8PC2-6技术规格书

- 格式:doc

- 大小:328.00 KB

- 文档页数:23

HT46R12AA/D 型八位OTP 单片机盛群知识产权政策专利权盛群半导体公司在全球各地区已核准和申请中之专利权至少有160件以上,享有绝对之合法权益。

与盛群公司MCU 或其它产品有关的专利权并未被同意授权使用,任何经由不当手段侵害盛群公司专利权之公司、组织或个人,盛群将采取一切可能的法律行动,遏止侵权者不当的侵权行为,并追讨盛群公司因侵权行为所受之损失、或侵权者所得之不法利益。

商标商标权权盛群之名称和标识、Holtek 标识、HT-IDE 、HT-ICE 、Marvel Speech 、 Music Micro 、 Adlib Micro 、 Magic V oice 、 Green Dialer 、 PagerPro 、 Q-V oice 、 Turbo V oice 、 EasyV oice 和 HandyWriter 都是盛群半导体公司在台湾地区和其它国家的注册商标。

著作权Copyright © 2007 by HOLTEK SEMICONDUCTOR INC.规格书中所出现的信息在出版当时相信是正确的,然而盛群对于规格内容的使用不负责任。

文中提到的应用其目的仅仅是用来做说明,盛群不保证或不表示这些应用没有更深入的修改就能适用,也不推荐它的产品使用在会由于故障或其它原因可能会对人身造成危害的地方。

盛群产品不授权使用于救生、维生器件或系统中做为关键器件。

盛群拥有不事先通知而修改产品的权利,对于最新的信息,请参考我们的网址; HT46R12A技术相关信息· 工具信息· FAQs· 应用范例-HA0004S HT48 & HT46 MCU UART的软件实现方法-HA0005S HT48 & HT46 MCU 用软件执行I2C总线的控制功能的方法-HA0011S HT48 & HT46 MCU 键盘扫描程序-HA0013S HT48 & HT46 MCU LCM接口设计-HA0101S HT46R12在电磁炉中的应用特性•工作电压:f SYS=4MHz:2.2V~5.5Vf SYS=8MHz:3.3V~5.5V•最多可有17个双向输入/输出口•2组8位可编程定时/计数器,具有溢出中断和7级预分频器•1组可编程脉冲发生器输出,带一组8位计数器,可设置预分频,输出电平可设置高或是低有效•内置晶体和RC振荡电路•看门狗定时器•2048×14程序存储器ROM•88×8数据存储器RAM •具有PFD功能,可用于发声•HALT和唤醒功能可降低功耗•在V DD=5V,系统频率为8MHz时,指令周期为0.5µs•8层硬件堆栈•4通道9位解析度的A/D转换器•两组比较器,可发生中断•位操作指令•查表指令,表格内容字长14位•63条指令•指令执行时间为1或2个指令周期•低电压复位功能•24-pin SKDIP/SOP封装概述HT46R12A是8位高性能精简指令集单片机,专门为需要A/D转换的产品而设计,例如传感器信号输入。

ESMERALDAS II(厄瓜多尔)热电项目12PC2-6B型柴油机台架交货试验大纲ESMERALDAS II(Ecuador) Thermal Power Plant Project Plan of Bench Test and Delivery for 12PC2-6B Engine编号:FILE NO.:SC2712SY03版次:EDITION NO.:02编制:工艺:Prepared by: Technology:校对:装配试验厂:Checked by: Assembly & Test Workshop 审核:检验部:Reviewed by: Inspection Dept:审定:标准化:Authorized by: Standardization:批准:Approved by:陕西柴油机重工有限公司Shaanxi Diesel Engine Heavy Industry CO., LTD二○一二年八月Oct, 2012ESMERALDAS II(厄瓜多尔)热电项目12PC2-6B型柴油机台架交货试验大纲ESMERALDAS II(Ecuador) Thermal Power Plant Project Plan of Bench Test and Delivery for 12PC2-6B Engine陕西柴油机重工有限公司:SHAANXI DIESEL HEA VY INDUSTRY CO.,LTD:用户代表:USER DEPUTY:陕西柴油机重工有限公司Shaanxi Diesel Engine Heavy Industry CO., LTD二○一二年八月Oct,20121. 总则Generals1.1 本大纲适用于ESMERALDAS II期热电项目12PC2-6B型柴油机在陕西柴油机重工有限公司进行的台架交货试验。

This plan shall be applicable to the bench test and delivery for 12PC2-6B engines for ERALDAS II thermal power plant project at SXD.1.2 本大纲的编制参照:While preparing this plan, referrences are made to the following: 《ESMERALDAS II热电项目柴油发电机组技术规格书》及技术协议Specifications for diesel engine of ESMERALDAS II thermal power plant and the Technical agreement.MDT法国的技术说明书及有关技术文件The technical instructions and relevant documentations from MDT French.《往复式内燃机性能》ISO3046ISO 3046 Performance of reciprocal internal-combustion engine《船用柴油机技术条件》CB/T 3253-1994CB/T 3253-1994 Technical conditions for marine-purpose engines《船用柴油发电机组通用技术条件》GB/T13032-2010GB/T13032-2010 General technical conditions for marine-purpose diesel genset《机械振动的测量与评定》ISO 8528-9-1998ISO 8528-9-1998 Messurement and evaluation of mechanical vibrations《包络面法测量空气噪声》ISO 8528-10-1998ISO 8528-9-1998 Measurement of airborne noise by the enveloping surface method 2. 12PC2-6B型柴油机主要技术参数:Major technical parameters of 12PC2-6B engine2.1旋向(面向输出端朝前端看):顺时针Rotation direction (when viewed facing the output end, towards the front end): clockwise2.2 型式:V型、四冲程、不可逆转、直接喷射、涡轮增压、两级空冷、压缩空气起动。

二氧化氯发生器技术规格书一、技术参数1. 设备类型:二氧化氯发生器2. 发电量范围:根据需求可定制不同规格的发电量3. 发电效率:≥95%4. 二氧化氯浓度:≥0.8%5. 设备电源:交流电供电,电压可根据需求定制6. 控制方式:自动控制,可根据需求定制自动化程度7. 设备材质:主要由不锈钢材料制成,抗腐蚀性能优良8. 设备寿命:≥10年9. 安全性能:设备应具备过压、过流、过温等保护功能,确保操作人员和设备安全二、设备结构1. 主体结构:采用模块化设计,包括发电单元、电解槽、电解液循环系统、控制系统等模块2. 发电单元:由发电池组成,能够稳定高效地产生二氧化氯气体3. 电解槽:容纳电解液的容器,具备良好的密封性和耐腐蚀性能4. 电解液循环系统:通过泵等设备将电解液循环输送到电解槽中,保证电解液的充分循环并维持稳定性5. 控制系统:利用PLC或微处理器控制设备的运行,包括开关控制、参数设定、报警等功能三、操作要求1. 设备应具备简单易懂的操作界面,方便操作人员使用和维护2. 设备运行过程中应稳定可靠,监测和报警系统应及时反馈设备运行情况和异常情况,确保设备安全运行3. 发电量和二氧化氯浓度应可根据实际情况进行调节,满足不同水处理需求4. 设备运行时应低噪音、低振动,不对环境造成污染和影响四、维护保养要求1. 设备应定期进行维护保养,清洁电解槽和电解液循环系统,检查设备运行状况并及时处理故障2. 设备零部件的更换和维修应方便快捷,不影响整个设备的正常运行3. 设备应具备完善的故障诊断和远程监控功能,方便远程维护和故障排除以上是二氧化氯发生器技术规格书的基本内容,具体规格书还需要根据实际需求进行详细定制。

2,6二甲基苯硫酚执行标准

2,6-二甲基苯硫酚是一种重要的有机物质,为了保障公众健康与安全,需要制定相关的执行标准。

据此,现制定以下2,6-二甲基苯硫酚执行标准:

1、名称:2,6-二甲基苯硫酚

2、化学式:C8H10S

3、相对分子质量:138.23

4、技术指标:

