大连苏尔寿样本

- 格式:pdf

- 大小:4.71 MB

- 文档页数:52

大连苏尔寿泵及压缩机有限公司--D泵大连苏尔寿泵及压缩机

有限公司--D泵

佚名

【期刊名称】《流程工业》

【年(卷),期】2008(000)005

【摘要】D泵是为工业工艺流程连续操作而设计的。

该泵可用于输送不同种类的液体和浆料。

该泵采用水平安装.单级、端吸、后拉式,ROTOKEY叶轮.简化了重载轴承部件等优点。

【总页数】1页(P87)

【正文语种】中文

【中图分类】TH45

【相关文献】

1.苏州苏尔寿泵业有限公司展位号:W1416A MSD ISO 13709(AP1610)BB3多级泵 [J],

2.艾格尔化工泵(大连)有限公司:ROTHO软管泵 [J],

3.大连苏尔寿泵及压缩机有限公司:D泵 [J],

4.艾格尔化工泵(大连)有限公司——ROTHO软管泵 [J],

5.大连苏尔寿泵及压缩机有限公司 [J],

因版权原因,仅展示原文概要,查看原文内容请购买。

恶性纤维组织细胞瘤的分化谱、异源性与核型演进

张众;李连宏;吕申;谢丰培

【期刊名称】《临床与实验病理学杂志》

【年(卷),期】2000(016)005

【摘要】@@ 恶性纤维组织细胞瘤(MFH)的概念仍存在争议.作者介绍其细胞的分化谱与异源性,并就其形态发生与细胞遗传学演进的关系加以探讨.

【总页数】3页(P409-411)

【作者】张众;李连宏;吕申;谢丰培

【作者单位】大连医科大学中日临床病理中心,大连,116027;大连医科大学中日临床病理中心,大连,116027;大连医科大学中日临床病理中心,大连,116027;大连医科大学中日临床病理中心,大连,116027

【正文语种】中文

【中图分类】R730.26

【相关文献】

1.斜纹夜蛾和甜菜夜蛾核型多角体病毒异源重组后的变异 [J], 王成燕;钟万芳;刘宝生;方继朝;郭慧芳

2.异源包装家蚕核型多角体病毒的特性研究 [J], 季平;沈卫德;于继彬;陈息林;何家禄

3.腹膜后伴有异源性分化的去分化脂肪肉瘤病例分析及文献复习 [J], 谢凯圣;张斌;郑绍光;韦永焦;黄羽;傅欣

4.异源多角体蛋白对家蚕核型多角体病毒粒子的包装 [J], 季平;查新民;张国英;于

继彬;顾维;沈卫德

5.银纹夜蛾感染异源核型多角体病毒后和因淋巴的病理生化分析 [J], 舒志群; 许琳因版权原因,仅展示原文概要,查看原文内容请购买。

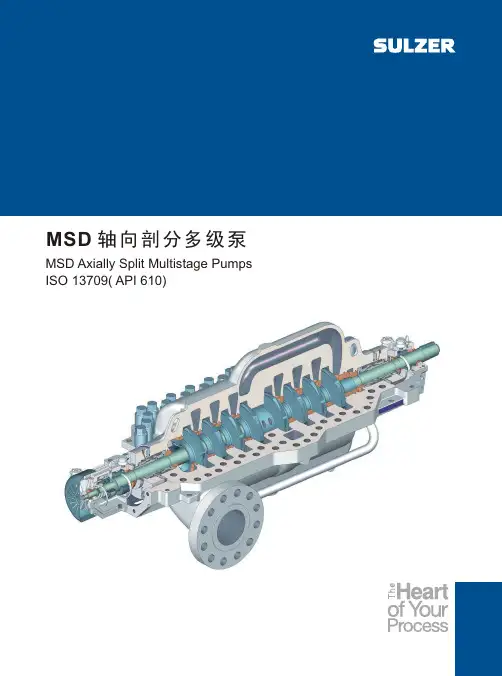

MSD 轴向剖分多级泵MSD Axially Split Multistage Pumps ISO 13709( API 610)Sulzer Pumps is a leading global supplier of reliable products and innovative pumping solutions for end users. Our active research anddevelopment, detailed process and application knowledge together with a comprehensive understanding of market demands keeps us consis-tently at the leading edge of technical development. Our global network ofmodern manufacturing and packaging facilities together with sales offices,service centers and represen-tativeslocated close to major markets providefast responses to customer needs.Sulzer Pumps – Leader in Pump Technology苏尔寿泵业是一个提供可靠产品和创新泵解决方案的全球领先的供应商。

积极的研究和开发,详尽的工艺制造和丰富的应用经验,加上对于市场需求的全面为最终用户苏尔寿泵业——泵技术的领导者Sulzer Pumps is active servingbusiness partners in the followingindustries:• Oil & Gas• Hydrocarbon Processing• Pulp & Paper• Power Generation• Food, Metals & Fertilizers• Water & Wastewater理解,使我们始终处于技术发展的前沿。

MSD 轴向剖分多级泵MSD Axially Split Multistage Pumps ISO 13709( API 610)Sulzer Pumps is a leading global supplier of reliable products and innovative pumping solutions for end users. Our active research anddevelopment, detailed process and application knowledge together with a comprehensive understanding of market demands keeps us consis-tently at the leading edge of technical development. Our global network ofmodern manufacturing and packaging facilities together with sales offices,service centers and represen-tativeslocated close to major markets providefast responses to customer needs.Sulzer Pumps – Leader in Pump Technology苏尔寿泵业是一个提供可靠产品和创新泵解决方案的全球领先的供应商。

积极的研究和开发,详尽的工艺制造和丰富的应用经验,加上对于市场需求的全面为最终用户苏尔寿泵业——泵技术的领导者Sulzer Pumps is active servingbusiness partners in the followingindustries:• Oil & Gas• Hydrocarbon Processing• Pulp & Paper• Power Generation• Food, Metals & Fertilizers• Water & Wastewater理解,使我们始终处于技术发展的前沿。

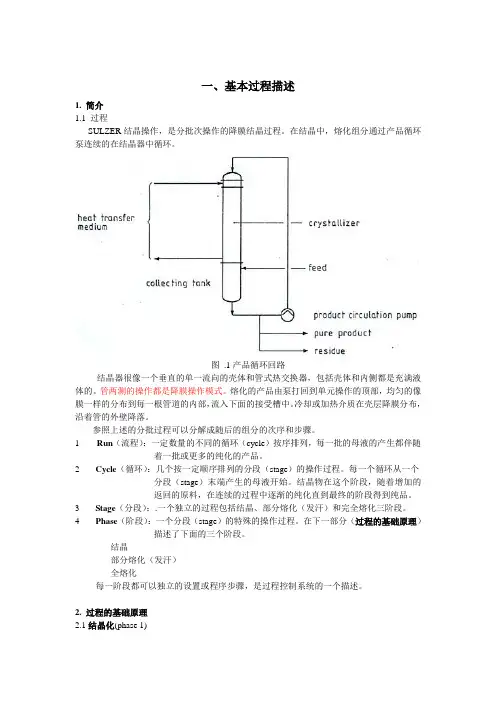

一、基本过程描述1. 简介1.1 过程SULZER结晶操作,是分批次操作的降膜结晶过程。

在结晶中,熔化组分通过产品循环泵连续的在结晶器中循环。

图.1产品循环回路结晶器很像一个垂直的单一流向的壳体和管式热交换器,包括壳体和内侧都是充满液体的。

管两测的操作都是降膜操作模式。

熔化的产品由泵打回到单元操作的顶部,均匀的像膜一样的分布到每一根管道的内部,流入下面的接受槽中。

冷却或加热介质在壳层降膜分布,沿着管的外壁降落。

参照上述的分批过程可以分解成随后的组分的次序和步骤。

1 Run(流程):一定数量的不同的循环(cycle)按序排列,每一批的母液的产生都伴随着一批或更多的纯化的产品。

2Cycle(循环):几个按一定顺序排列的分段(stage)的操作过程。

每一个循环从一个分段(stage)末端产生的母液开始。

结晶物在这个阶段,随着增加的返回的原料,在连续的过程中逐渐的纯化直到最终的阶段得到纯品。

3Stage(分段):.一个独立的过程包括结晶、部分熔化(发汗)和完全熔化三阶段。

4Phase(阶段):一个分段(stage)的特殊的操作过程。

在下一部分(过程的基础原理)描述了下面的三个阶段。

-结晶-部分熔化(发汗)-全熔化每一阶段都可以独立的设置或程序步骤,是过程控制系统的一个描述。

2. 过程的基础原理2.1结晶化(phase 1)熔化组分在管道内壁形成的降膜在结晶化阶段的降温过程中逐渐形成了一个晶体层。

在这个阶段过程中,冷媒的进料温度曲线呈下降趋势以补偿不断增加的晶体层的厚度而减少了的热传导和因循环熔化组分纯度的不断下降而将低了的熔点。

这种条件下使得纯的晶体层迅速增加,而不纯的杂质积累在逐渐减少的液体中。

当残存的一定量的母液进入预先设定的水平高度结晶化过程就结束了。

2.2部分熔化(phase 2)结晶层在结晶化阶段以相当快的速度增长,会包含杂质从而降低一个分段(stage)的分离效率。

随后的控制热载体的升温过程将改善悬浮的结晶层的纯度。

安装、使用及维护手册HSA/HSB尔寿泵(美国)公司目录介绍1.0 关于本手册2.0 如何使用本手册3.0 说明4.0 组成部件5.0 性能参数6.0 防爆区域定义7.0 质保安全1.0 围2.0 本手册中的警示指导标识3.0 人员的资格和培训4.0 不遵守安全规定可能导致的危险5.0 安全指导6.0 用户/操作员安全指导7.0 维护、检查和组装工作的安全指导8.0 禁止未经过授权的改型或改造9.0 不允许的操作方式10.0 防爆运输、接收和存放1.0 运输2.0 提升搬运3.0 检查4.0 存放安装1.0 安装顺序2.0 基础3.0 底板的安装4.0 主管道系统5.0 辅助管道系统和设备6.0 驱动器“空载”运行7.0 联轴器隔离套的安装8.0 最终对中找正9.0 存放安装顺序检查清单对中1.0 最初对中找正2.0 最终对中找正操作1.0 检查清单2.0 准备3.0 启动4.0 操作检查5.0 备用6.0 延长停泵时间启动前检查清单维护1.0 围2.0 记录和分析3.0 拆卸概述4.0 机械密封更换5.0 主要部分拆卸的准备工作6.0 至维修现场的运输7.0 联轴器毂组装泵壳/转动元件的组装1.0 围2.0 准备3.0 检查和清理4.0 泵壳上半部的拆除5.0 转动元件的拆除及拆卸6.0 涡形泵壳的检查7.0 其它部件的检查8.0 转动元件的拆卸9.0 泵壳的闭合10.0泵壳/旋转元件对中及密封套筒/滚珠轴承组件1.0 围2.0 准备3.0 检查和清洗4.0 组装–概述5.0 组装–径向轴承(驱动端- DE)6.0 组装–止推轴承(非驱动端- NDE)7.0 组装–附件8.0 轴承的润滑9.0 推荐的润滑剂粘度和温度报警设置10.0 可互换润滑剂11.0 拆卸–概述附录 1现场安装的驱动机附录 2扭矩值附录 3垫片切割附录 4故障的查找和清除附录 5转动元件端动作的调整附录8预灌浆填塞的底板现场安装附录9压盖盘根的安装1.0 关于本手册本手册适用于操作和维护人员。

