精品分享:《SAP供应链管理》(共68页)

- 格式:pptx

- 大小:1.37 MB

- 文档页数:68

sap供应链解决方案篇一:SAP 化工行业解决方案SAP 化工行业解决方案:使您灵活适应不断变化的业务情况全球化、法规、合并和收购、复杂的供应链、上市时间压力,这些挑战在化工行业中经常存在。

这就是你需要 SAP 化工行业解决方案的原因。

这一整套解决方案能使你拥有信息、可靠性和特定于行业的功能性。

这样,您的企业就可以不断创新、适应市场变化,并获得成功。

SAP 化工行业解决方案提供销售和运营规划、质量管理、配方和批次管理,以及供应链操作功能。

还有详细的客户、产品或部门的利润报表。

以及用于帮助您合并过程控制系统和监控生产执行的集成网络中心。

通过 SAP ERP 化工行业套装解决方案,大型和小型化工企业都可以根据行业最佳业务实践,快速、经济地部署一整套标准化的业务流程。

SAP 化工行业解决方案:商业价值SAP 化工行业解决方案是一套完整的综合性解决方案,为您提供丰富的信息、增强的可靠性和特定行业的功能。

通过 SAP 化工行业解决方案,无论是日用化工制造商还是特种化工制造商都能够从中获得如下的商业价值:实时、可见的结果 -- 在所有的业务流程上运行集成的 SAP 化工行业解决方案意味着,您企业中的所有员工都能实时地看到相同的信息。

您可以消除信息孤岛,避免依赖于专门的子系统,从而可以更迅速地响应市场变化。

深入洞察生产过程 -- 采用先进的分析方法来提高生产过程的可见性,帮助您精确识别生产成本的起源,从而使您了解计划变动所产生的结果。

降低风险 -- 有关项目、生产过程、运营绩效和市场的实时信息能对各种变化提供预警,使您有充足的时间根据需求变化、客户需求和经济状况作出调整。

简化的集成 -- SAP 化工行业解决方案提供独立的综合性软件基础,因此您无需维护异构软件系统及各种单点解决方案之间的昂贵接口。

扩大影响范围 -- 通过 SAP 化工行业解决方案,您可以加入电子市场,以及通过企业门户来推动员工、合作伙伴和客户之间的全球化协作。

SAP 供应链管理您需要一个完整、高效的解决方案来链接和增强您的业务您面临巨大的压力:要降低成本、增进创新、改善客户服务和提高应对能力。

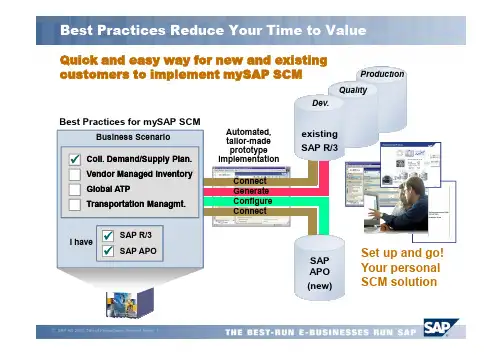

SAP供应链管理(SAP SCM) 能够实现了整个供应链网络的合作、规划、执行与协调。

今天,供应链(Supply Chain)已成为企业间竞争的关键领域,同时也意味着企业将面临一系列的挑战。

这些促使了他们必须不断加快前进的步伐,推出个性化和可配置的产品,确信的承诺、按时的交货、迅速响应客户不断变化着的需求、爱好及外界的经济环境。

为了取得成功,您必须尽快解决以下关于供应链方面的问题:我们如何在无需拥有大量库存的情况下,对需求作出快速反应?我们如何与供应商进行协同化工作,以便随时快速地更改运作计划?我们如何在保持服务水平的同时,将现有的库存、固定资产、运输工具减至最低水平?我们如何将新产品更快地推向市场?如果产品畅销,我们如何才能加快进度来满足更高要求?我们如何在供应链处于满负荷的状态下,转向基于因特网的电子销售并面对最终客户?我们如何运用强大的供应链功能来为客户提供更丰富的选择空间、更快速可靠的生产与交付,从而使我们从众多竞争者中脱颖而出?我们如何在供应商不能供货的情况之下,满足来自各方的需求?若要回答和解决上述问题,您就必需超越传统供应链。

