3240柴油机简介

- 格式:ppt

- 大小:17.82 MB

- 文档页数:56

MAN 9L32/40 Marine Main Engine Technical SpecificationTechnical Specification of Main EngineMAN 9L32/40(Type of Propulsion: FPP)Purchaser:Representative:Seller:Representative:Date:MAN Group’s Licensee in China-Hangzhou Zhonggao Engine Co.,LtdMAN 9L32/40-Technical Specification of Main EngineContent1. General (1)2. Rules and Regulations (1)3. Specification、Characteristic、Performance parameter (1)3.1 Specification (1)3.2 Characteristics (2)3.3 Performance parameter (3)4. Requirements of various subsystems (4)4.1 Fuel oil system (4)4.2 Lubricating system (4)4.3 Centre cooling system (5)4.4 compressed air system (6)4.5 Intake and exhaust system (6)4.6 Turning device (6)4.7 control system (6)5. Scope of supply (6)6. Technical documents (12)7. Shop test and inspection (14)8. paint color and nameplates (14)9. Oil seal and storage (14)10. Guarantees (14)11 Inspection on delivery (15)12 others (15)Attachment I Single engine FPP operating range (16)Attachment II standard spare parts (17)Attachment III Standard tools list (18)2MAN 9L32/40 Marine Main Engine Technical Specification1. General1.1 This technical specification, as a binding document which should be strictly complied with during engine production, delivery, test and inspection, stipulates the technical particulars,scope of supply, inspection on delivery etc of the marine main engine MAN 9L32/40, with propulsion type: FPP.1.2 MAN 9L 32/40 diesel engine, as marine main engine(one engine),coupled with flex coupling and gearbox, drives one fixed pitched propeller, and the engine seating is rigidly mounted on the foundation by means of epoxy chocks.2. Rules and Regulations2.1 Comply with IMO NO x limitation2.2 ISO2.3MAN technical standards2.4 CNS and Ministerial standards2.5 Company Standard2.6Classification class, unrestricted Navigation2.7 Norms and rules: none3. Specification、Characteristic、Performance parameter3.1 Specification3.1.1 Main SpecificationType ······················································MAN 9L32/40Style ······················································ Line, four stroke, non reverse,direct injection, turbo charger, twostage air cooler, compression airstarting, dry oil pan, TC oncoupling side, built-on L.O. pump,built-on CW pumps(i.e. LT & HTpumps)Bore ······················································ 320mm1MAN 9L32/40-Technical Specification of Main EngineStroke ··················································· 400mmCylinder Number (9)Displacement / cylinder. ························ 32.17dm3/cyl.Cylinder distance ·································· 530mmCompression Ratio ······························· 14.5Firing order ··········································· 1-6-3-2-8-7-4-9-5-1 (view fromcoupling side)Rotation ················································ clockwise (view from the couplingside),starboard engine MCR ······················································ 4320kW/750 r/minMin. steady revolution ···························· approx 250 r/minSpec. fuel oil consumption (SFOC) ········ 181g/kW·h, tolerance +5%Note: ① Lower calorific value 42700kJ/kg② with built-on pumps,SFOC will increase correspondingly:L.O. pump ········································ +2.0 g/kW·hPer CW pump ·································· +1.0 g/kW·hSpec .lub oil consumption ················· 0.8g/kW·h, tolerance + 20%3.1.2 ISO conditions:All value based on ISO 3046-1 conditions:Air temperature ····································· 25℃Air pressure ·········································· 100kPaRelative humidity ·································· 30%C. W. temp. before charge air cooler (LT-stage) 25℃3.1.3 Design conditionsUnder following condition ,engine can be operation without decrees power. But manufacture not simulate design condition make shop test. when overtop following condition, power should be modificated according to relevant documents from MAN.Air temperature (45)Air pressure ·········································· 100kPaRelative humidity (60)Exhaust back pressure ·························≤3kPaCooling water temperature before charge air cooler (LT-stage) ≤38℃3.2 Characteristics2MAN 9L32/40-Technical Specification