航空定位定姿系统PPOI-A系列

- 格式:pdf

- 大小:1.01 MB

- 文档页数:3

国产高精度位置和姿态测量系统LDPOS的发展与应用周落根邓晓光洪勇(摘要:本文详细介绍了高精度位置和姿态测量系统的发展,我国具有完全自主知识产权的移动测量和实景三维技术和产品的研究、应用和服务情况,以及地面无控航测系统,并对其未来的发展进行展望。

关键词:高精度位置和姿态测量系统LDPOS地面无控航测系统一引言高精度位置和姿态测量系统(Position and Orientation System, POS)集全球导航卫星系统、惯性测量单元、导航处理计算机技术于一体,可以实时获取运动物体的高精度空间位置和三维姿态信息,广泛应用于飞机、轮船和陆地载体的导航定位。

POS通过全球导航卫星系统(Global Navigation Satellite System ,GNSS)接收定位数据,利用高精度光学陀螺捷联惯性测量单元(Inertial Measurement Unit,IMU)提供设备瞬间的速度、加速度和方向信息,然后通过数据处理与融合软件对所接收的定位定姿信息进行数据处理,获得载体设备的高精度位置及姿态信息,同时给载荷传感器提供高精度同步信息,直接解算观测成果的高精度外方位元素,输出具有直接地理参考的影像数据。

POS解决了GNSS动态可靠性差,会出现信号遮挡、丢失,同时数据输出的频率低等问题。

POS系统将GNSS长期、低动态定位精度高的特性与惯性导航系统QNS)的短期、高动态定位精度高的性能有机地结合起来,不但提高了系统的精度,加强了系统的抗干扰能力,同时解决了GNSS动态应用采样频率低的问题。

POS系统可为载体或航空传感器提供高精度、高频率(200HZ)的实时位置与姿态(X,Y,Z,e,3, K)数据,应用于各种不同类型的传感器:如航空胶片或数字相机、线阵扫周落根,立得空间信息技术股份有限公司副总经理;邓晓光、洪勇,立得空间信息技术股份有限公司。

描仪、激光扫描仪、合成孔径雷达、成像光谱仪等。

在崇山峻岭、戈壁荒漠等难以通行的地区,如国界、沼泽滩涂等作业员根本无法到达的地区,采用POS系统和航空摄影系统集成进行直接空间对地定位,可迅速、及时地获取多频段、多时相、高精度、高分辨率的位置与图像信息,快速高效地编绘基础地理图件,大大提高了作业效率和成功率。

飞机泊位机型自动识别与指示系统1. 系统概述飞机泊位机型自动识别与指示系统是一种基于现代计算机技术和机器视觉技术的智能系统。

该系统可以实现对停机位上停放的飞机机型的自动识别,并向机组人员和地勤人员提供相应的机型信息和地面操作指示。

这一系统可以有效提高机场地面服务的效率和安全性,优化效益和提高服务质量。

本系统由基础软硬件组成:硬件部分主要包括机舱内部和地面设备。

而软件部分则由三大模块组成:图像处理模块、机型识别模块和指示信息输出模块。

在实际使用中,地勤人员通常通过自己的PDA或其他智能终端来接收与处理指示信息。

2. 系统功能2.1 机型识别功能机型识别模块可以对机场所有停机位停驻飞机的机身进行自动识别,识别出飞机的品牌、型号和所需的地勤操作等信息,并将信息上传到服务器,供地勤人员核实使用。

2.2 指示指令输出功能指示信息输出模块可以将相应的机型信息和泊位指令发送给机组和地勤人员,以指示地勤人员在相应的机型停靠停机位时该如何操作。

同时,地勤人员也可以通过自己的PDA和其他智能终端终端,随时随地接收相应的指令,提高操作准确性并减少出错率。

2.3 系统安全性本系统安全性高,对地勤人员和机组人员的操作进行严格的控制和管理。

系统需要使用密码和权限的验证才能进行操作,以防止不当操作引起的事故和损失。

3. 技术支持3.1 图像处理技术该系统采用计算机视觉技术和图像处理技术进行机型识别。

在识别过程中,对飞机图像进行深度学习和分析,以确保机型的准确识别。

3.2 指示信息输出技术地勤人员和机组人员可以通过智能终端,随时随地接收到相应的指令。

此外,该系统还可以将指令信息实时传送到大屏幕上,以便地勤和机组人员更好地了解运行情况和进程。

3.3 数据后台技术该系统还拥有一个后台数据库,用于存储机型信息、停机位信息、指令数据等。

系统管理员可以通过该后台数据库进行数据管理和维护,以确保系统的正常运行。

4. 系统优势4.1 自主化与人性化该系统可以自主完成相应的机型识别和指令输出,大大缩短了地勤人员的操作时间和人力成本。

产品介绍产品介绍ACGS-01 是CGSTECH 公司提供的基于MEMS 技术的低成本的,高性能三维运动姿态测量系统。

ACGS-01包含三轴陀螺仪、三轴加速度计(即IMU ),三轴电子罗盘等辅助运动传感器,通过内嵌的低功耗处理器输出校准过的角速度,加速度,磁数据等,通过基于四元数的Motion Sensor Fusion 算法进行数据融合,实时输出以四元数、欧拉角等表示的零漂移三维运动姿态数据。

ACGS-01可广泛应用于航模无人机、机器人、摄像云台、天线云台、地面及水下设备、虚拟现实、人体运动分析等需要低成本、高动态三维姿态测量的产品设备中。

ACGS-01微型AHRS 姿态方位参考系统姿态方位参考系统硬件系统高度集成硬件系统高度集成紧凑的外观设计,方便开发集成到其他的系统和应用中尺寸小,重量轻,功耗低具有高度的可扩展性,提供串口,SPI ,CAN 总线运动姿态捕捉显示系统运动姿态捕捉显示系统CGSTECH Explore 提供图形化的显示界面,使开发者对运动姿态所见即所得,通过使用CGSTECH Explore 内置工具可以迅速完成内置传感器的各种设置校准,包括软铁和硬铁的磁场校准,让开发者工作化繁为简,集中精力于系统设计输出模式输出模式三维全姿态数据(四元数 / 欧拉角 / 旋转矩阵) 三维加速度 / 三维角速度 / 三维地磁场强度可扩展性软件开发 SDKCGSTECH SDK 提供针对不同设备的多层次接口,保证用户不仅在桌面系统还是嵌入式设备都可以进行快速开发,满足系统开发的定制要求,使得用户在使用CGSTECH 系列产品时更加具有自主性特点高精度360 度全方位空间姿态输出。

无需水平静态下启动。

快速动态响应与长时间稳定性(无漂移,无积累误差)相结合。

全固态微型MEMS 惯性器件,三轴加速度、三轴角速度和三轴磁场强度计高度集成9DOF 。

快速更新率,多种可编程的数据输出模式(四元数,欧拉角,旋转矩阵等)。

POSPac 移动测图软件是 Applanix 公司研制的一套先进的、智能化的定位定姿数据处理软件,对集成全球导航卫星系统(GNSS)与惯性导航技术的定位定姿系统(POS AV)所采集的数据进行处理,通过软件解算处理,仍可获取测图传感器的高精度定位定姿数据。

POSPacMMS 软件的功能特点

POSPac 软件采用全球导航卫星系统与惯性导航技术对航空测图传感直接定位,可优化航空测图环境,兼容各种不同类型的传感器。

该软件采用全新的用户界面、先进的数据处理技术——Applanix SmartBa se与 Applanix IN-Fusion,智能化的数据处理方案可快速、高效地得到精确的定位定姿数据。

该软件包括以下的功能:

