BHS系列主机培训资料

- 格式:pdf

- 大小:970.19 KB

- 文档页数:23

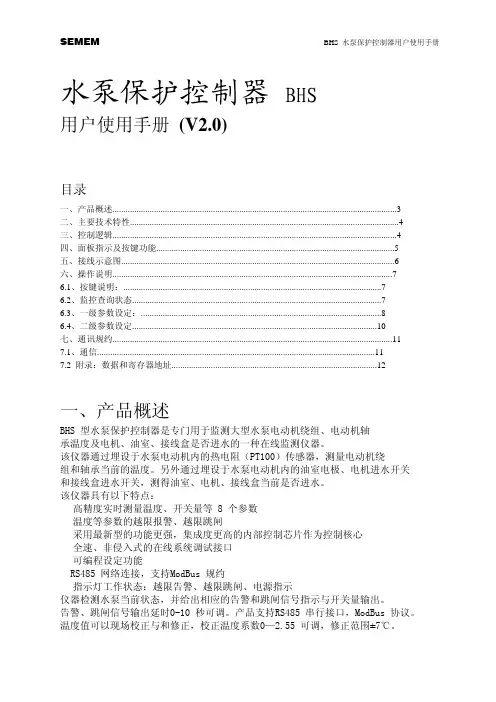

水泵保护控制器 BHS用户使用手册 (V2.0)目录一、产品概述 (3)二、主要技术特性 (4)三、控制逻辑 (4)四、面板指示及按键功能 (5)五、接线示意图 (6)六、操作说明 (7)6.1、按键说明: (7)6.2、监控查询状态 (7)6.3、一级参数设定: (8)6.4、二级参数设定 (10)七、通讯规约 (11)7.1、通信 (11)7.2 附录:数据和寄存器地址 (12)一、产品概述BHS 型水泵保护控制器是专门用于监测大型水泵电动机绕组、电动机轴承温度及电机、油室、接线盒是否进水的一种在线监测仪器。

该仪器通过埋设于水泵电动机内的热电阻(PT100)传感器,测量电动机绕组和轴承当前的温度。

另外通过埋设于水泵电动机内的油室电极、电机进水开关 和接线盒进水开关,测得油室、电机、接线盒当前是否进水。

该仪器具有以下特点:高精度实时测量温度、开关量等 8 个参数温度等参数的越限报警、越限跳闸采用最新型的功能更强,集成度更高的内部控制芯片作为控制核心全速、非侵入式的在线系统调试接口可编程设定功能RS485 网络连接,支持ModBus 规约指示灯工作状态:越限告警、越限跳闸、电源指示仪器检测水泵当前状态,并给出相应的告警和跳闸信号指示与开关量输出。

告警、跳闸信号输出延时0-10 秒可调。

产品支持RS485 串行接口,ModBus 协议。

温度值可以现场校正与和修正,校正温度系数0—2.55 可调,修正范围±7℃。

仪器采用标准的ModBus 通讯规约,被广泛作为系统集成的标准。

可与多个国际著名品牌的可编程顺序控制器(PLC)或第三方具有ModBus 兼容的监控系统 之间进行信息和数据的有效传递。

仪器具有故障保持功能,泵累计运行时间统计和故障记录和调阅功能。

BHS 产品为保障潜水泵安全可靠运行,防止潜水泵损坏引发机毁停产事故提供了一个十分有效的监测手段。

二、主要技术特性测量范围: 0℃~200℃测量精度: ±1℃使用环境: 温度:-20℃~60℃ 湿度:≤95%RH存贮环境: 温度:-30℃~90℃ 湿度:≤95%RH工作电源: AC220V外形尺寸: 120×120×80(mm)开 孔: 112×112(mm)嵌入式安装输出接点: AC220V/5A(告警输出一常开或一常闭,跳闸输出一常开或一常闭)通讯接口: RS485 串行接口,ModBus 协议,通讯波特率9600三、控制逻辑1、当前温度值小于 0 时,液晶屏对应显示“<0℃”。

