IEC 609501 标准介绍

- 格式:ppt

- 大小:5.33 MB

- 文档页数:11

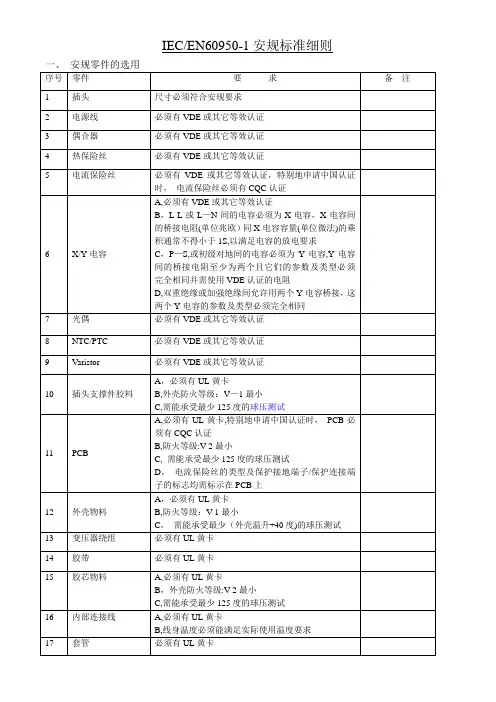

IEC/EN60950-1安规标准细则二、电气间隙及爬电距离1,L-N 间须至少满足基本绝缘2,保险丝两引脚间需至少满足基本绝缘3, 初次级电路之间,光藕初次级之间,变压器初次级之间(含初级绕组/初级PIN/初级铜箔对次级绕组/次级PIN/次级铜箔),Y电容初次级间均需满足双重绝缘或加强绝缘;初级带电部件同外壳外部可触及部位间需满足最少0。

4mm的穿透绝缘或双重绝缘/加强绝缘要求参考IEC60950-1 table 2H,2J,2L,基本绝缘,附加绝缘,加强绝缘(或双重绝缘)需满足以下要求(工作电压以250V AC 或354V峰值计算):基本绝缘/附加绝缘: 电气间隙CL:2。

mm Min, 爬电距离2。

5 mm Min双重绝缘/加强绝缘: 电气间隙CL:4.。

mm Min,爬电距离5.0 mm Min备注1:计算电气间隙及爬电距离,允许对内部零件施加10N的力备注2:计算电气间隙及爬电距离时,污染等级以2级计备注3:计算电气间隙及爬电距离时,物料级别通常为IIIb备注4:计算爬电距离时,允许用插值法三、高压及绝缘要求1备注:开关电源建议用DC电压进行高压测试.2、绝缘电阻IEC/EN60950-1对绝缘电阻无要求.四、正常温升(通常带满载进行测试)1,测试电压a,测试电压为电源电压的+6%- -10%,或b,额定电压为230V时,测试电压为230V的+/—10%,或c, 生产商指定的更宽的电压范围2,测试频率为50HZ 和/或60HZ3, 环境温度最大的环境温度为25度或生产商指定的更大值4, 绕阻允许的最高温度T《零件允许的最高温度+环境温度-生产商指定的最大的环境温度举例:B级绝缘物料允许的最高温度为120度, 测试的环境温度为25度,—若生产商没有指定最大的环境温度,则T《120+25-25,即T《120度(热偶法测试时T还需减10度)-若生产商指定最大的环境温度为40度,则则T《120+25—40,即T《105度(热偶法测试时T还需减10度)具体零件的温度限定见表4B5,正常温升测试的接收标准测试过程中,温度保险丝及电流保险丝不允许动作,零部件温度不得超出表4B的要求,测试后产品需立即通过高压测试五、异常测试(通常带满载进行测试)1, 测试电压a,测试电压为电源电压的+6%- —10%,或b,额定电压为230V时,测试电压为230V的+/-10%,或c, 生产商指定的更宽的电压范围2,测试频率为50HZ 和或60HZ3,环境温度最大的环境温度为25度或生产商指定的更大值4,测试方法a)开路或短路半导体零件和电容b)组合电路中会导致出现能量过分消耗的内部错误c)满足双重绝缘或加强绝缘的Y电容不必进行单一故障测试5,异常测试的接收标准异常测试过程中不允许出现:———火蔓延到设备外部,并且-——发出金属融化物——-外壳出现变形致使电气间隙及爬电距离不符要求-——A级绝缘物料温度超过150度,E级绝缘物料温度超过165度,B级绝缘物料温度超过175度,F 级绝缘物料温度超过190度,H级绝缘物料温度超过210度异常测试过程后不允许出现:—-——-高压失败六、接触电流(泄露电流)———可接触不见及电路没有连接到保护接地时,接触电流0.25mA Max-—-手持设备测试设备端子通过主保护接地端子时,接触电流0。

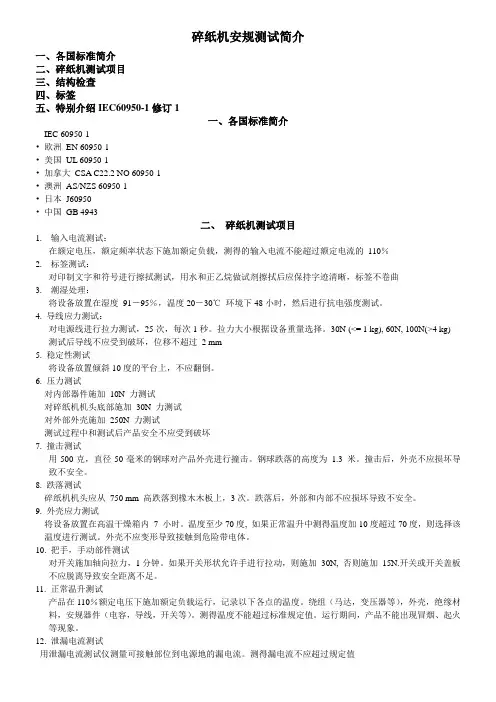

碎纸机安规测试简介一、各国标准简介二、碎纸机测试项目三、结构检查四、标签五、特别介绍IEC60950-1修订1一、各国标准简介IEC 60950-1•欧洲EN 60950-1•美国UL 60950-1•加拿大CSA C22.2 NO 60950-1•澳洲AS/NZS 60950-1•日本J60950•中国GB 4943二、碎纸机测试项目1. 输入电流测试:在额定电压,额定频率状态下施加额定负载,测得的输入电流不能超过额定电流的110%2. 标签测试:对印制文字和符号进行擦拭测试,用水和正乙烷做试剂擦拭后应保持字迹清晰,标签不卷曲3. 潮湿处理:将设备放置在湿度91-95%,温度20-30℃环境下48小时,然后进行抗电强度测试。

4. 导线应力测试:对电源线进行拉力测试,25次,每次1秒。

拉力大小根据设备重量选择。

30N (<= 1 kg), 60N, 100N(>4 kg) 测试后导线不应受到破坏,位移不超过 2 mm5. 稳定性测试将设备放置倾斜10度的平台上,不应翻倒。

6. 压力测试对内部器件施加10N 力测试对碎纸机机头底部施加30N 力测试对外部外壳施加250N 力测试测试过程中和测试后产品安全不应受到破坏7. 撞击测试用500克,直径50毫米的钢球对产品外壳进行撞击。

钢球跌落的高度为1.3 米。

撞击后,外壳不应损坏导致不安全。

8. 跌落测试碎纸机机头应从750 mm 高跌落到橡木木板上,3次。

跌落后,外部和内部不应损坏导致不安全。

9. 外壳应力测试将设备放置在高温干燥箱内7 小时。

温度至少70度, 如果正常温升中测得温度加10度超过70度,则选择该温度进行测试。

外壳不应变形导致接触到危险带电体。

10. 把手,手动部件测试对开关施加轴向拉力,1分钟。

如果开关形状允许手进行拉动,则施加30N, 否则施加15N.开关或开关盖板不应脱离导致安全距离不足。

11. 正常温升测试产品在110%额定电压下施加额定负载运行,记录以下各点的温度。

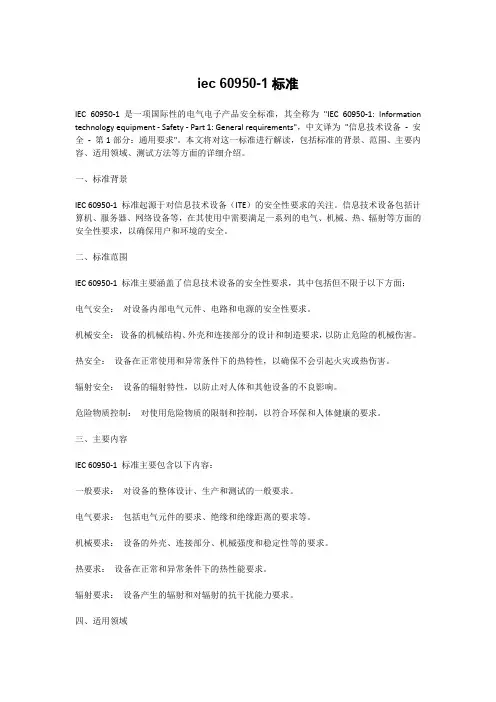

iec 60950-1标准IEC 60950-1 是一项国际性的电气电子产品安全标准,其全称为"IEC 60950-1: Information technology equipment - Safety - Part 1: General requirements",中文译为"信息技术设备-安全-第1部分:通用要求"。

