative Humidity Probe (Except for Duct Mount Model)Relative Humidity Control SystemThe HX93B and HX93BD Series interface directly with OMEgA’s iSeries meters and controllers to create a complete relative humidity control system. iSeries meters and controllers feature totally programmable color displays and embedded internet connectivity.Temperature/Relative Humidity TransmittersWall, Duct Mount, and Remote Probe Models With Optional Built-In Digital DisplayOptionalHu-2OutputHX93BC or HX93BDC:4 to 20 mA for 0 to 100% RH and -30 to 75°C (-22 to 167°F)HX93BV0: 0 to 1 Vdc for 0 to 100% RH and -30 to 75°C (-22 to 167°F)HX93BV1: 0 to 5 Vdc for 0 to 100% RH and -30 to 75°C (-22 to 167°F)HX93BV2: 0 to 10 Vdc for 0 to 100% RH and -30 to 75°C (-22 to 167°F)Relative Humidity Temperature Compensation: -30 to 75°C (-22 to 167°F)Temperature Response Time: 5 seconds minimum, 30 seconds maximumRelative Humidity Response Time: 8 second typicalRepeatability: ±0.1% RH, ±0.2°C (0.4°F)Sample Rate: 1 sample every 4 seconds Housing: gray polycarbonate, NEMA rated up to 13 (IP54)Connections: Liquid-tight nylon with neoprene gland, for 2.50 to 8.00 mm (0.09 to 0.315") diameter cable; internal 6 position terminal block accepts 14 to 22 gauge wire Dimensions:HX93B(*) (without Probe):80.01 L x 82.30 W x 55.63 D mm (3.15 x 3.24 x 2.19")HX93B(*)-D (with Probe):80.01 L x 82.30 W x 183.13 D mm (3.15 x 3.24 x 7.21")TP-SP (Short Probe):ø16 x 71.88 L mm (ø0.63 x 2.83")Weight:HX93B(*): 251 g (8.9 oz) HX93B(*)-D: 256 g (9.0 oz) HX93B(*)-RP1: 352 g (12.4 oz)Display (HX93BD Series Only)Indicators: Two 4 digit backlit LCD Display Rate: 1 reading per second Display Resolution:Relative Humidity: 0.1% RH Temperature: 0.1°C (0.1°F)*For 4 to 20 mA output specify “C”, for 0 to 1 Vdc output specify “V0”, for 0 to 5 Vdc output specify “V1”, and for 0 to 10 Vdc output specify “V2”.TH-SPshort probe with M12 HX93B(*)-D duct mount transmitter.HX93BD(*)-D duct mounttransmitter with display.All models shown smaller than actual size.HX93B(*)TH-RP remote probe with 3 m (10') cable and M12 connector.C o n n (not available with duct mount models).。

may be stored in a "configuration file" on the PC for future use.After configuration, and at periodic intervals, the calibration may be veri-fied by simulating and varying the input signal over the defined range and comparing the output signal to the ideal. If calibration is necessary,the PC software is used to adjust the transmitter's digital references. Be-cause of the self-calibrating technol-ogy utilized in the TX787, the cali-bration verification interval may be significantly longer than for earlier technology transmitters.The Calibration and Configuration Software, Isolated RS232/TX787Communications Adapter and User's Guide are included in the model TX780-SOFT.by spikes and surges on field wiring entering the computer via its unpro-tected serial port.The TX787 utilize state of the art microprocessor technology and yields higher accuracy and long-term stability with lower power con-sumption than prior generation trans-mitters. The device automatically performs frequent self-testing and auto-calibration while in service, re-sulting in very stable long-term per-formance - stability greater than 0.1% of span over 12 months.To maximize traceability, each unit may be assigned a tagID, a job or a project number, the purchase order and date on which it was procured,and a message in addition to its serial number. This data, along with the selected input type and range,last calibration date, and serial num-ber are stored in the transmitter.OPERATIONEvery TX788 is factory calibrated and may be simply configured to perform the desired function using the Device Configuration screen (fig-ure 1) and the Sensor Selection screen (figure 2) shown. Just fasten the DB-9 connector to the computer's serial port and the keyed 5-pin con-nector to the port under the access cover on the top or the transmitter.There is no need to provide an ex-ternal power supply and load to the TX787's output to configure the transmitter.Units previously placed in service may have their configuration " up-loaded" to the PC. Their operating parameters may be reviewed and if necessary revised and downloaded again. All configuration parametersAPPLICATIONModel TX787 and TX788 is an ex-tremely versatile two-wire transmit-ter that may be used in any applica-tion requiring an isolated 4-20mA current loop proportional to a ther-mocouple, RTD, millivolt, milliamp,voltage, resistance or potentiometer input. Typical applications include providing accurate, stable signals to distributed control systems (DCS),supervisory control and data acqui-sition systems (SCADA), environ-mental monitoring and control sys-tems (EMCS), data acquisition and control systems (DACS) and cus-tody transfer / pipeline systems. The output of the TX787 and TX788 may also be used by an analog or digital display device.DESCRIPTIONThe TX787 is a programmable two-wire transmitter that is configured to provide an isolated 4-20mA signal in proportion to the desired range of its input signal. The TX787 accepts ther-mocouple, 2-,3-, or 4 wire RTD, po-tentiometer, and millivolt inputs. The TX788 accepts millivolt, voltage, and milliamp inputs.Configuration is performed by con-necting the transmitter to a standard PC serial port (9-pin RS232C) using an isolated interface adapter and running a user-friendly, Windows-based program. Unique PC-Only technology in the TX787 allows all configuration information to be de-fined and modified with only a PC,the interface adapter, and the trans-mitter. No loop supply, input simula-tion, or meter on the output is re-quired! The fully isolated adapter reduces the risk of expensive dam-age to the PC which can be causedTX787, TX788Programmable, Isolating Two-Wire Temperature TransmittersInstruction Sheet M-2919SPECIFICATIONS Minimum Span t/c:200C if zero offset < 6500C500C if zero offset > 6500C 1250C if zero offset > 12500C (type C only)RTD:120C if zero offset < 750C200C if zero offset < 2750C 500C if zero offset > 2750CmV:1mV if zero offset < 25mV 5mV if zero offset < 150mV 10mV if zero offset > 150mV mA:1mA if zero offset < 15mA 3mA if zero offset > 15mAVolts:0.3V if zero offset < 5V0.5V if zero offset > 5VInput ImpedenceVolts: 