QC验货报告样板

- 格式:xls

- 大小:43.00 KB

- 文档页数:17

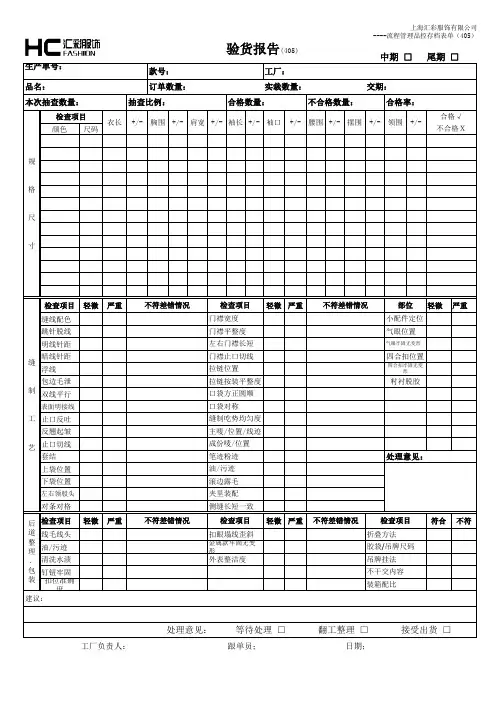

上海汇彩服饰有限公司

----流程管理品控存档表单(405)

颜色

尺码

检查项目轻微严重轻微严重轻微严重

缝线配色跳针脱线明线针距暗线针距浮线包边毛泄双线平行

表面明接线

止口反吐反翘起皱止口切线套结上袋位置下袋位置

左右领驳头

对条对格检查项目轻微

严重

轻微严重符合不符

线毛线头油/污迹清洗水渍钉钮牢固扣位准确度

+/-领围+/-

交期:

实裁数量:

订单数量:+/-检查项目籿衬脱胶

折叠方法胶袋/吊牌尺码吊牌挂法不干交内容装箱配比

油/污迹外表整洁度

侧缝长短一致

小配件定位气眼位置

不符差错情况

检查项目滚边露毛夹里装配本次抽查数量:

抽查比例:

合格数量:

不合格数量:

合格率:

合格√衣长

胸围+/-肩宽不符差错情况拉链按装平整度口袋对称缝制吃势均匀度主唛/位置/线迹口袋方正圆顺门襟平整度左右门襟长短门襟止口切线成份唛/位置笔迹粉迹拉链位置建议:

不合格X

规 格 尺 寸

缝 制 工 艺

生产单号:款号:工厂:品名:

后道整理.包装

+/-袖长+/-袖口 处理意见: 等待处理 □ 翻工整理 □ 接受出货 □

日期;

工厂负责人:跟单员;检查项目+/-腰围+/-检查项目不符差错情况门襟宽度气眼牢固无变形

四合扣位置

四合扣牢固无变形

部位 验货报告(405)

处理意见:

扣眼塌线歪斜

金属款牢固无变形

不符差错情况摆围。

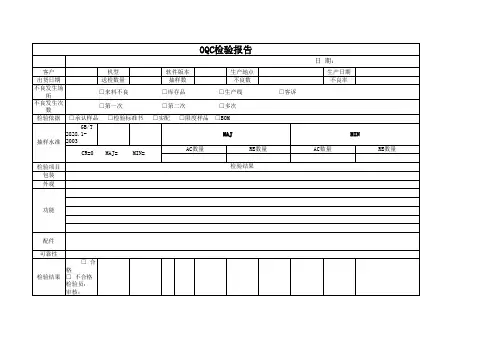

生产批次号产品名称生产车间

生产地点QC

日期验货地点抽查标准

验货时总数抽查数量

占%全部过金属探测器检查精度Fe Ф 1.5mm SUS Ф2.0mm

Cu Ф2.0mm 每1小时检

查机器记录检查方法

产品重量

(请注意记录数据为毛重)轻微:轻1.5克以下注:视情况每个单品或相同

的产品共计抽

查50-80单个产品以上.有

问题要加大抽查数量。

产品

包材要同时称

3-5套以上包材计平均重量。

一般:轻2-3克严重:轻3-5克不够重量总数

产品质量

(包括味道/颜色

/形状/工艺/产品

排列等) 验货要求AQL标准:抽检数量:501--1200:抽80;1201--3200:抽125;3201--10000:抽200;10001--35000:抽315;35001--150000:抽500;150001-500000:抽800订货数量验货情况