of Main Engine3.2.1 InclinationUnder following condition, engine can be reliably operating.Across inclination (15)Across wave ·········································· ±22.5°Vertical inclination (5)Vertical wave ········································ ±7.5°3.2.2 Engine noise & Exhaust noiseEngine noise: at MCR, noise measured 1m from engine surface:approx.101~108dB(A)Exhaust gas noise: at MCR, noise measured 1m from exhaust gas pipe outlet: approx.118dB (A) (without silencer)3.2.3 Dimension and weightEngine weight ···· 52729kg±5%(dry weight, incl. flywheel weight 1729 kg) Cooling water capability of engine……300LDimension (L×B×H) ··················7675×2948×4486mmMin. cylinder lifting height ·········3460mm (from crankshaft center line)3.2.4 Working rangeEngine operation curve(see Attachment I).3.2.5 Power take off on free end(power undetermined)3.3 Performance parameterUnder ISO conditions, performance parameter at MCR:Mean effective Pressure ····················· 2.49MPaMean piston speed ······························· 10m/sAir consumption ···································· 7.2kg/kW·hExhaust flow ········································· 7.4kg/kW·hExhaust gas temperature (After TC) (330)Charge air pressure ······························ 0.404MPa (absolute pressure)Charge air temperature before cylinder……43℃Exhaust temperature before TC (565)Exhaust temperature after cylinder ·······≤510℃, deviation per cylinder of exhaust temperature and mean exhaust temperature is ±50℃Max. Exploration pressure ···················· 19.0MPaLub. Oil pressure before engine ··········· 0.4~0.5MPa3MAN 9L32/40-Technical Specification of Main EngineLub. Oil temperature before engine (65)HT cooling water pressure before engine……0.3~0.4MPaHT outlet temperature (90)Injector cooling water pressure before engine……0.2~0.5MPaInjector cooling water temperature before engine……60℃Fuel oil pressure before engine ············ 0.4~0.8MPa4. Requirements of various subsystems4.1 Fuel oil systemFuel oil quality:Marine diesel oil (MDO): ambient temperature ≥ 0 ℃, 0# or 10# diesel fuel according to GB252-2000 applicable; ambient temperature < 0 ℃, -10# applicable.Heavy fuel oil ( low-grade oil): Red No.1 HFO viscosity ≤3500s/100°F (≤ 380 cSt/50℃), (BSMA 100-M9,characteristic stated in the instruction), (well preheated, separated and filtrated). However, after engine starting and before engine stop, the engine has to run with LDO at least for 30 min..MDO (LDO 0# or -10#) is used in the shop test.On operation with HFO, viscosity before engine should be kept at 12mm2/s ~14mm2/s, and a pressurized fuel oil system is necessary to avoid gas produced during fuel oil heating.Flux of electric fuel charge pump ···················1.6m3/h (0.7MPa)Flux of electric fuel booster pump ··················3.1m3/h (0.7MPa)Fineness of duplex filter for fuel oil before engine……34μmFineness of self-cleaning filter ·······················34μm4.2 Lubricating systemLub. oil brand: SAE40, total base number (TBN)depend on sulphur content (characteristics stated in the instruction).The electric filling pump for cylinder……0.25kW×AC380V×50Hz triphaseRated flow: 0.120L/min ( n=1400r/min)Rated revolution: 1400 r/min (50 Hz)Maximal outlet pressure: 6Mpa4MAN 9L32/40-Technical Specification of Main EngineMaximal inlet pressure: 0.5Mpa Built-on lub.oil pump……………………Rated flow: 162 m3/h(0.7MPa)Rated revolution: 1800r/minVacuum degree of inlet : -0.04~+0.04Mpa Stand-by electric lub.oil pump ········flow: 130+ Zm3/h (0.7MPa)Z is the flush flow of self-cleaning filter Fineness of self-cleaning filter ·······················34μmFineness of duplex filter ·······················60μmLub. oil tank volume ····························· 4.5m3The pre-heating temp. of lub.oil before engine starting……≥ 40 ℃4.3 Centre cooling systemCentre cooling system consists of L.T. cooling water, H.T. cooling water and sea water system. The LT cooling water successively flows through LT CW pump, the 2nd stage of the two stages air cooler, L.O cooler, LT cooling water cooler; HT cooling water flows through HT CW water pump, HT cooling water pre-heating unit, the 1st stage of the two stages air cooer, engine(cylinder, cylinder head) and HT cooling water cooler; sea water system flows through SW pump, LT cooling water cooler, HT cooling water cooler.Both L.T. and H.T. cooling water are treated fresh water.