200k ΩMillivolts: 10m ΩMilliamps: 5Ωt/c Burnout FunctionProgrammable: upscale or downscalet/c Burnout Detection Current<0.2µARTD Excitation CurrentFilter BandProgrammable from 0 to 120%DampingProgrammable from 0.0 to 32.0secondsCommon Mode Rejection120dBOperating Temperature Range-20 to 70o CDimensions mm(inches)H 55.3 (2.10) X W 77.7 (3.06)X D 61.0 (2.40)Weight0.56lbs Warranty3 yearsLong Term StabilityBetter than 0.1% of span in 12monthsTemperature Stability<0.01% of span per 0C Isolation1000VDC input to output Minimum Output Current3.85mAMaximum Output Current22.5mALoop Voltage Drop< 9VDC at 20mA Supply Voltage Range9 - 36 VDCMaximum Effect of Change in Supply Voltage<0.002% of span per Volt Effect of Ambient Temperature Change on Cold Junction Compensation0.020C/ 0C CJC Accuracy0.50C Update Time>3 Conversions per second Turn On Time< 4 SecondsFax: (95) 203-359-7807e-mail:*****************Fax: (514) 856-6886Fax: (203) 359-7700Servicing Europe:Fax: (31) 20 6434643Fax: 49 (07056) 8540Postbus 8034, 1180 LA Amstelveen, The Netherlands Tel: (31) 20 6418405Toll Free in Benelux: 06 0993344e-mail:************Ostravska 767, 733 01 Karvina Tel: 42 (69) 6311899e-mail:***************9, rue Denis Papin, 78190 Trappes Tel:33 0130-621-400Toll Free in France: 05-4-06342e-mail:****************Daimlerstrasse 26, D-75392 Deckenpfronn, GermanyTel:49 (07056) 3017Toll Free in Germany: 0130 11 21 66e-mail:*****************25 Swannington Road,Broughton Astely, Leicestershire,LE9 6TU, England Tel: 44 (1455) 285520Fax: 44 (1455) 283912Fax: 33 0130-699-120Fax: 42 (69) 6311114P.O. Box 7, Omega Drive Irlam, Manchester,M44 5EX, England Tel: 44 (161) 777-6611Fax: 44 (161) 777-6622Toll Free in England: 0800-488-488e-mail:************976 BergarLaval (Quebec) H7L 5A1Telephone: (514) 856-6928e-mail:****************For immediate technical sevice or application assistance:Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA Customer Service: 1-800-622-2378 / 1-800-622-BEST Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA Tel: (95) 800-TC-OMEGA En Espanol: (203) 359-1660 ext. 2203Stamford, CT 06907-0047Telephone: (203) 359-1660e-mail:**************ISO 9001 CertifiedCanada:USA and Canada:Mexico and Latin America:Benelux:Czech Republic:France:Germany/Austria:United Kingdom:ISO 9002 CertifiedRETURN REQUEST/ INQUIRIESDirect all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA,PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA'S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return package and on any correspondence.The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.FOR WARRANTY RETURNS, please have the following information available BEFORE contacting OMEGA:1.P.O. number under which the product was PURCHASED,2.Model and serial number of the product under warranty, and3.Repair instructions and/or specific problems relative to the productOMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with information provided by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER,EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MER-CHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The rem-edies of purchaser set forth herein are exclusive and the total liability of OMEGA with respect to this order, whether based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the compo-nent upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or special damages.CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a "Basic Component" under 10 CFR 21(NRC), used in or with any nuclear installation or activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsi-bility as set forth in our basic WARRANTY/DISCLAIMER language, and additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.FOR NON-WARRANTY REPAIRS, consult OMEGA for current repair charges. Have the following information available BEFORE contacting O MEGA:1.P.O. number to cover the COST of the repair,2.Model and serial number of product, and3.Repair instructions and/or specific problems relative to the product.OMEGA's policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and e ngineering.OMEGA is a registered trademark of OMEGA ENGINEERING, INC.ã Copyright 1996 OMEGA ENGINEERING, INC. All rights reserved. This documentation may not be copied, photocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without prior written consent of OMEGA ENGINEERING, INC.It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.The information contained in this document is believed to be correct but OMEGA Engineering, Inc. accepts no liability for any errors it contains, and reserves the right to alter specifications without notice.WARNING: These product are not designed for use in, and should not be used for, patient connected applications.721-0709-00A 8/98Figure 1 Device ConfigurationFigure 2 Sensor SelectionTable 1INPUT CONNECTIONS (1) Accuracy includes input accuracy, output accuracy, andlinearity for any 2500C span within the conformance range at astable 250C ambient temperature; minimum accuracy over entireconformance range is + 0.1% of full conformance span.(2) For other RTD Types, consult Factory(3) α =.00385 and .003916(4) Percent of full scale rangeTable 2FIELD MOUNTINGThe TX787 is designed for installation in industrial field environments. A sealed, die-cast aluminum housing protects against corrosion, moisture, dust and electrical noise such as radio frequency (RFI) and electromagnetic (EMI) inter-ference. All circuit boards are urethane coated for environmental protection.。