快乐园(江西)食品科技有限公司

验货总结

QC现场验货报告 编号:验货项目

产品名称

数量

产品毛重G.W:抽查数量QTY.:产品净重N.W:

包材重量P.W:重量总结。

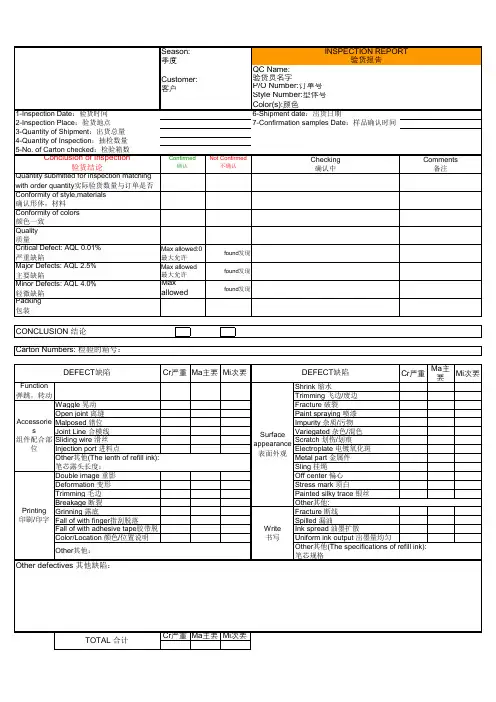

验货报告,模板篇一:通用验货报告Results1. 此报告仅作为本公司对所抽验货品质量之确认,,由厂方负全部责任. 2. 验货标准:MIL-STD-105E II级单次抽样. 此次验货 AQL MAJ= ,MIN =; MAJ= MIN =3. 验货时工厂应最少完成批货量80%的完整包装;验货时数量不足、无货或验货不通过,每次扣款QA验货费用RMB 元,- 1 -Page 1 sur 2表单编号: XX-QC-001/A1. 此报告仅作为本公司对所抽验货品质量之确认,,由厂方负全部责任. 2. 验货标准:MIL-STD-105E II级单次抽样. 此次验货 AQL MAJ= ,MIN =; MAJ= MIN =3. 验货时工厂应最少完成批货量80%的完整包装;验货时数量不足、无货或验货不通过,每次扣款QA验货费用RMB 元,- 2 -Page 2 sur 2 表单编号: XX-QC-001/A篇二:教你怎么写验货报告怎样写验货报告一份验货报告是一次验货的真实记录。

一份完整的验货报告应该真实、全面、公正,要让我们的客户在没有亲自到场的情况下,对委托给我们的货的各种状况有一个清晰的认识。

这就对报告提出了很高的要求。

以下是一份***杂货组GENERAL的空白报告模式,我们以它为例,分析一下该怎样写好一份合格的报告(黑体部分为原报告内容)。

CTION REPORTAPPLICANT:DESCRIPTION BUYER申请验货人的地址DATE: 验货日期(一般为客户,但也可能是中间商,具体情况参考BOOKING FORM SHEET上的信息。

)ATTN.: 联系人: 产产品描述,一般形似为:数量+产品。

例:5000PCS of Wooden Table: 客户名称: 中间商名称(如果该次验货有客户申请,则此处须填上;如果该次验货由中间商申SUPPLIER请,则此处不填。

) : 定单号ORDER NO. (注:要注意是ORDER NO.或CONTRACT NO.,例如一般为CONTRACT NO.)MODEL NO./STYLE NO. : 客人的货号(可在定单中找出): 中间商的货号(可在定单中找出) SUPPLIER ART. NO.: 产品颜色(如果有的话) COLORDATE OF INSPECTION : 验货日期to PLACE OF INSPECTION : 验货地点THE INSPECTION RESULTS OF THE ABOVE MENTIONED MERCHANDISE ARE FOUND AS FOLLOWS: A) QUANTITY AVAILABLE 验货员到厂时,所验的这批货的完整包装的数量是否达到客人的要求。