本文将对这一标准进行解读,包括标准的背景、范围、主要内容、适用领域、测试方法等方面的详细介绍。

一、标准背景IEC 60950-1 标准起源于对信息技术设备(ITE)的安全性要求的关注。

信息技术设备包括计算机、服务器、网络设备等,在其使用中需要满足一系列的电气、机械、热、辐射等方面的安全性要求,以确保用户和环境的安全。

二、标准范围IEC 60950-1 标准主要涵盖了信息技术设备的安全性要求,其中包括但不限于以下方面:电气安全:对设备内部电气元件、电路和电源的安全性要求。

机械安全:设备的机械结构、外壳和连接部分的设计和制造要求,以防止危险的机械伤害。

热安全:设备在正常使用和异常条件下的热特性,以确保不会引起火灾或热伤害。

辐射安全:设备的辐射特性,以防止对人体和其他设备的不良影响。

危险物质控制:对使用危险物质的限制和控制,以符合环保和人体健康的要求。

三、主要内容IEC 60950-1 标准主要包含以下内容:一般要求:对设备的整体设计、生产和测试的一般要求。

电气要求:包括电气元件的要求、绝缘和绝缘距离的要求等。

机械要求:设备的外壳、连接部分、机械强度和稳定性等的要求。

热要求:设备在正常和异常条件下的热性能要求。

辐射要求:设备产生的辐射和对辐射的抗干扰能力要求。

四、适用领域IEC 60950-1 标准适用于广泛的信息技术设备,包括但不限于:个人计算机和工作站服务器和数据中心设备网络设备,如路由器和交换机存储设备,如硬盘和光盘驱动器打印机和复印机视听设备,如电视、音响系统通信设备,如电话和传真机五、测试方法IEC 60950-1 标准中包含了一系列的测试方法,以确保设备在正常和异常条件下的安全性能。

IEC60950-1安规要求介绍讲义引言IEC60950-1是国际电工委员会(International Electrotechnical Commission)制定的安全标准,适用于信息技术设备(Information Technology Equipment,简称ITE)。

本文档将介绍IEC60950-1安规要求的基本概念和相关细节。

IEC60950-1的基本概念IEC60950-1是基于安全性原则的标准,其主要目的是保护使用者和操作员不受设备电气、机械和火灾等方面的危害。

该标准包含了一系列安全要求,以确保设备在正常使用中不会对人体造成伤害,并可以正常运行。

IEC60950-1的安全要求分为以下几个方面:1.电气安全:包括对设备内部电路的保护,以及对电气绝缘、接地和接触电流的要求。

2.机械安全:包括对设备结构和材料的要求,以及对可触及的部件和移动部分的安全保护。

3.火灾安全:包括对设备燃烧性能和防火措施的要求,以及对设备在故障条件下的火灾风险评估。

4.辐射安全:包括电磁辐射和光辐射的安全要求,以保护使用者和操作员的健康。

5.温度和湿度安全:包括对设备工作环境的温度和湿度要求,以确保设备的正常运行。

IEC60950-1安规的详细要求1. 电气安全要求1.1 设备内部电路的保护要求:•设备内部电路应采用双重绝缘或等效绝缘材料,以防止电气短路和触电风险。

•设备内部电路的绝缘电阻应满足规定的要求,以确保设备在正常工作和故障条件下不会引发危险。

•设备应具备过流和过压保护装置,以防止设备损坏和电气火灾。

1.2 电气绝缘和接地要求:•设备的外壳和外部连接部件应具备足够的机械强度和电气绝缘性能,以防止电气触电风险。

•设备应有可靠的接地装置,以确保设备在故障条件下能够及时排除电气故障。

2. 机械安全要求2.1 设备结构和材料的要求:•设备结构应有足够的机械强度和稳定性,以防止设备在正常使用过程中发生变形或损坏。

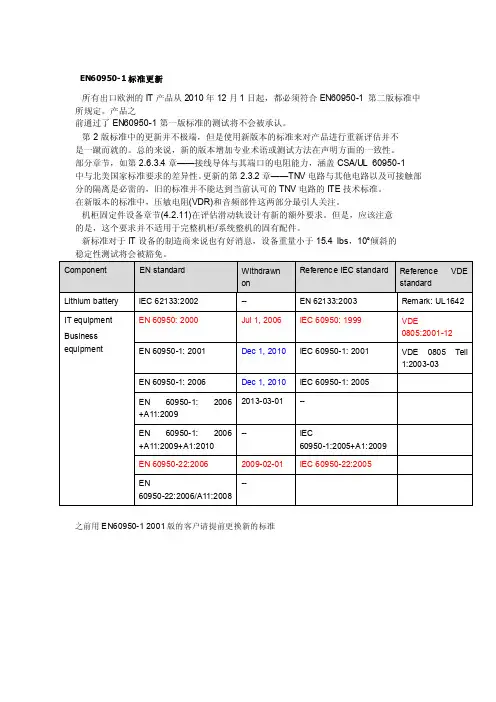

EN60950-1标准更新所有出口欧洲的IT产品从2010年12月1日起,都必须符合EN60950-1 第二版标准中所规定。

产品之前通过了EN60950-1第一版标准的测试将不会被承认。

第2版标准中的更新并不极端,但是使用新版本的标准来对产品进行重新评估并不是一蹴而就的。

总的来说,新的版本增加专业术语或测试方法在声明方面的一致性。

部分章节,如第2.6.3.4章——接线导体与其端口的电阻能力,涵盖CSA/UL 60950-1中与北美国家标准要求的差异性。

更新的第2.3.2章——TNV电路与其他电路以及可接触部分的隔离是必需的,旧的标准并不能达到当前认可的TNV电路的ITE技术标准。

在新版本的标准中,压敏电阻(VDR)和音频部件这两部分最引人关注。

机柜固定件设备章节(4.2.11)在评估滑动轨设计有新的额外要求。

但是,应该注意的是,这个要求并不适用于完整机柜/系统整机的固有配件。

新标准对于IT设备的制造商来说也有好消息,设备重量小于15.4 lbs,10°倾斜的稳定性测试将会被豁免。

之前用EN60950-1 2001版的客户请提前更换新的标准EN 55022:2006 (CISPR 22:2005)在欧盟(European Union,EU)自2009年10月1日正式生效。

现在相关的辐射干扰(radiated disturbances)测试范围是由30MHz至1GHz,但是修正案A1:2007将会加入1GHz至6GHz的测试范围,并于2010年10月1日生效。

因此在测量辐射干扰时,将采用30MHz至6Ghz的频段。

修改EN 55022:2006所产生的影响CISPR 22 (the Comite International Special des Perturbations Radioelectriques, or International Special Committee on Radio Interference, 国际无线电干扰特别委员会)是适用范围最广的一项重要的EMC (electromagnetic compatibility,电磁兼容)标准,并对资讯科技设备(information technology equipment,ITE)提出了一些要求,其中包括了「电讯装备和个人电脑」(telecommunications apparatus and PCs)。