308N2.5MEGSelect Rotary Position Sensors. Firmly positioned as the leader. The Honeywell Sensing and Control (S&C) Rotary Position Sensor lineup is comprised of encoders, potentiometers, and precision-crafted resolvers.Our Encoders are available in both mechanical and optical versions, and are best for potential applications requiring panel-mounted, manually-operated rotary sensing.Potentiometer Sensors utilize precision technology developed for potential military applications. Our proprietary conductive plastic offers extensive temperature range and infinite resolution, and is designed to provide precision position measurement. Resolvers are offered in pancake, brushless, and canned styles. Honeywell S&C is one of a handful of companies offering this highly precise sensor technology. But that’s what you’d expect from an industry leader.FEATURESENCODERS 510E Series.Features: Mechanical encoder • Employs 2-bit gray code with up to 36 positions or a 4-bit code • Cost effective • Eliminates need for A/D converters • Stability from -40 °C to 105 °C [-40 °F to 221 °F] • Positive detent feel • Continuouselectrical travel • Horizontal and vertical mountingBenefits: Operates as a cost-effective, high-resolution incremental switching device. The “L” channel leads the “R” channel by 90° electrically in the clockwise position. Often used in limited-space panel-mounted applications where the need for costly, front-panel displays can be completely eliminated. Potential applications include welding/heating equipment, sprinkler systems, manual controls, level control, cursor control, frequency control, temperature control, time control, and position sensing.Rotary Position Sensor Line Guidecontinued on page 7600 Series.Features: Optical encoder • Dualquadrature output generating 128 pulses per channel • Cost effective • Eliminates need for A/D converters • Stability from -40 °C to 65 °C [-40 °F to 149 °F] • Cable and printed circuit terminations available • Stainless steel shaft • Nickel-plated bushing • PC terminals and cable leads available • Outputs are TTL compatible Benefits: Enhanced life, no contactdevice capable of approximately 10 million revolutions. Outputs two square waves in quadrature at a rate of 128 pulses per channel per revolution as a standard with other resolutions down to 60 pulses available. Potential applications include robotics, welding/heating equipment, manual controls, motion sensing andcontrol, motor and flow control, low-to-high input for test and measurement, medical and instrumentation, and computer peripherals.CERMET AND WIREWOUND POTENTIOMETERS 309/409 Series.Features: Compact • Modular package • Cermet element • 1 W power rating • Enhanced performance • 409: sealed for board washing • PC and solder-hook terminalsBenefits: Reduced cost potentiometer that offers the temperature stability of a cermet element and a 1 watt power rating in a compact body. Stable over operating temperature. Potential applications include audio consoles, lighting controls, precision joysticks, telecom control systems, manual controls, medical equipment,telecommunications, and marine controls.389 Series.Features: Cermet element • 1 W power rating • Small size • Stackable – up to 6 modules • Rotary, push-pull, and momentary options • 1/4 in or 1/8 indiameter shafts • Single, dual-concentric,2 /sensingRotary Position Sensor Line GuideQuality. Reliability. Enhanced life. Global reach.Honeywell S&C rotary position sensors deliver the features you need and quality you demand. Even better, we offer worldwide support and manufacturing.Encoders: Our mechanical encoders have 2-bit and 4-bit graycode outputs for absolute electrical reference applications. Manually operated optical encoders output two square waves in quadrature. Variousresolutions, PC terminals, or cable leads are available. Potentiometers: The Honeywell S&C lineup is legendary in military and aerospace industries for reliability, durability, and enhanced life. Ourpotentiometer designs allow customization to your specs and cost requirementswithout sacrificing reliability and accuracy. Measuring linear, rotary position, or displacement, these units easily withstand exposure to harsh chemicals and high temperatures.Resolvers: These non-contact, enhanced precision rotary position sensors are available in standard styles and are fully customizable, offering remarkable specs for impressive performance./sensing 34 /sensingRotary Position Sensor Line Guide/sensing 5Rotary Position Sensor Line Guide6 /sensingor trimmer configurations • Wide range shafts, bushings, terminal styles, resistance values, tapers, and tolerances • Special detents availableBenefits: Basic construction suitsthe series for countless design options; over a billion configurations available. Potential applications include audio and lighting controls.43/RA20 Series.Features: Wirewound element • 2 W power rating • RA20 meets MIL-R-19 standards • Rugged metal construction • Nickel-plated brass shaft • Lock-style bushing available • Linear taper Benefits: Very stable over operating temperature. Potential applications include manual controls, welding, and heating.58/RA30 Series.Features: Wirewound element • 4 W power rating • RA30 meets MIL-R-19 standards • Rugged metal construction • Nickel-plated brass shaft • Lock-style bushing available • Linear taper Benefits: Designed to be stable over operating temperature. Potential applications include manual controls, welding, and heating.591 Series.Features: Compact size • Cermet element • 1 W power rating • Temperature stability • Linear taper • PC terminals • Brass shaft and bushing • Linear taperBenefits: Reduced cost potentiometer with the benefits of a cermet element. Designed to be stable over operating temperature. Potential applications include manual controls, welding and heating, telecommunications.73 Series.Features: Wirewound element • 2 W power rating • 10-turn construction• Nickel-plated brass shaft and bushings • Linear taperBenefits: Precision-type potentiometer made with a wirewound element. Offers 10 turns for enhanced resolution and accurate output. Potential applications include manual controls. CONDUCTIVE PLASTICPOTENTIOMETERS308/408 Series.Features: Compact • Modular package• Conductive plastic element• 0.5 W power rating • Nickel-platedbrass shaft and bushings • Enhancedperformance • 408: sealed for boardwashing • PC and solder-hook terminals• CW audio and linear tapers availableBenefits: Reduced cost potentiometer thatoffers 0.5 W power rating in a compactbody. Potential applications includemanual controls, audio and lightingconsoles, medical equipment, precisionjoysticks, and telecommunications.380/53/RV4 Series.Features: Conductive plastic elementdesigned to provide enhanced dynamicnoise and enhanced rotational life • 2 Wpower rating • RV4 meets MIL-PRF-94standards • 380/53: 2 in L shaft, round• RV4: 0.875 in L shaft, slotted • Solderlug terminals • CW audio and linear tapersavailableBenefits: Known as the “quiet ones.”Economical potentiometer with