油水分离器操作说明

- 格式:doc

- 大小:51.00 KB

- 文档页数:5

油水分离器使用方法油水分离器就是串联在机组进油管路中,将油和水分离开来的仪器,原理主要是根据水和燃油的密度差,利用重力沉降原理去除杂质和水份的分离器,内部还有扩散锥,滤网等分离元件。

Lees power 可针对不同地区油品以及客户要求在发电机组加装此装置,且确保机组出厂前每一个此装置都经过严格测试。

下面为大家讲诉如何使用油水分离器。

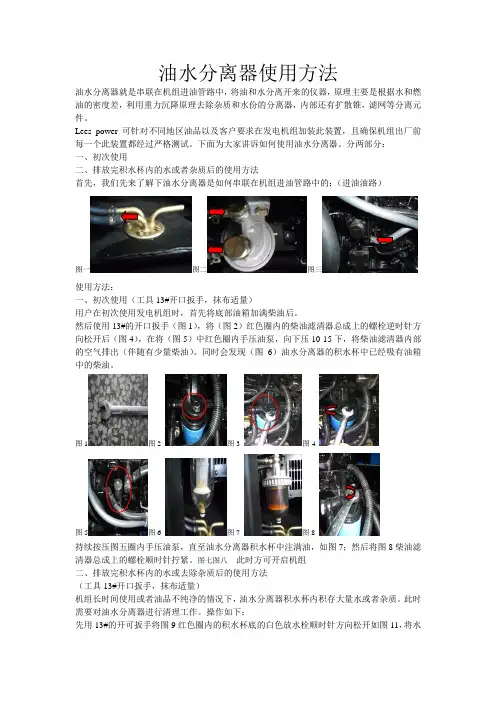

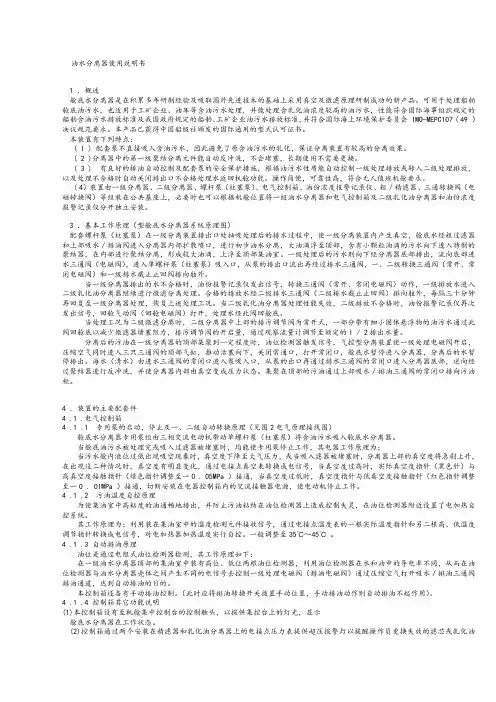

分两部分:一、初次使用二、排放完积水杯内的水或者杂质后的使用方法首先,我们先来了解下油水分离器是如何串联在机组进油管路中的:(进油油路)图一图二图三使用方法:一、初次使用(工具13#开口扳手,抹布适量)用户在初次使用发电机组时,首先将底部油箱加满柴油后。

然后使用13#的开口扳手(图1),将(图2)红色圈内的柴油滤清器总成上的螺栓逆时针方向松开后(图4),在将(图5)中红色圈内手压油泵,向下压10-15下,将柴油滤清器内部的空气排出(伴随有少量柴油)。

同时会发现(图6)油水分离器的积水杯中已经吸有油箱中的柴油。

图1图2 图3 图4图5图6 图7 图8持续按压图五圈内手压油泵,直至油水分离器积水杯中注满油,如图7;然后将图8柴油滤清器总成上的螺栓顺时针拧紧。

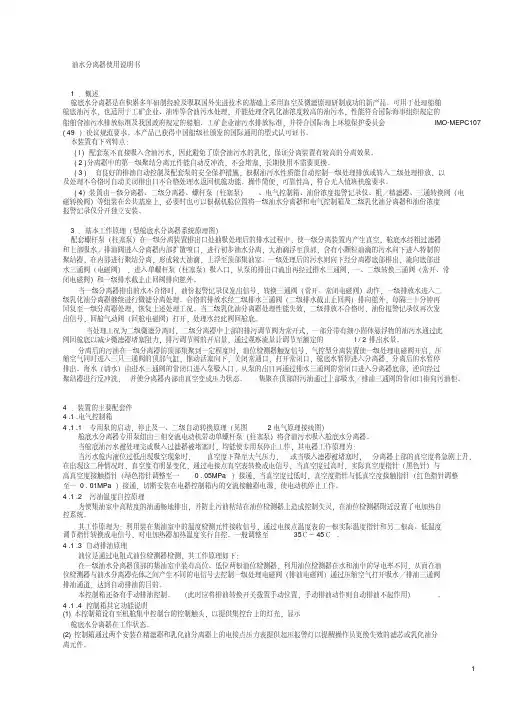

图七图八此时方可开启机组二、排放完积水杯内的水或去除杂质后的使用方法(工具13#开口扳手,抹布适量)机组长时间使用或者油品不纯净的情况下,油水分离器积水杯内积存大量水或者杂质。