合作伙伴间原有的直线型信息处理方式已不能适合新新经济的发展。

这种信息处理方式太慢,太不精确且成本太高,使您的企业容易被其他拥有协同供应链的竞争对手所蚕食。

由此可见,您需要创建协同化的环境,即建立供应链网络。

在此供应链网络中,供应商、制造商、分销商和客户可动态地共享信息,紧密协作,向着共同目标发展。

创建协同化的供应链网络为了帮助您的公司创建协同化的供应链网络,SAP提供了一个功能强大、全面集成的SAP 供应链管理(SAP SCM)解决方案。

其所具备的完善功能可协助您管理整个供应链网络:从供应链规划到物料询价、从需求计划到产品配送。

About the T utorialSAP Supply Chain Management is one of the key modules in SAP ERP and controls Production Planning, business forecasting and demand planning. It helps the organization to manage their supply chain process in a dynamic environment. SAP SCM is a complete software to cover key processes such as supply chain networking, supply chain planning and coordination, and supply chain execution.AudienceThis tutorial is meant for Project leaders, project team members, SAP consultants, sales consultant, and those related to the departments of planning and material management. PrerequisitesBefore you start proceeding with this tutorial, we are assuming you have familiarity, prior experience, and knowledge of the domain of supply chain management. However, it is sufficient if you are aware of the basics of computer applications and SAP tools. Copyright & DisclaimerCopyright 2018 by Tutorials Point (I) Pvt. Ltd.All the content and graphics published in this e-book are the property of Tutorials Point (I) Pvt. Ltd. The user of this e-book is prohibited to reuse, retain, copy, distribute, or republish any contents or a part of contents of this e-book in any manner without written consent of the publisher.We strive to update the contents of our website and tutorials as timely and as precisely as possible, however, the contents may contain inaccuracies or errors. Tutorials Point (I) Pvt. Ltd. provides no guarantee regarding the accuracy, timeliness or completeness of our website or its contents including this tutorial. If you discover any errors on our website or inthistutorial,******************************************T able of ContentsAbout the Tutorial (i)Audience (i)Prerequisites (i)Copyright & Disclaimer (i)Table of Contents (ii)1.SAP SCM – Overview (1)2.SAP SCM – Components (2)3.SAP SCM – Benefits (4)4.SAP SCM – Demand Management (5)Planning Strategies (5)5.SAP SCM – Creating PIR (7)Change and Delete PIR (8)6.SAP SCM – Material Requirement Planning (10)MRP Parameters (10)Running MRP for all Products (11)MRP Evaluation – Stock / Requirement List (15)SAP PP – MRP List (16)7.SAP SCM – Planned Order Creation (17)8.SAP SCM – Production Order Creation (22)9.SAP SCM – Goods Issue (25)Goods Issue Reversal (26)10.SAP SCM – Production Order Confirmation (28)11.SAP SCM – Production Order Cancellation (30)12.SAP SCM – Integration (31)13.SAP SCM – Integration Models (32)Activation and Deactivation of Integration Model (34)14.SAP SCM – Master Data (37)Bills of Material (BOM) (37)Material Master (38)Work Center (39)Routing (40)15.SAP SCM – Resources (42)Resource Types (42)Create and Change Resources (43)16.SAP SCM – Production Data Structures (44)Production Data Structure in SAP APO (45)Production Data Structure in ERP (46)17.SAP SCM – Transfer Changed Master Data (49)18.SAP SCM – Transfer Changed BOMs (51)19.SAP SCM – Model and Versions (53)Creating Model (54)Delete Model/Planning Version (57)20.SAP SCM – Applications (60)21.SAP SCM – Advanced Planning and Optimization APO (61)Supply Chain Monitoring (61)22.SAP SCM – Extended Warehouse (63)Communication Method (63)SAP EWM – Menu Structure (64)23.SAP SCM – Transportation Management (67)Custom Settings in APO (69)24.SAP SCM – Supply Network Collaboration (71)25.SAP SCM – Forecasting & Replenishment (73)SAP F&R Administration (73)26.SAP SCM – Consultant Responsibilities (75)1.SAP SCMSAP Supply Chain Management is one of the key modules in SAP ERP and controls Production Planning, business forecasting and demand planning.The key features of SAP SCM are-∙It helps the organization to manage their supply chain process in a dynamic environment.