外观:白色至淡黄色晶体或粉末

含量(以干基计):≥99.0%

熔点:60℃~63℃

水分:≤0.5%

铁:≤10ppm

重金属:≤10ppm

5、用途:2,6-二甲基苯硫酚是用作农药杀虫剂、微生物药物和染料的重要原料;制备过程中也可用作催化剂。

6、贮存:应存放在阴凉干燥处,远离火源和氧化剂。

7、包装:采用铝箔袋包装,每袋净重25kg。

本执行标准自发布之日起实行,有关单位和人员必须遵守,如有违反行为将面临法律责任。

TB-02规格书版本V1.0版权©2019免责申明和版权公告本文中的信息,包括供参考的URL地址,如有变更,恕不另行通知。

文档“按现状”提供,不负任何担保责任,包括对适销性、适用于特定用途或非侵权性的任何担保,和任何提案、规格或样品在他处提到的任何担保。

本文档不负任何责任,包括使用本文档内信息产生的侵犯任何专利权行为的责任。

本文档在此未以禁止反言或其他方式授予任何知识产权使用许可,不管是明示许可还是暗示许可。

文中所得测试数据均为安信可实验室测试所得,实际结果可能略有差异。

蓝牙联盟成员标志归蓝牙联盟所有。

文中提到的所有商标名称、商标和注册商标均属其各自所有者的财产,特此声明。

最终解释权归深圳市安信可科技有限公司所有。

注意由于产品版本升级或其他原因,本手册内容有可能变更。

深圳市安信可科技有限公司保留在没有任何通知或者提示的情况下对本手册的内容进行修改的权利。

本手册仅作为使用指导,深圳市安信可科技有限公司尽全力在本手册中提供准确的信息,但是深圳市安信可科技有限公司并不确保手册内容完全没有错误,本手册中的所有陈述、信息和建议也不构成任何明示或暗示的担保。

文件制定/修订/废止履历表版本日期制定/修订内容制定核准V1.02019.11.28首次制定谢一骥目录一、产品概述 (5)二、电气参数 (7)三、外观尺寸 (9)四、管脚定义 (10)五、原理图 (12)六、设计指导 (12)七、回流焊曲线图 (15)八、包装信息 (16)九、联系我们 (16)一、产品概述TB-02智能照明模块是一款基于TLSR8250F512芯片设计的符合BT5.0低功耗Tmall Genie Mesh的蓝牙模块;该模块支持天猫精灵直接控制且拥有蓝牙mesh组网功能的蓝牙模块;设备之间通过对等星型网络通讯,采用蓝牙广播进行通讯,可保证多设备情况下响应及时。