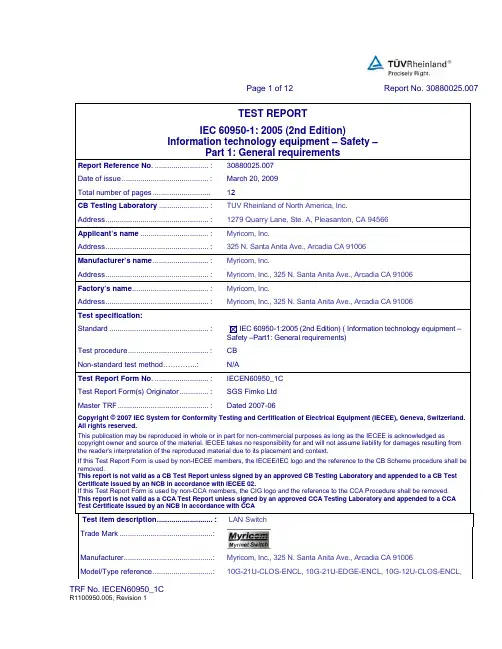

Page 1 of 12 Report No. 30880025.007 Myricom, Inc., 325 N. Santa Anita Ave., Arcadia CA 91006Page 2 of 12 Report No. 30880025.00710G-12U-SPINE-ENCL, 10G-7U-CLOS-ENCL, 10G-7U-SPINE-ENCL Ratings....................................................: Input: 100-240V, 50/60 Hz, 10A-5A (rating per input, up to 4 inputs)Page 3 of 12 Report No. 30880025.007General remarks:The test results presented in this report relate only to the object tested.This report shall not be reproduced, except in full, without the written approval of the Issuing testinglaboratory."(See Enclosure #)" refers to additional information appended to the report."(See appended table)" refers to a table appended to the report.Note: This TRF includes EN Group Differences together with National Differences and SpecialNational Conditions, if any. All Differences are located in the Appendix to the main body of this TRF. Throughout this report a comma (point) is used as the decimal separator.General product information:This test report is Amendment 2 to the original CB-report with document number 30880025.001 and the first amendmentCB report 30880025.004 and covers the addition of new line cards 10G-THRU-16Q, 10G-THRU-8M8ER, 10G-THRU-16WQP, 10G-SW32LC-16QP, 10G-S SW32LC-16ES, 10G-SW32LC-16EM. Each line card uses less power than linecards that have already been evaluated for the original report and subsequent amendment so no testing was performed as part of this investigation and the new line cards have been evaluated on a constructional basis only. Critical components within the line cards being added include Certified Class 1 lasers only.The product covered in this test report are LAN Switches with the model numbers: 10G-21U-CLOS-ENCL, 10G-21U-EDGE-ENCL, 10G-12U-CLOS-ENCL, 10G-12U-SPINE-ENCL, 10G-7U-CLOS-ENCL and 10G-7U-SPINE-ENCL. TheLAN Switch product comes with six different configuration codes: 10G-21U-CLOS-ENCL has the CLOS backplane boards, which accept eight 10G-2SW32LC line cards in the middle, one 10G-MONITOR-B in the top, and nearly any combination of the other line cards in the other slots. The 10G-21U-EDGE-ENCL has one 10G-MONITOR-B in the top,and the other slots accepts nearly any combination of the other line cards, excluding the 10G-2SW32LC line card (For details of line cards, see critical components list table 1.5.1). The 12U and 7U configurations are similar in functional configuration with the differences being the 12U is a smaller chassis intended for use with 2-4 power supplies and the7U is a still smaller chassis intended for use with 1-2 power supplies. The 12U configuration was tested per this investigation and it was determined via the test results and inspection that the data taken for the 21U is representativeof the 12U and 7U and as such the previously-measured 21 test results are applied to this report amendment.The enclosures contain a metal chassis, up four approved power supplies (different for each model), approved DC fans, a backplane, AC-Inlet/Filter and interface cards, which are all interchangeable. Model No. 10G-21U-CLOS-ENCL is a ‘21U high, 41-slot enclosure for switch networks up to 512 ports’ located on the rear panel of the unit. These ports areconnected to copper and fiber cables and there is no power available on these ports. All signals are AC coupled through470pF capacitorsDuring the testing the maximum power was generated by using resistive loads. Due to the expenses of each individualcard, a low-cost test configuration with these resistive loads cards generating 200W of power was used for thetemperature rise measurement and abnormal fault conditions.It should be noted that for the final configuration of the LAN Switches each individual card has two redundant temperature sensors which control the power to a card (thermal cut-out / power off at 60˚C). Also, the four DC fans at the back-side ofthe products are speed-adjustable depending on the temperature inside the LAN Switch enclosure. Individual temperature sensors are located on each line card and each fan controller PCBModel 10G-21U-CLOS-ENCL is intended to be fully operational with a minimum of three power supplies only. However,the four power supply configuration is intended for triple-AC systems( where there are three different sources of ACPage 4 of 12 Report No. 30880025.007 power), and the enclosure will continue to run will continue to run with one AC off and one power supply down. The unit contains; four fans, four power supplies and thirty cards – mixed.There are no connections to a Telecommunication Network (TNV).CDRH-Report for Optical Transceiver has to be provided by customer for US Approval.During the testing the maximum power was generated by using resistive loads. Due to the expenses ofeach individual card a low-cost test configuration with these resistive load cards, generating 200W ofpower, was used for the temperature rise measurements and abnormal fault conditions.Conditions of Acceptability:1.This unit is considered to operate under the conditions of:– Pollution Degree 2: Not sealed, not subjected to dust, dirt, and condensation– Equipment mobility: Rack mounted / fixed2. Rated ambient of 40°C at maximum rated loadPage 5 of 12 Report No. 30880025.007Page 6 of 12 Report No. 30880025.007 Summary of testing:Tests performed (name of test and test clause): = no testing performed for this amendment =Testing location:TUV Rheinland of North America, Inc.1279 Quarry Lane, Ste. A, Pleasanton, CA 94566Summary of compliance with National Differences:Comments:Summary of compliance with National Differences (for explanation of codes see below):AT, CA (temporary differences), DE, DK, FI, FR, GB, IT, JP, KR, NL, NO, PL, SE, SI, US (temporary differences).and Group Differences as listed at the end of this test reportExplanation of Codes:AT=Austria, CA-Canada, DE=Germany, DK=Denmark, FI=Finland, FR=France, GB=United Kingdom, IT=Italy,JP=Japan, KR=Korea, NL=The Netherlands, NO=Norway, PL=Poland, SE=Sweden, SI=Slovenia, US=United StatesThe following Attachments are integral part of this test report:= no attachments for this amendment =Page 7 of 12 Report No. 30880025.007Test item particulars..................................................:Equipment mobility....................................................: [] movable [] hand-held [] transportable[X] stationary [] for building-in [] direct plug-in Connection to the mains............................................: [] pluggable equipment [] type A [] type B[] permanent connection[X] detachable power supply cord[] non-detachable power supply cord[] not directly connected to the mainsOperating condition...................................................: [X] continuous[] rated operating / resting time:Access location .........................................................: [X] operator accessible[] restricted access locationOver voltage category (OVC) ...................................: [] OVC I [X] OVC II [] OVC III [] OVC IV[] other:Mains supply tolerance (%) or