( characteristics stated in the instruction)Built-on H.T. water pump ····················· Rated flow: 70 m3/h (0.45MPa)Rated revolution: 2200r/minFlow of stand-by electric H.T. water pump ·· 54 m3/h (0.43MPa)L.T./H.T. cooling water Expansion tank….min. capacity 0.5m3, distance from the tank bottom to crankshaft central line is 6-9m.Pre-heating unit of H.T. cooling water ··· required temperature before engine starting ≥ 60℃Electric L.T. water pump…………flux: depend on facility design (0.3MPa) Flow of built-on L.T. water pump · 85 m3/h( flow through lub.oil cooler & the 2nd stage of the two stage air cooler)L.T cooling water temperature at air cooler inlet ≤38℃( set-piont 32℃) Fuel injector cooling water pump ·········· flux: 1.6m3/h(0.3MPa)5MAN 9L32/40-Technical Specification of Main EnginePreheating temperature of fuel injector before engine starting (40)Flux of seawater pump ························ 165 m3/h (reference value)Seawater temperature at L.T. cooler ···· outlet ≤ 48℃4.4 compressed air systemstarting air pressure ······························ 1.0~3.0MpaConsumption of starting air ················· approx. 45N·m3 at a time (20℃) Consumption of assist jet air ··············· approx. 2.95N·m3 at a time (20℃) Air bottle Capability (for single main engine) ······2×510L(6 starting+1safety starting, 0 assist jet air) 4.5 Intake and exhaust systemTurbocharger(with air intake silencer)type: NR34/SAir cooler ·············································· 2 stages cooled by freshwaterCharger-air by-pass device ····································improve engineperformance during part load operation.4.6 Turning deviceThe electric turning device (include a switch cabinet +a suspended type press button control panel) & safety interlocking devicePower of motor ······································0.55kWInput voltage ········································A C380V×50HzRated torque ··········································800N·mSpeed of motor ······································1400rpm4.7 control systemElectric governor ···································· Heinzmann executor + speedcontrol deviceTerminal box ·········································· wirings of electric elementinstalled on the engine are exported from this terminal box 5. Scope of supply5.1 diesel engine…………………………………1 set/shipOne diesel engine is comprised of hereinafter major parts:Note: E: diesel engine H: hull○: standard supply from ZGPT6MAN 9L32/40-Technical Specification of Main Engine★: ZGPT can supply with extra price7MAN 9L32/40-Technical Specification of Main Engine85.1 standard spare parts ····························· 1set/ship(According to classification societies rules and MAN standard requirements, see attachment II)5.2 standard tools ······································ 1suit/ship(According to MAN standards’ requirement, see attachment III)6. Technical documents6.1 approved drawings: 2 set in paper edition+1set in CD, working drawings: 4 set in paper edition+1set in CD.The seller should offer the approved drawings to the buyer within 30 days after signing of contract.The purchaser should return 1 set of approved drawings within 25 days after receiving. Otherwise it will be regarded that the buyer accepts the approved drawings.After receiving the buyer’s accepted drawings, the seller should offer the work drawings within 20days.6.2 list of approved drawingsCross section drawingsGeneral arrangement drawing (incl. space size of lifting and maintenance space dimension ) (drawings in CAD electrical edition are just for reference ,and drawing in PDF electrical edition and/or paper edition are binding ones) Engine operating area curveEngine power modificationSFC modificationHFO, Lub.oil and fresh water quality requirementSystem drawings (fuel oil, Lub oil, cooling water, compressed air)Fuel oil leakage monitoring tank external dimensionsSupercharged air temperature control valve external dimensionsHT preheating unit external dimensionsInjector cooling water unit external dimensionsMain engine revolution