它主要应用于智能灯控,可满足低功耗、低延时、近距离无线数据通信的要求。

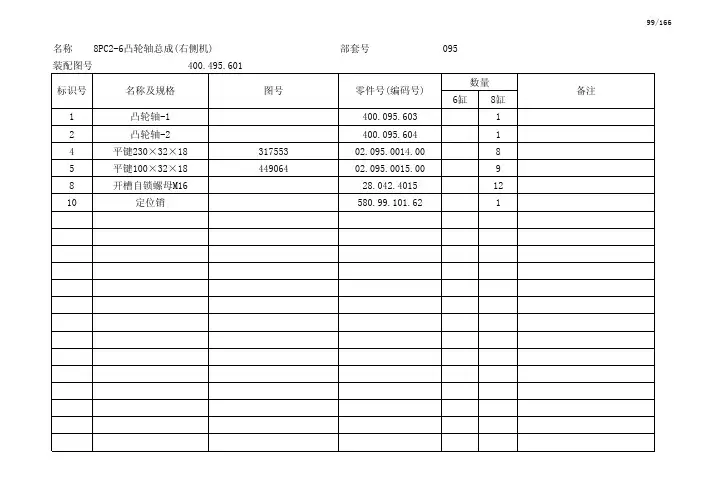

号名称8PC2-6凸轮轴总成(右侧机)部套号095装配图400.495.601标识号名称及规格图号零件号(编码号)数量备注6缸8缸1凸轮轴-1400.095.60312凸轮轴-2400.095.60414平键230×32×1831755302.095.0014.0085平键100×32×1844906402.095.0015.0098开槽自锁螺母M1628.042.40151210定位销580.99.101.62199/166号名称凸轮轴附加轴承部套号096装配图015327/02标识号名称及规格图号零件号(编码号)数量备注6缸8缸1轴承体11045802.096.001200112上半轴瓦307988/501.032.0102.00113下半轴瓦307989/501.032.0104.00116铰制孔螺栓M14×65NFE111500.015.1406.5844Q/SC304-80 M14×659螺钉NFE2711099.001.1016.0311Q/SC110-82 M16×35101/166102/166号名称凸轮轴推力轴承(不可逆转)部套号096装配图05437/3标识号名称及规格图号零件号(编码号)数量备注6缸8缸401右轴承103289/202.096.0401.0011314密封圈AN61NSE6.500.652.6270.6311Q/SC361-79 AN61322支撑圈41608102.050.0322.0011425轴瓦30665302.096.0425.001199调整垫片400.096.01211427调整垫片400.096.0091组1组428槽型螺母M42×2400.096.0101197垫圈405817/202.050.0097.001198推力球轴承“SKF”NO-5221799.505.2085.2211GB/T301-84 38217103/166104/166号装配图09344/4标识号名称及规格图号零件号(编码号)数量备注6缸8缸5搭接板31209102.097.0015.0036垫片310949/102.097.0006.0027端部垫片42782802.097.0007.0028上部纵向垫片105746/102.097.0301.00112下部纵向垫片105747/102.097.0401.00116垫片411064/100.683.2501.21617垫片454865219垫片φ13×20 δ=2NSE6.51100.661.1320.03122Q/SC363 13×20×2 25安全阀98.655.2020.032号装配图09344/4标识号名称及规格图号零件号(编码号)数量备注6缸8缸1-285钢丝螺套12×1.75C18NSE1.29116Q/SC339 12×1.75C18 2-285钢丝螺套12×1.75C18NSE1.29132Q/SC339 12×1.75C18 4-285钢丝螺套12×1.75C18NSE1.29116Q/SC339 12×1.75C18 5搭接板31209102.097.0015.0046垫片310949/102.097.0006.0037端部垫片42782802.09.0007.00210上部纵向垫片105746/102.097.0303.00114下部纵向垫片105747/102.097.0403.00116垫片411064/100.683.2501.21817垫片454865219垫片13×20 δ=2NSE6.51100.661.1320.03162Q/SC363 13×20×2 22顶环41106502.097.0283.00624过渡法兰2168902107/166号名称凸轮轴传动机构罩壳总成部套号100装配图015571/01标识号名称及规格图号零件号(编码号)数量备注6缸8缸2上罩壳014664/0102.100.0064.00113法兰450154/0002.100.0054.00114垫片450155/0002.100.0055.00116垫片450158/0002.100.0058.001110密封条 ø6 L1100NSE6.53200.658.06.110.311Q/SC362-79 6×110019垫片12NFE21.35100.651.12.17.4066Q/SC135-84 12×17×120垫片16NFE21.35100.651.16.22.401212Q/SC135-84 16×22×1108/166109/166号名称起动停车辅助传动机构(喷油泵控制辅助机构)部套号103装配图015058/1标识号名称及规格图号零件号(编码号)数量备注6缸8缸1本体101438/202.103.0001.00112盖板31759502.103.0195.00113盖板31759602.103.0196.00114盖板40933402.103.0110.00115盖板30392202.103.0111.00117活塞31671102.103.0047.00118活塞30392302.103.0112.001110螺塞40933302.103.0107.002211螺塞M18×1.5NFE2958100.060.18.10.0511Q/SC129-79 M18×1.512螺塞M22×1.5NFE2958100.060.22.10.0511Q/SC129-79 M22×1.514垫片18×24×1NFE2135100.651.18.24.4011Q/SC135-84 18×24×115垫片22×30×1NFE2135100.651.22.30.4011Q/SC135-84 22×30×116垫片12×17×1NFE2135100.651.12.17.4022Q/SC135-84 12×17×1号名称起动停车辅助传动机构(起动时,燃油齿条拉杆限制)部套号103装配图015058/1,015566/00标识号名称及规格图号零件号(编码号)数量备注6缸8缸17垫片14×19×1NFE2135100.651.14.19.4011Q/SC135-84 14×20×118垫片408103/100.685.090.21.11119垫片40810602.103.0027.001122密封圈AN35NSE6.500.652.35.53.7611Q/SC361-79 AN3524顶推螺钉408104/102.103.0025.002225止推螺钉44918002.103.0055.0011以下是015566/00中的件号3支架160920160920114螺钉44936902.102.0208.00115螺母44937099.110.20.15.031120放气孔过渡接头400.103.630111千斤顶Mecman 99.720.5346.06112螺塞Mecman 99.016.2523.0111号名称进气管总成部套号125装配图015645/00标识号名称及规格图号零件号(编码号)数量备注6缸8缸1垫片411620/102.125.0024.00682半止推环20671202.125.0044.00223卡圈总成10367202.525.8045.00574端盖11035802.525.8088.00115螺钉M18×45400.125.013243210螺塞M14×1.5Q/SC129-197911Q/SC129-79 M14×1.514密封圈 ø12 Di=348NSE653100.653.348.0.601216Q/SC36279 12×34815垫片14×19×1NFR9392000.651.14.19.4011Q/SC135-79 14×20×116夹紧环21269002.125.0021.001117半止推环31474102.125.0015.004418螺栓M12×150400.125.014121219螺塞M18×1.500.060.18.10.0511Q/SC129-79 M18×1.520垫片18×24×100.651.18.24.4011Q/SC135-79 18×24×121螺塞M42×200.060.42.10.0511Q/SC129-79 M42×222垫片42×52×1.000.651.42.52.4011Q/SC135-79 42×52×1.0114/166115/166号名称排气管总成部套号128装配图016651,016653标识号名称及规格图号零件号(编码号)数量备注6缸8缸1支架110947110947453支承端盖21655802.128.9004.00114密封垫片44600702.128.0197.00685螺钉454591/102.128.0491.0024326支架21436302.128.0463.00688膨胀接头21581502.128.9007.00689FLEX密封垫片45120900.662.319.001121610卡箍11029699.670.000.005121613角钢120×120×121109651109651114角钢120×120×131109661109661115角钢120×120×141109671109671216垫块4541944541946817隔热板453770453770243218弹簧板45419502.128.0674.006819护帽4537694537694421高温螺栓M16×70NSE1.18300.076.1607.0244Q/SC303-79 M16×70-T116/166号名称柴油机冷却水总管部套号130装配图014753/03标识号名称及规格图号零件号(编码号)数量备注6缸8缸12垫片 (厚2mm)44803400.689.1302.216813垫片 (厚3mm)400.130.604221进水总管21502502.530.8779.00111-4接头BM18×1.5 R=45L=40Q/SC123-198033Q/SC123-80 BM18×1.5 R=45L3=401-5垫片18×24×1Q/SC135-198411Q/SC135-84 18×24×11-6螺塞M18×1.5Q/SC129-197911Q/SC129-79 M18×1.5119/166120/166号名称增压器冷却水出水管系部套号130装配图016769标识号名称及规格图号零件号(编码号)数量备注6缸8缸3管夹400.130.624114管夹400.130.625118孔板454723454723229孔板454440/01454440/011110垫片45412800.687.075.22.76620螺塞M18×1.500.060.18.10.0533Q/SC129-79 M18×1.5 21垫片18×24×100.651.18.24.4033Q/SC135-84 18×24×1121/166122/166号名称增压器冷却水出水管系部套号130装配图016798标识号名称及规格图号零件号(编码号)数量备注6缸8缸8管夹4546944546942213方垫片PN6 B4000.672.06.15.2211Q/SC364-79 PN6 B4014密封圈AN2900.652.29.53.6822Q/SC361-79 AN2915密封圈AN3400.652.34.53.6811Q/SC361-79 AN3416螺塞M18×1.500.060.18.10.0511Q/SC129-79 M18×1.5 17垫片18×24×100.651.18.24.4011Q/SC135-84 18×24×118套管ø25×5×20400.130.62366123/166124/166号名称柴油机冷却水管部套号130装配图016799/01标识号名称及规格图号零件号(编码号)数量备注6缸8缸16管夹4545094545093317垫片45450802.130.1108.001118垫片45451102.130.1111.001120垫片PN16 A12500.670.16.80.1233Q/SC364-79 PN10 A12521螺母42973199.110.48.300.12222螺塞M24×1.500.060.24.10.0511Q/SC129-79 M24×1.5 23螺塞M18×1.500.060.18.10.0555Q/SC129-79 M18×1.5 24垫片24×32×1.500.651.24.32.4011Q/SC135-84 24×32×1.525垫片18×24×100.651.18.24.4055Q/SC135-84 18×24×1125/166126/166号装配图015662/02,015663/00标识号名称及规格图号零件号(编码号)数量备注6缸8缸1滑油总管(6PC2-6专用)111062/001滑油总管(8PC2-6专用)110294/0002.534.8082.0016滑油进油管(前端)110321/0002.534.8083.0011 7滑油连接管215845/0002.534.8077.0011 8上部滑油连接管215846/0002.534.807911 9外轴承供油管44827102.534.8471.0011 10第一档轴承进油管317774/0002.534.8062.001113出口朝向滤器,轴承和辅助机构滑油管318149/0002.534.8063.001114滤器进油管318150/0002.534.8064.0011 15调速器驱动机构滑油管215836/0002.534.8069.0011 16回油管(至罩壳)215838/0002.534.8075.0011 18超速安全装置供油管317776/0002.534.8061.0011号装配图015662/02,015663/00标识号名称及规格图号零件号(编码号)数量备注6缸8缸25中间小齿轮供油管215494/0002.534.8066.0011 26凸轮轴前端轴承油管215837/0002.534.8071.0011 27连接块454250/00454250/0011 28连接块出油管319102/00319102/0011 29凸轮轴轴承润滑油管21511702.534.8187.0011 33空气分配器供油管428127/102.534.8107.0011 34支架21549502.534.8067.0011 35压板400.134.60711 38支架318152/0002.534.8065.0011 39管夹451119/0002.134.0272.0022 40法兰215497/0002.134.0279.0011 42法兰44827500.632.123.88111 43"AUXIM"放气旋塞31172599.650.40.65.1211号装配图015662/02,015663/00标识号名称及规格图号零件号(编码号)数量备注6缸8缸44进口接头419871/102.134.0057.012246双接头42511603.134.0006.001151管接头12-10/8-13CYL NSE6.3299.621.10.129.111Q/SC356-79 12-10/8-13CYL 52管接头12-10/12-117CYL NSE6.3299.621.1015.9111Q/AIG101.1-88 G10/G3/8" 55空心螺钉418480/399.641.224.0032256空心螺钉401738/399.641.184.0078857空心螺钉410517/499.631.144.10.45559空心螺钉407410/199.641.122.0052261保持板215840/0002.134.0280.001198支撑板31815402.134.0278.0011101旋塞S20-3/8AUXZM99.650.4065.5111宁波埃美坷J11W-16T(302)3/8" DN10 黄铜截止阀102双接头44458502.134.0258.0011 106螺塞400.130.26911号装配图015662/02,015663/00标识号名称及规格图号零件号(编码号)数量备注6缸8缸107垫片27×35×1Q/SC135-198411Q/SC135-84 27×35×1 108螺塞M14×1.5Q/SC129-197911Q/SC129-79 M14×1.5 81螺塞M22×1.5NFE2958100.060.22.10.0511Q/SC129-79 M22×1.5 82螺塞M18×1.5NFE2958100.060.18.10.0577Q/SC129-79 M18×1.5 84垫片41257700.682.123.12.13385垫片42273700.672.10.08.121186衬垫NSE6.55100.672.16.07.121187O型圈AN20NSE6.500.652.20.35.632735Q/SC361-79 AN20 88O型圈AN30NSE6.500.652.30.53.6379Q/SC361-79 AN30 89垫片30×38NFR93.92000.651.30.38.4011Q/SC135-84 30×38×1 90垫片22×29NFR93.92000.651.22.30.401111Q/SC182-79 A22×29 91垫片18×24NFR93.92000.651.18.24.003232Q/SC135-84 18×24×1 92垫片16×22NFR93.92000.651.16.22.4022Q/SC135-84 16×22×1 93垫片14×19NFR93.92000.651.14.19.401313Q/SC135-84 14×20×1 94垫片12×17NFR93.92000.651.12.17.4022Q/SC135-84 12×17×1131/166。