absolute mains supplyvalues .......................................................................:Tested for IT power systems ....................................: [X] Yes [] NoIT testing, phase-phase voltage (V) .........................: 230VClass of equipment ...................................................: [X] Class I [] Class II [] Class III[] Not classifiedConsidered current rating (A) ...................................:Pollution degree (PD) ...............................................: [] PD 1 [X] PD 2 [] PD 3IP protection class ....................................................: IPX0Altitude during operation (m) ....................................: 2000 mAltitude of test laboratory (m) ...................................: 2000 mMass of equipment (kg) ............................................: 98kgPossible test case verdicts:- test case does not apply to the test object.................:N/A- test object does meet the requirement.......................:P (Pass)- test object does not meet the requirement.................: F (Fail) Testing..........................................................................:Date of receipt of test item............................................:N/ADate(s) of performance of tests....................................:N/A[constructional check only, all test data is based onpreviously issued reports 30880025.001 and30880025.004, all changes per this amendment are eithernon-safety critical or editorial in nature only]Page 8 of 12 Report No. 30880025.007 1 GENERAL P1.5 Components P1.5.1 General Complies PComply with IEC 60950-1 or relevant component standard Refer to appended table 1.5.1(list of critical components)P1.5.2 Evaluation and testing of components All safety critical componentsare certified. All componentsare used within their specifiedratings, plastic materials,PCBs and wiring materialsare UL listed, non-certifiedcomponents were testedaccording to this standard.P 1.5.1 TABLE: List of critical components PObject/part No. Manufacturer/trademark Type/model Technical data Standard (Edition/ year)Mark(s) ofconformity1)1.) Power Supply (up to 4 each) Astec DS850-3 Input:100-240,50/60Hz, 10A;Output: +12V/70A,+3.3V/6AIEC/EN/UL60950-1UL 1449 (VDR’s)CSA, cULus, TUV2.) DC Fan (up to 8 each) Delta FFB1212EHE-F0012VDC3.0A –5.38 m3/minIEC/EN/UL 60950-1 VDE, CE, UL,CSA3.) DC Fan Controller board Myricom 05-2896 Minimumflammability rating:V-0,UL94 ULPage 9 of 12 Report No. 30880025.0074.) Internal wiring Various Various Rated 600V,105˚C,flammability ratingminimum VW-1 4wire gage type10070 from outputpower distributionboard to the powerback plane busbars (2 cables;3feet long) +/-12V.Wire gages forline/neutral/safetyground: type“1015” wire , 18gafor +12/- Backplane tosignal/power/fansto backplane 18ga to 24 ga .-- UL5.) Cards Myricom 10G-Monitor –B Minimumflammabilityrating:V-0UL94 UL6.) Cards Myricom 10G-SW32LC-16M Minimumflammabilityrating:V-0UL94 UL7.) Cards Myricom 10G-THRU-16M Minimumflammabilityrating:V-0UL94 UL8.) Cards Myricom 10G-SW32LC-16Q Minimumflammabilityrating:V-0UL94 UL9.) Cards Myricom 10G-THRU-16Q Minimumflammabilityrating;V-0UL94 UL10.) Cards Myricom 10G-SW32LC-8Q8ER Minimumflammabilityrating:V-0UL94 UL11.) Cards Myricom 10G-THRU-8Q8ER Minimumflammabilityrating:V-0UL94 UL12.) Cards Myricom 10G-SW32LC-8M8ER Minimumflammabilityrating:V-0UL94 UL13.) Cards Myricom 10G-THRU-8M8ER Minimumflammabilityrating:V-0UL94 UL14.) Cards Myricom 10G-SW32LC-8M8EM Minimumflammabilityrating:V-0UL94 UL15.) Cards Myricom 10G-THRU-8M8EM Minimumflammabilityrating:V-0UL94 UL16.) Cards Myricom 10G-SW32LC-16QP Minimumflammabilityrating:V-0UL94 ULPage 10 of 12 Report No. 30880025.007 17.) Cards Myricom 10G-THRU-16QP Minimumflammabilityrating:V-0UL94 UL18.) Cards Myricom 10G-SW32LC-8QP8ER Minimumflammabilityrating:V-0UL94 UL19.) Cards Myricom 10G-SW32LC-16ES Minimumflammabilityrating:V-0UL94 UL20.) Cards Myricom 10G-SW32LC-16EM Minimumflammabilityrating:V-0UL94 UL21.) Cards Myricom 10G-2SW32LC Minimumflammabilityrating:V-0UL94 UL22.) Cards Myricom 10G-FAN v1.0 Minimumflammabilityrating:V-0UL94 UL23.) Backplane left Myricom 10G-21U-CLOSMinimumflammabilityrating:V-0UL94 UL24.) Backplane right Myricom 10G-21U-CLOSMinimumflammabilityrating:V-0UL94 UL25.) Backplane left Myricom 10G-21U-EDGEMinimumflammabilityrating:V-0UL94 UL26.) Backplane right Myricom 10G-21U-EDGEMinimumflammabilityrating:V-0UL94 UL27.) Backplane left Myricom 10G-12U-CLOSMinimumflammabilityrating:V-0UL94 UL28.) Backplane right Myricom 10G-12U-CLOSMinimumflammabilityrating:V-0UL94 UL29.) Backplane left Myricom 10G-12U-EDGEMinimumflammabilityrating:V-0UL94 UL30.) Backplane right Myricom 10G-12U-EDGEMinimumflammabilityrating:V-0UL94 UL31.) Backplane left Myricom 10G-7U-CLOSMinimumflammabilityrating:V-0UL94 UL32.) Backplane right Myricom 10G-7U-CLOSMinimumflammabilityrating:V-0UL94 UL33.) Backplane left Myricom 10G-7U-EDGEMinimumflammabilityrating:V-0UL94 UL34.) Backplane right Myricom 10G-7U-EDGEMinimumflammabilityrating:V-0UL94 UL35.)Power Cord (U.K.) Volex 2922 250V, 10A, 13Afuse, 1mm2-- ASTA,BSIPage 11 of 12 Report No. 30880025.00736.) Power Cord (Germany / Europe) Volex orequivalent17850or equivalentRating: 300V, 10A,1.0mm2-- VDE, N, FI, S, D, I37.) Power Cord (U.S.) Volex 17504 125V, 15A, 14AWG-- UL,CSA38.) Power Cord (Japan) Feller 5330-440 125V,15A,2.0mm2-- DENTORI39.) Transceiver (10G-SW32LC-16Q/10G-THRU-16Q/10G-SW32LC-8Q8ER/10G-THRU-8Q8ER)Zarlink ZL60304-MKDA Class I M laser IEC/EN 60825-1 TUV, UL40.) Transceiver (10G-SW32LC-8Q8ER/10G-THRU-8Q8ER/10G-SW32LC-16Q/10G-THRU-16Q)Avago HFBR-7934EHZ Class I M laser IEC/EN 60825-1 TUV, UL41.) Transceiver (10G-SW32LC-8M8ER/10G-THRU-8M8ER/10G-SW32LC-8Q8ER/10G-THRU-8Q8ER/10G-SW32LC-8QP8ER)Finisar FLTX8511D3 Class I M laser IEC/EN 60825-1 TUV, UL42.) Transceiver (10G-SW32LC-8M8ER/10G-THRU-8M8ER/10G-SW32LC-8Q8ER/10G-THRU-8Q8ER/10G-SW32LC-8QP8ER)Finisar FTLX1411D3 Class I M laser IEC/EN 60825-1 TUV, ULPage 12 of 12 Report No. 30880025.00743.) Transceiver ( 10G-SW32LC-8M8ER/10G-THRU-8M8ER/10G-SW32LC-8Q8ER/10G-THRU-8Q8ER/10G-SW32LC-8QP8ER) Finisar FTLX1412D3BCL Class I laser EN 60825-1EN 60825-2EN 60950-1CSA 60950-1-03CDRHTUV, CSA, FDA44.) Transceiver (10G-SW32LC-8QP8ER/10G-SW32LC-16QP/10G-THRU-16QP)Zarlink ZL60505MJDA Class I M laser IEC/EN 60825-1 TUV, UL45.) Transceiver ( 10G-SW32LC-16ES) Finisar FTLX8571D3BCL Class I laser EN 60825-1EN 60825-2EN 60950-1CDRHTUV, FDA46.) Transceiver ( 10G-SW32LC-16ES) Finisar FTLX1471D3BCL Class I laser EN 60825-1EN 60825-2EN 60950-1CDRHTUV, FDA47.) Transceiver ( 10G-SW32LC-8QP8ER/10G-SW32LC-16QP/10G-THRU-16QP) Tyco Electronics 1985554-x1985861-x1-198554-01-1985861-01-1985861-1Class I M laser EN 60825-1EN 60825-2EN 60950-1CSA 60950-1-03CDRHTUV, CSA, FDA48.) InsulationTape/ used on theinternal chassisadjacent to metalbus bar3M Type 1206 Rated 155˚C UL510 UL49.) Temperature Sensor NationalSemiconductorLM74 3.0V/2.65V to5.5V, -10˚C to65˚C- -50.) Power Distribution Board Myricom 10G-POWERv1.1.Minimumflammabilityrating:V-0UL94 UL END of TEST REPORT。