此时需要对油水分离器进行清理工作。

操作如下:先用13#的开可扳手将图9红色圈内的积水杯底的白色放水栓顺时针方向松开如图11,将水排出后(如是杂质直接卸下放水栓)再逆时针将白色放水栓拧上(放水栓为塑料易损件,故而确保不漏油即可),至图12状。

然后重复图1-图8动作将油水分离器积水杯内吸满油。

方可再开启机组。

注:无论在何时开启机组都请确认油水分离器积水杯内柴油是满的,方可开启机组。

否则机组开启后会立刻报警。

图9图10图11图12。

油水分离器使用说明书1 .概述舱底水分离器是在积累多年研制经验及吸取国外先进技术的基础上采用真空及微滤原理研制成功的新产品。

可用于处理船舶舱底油污水,也适用于工矿企业、油库等含油污水处理,并能处理含乳化油浓度较高的油污水,性能符合国际海事组织规定的船舶含油污水排放标准及我国政府规定的船舶、工矿企业油污水排放标准,并符合国际海上环境保护委员会 IMO-MEPC107 ( 49 )决议规范要求。

本产品己获得中国船级社颁发的国际通用的型式认可证书。

本装置有下列特点:( l ) 配套泵不直接吸入含油污水,因此避免了原含油污水的乳化,保证分离装置有较高的分离效果。

( 2 )分离器中的第一级聚结分离元件能自动反冲洗,不会堵塞,长期使用不需要更换。

( 3 ) 有良好的排油自动控制及配套泵的安全保护措施,根据油污水性质能自动控制一级处理排放或转入二级处理排放,以及处理不合格时自动关闭排出口不合格处理水返回机舱功能。

操作简便,可靠性高,符合无人值班机舱要求。

( 4)装置由一级分离器、二级分离器、螺杆泵(柱塞泵)、电气控制箱、油份浓度报警记录仪、粗/精滤器、三通转换阀(电磁转换阀)等组装在公共基座上,必要时也可以根据机舱位置将一级油水分离器和电气控制箱及二级乳化油分离器和油份浓度报警记录仪分开独立安装。

3 .基本工作原理(型舱底水分离器系统原理图)配套螺杆泵(柱塞泵)在一级分离装置排出口处抽吸处理后的排水过程中,使一级分离装置内产生真空,舱底水经粗过滤器和上部吸水/排油阀进入分离器内部扩散喷口,进行初步油水分离,大油滴浮至顶部,含有小颗粒油滴的污水向下进入特制的聚结器,在内部进行聚结分离,形成较大油滴,上浮至顶部集油室。

一级处理后的污水则向下经分离器底部排出,流向底部进水三通阀(电磁阀),进入单螺杆泵(柱塞泵)吸入口,从泵的排出口流出再经过排水三通阀,一、二级转换三通阀(常开、常闭电磁阀)和一级排水截止止回阀排向舷外。

油水分离器操作说明

一.使用前的准备,检查 :

(1)设备在使用前,检查设备管路连接是否正确,无

泄漏.

(2)检查电制与设备是否一致,电器接线是否正确.

(3)检查泵,仪器,仪表等配套件是否正常完好.

二.设备操作:

a)关闭设备上放泄阀;打开设备出口的截止阀.

b)将电控箱上的上排油,反冲洗水转换开关置于自动位置.

c)调整反冲洗水压力满足0.15~0.2MPa的要求。

建议压力调至0.2MPa。

d)打开设备的电源开关,按下设备启动按钮.

e)需停机时,按下设备关闭按钮,关闭设备的电源开关.

