苏尔寿给料泵说明书

- 格式:pdf

- 大小:12.58 MB

- 文档页数:61

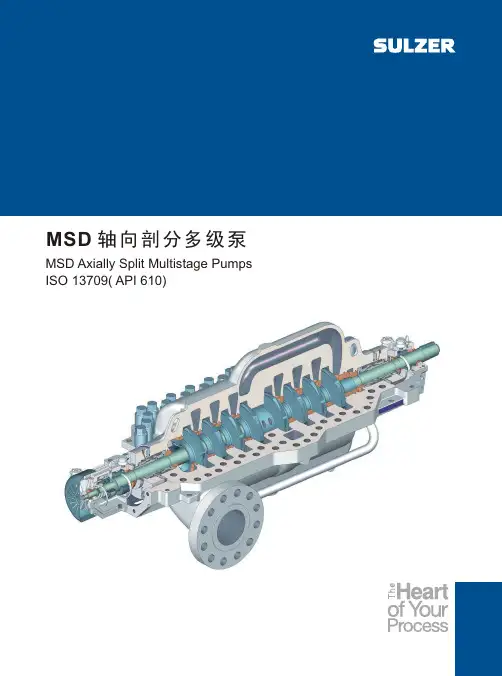

MSD 轴向剖分多级泵MSD Axially Split Multistage Pumps ISO 13709( API 610)Sulzer Pumps is a leading global supplier of reliable products and innovative pumping solutions for end users. Our active research anddevelopment, detailed process and application knowledge together with a comprehensive understanding of market demands keeps us consis-tently at the leading edge of technical development. Our global network ofmodern manufacturing and packaging facilities together with sales offices,service centers and represen-tativeslocated close to major markets providefast responses to customer needs.Sulzer Pumps – Leader in Pump Technology苏尔寿泵业是一个提供可靠产品和创新泵解决方案的全球领先的供应商。

积极的研究和开发,详尽的工艺制造和丰富的应用经验,加上对于市场需求的全面为最终用户苏尔寿泵业——泵技术的领导者Sulzer Pumps is active servingbusiness partners in the followingindustries:• Oil & Gas• Hydrocarbon Processing• Pulp & Paper• Power Generation• Food, Metals & Fertilizers• Water & Wastewater理解,使我们始终处于技术发展的前沿。