l

导入、管理与评估定位定姿系统(POS AV)与全球导航系统参考站数据。

2

通过 POS AV 记录的全球导航卫星系统与惯性导航数据,生成高精度的位置与姿态信息

3

能计算 UltraCam, DMC,RMK Top, RC20/30, LMK 2000 与 Ap planix DSS 系统中的

4

航空相机所采集的每一幅图像的外方位元素,输出到第三方摄影测量软件中进行处理

5

对惯性导航装置(IMU)、相机轴线与坐标系统校准

6

对外方位元素、相机校准与坐标转换的数据质量进行详细地评估与控制

7

提供详细的与航摄任务有关的文档和报告

8

可生成数字传感器系统(DSS)图像

9

从DSS 图像可直接快速生成正射影像。

Number:CTSO-C201Approved by:Xu ChaoqunChina Civil Aviation Technical Standard OrderAttitude and Heading Reference Systems (AHRS)1. Purpose.This China Civil Aviation Technical Standard Order (CTSO) is for manufacturers applying for Attitude and Heading Reference Systems (AHRS) CTSO authorization (CTSOA). This CTSO prescribes the minimum performance standards(MPS) that Attitude and Heading Reference Systems (AHRS) must first meet for approval and identification with the applicable CTSO marking.2. Applicability.This CTSO affects new application submitted after its effective date. Major design changes to article approved under this CTSO will require a new authorization in accordance with section 21.353 of CCAR-21-R4.3. RequirementsNew models of AHRS identified and manufactured on or after theeffective date of this CTSO must meet the MPS qualification and documentation requirements in sections 2.1, 2.2.1, and 2.2.2 of RTCA Document No. RTCA/DO-334, Minimum Operational Performance Standards (MOPS) for Solid-State Strap-Down Attitude and Heading Reference Systems (AHRS), dated March 21, 2012. If AHRS provides heading, turn and slip, degraded mode, uses aiding, includes a display, or provides information generated by the AHRS to a stand-alone display,then the applicant must also meet the requirements as listed in the table below.Optional Functions/Mode/Source FunctionalQualificationHeading 2.2.3Turn and Slip 2.2.5Degraded Mode 2.2.4Aiding 2.2.6Display 2.5a. Functionality. This CTSO’s standards apply to solid statestrap-down AHRS intended to output pitch and roll attitude that does notuse gimbaled sensors. It also addresses the optional functions of heading,turn, slip and the display of information provided by an AHRS.b. Failure Condition Classifications.There is no standard minimumfailure condition classification for this TSO. The failure condition classification appropriate for the equipment will depend on the intendeduse of the equipment in a specific aircraft. Document the loss of functionand malfunction failure condition classification for which the equipmentis designed.c. Functional Qualification. Demonstrate the required functional performance under the test conditions specified in RTCA/DO-334, Section 2.4. If the AHRS includes a display, demonstrate the required functional performance of the display under the test conditions specified in RTCA/DO-334, Section 2.6.d. Environmental Qualification. Demonstrate the required performance under the test conditions specified in RTCA/DO-334, Section 2.3, using standard environmental conditions and test procedures appropriate for airborne equipment. RTCA/DO-334 requires the use of RTCA/DO-160G; however, the applicant may use a different standard environmental condition and test procedure than RTCA/DO-160G, provided the standard is appropriate for AHRS.Note: The use of RTCA/DO-160D (with Changes 1 and 2 only, incorporated) or earlier versions is generally not considered appropriate and will require substantiation via the deviation process as discussed in paragraph 3.g of this CTSO.e. Software Qualification. If the article includes software, develop the software according to RTCA, Inc. document RTCA/DO-178B, Software Considerations in Airborne Systems and Equipment Certification, dated December 1, 1992 to at least the software level consistent with the failure condition classification defined in paragraph 3.b of this CTSO.Note: The certification liaison process objectives will be considered satisfied after CAAC review of the applicable life cycle data.f. Electronic Hardware Qualification. If the article includes complex custom airborne electronic hardware, develop the component according to RTCA/DO-254, dated April 19, 2000, Design Assurance Guidance for Airborne Electronic Hardware, to at least the design assurance level consistent with the failure condition classification defined in paragraph 3.b of this CTSO. For custom airborne electronic hardware determined to be simple, RTCA/DO-254, paragraph 1.6 applies.Note: The certification liaison process objectives will be considered satisfied after CAAC review of the applicable life cycle data.g. Deviations. For using alternative or equivalent means of compliance to the criteria in this CTSO, the applicant must show that the equipment maintains an equivalent level of safety. Apply for a deviation under the provision of 21.368(a) in CCAR-21-R4.4. Marking.a. Mark at least one major component permanently and legibly with all the information in 21.423(b) of CCAR-21-R4. The marking must include the serial number.b. Also, mark the following permanently and legibly, with at least the manufacturer’s name, subassembly part number, and the CTSOnumber:(1) Each component that is easily removable (without hand tools); and,(2) Each subassembly of the article that manufacturer determined may be interchangeable.c. If the article includes software and/or airborne electronic hardware, then the article part numbering scheme must identify the software and airborne electronic hardware configuration. The part numbering scheme can use separate, unique part numbers for software, hardware, and airborne electronic hardware.d. The applicant may use electronic part marking to identify software or airborne electronic hardware components by embedding the identification within the hardware component itself (using software) rather than marking it on the equipment nameplate. If electronic marking is used, it must be readily accessible without the use of special tools or equipment.5. Application Data Requirements.The applicant must furnish the responsible certification personnel with the related data to support design and production approval. The application data include a statement of conformance as specified in section 21.353(a)(1) in CCAR-21-R4 and one copy each of the followingtechnical data:a. A Manual(s) containing the following:(1) Operating instructions and equipment limitations sufficient to describe the equipment’s operational capability.(2) Describe in detail any deviations.(3) Installation procedures and limitations sufficient to ensure that the AHRS, when installed according to the installation or operational procedures, still meets this CTSO’s requirements. Limitations must identify any unique aspects of the installation. The limitations must include a note with the following statement:“This article meets the minimum performance and quality control standards required by a China civil aviation technical standard order (CTSO). Installation of this article requires separate approval.”(4) For each unique configuration of software and airborne electronic hardware, reference the following:(a) Software part number including revision and design assurance level;(b) Airborne electronic hardware part number including revision and design assurance level; and(c) Functional description.(5) A summary of the test conditions used for environmental qualifications for each component of the article. For example, a form asdescribed in RTCA/DO-160G, Environmental Conditions and Test Procedures for Airborne Equipment, Appendix A.(6) Schematic drawings, wiring diagrams, and any other documentation necessary for installation of the AHRS.(7) List of replaceable components, by part number, that makes up the AHRS. Include vendor part number cross-references, when applicable.b. Instructions covering periodic maintenance, calibration, and repair, for the continued airworthiness of AHRS. Include recommended inspection intervals and service life, as appropriate.c. If the article includes software: a plan for software aspects of certification (PSAC), software configuration index, and software accomplishment summary.d. If the article includes simple or complex custom airborne electronic hardware, a plan for hardware aspects of certification (PHAC), hardware verification plan, top-level drawing, and hardware accomplishment summary (or similar document, as applicable).e. A drawing depicting how the article will be marked with the information required by paragraph 4 of this CTSO.f. Identify functionality or performance contained in the article not evaluated under paragraph 3 of this CTSO (that is, non-CTSO functions). Non-CTSO functions are accepted in parallel with the CTSOauthorization. For those non-CTSO functions to be accepted, the applicant must declare these functions and include the following information with CTSO application:(1) Description of the non-CTSO function(s), such as performance specifications, failure condition classifications, software, hardware, and environmental qualification levels. Include a statement confirming that the non-CTSO function(s) don’t interfere with the article’s compliance with the requirements of paragraph 3.(2) Installation procedures and limitations sufficient to ensure that the non-CTSO function(s) meets the declared functions and performance specification(s) described in paragraph 5.f.(1).(3) Instructions for continued performance applicable to the non-CTSO function(s) described in paragraph 5.f.(1).(4) Interface requirements and applicable installation test procedures to ensure compliance with the performance data defined in paragraph 5.f.(1).(5) Test plans, analysis and results, as appropriate, to verify that performance of the hosting CTSO article is not affected by the non-CTSO function(s).(6) Test plans, analysis and results, as appropriate, to verify the function and performance of the non-CTSO function(s) as described in paragraph 5.f.(1).g. The quality system description required by section 21.358 of CCAR-21-R4, including functional test specifications. The quality system should ensure that it will detect any change to the approved design that could adversely affect compliance with the CTSO MPS, and reject the article accordingly.h. Material and process specifications list.i. List of all drawings and processes (including revision level) that define the article’s design.j. Manufacturer’s CTSO qualification report showing results of testing accomplished according to paragraph 3.c of this CTSO.k. Provide the AHRS modes of operation and attitude, heading, and turn and slip categories for equipment per RTCA/DO-334, section 1.7.1 in installation manual.6. Manufacturer Data Requirements.Besides the data given directly to the authorities, have the following technical data available for review by the authorities:a. Functional qualification specifications for qualifying each production article to ensure compliance with this CTSO.b. Article calibration procedures.c. Schematic drawings.d. Wiring diagrams.e. Material and process specifications.f. The results of the environmental qualification tests conducted according to paragraph 3.d of this CTSO.g. If the article includes software, the appropriate documentation defined in the version of RTCA/DO-178B specified by paragraph 3.e of this CTSO, including all data supporting the applicable objectives in Annex A, Process Objectives and Outputs by Software Level.h. If the article includes complex custom airborne electronic hardware, the appropriate hardware life cycle data in combination with design assurance level, as defined in RTCA/DO-254, Appendix A, Table A-l. For simple custom airborne electronic hardware, the following data: test cases or procedures, test results, test coverage analysis, tool assessment and qualification data, and configuration management records, including problem reports.i. If the article contains non-CTSO function(s), the applicant must also make available items 6.a through 6.h as they pertain to the non-CTSO function(s).7. Furnished Data Requirements.a. If furnishing one or more articles manufactured under this CTSO to one entity (such as an operator or repair station), provide one copy or technical data and information specified in paragraphs 5.a and 5.b of thisEnglish Translation Version for Reference Only CAAC CTSO-C201 CTSO. Add any data needed for the proper installation, certification, use, or for continued compliance with the CTSO, of the AHRS.b. If the article contains declared non-CTSO function(s), include one copy of the data in paragraphs 5.f.(1) through 5.f.(4).8. Availability of Referenced Documents.Order RTCA documents from:Radio Technical Commission for Aeronautics, Inc.1150 18th Street NW, Suite 910, Washington D.C. 20036You may also order them online from the RTCA Internet website at: .- 11 -。