三.提示事项:

a)为尽快排尽设备中空气,可用反冲洗工况操作.

b)设备停机或暂时不使用前,应进行手动反冲洗操作.

c)设备使用前,放泄阀一般不要开启.

d)设备停用一段时间,一般不需放空.。

油水分离器操作说明一、前言油水分离器是一种用于将油和水进行有效分离的设备,广泛应用于工业和环保领域。

本操作说明旨在介绍油水分离器的正确操作方法,确保设备的高效运行并保证分离效果。

二、设备介绍油水分离器通常由进水口、分离室、沉淀区、出水口等部分组成。

其工作原理是通过重力作用,利用油水比重差异将其中的油和水分离。

三、操作步骤1. 检查设备在操作前,需检查油水分离器的所有部分,确认设备完好无损,并清理污物和堵塞。

确保设备处于正常工作状态。

2. 连接管道连接好进水管道和出水管道,并确保管道无漏水现象。

3. 合理调整流量根据实际需要,合理调整进水的流量。

过大的流量可能导致分离效果降低,过小的流量则可能造成设备堵塞。

4. 分离室操作将待分离的油水混合物缓慢地倒入分离室,并确保不发生溅溢。

倒入速度应适中,避免剧烈的冲击和气泡的产生。

5. 沉淀区观察分离完成后,观察沉淀区内沉淀物的高度。

如果超过设备的最大容量,应及时清理沉淀物,以免影响分离效果。

6. 排出水分从出水口排出分离后的水。

注意,排出水分时应避免将油重新混入水中,可倾斜设备或采用其他技术手段确保分离效果。

7. 定期维护定期检查设备的各个部分,及时清理油垢和污物,保持设备的正常运行。

根据使用情况,可以制定相应的维护计划,定期更换滤芯或其他耗材。

四、注意事项1. 操作前,应熟悉设备的工作原理和操作流程,遵循操作说明进行操作。

2. 在设备运行过程中,应注意观察设备的工作状态,如有异常情况应及时停机检修。

3. 废弃物处理。

分离后的油和沉淀物应按照相关规定进行处理,切勿随意排放或倾倒。

4. 定期检查设备的维护情况,确保设备处于良好状态,及时处理设备故障或损坏。

5. 进行任何维护或修理操作前,应先切断电源或关闭进水阀等相应控制装置。

五、结语以上便是油水分离器的操作说明,希望本文内容能够详细、准确地介绍了油水分离器的操作流程以及注意事项,为您正确操作油水分离器提供参考。

油水分离器操作程序

Oily water separator operating

procedures

运转: 打开油水分离器出海一切阀门,打开控制箱电源开关,打开15PPM报警装置电源开关。

打开空气阀、15PP报警装置清水阀、工业水管路上得阀门、污水舱出口阀。

启动污水泵向装置内注入清水,打开三通转换阀有清水流出说明装置内注满清水,打开左滤器得污水阀,关闭工业水阀。

观察污水泵出口压力。

污水柜得污水是否进入装置。

当压力正常,说明设备正常运行。

停机:打开工业水阀。

关闭污水阀,向装置内注入清水十分钟左右,并手动打开排油阀,停泵,关闭工业水阀。

打开反冲洗阀五分钟然后关闭,当装置内无压力时15PPM将进行自动清洗,冲洗结束后关闭清水阀、空气阀、装置通舷外阀给通海阀上琐。

钥匙给轮机长保管。

善信轮。

油水分离器操作规程油水分离器是一种常见的设备,用于将含有油污物的废水分离成油和水两部分,以达到净化水质的目的。

为了确保分离器的正常运行和安全操作,制定一套操作规程是非常必要的。

以下是一份油水分离器的操作规程,详细介绍了操作步骤、安全措施、维护要求等。

一、操作步骤1.检查油水分离器的工作状态,确保设备无异常。

2.打开油水混合液的进口阀门,将废水缓慢地注入分离器。

3.分离器内的调节板应保持水平,以确保油水分离效果。

4.在油水混合液注入分离器的同时,打开分离器底部的排油阀门,使沉积的油脂顺利排出。

5.当油水分离比例达到设定值时,关闭废水进口阀门。

6.根据需要,定期检查油水分离器的工作情况,必要时清理设备。

7.定期排放分离器底部积累的沉积物,确保设备的正常运行。

二、安全措施1.操作人员应佩戴个人防护设备,包括防护眼镜、手套和工作服。

2.在操作过程中要注意保持设备的平衡,避免设备倾斜或摇晃。

3.在操作过程中,不得将手指或其他物体伸入分离器内部。

4.若发现设备异常,应立即停止操作,并通知相关人员进行检修。

5.不得将腐蚀性液体或固体投入油水分离器内,以防止设备受损。

6.在清理设备时,应采取适当的防护措施,避免直接接触废油物质。

7.废油物质应专门收集和处理,防止对环境造成污染。

三、维护要求1.油水分离器应根据使用情况而定期检查,确保设备的正常运行。

2.定期清洗设备内部,以防止油脂、污泥等沉积物附着。

3.检查设备的密封性能,及时更换密封垫片,确保设备的密封效果。

4.检查设备的排油阀门,确保其正常开启和关闭。

5.检查设备的储油罐容量,及时清理储油罐内的积累物。

6.对设备进行定期润滑,保证设备的灵活运转。

7.定期测试设备的工作效果,根据结果进行相应的调整和维修。

综上所述,油水分离器的操作规程对于保证设备的正常运行和操作人员的安全非常重要。

每位操作人员应严格遵守操作规程,配合设备的维护和检修工作,以确保设备的高效运行和废水的有效处理。

2023年油水分离器操作规程4篇书目第1篇油水分别器安装、调试、操作规程及维护保养的操作规程第2篇油水分别器平安技术操作规程第3篇sow-1-ex油水分别器平安操作规程第4篇液化石油气站sow-1-ex油水分别器平安操作规程液化石油气站sow-1-ex油水分别器平安操作规程第一条开车前打算:1、检查阀门是否处于关闭状态,保证设备内充溢清水。