ruggedindustrial construction. Model 53 isavailable in special construction thataccepts a rotary switch. Potentialapplications include manual controls(joysticks, panel dials, throttles), electricvehicles, personal mobility, off-roadvehicles, forklifts, welding/heating, andtelecommunications.381 Series.Features: Conductive plastic element• 1 W power rating • Solder lug terminals• Metal case and nickel-plated brass shaftand bushings • Locking-style bushing,rotary switch, or dual section optionsavailable • Linear taperBenefits: Robust construction in alow-cost industrial package. Potentialapplications include manual and audiocontrols, and telecommunications.388 Series.Features: Conductive plastic element• 0.5 W power rating • Small size• Stackable – up to 6 modules • Rotary,push-pull, and momentary options • 1/4 inor 1/8 in diameter shafts • Single, dual-concentric, or trimmer configurations• Wide range shafts, bushings, terminalstyles, resistance values, tapers, andtolerances • Special detents availableBenefits: Basic construction suitsthe series for countless design options;over a billion configurations available.Potential applications include audio andlighting controls, precision joysticks, andtelecom control systems.392/RV6 Series.Features: Compact size • Conductiveplastic element • RV6: Designed to meetMIL-PRF-94 standards, solderability, andwashability test requirements • 0.5 Wpower rating • Nickel-plated shaft andbushings • PC and solder hook terminals• Linear taperBenefits: Molded housing offers aninternal shaft seal for moisture protection.Potential applications include medicalequipment, manual controls, audioequipment, and telecommunications.574 Series.Features: Conductive plastic element• 0.5 W power rating • Reduced mountingprofile • Quiet electrical output • Verticalmounting with support bracket • PCstyle mounting • Smooth feel • Robustconstruction • All plastic construction• Metric bushing • Linear taperBenefits: Reduced cost commercialpotentiometer with the benefits of aconductive plastic element. Potentialapplications include welding/heatingcontrols, joysticks, and manual controls.575 Series.Features: Conductive plastic element• 0.5 W power rating • Reduced mountingprofile • Quiet electrical output • Solderhook terminals for panel mounting• Smooth feel • Robust construction • Allplastic construction • Linear taperBenefits: Reduced cost commercialpotentiometer with the benefits of aconductive plastic element. Potentialapplications include welding/heatingcontrols, joysticks, and manual controls./sensing 7578 Series.Features: Conductive plastic element • 0.5 W power rating • Variable resistor technology • Low mounting profile• Quiet electrical output • Precision control • PC terminals • Nickel-plated shaft and bushing • Smooth feel • Robust construction • Linear taper • Central tap version availableBenefits: Precision-type potentiometer with low torque and very linear tapers delivers enhanced control. Potential applications include off-road vehicles, electric vehicles, marine controls, material handling, personal mobility, manual controls, telecommunications, and audio equipment.585 Series.Features: Compact size • Carbon element • 0.05 W power rating • Horizontal mount • PC terminals • Metal shaft and bushings • Linear taperBenefits: Designed to be used as alow-wattage component that can be panel mounted or PC mounted. Robust construction in a low-cost commercial package, using carbon composition elements. Potential applications include manual and audio controls, heating equipment, and telecommunications.590 Series.Features: Compact size • Conductive plastic element • 0.5 W power rating• Linear taper • PC terminals• Brass shaft and bushing • Linear taper Benefits: Reduced cost potentiometer with the benefits of a conductive plastic element. Potential applications include manual controls, lighting and audio consoles, precision joysticks, welding and heating, and telecommunications.MKV Series.Features: Conductive plastic element • Linearity (accuracy) 0.5 % or less• 1 W power rating • Servo and bushing mounting • Custom electrical travels Benefits: A cost-effective way of obtaining enhanced accuracy and enhanced life position feedback. Potential applications include valve position feedback, panel control, instrumentation, and missile finfeedback position.SensorCube Series.Features: Conductive plastic element• Linearity (accuracy) 2 % or less • 1 Wpower rating • Sealed construction• Custom electrical travelsBenefits: Cost-effective potentiometer withsealed construction. Enhanced accuracyand reliability. Potential applicationsinclude valve position feedback, panelcontrol, instrumentation, and off-roadequipment.TH100 Series.Features: Conductive plastic element• Fully sealed construction • Enhancedrotational torque • Variable resistortechnology • 0.5 W power rating • Specialelectrical and mechanical configurations,including dual tracks and D-shaped rotorholes available • Linear taperBenefits: Enhanced performance rotaryposition transducer that works well inpotential angle-management applicationssuch as control-lever sensing andequipment position feedback. Potentialapplications also include off-road vehicles,electric vehicles, marine controls, materialhandling, and personal mobility.NON-CONTACT, HALL-EFFECTPOSITION TRANSDUCERSHRS100 Series.Features: Solid-state, Hall-effecttechnology • 90° mechanical rotation• Maximum ESD sensitivity of ±7 kV• Slotted shaftBenefits: Use of magnetically coupledinformation in place of a mechanicalwiper assembly designed to provide anenhanced life and cost-effective solutionfor harsh environments that includetemperature, vibration, dither, moisture,and dirt. Potential applications includethrottle/speed position and control,inboard lever control, foot pedal position,steering position, suspension systemposition, seat and mirror position, tiltposition, gimbal position and control, andmanipulator arm position.RESOLVERSHoneywell Hawk™ 1-Inch Series.Features: Non-contact magnetictechnology • Fully-housed configurationwith bearing/shaft • Small outer diameterof 1 inch • Single speed operation(1 magnetic pole pair) • Excitationvoltage range of 2 V to 15 V • Excitationfrequency range of 2000 Hz to 5000 Hz• Transformation ratio of 0.45 or 1.0• Accuracy of ±7 arcmin • Operatingtemperature range of -50.8 °C to 93.3°C [-60 °F to 200 °F] • Meets multiplemilitary/aerospace specifications:DO-160D, MIL-STD-202G, MIL-STD-810G, MIL-STD-81963B, MIL-STD-461F; complies with space outgassingrequirement SP-R0022Benefits: Non-contact magnetictechnology eliminates mechanical contact,reducing wear and improving reliabilityand durability by enhancing operation inharsh environments (performance is notaffected by sand, dust or water). Smallouter diameter of 1 inch allows for use insize-restricted applications. Single speedoperation (1 magnetic pole pair) allowsfor cost-effective angle resolution over a360°+ range. Wide voltage range allowscustomers to standardize on a resolverthat meets their excitation voltage needs,simplifying sourcing and delivery, andsaving time. Frequency range providesa wide variety of choices with which topower the device. Transformation ratiosoffer customers two choices, increasingflexibility within the application. Accuracyenables precise motion control of weaponsystems and space positioning devices.Wide operating temperature rangeallows for use in harsh environmentsand meets standard military and spaceapplication requirements. Productdelivery up to 1.5 times faster than manycompetitive products. Customization dueto Honeywell’s manufacturing process.Global support due to Honeywell’sworldwide presence. Engineeringexpertise due to Honeywell’s 30+ years’experience providing accurate, reliable,and durable resolvers for the aerospaceand defense industries. Potentialapplications include providing absoluteposition feedback of the azimuth and/or elevation angular planes for military8 /sensingelectro-optical systems, fire control systems, gimbals, infrared systems, ordnance delivery and test equipment,as well as satellite, space station, space vehicle solar panel array and antennae positioning for optimum function.Cased-Brushless Dual Speed Series.Features: (1/10 in) 30 • 20 arcsec accuracy • Speed: 1&32 • Non-contact measurement for enhanced reliability• 360° sensing range • Multi-speed designs available for enhanced accuracies over reduced ranges • Variety of excitation voltages and frequency• Environmentally sealed and qualified to RTCA DO-160DBenefits: One-speed and multi-speed resolver and rotary transformer. Potential applications include ATOM – gunners site position (azimuth and elevation), forward looking radar, missile guidance, solar panel position, and antenna position. Cased-Brushless Single Speed Series.Features: (1/10 in) 17 • 1.25 arcminto 3.5 arcmin accuracy • Non-contact measurement for enhanced reliability• 360° sensing range • Multi-speed designs available for enhanced accuracies over reduced ranges • Variety of excitation voltages and frequency• Environmentally sealed and qualified to RTCA DO-160DBenefits: One speed, one pole pair resolver and rotary transformer. Potential applications include ATOM – gunners site position (azimuth and elevation), forward looking radar, missile guidance, solar panel position, and antenna position. Pancake-Brushless Multi-Speed Series.Features: Redundant winding • (1/10 in) 38 to 63 • 3 arcmin to 30 arcsec accuracy (low-distortion harmonic) • Speed: 12 • Non-contact measurement for enhanced reliability • 360° sensing range• Multi-speed designs available for enhanced accuracies over reduced ranges • Variety of excitation voltages andfrequency • Environmentally sealed andqualified to RTCA DO-160DBenefits: Multiple pole pairs resolver androtary transformer. Potential applicationsinclude ATOM – gunners site position(azimuth and elevation), forward lookingradar, missile guidance, solar panelposition, and antenna position.Pancake-Brushless Dual SpeedSeries.Features: Full redundancy (duplex)• (1/10 in) 92 • 30 arcsec accuracy(multispeed) • Speed: 1&64 • Non-contactmeasurement for enhanced reliability• 360° sensing range • Multi-speeddesigns available for enhancedaccuracies over reduced ranges • Varietyof excitation voltages and frequency• Environmentally sealed and qualified toRTCA DO-160DBenefits: One-speed and multi-speedresolver and rotary transformer. Potentialapplications include ATOM – gunners siteposition (azimuth and elevation), forwardlooking radar, missile guidance, solarpanel position, and antenna position.Pancake-Dual Speed Series.Features: Simple and duplex • (1/10in) 31 to 130 • 36 arcsec to 4 arcsecaccuracy (multi-speed) • Variety of speedsavailable: 1&8, 1&16, 1&32, 1&36, 2&36,1&64, 1&128 • Non-contact measurementfor enhanced reliability • 360° sensingrange • Multi-speed designs availablefor enhanced accuracies over reducedranges • Variety of excitation voltages andfrequency • Environmentally sealed andqualified to RTCA DO-160DBenefits: One-speed and multiplespeed. Potential applications includeATOM – gunners site position (azimuthand elevation), forward looking radar,missile guidance, solar panel position, andantenna position.Pancake-Multi Speed Series.Features: Simple and duplex • (1/10 in)16 to 67 • 1 arcmin to 5 arcsec accuracy• Variety of speeds available: 4, 8, 16,32, 64 • Non-contact measurement forenhanced reliability • 360° sensing range• Multi-speed designs available forenhanced accuracies over reducedranges • Variety of excitation voltages andfrequency • Environmentally sealed andqualified to RTCA DO-160DBenefits: Multi-pole pairs. Potentialapplications include ATOM – gunners siteposition (azimuth and elevation), forwardlooking radar, missile guidance, solarpanel position, and antenna position.Pancake-Single Speed Series.Features: Simple and duplex • (1/10 in)24 to 68 • 3 arcmin to 30 arcsec accuracy• Non-contact measurement for enhancedreliability • 360° sensing range • Multi-speed designs available for enhancedaccuracies over reduced ranges• Variety of excitation voltages andfrequency • Environmentally sealed andqualified to RTCA DO-160DBenefits: One-speed, one-pole pair.Potential applications include ATOM– gunners site position (azimuth andelevation), forward looking radar, missileguidance, solar panel position, andantenna position./sensing 9Sensing and Control Automation and Control Solutions Honeywell1985 Douglas Drive North Golden Valley, MN 55422 USA+1-815-235-6847/sensing 009577-4-EN IL50 GLOJuly 2011Copyright © 2011 Honeywell International Inc. All rights reserved.