常用焊接材料对应表

- 格式:xls

- 大小:52.00 KB

- 文档页数:30

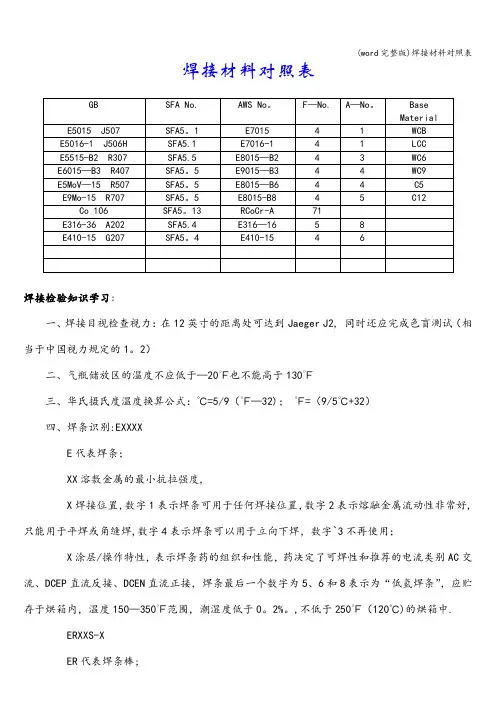

焊接材料对照表焊接检验知识学习:一、焊接目视检查视力:在12英寸的距离处可达到Jaeger J2, 同时还应完成色盲测试(相当于中国视力规定的1。

2)二、气瓶储放区的温度不应低于—20℉也不能高于130℉三、华氏摄氏度温度换算公式:℃=5/9(℉—32);℉=(9/5℃+32)四、焊条识别:EXXXXE代表焊条;XX溶敷金属的最小抗拉强度,X焊接位置,数字1表示焊条可用于任何焊接位置,数字2表示熔融金属流动性非常好,只能用于平焊或角缝焊,数字4表示焊条可以用于立向下焊,数字`3不再使用;X涂层/操作特性,表示焊条药的组织和性能,药决定了可焊性和推荐的电流类别AC交流、DCEP直流反接、DCEN直流正接,焊条最后一个数字为5、6和8表示为“低氢焊条”,应贮存于烘箱内,温度150—350℉范围,潮湿度低于0。

2%。

,不低于250℉(120℃)的烘箱中.ERXXS-XER代表焊条棒;XX溶甫敷金属的最小抗拉强度,S固态焊丝,数字1表示焊条可用于任何焊接位置,数字2表示熔融金属流动性非常好,只能用于平焊或角缝焊,数字4表示焊条可以用于立向下焊,数字`3不再使用;X化学成份,表示焊条药的组织和性能,药决定了可焊性和推荐的电流类别AC交流、DCEP直流反接、DCEN直流正接,焊条最后一个数字为5、6和8表示为“低氢焊条”,应贮存于烘箱内,温度150-350℉范围,潮湿度低于0。

2%。

,不低于250℉(120℃)的烘箱中.EXXT—X:E表示焊丝,第一位强度,第二位是位置,T是管状焊丝,最后是极性分类药芯焊丝焊气体包括:Co2或75%氩气+25%Co2,其它的混合气体也可适用。