2、开启阀门v5或v6视察是否有液体流出,假如没有则开启阀门v2、v3,接通电源,起动单螺杆泵补水,直到v5或v6有液体流出,关闭v2、v5、v6阀门。

3、开启阀门v1、v3、v4,关闭其它阀门。

4、单螺杆泵严禁干运转。

其次条运行:1、接通电源,起动限制箱泵运行开关,单螺杆泵运行,泵出口压力表指示出口压力,设备运行。

假如压力表没有显示,检查集水池是否有水;或者泵吸力不够,需进行加水。

2、运行过程中严禁关闭阀门v3或用其调整流量,以防因压力急剧上升引发事故。

第三条排油:1、定期检查集油箱是否集满油。

开启阀门v7或v8观测排出的是油或水,假如是油,说明集油室已集满油,应进行排油。

开启阀门v5或v6排油。

假如排油不畅可关小阀门v4。

2、两个集油室分别设有电加热器,排油不畅时可开启电加热器对油进行加热。

开启加热器时应限制加热温度不超过50℃,可视察集油室上的温度表进行限制。

第四条排污:设备应定期排污。

每次排油后开启阀门v9或v10,约1分钟排污。

第五条停车:关闭限制箱上泵开关,停止泵运行,关闭设备全部阀门。

sow-1-ex油水分别器平安操作规程第一条开车前打算:1、检查阀门是否处于关闭状态,保证设备内充溢清水。

2、开启阀门v5或v6视察是否有液体流出,假如没有则开启阀门v2、v3,接通电源,起动单螺杆泵补水,直到v5或v6有液体流出,关闭v2、v5、v6阀门。

3、开启阀门v1、v3、v4,关闭其它阀门。

4、单螺杆泵严禁干运转。

其次条运行:1、接通电源,起动限制箱泵运行开关,单螺杆泵运行,泵出口压力表指示出口压力,设备运行。

油水分离器操作须知一、使用前准备:1、首先将油水分离器注满海水或清水。

操作过程如下:合上电气控制箱电源开关,关闭油水分离器下方的排污放水旋塞,开泵注清水,同时打开各腔顶部之手动验油放气旋塞,使分离器内部空气排出,直至旋塞出水后,逐腔依次分别关闭,当海水或清水把分离器注满后,关闭注水阀,停泵。