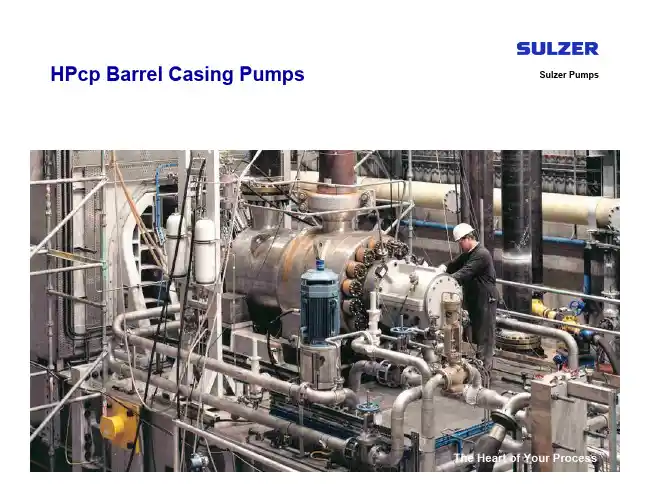

GSG Diffuser Style Barrel Pump ISO 13709 (API 610) Type BB5Extensive Product RangeSulzer Pumps has a long history of providing innovative pumping solutions to business partners in the following industries:Oil & GasHydrocarbon Processing Pulp and Paper Power Generation Food, Metals & Fertilizers Water and WastewaterHydrocarbon ProcessingHydrocarbon extraction plants,refineries, petrochemical plants and gas plants operate sophisticated production processes requiring reliable pumping solutions.Continuous product innovations such as our improved line of hermetically sealed, horizontal and vertical process pumps, are helping the industry improve its operational efficiency.Sulzer Pumps, with its high-quality product line, is known for being able to consistently meet these expectations.All our pumps are engineered in line with the latest standards issued by API, ISO and ANSI in order to ensure reliable and safe operation at your site. The Hydrocarbon Processing Industry is one of the core business segments within Sulzer Pumps.Following industry practice, we further subdivide the segment into:Synfuels Refining Gas Processing Petrochemicals Nitrogenous FertilizerThe market - and therefore our customers - requires specialty applications for each subsegment.Application RangeThousands of GSG pumps are installed around the world. They are found in:Power Plants RefineriesPetrochemical Plants Gas Processing Plants Onshore and offshore water injection servicesOnshore and offshore crude shipping serviceOnshore crude oil, refined product and LPG pipeline servicesHigh pressure and high or low temperatures are GSG services.DesignThe GSG is built to the latest edition of ISO 13709 (API 610). It is a type BB5,horizontal, radially split, diffuser type,multistage barrel pump. The rotor stack can be either inline (all the impellers facing towards the driver) or back-to-back. On the smaller pumps,the inboard seal chamber and bearing housing must be removed for cartridge removal. On larger pumps,the entire cartridge can be removed as an assembly to speed overhaul or re-rate turnaround time.The barrel is available as either a casting or forging with a variety of flange ratings to meet individual specifications. It is normally centerline supported for thermal stability and maximum nozzle load capacity. The barrel closure is either the traditional flanged head-studs and nuts, flanged head-Supernuts™, or Sulzer’s patented Twistlock closure for speedy removal and assembly.The inner cartridge consists of stacked diffuser/impeller sets. A double suction first stage impeller is available on all but the smallest sizes.Axial thrust is compensated by a balance drum for inline stacked rotors.The diffusers hydraulically balance radial forces. For those services where intermediate pressure takeoff is needed, higher flow diffuser/impeller sets can be utilized up to the takeoff stage, and then lower flow sets are used after the takeoff stage to optimize efficiency and performance.When design conditions change, re-rates are similarly achieved using different diffuser/impeller combin-ations, or blank stages—all in the same barrel.For applications on light gravity fluids with many stages, a back-to-back rotor stack is utilized to allow direct drive at normal motor speeds and provide improved rotordynamics. In such rotors, the opposed impellers cancel most of the axial thrust. The center bushing and throttle bushings take most of the residual axial thrust,so the thrust bearing loads are minimal. The back-to-back design allows the use of a 7300 series ball thrust bearing—and saves the substantial cost and maintenance components associated with lube oil systems. For high pressure and high energy levels, inline, or back-to-back stack, high speed, semi-stiff rotor designs are available.Depending upon pump size, power,and rotor design, the pumps can be supplied with ring oil or oil mist lubricated antifriction bearings, ring oil lubricated sleeve radial—ball thrust bearings, or pressure lubricated sleeve radial—tilting pad thrust bearings.MaterialsAll common ISO 13709 (API 610)material combinations are available.GSG Inline Design Features and BenefitsCasing CoverFlanged head, studs/nuts Flanged head, Supernuts™O-ring or spiral wound gasketMechanical SealsThrust Bearingbrass cages, orforce INPRO™with 360°Wear parts offered are the result of a year of wear testing by Sulzer Variety of materials, hardness, and hard coatings available depending on pump material and application PEEK with reduced clearances available on clean fluids for enhanced efficiencyfitsFor HPI applications shrink fit, axially secured impellers, and stepped shaft at each stageBlank stages can be supplied for future conditionsInterstage TakeoffPartial flow takeoff from intermediate stageAble to stack high capacity and low capacitydiffusers/impellers on same rotor for optimized stagetakeoffCommon on boiler feed pumps Available on recycle process applications Saves cost of additional pumpFirst Stage ImpellerLow Nss design is standardDouble suction available on all butsmallest sizesImproved NPSHr designs availableRadial BearingsInpro™bearing isolatorCarbon steel bearing housing with360°supportRing oil or oil mist lubricated rolleror ball bearing with C-3 clearanceRing oil or force feed lubricatedsleeve bearingsavailableRobust Shaft and RotorDesigned for low stress levelFully machinedDynamically balancedStraight bore, tapered bore, orhydraulic fit under couplingavailable per ISO 13709 (API610)BarrelCenterline mounted for thermal stabilityand maximum nozzle load capabilityCast with nozzles and flangesForged barrel with NDE of nozzle weldsWarm-up flow through discharge drain notrequired below 260°C (500°F). Warm-upflow required for higher temperaturesPin-and-key-slot thermal expansionsystemJacketing, insulation or noise blanketsavailablePump Inner Cartridge AssemblyStage