STANDARD & APPLICATION引言浪涌被称为瞬态过电压,是电路中出现的一种短暂电流、电压波动,会对电子设备造成危害。

压敏电阻作为信息技术设备等产品中常见的抗雷击浪涌的元器件,可以有效防止这种危害。

但是压敏电阻的使用位置、选型不当都可能造成整机产品不满足安全标准要求。

本文分析了IEC 60950-1: 2013中对压敏电阻的要求,以期对压敏电阻的正确使用提供帮助。

1 压敏电阻相关定义解析电子电路中的浪涌保护元器件,也称为浪涌抑制器。

常见的浪涌抑制器包括电压敏感电阻器(VDR)、碳块、气体放电管(GDT)和其他一些具有非线性电压电流特性的半导体器件,如瞬态抑制二极管(TVS diode)。

其中电压敏感电阻器按其使用材料的不同可分为碳化硅压敏电阻器、金属氧化物压敏电阻器(MOV)、钛酸钡压敏电阻器等,其中以氧化锌为主的金属氧化物压敏电阻是目前开关电源中最广泛使用的浪涌保护元器件。

本文所分析的压敏电阻特指金属氧化物压敏电阻。

2 典型浪涌保护元器件介绍浪涌的保护元器件一般分为开关型和钳位型。

压敏电阻属于钳位型的典型代表,而气体放电管属于开关型的典型代表。

两者的区别也使得在使用时有极大不同。

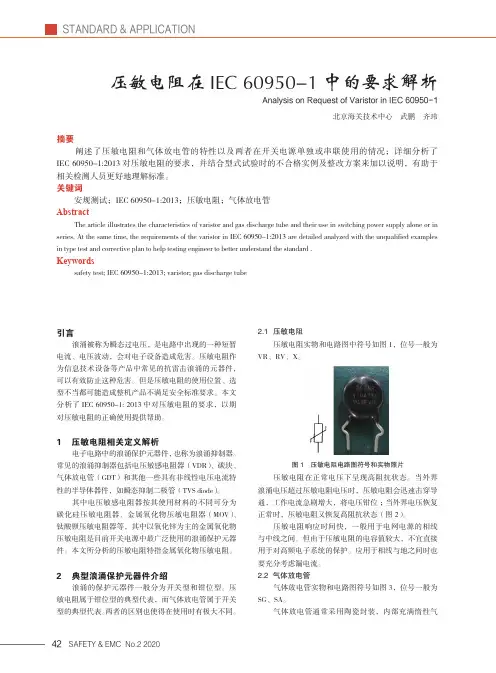

2.1 压敏电阻压敏电阻实物和电路图中符号如图1,位号一般为VR、RV、X。

压敏电阻在正常电压下呈现高阻抗状态。

当外界浪涌电压超过压敏电阻电压时,压敏电阻会迅速击穿导通,工作电流急剧增大,将电压钳位;当外界电压恢复正常时,压敏电阻又恢复高阻抗状态(图2)。

压敏电阻响应时间快,一般用于电网电源的相线与中线之间。

但由于压敏电阻的电容值较大,不宜直接用于对高频电子系统的保护。

应用于相线与地之间时也要充分考虑漏电流。

2.2 气体放电管气体放电管实物和电路图符号如图3,位号一般为SG、SA。

气体放电管通常采用陶瓷封装,内部充满惰性气压敏电阻在IEC 60950-1中的要求解析Analysis on Request of Varistor in IEC 60950-1北京海关技术中心 武鹏 齐玮摘要阐述了压敏电阻和气体放电管的特性以及两者在开关电源单独或串联使用的情况;详细分析了 IEC 60950-1:2013对压敏电阻的要求,并结合型式试验时的不合格实例及整改方案来加以说明,有助于相关检测人员更好地理解标准。