以后油水分离器正常使用时,一般不必再注入海水或清水,除非油水分离器内失水时,才需重新注水。

2、开车启动前,先用手盘动螺杆泵皮带轮,顺时针一周左右,方可启动电源,螺杆泵切忌无水运行。

对于使用柱塞泵的装置可免去盘车,但仍忌无水运行。

3、当分离器粗分离腔上部有空气时,电气控制箱上的排油灯亮并伴有报警声系正常情况。

4、当分离器排油腔中无水无油时,切忌打开电加热器开关,以免烧坏加热器。

二、运行1、起动电气控制箱开关,由泵向分离器中泵入油水混合物,即能正常工作。

2、每天运行时至少检查一次粗粒化腔上的旋塞和集油脱油腔上的旋塞,正常情况下流出液体应是水或水油混合物,当这两腔排出之水发白时,应打开粗分离腔的手动排油阀排油。

如果排油后,上述情况没有改变时,则应检查粗分离排油电极有无故障或停机清洗。

3、每次运行时均应检查粗分离腔上的排油阀排出的液体,不致因腔中聚集的污油未及时排出而影响分离效果。

4、探摸专用泵轴承外表温度及观察传动机构工作是否正常,水泵盍声是否正常。

5、安全阀已整定封固,用户不要随间旋动。

6、电控箱内,一旦自动排油失灵,可转换手动排油;当电磁阀失灵时,则可顺时针将电磁阀下应争顶杆旋动,用手强制排油。

7、对处理含大粘度油的污水,在水温低于20℃时,应打开控制箱上处动加热开关。

取水样时应注意事项:(1)初次取样,应在分离器运行1-2小时后进行。

(2)取样时,取样旋塞事先放流一分钟以上。

样瓶事先清洗干净。

(3)取样装入500ml样瓶,其速度时间可控制为2分钟。

三、停机当污水处理完后,先将加热器开关转向停止位置,停泵后切断电气控制电源即可。

油水分离器安全操作规程

一、准备

1.关闭筒体下部的泄放阀门。

2.打开出水管路阀门。

3.关闭反冲洗管阀门。

4.打开放气旋塞。

5.将电控箱排油旋钮拨向“自动”位置。

二、运行

1.打开油污水进口管路阀门。

2.接通电源,启动栓塞泵,向分离器内供水。

3.当圆筒上部的放气旋塞依次出水时,分别关闭放气旋塞。

4.打开取样旋塞排放一分钟后取水样。

5.打开第二筒与第三筒上部两个油位旋塞中的下旋塞,检查油位是否达到该部位。

如达到,则手动打开放油球阀排油,当上旋塞流水时关闭球阀。

6.当排入回水池的水达半池左右时启动栓塞泵。

7.运行过程中检查油污水池的水位,防止将浮油抽入分离器内(以下露出底阀为宜)。

三、停机

1.先向分离器内泵入清水,待分离器内的油污水清除

干净后,切断栓塞泵电源,关闭出水管路阀门。

四、反冲洗

1.打开全部泄放阀门,将分离器内的水放掉。

2.关闭泄放阀门,但第三筒的泄放阀门不关。

3.打开反冲洗管路阀门。

4.接通反冲洗水泵,以清水反向冲洗第三筒十五分钟。

5.关闭第三筒的泄放阀,打开第二筒的泄放阀冲洗十五分钟。

6.关闭第二筒的泄放阀,打开第一简左边的阀冲洗十五分钟。

7.关闭第一简的泄放阀,打开第一筒右边的阀冲洗十五分钟。

油水分离器安全技术操作规程油水分离器是一种用于处理含油污水的设备,它将含油污水通过物理和化学的方式进行分离,将油水分离,达到净化水质的目的。

对于使用油水分离器的工作人员来说,操作安全是非常重要的。

因此,下面将对油水分离器的安全技术操作进行规程说明。

一、操作前准备1.检查油水分离器有无泄露现象,如有泄露应及时处理。

2.检查油水分离器液位计是否正常,如有故障应及时维修。

3.检查油水分离器管道是否通畅,如有堵塞应及时清理。

4.检查油水分离器的电气设备是否正常,如有故障应及时维修。

二、操作步骤1.将含油污水输送至油水分离器,同时调整进水量。

2.开启油水分离器,将污水通过物理和化学的方式进行分离。

3.关注液位计的变化情况,在污水进入时,液位应逐渐升高,当液位达到一定高度时应关闭进水泵。

4.观察油水分离器内部的油层和水层的情况,当油层达到一定高度时应及时将油排放。

5.当水层的液位过高时,应及时将水泵开启,将污水抽出,以保持稳定的水位。

三、安全注意事项1.遵守相关的操作规程,严格按照要求进行操作,切勿盲目冒进。

2.注意排放油水分离器阳极污泥,以避免对环境造成污染。

3.在操作油水分离器时应保持设备清洁,避免油的泄漏或沉积。

4.电气设备需要由专业维修人员进行维护和检修,禁止非专业人员进行操作。

5.在操作油水分离器时,应注意防护措施,使用相应的个人防护装备。

总之,操作油水分离器是一项技术活,需要经过专业的培训和操作才能熟练掌握,同时也需要遵循相关的安全规程。

只有这样才能保证油水分离器正常运行,达到净化污水的目的,同时也保证了工作人员的安全。

油水分离器操作说明步骤一:检查设备在操作油水分离器之前,首先需要检查设备是否处于正常工作状态。