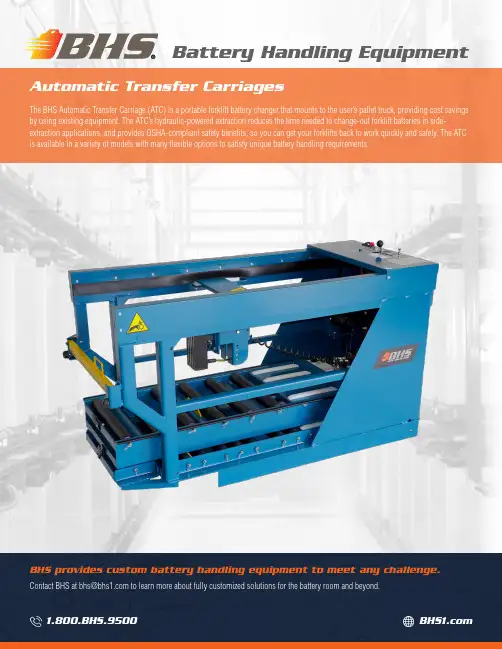

Battery Handling Equipment The BHS Automatic Transfer Carriage (ATC) is a portable forklift battery changer that mounts to the user’s pallet truck, providing cost savings by using existing equipment. The ATC’s hydraulic-powered extraction reduces the time needed to change-out forklift batteries in side-extraction applications, and provides OSHA-compliant safety benefits, so you can get your forklifts back to work quickly and safely. The ATC is available in a variety of models with many flexible options to satisfy unique battery handling requirements.BHS provides custom battery handling equipment to meet any challenge.The powerful extractor arm is hydraulic-powered to push and pull batteries into place using magnetic, vacuum, or hook-and-chain (pictured) attachment.ContainmentA steel Battery Containment Bar and battery flip-stop are used to enclose the compartment and keep the battery secure during transit.Enclosed Dashboard Sides Offers added protection against accidental contact with moving parts during operationThe ATC mounts easily to the user’s existing powered pallet truck. Consult BHS for pallet truck specificationsSimple Operator ControlsSimple, center-mounted controlsfor easy operation from left, right,or rear of the carriageBattery exchange is made easy by theroller bed which is outfitted with 10compartment rollers, providing betterwear and load distributionSmooth Battery Exchange Spark-Proof ProtectionATC OptionsVacuum Extraction (ATC-HC/VAC)Eliminates the need for manual hook-up and reduces wear and tear on batteries. Includes back-up Hook & Chain Extraction. Ideal for use with a dedicated battery room operator.Magnet Extraction (ATC-HC/MAG)Eliminates the need for manual hook-up, reduces wear and tear on batteries, and is ideal when batteries are too narrow for vacuum extraction. Includes back-up Hook & Chain Extraction. Ideal for use with non-dedicated battery room operators.7” Cantilever (ATC-CAN-7)Extends extractor arm reach an additional 7” (178 mm) and is ideal for use with 7” Cantilever & 6” Extended Bed (ATC-CAN-7-6)7” (178 mm) additional extractor arm reach is ideal for use with outriggers, and 6” (152 mm) bed extension accommodates longer batteries 7” Cantilever & 8” Extended Bed (ATC-CAN-7-8)14” Cantilever & 6” Extended Bed (ATC-CAN-14-6)14” Cantilever & 8” Extended Bed (ATC-CAN-14-8)SERVICING TRUCKS WITH OUTRIGGERSIf your forklifts have Outriggers/Base Legs or a picking platform, you will require a Cantilever option for additional arm reach.If you have batteries longer than 40”, you will require an Extended Bed option.* Consult factory for this option.† 24 V dc must be supplied from the host truck for powering the ATC (may require special taps and cable from SDCB battery), or optional on-board battery and charger packages are available if required.for use with pallet truck. See fork pocket dimensions below.3-Way Part-Time MountThree-Way Fork Pocket/QDY (ATC-FP-3-24/30, ATC-FP-3-36/42)†Designed for multi-purpose, multi-position and for applications where a pallet truck can’t be dedicated full time to the battery changing process. Rear-entry fork pockets are designed for use with pallet truck. Side-entry fork pockets are designed for use with SDCB lift trucks. Includes a welded Tongue Kit to enhance stability and an SB quick disconnect (ATC-QDY).3-Way Part-Time MountThree-Way Fork Pocket (ATC-FP-3)†BHS Fleet Tracker ® is a cloud-based fleet-management system, with detailed reporting that allows users to right-size their fleets for optimal efficiency. Connection to the IIoT allows managers to measure the health of batteries, stands, and trucks by logging into a secured Web Portal.Fleet Tracker’s touchscreen HMI mounted to the Automatic Transfer Carriage guides users to charged batteries, posts maintenance reminders, and updates the status of battery assets to the cloud. The Fleet Tracker system improves battery health, improves change-out efficiency, and givesmanagers the real-time data they need to eliminate waste by matching assets to needs exactly.Ask a BHS Representative for more information on Fleet Tracker.STREAMLINE & MONITOR BATTERY ROOM OPERATIONSReduce Maintenance Costs Increase Productivity Improve ProfitabilityNOTES: BHS recommends that high-speed travel be disabled on pallet truck and maximum speed set at turtle or lowest setting.1. Verify capacity of pallet truck being used at the specified load center (minimum 34” with 38” battery). Load center increases by 0.5” (12.7 mm) for every inch of battery over 38” (965 mm) in length. Certain options may affect load capacity. Consult factory.2. Minimum battery width for 10” (254 mm) diameter vacuum is 11.5” (292 mm). Minimum battery width for 12” (305 mm) diameter vacuum is 13.75” (350 mm).3. Consult factory for additional options.4. Weight does not include options. Add 80 lb (36 kg) for magnet extraction.facility maintain a productive battery room. From battery andcharger stands, to cable management and safety accessories,BHS has the total solution to fit the needs of any size facility.NORTH AMERICA:。