• DO NOT USE these products asFailure to comply with these• The information presented in thisFailure to comply with theseWarranty. Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship. Honeywell’s standard product warranty applies unless agreed to otherwise by Honeywell in writing; please refer to your order acknowledgement or consult your local sales office for specific warranty details. If warranted goods are returned to Honeywell during the period of coverage, Honeywell will repair or replace, at its option, without charge those items it finds defective. The foregoing is buyer’s sole remedy and is in lieu of all warranties, expressed or implied, including those of merchantability and fitness for a particular purpose. In no event shall Honeywell be liable for consequential, special, or indirect damages.WARNINGPERSONAL INJURYsafety or emergency stop devicesor in any other application wherefailure of the product could result inpersonal injury.instructions could result in death orserious injury.WARNINGMISUSE OF DOCUMENTATIONcatalogue is for reference only. DONOT USE this document as productinstallation information.• Complete installation, operation andmaintenance information is providedin the instructions supplied with eachproduct.instructions could result in death orserious injury.While we provide application assistancepersonally, through our literature andthe Honeywell web site, it is up to thecustomer to determine the suitability of theproduct in the application.Specifications may change without notice.The information we supply is believed tobe accurate and reliable as of this printing.However, we assume no responsibility forits use.For more information about Sensing andControl products, visit www.honeywell.com/sensing or call +1-815-235-6847*************************************308N2.5MEG。

FEATURES• Small, leaded, flat TO-92-style package allows for a compact PCB layout• Wide operating voltage range of 4.5 Vdc to 24 Vdc allows these sensors to be used in a variety of applications • Current consumption of only 5 mA max. at 4.5 Vdc for energy efficiency• Bipolar magnetics for ring magnet applications with alternating North and South poles• Robust design: Will operate up to 150°C [302°F]• RoHS-compliant materials meet Directive 2002/95/EC POTENTIAL APPLICATIONS• Industrial: Speed and RPM (revolutions per minute) sensing, tachometer, counter pickup, flow-rate sensing, brushless dc (direct current) motor commutation, motor and fan control, robotics control• Transportation: Speed and RPM (revolutions per minute) sensing, tachometer, counter pickup, motor and fan control, electric window lift, convertible roof position• Medical: Motor assemblies, medication dispensing control PORTFOLIOOther bipolar digital position sensor ICs include:• SS400 Series. SS500 Series (selected catalog listings)• SS311PT, SS411P • SS40F, SS40AF • SS51T• SS30AT, SS40A, SS50ATSensing and Internet of ThingsDESCRIPTIONThese small and versatile digital Hall-effect devices are operated by the magnetic field from a permanent magnet or an electromagnet, and are designed to respond to alternating North and South poles. The built-in regulator provides enhanced stability of operation from 4.5 Vdc to 24 Vdc supply voltage range, and internal circuitry is designed to prevent sensor damage in case the supply voltage polarity is accidentally reversed. The open-collector sinking output voltage is easily interfaced with a wide variety of electronic circuits. The SS41 is tested at both 25°C [77°F] and 125°C [257°F]. For design flexibility, these product are available in the following flat TO-92 package styles:• SS41: Straight standard leads, bulk pack • SS41-L: Straight long leads, bulk pack• SS41-T2: Formed leads, ammopack tape-in-box• SS41-T3: Straight standard leads, ammopack tape-in-box • SS41-S: Surface mount, bulk pack• SS41-SP: Surface mount, pocket tape and reelBipolar Hall-Effect Digital Position Sensor ICs:SS41, SS41-L, SS41-T2, SS41-T3, SS41-S, SS41-SP32312814Issue B2Sensing and Internet of ThingsNOTICEThese Hall-effect sensor ICs may have an initial output in either the ON or OFF state if powered up with an applied magnetic field in the differential zone (applied magnetic field >Brp and <Bop). Honeywell recommends allowing 10 us after supply voltage has reached 5 V for the output voltage to stabilize.NOTICEThe magnetic field strength (Gauss) required to cause the switch to change state (operate and release) will be as specified in the magnetic characteristics. To test the switchagainst the specified limits, the switch must be placed in a uniform magneticfield.Table 2. Performance SpecificationsNOTICEAbsolute maximum ratings are the extreme limits the device will momentarily withstand without damage to the device. Electrical and mechanical characteristics are not guaranteed if the rated voltage and/or currents are exceeded, nor will the device necessarily operate at absolute maximum ratings.Figure 5. Wiring Diagrams3Sensing and Internet of Things4Sensing and Internet of ThingsFigure 6. Mounting and Dimensional Drawings (continued)SS41-T3: Straight Standard Leads, Ammopack Tape-in-Box5Sensing and Internet of Things6Sensing and Internet of ThingsFigure 6. Mounting and Dimensional Drawings (continued)SS41-S: Surface Mount, Bulk PackArbor holePCB Land Pattern1,70PCB Land Pattern7Sensing and Internet of ThingsHoneywell Sensing and Internet of Things 9680 Old Bailes Road Fort Mill, SC 29707www. For more informationHoneywell Sensing and Internet of Things services its customers through a worldwide network of sales offices and distributors. For application assistance, current specifications, pricing or the nearest Authorized Distributor, visit or call:Asia Pacific +65 6355-2828Europe +44 (0) 1698 481481USA/Canada+1-800-537-694532320997-B-EN | B | 01/18© 2018 Honeywell International Inc. All rights reserved .Warranty/RemedyHoneywell warrants goods of its manufacture as being free of defective materials and faulty workmanship during the applicable warranty period. Honeywell’s standard product warranty applies unless agreed to otherwise by Honeywell in writing; please refer to your order acknowledgment or consult your local sales office for specific warranty details. If warranted goods are