五、焊接接头:对接、角接、T形、搭接、端接接头.六、圆整惯例:四舍五入;七、转换系数:面积尺寸:mm2=6。

452*102in2; in2=1。

550*10—3mm2电流密度:A/mm2=1。

550810—3A/in2; A/in2=6。

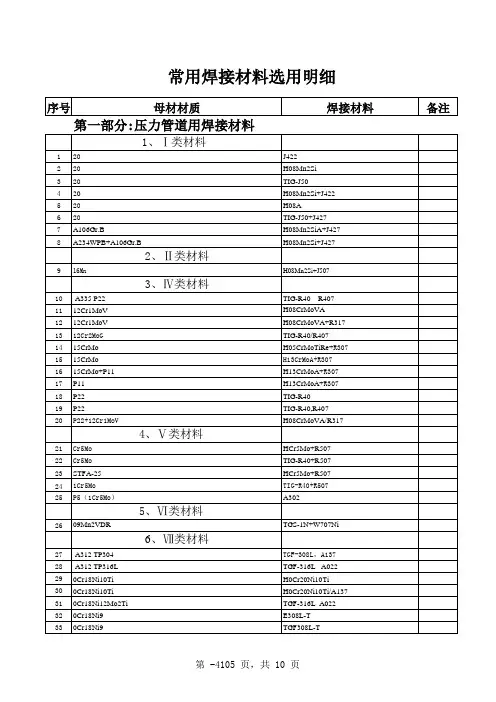

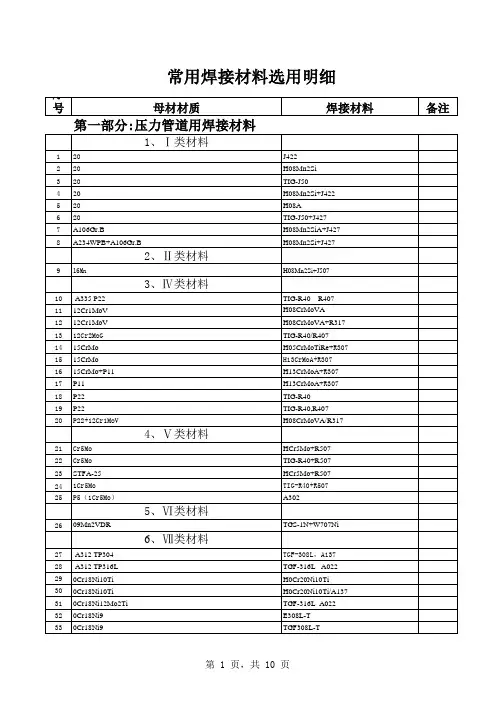

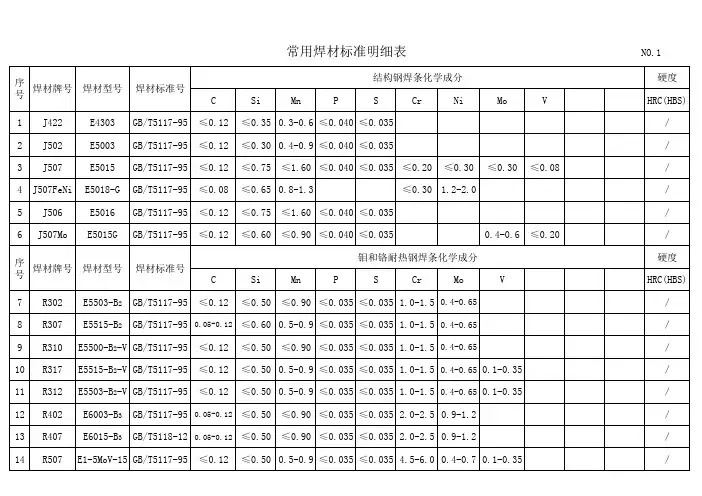

常用焊接材料选用明细序号母材材质焊接材料第一部分:压力管道用焊接材料1、Ⅰ类材料120J422220H08Mn2Si320TIG-J50420H08Mn2Si+J422 520H08A620TIG-J50+J4277A106Gr.B H08Mn2SiA+J4278A234WPB+A106Gr.B H08Mn2Si+J4272、Ⅱ类材料916Mn H08Mn2Si+J5073、Ⅳ类材料10A335 P22TIG-R40 R407 1112Cr1MoV H08CrMoVA 1212Cr1MoV H08CrMoVA+R317 1312Cr2MoG TIG-R40/R407 1415CrMo H05CrMoTiRe+R307 1515CrMo H13CrMoA+R307 1615CrMo+P11H13CrMoA+R30717P11H13CrMoA+R30718P22TIG-R4019P22TIG-R40,R40720P22+12Cr1MoV H08CrMoVA/R3174、Ⅴ类材料21Cr5Mo HCr5Mo+R50722Cr5Mo TIG-R40+R50723STFA-25HCr5Mo+R507241Cr5Mo TIG-R40+R50725P5(1Cr5Mo)A3025、Ⅵ类材料2609Mn2VDR TGS-1N+W707Ni6、VII类材料27A312 TP304TGF-308L,A137 28A312 TP316L TGF-316L A022 290Cr18Ni10Ti H0Cr20Ni10Ti 300Cr18Ni10Ti H0Cr20Ni10Ti/A137 310Cr18Ni12Mo2Ti TGF-316L A022 320Cr18Ni9E308L-T330Cr18Ni9TGF308L-T341Cr18Ni9Ti A13235316L H00Cr19Ni12Mo2/A022 36TP304H1Cr19Ni9Ti/A132 37TP316H0Cr19Ni12Mo2/A202 38TP321H0Cr20Ni10Ti/A13739TP321TGF347+A13740TP347H0Cr20Ni10Nb/A137 41TP347H0Cr20Ni10Nb/A1377、VIII类材料420Cr13H0Cr20Ni10Ti、A1328、复合钢管43304/20H1Cr24Ni13/A3029、异类材料4409Mn2DR+TP304H1Cr24Ni13/A307 451Cr5Mo+316L H1Cr24Ni13+A302 461Cr5Mo+T9H1Cr9Mo/R707 4720+00Cr17Ni14Mo2H1Cr24Ni13,A302 4820+1Cr5Mo H08Mn2SiA+J427 49304L+316Ti TGF316L+A02250A106 Gr.B+ 20MnMo H08Mn2SiA J427 51A106Gr.B+TP304H1Cr24Ni13/A407 52Cr5Mo+15CrMo13CrMoA/R30753Cr5Mo+1Cr18Ni9Ti H1Cr24Ni13/A302 54P1113CrMoA/R30755P11+2013CrMoA/J42756P11+TP304H1Cr24Ni13/A40710、特殊材料及其与异种钢570Cr25Ni20H0Cr25Ni20/A407 5815Mo3+ 15CrMo H08CrMoA、A107 5915Mo3+ 20TIG-J50、J427 6020Cr33NiNb ERNiCr-3 6120Cr33NiNb+Incoloy 800H ERNiCr-3 62800HT+TP347ENiCrCoMo-1 63904L904L64A333-6TGS-1N,W707Ni 65A335 P22+Incoloy 800H ERNiCr-3+Ni337 66A671 CC70TGS-1N,W707Ni 67B407 800H+Inconloy 800H ERNiCrCoMo-168B407 800HT +TP304ERNiCr-369B407 800HT+P11ERNiCrCoMo-170Incoloy 800H ERNiCr-371Incoloy 800H+P11ERNiCr-372P22+TP304H H1Cr24Ni13、A307 73SA333-6H08Mn2MoVA+W707Ni 74T9H1Cr9Mo/R70775TP1HSCCu20176UNS N04400Alloy60,Alloy190 77ZG4Cr35Ni45Nb+Inconloy 800H ERNiCrMo-378ZG4Cr35Ni45Nb+ZG4Cr25Ni35Nb