tachometer external dimensionsTurbocharger revolution tachometer external dimensionsDiesel engine electric drawing (incl. monitoring and alarm values, the terminal box wiring drawings)Electric governor revolution control wiring drawing, and executor wiring drawingsThe list of standard spare part (incl. external dimensions of large sized part) (turbocharger’s spare part will be supplied by the manufacturer) The list of standard tools (turbocharger’s tools will be supplied by the manufacture).Heat balance calculation tableParameters for diesel engine tensional vibration calculationLoading and unloading time curveHFO temperature-viscosity curveFlywheel and coupling connection size6.3 The buyer should offer hereinafter documents with 25 days after signing of the contract:Propeller characteristic curves respectively at port and sailing state (incl. work condition point)6.4 Finished drawings: 6 sets in paper editon/ship +1set in CDClassification society certificateEmission certificate on NO x (ELAPP)Bench test recordEngine operation and maintenance instructionGovernor operation instructionTurbocharger operation instructionEngine packing listIn addition, incl. documents stated in 6.26.5 languages in approved drawings, work drawings and finishing drawings: English7. Shop test and inspectionThe manufacturer should inform the ship owner, shipyard and the design institute 1 week in advance of the shop test date, and the shop test should be strictly in line with shop test outline approved by the classification society with ship-owner, shipyard and design institute attended. If the ship owner, the shipyard or the design institute can’t attend the test on time after receiving manufacturer’s advice, it will be regarded as giving up their rights and they have to accept the test result approved by the classification society.8. paint color and nameplates8.1 The paint color should comply with engine’s manufacturer’s regulation. 8.2 nameplates: units: metric system & international system.Name plate’s language: EnglishAlarm plate’s language: English9. Oil seal and storageThe valid period of the oil seal is half-year since delivery date. The purchaser should keep the engine in the dry stock where corrosive gas is not allowed, and regularly check the oil seal situation (once every other 3months), and if necessary make oil seal again. And have to change oil seal when it is out of valid period.10. Guarantees10.1 Guarantee period: 18 months counting from the engine delivered from the factory or 1 years countering from the date on which the built ship be delivered to the ship owner whichever comes earlier.10.2 The manufacturer will dispatch engineer to instruct during engine installation on board and take part in relevant dock trials and sea trial.10.3 If the customer strictly complies with the operation and maintenance instruction but damage is found by reason of interior quality and with assignable record, the seller should maintain and replace the damaged parts for free. If damage is found by reason of customer’s mistake, the seller will take no responsibility. But the seller should supply technical support and damage parts to the customer to help the customer resolve the problems in time.10.4 if damage occurs at abroad, the seller shall through MAN’s world-wide service network immediately dispatch. And if the engine is in guarantee period, the responsible party will take on all the expanses occurred, based on the invoice issued by MAN.11 Inspection on deliveryWithin 1 day after arrival of the goods at the purchaser’s, both the seller and purchaser should make the finial inspection of the goods and reach a signing approval.12 othersThis technical specification is an integrate part of the commercial contract reached by the seller and the purchaser, and will come into effect with signature.MAN 9L32/40 Marine Main Engine Technical SpecificationAttachment I Single engine FPP operating rangeNote:MCR:Maximum Continuous RatingⅠ:Operating range for CONTINUOUS SERVICEⅡ:Operating range temporarily admissibleFP:Design range of fixed–pitch propeller operating range during sea trialsAttachment II standard spare parts (unrestricted Navigation)Attachment III Standard tools list。