casings sealed by dischargepressureFree to expand towards discharge coverduring warm-upInner tie bolts for assembly/disassemblyCoupling hub, inboard radial bearing and inboard seal chamber removal required on small pumps to remove cartridgeLarger pumps have barrel bore diameters larger than bearing housing which allows cartridge to be removed with those partsassembledCenter and throttle bushing absorb residualthrust and only breakdown half of dischargeAxial thrust stable even with worn clearances BearingsInpro™360°First Stage ImpellerLow Nss design is standardDouble suction available on all but smallest sizes Improved NPSHr designs availableBarrelCenterline mounted on hot servicesGSG InlineFulfills the majority of requirements for BB5 pumps with either cast or forged barrels to meet customerspecifications.Multivane diffusers balance radial loads. Balancingdrum takes the majority of axial thrust load. Heavyduty bearings support the rotor and carry residualthrust loads.Smaller size pumps fitted with ring oil lubricated antifriction bearings. Oil mist lubrication optionalAll but smallest sizes may be fitted with pressure lubricated sleeve radial, double acting tilting pad thrust bearings, lube oil systems, bearing RTD’s, X-Y vibration probes and Keyphasor, etc.Maximum number of interchangeable stage pieces minimizes spares parts inventoryIn direct drive applications, clearly the best selection up to stage limits. If still more head is needed, first consider GSG back-to-back and direct drive. If that does not meet head requirement, then consider GSG inline with higher Speed—using gear box or VFD.For very high head and high energy levels beyond GSG back-to-back direct drive capabilities, GSG with semi-stiff rotor design (like Sulzer’s HPcp, HPT pumps) can be offered. Could justify stand-alone, single unit—no standby. Discussion recommended.GSG: Inline and Back-to-Back Design Features and BenefitsGSG Back-to-BackWith up to 16 stages available, fulfills direct driveapplications that require more head than is availablefrom direct drive inline GSGMultivane diffusers balance radial loads. Opposedimpellers balance majority of axial thrust. Centerbushing and throttle bushing take nearly all the residualaxial thrust. Even when clearances are worn, axialand radial loads remain balanced.Fan cooled, ring oil lubricated, sleeve / ball thrust bearing without lube systems are common up to ISO 13709 (API 610) Table 9 limits, or Sulzer limits depending upon application. Significantly reduces installed cost and provides simple, reliable pumps.When even high speed GSG with semi-stiff inline rotor does not meet head requirements, or cannot meet rotordynamic requirements a GSG with semi-stiff back-to-back rotor can be offered.To speed the repair of a GSG pump,larger sizes are designed using that cartridge concept. The pump coupling hub, inboard bearing housing, seal chamber and hydraulic cartridge slide through the barrel for quick removal.Re-installation is just as fast. For evenfaster turnaround, the Sulzer patented Twistlock design puts an end to hours of torquing the barrel cover nuts. For remote locations or offshore this can be especially time and cost saving.Small GSG pump barrel bore are so small that the coupling hub, sealchamber and bearing housing will not fit through. Those parts have to be removed on those pumps before the cartridge is pulled.Rapid pump dismantlingThe innovative Sulzer Twistlock barrel cover design provides effective sealing and eliminates the usual requirements of torquing many fasteners to very high values—taking hours. The Twistlock also reduces the end cover flange area required thus reducing weight—an added bonus for offshore installations.Sulzer’s patented TwistlockThe assembled cartridge can be removed as one piece on larger pumps.Installation sequence:Cover in placeCover introduced and partially rotatedCover locked and securedOther Sulzer Barrel Pump ModelsWhen preferred or for erosive, sandy services, Sulzer’s CP opposed impeller, dual volute barrel pumps are proven performers. Heads to 6,700 m (22,000 ft)Sulzer’s HPcp (inline or back-to-back) is the global leader in large water injection services from 5 MW to 30 MW.Heads to 6,500 m (21,000 ft)Sulzer’s HPT boiler feed pumps are renowned for their reliability. Sizes to over 40 MW (55,000 hp) cover the majority of power plant needs.Performance RangeOperating DataQ (m 3/h)Q (USgpm)Bearing optionsFan cooled ring oil, or oil mist lubricated antifrictionbearings, orRing oil lubricated sleeve radial bearings withantifriction thrust bearing, orForce feed lubricated sleeve radial bearing and double acting tilting pad thrust bearingA variety of bearing instrumentation is available tomeet specificationsRotor and Impeller optionsFor ISO 13709 (API 610) applications, impellers areindividually axially secured and are shrink fit to theshaft—which is stepped under each impeller for ease of assemblyFor other applications a slip-fit impeller stack isavailableStraight bore, tapered bore, or hydraulic fit couplinghub is available per ISO 13709 (API 610)GSG “inline” or “back-to-back” rotor design.Double Suction first stage impeller for lower NPSHr.High temperatures and options for bottoms / residuesProven coke crusher available for services with coke particlesPump warm-up not required below 260°C (500°F).Warm-up flow required for higher temperaturesPin-and-block thermal expansion system provided on hot servicesJacketing, insulation or noise blankets availableGSG OptionsCheck our worldwide offices at*******************************E 00612 10.2004 Copyright ©Sulzer PumpsThis brochure is a general presentation. It does not provide any warranty or guarantee of any kind. Please, contact us for description of the warranties and guarantees offered with our products. Directions for use and safety will be given separately. All information herein is subject to change without notice.。