Page 1 of 12 Report No. 30880025.007 Myricom, Inc., 325 N. Santa Anita Ave., Arcadia CA 91006Page 2 of 12 Report No. 30880025.00710G-12U-SPINE-ENCL, 10G-7U-CLOS-ENCL, 10G-7U-SPINE-ENCL Ratings....................................................: Input: 100-240V, 50/60 Hz, 10A-5A (rating per input, up to 4 inputs)Page 3 of 12 Report No. 30880025.007General remarks:The test results presented in this report relate only to the object tested.This report shall not be reproduced, except in full, without the written approval of the Issuing testinglaboratory."(See Enclosure #)" refers to additional information appended to the report."(See appended table)" refers to a table appended to the report.Note: This TRF includes EN Group Differences together with National Differences and SpecialNational Conditions, if any. All Differences are located in the Appendix to the main body of this TRF. Throughout this report a comma (point) is used as the decimal separator.General product information:This test report is Amendment 2 to the original CB-report with document number 30880025.001 and the first amendmentCB report 30880025.004 and covers the addition of new line cards 10G-THRU-16Q, 10G-THRU-8M8ER, 10G-THRU-16WQP, 10G-SW32LC-16QP, 10G-S SW32LC-16ES, 10G-SW32LC-16EM. Each line card uses less power than linecards that have already been evaluated for the original report and subsequent amendment so no testing was performed as part of this investigation and the new line cards have been evaluated on a constructional basis only. Critical components within the line cards being added include Certified Class 1 lasers only.The product covered in this test report are LAN Switches with the model numbers: 10G-21U-CLOS-ENCL, 10G-21U-EDGE-ENCL, 10G-12U-CLOS-ENCL, 10G-12U-SPINE-ENCL, 10G-7U-CLOS-ENCL and 10G-7U-SPINE-ENCL. TheLAN Switch product comes with six different configuration codes: 10G-21U-CLOS-ENCL has the CLOS backplane boards, which accept eight 10G-2SW32LC line cards in the middle, one 10G-MONITOR-B in the top, and nearly any combination of the other line cards in the other slots. The 10G-21U-EDGE-ENCL has one 10G-MONITOR-B in the top,and the other slots accepts nearly any combination of the other line cards, excluding the 10G-2SW32LC line card (For details of line cards, see critical components list table 1.5.1). The 12U and 7U configurations are similar in functional configuration with the differences being the 12U is a smaller chassis intended for use with 2-4 power supplies and the7U is a still smaller chassis intended for use with 1-2 power supplies. The 12U configuration was tested per this investigation and it was determined via the test results and inspection that the data taken for the 21U is representativeof the 12U and 7U and as such the previously-measured 21 test results are applied to this report amendment.The enclosures contain a metal chassis, up four approved power supplies (different for each model), approved DC fans, a backplane, AC-Inlet/Filter and interface cards, which are all interchangeable. Model No. 10G-21U-CLOS-ENCL is a ‘21U high, 41-slot enclosure for switch networks up to 512 ports’ located on the rear panel of the unit. These ports areconnected to copper and fiber cables and there is no power available on these ports. All signals are AC coupled through470pF capacitorsDuring the testing the maximum power was generated by using resistive loads. Due to the expenses of each individualcard, a low-cost test configuration with these resistive loads cards generating 200W of power was used for thetemperature rise measurement and abnormal fault conditions.It should be noted that for the final configuration of the LAN Switches each individual card has two redundant temperature sensors which control the power to a card (thermal cut-out / power off at 60˚C). Also, the four DC fans at the back-side ofthe products are speed-adjustable depending on the temperature inside the LAN Switch enclosure. Individual temperature sensors are located on each line card and each fan controller PCBModel 10G-21U-CLOS-ENCL is intended to be fully operational with a minimum of three power supplies only. However,the four power supply configuration is intended for triple-AC systems( where there are three different sources of ACPage 4 of 12 Report No. 30880025.007 power), and the enclosure will continue to run will continue to run with one AC off and one power supply down. The unit contains; four fans, four power supplies and thirty cards – mixed.There are no connections to a Telecommunication Network (TNV).CDRH-Report for Optical Transceiver has to be provided by customer for US Approval.During the testing the maximum power was generated by using resistive loads. Due to the expenses ofeach individual card a low-cost test configuration with these resistive load cards, generating 200W ofpower, was used for the temperature rise measurements and abnormal fault conditions.Conditions of Acceptability:1.This unit is considered to operate under the conditions of:– Pollution Degree 2: Not sealed, not subjected to dust, dirt, and condensation– Equipment mobility: Rack mounted / fixed2. Rated ambient of 40°C at maximum rated loadPage 5 of 12 Report No. 30880025.007Page 6 of 12 Report No. 30880025.007 Summary of testing:Tests performed (name of test and test clause): = no testing performed for this amendment =Testing location:TUV Rheinland of North America, Inc.1279 Quarry Lane, Ste. A, Pleasanton, CA 94566Summary of compliance with National Differences:Comments:Summary of compliance with National Differences (for explanation of codes see below):AT, CA (temporary differences), DE, DK, FI, FR, GB, IT, JP, KR, NL, NO, PL, SE, SI, US (temporary differences).and Group Differences as listed at the end of this test reportExplanation of Codes:AT=Austria, CA-Canada, DE=Germany, DK=Denmark, FI=Finland, FR=France, GB=United Kingdom, IT=Italy,JP=Japan, KR=Korea, NL=The Netherlands, NO=Norway, PL=Poland, SE=Sweden, SI=Slovenia, US=United StatesThe following Attachments are integral part of this test report:= no attachments for this amendment =Page 7 of 12 Report No. 30880025.007Test item particulars..................................................:Equipment mobility....................................................: [] movable [] hand-held [] transportable[X] stationary [] for building-in [] direct plug-in Connection to the mains............................................: [] pluggable equipment [] type A [] type B[] permanent connection[X] detachable power supply cord[] non-detachable power supply cord[] not directly connected to the mainsOperating condition...................................................: [X] continuous[] rated operating / resting time:Access location .........................................................: [X] operator accessible[] restricted access locationOver voltage category (OVC) ...................................: [] OVC I [X] OVC II [] OVC III [] OVC IV[] other:Mains supply tolerance (%) or absolute mains supplyvalues .......................................................................:Tested for IT power systems ....................................: [X] Yes [] NoIT testing, phase-phase voltage (V) .........................: 230VClass of equipment ...................................................: [X] Class I [] Class II [] Class III[] Not classifiedConsidered current rating (A) ...................................:Pollution degree (PD) ...............................................: [] PD 1 [X] PD 2 [] PD 3IP protection class ....................................................: IPX0Altitude during operation (m) ....................................: 2000 mAltitude of test laboratory (m) ...................................: 2000 mMass of equipment (kg) ............................................: 98kgPossible test case verdicts:- test case does not apply to the test object.................:N/A- test object does meet the requirement.......................:P (Pass)- test object does not meet the requirement.................: F (Fail) Testing..........................................................................:Date of receipt of test item............................................:N/ADate(s) of performance of tests....................................:N/A[constructional check only, all test data is based onpreviously issued reports 30880025.001 and30880025.004, all changes per this amendment are eithernon-safety critical or editorial in nature only]Page 8 of 12 Report No. 30880025.007 1 GENERAL P1.5 Components P1.5.1 General Complies PComply with IEC 60950-1 or relevant component standard Refer to appended table 1.5.1(list of critical components)P1.5.2 Evaluation and testing of components All safety critical componentsare certified. All componentsare used within their specifiedratings, plastic materials,PCBs and wiring materialsare UL listed, non-certifiedcomponents were testedaccording to this standard.P 1.5.1 TABLE: List of critical components PObject/part No. Manufacturer/trademark Type/model Technical data Standard (Edition/ year)Mark(s) ofconformity1)1.) Power Supply (up to 4 each) Astec DS850-3 Input:100-240,50/60Hz, 10A;Output: +12V/70A,+3.3V/6AIEC/EN/UL60950-1UL 1449 (VDR’s)CSA, cULus, TUV2.) DC Fan (up to 8 each) Delta FFB1212EHE-F0012VDC3.0A –5.38 m3/minIEC/EN/UL 60950-1 VDE, CE, UL,CSA3.) DC Fan Controller board Myricom 05-2896 Minimumflammability rating:V-0,UL94 ULPage 9 of 12 Report No. 30880025.0074.) Internal wiring Various Various Rated 600V,105˚C,flammability ratingminimum VW-1 4wire gage type10070 from outputpower distributionboard to the powerback plane busbars (2 cables;3feet long) +/-12V.Wire gages forline/neutral/safetyground: type“1015” wire , 18gafor +12/- Backplane tosignal/power/fansto backplane 18ga to 24 ga .-- UL5.) Cards Myricom 10G-Monitor –B Minimumflammabilityrating:V-0UL94 UL6.) Cards Myricom 10G-SW32LC-16M Minimumflammabilityrating:V-0UL94 UL7.) Cards Myricom 10G-THRU-16M Minimumflammabilityrating:V-0UL94 UL8.) Cards Myricom 10G-SW32LC-16Q Minimumflammabilityrating:V-0UL94 UL9.) Cards Myricom 10G-THRU-16Q Minimumflammabilityrating;V-0UL94 UL10.) Cards Myricom 10G-SW32LC-8Q8ER Minimumflammabilityrating:V-0UL94 UL11.) Cards Myricom 10G-THRU-8Q8ER Minimumflammabilityrating:V-0UL94 UL12.) Cards Myricom 10G-SW32LC-8M8ER Minimumflammabilityrating:V-0UL94 UL13.) Cards Myricom 10G-THRU-8M8ER Minimumflammabilityrating:V-0UL94 UL14.) Cards Myricom 10G-SW32LC-8M8EM Minimumflammabilityrating:V-0UL94 UL15.) Cards Myricom 10G-THRU-8M8EM Minimumflammabilityrating:V-0UL94 UL16.) Cards Myricom 10G-SW32LC-16QP Minimumflammabilityrating:V-0UL94 ULPage 10 of 12 Report No. 30880025.007 17.) Cards Myricom 10G-THRU-16QP Minimumflammabilityrating:V-0UL94 UL18.) Cards Myricom 10G-SW32LC-8QP8ER Minimumflammabilityrating:V-0UL94 UL19.) Cards Myricom 10G-SW32LC-16ES Minimumflammabilityrating:V-0UL94 UL20.) Cards Myricom 10G-SW32LC-16EM Minimumflammabilityrating:V-0UL94 UL21.) Cards Myricom 10G-2SW32LC Minimumflammabilityrating:V-0UL94 UL22.) Cards Myricom 10G-FAN v1.0 Minimumflammabilityrating:V-0UL94 UL23.) Backplane left Myricom 10G-21U-CLOSMinimumflammabilityrating:V-0UL94 UL24.) Backplane right Myricom 10G-21U-CLOSMinimumflammabilityrating:V-0UL94 UL25.) Backplane left Myricom 10G-21U-EDGEMinimumflammabilityrating:V-0UL94 UL26.) Backplane right Myricom 10G-21U-EDGEMinimumflammabilityrating:V-0UL94 UL27.) Backplane left Myricom 10G-12U-CLOSMinimumflammabilityrating:V-0UL94 UL28.) Backplane right Myricom 10G-12U-CLOSMinimumflammabilityrating:V-0UL94 UL29.) Backplane left Myricom 10G-12U-EDGEMinimumflammabilityrating:V-0UL94 UL30.) Backplane right Myricom 10G-12U-EDGEMinimumflammabilityrating:V-0UL94 UL31.) Backplane left Myricom 10G-7U-CLOSMinimumflammabilityrating:V-0UL94 UL32.) Backplane right Myricom 10G-7U-CLOSMinimumflammabilityrating:V-0UL94 UL33.) Backplane left Myricom 10G-7U-EDGEMinimumflammabilityrating:V-0UL94 UL34.) Backplane right Myricom 10G-7U-EDGEMinimumflammabilityrating:V-0UL94 UL35.)Power Cord (U.K.) Volex 2922 250V, 10A, 13Afuse, 1mm2-- ASTA,BSIPage 11 of 12 Report No. 30880025.00736.) Power Cord (Germany / Europe) Volex orequivalent17850or equivalentRating: 300V, 10A,1.0mm2-- VDE, N, FI, S, D, I37.) Power Cord (U.S.) Volex 17504 125V, 15A, 14AWG-- UL,CSA38.) Power Cord (Japan) Feller 5330-440 125V,15A,2.0mm2-- DENTORI39.) Transceiver (10G-SW32LC-16Q/10G-THRU-16Q/10G-SW32LC-8Q8ER/10G-THRU-8Q8ER)Zarlink ZL60304-MKDA Class I M laser IEC/EN 60825-1 TUV, UL40.) Transceiver (10G-SW32LC-8Q8ER/10G-THRU-8Q8ER/10G-SW32LC-16Q/10G-THRU-16Q)Avago HFBR-7934EHZ Class I M laser IEC/EN 60825-1 TUV, UL41.) Transceiver (10G-SW32LC-8M8ER/10G-THRU-8M8ER/10G-SW32LC-8Q8ER/10G-THRU-8Q8ER/10G-SW32LC-8QP8ER)Finisar FLTX8511D3 Class I M laser IEC/EN 60825-1 TUV, UL42.) Transceiver (10G-SW32LC-8M8ER/10G-THRU-8M8ER/10G-SW32LC-8Q8ER/10G-THRU-8Q8ER/10G-SW32LC-8QP8ER)Finisar FTLX1411D3 Class I M laser IEC/EN 60825-1 TUV, ULPage 12 of 12 Report No. 30880025.00743.) Transceiver ( 10G-SW32LC-8M8ER/10G-THRU-8M8ER/10G-SW32LC-8Q8ER/10G-THRU-8Q8ER/10G-SW32LC-8QP8ER) Finisar FTLX1412D3BCL Class I laser EN 60825-1EN 60825-2EN 60950-1CSA 60950-1-03CDRHTUV, CSA, FDA44.) Transceiver (10G-SW32LC-8QP8ER/10G-SW32LC-16QP/10G-THRU-16QP)Zarlink ZL60505MJDA Class I M laser IEC/EN 60825-1 TUV, UL45.) Transceiver ( 10G-SW32LC-16ES) Finisar FTLX8571D3BCL Class I laser EN 60825-1EN 60825-2EN 60950-1CDRHTUV, FDA46.) Transceiver ( 10G-SW32LC-16ES) Finisar FTLX1471D3BCL Class I laser EN 60825-1EN 60825-2EN 60950-1CDRHTUV, FDA47.) Transceiver ( 10G-SW32LC-8QP8ER/10G-SW32LC-16QP/10G-THRU-16QP) Tyco Electronics 1985554-x1985861-x1-198554-01-1985861-01-1985861-1Class I M laser EN 60825-1EN 60825-2EN 60950-1CSA 60950-1-03CDRHTUV, CSA, FDA48.) InsulationTape/ used on theinternal chassisadjacent to metalbus bar3M Type 1206 Rated 155˚C UL510 UL49.) Temperature Sensor NationalSemiconductorLM74 3.0V/2.65V to5.5V, -10˚C to65˚C- -50.) Power Distribution Board Myricom 10G-POWERv1.1.Minimumflammabilityrating:V-0UL94 UL END of TEST REPORT。