核电站应急发电用 16V240Z DA 型柴油机牟恕宽 郑翠玲摘要 : 16V240Z DA 型柴油机是为我国秦山核电站设计的应急发电用柴油机 。

该型机是在240/ 275系列柴油机的基础上加装改造研制而成的 。

本文介绍了 16V240Z DA 型柴油机的主要技术参数 、特殊性能参数 、主要设计结构特点和该柴油机作核电站应急发电而在台架上所进行的扭振 测量 、机油消耗量测量 、调速器的非直线度和不灵敏度 、转速波动率 、单双脉冲突加载荷 、无燃油输 送泵的快速起动 、冷机起动 、增压器旁通线路 、热机起动 、45s 内加载 、突加载荷和调速器稳定调速 率等特殊性能试验结果 。

关键词 : 柴油机 核电站 设计 试验应急发电 16V240ZDA意外事故情况下在一回路失水时及早冷却堆芯 ,以防前苏联切尔诺贝利灾难重演 ,核电站必须设置应 急发电用柴油机 ,并对柴油机的各种性能有相当高 的要求 。

正因为核电站应急发电用柴油机是确保 电站长期处于安全运行所必不可少的 15 项重大关 键设备之一 ,所以引起人们高度重视 ,因而研制工 作要非常认真 ,其价格也往往比一般柴油机高出几 倍 。

1 前言我国自行设计 、自己建造的第一座核电站秦山核电站采用的是近代化的压水堆 。

为使厂区 在意外断电时安全停堆和保证在发生地震 、空难等牟恕宽、郑翠玲 , 大连机车车辆厂 , 116021 辽宁省大连市收稿日期 : 1999203202轴瓦抱轴悬挂装置可成套互换 ,首台样车将于 1999 年 5 月份出厂 ,经过必要的运用考核后 ,将作为现 抱轴瓦抱轴悬挂装置的并列方案 ,今后将根据用户 的要求而提供 。

(2) 研制其三轴径向转向架 机车径向转向架是对传统转向架的重大变革 ,它既能大幅度降低轮轨磨耗 ,显著改善轮轨粘着 , 并能提高机车的曲线通过速度 ,特别适用于多曲线的山区铁路 。

它是目前国际上各大机车制造商竞 相研制的一大新技术 、新部件 ,也是我国目前机车 转向架设计领域的一大热门课题 。

12V240ZJ6F型柴油机1 柴油机工作原理当活塞由上向下运动时,外界的新鲜空气经过进气门被吸入气缸,而后活塞向上运动,对这部分新鲜空气进行压缩,使空气的温度和压力都有较大的升高。

这样的空气与从喷油器喷入气缸的柴油混合,能使柴油自行着火燃烧放出热能,此时燃气温度和压力急剧升高,而后急剧膨胀,推动活塞向下运动做功,经过连杆、曲轴输出扭矩。

柴油机的一个完整的工作过程是由进气、压缩、燃烧膨胀、排气四个冲程组成,即曲轴旋转两圈、活塞经过四个冲程。

1.2.1 进气冲程:在配气机构的作用下,进气门在活塞处于上止点前42º20’曲轴转角时开启,新鲜空气通过增压并冷却后,经稳压箱、进气支管、气缸盖进气道进入气缸内,当活塞运动到下止点后42º20’曲轴转角时,进气门关闭。

1.2.2 压缩冲程:当气门完全关闭时,活塞继续上行,压缩过程开始,随着活塞上行,气缸内的空气不断被压缩,其压力和温度不断升高,为柴油自燃创造了必要的条件。

当活塞到达上止点前21º时,柴油以雾状喷入燃烧室,与气缸内的高压高温的空气混合。

1.2.3 燃烧膨胀冲程:当喷入气缸内的柴油与高温高压空气混合后迅速燃烧,开始了燃烧过程,燃烧压力急骤上升,燃气最高温度可达1500℃。

1.2.4 排气冲程:当活塞到达下止点前42º20‘曲轴转角,排气门开启,开始了排气过程,这时气缸内经过膨胀做功的燃气开始排出,活塞经过下止点继续上行,直到活塞再次达到上止点后42º20‘曲轴转角,排气门完全关闭为止。