ERNiCr-311、卷制管79L245ER50-6、J42780L245+20ER50-6、J42281X42H08Mn2Si+J42782X52TIG-J50+J50683X60E6010+E8010+E8018 84X65TIG-J50+J557第二部分:压力容器板材用焊接材料1、Ⅰ类材料115#J422、H08A+HJ431 220#+20g TIG-J50/J427 320#+20g J427420g J427520g TIG-J50/J427 620g H08A+HJ431720g TIG-J50/J427 820R J427920R TIG-J50/J427 1020R H08A+HJ431 1120R H10MnSi+HJ431 1220R H08Mn2SiA 1325#+Q235-B J42714Q235-A J42715Q235-A E4315/H08A+HJ431 16Q235-A H08A+HJ43117Q235-A TIG-J50/J42718Q235-B J42719Q235-B J42220SA516 Gr.60LB52NS2、Ⅱ类材料2115MnV J5072216Mn H10MnSi+HJ431 2316Mng TIG-J50/E5015 2416MnR J5072516MnR J5062616MnR TIG-J502716MnR J427/H10MnSi+HJ431 2816MnR H08A+HJ431 2916MnR H10MnSi+HJ431 3016MnR H10Mn2+HJ431 3116MnR H08Mn2SiA 3216MnR A062、A002 3316MnR EG-13416MnR TIG-J50,J507 3516MnR+15MnNbR J5573620MnMo J5073720MnMo TIG-J50/J50738Q345E E501539SPV36N J507B3、Ⅲ类材料40CF62E6015-G41610U2LB-62ULSPV490QSR MG-6042SPV490QSR LB-6243SPV490Q LB-6244SPV490Q DWS-60G45SPV490Q DS-49/MF-33H4、Ⅳ类材料4613CrMo44R3074714Cr1MoR R307B4814Cr1Mo锻H11CrMo45A+R307B 4914Cr1Mo锻+14Cr1MoR H11CrMo45A+R307B 5015CrMo H13CrMoA+HJ250G 5115CrMoR R3075215CrMoR H05CrMoTIRe/R307 5315CrMoR H13CrMoA+HJ250G 5415CrMoR A3075515CrMo锻E309MoLT1-1 5615CrMo锻E309LT1-1,E316LT1-1 5715CrMo锻ER309L5815CrMo锻H05CrMoTiRe、R307 5915CrMo锻R3076015CrMo锻+15CrMoR R3075、Ⅴ类材料611Cr5Mo R5076、Ⅵ类材料6216MnDR H05MnSiTiRe、J507RH 6316MnDR J507RH6407MnNiCrMoVDR+08MnNiCrMoVD J607RH6508MnNiCrMoVD TGS-3N、J607RH 6608MnNiCrMoVD J607RH7、Ⅶ类材料67316H00Cr19Ni12Mo2-HJ260 68316A022690Cr18Ni9A132700Cr18Ni9H0Cr21Ni10+A102 710Cr18Ni9H0Cr20Ni10-HJ260 720Cr18Ni9A102730Cr18Ni9Ti H0Cr20Ni10Ti+HJ260 741Cr18Ni9Ti A137751Cr18Ni9Ti H0Cr20Ni10Ti/A132 761Cr18Ni9Ti H0Cr20Ni10Ti/HJ260 771Cr18Ni9Ti HJ260-H0Cr20Ni10Ti 78304L H0Cr20Ni10Ti/A002 79304L A00280316L A02281316L H00Cr19Ni12Mo2/A022 82316L H0Cr20Ni14Mo3+HJ260 83AISI304H0Cr20Ni10Ti/A1328、复合材料840Cr13/15CrMoR R307、Ni337850Cr13/15CrMoR WEL GTAW82、Ni337860Cr13/20R J427、H08A-HJ431、A302、A102 870Cr13Al/16MnR J507、A062880Cr13Al/20R J427、A062890Cr18Ni9/20R J427、H08A-HJ431、A302、A102 902205/20R J427、E22.9.3N91304L/16MnR J507/A302/A00292304L/20R J427/A302/A00293316L/16MnR J507、A022、A042、H10MnSiA+HJ431 94316L/16MnR J507/A042/A02295316L/20R H08A+HJ431、A042、A022 96316L/20R J427、A022、A04297316L/20R