本文部分内容来自网络整理,本司不为其真实性负责,如有异议或侵权请及时联系,本司将立即删除!== 本文为word格式,下载后可方便编辑和修改! ==qc验货报告模板篇一:SGS验货报告格式Inspection ReportBuyer : Agent : Supplier : Manufacturer :Product description: Style Number : P.O. Number: Service performed: Inspection Location :REFERENCE SAMPLE PROVIDED: ? Not Available? Not Available Inspection Date :INSPECTION SUMMARY: (in comparison to principal’s instructions and reference sample, as available)Page 1of 5INSPECTION METHOD APPLIED:Inspection method: P-INSP- WI - (version )ANSI / ASQ Z1.4- 201X, Single sampling plans for normal inspection, Level I or II or others____: Samples selected from carton numbers:1.WORKMANSHIP APPEARANCE / FUNCTION INSPECTION FINDINGS:Requested AQL Critical defective maximum allowed: _________ ? Within AQL? Beyond AQLMajor defective maximumallowed: _________ ? Within AQL? Beyond AQL Minor defective maximumallowed: _________ ? Within AQL? Beyond AQLPage 2of 52. QUANTITY:3. PRODUCT CONFORMITY: 3.1 Style conformity:3.2 Material conformity:3.3 Color conformity :? Conform? Not Conform ? Not applicable ? Subject to client’s evaluation? Conform? Not Conform ? Not applicable ? Subject to client’s evaluation? Conform? Not Confo rm ? Not applicable ? Subject to client’s evaluationNote: Two color shading lots in one color within grade 4 are acceptable commercially.Page 3of 54.PACKING:? Conform? Not Conform ? Subject to client’s evaluation4.1 Individual packingconformity : ? Details please see photo.? Conform? Not Conform ? Subject to client’s evaluation4.2 Inner packing conformity :? Details please see photo.? Conform? Not Conform ? Subject to client’s evaluation4.3 Export packing conformity :? Details please see photo.? Conform? Not Conform.5.MARKING / LABEL:? Conform? Not Conform ? Subject to client’s evaluation5.1 Export Carton MarkingPrinted/written/stuck on one/two long/short sideA. Shipping mark conformity:B. Side mark conformity:Details please see photo.Printed/written/stuck on one/two long/short side Details please see photo. ? Conform ? Not Conform ? Subject to client’s evaluation? Conform ? Not Conform ? Subject to client’s evaluation ? Conform ? Not Conform ? Subject to client’s evaluation5.2 Label / HangtagA.B.C. D. E. F. G.5.3 Bar code content5.4. Others6. PRODUCT-SPECIFIC DATA MEASUREMENTS/ FIELD TESTS ON REDUCED SAMPLE SIZE (asapplicable for specific product/order)6.1 Size measurement check on ____sub-samples: ? within ? beyond tolerance ? actual finding,Details please see attached size measurement chart.6.2. Product weight check on 3 pieces per size: ? within ? beyond tolerance ? actual finding. (unit: gm/piece)6.3 Function or assembly test: check on _____ sub-samples, found_____.Factory equipment: brand _________________; calibration record: yes or no, period: ______6.4 Thickness: ________6.5 Carton Information:。

本文部分内容来自网络整理,本司不为其真实性负责,如有异议或侵权请及时联系,本司将立即删除!== 本文为word格式,下载后可方便编辑和修改! ==qc验货报告模板篇一:SGS验货报告格式Inspection ReportBuyer : Agent : Supplier : Manufacturer :Product description: Style Number : P.O. Number: Service performed: Inspection Location :REFERENCE SAMPLE PROVIDED: ? Not AvailableNot Available Inspection Date :INSPECTION SUMMARY: (in comparison to principal’s instructions and reference sample, as available)Page 1of 5INSPECTION METHOD APPLIED:Inspection method: P-INSP- WI - (version )ANSI / ASQ Z1.4- 201X, Single sampling plans for normal inspection, Level I or II or others____: Samples selected from carton numbers:1.WORKMANSHIP APPEARANCE / FUNCTION INSPECTION FINDINGS:Requested AQL Critical defective maximum allowed: _________ ? Within AQL? Beyond AQLMajor defective maximumallowed: _________ ? Within AQL? Beyond AQL Minor defective maximumallowed: _________ ? Within AQL? Beyond AQLPage 2of 52. QUANTITY:3. PRODUCT CONFORMITY: 3.1 Style conformity:3.2 Material conformity:3.3 Color conformity :Conform Not Conform Not applicable Subject to client’s evaluationConform Not Conform Not applicable Subject to client’s evaluationConform Not Confo rm ? Not applicable ? Subject to client’s evaluationNote: Two color shading lots in one color within grade 4 are acceptable commercially.Page 3of 54.PACKING:Conform Not Conform Subject to client’s evaluation4.1 Individual packingconformity : ? Details please see photo.Conform Not Conform Subject to client’s evaluation4.2 Inner packing conformity :Details please see photo.Conform Not Conform Subject to client’s evaluation4.3 Export packing conformity :Details please see photo.Conform Not Conform.5.MARKING / LABEL:Conform Not Conform Subject to client’s evaluation5.1 Export Carton MarkingPrinted/written/stuck on one/two long/short sideA. Shipping mark conformity:B. Side mark conformity:Details please see photo.Printed/written/stuck on one/two long/short side Details please see photo. ? Conform ? Not Conform ? Subject to client’s evaluationConform Not Conform Subject to client’s evaluation Conform Not Conform ? Subject to client’s evaluation5.2 Label / HangtagA.B.C. D. E. F. G.5.3 Bar code content5.4. Others6. PRODUCT-SPECIFIC DATA MEASUREMENTS/ FIELD TESTS ON REDUCED SAMPLE SIZE (asapplicable for specific product/order)6.1 Size measurement check on ____sub-samples: ? within ? beyond tolerance ? actual finding,Details please see attached size measurement chart.6.2. Product weight check on 3 pieces per size: ? within ? beyond tolerance ? actual finding. (unit: gm/piece)6.3 Function or assembly test: check on _____ sub-samples, found_____.Factory equipment: brand _________________; calibration record: yes or no, period: ______6.4 Thickness: ________6.5 Carton Information:。