∙SAP SCM process helps suppliers, customers, manufacturers, business partners and retailers connect with each other to manage supply chain process effectively and efficiently.∙It helps organizations to accelerate and optimize end-to-end procure-to-pay process.∙SCM products from SAP allows an organization to integrate their processes and enforce contract compliance for supply-side and supplier-side requirements throughout using supply chain processes in distributed environment.∙SAP SCM is a complete software to cover the key processes- Supply Chain networking, supply chain planning and coordination, and supply chain execution.∙It includes different planning applications related to Advanced Planning and Optimization APO, and for the integration with other SAP execution applications.∙The primary applications are SAP General Areas, SAP Supply Network Collaboration SNC, SAP Extended Warehouse Management EWM, Advanced Planning and Optimization (APO), Forecasting and Replenishment FRE and SAP Transportation Management TM.In the image shown below, you can see SAP Supply Chain Management and its integration with other R/3 modules to manage supply chain process.2.SAP SCMSAP Supply Chain Management allows organizations to perform effective planning and execution of logistics within supply network and to perform workflow management.You can see the key steps in managing Supply network in an organization. Each step consists of defined set of activities and hence helping customers, suppliers, and retailers connect with each other to provide an effective supply-chain-management solution.SAP SCM consists of the following components-∙SC Collaboration: This is used to help in making collaborative forecasts and agreements.∙SC Planning: This is used to generate the operational plans as per current and relevant data in the system.∙SC coordination: This component in Supply Chain is used to coordinate the exchange of data and information between different business units.∙SC Execution: This is used to ensure that you execute the supply chain plans in the best possible manner to get the desired result.As per functionality, you can divide SCM/APO into three parts-∙Forecasting: To perform demand planning and forecasting, you can link to Customer Relationship Management CRM to get data related to customer campaigns, etc.∙Supply Network Planning (SNP): To view organization as a network of locations and to check stock projections and stock keeping criteria. Calculations in SNP drive dependent requirements down to supplying locations production and receiving stores.∙Production Planning and Detailed Scheduling: This is to check the dependent requirements from locations within the supply network, passed down from SNP.SAP SCM This is linked with Material Requirement Planning (MRP) in Production Planning, which determines the inbound material required to complete a production order.3.SAP SCMUsing Supply Chain Management in SAP, an organization can achieve the following benefits in a distributed environment-∙Reduce accounts receivable collections with better visibility into the AR process, aging, and extension of credit and consequently, help to reduce the day’s sales outstanding.∙Effectively manage forecasting and handling sudden changes in demand and supply process.∙Effectively use Net Fixed assets NFA like plants and equipment.∙To meet customer demands, you can smartly plan and manage Supply Chain Management process in an organization.∙Proper inventory optimization, order fulfillment, and shipping of the goods.∙Distribution of the key information to all the stakeholders spread across the network.∙Improve communication and collaboration between different business lines to manage demand and supply process in an organization.∙Improve production efficiency and reduction in production quality issues and hence reduce cost of goods sold.∙To reduce transportation duties and taxes, and increase rebates and incentives. It also helps to reduce transportation errors.4.SAP SCMDemand management is used to forecast, manage, and plan the demands of goods and has defined set of processes and capabilities to produce goods.The key features of Demand Management are-∙This component is used to improve the demand planning by utilizing promotions.