检查排出水管和进水管是否连接正常,检查电源是否正常连接。

步骤二:阅读操作手册在操作油水分离器之前,应阅读设备的操作手册。

操作手册中会详细介绍设备的功能和性能指标,以及使用方法和注意事项。

步骤三:设置参数根据实际情况,设置油水分离器的一些参数。

例如,可以设置油水分离的速度、温度和压力等。

不同的设备可能有不同的参数设置方法,请按照操作手册进行设置。

步骤四:投入污水当设备设置完毕后,可以开始将污水投入油水分离器中。

打开进水管阀门,将污水缓慢地注入设备中。

需要注意的是,不能一次投入过多的污水,以免影响设备的正常运行。

步骤五:分离油水在污水进入油水分离器后,根据设备的工作原理,油和水会进行分离。

在分离过程中,可以通过观察设备的显示屏或指示灯来了解分离的情况。

一般来说,油会浮在水的上方,水则会被排出设备。

步骤六:排放油和水当油水分离完成后,可以分别排出油和水。

打开油孔,将分离后的纯净油排出。

打开水孔,将分离后的纯净水排出。

需要注意的是,排放油和水时要注意排放的方法和环境,以免对环境造成污染。

步骤七:清洁设备在操作完成后,需要对油水分离器进行清洁和维护。

关闭进水阀门和排放阀门,断开电源。

使用清洁剂和水清洗设备,去除设备内的油污和污垢。

然后进行设备的维护,例如检查设备的各个部件是否正常运行,是否需要更换零部件。

注意事项:1.在操作油水分离器之前,要确保所有的人员都有足够的安全知识和操作经验。

对于没有相关经验的人员,不能独立操作设备。

2.在投入污水时,要注意污水的流速和压力。

不要一次投入过多的污水,以免影响设备的正常运行。

3.在排放油和水时,要根据当地法规和环境要求进行操作。

选择合适的排放方式和地点,以避免对环境造成污染。

4.在清洁设备和维护设备时,应使用合适的工具和清洁剂,注意安全操作。

对于维护不熟悉的部件,应请专业人员进行检修和更换。

油水分离器的操作

1接通控制箱电源,电气控制箱开关排油处于自动位置。

2关闭通向舱底污水柜的吸水阀2,打开清水阀4。

3启动柱塞泵6,清水注入油水分离器,使左,中,右室空气从左,中,右室集油室排油阀处排出。

4当左,中,右室集油室排油阀都排出清水后,关闭柱塞泵6,同时关闭中,右室排油旋塞12,13

5清水注满后,运行1小时,清除安装时管壁可能沾污的渣污。

6清洗完毕后,关闭清水阀4,打开舱底吸水阀2,再次启动柱塞泵6。

7正常运行情况下,精分离腔室的污油聚量很少,若从旋塞12,13中有污油排出时,可排入舱底,污油重新从左腔室自动排油回收。

8严格防止舱底水抽完后继续操作水泵,打入空气,致使前节的油污水压至后两节,造成精粒化元件污染,甚至污染出水口处,影响排放标准。

9取样打开取样考克14,待水空放2分钟,去除管壁上的残留油滴,后用取样瓶取水500ml,应及时送化验分析,存放时间要短,确保化验精确。

15油水分离器操作规程一、概述二、设备准备1.操作前,需要检查15油水分离器的各个部位是否完好无损,设备内部是否清洁。

2.确保设备中的油层高度适当,根据需要进行添加或排放。

3.准备好所需的工具和个人防护用品,包括手套、安全帽、防护眼镜和耳塞等。

三、操作步骤1.打开15油水分离器的控制开关,启动设备。

2.根据工艺要求,调节设备进出口阀门的开闭程度,保持适当的流量。

3.定期检查和维护设备的沉淀池,将其中的沉积物清理干净。

4.定期检查和维护设备的电机、泵和传动装置,确保其运转正常。

5.定期检查和维护设备的电器设备,确保其运行稳定可靠。

6.定期检查和维护设备的高低液位报警装置,确保其正常工作。

7.根据需要,定期添加或排放废水,保持适当的液位和流量。

8.操作过程中,注意观察设备的运行状态,如有异常情况及时处理,并记录相关数据。

9.操作结束后,关闭设备的控制开关,停止设备的运行。

四、安全注意事项1.操作人员必须经过必要的岗前培训和持证上岗。

2.操作过程中,必须严格遵守相关安全操作规程,如戴好个人防护用品,禁止随意触摸设备。

3.若设备出现故障或停机情况,必须及时报修,并通过专业人员进行维修。

4.禁止私自进行设备的改装或拆卸。

5.注意设备周围的环境卫生,保持设备周围的整洁。

五、应急处理2.在紧急情况下,如设备内有人员被困或伤员需要救治,应第一时间组织人员实施救援,并及时通知相关部门。

六、记录和报告1.运行班次结束后,需要对设备的运行情况进行记录,包括检查和维护情况、沉淀池清理情况等,并保存至设备操作记录本中。

2.如有需要,需要向上级主管领导或相关部门报告设备的运行情况和存在的问题,以便及时解决。