民用飞机惯性基准导航系统校准分析惯性基准导航系统是民用飞机中最重要的机载系统之一,该系统为飞机的显示系统、飞行控制系统等多个系统提供飞机的飞行姿态、航向、加速度等信息,其准确性对飞机的安全稳定飞行具有不可替代的作用。

文章对民用飞机惯性基准导航系统的结构以及系统的校准进行了研究,希望能够给民航机务维护的工作提供一定的参考。

标签:民用飞机;惯性基准系统;校准1 民用飞机惯性基准导航系统组成惯性基准导航系统是近几年发展起来的新型惯性导航系统。

该系统具有体积小、质量轻、可靠性高等特点,能够通过飞机主控中心总线系统向主控中心输出飞机的姿态、航向、加速度等信息。

惯性基准导航系统主要由惯性基准装置(IRU)、飞机个性化模块(APM)以及安装托架三个部分构成[1]。

其中IRU是惯性基准导航系统中最重要的部分,它包含了所有惯性测量元件以及计算功能,而APM则主要用于存储IRU的安装校准数据、飞机的具体型号等方面的数据,这样能够在更换IRU部件之后,直接读取数据,而无需从新对IRU装置进行校准。

每套惯性系统均有两种工作方式,分别为导航方式和姿态方式,其中导航方式是系统的正常工作方式,在此种工作方式下,惯性基准导航系统能够向飞机的控制中心提供全部导航参数;而姿态方式则是在飞机的系统导航功能失效之后所进行的一种降低精度的工作方式,此时,系统只能向飞机控制中心提供包括姿态和航向等的少量数据信息。

2 民用飞机惯性基准导航系统的校准2.1 正常校准飞机在停靠地面通电之后,将惯性导航控制显示组件上的工作方式按钮从OFF状态拨出置为NA V状态,系统会自动在5秒钟的电瓶测试之后进入到正常校准的状态中,此时,控制显示组件上的“ALIGN(校准)”灯会稳定的点亮,飞机中央电子监控显示屏中会显示“IRSIN ALING >7”的信息提示。

此时大气数据基准组件提供的计算空速、垂直速度以及气压高度数据会在正、副驾驶员位的主飞行显示器上进行显示[2]。

SPATIAL 惯性导航航姿参考单元SPATIAL是一个坚固耐用的微型GNSS/ INS惯性导航和AHRS航姿参考系统单元,在最苛刻的条件下提供精确的位置、速度、加速度和方向。

它结合了温度校准的加速度计、陀螺仪、磁场传感器、压力传感器和先进的GNSS接收机。

这些组合一个复杂的混合算法,提供准确,可靠的导航和定位。

在全球导航卫星系统、惯性导航系统、姿态与航向参考系统和其他3D导航技术处于领先地位。

“空间”精密船级铝合金外壳符合防水和防脏的IP67标准,防冲击达2000g,能够在最极端的条件下使用。

先进的通风系统,使“空间”单元能测量空气压力,同时又保持水份排出。

“空间”是市场上最小的全球导航卫星系统/INS,只有28x36x20毫米,亦是最低功耗5伏100mA的电力系统。

“空间”OEM只有25x25x6mm、4克重。

“空间”的下一代全球导航卫星系统接收器,支持所有当前和未来的卫星导航系统,包括GPS、GLONASS、GALILEO 和北斗。

这些额外的卫星导航系统能让“空间”,在只GPS 的单元不能继续工作——如城市峡谷和室内——的环境中提供精确的位置和速度数据。

“空间”是第一个在世界上的GNSS/ INS提供温度校准动态范围的传感器。

有三个不同幅度水平的加速度计、陀螺仪和磁场传感器,“空间”可以设置高准确度、高动态飞行。

“空间”包含一个下一代存储器备份系统,允许它从它的最后的位置在50毫秒内热启动导航,并在约3秒内获得GNSS 定位。

存储器备份系统在产品的生命周期内持续工作,并提供24小时断电备份。

“空间”的内部滤波器运行频率800HZ,数据可以以这样的速度在高速RS232接口输出。

这允许用于控制动态不稳定的平台。

“空间”也非常宽容动态运动和振动。

应用:机器人、运动科学、追踪与保安、赛车、极限运动<span lang="ZH-CN"style="font-size:10.0pt;font-family:SimSun;mso-ascii-font-famil y:Arial;mso-hansi-font-family:Arial;mso-bidi-font-family:Arial;color:# 333333;text-transform:uppercase;mso-fareast-language:ZH-CN">导航水平位置准确度2.5 m垂直位置准确度3.0 m速度准确度0.05m/s横滚、仰俯准确度(静态)0.2 °航向准确度(静态0.5 °横滚、仰俯准确度(动态)0.4 °航向准确度(动态0.8 °幅度不限热启时间50 ms内部滤波率800 Hz数据输出率高达800 Hz。

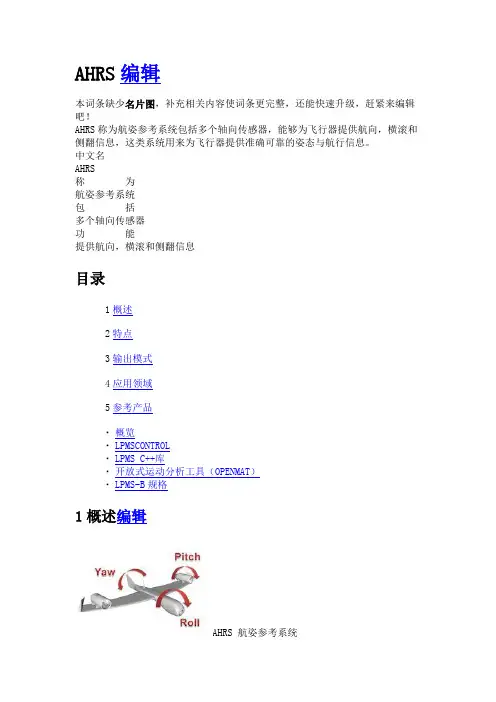

AHRS编辑本词条缺少名片图,补充相关内容使词条更完整,还能快速升级,赶紧来编辑吧!AHRS称为航姿参考系统包括多个轴向传感器,能够为飞行器提供航向,横滚和侧翻信息,这类系统用来为飞行器提供准确可靠的姿态与航行信息。

中文名AHRS称为航姿参考系统包括多个轴向传感器功能提供航向,横滚和侧翻信息目录1概述2特点3输出模式4应用领域5参考产品▪概览▪LPMSCONTROL▪LPMS C++库▪开放式运动分析工具(OPENMAT)▪LPMS-B规格1概述编辑AHRS 航姿参考系统航姿参考系统包括基于MEMS的三轴陀螺仪,加速度计和磁强计。

航姿参考系统与惯性测量单元IMU的区别在于,航姿参考系统(AHRS)包含了嵌入式的姿态数据解算单元与航向信息,惯性测量单元(IMU)仅仅提供传感器数据,并不具有提供准确可靠的姿态数据的功能。

目前常用的航姿参考系统(AHRS)内部采用的多传感器数据融合进行的航姿解算单元为卡尔曼滤波器。

2特点编辑高精度360 度全方位位置姿态输出,采用欧拉角的会具有万向锁,不能全向转动高效的数据融合算法快速动态响应与长时间稳定性(无漂移,无积累误差)相结合3输出模式编辑三维全姿态数据(四元数 / 欧拉角 / 旋转矩阵/原始数据)三维加速度 / 三维角速度 / 三维地磁场强度4应用领域编辑AHRS 原本起源于飞行器相关技术,但是近几年随着成本的器件成本的不断降低也被广泛的应用于机动车辆与无人机,工业设备,摄像与天线云台,地面及水下设备,虚拟现实,生命运动科学分析,虚拟现实,游戏界面,室内定位等需要三维姿态测量的产品中5参考产品编辑AHRS/IMULPMS-B是新型的高精度超小型姿态动作捕捉传感器,它使用蓝牙技术对数据进行无线通信, 高度满足了在机械系统以及人体动作信息测量应用上的高精度计算,无线传输数据的要求,并为用户提供多方面的软件平台支持。

LP-RESEARCH公司的姿态传感器(LPMS系列产品)使用了先进的数据融合算法,为用户提供高精度高稳定性的姿态动作信息以及3轴加速度/角速度/地磁量/方位角等数据。

2022-2023年注册测绘师《测绘综合能力》预测试题(答案解析)全文为Word可编辑,若为PDF皆为盗版,请谨慎购买!第壹卷一.综合考点题库(共50题)1.GPS三维无约束平差需要提供()点的已知坐标。

A.1个B.2个C.3个D.4个正确答案:A本题解析:C、D、E级GPS网无约束平差即,在基线向量检核符合要求后,以三维基线向量及其相应方差一协方差阵作为观测信息,以一个点在2000国家大地坐标系中各点的三维坐标作为起算依据,进行无约束平差。