returned to Honeywell during the period of coverage, Honeywell will repair or replace, at its option, without charge those items that Honeywell, in its sole discretion, finds defective. The foregoing is buyer’s sole remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and fitness for a particular purpose. In no event shall Honeywell be liable for consequential, special, or indirect damages.While Honeywell may provide application assistance personally, through our literature and the Honeywell web site, it is buyer’s sole responsibility to determine the suitability of the product in the application.Specifications may change without notice. The information we supply is believed to be accurate and reliable as of this writing. However, Honeywell assumes no responsibility for its use.ADDITIONAL INFORMATIONThe following associated literature is available on the Honeywell web site at :• Product Line Guide • Product Range Guide • Selection Guides•Application-specific Information。

Midas®GAS DETECTOR SPECIFICATIONS Gas Monitoring SystemTransmitter DimensionSize (unit with Sensor) 5.91 (H) x 2.56 (W) x 6.02 (D) in(150 x 65 x 153 mm)Weight (unit with Sensor) 1.76 lb (0.8 kg)NF3 Pyrolyzer DimensionSize (unit with Sensor) 2.75 (H) x 2.48 (W) x 3.35 (D) in(70 x 63 x 85 mm)Weight (unit with Sensor)0.9 lb (0.41 kg)High-Temperature PFC Pyrolyzer DimensionSize (unit with Sensor) 3.9 (H) x 4.0 (W) x 5.5 (D) in(100 x 101 x 140 mm)Weight (unit with Sensor) 3 lb (1.36 kg)Power RequirementsOperating Voltage24VDC, -15 to +10%Operating Voltage withPower over Ethernet (PoE)48 VDC via PoEPower ConsumptionTransmitter Unit<5 WFind out more Toll-free: 800.538.0363SS01115-EN_V6 8/18© 2016 Honeywell International Inc.Please Note:While every effort has been made to ensure accuracy in this publication, no responsibility can be accepted for errors or omissions. Data may change, as well as legislation, and you are strongly advised to obtain copies of the most recently issued regulations, standards, and guidelines. This publication is not intended to form the basis of a contract.OP3 Pyrolyzer DimensionSize (unit with Sensor) 5.2 (H) x 2.4 (W) x 3.9 (D) in(132 x 60 x 98 mm)Weight (unit with Sensor) 2.65 lb (1.20 kg)NP1 Pyrolyzer DimensionSize (unit with Sensor) 5.02 (H) x 2.56 (W) x 5.29 (D) in(128 x 65 x 134 mm) Weight (unit with Sensor) 1.8 lb (0.81 kg)Find out more Toll-free: 800.538.0363SS01115-EN_V6 8/18© 2016 Honeywell International Inc.* M IDAS-E-LEL Cartridge carries a 2-year warranty but can be calibrated up to 5 years ** Gases require Midas PyrolyzerMidas detectors are not ETL approved for monitoring in or sampling from classified areas above 25% LELMidas Cartridge Detectable Gases Gas Name Chemical Formula Range Sensor Part Number Ammonia NH 39-100 ppm MIDAS-E-NH3ArsineAsH 318-200 ppb MIDAS-E-ASH Boron Trichloride BCl 30.72-8 ppm MIDAS-E-HCL Boron TrifluorideBF 30.72-8 ppm MIDAS-E-HFX Boron Trifluoride (Low Level)BF 30.18-2 ppm MIDAS-E-HFL Bromine Br 20.036-0.4 ppm MIDAS-E-BR2Carbon Dioxide CO 20.15-2.0%MIDAS-E-CO2Carbon Monoxide CO 9-100 ppm MIDAS-E-COX Chlorine Cl 20.18-2 ppm MIDAS-E-HAL Chlorine Dioxide ClO 20.036-0.4 ppm MIDAS-E-BR2Diborane B 2H 636-400 ppb MIDAS-E-B2H Dichlorosilane H 2Cl 2Si 0.72-8 ppm MIDAS-E-HCL Difluoromethane**CH 2F 216-240 ppm MIDAS-E-XCF Disilane Si 2H 6 1.8-20 ppm MIDAS-E-SHX Fluorine F 20.36-4 ppm MIDAS-E-HAL GermaneGeH 470-800 ppb MIDAS-E-ASH Hexafluorobutadiene**C 4F 63-40 ppm MIDAS-E-CFX Hydrogen (%LEL)H 2 6.5-100% LEL MIDAS-E-LEL*Hydrogen (ppm)H 290-1000 ppm MIDAS-E-H2X Hydrogen Bromide HBr 0.72-8 ppm MIDAS-E-HCL Hydrogen Chloride HCl 0.72-8 ppm MIDAS-E-HCL Hydrogen Cyanide HCN 1.8-20 ppm MIDAS-E-HCN Hydrogen FluorideHF 1.05-12 ppm MIDAS-E-HFX Hydrogen Fluoride (Low Level)HFL 0.18-2 ppm MIDAS-E-HFL Hydrogen Sulfide H 2S 3.6-40 ppm MIDAS-E-H2S Methane (%LEL)CH 4 6.5-100% LEL MIDAS-E-LEL*Methyl Fluoride**CH 3F 8-120 ppm MIDAS-E-XHF Nitric Oxide NO 9-100 ppm MIDAS-E-NOX Nitrogen Dioxide NO 2 1.05-12 ppm MIDAS-E-NO2Nitrogen Trifluoride**NF 3 3.6-40 ppm MIDAS-E-HFX for 00P, XHF for NP1Octofluorocyclopentene**C 5F 83-40 ppm MIDAS-E-XCF Oxygen O 20.2-25% v/v MIDAS-E-O2X OzoneO 30.065-0.7 ppm MIDAS-E-O3H Ozone (Low Level)O 30.036-0.4 ppm MIDAS-E-O3X Phosphine PH 3110-1200 ppb MIDAS-E-PH3SilaneSiH 4 1.8-20 ppm MIDAS-E-SHX Silane (Low Level)SiH 40.18-2 ppm MIDAS-E-SHL Sulfur DioxideSO 20.7-8 ppm MIDAS-E-SO2Tetra Ethyl Ortho Silicate TEOS 3.6-40 ppm MIDAS-E-TEO。

Speed Sensors Product Range GuideWith more than 50,000 products ranging from snap-action, limit, toggle, and pressure switches to position, speed, pressure, and airflow sensors, Honeywell has one of the broadest sensing and switching portfolios.Honeywell sensor, switch, and control components are tailored to exact specifications for stronger performance, longer productivity, and increased safety. Enhanced accuracy and durability are built into every part, improving output and endurance. For our customers, this can reduce expenditures and operational costs. Our global footprint and channels help to competitively price such components for your chosen application and provide immediate technical support.While Honeywell’s switch and sensor solutions are suitable for a wide array of basic and complex applications, our custom-engineered solutions offer enhanced precision, repeatability, and ruggedness. We offer domain knowledge and technology resources, along with a close working relationship, to develop and deliver cost-effective, individually tailored solutions. Whether clean-slate development or simple modifications to an existing design are needed, our expertly engineered solutions help to meet the most stringent requirements with world-class product designs, technology integration, and customer-specific manufacturing.Global service, sourcing, and manufacturing. Industry-leading engineers. Value-added assemblies and solutions. A one-stop, full-service, globally competitive supplier.For innovation that’s well apart, there’s only HoneywellTable of ContentsMagnetoresistive Sensor ICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3Hall-effect Digital Sensor ICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5Hall-effect Digital and Linear Sensor ICs . . . . . . . . . . . . . . . . . . . . . . . . . . .6Value Added