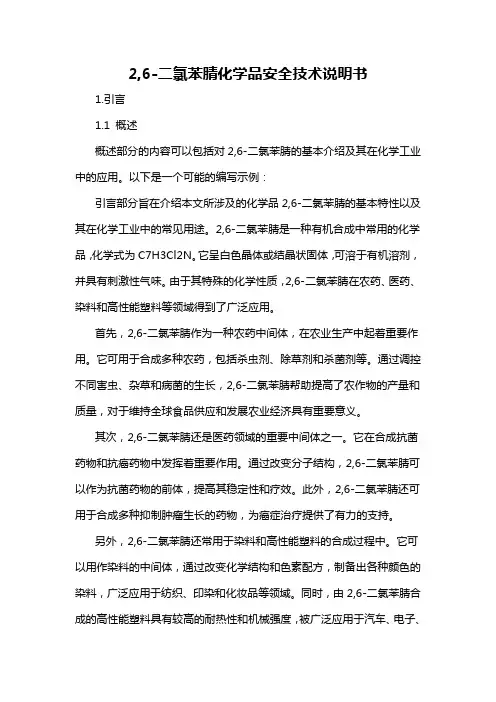

2,6-二氯苯腈化学品安全技术说明书1.引言1.1 概述概述部分的内容可以包括对2,6-二氯苯腈的基本介绍及其在化学工业中的应用。

以下是一个可能的编写示例:引言部分旨在介绍本文所涉及的化学品2,6-二氯苯腈的基本特性以及其在化学工业中的常见用途。

2,6-二氯苯腈是一种有机合成中常用的化学品,化学式为C7H3Cl2N。

它呈白色晶体或结晶状固体,可溶于有机溶剂,并具有刺激性气味。

由于其特殊的化学性质,2,6-二氯苯腈在农药、医药、染料和高性能塑料等领域得到了广泛应用。

首先,2,6-二氯苯腈作为一种农药中间体,在农业生产中起着重要作用。

它可用于合成多种农药,包括杀虫剂、除草剂和杀菌剂等。

通过调控不同害虫、杂草和病菌的生长,2,6-二氯苯腈帮助提高了农作物的产量和质量,对于维持全球食品供应和发展农业经济具有重要意义。

其次,2,6-二氯苯腈还是医药领域的重要中间体之一。

它在合成抗菌药物和抗癌药物中发挥着重要作用。

通过改变分子结构,2,6-二氯苯腈可以作为抗菌药物的前体,提高其稳定性和疗效。

此外,2,6-二氯苯腈还可用于合成多种抑制肿瘤生长的药物,为癌症治疗提供了有力的支持。

另外,2,6-二氯苯腈还常用于染料和高性能塑料的合成过程中。

它可以用作染料的中间体,通过改变化学结构和色素配方,制备出各种颜色的染料,广泛应用于纺织、印染和化妆品等领域。

同时,由2,6-二氯苯腈合成的高性能塑料具有较高的耐热性和机械强度,被广泛应用于汽车、电子、电器等领域。

综上所述,2,6-二氯苯腈是一种重要的化学品,具有广泛的应用领域。

理解其化学性质和安全使用技术对于化学工业的从业人员和相关领域的研究者至关重要。

接下来的文章将进一步介绍2,6-二氯苯腈的化学性质和安全使用技术,以提高人们对该化学品的认识和了解,促进其在相关领域的科学合理应用。

文章结构部分的内容可以按照以下方式撰写:文章结构文章主要分为引言、正文和结论三个部分。

1. 引言引言部分主要介绍了本文的背景和目的,通过概述和引出要讨论的2,6-二氯苯腈化学品的安全技术说明书内容,让读者对文章主题有一个初步的了解。

DDR2 SDRAM SODIMMMT16HTF12864HZ – 1GB MT16HTF25664HZ – 2GBMT16HTF51264HZ – 4GB Features•200-pin, small-outline dual in-line memory module (SODIMM)•Fast data transfer rates: PC2-3200, PC2-4200,PC2-5300, or PC2-6400•1GB (128 Meg x 64), 2GB (256 Meg x 64) or 4GB (512Meg x 64)•V DD = V DDQ = 1.8V •V DDSPD = 1.7–3.6V•JEDEC-standard 1.8V I/O (SSTL_18-compatible)•Differential data strobe (DQS, DQS#) option •4n -bit prefetch architecture•Multiple internal device banks for concurrent operation•Programmable CAS latency (CL)•Posted CAS additive latency (AL)•WRITE latency = READ latency - 1 t CK •Programmable burst lengths (BL): 4 or 8•Adjustable data-output drive strength •64ms, 8192-cycle refresh •On-die termination (ODT)•Halogen-free•Serial presence detect (SPD) with EEPROM •Gold edge contacts •Dual rankFigure 1: 200-Pin SODIMM (MO-224 R/C E)OptionsMarking•Operating temperature–Commercial (0°C ≤ T A ≤ +70°C)None –Industrial (–40°C ≤ T A ≤ +85°C)1I •Package–200-pin DIMM (halogen-free)Z •Frequency/CL 2– 1.87ns @ CL = 7 (DDR2-1066)-1GA – 2.5ns @ CL = 5 (DDR2-800)-80E – 2.5ns @ CL = 6 (DDR2-800)-800–3ns @ CL = 5 (DDR2-667)-667Notes:1.Contact Micron for industrial temperaturemodule offerings.2.CL = CAS (READ) latency.3.Not recommended for new designs.Table 1: Key Timing ParametersTable 2: AddressingTable 3: Part Numbers and Timing Parameters – 1GB Modules1Table 4: Part Numbers and Timing Parameters – 2GB Modules1Table 5: Part Numbers and Timing Parameters – 2GB Modules1Notes:1.The data sheet for the base device can be found on Micron’s Web site.2.All part numbers end with a two-place code (not shown) that designates component and PCB revisions.Consult factory for current revision codes. Example: MT16HTF25664HZ-80EM1.1GB, 2GB, 4GB (x64, DR) 200-Pin DDR2 SDRAM SODIMMFeatures质量等级领域:宇航级IC、特军级IC、超军级IC、普军级IC、禁运IC、工业级IC,军级二三极管,功率管等;应用领域:航空航天、船舶、汽车电子、军用计算机、铁路、医疗电子、通信网络、电力工业以及大型工业设备祝您:工作顺利,生活愉快!以深圳市美光存储技术有限公司提供的参数为例,以下为MT46H64M16LFBF-5IT_B的详细参数,仅供参考Electrical SpecificationsStresses greater than those listed may cause permanent damage to the module. This is a stress rating only, and functional operation of the module at these or any other condi-tions outside those indicated in the device data sheet are not implied. Exposure to abso-lute maximum rating conditions for extended periods may adversely affect reliability.1GB, 2GB, 4GB (x64, DR) 200-Pin DDR2 SDRAM SODIMMElectrical Specifications。

聚碳酸酯 PC Polycarbonate聚碳酸酯(PC)是一种无定形热塑性工程塑料。

它具有极为优良的韧性、透明度和高的热变形温度等综合性能。

在大多数应用中,一般都要求至少有上述这样性能中的两种。

聚碳酸酯其他杰出的性能还有尺寸稳定性、优良的电性能和特有的耐燃性。

主要应用领域为汽车、商业机器和仪表行业。

聚碳酸酯年增长率约为6%。

化学及性能最成功的工业生产的聚碳酸酯是用双酚A与光气界面缩聚工艺进行反应。

这一反应是在水相和有机相存在下的碱性条件进行的。

分子量通过使用酚的链终止剂加以控制。

生产双酚A聚碳酸酯的工艺由于界面反应和产品的回收而复杂化。

韧性是聚碳酸酯最突出的性能,的确,对于像学校窗户、防暴设备及运动设备方面应用来说,聚碳酸酯在韧性上几乎没有对手。

高分于结构中的碳酸酯链段使聚碳酸酯成为韧性最好和最耐用的塑料之一,而双酚A链段使聚合物有很高的热性能(Tg = 300F)。

典型的商品聚碳酸酯分子量为22 000 - 35 000,多分散性(MW /MN)一般为2.2 - 2.5。

除分子量外,聚碳酸酯的熔体流动速率(ASTM D 1238, 573F, 1.2kg)一般也有一定的范围。

标准的商品的熔体流动范围为4 - 23。

超过这一熔体的流动范围,除了流变学性能外其他性能相当稳定,只有缺口悬臂梁式冲击强度在较高的熔体流速下有轻微的下降。

通用级聚碳酸酯的性质如表1所示。

除成本外对聚碳酸酯实际仅有几种限制。

不宜长期暴露于高温及潮湿的环境中,因为聚碳酸酯在高温下的长期耐水解稳定性差。

可通过使用热稳定剂、紫外线稳定剂、脱模剂、玻璃纤维和阻燃剂对其改性。

商业化产品通常必须满足由FDA、NSF、UL和其他机构所确立的有关指标。

品级实用化的聚碳酸酯有通用级和符合美国食品和医药管理局(FDA)要求的品级两种。

这些品级含有脱模剂、紫外线稳定剂或两种之一。

在一定应用领域中要求较低的模塑收缩率和较高的模量时可使用玻璃填充产品。

船用主机8PC2-6/2L柴油机技术规格书陕西柴油机重工有限公司目录第一章、总则第二章、柴油机主要技术参数第三章、制造及验收第四章、供货范围第五章、色彩及铭牌第六章、油封和包装第七章、培训和售后服务附件一、运行区域曲线附件二、随机仪表清单附件三、随机备件清单附件四、随机工具清单第一章总则1.本技术规格书规定了船用主机8PC2-6L柴油机的技术性能、供货范围、质量保证、交货验收等内容,是柴油机制造、验收和交货的主要依据。