2.工程控制网的质量准则为()A.精度准则B.可靠性准则C.灵敏度准则D.费用准则E.多样性准则正确答案:A、B、C、D本题解析:工程控制网的质量准则包括:精度准则、可靠性准则、灵敏度准则、费用准则。

3.数字航摄影像的分辨率通常是指()A.每毫米线对数B.每平方厘米点数C.每平方厘米像素个数D.每个像素实地尺寸正确答案:D本题解析:影像分辨率。

数字航空影像或航天遥感影像而言,分辨率通常是指地面分辨率,一般以一个像素所代表地面的大小来表示。

4.房产测绘中,以下层高超过2.2m的建筑部位需要按水平投影计算一半建筑面积的有()。

A.有上盖未封闭的阳台B.有上盖未封闭的室外楼梯C.有上盖未封闭的单排柱永久使用的车棚D.有上盖未封闭的独立凉亭E.有上盖未封闭的架空走廊正确答案:A、C、E本题解析:有上盖的室外楼梯按外围水平投影计算全建筑面积,独立烟囱、亭、塔、罐、池,地下人防干、支线不计算建筑面积。

5.航外控制测量过程中,要求在现场用刺点针把目标点刺在主像片上,刺孔要小圆圈,刺孔直径不得大于()mm。

A.0.10B.0.15C.0.20D.0.25正确答案:A本题解析:野外控制点的目标选定后应根据像片上的影像,在现场用刺点针把目标准确地刺在像片上,刺点时应注意以下几点:(1)应在所有相邻像片中选择影像最清晰的一张像片用于刺点;(2)刺孔要小而透,针孔直径不得大于0.1mm;(3)刺孔位置要准,不仅目标要判读准确,而且下针位置也要准确,刺点误差应小于像片上0.1mm;(4)同一控制点只能在一张像片上有刺孔;(5)同一像片控制点在像片上只能有一个刺孔;(6)所有国家等级的三角点、水准点及小三角点均应刺点,当不能准确刺出时,对于三角点、小三角点可用虚线以相应符号表示其概略位置,在像片背面写出点位说明或绘出点位略图;(7)各类野外像控点根据刺孔位置在实地打桩,以备施测时用。