BBT/BBT-D Two Stage Radially Split Between Bearings Process Pump API 610, 9th Edition (ISO 13709)Extensive Product RangeSulzer Pumps has a long history of providing innovative pumping solutions to business partners in the following industries:•Oil & Gas•Hydrocarbon Processing •Pulp and Paper•Power Generation•Food, Metals & Fertilizers •Water and Wastewater Hydrocarbon Processing Hydrocarbon extraction plants, refineries, petrochemical plants and gas plants operate sophisticated production processes requiring reliable pumping solutions. Continuous prod-uct innovations such as our new line of hermetically sealed, horizontal and vertical process pumps, are helping the industry improve its operational efficiency. Sulzer Pumps, with its high-quality product line, is known for being able to consistently meet these expectations. All our pumps are engineered in line with the latest standards issued by API,ISO and ANSI in order to ensure reliable and safe operation at your site. The Hydrocarbon Processing Industry is one of the core business segments within Sulzer Pumps. Following industry practice, we further subdivide the segment into:• Synfuels• Refining• Gas Processing• PetrochemicalsThe market and therefore our customers require specialty appli-cations for each subsegment.Heavy Duty Applications The BBT and BBT-D pumps are designed for heavy duty, high pressure and high temperature applications in industrial and HPI services.Applications range from light hydrocarbons at low temperatures, to corrosive fluids, coker furnace charge, vacuum bottoms and other services at high temperatures.• Refinery• Petrochemical plants• Gas processing• Coal processing• Offshore installationFor low NPSH applications, the BBT-D with its double suction first stage impeller is utilized. A variety of hydraulics is available in each size to suit particular applications.DesignPumps are in full compliance with API610, 9th edition (ISO 13709). For highpressure applications, these pumptypes are designed as betweenbearings, horizontal two stage, andhave a radially split case construction.Centerline mounting is utilized tominimize thermally induced misalign-ment. Fully confined gaskets arefurnished as required by API 610.Suction and discharge nozzles arefurnished in accordance with ANSI orDIN Standards and are configured inthe top/top orientation.Seal chambers comply with API 682.Seal chamber pressure is equalizedby use of an internal balance line. Thisensures that the seals at each end ofthe pump can be usedinterchangeably. Cartridge typesingle, dual pressurized and dual un-pressurized seals are used asrequired to suit the application.All API 682 Seal piping plans areavailable.As required by API 610 the rotordesign is "classically stiff" with drycritical speed more than 120% abovedesign speed. Shaft deflections atseal faces and wear rings are wellwithin API 610 limits.Impellers are dynamically balanced,enclosed for high efficiency andpositively keyed and locked to theshaft. The impellers and casing areequipped with replaceable wear ringsand bushings.Baseplates comply with API 610.Optional baseplates that are designedto accept two times API 610 nozzleloads, non-grouted installation, pre-grouted for quick installation, oroffshore 3 point trundle mount, arecommon place.MaterialsAPI 610 material codes S-4, S-5, S-6,C-6, A-8, D-1, D-2 and 317L arestandard.Others are readily available.Design Features and BenefitsCasing•Extra heavy mounting feet for minimumdistortion under 2 times API nozzleloads• 3 mm (1/8") corrosion allowance asrequired by API 610•Radially split for high pressure services•Longer life even with severe serviceStiff shaft design•API 610•Greater mechanical seal life•Less wear due to lower deflection•Reliable rotor dynamic performance•Low vibrationHydraulics•radial load balance•Dual volute on larger sizes•axial loads•Variety of performances in each size•Provide efficient, reliable hydraulicconditionsThrust Bearing Assembly•40°angular contact bearings•Ring oil lubrication•INPRO™shaft seals•Finned carbon steel housing•Low bearing oil and bearingtemperatures•Ball/ball, sleeve/ball and sleeve/pivotshoe bearings are all available asrequired to suit the pump size andapplicationFlanges•300# RF or 600# RF flanges with API 610 required backfacing and serrations•Single or multiple drains and vent are available •ANSI or DIN flanges availableTapered Shaft•Tapered shaft is standard for ease of seal maintenance•Hydraulic fit couplings and shaft drilling is optionalImpellers•Enclosed and dynamically balanced for improved efficiency and reliability•Standard design limited to 11,000 Nss •Optional design on some sizes for improved suction performance•Double suction (BBT-D) for very low NPSH•Positively retainedAPI 682 Seal Chambers•Outside driven, API 682 cartridge type mechanical seal•Single, dual pressurized and dual unpressurized seals as required to meet the application•Seal chambers are pressure balanced to equalize seal chamber pressure for interchangeable seals•Registered fit on seal gland plates assures alignment•All API 682 seal piping plans available to improve seal lifePerformance RangeOperating DataQ (US gpm)Q (m 3/h)20501000200010050020005000601004008002000200400600H (m)H (ft)2002005001000Q (m 3/h)Q (US gpm)100200500010000201005002000300600200040001000100200300H (ft)100010006000H (m)Your Global PartnerSulzer operates over 20 test facilities world-wide. Our facilities are suitable for horizontal or vertical, open pit, high flow rate/high energy and multiphase testing. We have the ability to perform tests at 50 & 60Hz and, depending on the site, are able to operate using diesel engines, gas engines and gas turbines in addition to conventional electric motors.A specialty of Sulzer is the ability to fully string test large high-energy pumps to prove the pump package as a whole to our customers. This ability is particularly important for critical offshore applications where on site correction is both expensive and time consuming. Customer SupportServiceThrough our worldwide network ofover 50 service centers we provideour customers with a full range ofservices for pumps and otherassociated equipment. Local 24 hoursa day, 7 days a week customerservice backed up by our servicegroups’global solutions, conceptdevelopment and support team.Applying our unique combination ofexperience and expertise, we areconsistently able to deliver highquality, value added rotatingequipment support. Furthermore, wecan also design, deliver and fit highintegrity components for non-Sulzermachinery using our in-house re-engineering specialists.Sulzer CustomerAlliancesSulzer Pumps’business strategy issimply to work closely with ourpartners to gain an understanding oftheir requirements and expectations,and provide products and serviceswhich meet those expectations betterthan anyone else. We can look backon 10 years of alliance experience.Our customer alliance agreementsare key to our strategy and representa mutual long term commitment forthe purpose of achieving world classpumping system life cycle cost bymaximizing the effectiveness of ourPartner’s and Sulzer’s resources.Sulzer currently has agreements withmany of the major oil companiesfocusing on solving problems andsimplifying work processes.Divisional Headquarters Manufacturing facilitiesCustomer Support Service Centre Sales OfficeCheck our worldwide offices at*******************************E 00585 Copyright ©Sulzer PumpsThis brochure is a general presentation. It does not provide any warranty or guarantee of any kind. Please, contact us for description of the warranties and guarantees offered with our products. Directions for use and safety will be given separately. All information herein is subject to change without notice.。