第32卷 第3期V o l .32 No .3草 地 学 报A C T A A G R E S T I A S I N I C A2024年 3月M a r . 2024d o i :10.11733/j.i s s n .1007-0435.2024.03.030引用格式:意如乐,格根图,王志军,等.响应面法优化火绒草中总黄酮与总酚酸的提取工艺研究[J ].草地学报,2024,32(3):935-944Y IR u -l e ,G EG e n -t u ,WA N GZ h i -j u n ,e t a l .S t u d y o n t h eE x t r a c t i o nP r o c e s s o fT o t a l F l a v o n o i d s a n dT o t a l P h e n o l i c A c i d s i n L e o n t o p o d i u m l e o n t o po d i o i d e s (W i l d .)B e a u v [J ].A c t aA g r e s t i aS i n i c a ,2024,32(3):935-944响应面法优化火绒草中总黄酮与总酚酸的提取工艺研究意如乐1,格根图1*,王志军1,胡日查2,百 岁2,塞西雅拉图3(1.内蒙古农业大学草原与资源环境学院,农业农村部饲草栽培㊁加工与高效利用重点实验室,内蒙古呼和浩特010019;2.克什克腾旗林业和草原局,内蒙古赤峰025300;3.克什克腾旗绿色驿站环境保护监测站,内蒙古赤峰025300)收稿日期:2023-09-19;修回日期:2023-11-26基金项目:财政部和农业农村部:国家牧草产业技术体系(C A R S -34)资助作者简介:意如乐(1999-),女,蒙古族,内蒙古赤峰人,硕士研究生,主要从事牧草加工与利用方向研究,E -m a i l :yi r u l e 1207@126.c o m ;*通信作者A u t h o r f o r c o r r e s p o n d e n c e ,E -m a i l :g e ge n t u @163.c o m 摘要:为探究野生火绒草(L e o n t o p o d i u m l e o n t o p o d i o i d e s (W i l d .)B e a u v )总黄酮与总酚酸最佳提取工艺及抗氧化活性,本试验采用快速溶剂萃取法探索萃取温度㊁循环次数㊁加热时间及萃取压力对火绒草总黄酮㊁总酚酸提取含量的影响,通过单因素试验和响应面设计法确定了活性物质的最佳提取工艺㊂结果表明:当使用70%乙醇提取火绒草中总黄酮时最佳提取工艺为:萃取温度93ħ,循环次数3次,加热时间20m i n ,萃取压力102b a r,提取含量为(45.45ʃ0.36)m g㊃g -1;总酚酸最佳提取工艺为:萃取温度90ħ,循环次数3次,加热时间19m i n ,萃取压力97b a r ,提取含量为(23.52ʃ0.34)m g ㊃g -1㊂火绒草总黄酮提取液对D P P H 自由基和A B T S 自由基的I C 50为0.012m g ㊃m L -1和0.356m g ㊃m L -1,具有一定的还原力㊂本研究可为火绒草活性物质的提取工艺及加工利用提供可靠的理论依据和详实的科学参考㊂关键词:火绒草;总黄酮;总酚酸;快速溶剂萃取;响应面法优化;抗氧化活性中图分类号:P 746.2+2 文献标识码:A 文章编号:1007-0435(2024)03-0935-10S t u d y on t h eE x t r a c t i o nP r o c e s s o fT o t a l F l a v o n o i d s a n dT o t a l P h e n o l i cA c i d s i n L e o n t o p o d i u m l e o n t o po d i o i d e s (W i l d .)B e a u v Y IR u -l e 1,G EG e n -t u 1*,WA N GZ h i -ju n 1,HU R i -c h a 2,B A I S u i 2,S A IX iY aL a -t u 3(1.K e y L a b o r a t o r y o fF o r a g eC u l t i v a t i o n ,P r o c e s s i n g a n dH i g hE f f i c i e n tU t i l i z a t i o no fM i n i s t r y o fA g r i c u l t u r e ,C o l l e ge of G r a s s l a n dR e s o u r c e s a n dE n v i r o n m e n t ,I n n e rM o ng o l i aA g r i c u l t u r a lU n i v e r s i t y ,H oh h o t ,I n n e rM o n g o li a 010019,C h i n a ;2.F o r e s t r y a n dG r a s s l a n dB u r e a uo fK e s h i k e t e n g B a n n e r ,C h i f e n g ,I n n e rM o n g o l i a 025300,C h i n a ;3.G r e e nS t a t i o n E n v i r o n m e n t a l P r o t e c t i o n M o n i t o r i n g S t a t i o no fK e s h i k e t e n g B a n n e r ,C h i f e n g ,I n n e rM o n g o l i a 025300,C h i n a )A b s t r a c t :I no r d e r t o e x p l o r e t h e o p t i m a l e x t r a c t i o n p r o c e s s a n d a n t i o x i d a n t a c t i v i t y of t o t a l f l a v o n o i d s a n d t o t a l p h e n o l i ca c i d si n w i l d L e o n t o p o d i u ml e o n t o po d i o i d e s ,t h ee f f e c t so fe x t r a c t i o nt e m p e r a t u r e ,c y c l e t i m e s ,h e a t i n g ti m e a n d e x t r a c t i o n p r e s s u r e o n t h e e x t r a c t i o nc o n t e n t o f t o t a l f l a v o n o i d s a n d t o t a l p h e n o l i c a c i d s i n L e o n t o p o d i u ml e o n t o po d i o i d e s w e r ee x p l o r e db y r a p i ds o l v e n t e x t r a c t i o n ,a n d t h eo p t i m a l e x t r a c -t i o n p r o c e s s o f a c t i v e s u b s t a n c e sw a s d e t e r m i n e db y t h e s i n g l e -f a c t o r e x p e r i m e n t a n d t h e r e s p o n s e s u r f a c e d e s i g n .T h e r e s u l t s s h o w e d t h a t t h e o pt i m a l e x t r a c t i o n p r o c e s s f o r t h e e x t r a c t i o no f t o t a l f l a v o n o i d s i n L e -o n t o p o d i u ml e o n t o po d i o i d e s u s i n g 70%e t h a n o lw a s 93ħe x t r a c t i o n t e m p e r a t u r e ,3t i m e s ,20m i n e x t r a c t i o n t i m e ,a n d 102b a r e x t r a c t i o n p r e s s u r e .E x t r a c t i o nc o n t e n tw a s (45.45ʃ0.36)m g ㊃g -1.T h eb e s t e x t r a c -t i o n p r o c e s s o f t o t a l p h e n o l i c a c i dw a s 90ħe x t r a c t i o nt e m pe r a t u r e ,3t i m e s ,19m i ne x t r a c t i o n ,a n d97b a r e x t r a c t i o n p r e s s u r e .E x t r a c t i o n c o n t e n tw a s (23.52ʃ0.34)m g ㊃g -1.T h e I C 50o f L e o n t o p o d i u m l e o n t o po -d i o i d e s t o t a l f l a v o n o i d e x t r a c t a g a i n s tD P P Hr a d i c a l s a n dA B T S r a d i c a l sw e r e 0.012m g㊃m L -1a n d 0.356草地学报第32卷m g㊃m L-1,r e s p e c t i v e l y.I t h a da c e r t a i nr e d u c i n gp o w e r.T h i s s t u d yp r o v i d e da r e l i a b l e t h e o r e t i c a l b a s i s a n dd e t a i l e d s c i e n t i f i c r e f e r e n c e f o r t h e e x t r a c t i o n p r o c e s s a n d p r o c e s s i n g a n du t i l i z a t i o no f t h e a c t i v e s u b-s t a n c e o f L e o n t o p o d i u ml e o n t o p o d i o i d e s.K e y w o r d s:L e o n t o p o d i u m l e o n t o p o d i o i d e s(W i l d.)B e a u v;T o t a l f l a v o n o i d s;T o t a l p h e n o l i c a c i d s;A c c e l e r a t e d s o l v e n t e x t r a c t i o n;R e s p o n s e s u r f a c em e t h o do p t i m i z a t i o n;A n t i o x i d a n t a c t i v i t y火绒草(L e o n t o p o d i u m l e o n t o p o d i o i d e s (W i l d.)B e a u v.)是菊科火绒草属(L e o n t o p o d i u m)多年生草本植物[1],广泛分布于世界各地,常见于欧洲和亚洲的寒带㊁温带和亚热带地区[2]㊂在我国约有41种火绒草属植物,主要分布于我国的东北㊁西北㊁华北和西南地区,其中有20多种在民间作为药用植物[3]㊂近年来有关火绒草化学成分及其药理活性研究较多,从火绒草属中发现了多种具有药理活性的化合物㊂如黄酮类㊁苯丙素类㊁葡萄糖二酸类等化合物[4-5]㊂现已将火绒草提取物用于治疗腹部疾病㊁心脏病㊁腹泻㊁痢疾㊁肺炎㊁扁桃体炎和各种癌症等多种人类和牲畜疾病,其中具有主要药理活性的成分是黄酮类及酚酸类物质[6-7],绿原酸和阿魏酸等成分具有明显抗氧化作用[8]㊂目前,人们通常使用热回流提取法㊁超声波辅助提取法㊁二氧化碳超临界流体萃取法等方法来萃取火绒草中的活性物质[9-10],但上述方法存在效率低㊁时间长㊁不环保等问题㊂本试验中使用的快速溶剂萃取法是一种新型提取技术,在高温高压条件下使用有机溶剂萃取固体或半固体样品的一种全自动萃取技术,具有成本低㊁萃取率高㊁萃取时间短㊁萃取纯度高㊁绿色环保等优点[11-12]㊂近年来,随着活性物质提取工艺的发展,该技术已逐渐应用到提取多酚㊁多糖类化合物当中[13]㊂孙海燕等[14]采用快速溶剂萃取法及正交试验对樱桃(P r u n u s p s e u d o c e r a s u s L i n d l.)