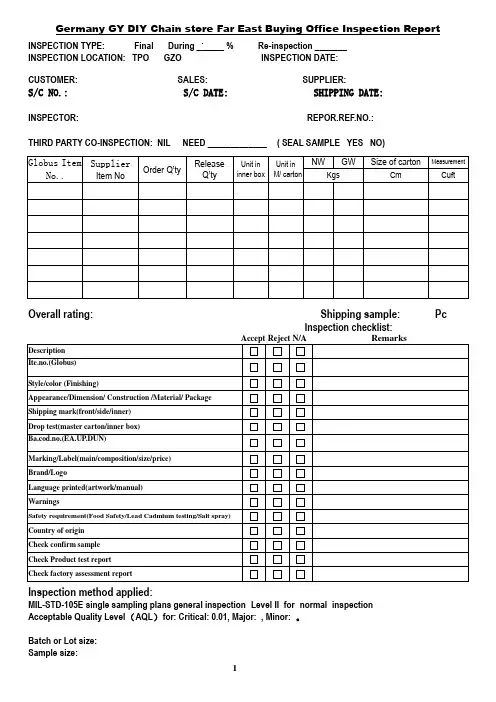

qc验货报告模板qc验货报告模板Inspection ReportBuyer : Agent : Supplier : Manufacturer :Product description: Style Number : Number: Service performed: Inspection Location :REFERENCE SAMPLE PROVIDED: ? Not AvailableNot Available Inspection Date :INSPECTION SUMMARY:Page 1of 5INSPECTION METHOD APPLIED:Inspection method: P-INSP- WI -ANSI / ASQ xx, Single sampling plans for normal inspection, Level I or II or others____: Samples selected from carton numbers: APPEARANCE / FUNCTION INSPECTION FINDINGS:Requested AQL Critical defective maximum allowed: _________ ? Within AQL? Beyond AQLMajor defective maximumallowed: _________ ? Within AQL? Beyond AQL Minor defective maximumallowed: _________ ? Within AQL? Beyond AQLPage 2of 52. QUANTITY:3. PRODUCT CONFORMITY: Style conformity:Material conformity:Color conformity :Conform? Not Conform ? Not applicable ? Subject to client’s evaluationConform? Not Conform ? Not applicable ? Subject to client’s evaluationConform? Not Conform ? Not applicable ? Subject to client’s evaluationNote: Two color shading lots in one color within grade 4 are acceptable commercially.Page 3of 5:Conform? Not Conform ? Subject to client’s Individual packingconformity : ? Details please see photo.Conform? Not Conform ? Subject to client’s Inner packing conformity :Details please see photo.Conform? Not Conform ? Subject to client’s Export packing conformity :Details please see photo.Conform? Not Conform./ LABEL:Conform? Not Conform ? Subject to client’s Export Carton MarkingPrinted/written/stuck on one/two long/short sideA. Shipping mark conformity:B. Side mark conformity:Details please see photo.Printed/written/stuck on one/two long/short side Details p lease see photo. ? Conform ? Not Conform ? Subject to client’s evaluation ? Conform ? Not Conform ? Subject to client’s evaluation ? Conform ? Not Conform ? Subject to client’s evaluationLabel / HangtagA.D. E. F. G.Bar code contentOthers6. PRODUCT-SPECIFIC DATA MEASUREMENTS/ FIELD TESTS ON REDUCED SAMPLE SIZESize measurement check on ____sub-samples: ? within ? beyond tolerance ? actual finding,Details please see attached size measurement chart.Product weight check on 3 pieces per size: ? within ? beyond tolerance ? actual finding.Function or assembly test: check on _____ sub-samples, found _____.Factory equipment: brand _________________; calibration record: yes or no, period: ______Thickness: ________Carton Information:Carton weight: ________ kgs/ cartonCarton size: L x W x H = ______ x _______ x_______ cm Carton with Metal Staple: ? Yes ? No Carton with Nylon Band:? Yes ? No7. FOLLOW UP ACTIONS: ? Inspection certificate will be issued ? Supplier advised shipment scheduled forPlease instruct regarding issuance of inspection certificate.8. Informative Remark:Inspection Environment: Lighting : ?Daylight ?Room lighting ?Sufficient ?Insufficient ?Other: Inspection place : ?Factory workshop ?Warehouse ?Other: Inspection done on: ?Table?Top of cartons ?Other: Cleanliness : ?Clean ?Dirty ?Weather condition: ?Rainy ?Dry ?Other:Grey ScaleGB250-1995 standard grey scale is applied for color shade checking in nature environment.The result is only for reference .Others.9. Attachments:******* END ********Page 5of 5Outgoing Quality Control ReportInspection Date:Inspector:出货检验报告检验日期:检验员QC:外贸QC验货流程职责:工厂所生产的货物必须保证品质合格及数量准确;针对产品进行资料、外观、性能、尺寸的核对,以保证产品到消费者手中的使用。