2. 本技术规格书是根据法国S.E.M.T提供的技术文件及企业的相关标准编制而成,引用的主要标准有:《钢制海船入级与建造规范(2002版)》GB1105.1-87 内燃机台架性能试验方法标准环境状况及功率燃油消耗和滑油消耗的标定GB1147-87 内燃机通用技术条件GB5741-85 船用柴油机排气烟度测量方法GB6301-86 船用柴油机燃油消耗测定方法GB/T14363-93 柴油机机油消耗测定方法CB*3154-83 船用柴油机振动测量方法CB*3256-85 船用柴油机振动评级CB/T3253-94 船用柴油机技术条件CB/T3254.2-94 船用柴油机台架试验试验方法法国国家标准(NF)及中国国家标准(GB)法国热机协会标准(NSE)制造厂企业标准(Q/SC)GB8840 船用柴油机排气烟度限制GB/T19001-2000 质量管理体系第二章主要技术参数1. 柴油机可在下列环境中正常运行:横倾:±15°;横摇:±22.5°;纵倾:±5°;纵摇:±7.5°环境温度:45℃大气压力:100Kpa空气相对湿度:≤95%冷却海水进机最高温度:32℃有盐雾、油雾、霉菌和正常航行所产生的震动和冲击2、接口柴油机与外界系统接口见柴油机总体布置图3、主要技术参数(1) 型号: 8PC2-6L(M.P.C增压)(2) 型式:直列式、四冲程、不可逆转、增压器空冷器位于输出端、机不带泵(淡水泵、海水泵、滑油泵和燃油输送泵)(3) 气缸直径: 400mm(4) 活塞行程: 460mm(5) 气缸数: 8(6) 气缸中心距: 740mm(7) 几何压缩比: 11.4(8) 发火顺序: 1-5-7-3-8-4-2-6-1从输出端看曲轴顺时针旋转(9) 柴油机额定功率的标准环境条件:吸入空气温度: 27℃大气压力: 100KPa空冷器进口冷却水温度: 27℃排气背压:≤2.5KPa进气真空度:≤2.5Kpa燃油低热值 42700Kj/Kg(10) 功率标准环境条件下,柴油机输出法兰后最大持续功率(MCR): 4400KW持续使用功率(CSR): 3960KW(90%MCR)超负荷功率(110%MCR): 4840KW(每12小时内允许1小时)(11) 转速a.最大持续功率(MCR)时的转速: 520转/分b.超负荷功率时的转速:536转/分c.最低稳定转速:200转/分(12) 在标准环境条件下,最大持续功率时的性能参数:平均有效压力: 2190KPa活塞平均速度: 7.97m/s进气流量: 6.8kg/kwh排气流量: 7.0kg/kwh排气阀后平均排气温度: 450±50℃,两缸间温差≤80℃涡轮进口废气温度:≤650℃增压器后排气温度:≤400℃±20℃进气总管内增压空气压力: 230Kpa最大燃烧压力: 14.2Mpa主轴承温度:<85℃燃油消耗率: 186g/kw.h,允差+5%(轻柴油,燃油低热值为42700kj/kg)当燃用重油时,燃油消耗率按燃油低热值折算。

化学品安全技术说明书 SDS ALC-SDS- P057Ver.1六甲基二硅氧烷Hexamethyldisiloxane化学品中文名称:六甲基二硅氧烷;硅醚;二聚硅氧烷;六甲基二硅醚;六甲基二硅氧烷;六甲基二矽烷;六甲基乙硅氧烷;六甲基氧二硅烷;六甲基二硅氧烷(硅醚);六甲基二硅醚(HMDO)化学品英文名称:Hexamethyldisiloxane; HDMSO化学分子式:C6H18OSi2企业名称(中英文):液化空气(中国)投资有限公司Air Liquide (China)Holding Co., Ltd.地址:上海市徐汇区古美路1515号18号楼Building18, No.1515 Gu Mei Road, Shanghai, China电话:************传真:************电子邮件地址:************************24小时化学事故应急咨询专线:*************产品推荐及限制用途:半导体等工业使用。

危害概述:无色透明易流动、易燃液体,带有轻微气味。

GHS危险性类别:●物理化学危险易燃液体–类别2。

标签要素●象形图:●警示词:危险●危险性说明:高度易燃液体和蒸气防范说明●预防戴防护手套/穿防护服/戴防护眼罩/戴防护面具;远离热源/火花/明火/热表面-禁止吸烟;保持容器密闭;容器和接收设备接地/等势连接;使用防爆的电气/通风照明设备;只能使用不产生火花的工具;采取防止静电放电的措施;●应急如皮肤(或头发)沾染,立即去除/脱掉所有沾染的衣服,用水清洗皮肤/淋浴;火灾时,使用生产商/供应商或主管部门列明的媒介灭火;●贮存存放在通风良好的地方,保持低温;●处置处置内装物/容器按照地方/区域/国家/国际规章。

危险/危害的识别:危险!该产品为透明、易燃液体。

●物理化学危险:本产品为无色,极易燃液体。

纯物质/混合物:物质 ■ 混合物 □纯品或危险组分:化学名CAS No浓度或浓度范围六甲基二硅氧烷107-46-0100%营救人员不可尝试在没有配备足够个人防护设备的条件下或自行救出接触该产品的患者。