核中类黄酮提取工艺进行优化;王国明等[15]研究发现使用快速溶剂萃取法萃取人参(P a n a x g i n s e n g C.A.M e y.)多糖得率高于传统的水提法㊂本研究以野生火绒草为原料,采用快速溶剂萃取法探究萃取时间㊁循环次数㊁加热时间及萃取压力等参数对总黄酮与总酚酸影响,通过响应面法对提取工艺进行优化,为火绒草开发利用提供详实的资料㊂1材料与方法1.1试验材料供试火绒草样品于2022年8月取自内蒙古自治区赤峰市克什克腾旗,经鉴定为菊科火绒草属长叶火绒草(L e o n t o p o d i u m j u n p e i a n u m K i t a m.),将样品阴干,用粉粹机磨成粉,过60目筛后备用㊂1.2供试品溶液制备精密称取火绒草3g,置于40m L萃取池中,加入一定量的石英砂,以70%乙醇作为提取溶剂,按一定条件进行萃取,过滤,用70%乙醇定容至50 m L,即得供试品溶剂,冷藏保存,备用㊂1.3总黄酮含量检测方法参照Z h i等[16-18]方法,稍作修改㊂取200μL不同浓度的芦丁对照品与40μL质量分数为5%的N a N O2溶液反应6m i n后加入40μL质量分数10%的A l(N O3)3溶液,放置6m i n,再加入400μL1m o l㊃L-1的N a O H和400μL的蒸馏水,摇匀,放置15m i n后,在510n m处测定吸光度㊂以质量浓度为横坐标,吸光度为纵坐标,构建标准曲线方程㊂得线性回归方程: y=5.9056x-0.0025R2=0.9994取200μL供试溶剂,按标准曲线方法检测供试溶剂总黄酮吸光度,参照公式计算出总黄酮含量㊂M=(CˑVˑn)/m式中M为黄酮含量,单位:m g㊃g-1;C为浓度,单位:m g㊃m L-1;V为体积,单位:m L;n为倍数;m为质量,单位:g㊂1.4总酚酸含量检测方法参照N a i d u等[19-20]方法,稍作修改㊂取200μL 不同浓度没食子酸标品与0.5m L F o l i n-C i o c a l t e u 试剂充分混匀,5m i n后加入1.5m L质量分数为20%的N a C O3溶液,蒸馏水定容至10m L,置于75ħ水浴中避光反应10m i n,在765n m处测定吸光度值㊂以质量浓度为横坐标,吸光度为纵坐标,构建标准曲线方程㊂得线性回归方程:y=49.229x+0.0075R2=0.9991取200μL供试溶剂,按标准曲线方法检测供试溶剂总酚酸吸光度,参照公式计算出总酚酸含量㊂M=(CˑVˑn)/m式中M为黄酮含量,单位:m g㊃g-1;C为浓度,单位:m g㊃m L-1;V为体积,单位:m L;n为倍数;m为质量,单位:g㊂639第3期意如乐等:响应面法优化火绒草中总黄酮与总酚酸的提取工艺研究1.5 抗氧化活性测定1.5.1 D P P H 自由基清除试验 参照W a n g 等[21]方法,取1.5m L 不同浓度的火绒草提取液(0.02,0.04,0.06,0.08,0.1m g ㊃mL -1)与0.75m L 的0.1m o l ㊃m L -1D P P H 溶液充分混匀,避光反应30m i n 后以无水乙醇作为空白在517n m 处测定吸光度,得A 1㊂取1.5m L 不同浓度的火绒草提取液与0.75m L 无水乙醇混匀,避光反应30m i n 后在517n m 处测定吸光度,得A 2㊂取1.5m L 无水乙醇与0.75m L 的0.1m o l ㊃m L -1D P P H 溶液混匀,避光反应30m i n 后在517n m 处测定吸光度,得A 0㊂以抗坏血酸作为阳性对照㊂根据吸光值计算D P P H清除率,并计算火绒草对D P P H 自由基的半数清除率I C 50㊂D P P H 自由基清除率%=[1-(A 1-A 2)/A 0]ˑ100%1.5.2 A B T S 自由基清除试验 参照L i a n g 等[22]方法,取3.9m L 的A B T S 反应液分别加入100μL 不同浓度的火绒草提取液(0.02,0.04,0.06,0.08,0.1m g ㊃m L -1)A 2或100μL 无水乙醇溶液A 1,避光反应30m i n 后,在734n m 处测定吸光值㊂以抗坏血酸作为阳性对照㊂根据吸光值计算A B T S 清除率,并计算火绒草对A B T S 自由基的I C 50㊂A B T S 自由基清除率%=[(A 1-A 2)/A 1)]ˑ100%1.5.3 总还原力测定试验 参照刘秀敏等[23]方法,稍作修改㊂取1m L 不同浓度的供试溶剂分别加入0.2m L 浓度为0.2m o l㊃L -1的磷酸盐缓冲溶液(p H6.6)和0.5m L 质量分数为5%的氢化钾,摇匀后置于50ħ水浴中反应20m i n ㊂反应结束后迅速冷却,加入1m L 质量分数为10%三氯乙酸后在5000r ㊃m i n -1下离心10m i n ,取1.5m L 上清液加入0.2m L 质量分数为1%的F e C l 3和3m L 蒸馏水静置10m i n 后在700n m 处测定吸光度,以抗坏血酸作为阳性对照㊂吸光值越大表示样品还原力越强㊂1.6 火绒草总黄酮、总酚酸提取的单因素试验采用快速溶剂萃取仪提取火绒草中总黄酮与总酚酸,主要考察萃取温度(45ħ,60ħ,75ħ,90ħ和105ħ)㊁循环次数(1,2,3,4和5次)㊁提取时间(5,10,15,20和25m i n )和萃取压力(80,90,100,110和120b a r )等4个因素对火绒草总黄酮和总酚酸提取率的影响㊂以萃取温度45ħ㊁循环一次㊁提取5m i n 和80b a r 设置为单因素基础条件,当研究某一因素时确定其他因素保持不变㊂所得提取液按照标准曲线方法测定吸光度,计算总黄酮与总酚酸含量㊂1.7 响应面试验优化火绒草总黄酮和总酚酸提取工艺基于B o x -B e n h n k e n 试验设计,综合单因素试验结果,固定萃取投料量3g ,以总黄酮和总酚酸含量为响应值,选择萃取温度(A )循环次数(B )提取时间(C )和萃取压力(D )为自变量,设计四因素三水平响应面优化试验,确定最佳提取工艺条件,验证最佳提取方法㊂方案如表1所示㊂表1 响应面试验因素与水平T a b l e 1 F a c t o r s a n d l e v e l s o f r e s po n s e s u r f a c e t e s t 水平L e v e l因素f a c t o rA 萃取温度E x t r a c t i o n t e m pe r a t u r e /ħB 循环次数C yc l e s C 时间T i m e /m i nD 萃取压力E x t r a c t i o n p r e s s u r e /b a r-1752159009032010011054251101.8 数据统计分析利用E x c e l 2016整理试验数据作表,利用O r i gi n2021软件作图,利用S P S S24软件进行方差分析,所有试验均重复3次利,用D e s i gi n -E x -pe r t 11软件进行响应面试验分析㊂P <0.05表示具有显著性差异,P <0.01表示具有极显著性差异㊂2 结果与分析2.1 提取火绒草总黄酮的单因素试验由图1可知,在萃取温度为45ħ~90ħ时,随着温度的增加提取含量随之上升,萃取温度为90ħ时提取含量最高;继续提高温度,总黄酮提取含量有所下降;在循环1~3次时,随着次数的增加提取含739草 地 学 报第32卷量有所上升,循环次数为3时提取含量最高,继续增加次数,总黄酮提取含量并没有得到增加,分析是火绒草在提取溶剂中的溶解度达到了饱和,不在溶出;在提取时间5~20m i n 时,随着时间的增加提取含量上升,15m i n 时提取含量达到最高值;在25m i n 后总黄酮提取含量有所下降;在萃取压力80~100b a r 时,随着压力的增加提取含量有所上升,在100b a r 时提取含量达到最高值,在120b a r 时总黄酮提取含量虽有上升趋势,但是没有超过最高值,在高温高压条件下黄酮类的结构可能发生变化,因此将75ħ~105ħ㊁2~4次㊁15~25m i n ㊁90~110b a r 设定为各因素考察范围㊂图1 火绒草总黄酮的单因素试验结果F i g .1 R e s u l t s o f a s i n g l e -f a c t o r t e s t o f t o t a l f l a v o n o i d s i n L e o n t o p o d i u m l e o n t o po d i o i d e s 2.2 提取火绒草总酚酸的单因素试验由图2可知,在90ħ时,提取含量达到最高,为20.63m g ㊃g -1;但温度达到105ħ时总酚酸提取含量有所下降;在循环1~3次时,随着次数的增加提取含量上升,但循环次数超过3时提取含量迅速下降;在提取5~15m i n 时,提取含量并没有明显上升,20m i n 后提取含量迅速上升,到达最高点;在萃取压力为80~100b a r 时,随着压力的增加提取含量有所上升,在100b a r 时提取含量达到最高值,之后下降㊂因此将75ħ~105ħ㊁2~4次㊁15~25m i n ㊁90~110b a r 设定为提取考察范围㊂839第3期意如乐等:响应面法优化火绒草中总黄酮与总酚酸的提取工艺研究图2 火绒草总酚酸的单因素试验结果F i g .2 R e s u l t s o f a s i n g l e f a c t o r t e s t o f t o t a l p h e n o l i c a c i d s i n L e o n t o p o d i u m l e o n t o po d i o i d e s 2.3 响应面试验优化分析2.3.1 响应面多元回归方程建立 以火绒草总黄酮与总酚酸的含量为响应值,采用四因素三水平的响应面试验设计得到最佳提取工艺参数,试验结果见表2,方差分析结果见表格3㊂对表2中响应面的结果进行了多元回归方程拟合,并获得以火绒草总黄酮含量和总酚酸含量为响应值的多元回归方程:Y 1=-337.35+1.32A+20.76B+4.49C+4.87D-0.07A B+0.001A C-0.002A D-0.0024B C-0.066B D-0.0067C D -0.0049A 2-1.37B 2-0.098C 2-0.021D 2,Y 2=-173.6+1.9442A+9.2442B +1.3468C +1.6664D-0.047A B -0.002A C -0.005A D+0.0395B C-0.005B D-0.003C D-0.007A 2-0.885B 2-0.026C 2-0.006D2㊂由表3可知,该模型极显著(P <0.01),失拟项不显著,R 2,R 2A d j,R 2P r e d 及变异系数均在可接受范围内,说明模型具有较高的拟合度和可信度,可较好的分析与预测火绒草的提取工艺条件;其中A ,B ,C 和BD 对总黄酮提取含量有显著影响(P <0.05),D ,A B ,A 2,B 2,C2和D 2对总黄酮提取含量有极显著影响(P <0.01);而A ,D ,A B ,A D ,及二次项A 2,B 2,C2和D 2对总酚酸含量均有极显著影响㊂各因素对总黄酮提取含量的影响从高到低为:压力>温度>循环次数>提取时间;各因素对总酚酸提取含量的影响从高到低为:压力>温度>提取时间>循环次数㊂939草 地 学 报第32卷表2 火绒草总黄酮、总酚酸提取工艺条件响应面优化方案及结果T a b l e 2 O p t i m i z a t i o n s c h e m e a n d r e s u l t s o f r e s p o n s e s u r f a c e o f t o t a l f l a v o n o i d s a n d t o t a l ph e n o l i c a c i de x t r a c t i o n p r o c e s s o f L e o n t o p o d i u m l e o n t o po d i o i d e s 试验号T e s t n u m b e rA :温度E x t r a c t i o nt e m pe r a t u r e /ħB :循环次数C y c l e s C :时间T i m e /m i n D :压力E x t r a c t i o n p r e s s u r e/b a rY 1总黄酮含量T o t a l f l a v o n o i d c o n t e n t /m g㊃g -1Y 2总酚酸含量T o t a l ph e n o l i c a c i d c o n t e n t /m g㊃g -11-1-1042.6320.1921-10044.5321.983-110043.6621.844110041.6420.79500-1-139.7322.546001-139.4822.79700-1143.1922.268001141.621.979-100-140.5720.3510100-142.6122.7511-100142.7321.1312100143.3520.46130-1-1042.2422.011401-1041.8121.57150-11041.8421.5616011040.9421.9117-10-1041.6721.231810-1042.8521.8419-101041.0421.0720101042.5721.14210-10-141.3222.4622010-142.0322.29230-10143.4721.9124010141.5521.5525000045.4423.4126000045.2223.1327000045.8723.7528000045.2623.67290046.0123.47表3 响应面回归模型方差分析T a b l e 3 R e s p o n s eR e g r e s s i o nm o d e l v a r i a n c e a n a l ys i s 方差来源S o u r c e平方和S u mo f s q u a r e s 自由度D F均方M e a ns qu a r e F 值P 值Y 1Y 2Y 1Y 2Y 1Y 2Y 1Y 2Y 1Y 2模型M o d e l81.325.4214145.811.8220.2723.05<0.0001<0.0001A -温度T e m p e r a t u r e 2.30.8269112.30.82698.0210.50.01330.0059B -循环次数C y c l e s 1.610.0021111.610.00215.630.02710.03250.8716C -时间T i m e 1.350.085111.350.0854.71.080.04790.3165D -压力P r e s s u r e 8.591.27118.591.2729.9616.09<0.00010.0013A B3.842.02113.842.0213.4125.60.00260.0002A C 0.03060.0729110.03060.07290.10690.92550.74860.3523A D 0.50412.36110.50412.361.7629.910.2059<0.0001B C 0.05520.156110.05520.1560.19271.980.66730.1811B D 1.730.009111.730.0096.040.11460.02770.74C D 0.44890.0729110.44890.07291.570.92550.23120.3523A 27.7415.51117.7415.5127.02196.920.0001<0.0001B 212.115.081112.115.0842.2664.51<0.0001<0.0001C 239.052.791139.052.79136.335.48<0.0001<0.0001D 229.152.221129.152.22101.7428.19<0.00010.0001残缺R e s i d u a l 4.011.114140.28650.0788失拟项L a c ko f f i t 3.490.866410100.34930.08662.691.470.1760.3798纯误差P u r e e r r o r 0.51860.2363440.12960.0591总误差C o r t o t a l85.3226.522828R 20.9530.9584R 2A d j 0.9060.9169R 2P r e d 0.7550.7979变异系数C V1.261.2849第3期意如乐等:响应面法优化火绒草中总黄酮与总酚酸的提取工艺研究2.3.2 响应面交互作用分析 如图3a ~3b 所示,循环次数不变时,总黄酮提取含量随着萃取温度的增加先呈上升后下降的趋势;当萃取温度不变时,总黄酮提取含量随着循环次数的增加同样先呈上升后下降的趋势㊂萃取温度与循环次数的等高线图呈椭圆状,说明两项之间的交互影响较强;从等高线图和三维图的倾斜度可知,萃取温度对总黄酮提取含量的影响大于循环次数㊂从图3c ~3d 可知,循环次数不变时,总黄酮提取含量随着萃取压力的增大先呈略上升后下降的趋势;当萃取压力不变时,总黄酮提取含量随着循环次数的增加先呈升高后略微下降的趋势㊂从等高线图和三维图的倾斜度可知,萃取压力对总黄酮提取含量的影响略大于循环次数㊂如图4a ~4b 所示,萃取温度不变时,总酚酸提取含量随着循环次数的增加呈上升后迅速下降趋势;当循环次数不变时,总酚酸提取含量随着萃取温度的增加先呈上升后略微下降趋势㊂从等高线图和三维图的倾斜度可知,萃取温度对总酚酸提取含量的影响大于循环次数㊂从图4c ~4d 可知,萃取温度不变时,总酚酸提取含量随着萃取压力的增大先呈略上升后下降的趋势;当萃取压力不变时,响应面值随着萃取温度的增加先呈升高后下降趋势㊂从等高线图和三维图的倾斜度可知,萃取压力对总酚酸提取含量的影响大于萃取温度㊂综上可知,结合模型结果和等高线得到提取总黄酮最佳工艺为:萃取温度92.62ħ,循环次数2.82次,提取时间19.66m i n ,萃取压力102.15b a r,总黄酮提取含量为45.92m g㊃g -1㊂根据实际情况,修改为萃取温度93ħ,循环次数3次,提取时间20m i n,萃取压力102b a r㊂总酚酸最佳提取工艺为:萃取温度93.117ħ,循环次数2.914次,提取时间19.72m i n,萃取压力95.963b a r ,总酚酸提取含量为23.582m g ㊃g -1㊂根据实际情况,修改为萃取温度93ħ,循环次数3次,提取时间20m i n ,萃取压力96b a r㊂在所得最佳提取工艺条件下进行3次平行验证试验,总黄酮提取含量为(45.45ʃ0.36)m g ㊃g -1,总酚酸提取含量为(23.52ʃ0.34)m g ㊃g -1,与模型得到的预测值相近,表明该模型优化参数稳定,且具有较高的可靠性㊂图3 各因素交互作用对总黄酮提取含量影响F i g.3 F a c t o r i n t e r a c t i v e e f f e c t s o n t h e c o n t e n t o f t o t a l f l a v o n o i de x t r a c t i o n 2.4 抗氧化活性研究2.4.1 火绒草总黄酮对D P P H 自由基的消除影响以抗坏血酸作为阳性对照,火绒草总黄酮对D P -P H 自由基的消除作用如图5所示,随着质量浓度的增加D P P H 自由基消除率持续上升,火绒草总黄酮质量浓度与D P P H 自由基清除率呈正相关作用,149草 地 学 报第32卷其I C 50为0.012m g ㊃m L -1㊂当火绒草质量浓度达到0.08m g㊃m L -1时消除率可达到80%以上㊂虽然低于抗坏血酸,但是对于D P P H 自由基,火绒草总黄酮表现出较好的消除作用㊂图4 各因素交互作用对总酚酸提取含量影响F i g .4 T h e e f f e c t s o f f a c t o r i n t e r a c t i o no n t h e e x t r a c t i o n c o n t e n t o f t o t a l ph e n o l i c a c i de x t r a c t i on 图5 火绒草对D P P H 的消除作用F i g .5 T h e e l i m i n a t i o ne f f e c t o f L e o n t o po d i u m l e o n t o po d i o i d e s o nD P P H 2.4.2 火绒草总黄酮对A B T S 自由基的消除影响以抗坏血酸作为阳性对照,火绒草总黄酮对A B T S 自由基的消除作用如图6所示,随着质量浓度的增加A B T S 自由基消除率呈缓慢上升的趋势,火绒草总黄酮质量浓度与A B T S 自由基清除率呈正相关作用,其I C 50为0.356m g ㊃m L -1㊂与相同浓度的抗坏血酸相比,火绒草总黄酮对A B T S 的清除率低于抗坏血酸㊂但也能表现出一定的消除能力㊂图6 火绒草对A B T S 的消除作用F i g.6 T h e e l i m i n a t i o ne f f e c t o f L e o n t o p o d i u m l e o n t o po d i o i d e s o nA B T S 2.4.3 火绒草总黄酮的总还原力 以抗坏血酸作为阳性对照,火绒草总黄酮的还原力如图7所示,随着质量浓度的增加吸光度呈上升的趋势,说明火绒249第3期意如乐等:响应面法优化火绒草中总黄酮与总酚酸的提取工艺研究草总黄酮质量浓度与总还原力呈正相关㊂虽然总还原力低于抗坏血酸,但还是能表现出具有一定的还原能力㊂图7 火绒草总还原力F i g .7 T o t a l r e d u c i n gp o w e r o f L e o n t o po d i u m l e o n t o po d i o i d e s 3 讨论本试验采用快速溶剂萃取法得出了火绒草中总黄酮与总酚酸的最佳提取工艺条件㊂快速溶剂萃取法是一种新兴的高压自动萃取技术[24],通过改变萃取温度㊁提取时间㊁循环次数以及萃取压力等因素来提高活性物质的提取率㊂C h u a n g 等[25]研究表明,与索式提取和热回流提取相比,快速溶剂萃取法是一种简单㊁有效㊁省时又先进的一项技术㊂王铎[26]分别采用超声提取㊁回流提取㊁温浸提取以及快速溶剂萃取四种方法对甘草(G l y c yr r h i z au r a l e n s i s F i s c h .)中的总黄酮进行了提取,结果表明快速溶剂萃取法对甘草中总黄酮的提取为最佳,平均总黄酮含量达到10.63m g ㊃g -1;C h a m a l i 等[27]探索出快速溶剂萃取法萃取桉树(E u c a l y pt u s s p p .)总酚酸的最佳提取方法为:提取温度179ħ㊁提取时间36m i n㊂而有关火绒草活性物质提取㊁纯化工艺方面的研究较少,本研究对火绒草总黄酮与总酚酸提取工艺优化进行了初步探索,为后续火绒草活性物质开发利用提供有效的技术支撑㊂本研究中火绒草总黄酮提取含量受萃取温度㊁萃取次数㊁加热时间和萃取压力的影响,其中提取时间的影响最小㊂唐巧玉等[28]研究使用快速溶剂萃取法提取水芹(O e n a n t h e ja v a n i c a (B l u m e )D C .)中总黄酮时得出提取时间对总黄酮提取含量的的影响较小㊂而吴桐[29]在研究中指出影响芦丁㊁金丝桃苷提取效果的因素顺序为提取温度>循环次数>提取压力>提取时间,这与本试验的结果有相同之处㊂原因可能是快速溶剂萃取法本身是一种快速提取的方法,大大节约了萃取时间,从而导致提取时间对提取率没有较大影响㊂刘叶等[30]采用单因素试验研究了快速溶剂萃取仪提取葡萄(V i t i s v i n i f e r a L .)籽中多酚物质的工艺并进行了正交试验优化,在文中指出影响提取含量的主要影响因素为提取时间其次是提取温度,提取压力的影响效果最小,与本试验结果存在差异,可能是因为本试验中萃取压力设置的水平之间差异较大,从而导致萃取压力对总酚酸提取含量影响较大㊂W a n g 等[31]在研究中提出随着温度㊁循环次数㊁提取时间和萃取压力的增加总酚酸含量有所上升,到达一定程度后又开始下降,在本试验结果中也存在这种现象,而这种现象可用快速溶剂萃取仪的基本原理来解释:高压的应用使萃取溶剂高于其沸点,并迫使溶剂扩散进入样品基质,而更高的温度使得溶剂具有更好的溶解能力和更低的粘度,并减弱样品与溶剂之间的相互作用,从而增加了传质,提高了萃取率[32-33]㊂本研究通过测定火绒草总黄酮提取液对D P -P H ㊁A B T S 自由基的消除率及总还原力来检测火绒草活性物质的抗氧化活性㊂D P P H 自由基在可见光范围内有特征吸收[34],A B T S 自由基会被抗氧化物抑制[35],因此都是测定抗氧化活性的重要指标㊂总还原力是测定潜在抗氧化活性的重要指标,其机理是通过样品将F e 3+还原成F e2+,中断自由基的链式反应[36]㊂展锐等[37]通过测定火绒草提取物的总还原力㊁羟自由基清除能力等比较了火绒草醇提物和水提物的抗氧化活性,结果表明,火绒草提物都具有较强的抗氧化活性,且醇提物的作用比水提物更有佳㊂吴楠贞等[3]研究发现火绒草醇提物有较强的抗氧化活性,这与本研究结果相似㊂综上所述,火绒草提取物可作为一种天然的抗氧化剂,有清除体内的自由基和抗脂质氧化等功能㊂4 结论本试验以火绒草为原料使用快速溶剂萃取法萃取火绒草中总黄酮与总酚酸,结果表明,总黄酮最佳提取方法为:萃取温度93ħ,循环次数3次,提取时间20m i n ,萃取压力102b a r;总酚酸最佳提取方法为:萃取温度93ħ,循环次数3次,提取时间20m i n ,萃取压力96b a r㊂验证试验结果表明,总黄酮提取含量为(45.45ʃ0.36)m g ㊃g -1,总酚酸提取含量为(23.52ʃ0.34)m g ㊃g -1,与模型拟合度高,可用于优化提取工艺㊂349草地学报第32卷本试验对火绒草总黄酮提取液进行了抗氧化活性研究,研究发现,火绒草总黄酮提取液对D P P H 自由基的I C50为0.012m g㊃m L-1;对A B T S自由基的I C50为0.356m g㊃m L-1;具有一定还原力,说明火绒草具有较好的抗氧化活性㊂参考文献[1]马晓玲,陈秋,夏提古丽,等.