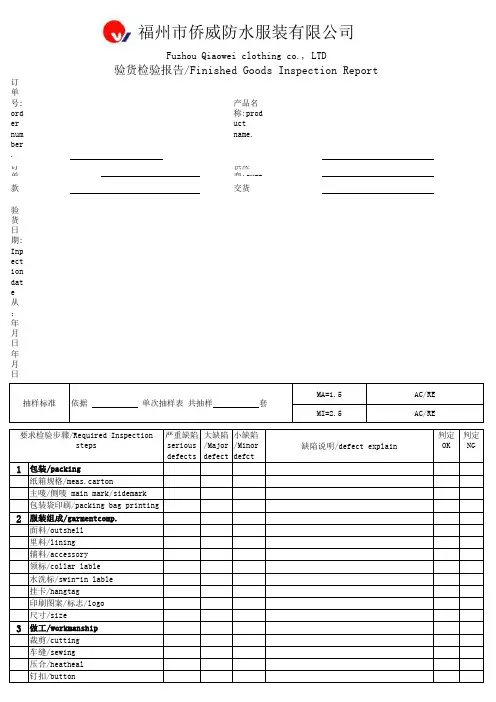

日期Date:质检人Inspection by:开始时间 Beginning time :结束时间 Finish time:工厂地址 Factory adress:负责人 Person in charge: 天气 Weather:晴Sunny( )多云Cloudy ( )雨Rain( )产品重量 Product weight:外箱尺寸 Outside carton size :内箱包装 Inside carton packing:外箱包装 箱/层 Outside carton packing case/level:落体(一米试摔)The free drop (one meter tries to fall):毛重 Gross weight:通过Pass( )失内盒正面唛头 Inside carton frontage mark:通过Pass( )失内盒侧面唛头 Inside carton side mark:主要Main 次要

Secondary 通过质检&装船 Pass the inspection&shipment :

已完成产品%箱 Has completed product % box :

已检查箱数 Inspected box quantity:

已检查产品数 Inspected product quantity:

验货报告 Inspection Report

订货单号码PO#:

货号Item#:

总数/箱数 Total /Box Quantity:

条形码号码 Bar code number :

产品描述 Product describes:

颜色 Colour:

材料 Product material:

产品尺寸 Product size :

件数/内盒Number of products/Inside carton:

件数/外箱Number of products/outside carton:

外箱正面唛头 Outside carton frontage mark:

产品规格 Product specification :

包装资料 Packing information :

净重 Net weight :

设计 Design:

箱号 Carton number:问题 Question:主要数量/次要数量

Main quantity/secondary

通过Pass( )失败Fail( )外箱侧面唛头 Outside carton side mark:

通过Pass( )失败Fail( )问题所在 The question position :

船唛 shipping mark :

建议/意见 Suggestion/opinion :

由生产部待定 By production 质检部及格&原因 QC department passed inspection & reason :

备注 Note :。