航空专业术语缩写英汉AVIATION GLOSSARY A-E--ATIS Airport Terminal Information Service机场终端信息服务ATIS Automated(automatic)Terminal Information Service自动终端情报服务ATM Air Traffic Management空中交通管理ATN Aeronautical Telecommunications Network航空电信网ATNP(ICAO)Aeronautical Telecommunication Network Panel (国际民航组织)航空电信网专家组ATO Actual Time Over实际经过时间ATRK Along-Track Error沿航线误差ATS Air Traffic Services空中交通服务ATSC Air Traffic Services Communication空中交通服务通信ATT Attitude姿态AUSSAT Australian Satellite澳大利亚卫星AUTODIN Automated Digital Network自动化数字网络AUTOVON Automatic Voice Network自动化话音网络AUX Auxiliary辅助AVOL Aerodrome Visibility Operational Level机场能见度运行等级AVPAC Aviation VHF Packet Communications航空甚高频分组通信AVS Aviation Standards航空标准AWANS Aviation Weather And NOTAM System航空气象和航行通告系统AWOP(ICAO)All Weather Operations Panel(国际民航组织)全天候运行专家组AWOS Automated Weather Observing System自动化气象观测系统AWP Aviation Weather Processor航空气象处理器AWS Aviation Weather Service航空气象服务AZ Azimuth transmitter方位台BBARO Barometric气压BAZ Back Azimuth后方位,背航道BER Basic Encoding Rules基本编码规则BER Bit Error Rate误码率BIT Built-In-Test机内测试BITE Built-In-Test Equipment机内测试设备BOP Bit Oriented Protocol面向位的协议BPS bits per second每秒传送位数;每秒比特数BPSK Biphase Shift Keying两相相移键控BRITE Bright Radar Indicator Tower Equipment塔台高亮度雷达显示设备BRL Bearing Range Line方位距离线BSU Beam Steering Unit天线方位控制组件BUEC Backup Emergency Communications备用紧急通信C通信C-Band Approx.5,000MHz C波段C/A(CA)Code Course Acquisition Code粗获码(民用的)C/I Carrier-to-Interference Ratio信号干扰比C/N Carrier-to-Noise Ratio信噪比CA Conflict Alert冲突告警CA GPS Course-Acquisition Code粗捕获码(民用码)CA/MSAW Conflict Alert/Minimum Safe Altitude Warning冲突告警/最低安全高度警告CAA Civil Aviation Administration,Civil Aeronautical Authority,Civil Aviation Authority民航局CAAC General Administration of Civil Aviation of China中国民用航空总局CAASD Center for Advanced Aviation System Development(The MITRE Corporation)(MITRE公司)高级航行系统开发中心CAB Civil Aeronautical Bureau民航局CARF Central Altitude Reservation Function中央飞行高度保留功能CARs Civil Air Regulations民用航空规则CASITAF CNS/ATM implementation task force新航行系统实施特别工作组CAT Category仪表着陆等级CATⅠCategoryⅠ一类仪表着陆CATⅡCategoryⅡ二类仪表着陆CATⅢa CategoryⅢa三类a级仪表着陆CATⅢb CategoryⅢb三类b级仪表着陆CATⅢc CategoryⅢc三类c级仪表着陆CATC Civil Aviation Training Center民航培训中心CATMAC Co-operative Air Traffic Management Concept空中交通管理合作方案CBA Cost/Benefit Analysis成本效益分析C-BAND The frequency range between4000and8000MHz4000到8000MHz频段CBI Computer Based Instruction计算机基本指令CBT Computer-Based Training计算机辅助训练CC Connection Confirm联接确认CCA Continental Control Area大陆管制区CCC蜂窝式CNS概念CCD Consolidated Cab Display综合机舱显示器CCIR International Radio Consultative Committee国际无线电咨询委员会CCITT International Telegraph and Telephone ConsultativeCommittee国际电报电话咨询委员会CCP Contingency Command Post应急指挥站CCWS Common controller workstation通用管制员工作站CD Common Digitizer通用数字化仪设备CDC Computer Display Channel计算机显示通道CDI Course Deviation Indicator偏航指示器CDM Code division multiplex码分复用CDM Continuous Delta Modulation连续增量调制CDMA Code Division Multiple Access码分多址CDT Controlled Departure Times管制离场时间CDTI Cockpit Display of Traffic Information驾驶舱交通信息显示CDU Control Display Unit控制显示组件CEP Circular error probability圆概率误差CERAC Combined Center Radar Approach Control雷达进近管制联合中心CFCC Central Flow Control Computer中央流量管制计算机CFCF Central Flow Control Facility中央流量管制设施(功能) CFDPS Compact Flight Data Processing System小型飞行数据处理系统CFWP Central Flow Weather Processor中央流量气象处理机CFWSU Central Flow Weather Service Unit中央流量气象服务单元(组件)CHI Computer Human Interface机人接口CIDIN Common ICAO Data Interchange Network国际民航组织公用数据交换网CIS Cooperative independent surveillance合作式独立监视CLAM Cleared Level Adherence Monitoring放行高度保持监视CLB Climb爬升CLK Clock时钟CLNP Connectionless Network Protocol无连接网络规程(协议)CLR Clear清除CMC Central Maintenance Computer中央维护计算机CMD Command命令CMS Cabin Management System机舱管理系统CMU Communications Management Unit通信管理单元CNDB Customized Navigation Database用户导航数据库CNS Consolidated NOTAM System综合航行通告系统CNS/ATM Communication Navigation,Surveillance/AirTraffic Management通信导航监视/空中交通管理CODEC Coder/Decoder编码器/解码器COM/MET/OPS Communication/Meteorology/Operations通信/气象/运行COMLO Compass Locator罗盘定位器;罗盘示位信标COMM Communication通信COMP Compressor压缩器COMSEC Communications Security通信保安CON Continuous连续CONUS Continental,Contiguous,or Conterminous United States美国大陆本部(四十八州)COP Change Over Point转换点COP Character Oriented Protocol面向字符协议COTS Commercial Off-the-Shelf商业货架产品供应CPDLC Controller Pilot Data Link Communications管制员驾驶员数据链通信CPFSK Continuous Phase Frequency Shift Keying连续相位频移键控CR Connection Request联接申请CRA Conflict Resolution Advisory冲突解脱咨询CRC Cyclic Redundant Check循环冗余校验CRCO Central Route Charges Office中央航路收征费办公室CRM C Reference Model C参考模式CRM Collision Risk Modeling碰撞危险模型CRM Crew Resource Management机组人员安排CRT Cathode Ray Tube阴极射线管CRZ Cruise巡航CSA Standard Accurate Channel标准精度通道CSE Course Setting Error航线设定误差CSMA Carrier Sense Multiple Access(datalink protocol)载波侦听多址访问C/SOIT Communication/Surveillance Operational Implementation Team通信监视运行实施小组(美国)CTA Calculated Time of Arrival计算到达时间CTA Control Area管制区CTAS Central Tracon Automation System中央终端雷达进近管制自动系统CTL Control控制CTMO Central traffic Management Organization中央交通流量管理组织CTMO Centralized Traffic Management Organization中央交通管理组织CTOL Conventional Take Off and Landing常规起飞着陆CTR Control zone管制地带CTS Control Tracking Station控制跟踪站CU Control Unit控制单元C§W Control and Warning控制和告警CW Carrier Wave载波CWI Continuous Wave Interference连续波干扰CWP Central Weather Processor中央气象处理器CWSU Center Weather Service Unit中央气象服务单元DD/A Digital-to-Analog数/模转换DABS Discrete Addressable Beacon System离散寻址信标系统DADC Digital Air Data Computer数字大气数据计算机D-ATIS Digital Automatic Terminal Information Service数字自动终端信息服务DA Decision Addressing beacon system决断寻址信标系统DA Demand Assignment按需分配DA/H Decision Altitude(Height)决断高度DARC Direct Access Radar Channel直接存取雷达信道DARP Dynamic Air Route Planning动态航线计划DARPS Dynamic Aircraft(Air)Route Planning Study动态飞机航线计划研究DC Departure Clearance离场放行许可DC Direct Current直流(电)DCC Display Channel Complex显示通道组合DCIU Data Control Interface Unit数据控制接口单元DCL Departure Clearance Delivery起飞许可传送DCPC Direct Controller Pilot Communication管制员驾驶员直接通信DES Data Encryption Standard数据加密标准DF Direction Finder测向器DFCS Digital Flight Control System数字飞行控制系统DFDAU Digital Flight Data Acquisition Unit数字飞行数据采集单元DGCA Director-General Civil Aviation民航局长DGNSS Differential Global Navigation Satellite System差分全球导航卫星系统DGPS Differential Global Positioning System差分全球定位系统DH Decision Height决断高度DIP Diplexer双工器DL Data Link数据链DLAC Data Link Applications Coding数据链应用编码DLAS Differential GNSS Instrument Approach System差分GNSS仪表进近系统DLK data link数据链DLORT FAA Data Link Operational Requirements Team FAA 数据链运行要求工作组DMAP ICAO Data Link Mobile Applications Panel(proposed) 国际民航组织数据链移动应用专家组(建议)DME Distance Measuring Equipment测距设备DME/N Distance Measuring Equipment/Normal标准测距设备DME/P Distance Measuring Equipment/Precision精密测距设备DMU Data Management Unit数据管理单元DO(DOC)Document记录(文件)DOD Department of Defense(美国)国防部DOP Dilution of Precision精度扩散因子DOT Department of Transportation(美国)运输部DOTS Dynamic Ocean Tracking System动态海洋跟踪系统DP Disconnect Request分离拆线请求DPF Data Processing Function数据处理功能D8PSK Differential Eight-Phase Shift Keying差分8相移键控DPSK Differential Phase Shift Keying差分相移键控DRMS Distance Root Mean Square距离均方根值DRN Document Release Notice文件发放通告DSB-AM Double Sideband Amplitude双边带调幅DSDU Data Signal Display Unit数据信号显示单元DSP Departure Sequencing Program起飞排序计划;离港排序计划DT Data数据DTE Data Terminal Equipment数据终端设备DT&E Development Test and Evaluation开发测试和评估DTF Data Test Facility数据检测设备DTG待飞距离DTN Data Transport Network数据传输网络DUAT Direct User Access Terminal用户直接存取终端DVOR Doppler Very high frequency Omni-directional Range 多普勒甚高频全向信标EEANPG European Air Navigation Planning Group欧洲航行规划小组E-DARC Enhanced Direct Access Radar Channel增强的直接存取雷达信道EARTS En route Automated Radar Tracking System航路自动化雷达跟踪系统EASIE Enhanced ATM and Mode S Implementation in Europe 欧洲S模式和增强的空中交通管理实施项目EATCHIP European ATC Harmonization Implementation Program 欧洲空中交通管制协调实施计划EATMS European Air Traffic Management System欧洲空中交通管理系统ECAC European Civil Aviation Conference欧洲民航会议ECEF 地心地固坐标EDCT Estimated Departure Clearance Time预计离港起飞放行时间EET Estimated Elapsed Time预计经过时间EFAS En route Flight Advisory Service航路飞行咨询服务EFAS Extended Final Approach Segment扩展最后进近段EFIS Electronic Flight Instrument System电子飞行仪表系统EFC Expect Further Clearance预期进一步放行许可EFIS Electronic Flight Information System电子飞行情报系统EGNOS European global navigation overlay system欧洲全球导航重迭系统EHSI Electronic Horizontal Situation Indicator电子平面状态显示器EIRP Equivalent Isotropic Radiate Power等效各向同性辐射功率EISA Extended Industry Standard Architecture扩展的工业标准结构EL Elevation Transmitter仰角台ELOD En route sector Load航路扇区负载管制飞机数量ELT Emergency Locator Transmitter紧急示位发射机EMC Electromagnetic Compatibility电磁兼容EMI Electromagnetic Interference电磁干扰ENRI Electronic Navigation Research Institute(日本)电子导航研究所EOF Emergency Operations Facility应急运行设施EPA Environmental Protection Agency环境保护署ER Error误差ERL Environmental