火绒草化学成分的分离与鉴定[J].沈阳药科大学学报,2018,35(9):729-732[2]李礼,张国刚,左甜甜,等.中药火绒草化学成分的研究(Ⅱ)[J].中南药学,2008(4):422-423[3]吴楠贞,展锐,苟萍.火绒草抗氧化活性成分及其结构分析[J].天然产物研究与开发,2013,25(3):296-301[4]肖阳央,苟萍,谢海辉.火绒草的苯丙素类成分[J].热带亚热带植物学报,2017,25(2):195-201[5]黄利权,伍义行.火绒草及火绒草属植物研究进展[J].中兽医医药杂志,2004(3):24-26[6] H O R N I C KA,S C HW A I G E R S,R O L L I N G E R JM,e t a l.E x t r a c t sa n dc o n s t i t u e n t s o f L e o n t o p o d i u m a l p i n u m e n h a n c e c h o l i n e r g i ct r a n s m i s s i o n:B r a i nA C h i n c r e a s i n g a n dm e m o r y i m p r o v i n gp r o p e r-t i e s[J].B i o c h e m i c a l P h a r m a c o l o g y,2008,76(2):236-248 [7]杨正明,地久此呷,兰建龙,等.基于U P L C指纹图谱及多成分含量测定的火草质量控制研究[J].中国中药杂志,2023,48(11):3000-3013[8]赵玥,张颖,王光函,等.基于抗氧化作用的火绒草药效物质基础研究[J].时珍国医国药,2021,32(8):1871-1873 [9]杨金部,袁桢燕,苟萍,等.火绒草种子萌发特性的研究[J].种子,2020,39(5):77-80[10]赵小燕,李波,杨正明,等.坚杆火绒草中总酚酸的提取及含量测定[J].中国实验方剂学杂志,2015,21(9):19-21 [11]潘春媛,武瑞,贾永全,等.火绒草乙醇提取物的化学成分研究[J].黑龙江八一农垦大学学报,2011,23(4):50-52[12]B O B I N A I TR,K R A U J A L I SP,T AMK U L,e t a l.R e c o v e r y o fb i o ac t i v e s u b s t a n c e sf r o m r o w a n b e r r yp o m a c eb y c o n s e c u t i v ee x t r a c t i o n w i t h s u p e r c r i t i c a lc a r b o n d i o x i d ea n d p r e s s u r i z e ds o l v e n t s[J].J o u r n a l o f I n d u s t r i a l a n dE n g i n e e r i n g C h e m i s t r y, 2020(85):152-160[13]闫佳佳,万璐,吴桐,等.快速溶剂萃取技术在2种食药用真菌多糖提取中的应用[J].中国农学通报,2021,37(16):150-155 [14]孙海燕.樱桃核中类黄酮快速溶剂萃取工艺优化及抗氧化研究[J].食品工业,2017,38(8):106-109[15]王国明,徐清华,徐芳菲,等.快速溶剂萃取仪提取人参多糖的工艺研究[J].人参研究,2019,31(6):2-6[16]Y I ZB,Y U Y,L I A N GYZ,e t a l.I n v i t r o a n t i o x i d a n t a n d a n-t i m i c r o b i a l a c t i v i t i e s o f t h e e x t r a c t o f P e r i c a r p i u mC i t r i R e t i c u-l a t a e o fa n e w C i t r u sc u l t i v a ra n di t s m a i nf l a v o n o i d s[J].L WT-F o o dS c i e n c e a n dT e c h n o l o g y,2008,41(4):597-603 [17]李红,李波,李晨阳,等.大孔树脂纯化苜蓿总黄酮及纯化前后抗氧化能力比较[J].草地学报,2022,30(3):750-757 [18]郝宁,张晓明,穆赢通,等.红三叶个体水平异黄酮含量的差异及其形态特征和草产量比较研究[J].草地学报,2023,31(1):196-201[19]N A I D U M M,S H Y AMA L ABN,N A I KJ P,e t a l.C h e m i c a lc o m p o s i t i o n a nd a n t i o x i d a n t a c t i v i t y o f t he h u s k a n d e n d o s p e r mo f f e n u g r e e ks e e d s[J].L WT-F o o dS c i e n c ea n d T e c h n o l o g y, 2011,44(2):451-456[20]陈誉华,魏元浩,吉慧敏,等.褐藻多酚提取物对奶牛瘤胃发酵性能及主要瘤胃细菌含量的影响[J].草地学报,2023,31(8): 2343-2351[21]WA N GSP,D O N GXF,T O N GJM.O p t i m i z a t i o no f e n z y m e-a s s i s t e de x t r a c t i o no f p o l y s a c c h a r i d e s f r o m a l f a l f aa n d i t sa n-t i o x i d a n t a c t i v i t y[J].I n t e r n a t i o n a l J o u r n a l o fB i o l o g i c a lM a c-r o m o l e c u l e s,2013(62):387-396[22]J I N GCL,D O N GXF,T O N GJM.O p t i m i z a t i o no fU l t r a s o n-i c-A s s i s t e dE x t r a c t i o n o f F l a v o n o i dC o m p o u n d s a n dA n t i o x i d a-n t s f r o m A l f a l f a U s i n g R e s p o n s eS u r f a c e M e t h o d[J].M o l e-c u l e s,2015,20(9):15550-15571[23]刘秀敏,单春会,张雪,等.超声波辅助提取红枣中黄酮类物质的研究[J].食品研究与开发,2021,42(17):107-113 [24]王慧颖,刘燕飞,张敬远,等.响应面法优化龙须菜多糖快速溶剂萃取提取工艺及其抗炎活性研究[J].食品工业科技,2023, 44(23):110-117[25]C HU A N G Y H,Z HA N G YJ,Z H A N G W,e t a l.C o m p a r i s o no f a c c e l e r a t e ds o l v e n te x t r a c t i o na n d q u i c k,e a s y,c h e a p,e f f e c-t i v e,r u g g e da n ds a f em e t h o df o re x t r a c t i o na n dd e t e r m i n a t i o n o f p h a r m a c e u t i c a l s i nv e g e t a b l e s[J].J o u r n a l o fC h r o m a t o g r a-p h y A,2015(1404):1-9[26]王铎.甘草中黄酮类化合物的分离提取及抗氧化活性评价研究[D].长春:长春师范学院,2011:16[27]S A O U S A NC,H O U C I N EB,J A L L O U LB,e t a l.O p t i m i z a t i o no f a c c e l e r a t e ds o l v e n te x t r a c t i o no fb i o a c t i v ec o m p o u n d s f r o mE u c a l y p t u s i n t e r t e x t au s i n g r e s p o n s e s u r f a c em e t h o d o l o g y a n de v a l u a t i o nof i t s p h e n o l i cc o m p o s i t i o na n db i o l og i c a l a c t i v i t i e s[J].J o u r n a l o fA p p l i e dR e s e a r c ho n M e d i c i n a l a n d A r o m a t i c P l a n t s,2023(35):100464[28]唐巧玉,周毅峰.快速溶剂萃取法提取水芹中总黄酮工艺研究[J].食品科学,2010,31(22):190-193[29]吴桐,徐慧春,郑春英,等.快速溶剂萃取法提取刺五加叶中的黄酮类成分[J].中国食品学报,2013,13(7):59-65 [30]刘叶,李华,郑亚蕾,等.快速溶剂萃取仪提取葡萄籽中多酚物质的工艺优化[J].食品工业科技,2015,36(18):244-247 [31]WA N GZR,B I N GY,X UHU I C,e t a l.O p t i m i z a t i o n a n d c o m-p a r i s o no fn o n c o n v e n t i o n a le x t r a c t i o nt e c h n i q u e sf o rs o l u b l e p h e n o l i cc o m p o u n d sf r o m b r o c a d eo r a n g e(C i t r u ss i n e n s i s) p e e l s.[J].J o u r n a l o f f o o d s c i e n c e,2022,87(11):4917-4929[32]T H I B A U L T L,E M I L I E D,E R I C L.S e l e c t i v ee x t r a c t i o no fb i o ac t i v e c o m p o u nd s f r o m p l a n t su s i n g re c e n t e x t r a c t i o nt e c h-n i q u e s:A r e v i e w[J].J o u r n a lo f C h r o m a t o g r a p h y A,2021 (1635):461770[33]S U N H,G EX,L I U Y,e t a l.A p p l i c a t i o n o f a c c e l e r a t e d s o l v e n te x t r a c t i o ni nt h ea n a l y s i so fo r g a n i cc o n t a m i n a n t s,b i o a c t i v ea n dn u t r i t i o n a lc o m p o u n d si nf o o da n df e e d[J].J o u r n a lo fC h r o m a t o g r a p h y A,2012(1237):1-23[34]许英一,王宇,杨伟光.紫花苜蓿叶总黄酮提取及抗氧化性[J].草地学报,2018,26(3):757-763[35]吴静,顾震,谢传奇,等.油茶果壳多糖纯化工艺及其抗氧化活性研究[J].食品工业,2023,44(11):72-76[36]黎侠,童健全,叶立红,等.菊属花茶活性物质含量及体外抗氧化活性的比较研究[J].浙江农业科学,2023,64(10):2521-2524 [37]展锐,库尔班,苟萍,等.火绒草提取物抗氧化活性的研究[J].食品科学,2010,31(3):153-159(责任编辑刘婷婷)449。