J427、A022、A042、H08A+HJ431 98405/16MnR J507.A132.A30299405/20g J427.A132.A302、H08A+HJ431 100405/20R J427、A302、A132、H08A+HJ431 101405/20R J427、A062102405/20R+2205/20R J427、A062103SA405/20R J427、A062104SA405/20R J427、H08A-HJ431、A062105SUS321/15CrMo HJ250G+H13CrMoA、A062、A132 106SUS321/15CrMo HJ250G+H13CrMoA、A062、A132 107SUS321/15CrMo R307、A062、A1329、异类材料1080Cr13/15CrMoR+15CrMoR R307、Ni3371090Cr13/15CrMoR+1Cr5Mo WEL TIG82、Ni3371100Cr13/20R+0Cr18Ni9H0Cr20Ni10Ti,A302,A102 1110Cr13Al+0Cr18Ni9A0621120Cr18Ni9+20R A06211315CrMo+0Cr18Ni9H1Cr24Ni13、A30211415CrMo+16MnR A30211515CrMo+20g J42711616Mn/316L+316L A022、A04211716Mn/405+16Mn E5015、A30211816MnDR+00Cr17Ni14Mo2H1Cr24Ni13、A30211916MnDR+0Cr18Ni9H1Cr24Ni13、A30212016MnDR+16MnR H10Mn2+E5015-G12116MnR+0Cr13H1Cr24Ni13、A30212216MnR+12Cr2Mo TIG-J50+J50712316MnR+14Cr1MoR J05712416MnR+1Cr18Ni9Ti A30712516MnR+SA350 LF2TIG-J50+J50712620g+15CrMo A30212720g+1Cr18Ni9Ti A30712820R/316L+316L A042、A02212920R/405+0Cr13A132、A30213020R/405+20R E4315、A302、H08A+HJ431 13120R/405+奥18-8A132、A30213220R+15CrMoR H08A+HJ43113320R+1Cr18Ni9Ti H1Cr24Ni13/A307 13420R+304L/20R J427/A30213520R+SA405/20R J427、A062 136304L/16MnR+316L/16MnR J507/A042/A022 137304L/20R+316L/20R J427/A042/A022 138316L+16MnR A042139316L+Q235-B A042140CF62+16MnR E6015-G141Q235-A+15CrMoR J427142Q235B+SPV490Q LB62143SA105+16MnR J507144SB409+20R A50710、特殊材料及其与异种钢14509CrCuSb J42714609CrCuSb+0Cr18Ni9A30214709CrCuSb+16MnR ND14809CrCuSb+Q235A ND1490Cr25Ni20A4021500Cr25Ni20+0Cr18Ni9A3021510Cr25Ni20+16MnR A3021525A02S331153SA516 Gr.70J507RH154SA516-70N E601,E7018155SA671 CC70ER80S-G,E7016-1156TA2TA2157UNS N08810Ni135158UNS N08810Ni327159UNS N08810+0Cr18Ni9Ni135160UNS N08810+20R Ni135161UNS N08810+20R Ni327162UNS N08811Ni337163UNS N08811(SB564+SB409)Ni337164UNS N08811+15CrMoR Ni33711、换热器用16508Cr2AlMo(φ25×2.5)与20R(δH08Cr2AlMo16609CrCuSb(φ38×3)与16MnR(δH09CrCuSb1670Cr18Ni9(φ19×2)与0Cr18Ni9(δ=20)H0Cr24Ni10Ti16815CrMo(φ19×2)与15CrMoR(δH05CrMoTiRe 16915CrMoR+15CrMo TIG-R30 17016Mn(φ14×2)与16MnR(δ=20)ER50-6 17120(φ25×2.5)与16Mn(δ=24)H08Mn2SiA 17220(φ38×3.5)与16Mn(δ=22)ER50-6 17320(φ38×4)与20g(δ=16)J427 17420(φ57×3.5)与16Mn(δ=20)H08Mn2SiA12、球罐17507MnCrMoVDR J607RH 17615MnNbR J55717715MnNbR J507RH 17816MnR J50717916MnR E712C 