OPERATION MANUALFORMODELSR8 and R8U robot coupe U.S.A., Inc.P.O. Box 16625, Jackson, MS 39236-6625280 South Perkins St., Ridgeland, MS 39157email:*******************website: 1-800-824-1646IMPORTANT NOTICE3-PHASE MOTORSDRIVE SHAFT ROTATIONThree phase motors may rotate either direction.The required motor rotation is counterclockwise.Check the rotation before attaching the cutter blades. Changing the motor rotation requires a qualified electrician. Also, see the note attached to the end of the power cord.I. IntroductionII. Operation InstructionsA. Blade AssemblyB. ControlsC. OperationD. Emptying the bowlE. CleaningIII. Preventative MaintenanceIntroductionRobot Coupe offers the most complete line of food proces-sors available in the food service industry. The Robot Coupe model R8, 8 quart Vertical Cutter Mixer, is specifically de-signed for quality, high-speed food preparation. The R8 can prepare a variety of foods ranging from a coarse chop to a fine puree. You can prepare fresh salads, sauces, pates, mousses, salad dressings, prepare fine and coarse sausage mixtures, meat salads, mashed potatoes, mix and knead all doughs, pie crusts, flake pastries, and emulsify meats, nuts, and other fruits and vegetables.The R8 is constructed of sturdy stainless steel, fiberglass, and cast aluminum. The stainless steel bowl with the adjust-able knife is designed to allow for small and large batches without any mixing baffle required. A large see-through lid with a funnel opening allows you to carefully control the con-sistency of the product as it is being processed. The Robot Coupe model R8 is designed to give years of safe quality food preparation.Maintain a copy of this manual for reference by all users. Follow the instructions as indicated in this manual. Pay close attention to the special notes of caution.MODEL SPECIFICATIONSR8 & R8U * 8 Quart Capacity208-240 Volt, 3 phase,2.0 /3.0 Hp, 8.2/ 8.3 Amp2 speed, 1725/3450 RPMR8U *Is the same as an R8 but with a 3-1/2 qt. minibowl attachment. The mini bowl may bepurchased with the machine as model R8Uor separate as part number R8U090The R8 is equipped with auto-reset thermal overload protec-tion. If the unit overheats due to an overload condition, it will automatically shut off. After a cooling period of ten to fifteen minutes the thermal overload protection will automatically re-set and the unit may then be restarted. It will not restart until the thermal overload has reset.The suggested breaker size is 20 AMPS. Check the localcodes they may supersede the suggested breaker size.II. Operating InstructionsThis manual is broken down into step by step instructions to assist the operator in easy and quality food preparation. This manual should be read completely before use by each op-erator. Additionally, this manual should be kept as a refer-ence for future operators. Adherence to the guidelines set forth by this manual will ensure a safe, long life utilization of the vertical cutter mixer.A. Blade AssemblyWear cut-resistant gloves when handling the blades.The R8 blade assembly comes assembled from the factory. The blade assembly is designed so that the blades can be adjusted for large or small batches. The blade assembly should be completely disassembled after each days use, washed completely, and allowed to air dry before reassem-bling. Additionally, the blades should be kept sharp to pro-vide the best performance. The blades can be sharpened by means of a fine stone; a stone is provided with each ma-chine.The blades are set at the factory to allow for most operations. The bottom blade should always stay on the bottom, followed by two small spacers, then the second blade, followed by the large aluminum spacer. Note: the white Nylon spacer should always be used between the locking nut and large aluminum spacer. Most low speed operations can be run using this blade configuration. High speed operations and operationsThere are seven important points to remember about the blade assembly:(1) The blades are sharp, always wear cut-resistant gloves when handling the blades.(2) The bottom blade must always stay on the bottom of the blade support.(3) The blade assembly, when installed, should drop to the bottom of the bowl such that the bottom blade is almost touch-ing the bottom of the bowl.(4) Disassemble the blade assembly at least after each days use, wash completely, and allow to air dry before reassem-bly. Lubricate the threads with a food-grade grease periodi-cally.(5) Ensure that the blade assembly is correctly assembled, and all parts fit tightly together before beginning each opera-tion.(6) Sharpen the blades as necessary.(7) A large spacing between the blades can cause exces-sive, vibration, especially on high speed.D: Mini Bowl InstructionsThe Robot Coupe Model R8 Vertical Cutter Mixer has avail-able a 3 1/2 quart mini bowl attachment. The mini bowl kit may be purchased with the machine as model R8U or sepa-rate as part number R8U090. The mini bowl fits inside the larger 8 quart bowl and uses the same lid. Extra mini bowl kits may be purchased and are available through the regular distribution network.Included in the mini bowl kit is a 3 1/2 quart bowl, S-blade assembly with disassembly tool, and gasket for lid. ASSEMBLY OF THE MINI BOWLThe mini bowl fits inside the larger 8 quart bowl and is held in place by the lid. To assemble the mini bowl, secure the larger 8 quart bowl and lid assembly to the motor base. The center stem of the large bowl has a notch cut into the top which fits to a pin located on the under side of the mini bowl. Place the mini down on to the center stem of the large bowl and rotate until the pin of the mini bowl drops into the notch of the large bowl stem. Note: The large S-blade is not used with the mini bowl assembly. The mini bowl must be fully seated on the stem to work correctly.Place the mini bowl gasket on to the center ring of the lid assembly with the bevel of the seal down. This seal secures the mini bowl in place when the lid is closed. Place the mini bowl S-blade assembly down into the bowl and over the mo-tor shaft. Rotate the blade so that it drops completely on the shaft; the bottom blade should be located just off the bowl bottom when assembled correctly.E. ControlsThe Robot Coupe model R8 is designed with an easy to use control panel. This machine offers a two speed selector switch, push button run switch, push button pulse switch, oversized mushroom type off switch, and a power on and running indicator lamps. The following gives a brief descrip-tion of each.Two Speed Selector: This switch allows the user to select either Low (1725 RPM) or High (3450 RPM) speed for the operation. For best results, the speed selector should only be moved while the machine is off and not running. A speed must be selected before the power on lamp will light, also the lid must be closed - closing the safety switch.Run Switch: This switch is used to start the machine. The machine will not run unless the lid/safety switch is closed and a speed has been selected.Pulse Switch: This switch is used to jog or pulse the motor off and on. The machine will not pulse on unless the lid/ safety switch is closed and a speed has been selected.Stop Switch: The stop switch will stop the motor from run-ning after the run switch has been pressed. Always use this switch to turn the machine off. Do not open the lid without pressing the off switch.Red (power) Indicator Lamp: This lamp will light when the machine is plugged in, the lid/safety switch is closed and a speed has been selected. NOTE: The red lamp will not lightF. OperationBecause of the special bowl and blade design of the Robot Coupe Vertical Cutter Mixers, most operations are completed in a matter of seconds. The operator should pay close atten-tion to the product as well as the amount of time required to process. Operations should be run on Low speed, using High speed only when an extremely fine puree consistency is de-sired.There are two ways to run your VCM. First of all, you may run the unit continuously by filling the bowl with food and sim-ply letting it run until the desired consistency has been reached. Use this method to grind, mix, blend, puree, or emulsify. Secondly, you may chop with your unit by pulsing the machine.Cut round vegetables into halves or quarters and prep long vegetables into 3 to 4 inch pieces. Place these into the bowl, and using Low speed, pulse the unit on the off quickly. Usu-ally 4 to 5 pulses yields an evenly mixed chopped substance.SPECIAL NOTE: The model R8 three phase must be limited to no more than 80 pulses (quick starts and stops) within a one hour period. Exceeding this limitation can cause dam-age to the electrical components of the machine which is not covered under warranty.TO CHOPTo achieve a chopped consistency for vegetables, cheese, meats, etc. fill the bowl with the product no more than 3/4 full, or as low as two to three onions. Small batches would re-quire lowering the top cutting blade. With the lid secured, and the speed selector in Low speed, press the pulse button quickly then release. Repeat this pulsing action, allowing the blades to stop each time, until the desired cut is achieved. TO PUREE OR MIXFill the bowl with the product no more than 3/4 full. Start the machine in Low speed and allow to run until the product is completely reduced. If necessary, turn the machine off and select High speed to finish the product. It may be necessary to add some liquids to a puree to achieve the desired consis-tency.DOUGHS AND PASTRIESPrepare doughs and pastries on Low speed only. In many cases it may be helpful to first mix all dry products then add the liquids. The unit should be run continuously until the prod-uct is completely processed. For thick doughs, such as for pizza, the machine will form a ball of dough when the