操作说明书MC买方买方订单号用户项目安装地位号苏尔寿设备号苏尔寿订单号泵型号苏州苏尔寿泵业有限公司目录1. 总论1.1 关于本说明书1.2 保修1.3 操作说明书型号2. 安全2.1 操作说明书中的说明符号2.2 人员资质和培训2.3 不遵守安全规则的危险2.4 安全指导工作2.5 用户和操作者安全说明2.6 保养、检查和装配工作安全说明2.7 严禁未授权的改装措施或更改2.8 不允许的运转模式2.9 防爆装置3. 运输和贮藏3.1 到货验收3.2 运输和起吊3.3 保存和贮藏4. 描述4.1 概述4.2 泵的描述4.3 轴承支架和润滑4.4 轴向推力吸收-平衡鼓5. 安装5.1 泵组的安装5.2 联轴器校正5.3 吸水和排水管道工程5.4 辅助设备5.5 最小流量装置6. 运行6.1 概述6.2 试运行6.3 泵启动和运行6.4 不允许的运转模式6.5 关闭6.6 重启程序6.7 使用控制6.8 运行故障7. 保养7.1 泵概述7.2 轴封7.3 轴承/润滑8. 维护8.1 泵的拆除8.2 易损件检查8.3 泵装配8.4 工具8.5 螺丝拧紧转矩附件操作说明书附表4000/e0-1-00-0001. 总论1.1 关于本说明书本操作说明包括如何安全、正确并且有效的操作泵的重要信息。

