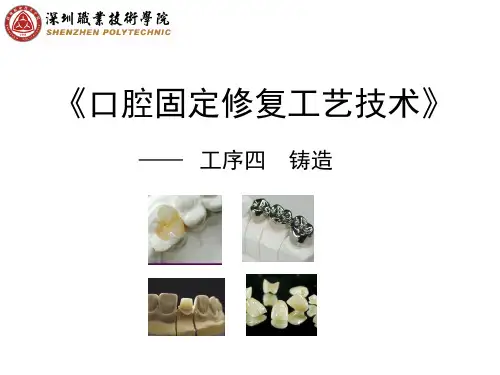

固定修复体的制作工艺

- 格式:ppt

- 大小:2.74 MB

- 文档页数:114

传统固定修复工艺技术的工艺流程下载温馨提示:该文档是我店铺精心编制而成,希望大家下载以后,能够帮助大家解决实际的问题。

文档下载后可定制随意修改,请根据实际需要进行相应的调整和使用,谢谢!并且,本店铺为大家提供各种各样类型的实用资料,如教育随笔、日记赏析、句子摘抄、古诗大全、经典美文、话题作文、工作总结、词语解析、文案摘录、其他资料等等,如想了解不同资料格式和写法,敬请关注!Download tips: This document is carefully compiled by the editor. I hope that after you download them, they can help yousolve practical problems. The document can be customized and modified after downloading, please adjust and use it according to actual needs, thank you!In addition, our shop provides you with various types of practical materials, such as educational essays, diary appreciation, sentence excerpts, ancient poems, classic articles, topic composition, work summary, word parsing, copy excerpts,other materials and so on, want to know different data formats and writing methods, please pay attention!传统固定修复工艺技术在牙科领域中具有非常重要的作用,是一种常见且有效的修复方法。

固定修复体工艺流程固定修复体是一种常见的修复技术,用于修复牙齿缺损或损坏,恢复其形态和功能。

固定修复体的工艺流程主要包括模型制作、牙齿准备、印模、制作固定修复体和修复体的安装。

下面将详细介绍这一流程。

首先是模型制作。

固定修复体的制作需要根据患者的口腔情况制作模型,以便进行设计和制作。

通常采用的方法有直接法和间接法。

直接法是将模型材料直接应用于患者口腔中,然后制作模型。

间接法是将患者的牙齿印模,然后制作模型。

接下来是牙齿准备。

在制作固定修复体之前,需要先对患者的牙齿进行准备。

这包括去除损坏的牙齿组织,使其适应于安装修复体。

通常需要对牙齿进行磨牙、根管治疗和固位牙冠等步骤,以确保修复体的贴合和稳定。

然后是印模。

印模是制作固定修复体的重要步骤,直接关系到修复体的质量和适合度。

印模是通过将硅橡胶或其他材料应用于患者的牙齿上以制作的。

这个模型会成为制作固定修复体的依据,所以印模的精确度非常重要。

接下来是制作固定修复体。

根据印模制作的模型,技师会进行修复体的设计和制作。

首先是选择适当的材料,根据患者的需求和情况,选择合适的陶瓷材料或金属材料。

然后使用CAD/CAM技术或传统手工制作的方法来制作修复体。

制作过程中需要考虑牙齿的形态、颜色和咬合等因素,以确保修复体的质量和适应性。

最后是修复体的安装。

当固定修复体制作完成后,技师会将其安装在患者的口腔中。

这个过程需要剔除患者牙齿表面的组织,将修复体粘合在牙齿上。

安装后需要进行适当的调整和磨合,以确保修复体的合适和舒适。

总之,固定修复体的制作工艺流程包括模型制作、牙齿准备、印模、制作固定修复体和修复体的安装。

这一流程需要严格按照规范操作,以确保修复体的质量和适应性。

同时,技术人员需要具备扎实的专业知识和丰富的经验,以保证整个流程的顺利进行,并达到满意的效果。

固定修复体工艺流程英文回答:Fixed repair process is a standardized procedure used to address specific issues in a consistent and efficient manner. It is commonly employed in various industries, such as manufacturing, automotive, and technology. The goal of a fixed repair process is to ensure that repairs are carried out correctly and promptly, minimizing downtime and maximizing productivity.The fixed repair process typically involves several steps. First, the issue or problem is identified. This can be done through various means, such as customer complaints, equipment malfunction, or routine inspections. Once the problem is identified, it is important to gather all necessary information related to the issue, such as error codes, diagnostic reports, or customer feedback.After gathering the necessary information, the nextstep is to analyze the problem. This involves examining the root cause of the issue and determining the best course of action to rectify it. In some cases, this may require consultation with experts or conducting further tests or investigations.Once the analysis is complete, a repair plan is developed. This plan outlines the specific steps and procedures that need to be followed to fix the problem. It includes details such as the required tools and equipment, the estimated time for completion, and any safety precautions that need to be taken.Once the repair plan is in place, the actual repair work can begin. This involves carrying out the necessary repairs or replacements according to the established plan. It is important to follow the plan precisely to ensure that the repairs are done correctly and effectively.After the repairs are completed, a thorough inspection is conducted to verify that the issue has been resolved. This may involve testing the repaired equipment, conductingquality checks, or seeking feedback from the customer. If any further issues are identified during the inspection, additional repairs or adjustments may be necessary.In conclusion, a fixed repair process is a structured approach to addressing specific issues in a consistent and efficient manner. It involves identifying the problem, analyzing its root cause, developing a repair plan, executing the repairs, and conducting a thorough inspection. By following this standardized process, organizations can ensure that repairs are done correctly and promptly, minimizing downtime and maximizing productivity.中文回答:固定修复工艺流程是一种标准化的程序,用于以一致和高效的方式解决特定问题。