mixing is complete. When a ball is formed the machine should be turned off immediately to prevent over processing. Prepara-tion times and all ingredients should be noted for different recipes.G. Emptying The BowlAfter the product has been run in the bowl, make certain that the speed selector is in the middle off position, and for extra safety unplug the machine. NEVER attempt to open the lid until the blades have come to a complete stop.To remove the bowl, loosen the knob on the front of the bowl and twist the bowl clockwise, thus releasing the locking lugs. Then lift the entire bowl, with the blade assembly intact, up and off of the motor shaft. The bowl can then be emptied by holding the blade in place and tilting the bowl to one side into a catch pan or other container.H. CleaningCleaning is one of the most important measures to ensure safe quality food preparation. The machine should be cleaned after each session. Failure to keep the machine clean can result in high repair costs and shortened machine life. Follow the cleaning instructions detailed below, or according to local Health Department Regulations.NOTE: The aluminum bowl lid and the blade assembly should be washed in a soft-metal-safe detergent. Detergents con-taining caustic soda will cause soft metals to oxidize leaving an undesirable black residue on the surface.The bowl, blades, and lid can be removed and cleaned in a pot sink or dishwasher. Take care not to bend, drop, or break any of the components.The lid is removed by removing the lid hinge pin located at the base of the lid. The blades can be lifted out, and the bowl removed by loosening the locking nut on front of the bowl and twisting the bowl clockwise.The blade assembly should be disassembled and cleaned completely. Assemble the blade only after it has dried com-pletely.With the bowl removed, the motor shaft and seal should be cleaned. Use a soft brush or cloth to clean the seal area. The seal is designed to prevent penetration of liquids and food products into the motor housing. Clean the seal area com-pletely, but do not damage the seal. Do not allow food or liquids to remain built up around the seal area. The seal should not be cleaned by use of spraying water. Inspect the seal during each cleaning for damage or wear. This seal is de-signed for easy removal by use of a large wrench. The seal should be replaced if any wear or damage is noted. Contact an authorized service agent for additional seals. NOTICE: It is recommended that the seal be lubricated at least once a week or after cleaning as practical. A food grade grease, vegetable oil, or mineral oil will work well.Clean the motor base housing using a cloth lightly dampened with a soapy water solution. Maintaining a clean machine will improve the overall life of the unit.SPECIAL NOTE: Pressure cleaning with water can cause damage to the electrical components contained within the housing. Do not allow the motor base to be sprayed or immersed in any liquid.III. PREVENTATIVE MAINTENANCE Motor Seal ReplacementNOTE: ONLY QUALIFIED SERVICE OR REPAIR TECH-NICIANS SHOULD PREFORM THIS SERVICE.The machine comes equipped with a removable seal assem-bly that is screwed down around the motor shaft. To replace the seals, this assembly must be unscrewed. A tool is sup-plied for use in removing the insert.Follow steps 1-6 below to replace the motor seals.The Robot Coupe Vertical Cutter Mixers are designed to give years of maximum trouble free performance. Adherence to the operating instructions as well as keeping the unit clean will further ensure good performance.An examination should be made periodically to ensure that all parts are in good working condition. Special attention should be given to all seals to insure that they are well lubri-cated and clean. Replacement of the seals may be neces-sary if they are dry rotted or torn.If service is required, contact the nearest authorized service agency, or your distributor, to see where service is available. If you wish your machine to be serviced at the factory, call for a Return Merchandise Authorization (RMA) number and upon receipt of the same, ship the unit, prepaid and insured, to our factory address.Robot Coupe, USA Inc.730 South Ridgewood Rd.Ridgeland MS 391571-800-824-16461. Remove the seal assembly: Place the tool over the shaft and around the seal assembly. Turn the tool counterclockwise to loosen. Place a heavy-duty screwdriver through the holes in the tool for more leverage.2. Pry out the seals and cleanthe seal cavity.3. Grease the seals4. Clean the shaft, then tape the step on the shaft with plastic electrical tape for protection during reassembly.Using a food-grade grease, lightly lubricate the shaft.5. Install new seals withgrooved greased sides facingeach other. The seals must befully seated. Gentely tap theminto place with a hammer andsmall block of wood if neces-sary, but do not damage them.6. Reinstall the seal assembly:Before reassembly, lightly grease the threads onthe seal assembly insert. Place the seal assem-bly over the motor-shaft and screw it down gentlyturning first by hand, then with the tool in a clock-wise rotation until it is firmly in place.Remove the plastic tape and excess grease be-fore using the machine.R8-R8UPart ListR8U CL689SEAL REMOVAL TOOLR8U00915MM S.S. SPACER R1004TOP SEAL, MOTORR8U01045MM S. S. SPACER R1005FOOTR8U012BLADE LOCKING NUT R1006BRACKET, FOOTR8U013BLADE ONLY (SMOOTH)R1023COVER, SCREW*R8U013A BLADE ONLY, (SERRATED)R1024SCREW, MOTOR SUPPORTR8U017BLADE ASSEMBLY R1027SEAL ASSEMBLY, MOTOR SUPPORTR8U021SCREW & NUT/LID SWITCH R1029Seal, MOTOR SUPPORTR8U022LID SEAL R1034COVER, SCREWR8U023LID ASSEMBLY R1036A SCREW, LID LEVERR8U024BOWL R1046THERMAL OL (LR2 D1314) (7-10 AMP)R8U026MOTOR SUPPORT R1049BOWL MAGNET ASSEMBLYR8U026.1MOTOR SUPPORT SCREW R1062BOLTS, SHOCK ABSORBINGR8U028BUSHING FOR MECHANICAL SWITCH R1075TOOL, BLADE LOCKINGR8U029LID HINGE R1077PLASTIC SPACER (10CM)R8U030HINGE PIN R1090CONTROL RELAYR8U031FRONT DATA PLATE R1091B LEVER, LATCH ASSEMBLY LIDR8U032MOTOR R114SWITCH ONLYR8U033BACK ACCESS COVER SEAL R1547BUSHING, HINGE PINR8U034MAGNETIC SWITCH ASSEMBLY R237BEARINGR8U035BACK ACCESS COVER R25126A BOWL MAGNETR8U036BRACKET FOR MAGNETIC SWITCH R25127BOWL MAGNET CPR8U038SPEED SELECTOR SWITCH R2534A MECHANICAL SWITCHR8U055TOOL BLADE DISASSEMBLY R3062U OFF PUSH BUTTON/REDR8U057MINI BOWL BLADE SUPPORT R3063U PULSE PUSH BUTTON/BLACKR8U058MINI BOWL BLADE ONLY, SMOOTH R3067U ON PUSH BUTTON/GREEN*R8U058E MINI BOWL BLADE, SERRATED R403CORD WITHOUT PLUGR8U0594MM SPACER (MINI BOWL)R40351TP GREEN LAMP 220VR8U062 1.5CM SPACER (MINI BOWL)R40371TP RED LAMP 220VR8U064MINI BOWL BLADE LOCKING NUT R413VOLTAGE RELAYR8U065MINI BOWL R4904PLUG, 3 PHASER8U066MINI BOWL BLADE ASSEMBLY R611MOTOR SUPPOR SEALR8U070MINI BOWL LID SEAL R662BEARING, TOP MOTOR*R8U071MACHINE STAND (25-1/4" x 33 -1/4" x 21 - 3/16")R8U003BASER8U072RELAY BRACKET (9" x 4.5")R8U004SWITCH PLATER8U090MINI BOWL ASSEMBLY R8U008BLADE SUPPORTRA490STRAIN RELIEF Robot Coupe Vertical Cutter Mixer with eight quart bowland 3 quart mini bowl assembly*Denotes Accessories 6/6/02U.S.A., Inc.280 South Perkins St., Ridgeland, MS 39157email:*******************website: www.rwebsite: 1-800-824-1646ROBOT COUPE U.S.A., INC. LIMITED WARRANTYYOUR NEW ROBOT COUPE PRODUCT IS WARRANTED TO THE ORIGINAL PURCHASER FOR A PERIOD OF ONE YEAR FROM THE DATE OF PURCHASE.This LIMITED WARRANTY is against defects in the material and/or workmanship, and includes labor for replacement of defective parts, provided repairs are performed by an authorized service agency (see attached list). The CUSTOMER must inform the Service Agency of the possibility of warranty coverage and provide a copy of the dated sales or delivery receipt BEFORE WARRANTY REPAIRS ARE BEGUN. Replacement parts and accessories are warranted for ninety (90) days from the date of purchase when purchased separately and will be verified by dated sales receipt OR packing slip which lists that item. All parts or accessories replaced under warranty must be returned to the Service Agency.THE FOLLOWING ARE “NOT” COVERED UNDER WARRANTY:1.Damage caused by abuse, misuse, dropping, or other similar incidental damage caused by or asa result of failure to follow assembly, operating, cleaning, user maintenance, or storageinstructions.bor to sharpen and/or parts to replace knife assemblies or blades which have become dull,chipped, or worn due to normal use.3.Material or labor to renew or repair scratched, stained, chipped, dented or discolored surfaces,blades, knives, attachments, or accessories.4.Transportation charges to or from an authorized service agency for repairs of a machine designatedas “CARRY IN SERVICE” (table top models). NOTE: R4N/R6N are now field service units.bor charges to install or test attachments or accessories (i.e., bowls, cutting plates, blades, attachments) which are replaced for any reason.6.Charges to change Direction-of-Rotation of Three Phase electric motors (INSTALLER IS RESPONSIBLE).7.SHIPPING DAMAGE IS NOT COVERED BY WARRANTY. Visible and hidden damages are the responsibility of the freight carrier. The consignee must file a damage claim promptly against thecarrier, or upon discovery in the case of hidden damage.KEEP ALL ORIGINAL CONTAINERS AND PACKING MATERIALS FOR CARRIER INSPECTION. Robot Coupe U.S.A., Inc., Robot Coupe S.A. or any of their affiliates, distributors, officers, directors, agents, employees, or insurers will not be obligated for consequential or other damages, losses, or expenses in connection with or by reason of the use of or inability to use the machine for any purpose.THIS WARRANTY IS GIVEN EXPRESSLY AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, FOR MERCHANTABILITY AND FOR FITNESS TOWARD A PARTICULAR PURPOSE AND CONSTITUTES THE ONLY WARRANTY MADE BY ROBOT COUPE, U.S.A., Inc.。