遵守这些说明可以帮助避免危险,减少修理成本和停机时间,并可以增加泵的可靠性和使用寿命。

如何使用本说明书本操作说明书必须在泵使用的地方随时可以获得。

任何负责与泵相关工作和操作泵的人员必须阅读和应用这些说明,例如:运输、贮藏、安装、运行和保养。

本说明书应该和所有其他机器的文件结合起来一起使用,以便获得关于泵的准确信息。

在没有完全理解泵系统和所有辅助系统(例如:驱动器,冷却装置、密封冲洗等)之前不要启动或运行泵。

1.2 保修按照合约协议,应提供保修。

一般苏尔寿的保修包括生产或材料缺陷,但不包括由于不合适的贮藏环境、不正确的安装、操作以及不按照指定用途使用而导致泵损坏。

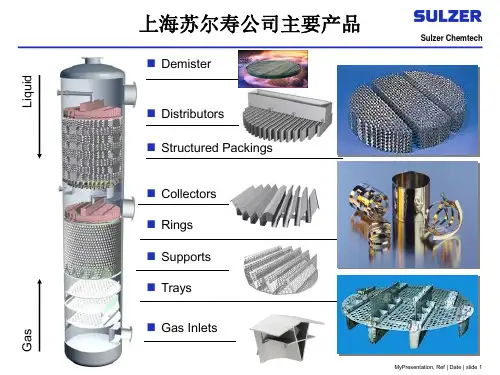

Sulzer Chemtech Process Technology0611 4502Process Technology at Sulzer ChemtechSulzer Chemtech, a member of the Sulzer Corporation, with headquarters in Winterthur, Switzerland, is active in the field of process engineering, employing 3'000 persons worldwide. Sulzer Chemtech is represented in all important industrial countries setting standards in the fields of mass transfer and static mixing with its advanced and economical solutions.Sulzer Chemtech is organized into four business units, one of which is the Process Technology group. This business unit was formed in early 2009 following the acquisition of Kühni, a Swiss company with more than 75 years experience in innovative separation processes. Today, Sulzer Chemtech Process Technology is headquartered in Allschwil (Basel), Switzerland.By combining Sulzer's and former Kühni's proven process technologies and exper-tise, Sulzer Chemtech Process Technol-ogy is now uniquely positioned to offer process solutions for demanding, indus-trial separations based on an excellent portfolio of the following unit operations:• Distillation, absorption and reactive distil-lation• Film evaporation• Liquid-liquid extraction• Crystallization• Membrane separationIn addition, Sulzer Chemtech has exten-sive experience and know-how in provid-ing process solutions for a wide range of process applications such as:• Solvent recovery• Product purification• Wastewater and vent gas treatment • Food and beverage• Biofuels and biochemicals• Reaction technology• Polymer production, including Polysty-rene (PS), Expandable Polystyrene (EPS) and Poly Lactic Acid (PLA) production This establishes our active position in thefollowing industry segments:• Fine and specialty chemical industry• Chemical and petrochemical industry• Pharmaceutical industry• Polymer production industry• Food and beverage industry• Biofuels and biorefinery industryOur services and sales activities are orga-nized globally, with the support of repre-sentatives in all key countries of Europe,Asia and the Americas. This way we areclose to our customers.One of our core strengths is that the en-tire project scope is provided from a singlepoint of responsibility. Our activities coverthe full project development cycle from theinitial conceptual design and testing up tostart-up of complete plant solutions. Weoffer:• Testing and sample production services,provided by state-of-the-art laboratoryand pilot test centers• Engineering services including feasibilitystudies, plant optimization, revamp anddebottlenecking studies, and concep-tual designs• Basic and detail engineering packages• Fabrication and supply of proprietaryand key process equipment• Fabrication and supply of complete pro-cess plants as modular units• Project management, installation, com-missioning, start-up and after sales ser-vicesWe have a proven track record in develop-ing innovative solutions to complex sepa-ration problems, where our unique and ex-tensive experience in combining processunit operations from our wide portfolio intohybrid plant solutions is paramount. This,together with our capabilities to supplystate-of-the-art process equipment andcomplete plant solutions are key to oursuccess.We are a reliable innovation partner andpreferred supplier for our customers glob-ally. We deliver our solutions with guaran-teed performance.0611 4503-123Distillation, Absorption & Reactive DistillationDistillation and AbsorptionDistillation is the most commonly applied separation technology. Sulzer Chemtech has been supplying process solutions in this fi eld since 1940. To date more than 100'000 columns are operating with Sul-zer equipment, in over 500 different ap-plications.Sulzer Chemtech is a leading expert and solutions provider for a range of distillation technologies:• Continuous and batch distillation • Single- and multi-stage distillation • Extractive distillation • Azeotropic distillation • Pressure swing distillation • Reactive distillation • Divided wall columnsOur product portfolio includes a unique and complete range of the best perform-ing, state-of-the-art column internals:Sulzer Chemtech has a long-standing experience in distillation and adsorption, with innovative solutions such as reactive distillation• Structured packing (like MellapakPlus TM and BXPlus TM gauze packing)• Random packing• Trays (conventional, high performance and cartridge trays)• Column internals (like distributors and collectors)• Vapor-liquid and liquid-liquid phaseseparators (like KnitMesh TMmist elimina-tors and Mellachevron TM vane packs)The design of distillation units is geared to deliver an improved product quality, increased capacity and reduced energy consumption. Design activities are sup-ported by computer simulations and in-house pilot plant testing. Our vast experi-ence and know-how in the fi eld of distil-lation combined with a profound under-standing of column hardware ensures we offer the optimum solution to our clients. We offer customers either a basic engi-neering package including key equipment (column shells, internals, heat exchangers and decanters), or a complete, often skid-mounted unit including process control and start-up support services.Reactive DistillationReactive distillation is a state-of-the-art development combining distillation and chemical reaction in one single operat-ing unit. This technology is highly valuable for equilibrium-limited reactions, such as esterifi cation. The level of conversion is increased by continuously removing the reaction products from the reaction zone via distillation. In general, reactive distilla-tion units feature:• Fewer distillation columns • No or smaller recycle streams• Utilization of heat of reaction for mass transfer• Higher product yields • Lower capital investment• Lower energy costsL i q u i dG a sInstallation of a slit trayDistillation column sketch with different internals0611 45040610 4502Vacuum conditions and a short contact time of the product with a heated surface are two essential parameters to prevent secondary reactions (like polymerization and condensation) and to preserve or-ganoleptic properties (color, smell, taste), as required in many industries - food, fine chemical, pharmaceutical. These param-eters are incorporated in our film evapora-tion technologies.Falling Film EvaporatorThe tubular falling film evaporator is spe-cifically suited for processing temperature sensitive products with a low viscosity and tendency for fouling. It consists of a tube bundle crowned by a proprietary liquid distribution device, which ensures an ef-ficient and uniform distribution of the liquid to all the tubes, as well as a continuous film along the tube length.4Film EvaporationSulzer Chemtech's film evaporation technology produces high-purity substances from heat sensitive and complex productsUsually the liquid and resulting vapors flow co-currently from the top to the bottom and a gas-liquid separator is applied to separate the exhaust streams. This sepa-rator is not required in counter-current applications (stripping) or when the falling film evaporator is used as a reboiler of a distillation column.Thin or Wiped Film EvaporatorThe thin or wiped film evaporator is the ideal apparatus for continuous processing of heat sensitive, viscous and/or fouling products. It consists of a single evapora-tion tube fitted with a mechanical rotating device that ensures a uniform distribution of the liquid on the heated surface, a con-stant mixing of the film and minimal fouling of the evaporation surface.The vapors produced rise upwards, counter-currently to the liquid and, when required, pass trough a mist eliminator mounted in the top section. Thanks to the large cross-sectional area, the pressure drop across the evaporator is low (typi-cally less than 0.05 mbar) and operation in the vacuum range as low as 0.5 mbar is possible.Short Path EvaporatorIn the short path evaporator, a vertical condenser is placed inside the wiped evaporation chamber. This results in a very short distance between the heating and condensing surface. The pressure drop across the system is thus minimized and evaporation in the pressure rangebelow 1 mbar is feasible. Due to the shortresidence time, highly temperature sensi-tive substances and compounds with high molecular weight can be purified at high purities and yields.Typical ApplicationsSulzer Chemtech’s falling and thin film evaporators are widely used in the organic chemical industry, as column reboilers in (high) vacuum distillation systems. Other typical applications are:• Product purification • Solvent recovery• Concentration of solutions and slurries • Crystallization • Drying• Treatment of industrial waste streams0610 45030611 45060611 4505Test rig for a wiped film evaporatorRotor of a wiped film evaporator Falling film evaporator5Liquid-Liquid ExtractionSulzer Chemtech’s liquid-liquid extraction is a technically sophisticated separation technology, offering a solution where other technologies are uneconomical or not suitableLiquid-liquid extraction is a complex sepa-ration process in which the components are extracted from the feed stream with the help of an extractant, or solvent. The components to be extracted have a dif-ferent solubility in the two immiscible, or partially miscible, liquids. Both liquids have to be thoroughly contacted and subsequently separated. The liquids fl ow counter-currently and the required purity and yield determines the number of sepa-ration stages.In the fi eld of liquid-liquid extraction, Sulzer Chemtech's range of equipment covers many industrial applications and is based on a number of modern, effi cient types of extractors.Column Type Extractors• Kühni Agitated Column (ECR)In applications with high mass transfer and/or changing physical properties, this is the column of choice. The com-partment geometry can be adapted to compensate for changing conditions re-sulting in a constant high column perfor-mance. The main features are the spe-cial mixing turbines and the perforated partition plates.• Packed Column (ECP) The key benefi t of a packed column is the high throughput which leads to small column diameters. Together with specially adapted liquid distributors, our structured packing provides the best ex-traction performance.Mixer-Settler Type ExtractorsMixer-settlers, both as stand-alone and as in-column type, are offered for special ap-plications:• Mixer-Settler (EMS)Due to the pump-mix turbine no addi-tional feed pumps are required in most cases.• Kühni Mixer-Settler-Column (ECMS)This special type of equipment com-bines the stage-wise operation of mixer-settlers with the small footprint of a col-umn.Typical applications are:• Recovery of carboxylic acids, for exam-ple, acetic acid• Extraction of aromatics, for example, from oil• Washing of organic solvents• Cleaning of aqueous effl uents from high boiling impurities like phenol• Wet purifi cation of phosphoric acid (food grade)• Recovery and purifi cation of Active Phar-maceutical Ingredients (API's)• Solvent de-asphalting • Solvent recoverySulzer Chemtech is a market leader withextensive experience in these applications. Our broad know-how covers selection of the most suitable solvent and optimum equipment selection and design. Equip-ment design is backed-up by elaborate research by universities. Furthermore, testing activities provide a solid basis for reliable designs and scale-up procedures, and a complete range of test equipment is available in our in-house test center. This way, even in diffi cult cases, the optimum process solution is achieved.0682 2018-10610 45010611 4507Kühni agitated column internalsLiquid-liquid extraction packing6CrystallizationSulzer Chemtech’s crystallization technology is solvent-free and has proven to be a most reliable and environmentally friendly separation technologySulzer Chemtech is the leading supplier of technology, proprietary equipment and engineering services for fractional crystal-lization. Crystallization is often the best alternative when distillation is difficult, or even impossible. High purity products are manufactured from close boiling or azeo-tropic mixtures or components that are thermally unstable at their boiling point. The technology has proven to be the most reliable and environmentally friendly crys-tallization process, because crystals grow directly from the melt without the use of solvents. Selection of the most suitable technology is supported by bench and pi-lot scale testing. Typical applications are the purification of:• Monomers • Carboxylic acids • Tar chemicals • Waxes• Organic and inorganic chemicals at high puritiesStatic CrystallizationThe Sulzer Chemtech static crystallizer is equipped with vertical plates immersed in a stagnant melt. Crystal layers grow on the cooled plates. Following crystallization, the remaining impure melt is drained from the crystal layer, which then is further pu-rified by sweating. Hereafter, the purified product is recovered by melting the crystal layer. Sweating and melting is established by heating the plates.Falling Film CrystallizationThe falling film crystallizer contains verti-cal tubes through which the melt flows as a falling film. The crystal layers grow in the form of cylindrical shells inside the cooled tubes. Crystallization is followed by sweating and subsequent melting of the product. A high thermal gradient can be imposed and crystal growth rates are fast.Suspension CrystallizationSulzer Chemtech's suspension crystalliza-tion is an advanced, highly selective, en-ergy efficient separation process. Crystals are formed in one or more scraped wall crystallizers. A stirred growth vessel pro-vides the needed residence time for the crystals to grow to a separable size. Crys-tals are separated from the mother liquor in one or more wash columns and sub-sequently melted to produce a high purity product.Freeze ConcentrationFreeze concentration is a special applica-tion of suspension crystallization. Freeze concentration of food and beverage products leads to selective removal of water at sub zero temperatures. It