Research Laboratories环境研究实验室ERM En Route Metering航路计量管制ERN Earth Referenced Navigation大地参考导航ERP Effective Radiated Power有效幅射功率ES End System终端系统ESA European Space Agency欧洲航天局ESCAN Electronic Scanning(radar antenna)ESMMC Enhanced SMMC增强的系统维护监视台ESP En route Spacing Program航路间隔计划EST Estimated message预计信息ETA Estimated Time of Arrival预计到达时间ETB Estimated Time of Boundary预计边界时间ETD Estimated Time of Departure预计离港时间ETG Enhanced Target Generator增强的显示目标产生器ETN Estimated Time of Entry预计进入时间ETO Estimated Time Over预计飞越时间ETSI European Telecommunications Standards Institute欧洲电信标准学会EU European Union欧洲联盟EURATN European ATN欧洲航空电信网EUROCAE European Organization for Civil Aviation Electronics欧洲民用航空电子学组织EUROCONTROL European Organization for the Safety of Air Navigation欧洲航行安全组织(欧安局)EVS Enhanced Vision System增强视景系统EWAS En-route Weather Advisory Service航路气象咨询服务FF&E Facilities and Equipment设施和设备F,E&D Facilities,Engineering,and Development设施、工程和开发FAA Federal Aviation Administration(美国)联邦航空局FAATC FAA Technical Center(美国)联邦航空局技术中心FAF Final Approach Fix最终进近坐标FANS ICAO Future Air Navigation Systems(国际民航组织)未来航行系统FANS Special Committee on Future Air Navigation Systems 未来航行系统特别委员会FANS(Phase II)Special Committee for the Monitor-ing and Co-ordination of Develop-ment and Transition Planningfor the Future Air Navigation System未来航行系统监督、协调发展与过渡规划专门委员会FAR Federal Aviation Regulation联邦航空条例FAS Final Approach Segment最后进近段FASID Facilities And Services Implementation Document设施和服务实施文件FCC Flight Communication Center飞行通信中心FCC Federal Communication Commission联邦通信委员会FCC Flight Control Computer飞行控制计算机FDAU Flight Data Acquisition Unit飞行数据收集单元FDDI Fiber Distributed Data Interface光纤分布数据接口FDEP Flight Data Entry and Printout飞行数据输入和输出FDI Fault Detection and Isolation故障检测和隔离FDIO Flight Data Input/Output飞行数据输入/输出FDM Frequency Division Multiplex频分复用FDMA Frequency Division Multiple Access频分多址FDP Flight Data Processor飞行数据处理器FDPS Flight Data Processing System飞行数据处理系统FDR Flight Data Recorder飞行数据记录仪FEATS Future European ATS System Concept未来欧洲空中交通服务系统方案FEATS ICAO Future European Air Traffic Management System 国际民航组织未来欧洲空中交通管理系统FEC Forward Error Correction前向纠错FGC Flight Guidance Computer飞行引导计算机FGCC Federal Geodetic Control Committee联邦大地测量管理委员会FI Flight Inspection飞机校验FIC Flight Information Center飞行信息中心FIFO First In-First Out先入先出FIFO Flight Inspection Field Office飞行检查现场办事处FIR Flight Information Region飞行情报区FIS Flight Information Services飞行情报服务FISA Automatic Flight Information Service自动飞行信息服务FL Flight Level飞行高度层FLIR Forward Looking Infra-red Detection前视红外线探测FM Frequency Modulation调频FMC Flight Management Computer飞行管理计算机FMEA Failure Mode Effects Analysis故障模式效果分析FMS Flight Management System飞行管理系统FMS Frequency Management System频率管理系统FMSG Frequency Management Study Group频率管理研究组FMU Flight Management Unit飞行管理组件FMU Flow Management Unit流量管理单元FOC Full Operation Capability全运行能力FOM Figure of Merit性能指数FPA Flight Path Angle航迹倾角FPD Flight Plan Data飞行计划数据FPS Military Primary Radar军用一次雷达FREQ Frequency频率FRP Federal Radio navigation Plan联邦无线电导航计划(美国)FS Functional Statement功能描述FSAS Flight Service Automation System飞行服务自动化系统FSDPS Flight Service Data Processing System飞行服务数据处理系统FSK Frequency Shift Keying频移键控FSP Flight Strip Printer飞行进程单打印机FSS Flight Service Station飞行服务站FSTN Federal Security Telephone Network联邦政府保安电话网络FT Functional Test功能测试FTE Flight Technical Error飞行技术误差FY Fiscal Year财政年度;会计年度GGA General Aviation通用航空GA Ground annta地面天线Gatelink Datalink for packed aircraft网关数据链路GADS Generic Aircraft Display System通用航空器显示系统GAIT Ground-based Augmentation and Integrity Technique陆基增强和完好性技术GAO Government Accounting Office(联邦)政府会计署GBA Geostationary broadcast area静止卫星广播区域GCAS Ground Collision Avoidance System地面防撞系统GCS Ground Controlled Approach地面控制系统GDLP Ground Data Link Processor地面数据链处理器GDOP Geometic Dilution of Position位置几何扩散因子GDOP Geometry Dilution of Precision精度几何扩散因子GEO Geostationary静地的GEO Geostationary Earth Orbit相对地球静止轨道静止卫星GES Ground Earth Station地面地球站GFE Government-Furnished Equipment政府提供的设备GHz Giga hertz千兆赫兹GIB GNSS integrity broadcast全球导航卫星系统完好性数据广播GIC GNSS Integrity Channel全球卫星导航系统完好性通道GICB Ground-initiated Comm-B地面启动的B类通信GIRU Ground Interrogator Receiver Unit地面应答机接收单元GIS Geographical Information System地理信息系统GLONASS Global Orbit Navigation Satellite System全球轨道导航卫星系统(俄罗斯)GLS GPS Landing System GPS着陆系统GM Guidance Material指导材料GMC Ground Movement Control地面活动管制GMSK Gaussian Minimum Shift KeyingGMT Greenwich Mean Time格林威治时间GNAS General NAS综合国家空域系统GND Ground地GNE Gross Navigational Error总导航误差GNR Global Navigation Receiver全球导航接收机GNSS Global Navigation Satellite System全球导航卫星系统GNSSP ICAO Global Navigation Satellite Systems Panel国际民航组织全球卫星导航系统专家组GPSSU Global Positioning System Sensor Unit全球定位系统(GPS)传感器组件GOES Geostationary Operational Environmental Satellite静地运行环境卫星GOS Grade of Service服务等级GOSEP Government Open Systems Interconnection Profile政府开放系统互联结构GOSIP Government Open systems Implementation Profile政府开放系统实施结构GP Glide-Path下滑道GPIP Glide-Path Intercept Point下滑道截获点GPIWP Glide Path Intercept Waypoint滑行道切入点GPO/GPI General Purpose Output/General Purpose Input通用输出/通用输入GPS Global Positioning System全球定位系统GPWS Ground Proximity Warming System近地告警系统GREPECAS Caribean/South American Planning and Implementation Regional Group加勒比/南美洲计划和实施区域小组GRS Ground-Reference Station地面基准站GRS80Geodetic-Reference System-80大地基准系统-80GS(G/S)Glide Slope下滑坡度GS Ground Speed地速GSA General Services Administration综合服务管理局(联邦政府下属)GSL General Support Laboratory综合保障实验室GSM Global System(or Mobile)Communication全球通信系统GWS Graphic Weather Service图形气象服务HH Homing radio beacon归航无线电信标HARN High Accuracy Reference Network高精度参考网HAT Height Above Touchdown高于接地点的高度HCI Human Computer Interface人机接口HDD Head Down Display下视显示器HDG Heading航向HDOP Horizontal Dilution Of Precision精度水平扩散因子HEMP High Altitude Electromagnetic Pulse高空电磁脉冲HEO High Elliptical Orbit高椭圆率轨道HF High Frequency(3-30MHz)高频HFDL High Frequency Data Link高频数据链HGA High Gain Antenna高增益天线HIRF High Intensity Radiated Fields高强度辐射场HIWAS Hazardous In-flight Weather Advisory Service飞行时遇危险天气的咨询服务HMI Human Machine Interface人机接口HPA high power amplifier高功率放大器HPF Horizontal Position Fix Error水平位置坐标误差HSI Horizontal Situation Indicator水平位置指示器HUD Head-up Display平视显示仪HUI Head up DisplayHVAC Heating,Ventilating,And air Conditioning加热,通风和空调Hybird GNSS/ILS Precision Approach/Landing based on combination of GNSS localizer and ILS glide path基于GNSS 航向和ILS下滑道组合的精密进近/着陆系统Hz Hertz赫兹IIA5International Alopabet5国际字母表第5号码IACA International Air Carrier Association国际航空公司协会IACSP International Aeronautical Communication Service Provider国际航空通信业务提供者IAF Initial Approach Fix初始进近点(坐标)IAG International Association of Geodetical国际测地协会IAIN International Association of Institutes of Navigation国际导航学会联合会IAOPA International Council of Aircraft Owner and Pilot Associations航空器企业主和驾驶员协会国际委员会IAP Instrument Approach Procedure仪表进近程序IAR Intersection of Air Routes航路交叉点IAS Indicated Air Speed指示空速IASC Inter Area Speech Circuit区域间话音线路IATA International Air Transport Association国际航空运输协会IBAC International Business Aviation Council国际商业航空委员会ICAO International Civil Aviation Organization国际民航组织ICCAI(A)International Co-ordination Council of Aerospace Industries Associations国际宇航工业联合会合作委员会ICD Interface Control Document接口控制文件ICO Interim Circle Orbit中高度圆轨道ICSS Integrated Communications Switching System综合通信转换系统ID Identifier(Identification)标识码(编码、识别标志)ID Instrument Departure仪表离场IDSG ICAO Internet Working Standards Drafting Group国际民航组织网间标准起草小组IEEE Institute of Electrical and Electronic Engineers电气和电子工程师学会IF Intermediate approach Fix中间进近定位点IFALPA International Federation of Airline Pilots Associations 航空公司驾驶员协会国际联合会IFATCA International Federation of Air TrafficControllers'Associations空中交通管制员协会国际联合会IFCN Interfacility Flow Control Network设施(单位)间流量管制网络IFF敌我识别器IFM Integrated Flow Management综合流量管理IFR Instrument Flight Rules仪表飞行规则IFRB International Frequency Registration Board国际频率注册委员会IFSS International Flight Service Station国际飞行服务站IBM International Business Machines(美国)国际商用机器公司ILA International Law Association国际法律协会ILS Instrument Landing System仪表着陆系统IMA Integrated Modular Avionics集成化模块式航空电子设备IMAWP Initial Missed Approach Waypoint起始复飞航路点IMC Instrument Meteorological Conditions仪表气象条件IMCS Interim MCS过渡性监控/管制软件IMO International Maritime Organization国际海事组织IMS Integrity Monitoring System完好性监视系统IN Information Need信息需求INMARSAT International Marine Satellite Organization国际移动卫星组织(原名国际海事卫星组织)INS Inertial Navigation System惯性导航系统INS Insert插入INTNET Integrated Data Communications Network集成化数据通信网络I/O input/output输入/输出IOACG Informal Indian Ocean Air Traffic Services Coordinating Group非正式印度洋空中交通服务协调小组IOC Initial Operational Capability初始运行能力IOD GPS Issue of Data全球定位系统数据发布ION Institute of Navigation导航学会IOR Indian Ocean Region印度洋区域IOT§E Initial Operational Test and Evaluation初始运行测试和评估IP Internetwork Protocol网络间协议IPACG Informal Pacific Air Traffic