吉林燃料乙醇有限公司SULZER自吸泵合同技术附件甲方:吉林燃料乙醇有限公司乙方:大连苏尔寿泵及压缩机有限公司时间:2011年3月23日目录一、物料参数及设备性能二、设备设计制造要求三、设计分工及设计原则四、图纸及技术资料交付五、供货范围及清单六、设备保证期七、技术附件生效与变更八、附表:《检验项目汇总表》一、物料参数及设备性能1、操作条件(设计数据表)1.1 物料名称:生产污水1.2 工况条件:室内,常压1.3 安装地点:生产污水提升泵房1.4 运行方式:连续2、设计性能要求(设计数据表)2.1流量:300 m3/h2.2扬程:20m2.3自吸高度:4.5m2.4电机功率kw:372.5防护等级:IP55,防爆等级DIIBT42.6电压V:3802.7转速(r/min):14502.8设备材质:双相钢3、设备主要技术规格及性能参数(乙方提供设备)3.1设备型号:ASP31-150 O3.2流量:300 m3/h3.3扬程:20m3.4必需汽蚀余量NPSHr:3m3.5电机功率kw:373.6防护等级:IP55,防爆等级DIIBT43.7转速(r/min):14703.8设备材质:双相钢ASTM A890 3A二、设备设计制造要求1、设计、生产、检验、包装使用的标准:(国家或行业标准)1.1设计标准ISO51991.2尺寸标准:ISO 28581.3测试标准:ISO 9906 Grade 21.4法兰标准:ISO 7005-1 PN 162、设备主要零部件材质2.1双相钢ASTM A890 3A3、设备设计、制造主要技术要求3.1设计制造标准ISO51994、主要部位装配图及技术要求4.1需提供连续冲洗水,流量5l/min4.2 排气管及管口不能高于泵中心线,同时管口不能没入坑池液面。