18016MnR J507R 18116MnR TIG-J50,J507R 18216MnR E71T-1 18320g J42718420MnMo J557RH 18520MnMo+15MnNbR J557RH 186610U2LB62-UL187A537CL1E7018-G188CF-62J607RH第三部分:压力容器用焊接材料(管材)1、Ⅰ类材料120J422220H08Mn2Si320TIG-J50420H08Mn2Si+J422 520H08A620TIG-J50+J4277A106Gr.B H08Mn2SiA+J427 8A234WPB+A106Gr.B H08Mn2Si+J4272、Ⅱ类材料916Mn H08Mn2Si+J5073、Ⅳ类材料10A335 P22TIG-R40 R407 1112Cr1MoV H08CrMoVA+R317 1212Cr1MoV H08CrMoVA 1312Cr2MoG TIG-R40/R407 1415CrMo H05CrMoTiRe+R307 1515CrMo H13CrMoA+R307 16P22TIG-R4017P22TIG-R40,R4074、Ⅴ类材料18Cr5Mo HCr5Mo+R50719Cr5Mo TIG-R40+R507 20STFA-25HCr5Mo+R507 211Cr5Mo TIG-R40+R507 22P5(1Cr5Mo)A3025、Ⅵ类材料2309Mn2VDR TGS-1N+W707Ni6、Ⅶ类材料24A312 TP304TGF-308L,A137 25A312 TP316L TGF-316L A022 260Cr18Ni10Ti H0Cr20Ni10Ti270Cr18Ni10Ti H0Cr20Ni10Ti/A137 280Cr18Ni12Mo2Ti TGF-316L A022 290Cr18Ni9E308L-T300Cr18Ni9TGF308L-T311Cr18Ni9Ti A13232316L H00Cr19Ni12Mo2/A022 33TP304H1Cr19Ni9Ti/A132 34TP316H0Cr19Ni12Mo2/A202 35TP321H0Cr20Ni10Ti/A137 36TP321TGF347+A13737TP347H0Cr20Ni10Nb/A137 38TP347H0Cr20Ni10Nb/A1377、Ⅷ类材料390Cr13H0Cr20Ni10Ti、A1328、复合钢管40304/20H1Cr24Ni13/A3029、异类材料4109Mn2DR+TP304H1Cr24Ni13/A307 421Cr5Mo+316L H1Cr24Ni13+A302 431Cr5Mo+T9H1Cr9Mo/R707 4420+1Cr5Mo H08Mn2SiA+J427 45304L+316Ti TGF316L+A02246A106 Gr.B+ 20MnMo H08Mn2SiA J427 47Cr5Mo+15CrMo13CrMoA/R30748Cr5Mo+1Cr18Ni9Ti H1Cr24Ni13/A30210、特殊材料及其与异种钢490Cr25Ni20H0Cr25Ni20/A407 5020Cr33NiNb ERNiCr-35120Cr33NiNb+Incoloy 800H ERNiCr-3 52904L904L53A333-6TGS-1N,W707Ni 54A671 CC70TGS-1N,W707Ni 55SA333-6H08Mn2MoVA+W707Ni 56T9H1Cr9Mo/R70757A335 P22+Incoloy 800H ERNiCr-3+Ni337 58P22+12Cr1MoV H08CrMoVA/R31711、卷制管59L245ER50-6、J42760L245+20ER50-6、J42761L245+20ER50-6、J42262X65TIG-J50+J557第四部分:锅炉焊接1、Ⅰ类材料120#管(φ57×3.5)钨极氩弧焊H08Mn2Si220#管(φ108×4.5)钨极氩弧焊/焊条电弧焊H08Mn2Si+J422320#管(φ273×18)钨极氩弧焊/焊条电弧焊H08Mn2Si+J4224Q235B板(δ=12)焊条电弧焊J4275Q235A板(δ=18)焊条电弧焊J4272、Ⅱ类材料616MnR板(δ=12)焊条电弧焊J507716MnR板(δ=14)埋弧焊HJ431/H10MnSi816Mn管(φ60×9)与16MnR板(δ=12)焊条电弧焊J507916MnR管(φ90×16)与16MnR板(δ=24)焊条电弧焊J5073、Ⅲ类材料1015CrMo板(δ=14)焊条电弧焊R307 1112Cr1MoV管(φ42×4)钨极氩弧焊H08CrMoVA1212Cr1MoV管(φ42×4)钨极氩弧焊/焊条电弧焊H08CrMoVA/R3171312Cr1MoV管(φ133×12)钨极氩弧焊/焊条电弧焊H08CrMoVA/R3174、电力标准1420G+15CrMoG TIG-J50/J4271512Cr2MoVWTIB TIG-R34/R317双相不锈钢的焊接1.双相不锈钢可焊性良好,热裂倾向小,一般焊前不需预热,焊后不需热处理,可与18-8型奥氏体不锈钢或碳钢等异种钢焊接。