ul60950-1标准UL60950-1标准是针对信息技术设备,如计算机和通信设备,安全性评估的国际性安全标准。

该标准由美国安全实验室(Underwriters Laboratories)开发,并得到了国际电工委员会(IEC)的承认和采纳。

它规定了产品必须符合的安全要求和测试方法,以确保设备在正常使用和意外情况下不会对人员造成伤害。

UL60950-1标准的文件包括一系列安全要求和测试规程,以评估设备的设计、结构和功能是否满足标准的要求。

以下是该标准涵盖的主要内容:1.基本安全原则:UL60950-1标准要求设备在正常使用条件下不能对用户、维护人员和环境造成伤害。

设备应设计成能够防止电击、火灾和其他伤害的情况。

2.电气安全要求:该标准包括了关于电气部件、电路设计和电气隔离的安全要求。

设计者需要确保设备符合电气安全方面的规定,例如防护电路、隔离电源和接地要求。

3.机械安全要求:设备的机械结构和组件必须满足标准的机械安全要求,以确保不会有危险的边缘、尖锐的部件或不稳定的结构。

4.热和火灾安全要求:设备必须能够在正常使用条件下正常散热,并且在发生故障或过载时不会引起火灾或热能积累。

标准要求检查设备的散热系统和使用材料的热性能。

5.辐射安全要求:设备的电磁辐射必须符合国家和国际标准,以避免对人员或其他电子设备造成不良影响。

为了确保设备符合UL60950-1标准的要求,设计者需要进行一系列安全测试。

这些测试包括静态电压测试、接地电阻测试、电气隔离测试、机械强度测试、温升测试、电磁辐射测试等。

测试的结果将被记录在产品测试报告中,以证明设备符合标准的要求。

UL60950-1标准的应用范围非常广泛,涵盖了计算机、网络设备、电话、打印机、监视器、电源适配器等各种电子设备。

通过遵守该标准,制造商能够提供更安全可靠的产品,并确保他们的设备在全球范围内获得市场准入。

总之,UL60950-1是一项为了确保信息技术设备安全性而制定的国际标准。

Page 1 of 12 Report No. 30880025.007 Myricom, Inc., 325 N. Santa Anita Ave., Arcadia CA 91006Page 2 of 12 Report No. 30880025.00710G-12U-SPINE-ENCL, 10G-7U-CLOS-ENCL, 10G-7U-SPINE-ENCL Ratings....................................................: Input: 100-240V, 50/60 Hz, 10A-5A (rating per input, up to 4 inputs)Page 3 of 12 Report No. 30880025.007General remarks:The test results presented in this report relate only to the object tested.This report shall not be reproduced, except in full, without the written approval of the Issuing testinglaboratory."(See Enclosure #)" refers to additional information appended to the report."(See appended table)" refers to a table appended to the report.Note: This TRF includes EN Group Differences together with National Differences and SpecialNational Conditions, if any. All Differences are located in the Appendix to the main body of this TRF. Throughout this report a comma (point) is used as the decimal separator.General product information:This test report is Amendment 2 to the original CB-report with document number 30880025.001 and the first amendmentCB report 30880025.004 and covers the addition of new line cards 10G-THRU-16Q, 10G-THRU-8M8ER, 10G-THRU-16WQP, 10G-SW32LC-16QP, 10G-S SW32LC-16ES, 10G-SW32LC-16EM. Each line card uses less power than linecards that have already been evaluated for the original report and subsequent amendment so no testing was performed as part of this investigation and the new line cards have been evaluated on a constructional basis only. Critical components within the line cards being added include Certified Class 1 lasers only.The product covered in this test report are LAN Switches with the model numbers: 10G-21U-CLOS-ENCL, 10G-21U-EDGE-ENCL, 10G-12U-CLOS-ENCL, 10G-12U-SPINE-ENCL, 10G-7U-CLOS-ENCL and 10G-7U-SPINE-ENCL. TheLAN Switch product comes with six different configuration codes: 10G-21U-CLOS-ENCL has the CLOS backplane boards, which accept eight 10G-2SW32LC line cards in the middle, one 10G-MONITOR-B in the top, and nearly any combination of the other line cards in the other slots. The 10G-21U-EDGE-ENCL has one 10G-MONITOR-B in the top,and the other slots accepts nearly any combination of the other line cards, excluding the 10G-2SW32LC line card (For details of line cards, see critical components list table 1.5.1). The 12U and 7U configurations are similar in functional configuration with the differences being the 12U is a smaller chassis intended for use with 2-4 power supplies and the7U is a still smaller chassis intended for use with 1-2 power supplies. The 12U configuration was tested per this investigation and it was determined via the test results and inspection that the data taken for the 21U is representativeof the 12U and 7U and as such the previously-measured 21 test results are applied to this report amendment.The enclosures contain a metal chassis, up four approved power supplies (different for each model), approved DC fans, a backplane, AC-Inlet/Filter and interface cards, which are all interchangeable. Model No. 10G-21U-CLOS-ENCL is a ‘21U high, 41-slot enclosure for switch networks up to 512 ports’ located on the rear panel of the unit. These ports areconnected to copper and fiber cables and there is no power available on these ports. All signals are AC coupled through470pF capacitorsDuring the testing the maximum power was generated by using resistive loads. Due to the expenses of each individualcard, a low-cost test configuration with these resistive loads cards generating 200W of power was used for thetemperature rise measurement and abnormal fault conditions.It should be noted that for the final configuration of the LAN Switches each individual card has two redundant temperature sensors which control the power to a card (thermal cut-out / power off at 60˚C). Also, the four DC fans at the back-side ofthe products are speed-adjustable depending on the temperature inside the LAN Switch enclosure. Individual temperature sensors are located on each line card and each fan controller PCBModel 10G-21U-CLOS-ENCL is intended to be fully operational with a minimum of three power supplies only. However,the four power supply configuration is intended for triple-AC systems( where there are three different sources of ACPage 4 of 12 Report No. 30880025.007 power), and the enclosure will continue to run will continue to run with one AC off and one power supply down. The unit contains; four fans, four power supplies and thirty cards – mixed.There are no connections to a Telecommunication Network (TNV).CDRH-Report for Optical Transceiver has to be provided by customer for US Approval.During the testing the maximum power was generated by using resistive loads. Due to the expenses ofeach individual card a low-cost test configuration with these resistive load cards, generating 200W ofpower, was used for the temperature rise measurements and abnormal fault conditions.Conditions of Acceptability:1.This unit is considered to operate under the conditions of:– Pollution Degree 2: Not sealed, not subjected to dust, dirt, and condensation– Equipment mobility: Rack mounted / fixed2. Rated ambient of 40°C at maximum rated loadPage 5 of 12 Report No. 30880025.007Page 6 of 12 Report No. 30880025.007 Summary of testing:Tests performed (name of test and test clause): = no testing performed for this amendment =Testing location:TUV Rheinland of North America, Inc.1279 Quarry Lane, Ste. A, Pleasanton, CA 94566Summary of compliance with National Differences:Comments:Summary of compliance with National Differences (for explanation of codes see below):AT, CA (temporary differences), DE, DK, FI, FR, GB, IT, JP, KR, NL, NO, PL, SE, SI, US (temporary differences).and Group Differences as listed at the end of this test reportExplanation of Codes:AT=Austria, CA-Canada, DE=Germany, DK=Denmark, FI=Finland, FR=France, GB=United Kingdom, IT=Italy,JP=Japan, KR=Korea, NL=The Netherlands, NO=Norway, PL=Poland, SE=Sweden, SI=Slovenia, US=United StatesThe following Attachments are integral part of this test report:= no attachments for this amendment =Page 7 of 12 Report No. 30880025.007Test item particulars..................................................:Equipment mobility....................................................: [] movable [] hand-held [] transportable[X] stationary [] for building-in [] direct plug-in Connection to the mains............................................: [] pluggable equipment [] type A [] type B[] permanent connection[X] detachable power supply cord[] non-detachable power supply cord[] not directly connected