船用主机8PC2-6/2L柴油机技术规格书陕西柴油机重工有限公司目录第一章、总则第二章、柴油机主要技术参数第三章、制造及验收第四章、供货范围第五章、色彩及铭牌第六章、油封和包装第七章、培训和售后服务附件一、运行区域曲线附件二、随机仪表清单附件三、随机备件清单附件四、随机工具清单第一章总则1.本技术规格书规定了船用主机8PC2-6L柴油机的技术性能、供货范围、质量保证、交货验收等内容,是柴油机制造、验收和交货的主要依据。

2. 本技术规格书是根据法国S.E.M.T提供的技术文件及企业的相关标准编制而成,引用的主要标准有:《钢制海船入级与建造规范(2002版)》GB1105.1-87 内燃机台架性能试验方法标准环境状况及功率燃油消耗和滑油消耗的标定GB1147-87 内燃机通用技术条件GB5741-85 船用柴油机排气烟度测量方法GB6301-86 船用柴油机燃油消耗测定方法GB/T14363-93 柴油机机油消耗测定方法CB*3154-83 船用柴油机振动测量方法CB*3256-85 船用柴油机振动评级CB/T3253-94 船用柴油机技术条件CB/T3254.2-94 船用柴油机台架试验试验方法法国国家标准(NF)及中国国家标准(GB)法国热机协会标准(NSE)制造厂企业标准(Q/SC)GB8840 船用柴油机排气烟度限制GB/T19001-2000 质量管理体系第二章主要技术参数1. 柴油机可在下列环境中正常运行:横倾:±15°;横摇:±22.5°;纵倾:±5°;纵摇:±7.5°环境温度:45℃大气压力:100Kpa空气相对湿度:≤95%冷却海水进机最高温度:32℃有盐雾、油雾、霉菌和正常航行所产生的震动和冲击2、接口柴油机与外界系统接口见柴油机总体布置图3、主要技术参数(1) 型号: 8PC2-6L(M.P.C增压)(2) 型式:直列式、四冲程、不可逆转、增压器空冷器位于输出端、机不带泵(淡水泵、海水泵、滑油泵和燃油输送泵)(3) 气缸直径: 400mm(4) 活塞行程: 460mm(5) 气缸数: 8(6) 气缸中心距: 740mm(7) 几何压缩比: 11.4(8) 发火顺序: 1-5-7-3-8-4-2-6-1从输出端看曲轴顺时针旋转(9) 柴油机额定功率的标准环境条件:吸入空气温度: 27℃大气压力: 100KPa空冷器进口冷却水温度: 27℃排气背压:≤2.5KPa进气真空度:≤2.5Kpa燃油低热值 42700Kj/Kg(10) 功率标准环境条件下,柴油机输出法兰后最大持续功率(MCR): 4400KW持续使用功率(CSR): 3960KW(90%MCR)超负荷功率(110%MCR): 4840KW(每12小时内允许1小时)(11) 转速a.最大持续功率(MCR)时的转速: 520转/分b.超负荷功率时的转速:536转/分c.最低稳定转速:200转/分(12) 在标准环境条件下,最大持续功率时的性能参数:平均有效压力: 2190KPa活塞平均速度: 7.97m/s进气流量: 6.8kg/kwh排气流量: 7.0kg/kwh排气阀后平均排气温度: 450±50℃,两缸间温差≤80℃涡轮进口废气温度:≤650℃增压器后排气温度:≤400℃±20℃进气总管内增压空气压力: 230Kpa最大燃烧压力: 14.2Mpa主轴承温度:<85℃燃油消耗率: 186g/kw.h,允差+5%(轻柴油,燃油低热值为42700kj/kg)当燃用重油时,燃油消耗率按燃油低热值折算。

滑油消耗率: 1.36g/kw.h(13)增压器型号VTR354,空气室内吸气形式增压方式MPC增压润滑方式自润滑涡轮进口废气温度≤650 ℃增压器允许最高转速≤21900r/min增压器出口废气温度400℃±20℃(14) 调速器型号PGA70瞬态调速率δ1≤12%稳态调速率δ2≤8%稳定时间t ≤15秒(15) 空冷器海水冷却水流量160m3/h(16) 燃油系统可燃用0#或-10#柴油,也可燃用重油,雷氏一号≤1500秒。

电动燃油输送泵流量≥2.24m3/h燃油进机压力≥0. 5MPa燃油滤器过滤精度10μm(17)滑油系统滑油牌号CD40电动滑油泵流量≥84m3/h滑油泵出口压力0.7MPa柴油机进口滑油压力0.55MPa柴油机进口滑油温度50~60℃滑油滤器过滤精度30μm摇臂独立滑油系统:电动滑油泵流量≥1.0m3/h 出口压力≥0.3MPa滑油进机压力≥0.1Mpa滑油滤器过滤精度90μm增压器和调速器滑油: L-TSA68 (GB11120-89)(18)冷却水系统水质处理过的淡水(处理方法按SEMT的要求)柴油机淡水出机温度75~85℃电动淡水泵流量≥105m3/h淡水进机压力0.35Mpa海水泵流量≥160m3/h海水进机压力0.2 Mpa海水进机温度≤32℃喷油器独立冷却水系统:喷油器冷却水最小流量≥1.0m3/h喷油器冷却水进机压力0.35MPa喷油器冷却水进机温度50±3℃(19)盘车机构柴油机配有电动盘车装置及起动安全联锁装置输入电压AC380V 50Hz(20)起动压缩空气起动,起动空气压力:3~1.2Mpa起动空气耗量:5m3/次(标准大气状态)3.2.2 物理特性a. 重量66000kg±5%(干重,不带联轴节,不带泵)b. 外型尺寸(L×B×H):8585×2070×3920(高度为安装基座以上尺寸)c. 电源辅助设备AC380V、AC220V,三相50Hz安全控制电路DC24Vd.气源起动气源 3.0MPa调速气源 0.7MPae.柴油机上的监测仪器信号通过主机上的接线箱输出3.2.3 可靠性按使用说明书操作,按维护保养说明书维修。

吊缸检修期≥12000小时大修期≥24000小时3.2.4 维修性(1)柴油机的维修性满足《PC2-6维修说明书》规范要求,符合PC2-6柴油机维修规定。

(2)平均修复时间:MTTR≤4h3.3 制造柴油机零部件按照SEMT图纸、文件的要求制造,制造质量须达到专利图纸、技术文件及技术规格书、相关标准的要求。

3.4 互换性按同一图号(或编码号)生产的单一零件应具有互换性(有些零件更换后需随机调整如定时、进排气间隙等),成套安装的部件(如轴瓦等)可成套更换。

零件更换时须参照维修说明书。

3.5 标准化要求柴油机已标准化、系列化、组合化、同型柴油机具有相同的配套和布置,所选用的标准符合PC2-6柴油机采用的标准和我国的有关标准。

第三章交货验收1 .交货试验验收交货试验按照制造厂的《交货试验大纲》在制造厂的试车台上进行,并通知船东参加,由中国船检社负责验收。

2 .试验项目试验依据《交货试验大纲》进行。

第四章供货范围1. 供应范围1.1 完整的柴油机一台1.2 监测仪表一套(见随机仪表清单)1.3 随机备件一套(见随机备件清单)1.4 随机工具一套(见随机工具清单)2.提供的资料供货合同签订后,制造厂向设计单位提供下列工作资料各两套:(1)柴油机安装参考图(2)柴油机总布置图(含柴油机与各系统的接口及尺寸、柴油机各仪表接口尺寸及位置,柴油机输出法兰尺寸)(3)柴油机操纵系统原理图(4)柴油机监测报警值(5)柴油机热平衡计算数据(6)柴油机振动计算用参数(7)柴油机各系统原理图(8)使用说明书(10)维护说明书(11)柴油机电气系统原理图(12)排气出口过渡连接法兰图3. 随机资料a.柴油机出厂合格证、主要辅助设备船检合格证 1套(包括增压器、调速器和中冷器合格证)b. 柴油机使用说明书 1套c. 柴油机维修说明书 1套d. 随机图纸 1套(包括柴油机总布置图及柴油机主要部件装配图)e. 柴油机电气系统原理图 1套f. 随机备件清单 1套g. 随机工具清单 1套h. 柴油机装箱清单 1套第四章色彩和铭牌(1)油漆柴油机上除有色铸件外,其余零件及管子外表面均涂面漆,涂覆色按GB/T13181-1995的中绿灰BG01执行。

(2)铭牌和标志主机及其附属设备按GB/T13306-91装设铭牌,铭牌要求黄铜(进口件除外)、铆接、黄底、黑字、阳文、设备各进出口处加流向标志。

(3)柴油机包装箱上标明重心位置和起吊位置。

第六章油封及包装柴油机验收后按照《PC型柴油机油封工艺》及时进行油封。

柴油机的备件、工具一律喷涂防锈漆。

柴油机上所有管路对外的孔、洞均用闷塞(或木板)封闭,油封有效期为半年,设备到货后,订货方应将柴油机及其备件、工具等置于干燥的地方妥善保管,并定期(每隔3个月)仔细检查油封状况,必要时重新油封。

第七章培训和售后服务1.人员培训由主机厂编制培训教材及VCD光盘,负责对柴油机操作岗位人员进行培训,培训内容包括:柴油机运行原理、结构和日常操作维护。

2. 质量保证柴油机的保修期为交船后12个月,在保修期内如确因零件质量问题造成的损坏,制造商免费提供零件并派人进行维修和技术服务。

3. 售后服务a)制造厂派人协助柴油机在船厂的安装和试航试验。

b)制造厂保证及时、长期供应价格合理的备件,提供技术支持。

附件二 8PC2-6L柴油机随机主要仪表清单序号名称1 测速发电机及转速表2 油、水温度传感器3 温度表4 排温传感器5 增压器转速测量装置6 主轴承温度测量装置7 行程开关(超保装置用)8 行程开关(起动盘车用)9行程开关(停车位置指示用)10接线盒及连接电缆11 油、水压力传感器12 压力开关附件三 8PC2-6L(M.P.C)型柴油机随机备件清单附件四8PC2-6L(M.P.C)型柴油机随机工具清单陕西柴油机重工有限公司说明一、随机工具清单所包括的工具是维护和检修PC2—6柴油机所必备的工具。

具体项目见02 240 60MX。

二、工具分为A、B、C类;A类工具由二个以上零件组成通称为专用组件工具。

B类工具由单个零件组成,通称为专用单件工具。

C类工具为通用工具,用户自备。

三、 A类和B类专用工具随机供应一套。