∙Based on historical sales data, you can handle demand for every store, product from different customers and hence you can see customer responses as per change in pricing policies, and profit for a particular product in the organization.∙You use demand models to predict consumers’ reaction with price change. As per organization goals like- increase profit, revenue, etc. you can define selling strategies for the products.In SAP PP system, demand management is performed by Planned Independent requirement PIR. Planned Independent Requirement provides input for production planning. A PIR contains one planned quantity of product and one date for material or a Planned quantity is split over a span of time period.To set your PIR version active use value 00 to specify requirement would be considered in material requirement planning. To maintain number of versions of planned independent requirement, you can set some numbers to active and others to inactive.PIRs define the planning strategy in material master, which determines planning methods- make to order and make to stock.In Make-to-Stock environment, PIRs are used where stock is built based on the forecast and not on sales order.Planning StrategiesPlanning strategies are divided into two categories-Make to Stock Planning strategy (MTS)This is planning strategy where stock is produced without sales order. It is used to meet the customer demands in future.When you use Planning strategy 10, only PIR quantity is considered for MRP run and sales order are completely ignored. In this PIR requirement type LSF is reduced when you deliver stock to customer.When you use Planning strategy 40, for MRP run maximum of 2 PIR and Sales order can be considered and PIR is reduced when enter the Sales order. PIR requirement type is VSF in this case.SAP SCMMake to Order Planning strategy (MTO)In this planning strategy, finished products are not produced until you receive sales order from a customer. For MRP run, you only consider Sales order.In MTO strategy, you only produce sales order stock and products are delivered as per sales orders from specific customer.You use Planning strategy 20 for make to order MTO process and planning strategy 25 is used to produce product variants when there is request for variant products from customer.5.SAP SCMIn this chapter, we will learn how to create, change, or delete PIRs.To create PIR, follow the given steps-Step 1: Use T-code MD61 or go to Logistics -> Production -> Production Planning-> Demand Management -> Planned Independent Requirements -> CreateStep 2: In the next window, enter the following details-∙Enter the single material for which demand needs to be created.∙Enter MRP area and Plant Code.∙Enter version as 00, which shows the active version and requirements would be considered in MRP run.∙Enter the Planning horizon dates for which demand needs to be created.∙Enter planning period as month M and click the tick mark given above.Step 3: Enter Version 00. By default, active check box is flagged. It shows it is an active requirement and would be considered in the MRP run. Enter the requirement quantity in monthly buckets.Click the save icon to save the PIR.Change and Delete PIRTo delete a PIR, select the row in above screen and click the Delete button.Step 1: To change PIR, use T-code: MD62 or go to Logistics -> Production -> Production Planning -> Demand Management -> Planned Independent Requirements -> ChangeStep 2: Enter the following details-∙Enter parent material for which PIR needs to be changed.∙Enter Plant Code.∙Enter version as 00.∙Input the planning horizon dates with planning period as month M.In the next window make changes to the requirement quantity and click the Save button to enter the changes.End of ebook previewIf you liked what you saw…Buy it from our store @ https://。