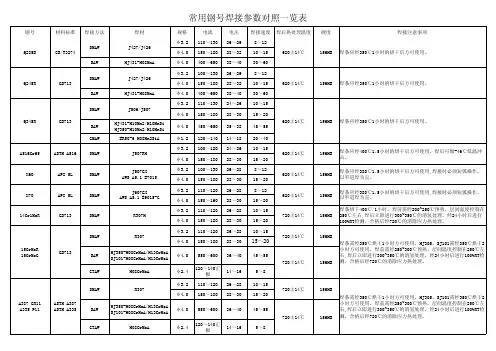

常用钢号焊接参数对照一览表钢号材料标准焊接方法焊材规格电流电压焊接速度焊后热处理温度硬度焊接注意事项Q235B GB/T3274SMAW J427/J426φ3.2110~13026~298~12620±14℃156HB焊条应经350℃1小时的烘干后方可使用。

φ4.0150~18028~3210~15SAW HJ431-H08MnAφ4.0400~65038~4030~60Q245R GB713SMAW J427/J426φ3.2100~13026~298~12620±14℃156HB焊条应经350℃1小时的烘干后方可使用。

φ4.0150~18028~3210~15SAW HJ431-H08MnAφ4.0400~65038~4030~60Q345R GB713SMAW J506/J507φ3.2110~13024~2610~15620±14℃156HB焊条应经350℃1小时的烘干后方可使用。

φ4.0150~18028~3015~20SAWHJ431-H10Mn2/H10MnSiHJ350-H10Mn2/H10MnSiφ4.0450~65035~3845~55GMAW ER50-6 H08Mn2SiAφ1.2120~14014~1820~40A516Gr65ASTM A516SMAW J507RH φ3.2100~12024~2610~15620±14℃156HB焊条应经400℃1.5小时的烘干后方可使用,焊后可做-46℃低温冲击。

φ4.0150~18028~3015~20X60API 5L SMAWJ507GXAWS A5.1 E7015φ3.2100~13026~288~12620±14℃156HB焊条应经380℃1.5小时的烘干后方可使用,焊接时必须短弧操作,以窄道焊为宜。

φ4.0150~18028~3015~20X70API 5L SMAWJ607GXAWS A5.1 E9015-Gφ3.2110~12026~288~12620±14℃156HB焊条应经380℃1.5小时的烘干后方可使用,焊接时必须短弧操作,以窄道焊为宜。