Control Coordination Group 非正式太平洋空中交通管制协调小组IRS Inertial Reference System惯性参考系统ISA International Standard Atmosphere国际标准大气ISDN Integrated Service Digital Network综合业务数字网络ISNS国际卫星导航服务ISO International Organization for Standardization国际标准化组织ISPACG Informal South Pacific ATS Co-Ordination Group非正式南太平洋空中交通服务协调小组ISSS Initial Sector Suite Subsystem起始扇区管制席位分系统ITU International Telecommunication Union国际电信联盟ITWS Integrated T erminal Weather Service综合终端气象服务IVAD Integrate Voice and Data综合话音和数据(通信数据链)IVRS Interim Voice Response System过渡性话音响应系统IWP Interim Working Party临时工作组JAWS Joint Airport Weather Studies联合机场气象研究JCAB Japan Civil Aviation Bureau日本民航局JAWS Joint Airport Weather Studies联合机场气象研究JPO Joint GPS Planning Office联合GPS规划办公室JSS Joint Surveillance System联合监视系统Kbps Kilo bits per second千位每秒KDP Key Decision Point关键性决定点kHz Kilohertz千赫KLAAS Kinematics Local Area Augmentation System动态地面局域增强系统KLADGNSS Kinematics Local Area Differential GNSS 动态地局域差分GNSSkW Kilowatt千瓦kWh Kilowatt hour千瓦小时LL11575.42MHz L-Band carrier L1频率L21227.6MHz L-Band carrier L2频率LAAS Local Area Augmentation System局域增强系统LACAC Latin American Civil Aviation Commission拉丁美洲民航委员会LADGNSS Local Area Differential GNSS局域差分全球卫星导航系统LADS局域差分系统LAN Local Area Network局域网LAT/LONG Latitude/LongitudeLat/Long Reference Waypoint经/纬度经/纬度参考点L-Band Approx1,500MHz L波段(1500兆赫附近频段)LCD Liquid Crystal Display液晶显示LCN Local Communications Network局域通信网络LDGPS Local Differential GPS本地差分GPSLEO Low Earth Orbit近地轨道、低高度轨道LGA Low Gain Antenna低增益天线LCN Local Communications NetworkLLWSA(S)Low Level Wind Shear Alert System低空风切变报警系统LMM Locator Middle Marker航向中指点标LNA Low Noise Amplifier低噪音放大器LNAV Lateral Navigation侧向导航LOC Localize Transmitter(Localizer)航向台发信机LOM Locator Outer Marker航向外指点标LON Longitude经度LORAN-C Long Range Navigation System罗兰-C导航系统LPC Linear Predicative Coding线性预测编码LRR Long Range Radar远程雷达LRU Line Replaceable Unit在线替换部件LSB Least Significant Bit最低有效位LVA Large Vertical Aperture大垂直孔径MMALSR Medium-intensity Approach Lighting System with Runway alignment indicator lights中级亮度进近照明系统,并有跑道对准线显示灯MAP Missed Approach Point复飞点MAR Minimally Attended Radar需低度护理的雷达MASPS Minimum Aeronautical System Standards最低航空系统标准MASPS Minimum Aircraft(Aviation)System Performance Specification(Standards)最小飞机(航空)系统性能标准扩展频谱MAWP Missed Approached WaypointMB Market Beacon指点标MBI Message Block Identifier信息块指示器mbps、Mbit/s mega bits per second兆位每秒MCA Minimum Crossing Altitude最低穿越高度MCC Maintenance Control Center维护控制中心MCDU Multifunction Control Display Unit多功能控制显示单元MCI Mode C intruder装有C模式应答器的入侵飞机MCS Master Control Station主控站MCS Monitoring/Control Software监控/管制软件MDA Minimum Descent Altitude最低下降高度MDT Maintenance Data Terminal维护数据终端MEA Minimum En-route Altitude最低航路高度MED Manual Entry Device人工输入器MET Meteorology气象METAR Meteorological Report of Aerodrome Conditions机场条件气象报告MFCP Multifunction Control Display Panel多功能控制显示面板MFDU Multifunction Display Unit多功能显示单元MHz Megahertz兆赫MIDANPIRG Middle East Air Navigation Planning and Implementation Regional Group中东地区航行规划<请合法使用í?t>实施小组MIFR Master International Frequency Registration国际频率注册管理站(员)MIL Military军方MKR Marker指点标MLS Microwave Landing System微波着陆系统MMALS Multi-Mode Approach and Landing System多模式进近和着陆系统MMI Man-Machine Interface人机接口MMR Multi-Mode Receiver多模式接收机MMS Maintenance Management System维护管理系统MMW Millimeter Wave毫米波MNPS Minimum Navigation Performance Specification最低导航性能规范MNPSA MNPS airspace最低导航性能规范空域MNT Mach Number Technique马赫数技术MOCA Minimum Obstruction Clearance Altitudes最低超障净空高度Mode S specific services S模式特定业务MODEM Modulator-Demodulator调制解调器MOPR Minimum Operational Performance Requirements最低运行性能要求MOPS Minimum Operational Performance Standards最低运行性能规范MORA Minimum Off-Route Altitude<请合法使用软件>低偏离航路高度MOS Metal-Oxide Semiconductor金属-氧化物半导体MOU Memorandum Of Understanding备忘录MPS Maintenance Processor Subsystem维护处理机分系统MRA Minimum Reception Altitude最低接受高度MRT Multi-Radar Tracking多雷达跟踪MRT-VU Multi-Radar Tracking using Variable Update采用变化更新的多雷达跟踪MSA Minimum Sector Altitude最低扇区高度MSAT移动业务卫星系统(美国的)MSAW Minimum Safe Altitude Warning最低安全高度警告MSCP Mobile Satellite Service Provider移动卫星业务提供者MSE Mean Square Error均方误差MSK Minimum Shift Keying最小移频键控MSL Mean Sea Level平均海平面MSP Mode S specific protocol S模式特别协议(规程)MSU Mode Select Unit模式选择单元MTBA Mean Time Between Alarm(Warning)平均告警间隔时间MTBF Mean Time Between Failure平均故障间隔时间MTBO Mean Time Between Outage平均故障停工间隔时间MTBR Mean Time Between Repairs平均故障修复间隔时间MTBUR Mean Time Between Unit Replacements平均更换故障单元间隔时间MTBW Mean Time Between Warning平均告警间隔时间MTD Maintenance Terminal Display维护终端显示器MTI Moving Target Indicator活动目标指示器MTM Module Test and Maintenance模块测试和维护MTMIU Module Test and Maintenance Bus Interface Unit模块测试和维护总线接口单元MTN MEGA Transport Network MEGA运输网络MTSAT Multi-Functional Transport Satellite多功能传送卫星(日本)MTTDA Mean Time To Dispatch Alert平均签派告警时间MTTF Mean Time To Failure平均故障时间MTTM Mean Time To Maintenance平均维护时间MTTR Mean Time to Repair维平均修时间MTTR Mean Time to Restore平均恢复时间MU Management Unit管理单元MUS Minimum Use Specification最低应用规格MUX Multiplexer复用器MN Multisensor Navigation多传感器导航MUX Multiplexer多工器,复用器MWARA Major World Air Route Area世界主要航路区MWO Meteorological Watch Office气象观测台NN Navigation导航NA Not Applicable不可用NACK Negative Acknowledgment出错通知NAD North American Datum北美数据(基准)NADIN National Airspace Data Interchange Network国家空域数据交换网NAGU咨询报告NAILS National Airspace Integrated Logistics Support国家空域综合后勤保障NAPA国家公共管理科学院(美国)Nanosecond One billionth of a second十亿分之一秒NAR National Airspace Review国家空域审议NARACS National Radio Communications System国家无线电通信系统NAS National Airspace System国家空域系统NASA National Aeronautics and Space Administration国家航空和宇航局(美国)NASNET National Airspace System Network国家空域系统网络NASP National Airport System Plan国家航空港系统计划NASPALS NAS Precision Approach and Landing System国家空域系统进近和着陆系统NAT North Atlantic北大西洋地区NAT ADSG North Atlantic Automatic Dependent Surveillance Development Group北大西洋自动相关监视开发小组NAT ATS North Atlantic Air Traffic Services北大西洋空中交通服务NAT SPG North Atlantic Systems Planning Group北大西洋系统规划组NATCOM National Communications Center,Kansas City, Missouri国家通信中心(位于密苏里州堪萨斯城)NATS National Air Traffic Service国家空中交通服务NAV NavigationNAVAID Navigational Aid导航设施NAVAID Radio Aid to Navigation无线电助(导)收设备NAVD North American Vertical Datum北美垂直向数据NCA National Control Authority国家指挥当局NAWP National Aviation Weather Processor国家航空气象处理机NCC Network Control Center网络控制中心NCD No-Computed Data无算出数据NCIU NEXRAD communications interface unit改进型气象雷达通信接口单元NCP Network Control processor网络控制处理器NCS Network Coordinating Station网络协调台NDB Nondirectional Radio Beacon无方向信标NEAN North European ADS-B Network北欧ADS-B网络NEOF National Emergency Operations Facilities国家应急指挥设施NEXRAD Next Generation Weather Radar改进型气象雷达;下一代气象雷达NGRS National Geodetic Reference System国家测地参考系统NGS National Geodetic Survey国家测地勘察NICS NAS Interfacility Communications System国家空域系统设施间的通信系统NIST National Institute of Standards and Technology国家标准和技术研究所NLES导航岸站NM(NMI)Nautical Mile海里,节NMC National Meteorological Center国家气象中心(美国) NMCE Network Monitoring and Control Equipment网络监控设备NMDPS Network Management Data Process System网络管理数据处理系统NMS Navigation Management System导航管理系统NOAA National Oceanic and Atmospheric Administration国家海洋和大气局(美国)NOPAC North Pacific北太平洋NOTAM Notice to Airmen航行通告NPA Non-Precision Approach非精密进近NPDU Network Protocol Data Unit网络协议数据单元NPLAS National Plan of Integrated Airport Systems国家综合航空港系统的计划NRC National Research Committee国家科学研究委员会(美国的)NSAP Network Service Access Point网络服务访问点NSB National Secure Bureau国家保安局(美国的)NSC Network Service Centre网络服务中心NSDU Network Service Data Unit网络服务数据单元NSE Navigation System Error导航系统误差NSSF NAS Simulation Support Facility国家空域系统的仿真保障设施NTLA National Telecommunications Information Agency国家电信资料署(美国)NTSB National Transportation Safety Board国家运输安全委员会(美国)NWS National Weather Service国家气象服务(美国)OO&M Operation and Maintenance运行和维修O.R.Operational Requirement运营要求OACC Oceanic Area Control Center海洋区域管制中心OAS Obstacle Assessment Surface障碍物评价面OAS Oceanic Automation System海洋自动化系统OCA Obstacle Clearance Altitude超障净高度OCA Oceanic Control Area海洋管制区OCH Obstacle Clearance Height超障高OCM Oceanic Clearance Message海洋放行许可信息OCP ICAO Obstacle Clearance Panel国际民航组织超障净空专家组OCS运行控制系统OCS Obstacle Clearance Surface超障面ODALS Omnidirectional Approach Lighting System全向进近灯光系统ODAPS Oceanic Display and Planning System远洋飞行显示和规划系统ODF Oceanic Development Facility海洋开发设施ODIAC Operational Development of Initial Air-ground data Communications早期空-地数据通信运行开发ODL Oceanic Data Link海洋数据链OEM Original Equipment Manufacturer原始设备制造商OFDPS Offshore Flight Data Processing System近海飞行数据处理系统OLAN Onboard Local Area Network机载局域网OLDI On-line Data Interchange联机数据交换OMB Office of Management and Budget国家管理和预算局(美国) OMEGA A navigation system that uses two high-powered transmitter grounds stations to broadcast a continuous wave signal.奥米加导航系统ODALS Omnidirectional Approach Lighting System全向进近灯光系统OOOI Out-Off-On-In滑出-起飞-接地-停靠门位OP Operational 运行。