5、主要零部件分供货商及产地5.1爆电机厂家:无锡锡安达电机有限公司或佳木斯电机有限公司5.2联轴器生产厂家:上海马丁5.3轴承:SKF或NSK三、设计分工及设计原则1、乙方选型原则:按照甲方提供的数据表要求进行选型。

操作说明书MC目录1. 总论1.1 关于本说明书1.2 保修1.3 操作说明书型号2. 安全2.1 操作说明书中的说明符号2.2 人员资质和培训2.3 不遵守安全规则的危险2.4 安全指导工作2.5 用户和操作者安全说明2.6 保养、检查和装配工作安全说明2.7 严禁未授权的改装措施或更改2.8 不允许的运转模式2.9 防爆装置3. 运输和贮藏3.1 到货验收3.2 运输和起吊3.3 保存和贮藏4. 描述4.1 概述4.2 泵的描述4.3 轴承支架和润滑4.4 轴向推力吸收-平衡鼓5. 安装5.1 泵组的安装5.2 联轴器校正5.3 吸水和排水管道工程5.4 辅助设备5.5 最小流量装置6. 运行6.1 概述6.2 试运行6.3 泵启动和运行6.4 不允许的运转模式6.5 关闭6.6 重启程序6.7 使用控制6.8 运行故障7. 保养7.1 泵概述7.2 轴封7.3 轴承/润滑8. 维护8.1 泵的拆除8.2 易损件检查8.3 泵装配8.4 工具8.5 螺丝拧紧转矩附件操作说明书附表4000/e0-1-00-0001. 总论1.1 关于本说明书本操作说明包括如何安全、正确并且有效的操作泵的重要信息。