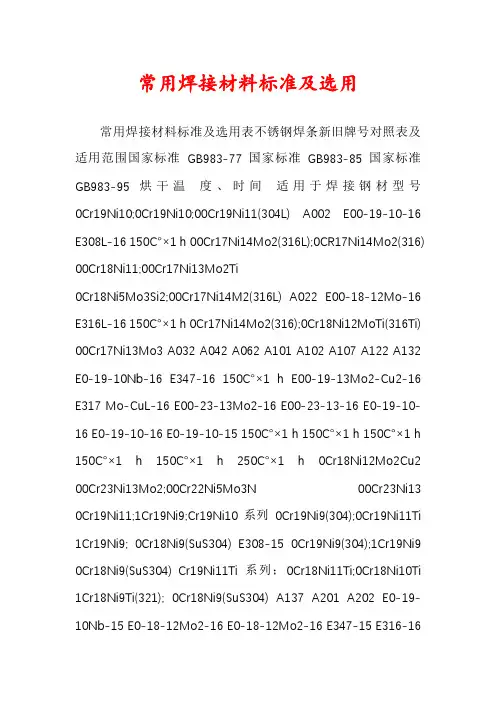

常用焊接材料标准及选用常用焊接材料标准及选用表不锈钢焊条新旧牌号对照表及适用范围国家标准GB983-77 国家标准GB983-85 国家标准GB983-95 烘干温度、时间适用于焊接钢材型号0Cr19Ni10;0Cr19Ni10;00Cr19Ni11(304L) A002 E00-19-10-16 E308L-16 150℃×1 h 00Cr17Ni14Mo2(316L);0CR17Ni14Mo2(316) 00Cr18Ni11;00Cr17Ni13Mo2Ti0Cr18Ni5Mo3Si2;00Cr17Ni14M2(316L) A022 E00-18-12Mo-16 E316L-16 150℃×1 h 0Cr17Ni14Mo2(316);0Cr18Ni12MoTi(316Ti) 00Cr17Ni13Mo3 A032 A042 A062 A101 A102 A107 A122 A132 E0-19-10Nb-16 E347-16 150℃×1 h E00-19-13Mo2-Cu2-16 E317 Mo-CuL-16 E00-23-13Mo2-16 E00-23-13-16 E0-19-10-16 E0-19-10-16 E0-19-10-15 150℃×1 h 150℃×1 h 150℃×1 h 150℃×1 h 150℃×1 h 250℃×1 h 0Cr18Ni12Mo2Cu2 00Cr23Ni13Mo2;00Cr22Ni5Mo3N 00Cr23Ni13 0Cr19Ni11;1Cr19Ni9;Cr19Ni10系列0Cr19Ni9(304);0Cr19Ni11Ti 1Cr19Ni9; 0Cr18Ni9(SuS304) E308-15 0Cr19Ni9(304);1Cr19Ni9 0Cr18Ni9(SuS304) Cr19Ni11Ti系列;0Cr18Ni11Ti;0Cr18Ni10Ti 1Cr18Ni9Ti(321); 0Cr18Ni9(SuS304) A137 A201 A202 E0-19-10Nb-15 E0-18-12Mo2-16 E0-18-12Mo2-16 E347-15 E316-16E316-16 250℃×1 h 0Cr18Ni11Ti;0Cr18Ni11Nb ;0Cr18Ni10Ti; 1Cr18Ni9Ti(321) 250℃×1 h 0Cr18Ni12Mo2(SuS316) (禁反复烘) 150℃×1 h 0Cr17Ni12Mo2(316);00Cr17Ni13Mo2Ti 0Cr18Ni12Mo2(SuS316) A207 A212 A242 A232 A302 A307 A312 A402 A407 A412 A422 说明:15、25―碱性,直流反接;E1-23-13-16 E1-23-13-15 E1-23-13Mo2-16 E2-26-21-16 E2-26-21-15 E1-21-21Mo2-16 E0-19-13Mo3-16 E0-18-12Mo2-15 E316-15 E318-16 E317-16 E318V-16 E309-16 E309-15 E309 Mo -16 E310 -16 E310 -15 E310Mo -16 150℃×1 h 250℃×1 h 150℃×1 h 150℃×1 h 250℃×1 h 150℃×1 h 150℃×1 h 250℃×1 h 0Cr17Ni12Mo2(316);0Cr18Ni12Mo2;Cr1300Cr17Ni13Mo2Ti;Cr17系列00Cr17Ni13Mo2Ti;0Cr18Ni12MoTi(316Ti) Cr19Ni13Mo3系列0Cr17Ni13Mo2Ti;0Cr18Ni9Ti;1Cr18Ni9Ti Cr23Ni13系列; 0Cr18Ni5Mo3Si2 Cr23Ni13系列Cr23Ni13Mo2系列; 0Cr18Ni5Mo3Si2 Cr25Ni20系列Cr25Ni20系列Cr26Ni21Mo2系列Cr25Ni20Si2系列16、17、26―钛钙型,交流或直流反接。

表1 常用钢号推荐选用的焊接材料1 常用钢号推荐选用的焊接材料1 常用钢号推荐选用的焊接材料1 常用钢号推荐选用的焊接材料1 常用钢号推荐选用的焊接材料完JB/T4709—2000表2 常用钢号分类分组5.2坡口制备5.2.1碳素钢和标准抗拉强度下限值不大于540MPa的强度型低合金钢可采用冷加工方法,也可采用热加工方法制备坡口;5.2.2耐热型低合金钢和高合金钢、标准抗拉强度下限值大于540MPa的强度型低合金钢,宜采用冷加工方法;若采用热加工方法,对影响焊接质量的表面层,应用冷加工方法去除;5.3焊接坡口应保持平整,不得有裂纹、分层、夹杂等缺陷,形式和尺寸应符合相应规定;5.4坡口表面及两侧以离坡口边缘的距离计焊条电弧焊各10mm,埋弧焊、气体保护焊各20mm,电渣焊各40mm应将水、铁锈、油污、积渣和其它有害杂质清理干净;5.5为防止沾附焊接飞溅,奥氏体高合金钢坡口两侧各100mm范围内应刷涂料;5.6焊条、焊剂按规定烘干、保温,常用焊材烘干温度及保持时间见表4;焊丝需去除油、锈;保护气体应保持干燥;5.7预热5.7.1根据母材的化学成份、焊接性能、厚度、焊接接头的拘束程度、焊接方法和焊接环境等综合考虑是否预热,必要时通过试验确定;常用钢号推荐的预热温度见表5;5.7.2不同钢号相焊时,预热温度按预热温度要求较高的钢号选取;5.7.3采取局部预热时,应防止局部应力过大;预热的范围为焊缝两侧各不小于焊件厚度的3倍,且不小于100mm;表3 不同钢号相焊推荐选用焊接材料表不同钢号相焊推荐选用焊接材料表—表3 不同钢号相焊推荐选用焊接材料表表3不同钢号相焊推荐选用焊接材料表不同钢号相焊推荐选用焊接材料表完JB/T4709—2000表4 常用焊材烘干温度及保持时间JB/T4709—2000表5 常用钢号推荐的预热温度5.7.4需要预热的焊件在整个焊接过程中应不低于预热温度;5.7.5当用热加工法下料、开坡口、清根、开槽或施焊临时焊缝时,亦需考虑预热要求;5.8焊接设备及辅助装备等应处于正常工作状态,安全可靠,仪表应定期校验;5.9组对定位5.9.1组对时,坡口间隙、错边量、棱角度等应符合规定;5.9.2尽量避免强力组装,定位焊缝间距要符合规定;5.9.3焊接接头拘束度大时,推荐采用抗裂性能更好的焊条施焊;5.9.4定位焊缝不得有裂纹,否则应清除重焊;如存在气孔、夹渣时亦应去除;5.9.5熔入永久焊缝内的定位焊缝两端应便于接弧,否则应予修整;6焊接焊前应按接头编制焊接工艺规程推荐表格见附录B,焊工应按图样、工艺文件、技术标准施焊;。