POS MV WAVEMASTER II 将帮助您实现投资回报率最大化性能列表- POS MV WAVEMASTER II 的精度1POS MV WaveMaster II 是一款即买即用的综合性船载定位定姿产品,其具有非常友好的用户接口,能够精确地提供船体的姿态、航向、垂荡、位置和速度数据。

POS MV 已在各种环境下经过充分测试,其优秀品质已得到证实。

POS MV 能够提供精确的位置参考和运动补偿,是完成海道测量的专业级产品。

POS MV 将GNSS 数据与IMU (惯性测量单元) 的角速率和加速度数据,GAMS (GPS Azimuth Measurement System/GPS 方位角测量系统) 的航向数据进行融合,以便生成稳定而精确的全六自由度定位定姿解算。

11σ, 除非另有说明2 取决用差分校正数据的质量3假定1米的 IMU-GNSS 天线偏差 4没有范围限制5周期为20秒或更少时,其它将更大6周期为35秒或更少时,其它将更大7不包括接头高度1. 以太网输入/输出以太网(10/100 base-T)参数时间标签、状态、位置、姿态、垂荡、速度、航迹和速度、动态参数、性能指标、 原始IMU数据、原始GNSS数据显示端口低速率(1 Hz) UDP 协议输出控制端口 TCP/IP 输入系统控制命令主端口实时(大于200 Hz) UDP协议输出次端口缓存TCP/IP 协议输出,将数据记录到外设中2. RS232串口输入/输出5 COM端口用户可配置:NMEA输出(0-5)、二进制输出 (0-5)、GNSS 辅助数据输入 (0-2)、基准站GNSS 校正数据输入 (0-2)3. NMEA ASCII 输出参数标准NMEA ASCII 信息:位置 ($INGGA)、航向信息 ($INHDT)、轨迹和速度信息 ($INVTG)、统计信息 ($INGST)、姿态信息 ($PASHR,$PRDID)、时间和日期信息 ($INZDA, $UTC)速率最大50 Hz (用户可选)配置可单独对任意指定端口进行输出和速率的配置4. 高速率姿态数据输出参数用户可选择输出的二进制信息: 姿态、航向、速度速率最大 200 Hz (用户可选)配置可单独对任意指定端口进行输出和速率的配置5. GNSS 辅助数据输入参数标准NMEA ASCII 信息: $GPGGA, $GPGST、$GPGSA、$GPGSV采用数据质量最好的辅助数据输入速率 1 Hz6. 基准站GNSS校正数据输入参数 RTCM V2.x、RTCM V3.x、CMR和CMR+、支持CMRx输入格式。

PAT在航空行业的应用作业引言随着信息技术的迅速发展,各行各业纷纷应用智能化技术来提升效率和安全性。

航空行业也不例外,航空公司和机场利用智能化技术来提供更好的服务和管理。

本文将探讨如何应用航空旅客自助系统(PAT)在航空行业中。

什么是航空旅客自助系统(PAT)?航空旅客自助系统(Passenger Automated Terminal,简称PAT)是一种智能化的技术,旨在提供便捷的服务和提升旅客的体验。

PAT利用自动化设备和信息技术来完成航空旅客检票、行李托运、安全检查等环节,减少人工操作,简化流程,为旅客提供更快速、高效和准确的服务。

PAT在航空行业的应用1. 自助值机航空旅客可以通过PAT自助设备进行登记和值机,无需排队等候服务员处理。

旅客只需刷取有效的身份证件,系统即可自动识别并核对旅客身份信息。

这样不仅减少了人工操作的时间和错误率,还提高了值机的效率和准确性。

2. 自助托运行李PAT还可以用于旅客行李的自助托运。

旅客只需要将行李放在指定的托运设备上,系统即可自动称重并打印行李标签。

这样,旅客可以快速完成托运手续,不再需要排队等待人工操作,节省了时间和精力。

3. 自助安全检查传统的安全检查通常需要旅客逐个通过人工安检通道。

而通过PAT,旅客可以通过自助安检门或自助输送带,系统会自动扫描身体和行李,检测可疑物品。

这种自助安检方式不仅提高了安检效率,也减少了人员聚集,提供了更好的安全性。

4. 自助登机利用PAT,航空公司可以为旅客提供自助登机服务。

旅客只需通过自助设备扫描登机牌,系统会自动识别并核对信息,放行旅客通过登机口。

这种自助登机方式不仅加快了登机速度,还减少了登机人员的工作量。

结论航空旅客自助系统(PAT)的应用在航空行业中带来了很多好处。

它可以提高航空公司和机场的效率和准确性,减少人工操作所带来的错误和时间成本。

对于旅客而言,PAT为其提供了更快捷、便利和舒适的服务体验。

可以预见,在未来,航空旅客自助系统(PAT)的应用会进一步得到发展和完善,为航空行业带来更多的创新和改变。

rnp ar原理RNP AR(Required Navigation Performance Authorization Required)是一种先进的仪表飞行程序,可以为飞行员提供更高的导航精度和航线灵活度。

它是全球导航卫星系统(GNSS)和航空电子设备的结合,可以允许飞机在特定空域内进行更精确和高效的飞行,同时提高航空安全性。

RNP AR将飞行程序和现代化设备相结合,通过利用卫星定位技术和惯性导航技术来实现更准确的航点通航。

其核心原理是通过高度准确的导航系统来定义和控制飞机的飞行路径。

与传统的仪表进近和离场程序不同,RNP AR允许飞行员以更低的最低下降高度(MDA)或最低高度(MA)进行仪表进近,从而提供更好的可视条件,提高飞行安全性。

RNP AR的实现需要飞行员、航空公司、航空发动机制造商、航空管制和航空管理机构的紧密合作。

首先,航空公司需要确保飞机上装备了符合RNP AR要求的导航设备。

其次,飞行员需要接受特定的训练和认证,以掌握RNP AR的操作和规程。

在航空管制方面,航空管理机构需要对相关领域进行研究和规划,制定符合RNP AR要求的飞行程序和空域限制。

最后,航空发动机制造商需要提供满足RNP AR运行要求的发动机。

RNP AR的飞行程序主要包括准备阶段、进近阶段和机组操作阶段。

在准备阶段,机组需要导入航路、进场和进近程序,并确保导航设备数据正确。

在进近阶段,飞行员会根据航路点和航线要求,设定正确的飞行速度和高度,并依靠导航系统的精确位置信息来正确找到飞机的位置和航向。

在机组操作阶段,飞行员需要掌握RNP AR的操作方式,并根据航线上的制导点和航迹角来正确飞行。

RNP AR的优点主要体现在以下几个方面。

首先,RNP AR可以大大降低飞行员的工作负担,减少人为因素对飞行安全带来的影响。

其次,RNP AR可以提高飞机飞行的精确度和航线的稳定性,从而提供更加流畅和高效的飞行。

再次,RNP AR可以加强对特定空域的管理和控制,减少空中交通拥堵和碰撞风险。