Magnetic Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8Active Speed Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-10Passive Speed Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113NanopowerSeriesStandardPowerSeries2SS52MSeriesVF401APS00BDescription omnipolar MRsensor IComnipolar MRsensor IComnipolar MRdigital sensor IC2-wire MRfine pitch ringmagnet sensor IChigh resolutionmagneticdisplacementMagnetic Sensors |Magnetoresistive Sensor ICs1Dimensions:• SOT-23: 2,8 mm x 2,9 mm [0.11 in x 0.11 in]• Flat TO-92-style: 3,0 mm x 4,0 mm [0.12 in x 0.16 in] (not including leads)• VF-401 flat TO-92-style: 3,0 mm x 4,06 mm [0.12 in x 0.16 in] (not including leads)• SOT-89B: 4,2 mm x 4,5 mm [0.16 in x 0.18 in]• U-Pack: 4,5 mm x 4,5 mm [0.18 in x 0.18 in] (not including leads)• SOIC-8: 4,9 mm x 6,0 mm [0.19 in x 0.24 in]SL353SS30AT,SS40A,SS50ATSS311PT,SS411PSS340RT,SS440RSeriesDescriptionmicropower omnipolarHall-effect digitalsensor IClow-cost bipolarHall-effect digitalsensor IClow-cost bipolarHall-effect digital sensorIC with built-in pull-uplow-cost unipolarHall-effect digitalsensor ICFeaturescombined with very lowaverage current reducespower consumptionspeed capability, reversepolarity protectionlow voltage, enhancedsensitivityNorth pole (SS340RT)or South pole (SS440R),multiple magneticsensitivities (high,medium, and low) Magnetic Sensors |Hall-effect Digital Sensor ICs1Dimensions:• SOT-23: 2,8 mm x 2,9 mm [0.11 in x 0.11 in]• Flat TO-92-style: 3,0 mm x 4,0 mm [0.12 in x 0.16 in] (not including leads)• SOT-89B: 4,2 mm x 4,5 mm [0.16 in x 0.18 in]5SS345PT, SS445PSS351AT, SS451A, SS551ATSS360NT , SS360ST , SS360ST-10K, SS460S, SS460S-T2 VF360NT , VF360ST , VF460SSS360PT, SS460P, SS460P-T2unipolar Hall-effect digital sensor IC with built-in pull-up resistor low-cost omnipolarHall-effect digital sensor IC high sensitivity, latching Hall-effect digital sensor IC high sensitivity, latching Hall-effect digital sensor IC high sensitivity latching digital Hall-effect sensor IC with built-in pull-up resistor pole (SS345PT) or a South pole (SS445P)protection, typical operating point of 85 G at 25°C [77°F]no chopper stabilizationstandard for potential use in automotive applications, fastest response time in its class class, no chopper stabilization, operates from only 30 Gausstypical, at 25°C [77°F]Magnetic Sensors |Hall-effect Digital and Linear Sensor ICsDigitalVF526DTLinearSS490 SeriesSS39ET, SS49E, SS49E-F, SS49E-L, SS49E-T2, SS49E-T3, SS59ET1Dimensions:• 4-Pin SIP: 3,6 mm x 5,1 mm [0.14 in x 0.20 in]• SOT-89B: 4,2 mm x 4,5 mm [0.16 in x 0.18 in]• Flat TO-92-style:3,0 mm x 4,0 mm [0.12 in x 0.16 in] (not including leads)7Series103SR (digital)103SR (linear)Magnetic Sensors | Value AddedSeries SR16/SR17SR3SR4Description low-cost Hall-effect vane sensor Hall-effect digital position sensor magnetoresistive digitalMagnetic Sensors |Value Added9Series SNG-Q SNDH-T SNDH-HDescription quadrature speed and direction quadrature speed and direction single Hall-effect speed sensorFeaturesplatform-based approachenables cost-competitivenessand mechanical and electricalconfigurability; designed forpotential applications whereenhanced accuracy is required todetect small target featuresoffset self calibration, short circuitand reverse voltage protection,low jitter output, near zero speedavailable, zero speed sensingversions available, range of con-nector options Speed Sensors |ActiveSpeed Sensors |ActiveSeries584XXFeaturesproduces constant amplitude output signals suitable for direct use in many digital andlogic control applications, internal digital signal conditioningSeriesLCZZH10Featuresomni-directional sensor to target, low power consumption, zero speed, digital outputomni-directional sensor to target, low powerconsumption, zero speed, digital output11SeriesVRS General PurposeVRS Hazardous LocationVRS High OutputDescription/potential applicationsused where medium to high speeds or in electrically noisy environments with relatively small air gaps existused where explosion-proof or intrinsically safe sensors are requiredused where higher output voltages are needed, perform best at low to mediumspeeds with medium to high impedance loads (sealed front-end versions for use where the sensor is exposed to fluids, lubricants or adverseSeriesVRS High ResolutionVRS High TemperatureVRS Power OutputDescription/potential applicationsused where precise timing pulse is required, and/or fine pitch gears are usedused where the sensor is exposed to temperatures up to 260ºC [450ºF] (sealed front-end versions for use where the sensor is exposed to fluids, lubricants or adverse used where driving lowresistance loads at large air gaps is required, and larger actuators are usedSpeed Sensors |PassiveWarranty/RemedyHoneywell warrants goods of its manufacture as being free of defective materials and faulty workmanship during the applicable warranty period . Honeywell’s standard product warranty applies unless agreed to otherwise by Honeywell in writing; please refer to your order acknowledgement or consult your local sales office for specific warranty details . If warranted goods are returned to Honeywell during the period of coverage, Honeywell will repair or replace, at its option, without charge those items that Honeywell, in its sole discretion, finds defective . The foregoing is buyer’s sole remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and fitness for a particular purpose. In no event shall Honeywell be liable for consequential, special, or indirect damages.While Honeywell may provide application assistance personally, through our literature and the Honeywell web site, it is buyer’s sole responsibility to determine the suitability of the product in the application .Specifications may change without notice . The information we supply is believed to be accurate and reliable as of this writing . However, Honeywell assumes no responsibility for its use .005911-11-EN IL50 GLO Printed in USA May 2017© 2017 Honeywell International Inc . All rights reserved .Find out moreTo learn more about Honeywell’s sens-ing and switching products, call +1-815-235-6847, email inquiries to *********************, or visit Honeywell Sensing and Internet of Things 9680 Old Bailes Road Fort Mill, SC 29707 honeywell .com。