德国BHS公司混凝土设备技术张金宏;陆好剑;李京生;柳利君;李启涛;鲁学恩【期刊名称】《中国水利》【年(卷),期】2002(000)001【摘要】@@ 德国桑索霍芬机械和矿业公司(简称BHS公司)年平均生产100~120台套混凝土搅拌设备销往世界各地,销售额4000~5500万德国马克.公司主要产品:混凝土搅拌机、搅拌站、石料破碎及制砂设备.双卧轴搅拌机技术居世界领先地位,其容量为0.5~9.0m3,标志性产品包括:固定式单机组搅拌站(拌合主机7.0m3,生产率320m3/h);全移动式单机组搅拌站(生产率300m3/h);双卧轴拌合主机(干料充料容积13.5m3,混凝土搅拌容积9.0m3,生产率383m3/h),三者均为世界之冠.【总页数】2页(P66-67)【作者】张金宏;陆好剑;李京生;柳利君;李启涛;鲁学恩【作者单位】水利部综合事业局;水利部综合事业局;水利部综合事业局;水利部综合事业局;水利部淮河水利委员会;山东省水利厅【正文语种】中文【中图分类】TV5【相关文献】1.引进德国砂子加气混凝土设备生产粉煤灰加气混凝土的工艺措施 [J], 刘华章2.德国依米泰克公司和德国MAN汽车公司的通力协作赢得了"BDI新一代柴油机颗粒捕集器环境奖" 后处理技术——最有效的净化柴油机颗粒排放 [J],3.加压过滤——德国BHS公司加压转鼓过滤机的最新发展 [J], StefanScharnhorst;陈荣茂;贺晓东4.德国惠朋的丝绸之路——访德国惠朋(VIPA GmbH)公司总裁Mr.SEEL德国惠朋(VIPA GmbH)公司营销总监Mr.Linkenbach德国惠朋(VIPA GmbH)公司中国区总经理许勇先生 [J],5.美盈森与德国BHS公司强强联合 [J],因版权原因,仅展示原文概要,查看原文内容请购买。