SAPAPO供应链管理方案(精选五篇)第一篇:SAP APO 供应链管理方案SAP APO 供应链管理方案的一些概念SAP高级计划和优化器(SAP APO),包含了许多集成在一起的模块,这些模块使用了基于限制的规划和优化哲学。

SAP APO协同性计划,正如其名字所说的,就是要帮助企业与他们的业务合作伙伴一同进行协同性供应链规划。

供应链驾驶舱向用户提供查看所有的活动和应用程序的强大功能。

供应链驾驶舱可以用特别设计的用户图形界面对供应链进行建模、监控和管理,向用户提供对查看所有的活动和应用程序的强大功能。

通过设置,SAP APO 供应链驾驶舱能方便地描绘您的生产工厂、配送中心、供应商和客户,以及他们之间的运输链接。

您可以通过网络模型为您自己导航,从不同的角度观察它,并深挖至更详细的层次。

运用供应链警报器,您可以根据当前情况检查预测、规划及日程表的精确性和恰当性。

它还将自动地引起您对异常情况、瓶颈及不寻常事件的注意。

您可以自动切换到规划和执行应用程序以解决所有问题。

需求计划关注的是未来中长期的市场的需求水平。

激烈的竞争,顾客需求的不断变化,市场的快速发展,都使得需求计划越来越困难,也越来越重要。

需求计划将销售的历史数据、客户的数据、及供应链合作伙伴的数据,包括POS数据,进行校对分析。

SAP APO 需求计划提供多种模型能动态地调整数据,并且自动提醒您需求模式中的突发性变动。

多元化的数据模型和分析功能使您可以通过不同的途径检查数据。

您也可以将该模块与SAP BW 强大的分析功能联合起来使用。

您甚至可以模拟新的市场策略对需求的影响效果。

供应网络计划将采购、生产、以及运输过程与需求相匹配,从而平衡和优化您的整个供应网络。

使用供应网络规划和部署组件,您可以为您的整个供应网络及其所有限制性条款开发一个模型。

然后,使用这一模型,您可以同步化您的活动,并规划整条供应链的物流。

您可以为采购、制造、存货、及运输制订可行的计划,以使供求相匹配。

SAP供应链计划和协同解决方案SAP供应链计划和协同解决方案何晓晔 /供应链方案架构师2012-07SAP 提供全面端到端的供应链解决方案协同需求和供给计划供应链执行制造网络计划及执行客户订单承诺制造网络计划协同需求管理运输管理生产计划及执行供给计划销售和运作计划反应灵敏的供应链网络外协制造原料供给和补货仓库管理全球贸易管理SCM APO-PP/DS SAP MII/MESCM APO-SNP/SCRMSCM SNC-外协制造 SCM SNC-供应商协同SCM APO-DP/ SCM SNC –客户协同/ DSRSCM APO-SNP/SCRMSCM S&OP on SAP HANASCM APO-GATP产品安全&追溯上游产品安全制造及分销安全产品供给网络追溯&召回供应链绩效管理SCPM整体需求管理模式协同需求和供给计划协同需求管理供给计划销售和运作计划反应灵敏的供应链网络SCM APO-DP/ SCM SNC –客户协同/ DSRSCM APO-SNP/SCRMSCM S&OP on SAP HANA供应链执行客户订单承诺 SCM APO-GATP运输管理仓库管理全球贸易管理需求计划 (APO-DP)销售&运作计划(S&OP)需求信号管理(DSR)客户订单承诺 (APO-GATP)覆盖需求采集,计划, 供销协调及客户服务的需求管理模块协同供应链各个相关方,管理流程&绩效–销售&运作计划 (现在) 建立基准预测,自动历史数据分析,自适应最佳预测算法选择–需求计划(现在)另一层次的需求可视,感知全面的需求信号&协助响应–需求信号管理 (2012-Q4)支持客户订单需求响应,达交承诺–客户订单达交承诺(现在)S&OP 协同,管理绩效预测&销售机会销售/市场需求计划物料管理/供应链生产/运作供应,库存,能力计划财务预算计划财务计划,预算销售和运作计划 (S&OP)除供应链部门/计划部门外,还可以让其他需求相关方-- 销售,市场和财务等,便捷地输入相关需求影响信息。

(供应链管理)适者生存把供应链转为适应性商务网络适者生存——把供应链转为适应性商务网络2 ERP系统的管理问题5SAP商务解决方案丛书8MySAP 商务套件和供应链8mySAP ERP财务管理与应用(上、中、下)9 mySAP集团战略管理11mySAP ERP运营管理14mySAP 客户关系管理16mySAP ERP人力资本管理19mySAP供应商关系管理20mySAP供应链管理22MySAP产品生命周期管理23SAP行业解决方案25SAP最佳业务实践27SAP NetWeaver——SAP新一代业务平台29 SAP NetWeaver精要丛书30SAP NetWeaver路线图30SAP业务信息仓库专业版32SAP 企业门户:技术与编程34SAP 交换架构36SAP 应用服务器的网页编程38SAP 应用服务器的JAVA编程39SAP技术图书42SAP APO 系统管理42基于ABAP的JAVA开发指南44SAP智能窗体45SAP 集团战略管理的商业计划47SAP 数据迁移48SAP 系统场景优化50SAP 权限系统51SAP 性能优化指南53SAP Business One中文版2004B55SAP软件实施系列56SAP软件实施56SAP业务蓝图:理解供应链管理58SAP报表与电子商务智能59SAP业务信息仓库应用指南60适者生存——把供应链转为适应性商务网络定价:40.00(精装)读者对象:期望提高企业的商业灵敏性和高效性的企业管理者以及对此问题感兴趣的社会人士。

内容简介本书将企业的商业灵敏性和高效性提高到了一个新的层次,同时也为企业提供了一个比较完美的解决办法——自动调整型企业网络。

自动调整型企业网络创建了一个便捷高效的网络,使得供应链上所有的利益相关者和顾客可以进行相互交流,从而精简优化了企业的供应链,并提高了客户服务质量。

基于世界第三大软件公司——SAP公司众多供应链专家多年的精心研究,自动调整型企业网络能够使企业对市场环境的变化做出更为迅速灵敏的反应,从而大大提高了企业的获利空间,也降低了利益相关者的成本耗费。