以上就是15油水分离器的操作规程,以确保设备能够正常运行和安全生产。

在操作过程中,一定要注意安全防护,及时进行设备的维护和检查,并进行详细的记录和报告。

只有这样,才能保证15油水分离器的高效、稳定和安全运行。

油水分离器操作程序

一、启动

1、打开污水器或污水柜吸入阀,污水泵进出口阀及分离器出海阀。

2、和上分离器开关。

3、起动污水泵向油水分离器供污水。

4、打开检测水考克,使检测水流经油分浓度计。

二、进行中管理

1、经常检查油污浓度显示,如超过15PPM仍未报警,应立即停泵检查。

2、注意两级滤筒之间的压差如超过400Kpa,则应清洗滤器,第一级滤筒压力不超过0.2Mpa,否则

安全阀跳开。

3、检查低位检验考克,如有油流出,则积油过多,应立即排油。

4、用手模分离器出口回油污水柜管路,如发凉说明气控阀没有气源(可能是信号水压力太小、

电磁阀不动作、三通阀不供气)。

5、定期打开顶部放气旋塞放气。

三、停止工作

1、关闭污水井或污水柜吸入阀,开海水进泵阀冲洗油水分离器约15分钟。

2、停泵关进出口阀,关油水分离器开关。

3、关油水分离器检测考克,打开淡水进浓度检控装置连通阀,冲洗浓度计3分钟后关掉。

油水分离器操作规程1.安全操作:(1)在操作前,要检查油水分离器的各个阀门、仪表等设备是否正常,如有异常及时进行修理或更换。

(2)在操作过程中,要始终关注油水分离器的温度、压力等工艺参数。

如果发现参数异常,要及时采取措施。

(3)操作人员要熟悉油水分离器的工作原理和设备结构,必要时可以请专业人员进行操作指导。

2.上岗前准备:(1)操作人员进入操作区域前,必须穿戴好个人防护装备,如安全帽、安全鞋、工作服等。

(2)操作人员应该熟悉油水分离器的工作原理和设备结构,并对各种仪表设备进行检查,确保设备处于正常工作状态。

3.操作步骤:(1)打开进料阀门,将含油污水缓慢地注入油水分离器中。

(2)根据需求调整油水分离器的流量和液位,确保设备的正常运行。

(3)注意观察油水分离器的出水口,当出水口流出清水时,表示分离效果良好。

(4)定期检查沉淀池的沉淀物,如有需要可以清理沉淀物,以保证设备的长期运行和分离效果。

(5)操作结束后,要关闭所有阀门,并对设备进行清理和维护。

4.设备维护:(1)定期对油水分离器进行清洗和维护。

清洗时,要关闭进水阀门,放空油水分离器内的水,并进行内外部的清洗。

(2)定期检查油水分离器的密封性能,如有损坏或老化,要及时更换。

(3)定期检查油水分离器的电气设备是否正常运行,如有异常现象要及时处理。

5.注意事项:(1)操作人员在操作过程中要保持清醒和专注,严禁饮酒、吃饭等影响操作的行为。

(2)操作人员要定期进行自我培训和技术交流,提高自身的操作技能和安全意识。

(3)在操作过程中要始终关注环境保护问题,做到废水零排放、垃圾分类处理。

以上是关于油水分离器操作规程的详细内容,操作人员在使用油水分离器时应严格按照规程进行操作,确保设备的正常运行和安全使用。

同时,还需要定期对设备进行维护和保养,以延长设备的使用寿命。

食堂油水分离器使用说明

1、该产品可直接安装在合油污水流经的通道上,把污水出口对准油水分离器的进口即可,与其它设备可用管道连接。

底部的排污管线与污泥脱水装置连通,如未配污泥脱水装置可直接排入排污管。

2、无动力箱式隔油器安装时必须调擎其水平位置,不得有误差。

3、第一次使用前,应先把设备注满自来水,直到出油口只出油不出水为止。

4、设备安装后,请不要随意乱动,否则将影响出水水质。

5、每天使用后,应将进水口过滤网上的杂物倒掉,并清理干净。

(餐饮业应用热水冲刷滤网上的油污,以免堵塞滤网,影响进水。

如果是用泵提升进水,请每天清理水泵进水底阀旁污物,以免堵塞泵阀,影响进水流量。

6、每天使用后,应将杂物筐每天提出挂油倒垃圾,并将水上浮油清除掉,箱体每2周清扫一次,将粘在隔板金属表面的油污用刀刮掉,底部垃圾要求清除干净。

清理完毕恢复原状。

7、当油水分离器的出水、排水管堵塞时,将箱盖罩拿掉,因有臭气溢出,应快速清通,清通

8、在使用过程中应定期冲洗设备内部,一般每半月冲洗一次,或视情况而定。

油水分离器操作说明书Operation Instruction to Oil-Water Separator一、概述SummarizeYSF型油水分离组合装置是由中国船舶工业总公司第九设计研究院针对陆域含油废水特性设计的一种新颖油水分离装置,采用了多项油水分离的最新成果,可以适用于不含表面活性剂的各类机油、柴油、润滑油、动植物油等油品的含油废水处理,具有结构紧凑,操作管理维修简便,能耗低,分离效率高等特点。