OPERATING INSTRUCTIONSFORBHS ROTARY PRESSURE FILTERATEXBHS-Sonthofen GmbHAn der Eisenschmelze 47D-87515 SonthofenPostfach 1164Telefon +49 8321- 6099-0Telefax +49 8321- 6099-220E-mail info@bhs-sonthofenTable of Contents PageTables and pictures表和照片... ................................................................................................................................... (4)1. General 综述... ..................................................................................................................................................... .. 5 1.1 General Safety Information .一般性安全信息 .. (5)1.1.2 Marking of hints in the operating instructions . 标记提示的操作指令.. .............................................. (5)1.1.3 Qualification and training of personnel 人员资格和培训....................................................................... . 61.1.4 Dangers in the event of non-compliance with the safety information.不符合安全的危险事件的信息.. .................................................................................................................. (6)1.1.5 Safety-conscious working .注意安全工作.. ........................................................................................... . 71.1.6 Safety hints for the user/operator 用户/操作员的安全提示... ............................................................ .. 71.1.7 Safety hints for maintenance, inspection and assembly .安全提示维护、检查和组装.. ............................................................................................................................. . 71.1.8 Safety hints for use in hazardous areas .使用在危险区域的安全提示.. ............................................ . 71.1.8.1 Grouping of components/machines to form plants 组件/机器分组形成安置... ............................ (8)1.1.8.2 Design of protections against accidental contact for shaft couplings .为轴联轴器设计保护免受意外接触.. ............................................................................................................ . 81.1.8.3 Monitoring of technical parameters 监测技术参数... ........................................................................ .. 91.1.8.4 Avoiding sparks by external impact 避免火花由外部影响... ........................................................... .. 91.1.8.5 Unauthorised modifications and genuine spare parts .未经授权的修改和真正的备件.. .............. .. 91.1.8.6 Unacceptable modes of operation 不可接受的操作模式... ............................................................ (9)1.1.8.7 Warranty / Guarantee .质量保证/担保.. ............................................................................................ . 91.2 Unpacking .拆箱.. ............................................................................................................................................ .101.3 Transportation 运输...................................................................................................................................... (10)1.4 Storage and preservation .存放.. ................................................................................................................ ..112. Description .产品描述.. ...................................................................................................................................... (12)2.1 Intended use ..预期用途 (12)2.2 Operating principle .工作原理;操作原理 (12)2.3 Mechanical set-up .机械安装. ..................................................................................................................... (13)2.4 Designs and types..设计和类型. ................................................................................................................. (13)2.5 Technical application limits .技术应用的限制. ........................................................................................... (15)2.6 Accessories .配件附件 ................................................................................................................................. .153. Assembly .装配 .................................................................................................................................................. .. 163.1 Space requirements .空间要求. ............................................................................................................. .163.2 Foundations ..基础................................................................................................................................... ..163.3 Erection .架设.......................................................................................................................................... (17)3.4 Installation of pipework ..安装管道工程................................................................................................. ..183.4.1 General 综述. ....................................................................................................................................... (19)3.4.2 Separating plate contact pressure ..分离板接触压力........................................................................ .. 203.4.3 Supply lines for suspension, washing and drying media .供应链对悬架、洗涤和干燥介质........ (21)3.4.4 Blow back for cake discharge and cloth rinsing 吹了块状物排出和布清洗................................. (22)3.4.5 Filter cloth rinsing 滤布清洗......................................................................................................... .. 223.4.6 Draining piping ..排水管道.......................................................................................................... (22)3.5 Electric installation .电气装置................................................................................................................... (23)4.1 Start-up .启动................................................................................................................................... (26)4.2 Shut-down ..停车 ................................................................................................................................ ..27 4.3 Periodical checks during operation ..在操作期间定期检查........................................................ (28)4.4 Malfunctions 故障... ............................................................................................................................. .295. Maintenance .维护维修保养 . (30)5.1. Safety measures .安全防护措施......................................................................................................... .305.2. Recommended spare parts and annual overhaul .推荐的备件和年度检修 ................................... .315.3. Cell inserts ..电池插入接口................................................................................................................. .325.3.1 General ..综述........................................................................................................................... .. 325.3.2 Cell insert covering ...电池插入接口遮盖物 ............................................................................ (32)5.4 Separating elements (TE) 分离份子 ................................................................................................. .345.4.1 General .综述............................................................................................................................ .. 345.4.2 Replacement of separating elements .更换分离份子。