固定修复体工艺流程英文回答:Fixed repair process is a standardized procedure that is followed to fix a particular issue or problem. It ensures that the same steps are followed every time a repair is needed, which helps in maintaining consistency and efficiency in the repair process.The fixed repair process typically includes the following steps:1. Diagnosis: This is the first step in the repair process, where the issue or problem is identified and diagnosed. It involves analyzing the symptoms, conducting tests, and identifying the root cause of the problem.For example, if a car is not starting, the diagnosis process would involve checking the battery, starter motor, ignition system, and other related components to identifythe cause of the problem.2. Planning: Once the problem is diagnosed, a plan is created to fix the issue. This includes determining the required resources, tools, and parts needed for the repair, as well as estimating the time and cost involved.Continuing with the car example, if the diagnosis reveals a faulty starter motor, the plan would involve procuring a new starter motor and scheduling a time for its replacement.3. Repair: This is the actual repair process, where the identified issue is fixed. It involves following the necessary steps and procedures to replace or repair the faulty component or system.In the car example, the repair process would involve removing the old starter motor, installing the new one, and ensuring that it is properly connected and functioning.4. Testing: Once the repair is completed, the repairedsystem or component is tested to ensure that it is working properly. This involves conducting functional tests, performance tests, and any other necessary checks to verify the effectiveness of the repair.For the car example, the testing process would involve starting the car multiple times to ensure that the new starter motor is functioning correctly.5. Documentation: Finally, the repair process is documented, which includes recording the details of the repair, such as the problem identified, the steps taken to fix it, and any additional notes or observations.In the car example, the documentation would include recording the details of the faulty starter motor, the replacement process, and any other relevant information.中文回答:固定修复体工艺流程是一种标准化的程序,用于修复特定的问题或故障。

固定修复体制作的工艺流程英文回答:Fixed Restorations Fabrication Process.1. Preoperative Evaluation.Comprehensive examination to determine the need for fixed restorations.Assessment of patient's oral health, bite relationship, and occlusion.Evaluation of existing restorations and any potential risk factors.2. Treatment Planning.Determination of the type of fixed restorations required (e.g., crowns, bridges, inlays, onlays)。

Selection of appropriate materials and designs.Estimation of treatment duration and cost.3. Tooth Preparation.Removal of decay or damaged tooth tissue.Creation of a proper shape and size for the restoration.Ensuring adequate retention and stability.4. Impression Making.Taking an impression of the prepared tooth and surrounding tissues.Using an appropriate impression material to accurately capture the details.5. Fabrication of Provisional Restoration (Optional)。

固定修复体制作的工艺流程1. 设计阶段:

- 确定修复体制的功能和用途

- 选择合适的材料和制造方法

-设计修复体制的结构和尺寸

- 进行力学分析和模拟测试

2.材料准备:

- 根据设计要求选择合适的金属、陶瓷或聚合物材料 - 准备所需的原材料和辅助材料

3.制造阶段:

- 根据设计进行模具制作或3D打印

- 进行金属铸造、注塑成型或其他制造工艺

- 对制造出的修复体进行机加工和表面处理

4.检测和评估:

- 对修复体的尺寸、形状和表面质量进行检测

- 进行力学性能和生物相容性测试

- 评估修复体是否符合设计要求和安全标准

5.无菌包装:

- 对合格的修复体进行无菌包装

- 确保产品在运输和储存过程中保持无菌状态

6.标识和存储:

- 在包装上标注产品信息、批号和有效期

- 按照规定的条件存储修复体制作品

7.质量控制:

- 建立严格的质量控制体系

- 对每一个生产环节进行监控和记录

- 确保修复体制作品的质量和一致性

8.上市和临床应用:

- 获得相关部门的审批和认证

- 向医疗机构和患者提供产品信息和使用说明

- 收集临床反馈,持续改进和优化产品设计

以上是固定修复体制作的一般工艺流程,具体细节可能因材料、制造方法和产品类型而有所差异,需要根据实际情况进行调整和优化。