处理后出水的含油量能有效地控制在5mg/L以下,可直接排放或适当回用,分离出的废油也可回收利用,因此在节能、节水、保护环境等方面均显示出良好的技术经济效益。

YSF type oil-water separator combiner, one of latest oil-water separating device, which has been designed in the light of oiled wastewater’s characteristic by No. 9Design and Research Institute of Ship Industry Parent Company of China and has adopted many latest oil-water separating research results, is suit for many kinds of oiled wastewater treatment such as machine oil, diesel oil, lubricating oil and tallow, vegetable tallow. And it has the advantage of compact structure, easy operation and maintenance, low consumption, high separating effect etc. So, the oil percentage of effluent by treatment can be up to down 5mg/L effectively and may directly discharge or reuse properly, also, the removal oil can reuse. Thereby above, it is indicative that it has upstanding technical economical benefits at aspects of energy and water saving, environment protection.本装置采用简便、低运行耗费的全物理法处理工艺。

It had adopted true physical treatment process, which is easy, and low energy consumption.处理装置将一至三级处理工艺组合成一钢制圆筒形整体结构,与螺杆泵,油水层析槽及电器控制盒组合成具有完整功能的处理装置。

The complete device is one combiner from the first level treatment to the second into one cylinder steel structure with screw pump, oil-water separating trough and electric control box.处理工艺充分利用了重力分离特性,不同分离材料的浸润特性等有利于提高油水分离率的物理特性,对于工况较复杂的各种机械混合类含水量油废水具有广泛的适应能力。

The process will make all best use of gravity separating characteristic, different soakage of different material, coarse grain, adsorption aggregation to increase oil-water separating coefficient, and even for different complicated oilness wastewater, it still can be dealt with.二、操作说明:Operation manual1、检查:装置启动前应先检查各阀门阀位,螺杆泵及电气控制工况是否符合要求。

Check: before starting, check whether all valves, screw pumps and electric control are right or not.2、运行准备:Running prepare2.1新装置第一次起动:将螺杆泵进水管转接清水池(水槽及水箱),开启排油阀,排气阀后启动螺杆泵,逐级进液,排气,直至相应筒体满流后关闭相应的排油、排气阀,各级全部满流后继续运行半小时,一般采用循环运行方式,即运行也水可返回水池(槽或箱)。

First starting: Turn the inlet of screw pumps to clearing water reservoir, turn on the oil discharge valve, air exhaust valve, then, turn on screw pumps, influent enters and air escapes step by step, until the cylinder is full and all units work half an hour, we just shut then down.2.2一般启动:先将螺杆泵进出水管转接清水池运行半小时,并逐级排气至满流。

Common starting: first turn screw pumps to clearing water reservoir and let it run 30mins, and exhaust step by step up to full-flow.2.3 含油废水处理运行:处理装置经清水运行半小时,并逐级排气至满流后,可将进水管转入废水池进入处理运行,同时根据含油废水的含油浓度确定排油周期,排油只需开启排油阀,并通过排油观察控制开启时间,一般条件下,每班只需开启一次(8小时一次)。

Oilness wastewater processing running: After doing a running with clearing water half an hour and step by step exhaust air to full-flow, we turn the wastewater over to the sewerage pool to treat and make the discharge period of oil in the light of oil concentration. And only turn on the oil discharge when it is necessary and observe the start time, generally speaking, only one for one shifti.e. 8hrs once.2.4 停车:结束运行前应将螺杆泵进水管转入清水池(槽或箱)运行半小时,然后再停泵,停泵时就关闭所有阀门,保持筒体的满流状态。

Shut down: before running over, turn the inlet of screw pump to clearing water reservoir and make it work 30mins, then, shut it down; when the pumps are off, all valves are off and the cylinder is full-flow.三、装置特点:Apparatus Features1、由于陆域含油废水的处理工艺一般总先利用含油废水池进行沉砂、隔油预处理,可大大降低进入处理装置的含油废水浓度,因此处理装置的排油周期可以较长,一班排油一次就可以了。

Because generally first do the settling grit and skimming oil treatment for field oilness wastewater, which can decrease the oilconcentration greatly before treating, so this oil discharge period of equipment is longa litter, we can select once per one shift.2、设置专用贮油器贮存废油,以便于排油操作和进一步油水分离。

Equip with special oil storage tank for removal oil to separate them further.3、本装置采用组装结构,结构紧凑,便于运输、安装及保养。

This equipment adopts combined structure, which is compact for shipping, installation and maintenance.四、注意事项:Notices1、本装置应在清水满流的前提下启动,因此启动和停车要清水运行半小时,并在此过程中逐级排气。

Start the equipment on condition of full-flow, and before and after be done those running with clearing water respectively, start up and shut down, and meanwhile exhaust step by step.2、含油废水应经过澄清、隔油设施预处理,泵前应设置机械过滤器。

Place mechanism filter before pump, and the wastewater will go through clarifier and oil separator.3、应注意含油废水池液位,以免抽空后磁体空转发热损坏,必要时可设置液位报警信号或液位联动可自控系统。