遵守这些说明可以帮助避免危险,减少修理成本和停机时间,并可以增加泵的可靠性和使用寿命。

如何使用本说明书本操作说明书必须在泵使用的地方随时可以获得。

任何负责与泵相关工作和操作泵的人员必须阅读和应用这些说明,例如:运输、贮藏、安装、运行和保养。

本说明书应该和所有其他机器的文件结合起来一起使用,以便获得关于泵的准确信息。

在没有完全理解泵系统和所有辅助系统(例如:驱动器,冷却装置、密封冲洗等)之前不要启动或运行泵。

1.2 保修按照合约协议,应提供保修。

一般苏尔寿的保修包括生产或材料缺陷,但不包括由于不合适的贮藏环境、不正确的安装、操作以及不按照指定用途使用而导致泵损坏。

在保修期内,维修或改装只能由我们的服务人员或经过我们书面同意的情况下进行。

一、基本过程描述1. 简介1.1 过程SULZER结晶操作,是分批次操作的降膜结晶过程。

在结晶中,熔化组分通过产品循环泵连续的在结晶器中循环。

图.1产品循环回路结晶器很像一个垂直的单一流向的壳体和管式热交换器,包括壳体和内侧都是充满液体的。

管两测的操作都是降膜操作模式。

熔化的产品由泵打回到单元操作的顶部,均匀的像膜一样的分布到每一根管道的内部,流入下面的接受槽中。

冷却或加热介质在壳层降膜分布,沿着管的外壁降落。

参照上述的分批过程可以分解成随后的组分的次序和步骤。

1 Run(流程):一定数量的不同的循环(cycle)按序排列,每一批的母液的产生都伴随着一批或更多的纯化的产品。

2Cycle(循环):几个按一定顺序排列的分段(stage)的操作过程。

每一个循环从一个分段(stage)末端产生的母液开始。

结晶物在这个阶段,随着增加的返回的原料,在连续的过程中逐渐的纯化直到最终的阶段得到纯品。

3Stage(分段):.一个独立的过程包括结晶、部分熔化(发汗)和完全熔化三阶段。

4Phase(阶段):一个分段(stage)的特殊的操作过程。

在下一部分(过程的基础原理)描述了下面的三个阶段。

-结晶-部分熔化(发汗)-全熔化每一阶段都可以独立的设置或程序步骤,是过程控制系统的一个描述。

2. 过程的基础原理2.1结晶化(phase 1)熔化组分在管道内壁形成的降膜在结晶化阶段的降温过程中逐渐形成了一个晶体层。

在这个阶段过程中,冷媒的进料温度曲线呈下降趋势以补偿不断增加的晶体层的厚度而减少了的热传导和因循环熔化组分纯度的不断下降而将低了的熔点。

这种条件下使得纯的晶体层迅速增加,而不纯的杂质积累在逐渐减少的液体中。

当残存的一定量的母液进入预先设定的水平高度结晶化过程就结束了。

2.2部分熔化(phase 2)结晶层在结晶化阶段以相当快的速度增长,会包含杂质从而降低一个分段(stage)的分离效率。

随后的控制热载体的升温过程将改善悬浮的结晶层的纯度。

苏尔寿泵机械密封的使用及维护机械密封式苏尔寿泵的主要部件,主要作用就是密封防止输送介质的渗漏。

由于管道输油行业的特点需要泵能够连续、高效的运转,机械密封的密封效果将会直接影响整机的运行,机械密封一旦出现泄漏,将会严重影响生产正常进行,甚至严重的还会出现重大安全事故。

标签:机械密封;使用及维护;失效;装配;渗漏苏尔寿泵在管道输油行业的应用越来越广,近几年不管是在输油管网的改造还是在新线建设中都大量采用苏尔寿泵,因管道输送行业的特点需要大排量、高扬程的稳定输送设备,恰恰苏尔寿泵就具备这些有点。

烟淄管道公司是新建设的管道输油企业,其泵站的主要输送设备就是选用苏尔寿泵,以招远站为例一共安装4台苏尔寿泵,按3大1小配备,排量都是1930m3/h,扬程分别为260m和140m。

招远站4台输油泵共8副机械密封,在试运过程中有6副出现了不同程度的渗漏。

机械密封的故障主要体现在以下几个方面:①密封面的故障:磨损、热裂、变形、破损(尤其是非金属密封面);②弹簧的故障:腐蚀、松弛以及断裂;③密封圈的故障:安装过程中出现的故障有卷边和扭曲以及掉块、裂口和碰伤;运行中出现的故障有变形、变质、硬化、破裂。

机械密封故障在运行中主要体现为振动、发热、磨损,并以介质泄漏的形式出现。

经过专家分析机械密封处渗漏可能由四个方面原因造成的,因机械密封是靠一对相对运动的环的端面相互贴合形成的微小轴向间隙起密封作用。

机械密封由动环、静环、压紧元件以及密封元件组成。

其中动、静环的端面组成摩擦副,动环是靠密封室中介质的压力使其端面紧压在静环端面上,并在两环端面上产生一定的比压和保持一层非常薄的膜而达到密封的目的。

1 机械密封故障原因分析1.1 机械密封的动、静环端面磨损,而造成动、静环端面磨损的原因有以下几个方面:①安装过紧。

机械密封的动、静环端面,如端面有严重烧焦现象、发黑和很明显的痕迹,密封橡胶圈变硬,失去弹性,这种就是安装过紧造成的。

处理办法:调整安装距离,泵叶轮安装后,用工具拔动弹簧,弹簧有比较强的弹力,松开后马上复位,有2-4mm的移动空间就行;②安装过松。