to the mainsOperating condition...................................................: [X] continuous[] rated operating / resting time:Access location .........................................................: [X] operator accessible[] restricted access locationOver voltage category (OVC) ...................................: [] OVC I [X] OVC II [] OVC III [] OVC IV[] other:Mains supply tolerance (%) or absolute mains supplyvalues .......................................................................:Tested for IT power systems ....................................: [X] Yes [] NoIT testing, phase-phase voltage (V) .........................: 230VClass of equipment ...................................................: [X] Class I [] Class II [] Class III[] Not classifiedConsidered current rating (A) ...................................:Pollution degree (PD) ...............................................: [] PD 1 [X] PD 2 [] PD 3IP protection class ....................................................: IPX0Altitude during operation (m) ....................................: 2000 mAltitude of test laboratory (m) ...................................: 2000 mMass of equipment (kg) ............................................: 98kgPossible test case verdicts:- test case does not apply to the test object.................:N/A- test object does meet the requirement.......................:P (Pass)- test object does not meet the requirement.................: F (Fail) Testing..........................................................................:Date of receipt of test item............................................:N/ADate(s) of performance of tests....................................:N/A[constructional check only, all test data is based onpreviously issued reports 30880025.001 and30880025.004, all changes per this amendment are eithernon-safety critical or editorial in nature only]Page 8 of 12 Report No. 30880025.007 1 GENERAL P1.5 Components P1.5.1 General Complies PComply with IEC 60950-1 or relevant component standard Refer to appended table 1.5.1(list of critical components)P1.5.2 Evaluation and testing of components All safety critical componentsare certified. All componentsare used within their specifiedratings, plastic materials,PCBs and wiring materialsare UL listed, non-certifiedcomponents were testedaccording to this standard.P 1.5.1 TABLE: List of critical components PObject/part No. Manufacturer/trademark Type/model Technical data Standard (Edition/ year)Mark(s) ofconformity1)1.) Power Supply (up to 4 each) Astec DS850-3 Input:100-240,50/60Hz, 10A;Output: +12V/70A,+3.3V/6AIEC/EN/UL60950-1UL 1449 (VDR’s)CSA, cULus, TUV2.) DC Fan (up to 8 each) Delta FFB1212EHE-F0012VDC3.0A –5.38 m3/minIEC/EN/UL 60950-1 VDE, CE, UL,CSA3.) DC Fan Controller board Myricom 05-2896 Minimumflammability rating:V-0,UL94 ULPage 9 of 12 Report No. 30880025.0074.) Internal wiring Various Various Rated 600V,105˚C,flammability ratingminimum VW-1 4wire gage type10070 from outputpower distributionboard to the powerback plane busbars (2 cables;3feet long) +/-12V.Wire gages forline/neutral/safetyground: type“1015” wire , 18gafor +12/- Backplane tosignal/power/fansto backplane 18ga to 24 ga .-- UL5.) Cards Myricom 10G-Monitor –B Minimumflammabilityrating:V-0UL94 UL6.) Cards Myricom 10G-SW32LC-16M Minimumflammabilityrating:V-0UL94 UL7.) Cards Myricom 10G-THRU-16M Minimumflammabilityrating:V-0UL94 UL8.) Cards Myricom 10G-SW32LC-16Q Minimumflammabilityrating:V-0UL94 UL9.) Cards Myricom 10G-THRU-16Q Minimumflammabilityrating;V-0UL94 UL10.) Cards Myricom 10G-SW32LC-8Q8ER Minimumflammabilityrating:V-0UL94 UL11.) Cards Myricom 10G-THRU-8Q8ER Minimumflammabilityrating:V-0UL94 UL12.) Cards Myricom 10G-SW32LC-8M8ER Minimumflammabilityrating:V-0UL94 UL13.) Cards Myricom 10G-THRU-8M8ER Minimumflammabilityrating:V-0UL94 UL14.) Cards Myricom 10G-SW32LC-8M8EM Minimumflammabilityrating:V-0UL94 UL15.) Cards Myricom 10G-THRU-8M8EM Minimumflammabilityrating:V-0UL94 UL16.) Cards Myricom 10G-SW32LC-16QP Minimumflammabilityrating:V-0UL94 ULPage 10 of 12 Report No. 30880025.007 17.) Cards Myricom 10G-THRU-16QP Minimumflammabilityrating:V-0UL94 UL18.) Cards Myricom 10G-SW32LC-8QP8ER Minimumflammabilityrating:V-0UL94 UL19.) Cards Myricom 10G-SW32LC-16ES Minimumflammabilityrating:V-0UL94 UL20.) Cards Myricom 10G-SW32LC-16EM Minimumflammabilityrating:V-0UL94 UL21.) Cards Myricom 10G-2SW32LC Minimumflammabilityrating:V-0UL94 UL22.) Cards Myricom 10G-FAN v1.0 Minimumflammabilityrating:V-0UL94 UL23.) Backplane left Myricom 10G-21U-CLOSMinimumflammabilityrating:V-0UL94 UL24.) Backplane right Myricom 10G-21U-CLOSMinimumflammabilityrating:V-0UL94 UL25.) Backplane left Myricom 10G-21U-EDGEMinimumflammabilityrating:V-0UL94 UL26.) Backplane right Myricom 10G-21U-EDGEMinimumflammabilityrating:V-0UL94 UL27.) Backplane left Myricom 10G-12U-CLOSMinimumflammabilityrating:V-0UL94 UL28.) Backplane right Myricom 10G-12U-CLOSMinimumflammabilityrating:V-0UL94 UL29.) Backplane left Myricom 10G-12U-EDGEMinimumflammabilityrating:V-0UL94 UL30.) Backplane right Myricom 10G-12U-EDGEMinimumflammabilityrating:V-0UL94 UL31.) Backplane left Myricom 10G-7U-CLOSMinimumflammabilityrating:V-0UL94 UL32.) Backplane right Myricom 10G-7U-CLOSMinimumflammabilityrating:V-0UL94 UL33.) Backplane left Myricom 10G-7U-EDGEMinimumflammabilityrating:V-0UL94 UL34.) Backplane right Myricom 10G-7U-EDGEMinimumflammabilityrating:V-0UL94 UL35.)Power Cord (U.K.) Volex 2922 250V, 10A, 13Afuse, 1mm2-- ASTA,BSIPage 11 of 12 Report No. 30880025.00736.) Power Cord (Germany / Europe) Volex orequivalent17850or equivalentRating: 300V, 10A,1.0mm2-- VDE, N, FI, S, D, I37.) Power Cord (U.S.) Volex 17504 125V, 15A, 14AWG-- UL,CSA38.) Power Cord (Japan) Feller 5330-440 125V,15A,2.0mm2-- DENTORI39.) Transceiver (10G-SW32LC-16Q/10G-THRU-16Q/10G-SW32LC-8Q8ER/10G-THRU-8Q8ER)Zarlink ZL60304-MKDA Class I M laser IEC/EN 60825-1 TUV, UL40.) Transceiver (10G-SW32LC-8Q8ER/10G-THRU-8Q8ER/10G-SW32LC-16Q/10G-THRU-16Q)Avago HFBR-7934EHZ Class I M laser IEC/EN 60825-1 TUV, UL41.) Transceiver (10G-SW32LC-8M8ER/10G-THRU-8M8ER/10G-SW32LC-8Q8ER/10G-THRU-8Q8ER/10G-SW32LC-8QP8ER)Finisar FLTX8511D3 Class I M laser IEC/EN 60825-1 TUV, UL42.) Transceiver (10G-SW32LC-8M8ER/10G-THRU-8M8ER/10G-SW32LC-8Q8ER/10G-THRU-8Q8ER/10G-SW32LC-8QP8ER)Finisar FTLX1411D3 Class I M laser IEC/EN 60825-1 TUV, ULPage 12 of 12 Report No. 30880025.00743.) Transceiver ( 10G-SW32LC-8M8ER/10G-THRU-8M8ER/10G-SW32LC-8Q8ER/10G-THRU-8Q8ER/10G-SW32LC-8QP8ER) Finisar FTLX1412D3BCL Class I laser EN 60825-1EN 60825-2EN 60950-1CSA 60950-1-03CDRHTUV, CSA, FDA44.) Transceiver (10G-SW32LC-8QP8ER/10G-SW32LC-16QP/10G-THRU-16QP)Zarlink ZL60505MJDA Class I M laser IEC/EN 60825-1 TUV, UL45.) Transceiver ( 10G-SW32LC-16ES) Finisar FTLX8571D3BCL Class I laser EN 60825-1EN 60825-2EN 60950-1CDRHTUV, FDA46.) Transceiver ( 10G-SW32LC-16ES) Finisar FTLX1471D3BCL Class I laser EN 60825-1EN 60825-2EN 60950-1CDRHTUV, FDA47.) Transceiver ( 10G-SW32LC-8QP8ER/10G-SW32LC-16QP/10G-THRU-16QP) Tyco Electronics 1985554-x1985861-x1-198554-01-1985861-01-1985861-1Class I M laser EN 60825-1EN 60825-2EN 60950-1CSA 60950-1-03CDRHTUV, CSA, FDA48.) InsulationTape/ used on theinternal chassisadjacent to metalbus bar3M Type 1206 Rated 155˚C UL510 UL49.) Temperature Sensor NationalSemiconductorLM74 3.0V/2.65V to5.5V, -10˚C to65˚C- -50.) Power Distribution Board Myricom 10G-POWERv1.1.Minimumflammabilityrating:V-0UL94 UL END of TEST REPORT。