常用焊接材料选用表一、一般情况下的焊材选用注:(1)焊接二、三类容器承压焊缝时,必须选用结427焊条。

(2)对于16MnR、15MnVR钢,在下列情况之一者,必须选用J507焊条:a)产品工作压力:Pg≥16Kg/cm2的容器承压焊缝;b)产品工作温度:T≤-20℃的容器承压焊缝;c)盛装液化石油气等易燃介质容器的承压焊缝;d)筒体板厚δ≥20mm,且整个焊缝厚度全部由手工焊完成的承压焊缝,包括接管外补强圈的外角缝。

(对于板厚δ≥20mm的筒体环缝自动焊手工焊打底焊缝除外);e)焊接操作环境温度低于0℃时,除上述情况外,均可选用J502焊条施焊(包括δ≥20mm的自动焊手工打底焊缝)。

(3)对于16MnR、15MnVR钢的自动焊丝选用如下:当需要预热焊接时(即16MnR δ>30mm,15MnVR δ>28mm)均需选用高档的焊材。

16MnR应选用H10MnSi;15MnVR 应选用H108MnMoA,否则选用低档焊丝。

(4)18MnMoNbR自动焊时,本选用250焊剂,但鉴于目前国内不生产该种焊剂,故采用250G焊剂代用。

(5)与之相对应的美国牌号为:ASTM A387-72a标准中:A387BASTM A387-74a标准中:A387Gr12(6)与之相对应的美国牌号为:ASTM A387-72a标准中:A387DASTM A387-74a标准中:A387Gr22(7)a) 按化学成分对照,SUS403相当于我国钢号1Cr13;SUS405相当于我国钢号0Cr13,但鉴于我厂订货要求SUS403板含碳量均≤0.08%,故相当于0Cr13。

b) 表中所列的奥302焊条只限于复合板的复层材质为SUS403、SUS405或板厚δ≤6mm的单层钢板焊接时所用。

其它情况下应另行考虑焊材。

二、复合钢板焊接情况下的焊材选用三、异种钢板焊接情况下的焊材选用四、当封头或筒体需要经过正火处理或相当于正火温度下加热(热冲压成型)时,若封头拼板缝或筒体纵缝是用埋弧自动焊接时为保证焊缝强度不低于母材,其自动焊丝不能按表1选取,而应按表4选用。

附录A常用焊材推荐表A.0.1本附录给出常用钢材焊接材料选用推荐表。

对Q345级别以上钢材,厚板时宜考虑板厚效应使钢板强度标准值的降低,匹配低一级焊材仍能满足焊缝金属强度高于母材,同时可获得更好的综合性能。

A.0.2常用结构钢材焊条电弧焊焊接材料宜按表A.0.2选用。

表A.0.2常用结构钢材焊条电弧焊焊接材料推荐表钢材牌号焊条电弧焊焊条焊条型号焊缝金属性能最低要求屈服强度R eL抗拉强度R m伸长率A冲击功KV2(MPa)(MPa)(%)(J)T(℃)Q235 Q235GJ E4303①33043020270 E4319、E4328-20 E4315、E4316-30Q345 Q345GJ E5015E5016E50184004902027-30 E50XX-G②②②Q390 Q390GJ E5015、E5016E50183904902227-30E5515-3M3E5516-3M34605501727-50 E55XX-G②②②Q420 Q420GJ E5515-3M3E5516-3M34605501727-50 E55XX-G②②②Q460 Q460GJ E5515-3M3E5516-3M3E571653062015--E57XX-G②E62XX-G②②②注:①用于一般钢结构及板厚小于25mm的钢结构焊接;②按双方协议进行采购,以确保焊缝金属冲击功满足要求。

A.0.3常用结构钢材实心焊丝C02气体保护焊焊丝宜按表A.0.3选用。

表A.0.3常用结构钢材实心焊丝C02③气体保护焊焊丝的推荐表钢材牌号CO2气体保护焊焊丝焊丝型号焊缝金属性能最低要求屈服强度R eL抗拉强度R m伸长率A冲击功KV2(MPa)(MPa)(%)(J)T(℃)Q235 Q235GJ ER49-1①3724902047④常温ER50-34205002227-20 ER50-2、-6、-7-30 ER50-G②②Q345 Q345GJ ER49-1①、3724902047④常温ER50-34205002227-20 ER50-2、-6、-7-30 ER50-G②②Q390 Q390GJ ER49-1①、3724902047④常温ER50-34205002227-20 ER50-2、-6、-7-30 ER50-G②②Q420 Q420GJ ER55-D2、ER55-D2-Ti4705501727-30 ER55-G②②②Q460 Q460GJ ER55-D2ER55-D2-Ti4705501727-29ER55-G②②②ER62-G②注:①用于一般钢结构及板厚小于25mm的钢结构焊接;②按双方协议进行采购,以确保焊缝金属性能满足设计或母材要求。