is the preferred technology for supreme quality liquid food concentrates because all fla-vor and aroma components are retained. Typical applications are the concentration of juices, wine and beer, coffee and tea.Static crystallizers for paraffin deoilingAcrylic acid crystallization plantSkid mounted suspension crystallization plant for MDI0611 28030611 28020611 2801Membrane SeparationSulzer Chemtech is the world leader in pervaporation and supplies process solutions for a vast variety of applications including membrane filtration systemsPervaporationPervaporation can be used to dehydrate solvents without the use of any third sub-stance. Azeotropes can simply be split, irrespective of vapor-liquid equilibrium conditions and at low cost. In the same way, methanol can be removed from other organic solvents. A vacuum driving force is applied to the back side of the mem-branes, allowing almost complete removal of the permeating component (vapor). The feed to the membranes can either be in the liquid (pervaporation) or vapor phase (vapor permeation). Separation is predomi-nantly affected by differences in polarity. The process features of pervaporation are:• Tailor-made membranes which selec-tively remove one or more components • Flexible operation - a single unit can be designed to treat a large number of solvents with different component feed concentrations• Flexibility for batch or continuous opera-tion depending on the solvent properties and energy costs• Possibility of process intensification via hybrid operation with distillation• Standard skid mounted units PERVAP™ and CeramicMembranesSulzer Chemtech has a wide range of su-perior, proprietary PERVAP™ polymericmembranes. A co-operation with MitsuiEngineering and Shipbuilding Ltd., Japan,alternatively enables us to offer world-class inorganic pervaporation membranes.Hereby, selection of the best suitablemembrane for a most reliable and eco-nomic treatment of each product is pos-sible on a case by case basis. Key appli-cation areas are:• Solvent production and recycling• Dehydration of alcohols• Production of Active PharmaceuticalIngredients (API's)• Production of fine chemicals• Production of flavor and fragrances• Production of food and beverageMembrane FiltrationSulzer Chemtech's membrane filtrationsystems are specifically suitable for thetreatment of organic solvents and acidsas well as for other advanced applications.Reverse Osmosis (RO), Nanofiltration (NF),Ultrafiltration (UF), Microfiltration (MF) foraqueous systems, and Organic SolventNanofiltration (OSN) systems can be sup-plied as a stand-alone unit operation, or inhybrid combinations with other technolo-gies. Hybrid solutions offer a lower energyconsumption, a smaller footprint, lower in-vestment costs and lower heat effects onthe product.Typical applications for our pressure drivenmembrane filtration systems include:• Concentration or purification of API's• Catalyst recovery• Clarification or concentration of organicand mineral acids• Monomer / polymer separation• Decolorization of solvents• Recovery of spent solvents• Solvent exchange0611 4508Ceramic membrane module Skid mounted PERVAP TM membrane plant0611 45167Over the years Sulzer Chemtech has built-up extensive experience in a broad number of applicationsApplication TechnologySulzer Chemtech has extensive experience in a wide range of applications. Many of these are based on our proprietary unit operations, or combinations thereof, the so-called hybrid processes. A non-exhaustive selection of applications we have extensive experience with is presented below. And there are many more…Solvent RecoveryAqueous non-azeotropic systems:• Methanol• Acetone• DMF / DMAC• NMP• Acetic acidOther non-azeotropic systems:• Methanol / ethanol• Ethyl acetate / toluene• DCM / ethyl acetate• DCM / pyridine• IPA / methoxyethanol Heterogeneous azeotropic systems:• Butanol• Acetates• MIBK, MEK• Triethylamine• Dichloromethane• Toluene• Xylene / water / methanol• Hexane / water / methanol Aqueous homogeneous azeotropic systems:• Ethanol, IPA• THF• Acetonitrile• Phenol• PyridineOther homogeneous azeotropic systems:• Ethyl acetate / cyclohexane• Ethyl acetate / ethanol• Methyl acetate / methanol• DCM / methanol• Methanol / dioxane• Hexane / methanol / butane• THF / ethyl acetate• Decane / THF / ethyl acetate• Methanol / xylene• Acetone / methanolProduct Purifi cationVacuum rectifi cation, stripping:• Herbizide• Octadecanol / additive• Hydrogen peroxide• Fatty acids and fatty alcohols• Ethanolamine• Glycols and glycol ethers• MDA / MDI and TDA / TDI• Halogenated and nitrated aromatics(NT, DCB, NCB)• Xylenes• Alkylphenols• CaprolactamFilm evaporation:• Amino acids• Sugars• Thioglycols• Esters• Fatty acids and derivatives• Active Pharmaceutical Ingredients(API's)• ResinsLiquid-liquid extraction:• API's and vitaminsSulzer Chemtech’s solutions forwastewater and vent gas treatmentfeature regeneration techniques forthe recovery of valuable components.Steam stripping:• Methanol, ethanol, butanol, IPA• MTBE, isopropyl ether• Ethyl acetate, butyl acetate• MEK, MIBK• DCM• Dioxane, tolueneLiquid-liquid extraction:• Acetic acid• Phenol• Agrochemicals• Flavors• Wet purifi cation of precious metals• Food grade phosphoric acidCrystallization:• Acrylic and methacrylic acid• Anthracene / naphthalene• Alkylphenols, Bisphenol A• Benzoic and phosphoric acid• Caprolactam, DMT• Chlorinated and nitrated aromatics• Para- and meta-xylene• Lactide• Paraffi n waxes• Pyrrolidone• MDI, TDI• Sterol• Trioxane• XylenolMembrane separation:• Removal of water / methanol fromsolvents• Acetic acid / water• DMF, DMAC, NMP• Agrochemicals and pesticidesAbsorption, with water:• Methanol, ethanol, IPA• Acetone• AmmoniaAbsorption, with high boiling oil fol-lowed by steam stripping:• Complex mixtures of, for example,hydrocarbons, alcohols, chlorinatedhydrocarbons, ketones, ethers andestersWastewater and Vent Gas Treatment8Biofuels and Biochemicals Sulzer Chemtech is the leading sup- plier for the distillation of fi rst generation biofuels, and is continuing its strong in-volvement for second generation biofu-els and biorefi neries. Sulzer Chemtech has experience in the following fi elds:• Mash / beer column (heavy fouling ap-plications) and rectifi er• Dehydration of ethanol by pervapo-ration / vapor permeation, heat inte-grated with the overall process• Membrane fi ltration (MF / UF / NF) be-fore fermentation• Liquid-liquid extraction for strong acid hydrolysis route• BiodieselFood and BeverageAdvanced distillation technology isapplied in the food and beverage in-dustry to recover and produce fl avors,fragrances and vitamins. This requiresprocessing of single chemicals tohighly complex mixtures thereof. Prod-ucts typically are temperature sensitivewith close boiling points. In distillationthis implies a high number of separa-tion stages with low pressure drop.More than 300 industrial columnsbased on Sulzer Chemtech technol-ogy are in operation for the productionof citral, menthol, citronellol, pinene,eugenol, tocopherol, limonene, andmany other components.Other examples of what Sulzer Chem-tech offers in this fi eld are:• Mild fi lm evaporation of temperaturesensitive products• Liquid-liquid extraction of vanilla, winefl avor, lemon and other essential oil• Freeze concentration of beverageslike fruit, vegetable juices and coffee• Pervaporation to remove or concen-trate aromaRectifi cation and ReactionTechnologyIn addition to recovery and purifi ca-tion systems, Sulzer Chemtech offersselected chemical reaction processpackages including downstream pro-cessing. The scope of supply typicallyconsists of a basic engineering pack-age and key equipment that is usuallyprovided with process guarantees. Atypical application where Sulzer Chem-tech has specialist process know-howis the production of ethanolamines.Continuous reaction is another fi eldwhere Sulzer Chemtech has gainedsubstantial know-how. For continu-ous cascade reactions various types ofstatic and agitated multi-compartmentreactors have been developed. Themain advantages of a continuous re-actor compared to a series of stirredvessels are a compact design, a longoverall residence time and a narrowresidence time distribution.0698 2530-3Freeze concentration unit for coffee Ethanolamine plant0611 28049Two Typical ExamplesThe following examples give a taste of our collection of successful applicationsHydrogen PeroxideFollowing its production, hydrogen perox-ide is concentrated by partial dehydrationvia distillation. The main features of SulzerChemtech's hydrogen peroxide concen-tration concept are its operational safety,flexible product purity and low energyconsumption. Our plants are designedto produce the entire range of hydrogenperoxide purities required by the market.The addition of a feed evaporator evenenables our customers to simultaneouslyproduce hydrogen peroxide of differentpurities.A cornerstone of Sulzer Chemtech's H2O2concentration concept is the implemen-tation of very high safety standards by a combination of features including low liq-uid hold-up, pressure drop and operating temperature, provision of a safety water tank and rupture discs, and an appropri-ate process control. This unique approach to safety has gained worldwide accep-tance and has made Sulzer Chemtech the market leader in hydrogen peroxide with more than 40 distillation plants in opera-tion.MDI PurificationMethylene diphenyl diisocyanate (MDI) isone of the most commonly used sourcesfor polyurethane production. In additionto MDA (methylenedianiline) purification,Sulzer Chemtech offers specialized MDIpurification and isomer separation pro-cesses. Our MDI purification technology iswell proven with a current installed base ofmore than 30 industrial plants using SulzerChemtech's distillation and/or crystalliza-tion technology.MDI has the tendency to form dimers dur-ing the purification process. Therefore, lowtemperature, pressure drop, residencetime and liquid hold-up are all determin-ing criteria for the distillation as well as forthe final product quality. The use of SulzerChemtech's BXPlus TM gauze packing incombination with dedicated distributorsoptimizes these factors, thus minimizingdimer formation.Suspension crystallization is an incom-parably gentle (Tmax ~40 °C), robustand flexible process. It enables the MDIproduct purity to be tailored to particularend-use applications. A product purity ofat least 99.5% is reached in just one crys-tallization cycle. Higher product puritiescan be achieved by further sweating, orby repeating the crystallization cycle. Sus-pension crystallization ensures a colorlessproduct, even in cases of process upsetsin the synthesis section.Suspension crystallization can be addeddownstream of the distillation unit in ex-isting plants, thereby boosting overallprocessing capacity. For a new MDI plant,the optimized process integration of distil-lation and suspension crystallization leadsto a maximum in operating flexibility interms of capacity and product quality, anda substantial reduction of capital and op-erating costs.Hydrogen peroxide distillation withfeed evaporation MDI Process10Polymer Production TechnologySulzer Chemtech’s continuous polymer production technology delivers an optimum product quality while featuring a high fl exibility in production and low operating costSulzer Chemtech's novel technologies for continuous polymer production largely benefi t from the in-house static mixing and heat exchanger technologies as well as from the system integration know-how. Continuous Polymerization Reaction TechnologiesHighly exothermic polymerization reac-tions require accurate temperature control along the reaction. The unique geometry of the Sulzer Mixing Reactor (SMR TM) is highly suited for an accurate control of the polymerization temperature and also op-timizes mixing. Other characteristics are:• Continuous polymerization reactions • Plug fl ow behavior• High conversion rate• Homogeneous high polymer product quality• Ability to process polymers with a vis-cosity up to 10'000 Pa·s• High heat exchange surface area to re-actor volume ratio of up to 120 m2/m3• High fl exibility to switch production to a different polymer grade• Reliable scale-up Devolatilization TechnologyEffi cient removal of monomer, solvent andother impurities after the reaction sec-tion is mandatory to avoid too high VOC(Volatile Organic Compound) levels in theend-product. Sulzer Chemtech's propri-etary degassing technology is based ona single, or multiple stage fl ash devola-tilization process. Each stage features aheat exchanger with Sulzer Chemtech'sproprietary SMXL TM mixer inserts, a strip-ping agent dosing mixer, and uniquely de-signed degassing chambers that containspecial polymer distributors. The technol-ogy is further characterized by:• Highly effi cient VOC removal to meet themost stringent industrial and legislativestandards• Prevention of polymer degradation byminimizing residence time and avoidinghigh temperatures and shear• Narrow residence time distribution• Moderate capital cost (no moving parts)• Low operating costsUpgrading TechnologyAfter devolatilization, additives can bemixed into the polymer melt to upgradethe fi nal product. Sulzer Chemtech hasmany years of experience in providingsuccessful upgrading solutions for im-proved product quality and profi tability.Sulzer Chemtech's static mixing technol-ogy (SMX TM and SMX TM plus) makes mix-ing of highly viscous polymers with lowviscosity additives possible, for viscosityratios of up to 10 million. Other featuresof our proprietary mixing devices include:• High mixing effi ciency• Prevention of polymer degradation byavoiding high shear forces• The use of static equipment, no movingparts• Low investment and operating costsSulzer Chemtech's sophisticated heatexchanger technology is also applied incooling the highly viscous polymer prod-uct (SMR TM, SMR TM plus, SMXL TM andSMXL TMplus).0605 2706-6Sulzer Mixing Reactor (SMR TM)Sulzer static mixer-heat exchanger (SMXL TM)11。

国家核安全局关于大连苏尔寿泵及压缩机有限公司许可证外协项目变更申

请的复函

正文:

---------------------------------------------------------------------------------------------------------------------------------------------------- 国家核安全局关于大连苏尔寿泵及压缩机有限公司许可证外协项目变更申请的复函

(国核安函〔2009〕37号)

大连苏尔寿泵及压缩机有限公司:

你公司关于《大连苏尔寿泵及压缩机有限公司民用核承压设备制造许可证外协项目变更》(苏连泵字〔2009〕02号)的申请收悉。

经审查,我局同意在你公司原许可证外协项目中增加“超声波检验”,其他项目不变。

特此函复。

二○○九年三月三十日

——结束——。