2 柴油机简要介绍2.1 柴油机总体结构12V240ZJ6F型柴油机为四冲程、V型、废气涡轮脉冲式增压、增压空气中间冷却、开式燃烧室的中速柴油机。

柴油机两排气缸V型排列,V型夹角为50°,活塞连杆装在气缸套内,连接在曲轴的曲柄销上,每个缸有六条气缸螺栓将气缸盖紧固在机体上。

柴油机曲轴输出端通过联轴节与主发电机的转子相连进行功率输出,机体的输出端通过连接箱与主发电机的定子连接。

柴油机基础知识第一章柴油机基础知识第一节柴油机概述内燃机是一种复杂的能量转换机器。

随着技术水平的不断提高,各种类型内燃机的构造及其布置也就各有差异。

往复活塞式内燃机的基本构造,都由下列二个机构和五个系统所组成。

以柴油作燃料,当空气在气缸内受压缩而产生高温,使喷入的柴油自然,燃气膨胀而作功的内燃机,称为柴油机。

我国现生产柴油机的功率覆盖面为2.2—47280KW,柴油机的气缸直径65—900mm,转速5.6—4400r/min。

特点:易于起动、操作维护方便、结构紧凑、体积小、重量轻、便于运输安装、经济性好、使用范围广,是较理想的动力机械,广泛用作发电、船舶、排灌、汽车、拖拉机和工程机械等动力。

第二节柴油机分类按照工作循环分类:二冲程柴油机和四冲程柴油机;按照气缸数量分类:单缸柴油机和多缸柴油机;按照汽缸排列方式分类:立式、卧式、直列式、斜置式、V形、X形、W形、对置汽缸、对置活塞等;按照冷却方式分类:水冷柴油机和风冷柴油机;按照进气方式分类:自然吸气式和增压式;增压式可分为:低增压、中增压、高增压和超高增压等;按照曲轴转速分类:高速机、中速机、低速机;按照用途分类:固定式、移动式;第三节柴油机工作原理按照一定规律,不断地将柴油和空气送入气缸,柴油在气缸内着火燃烧,放出热能,高温高压的燃气推动活塞作功,将热能转化成机械能。

四冲程柴油机的正常运转通过以下四个工作过程来完成;进气过程: 活塞由上止点移动到下止点,即曲轴的曲柄内0°转到180°(活塞位于第一冲程上止点时,曲轴的曲柄位置定为0°)。

在这个冲程中,进气门打开,新鲜空气被吸入气缸。

压缩过程: 活塞由下止点移动到上止点,即曲柄由180°转到360°。

在这个冲程中,气缸内的气体被压缩;燃烧膨胀过程(工作过程): 活塞再由上止点移动到下止点,即曲柄由360°转到540°。

在这个冲程中燃气膨胀做功,所以又称为工作冲程或做功冲程。

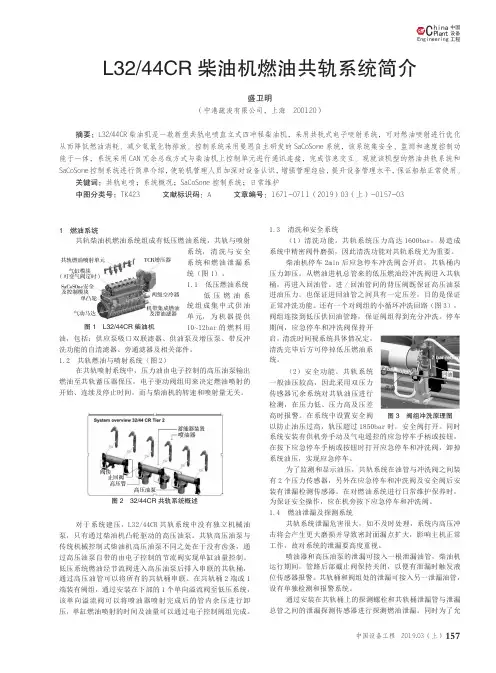

157中国设备工程Engineer ing hina C P l ant中国设备工程 2019.03 (上)1 燃油系统共轨柴油机燃油系统组成有低压燃油系统,共轨与喷射系统,清洗与安全系统和燃油泄漏系统(图1)。

1.1 低压燃油系统低压燃油系统组成集中式供油单元,为机器提供10~12bar 的燃料用油,包括:供应泵吸口双联滤器、供油泵及增压泵、带反冲洗功能的自清滤器、旁通滤器及相关部件。

1.2 共轨燃油与喷射系统(图2)在共轨喷射系统中,压力油由电子控制的高压油泵输出燃油至共轨蓄压器保压,电子驱动阀组用来决定燃油喷射的开始、连续及停止时间,而与柴油机的转速和喷射量无关。

图2 32/44CR 共轨系统概述对于系统建压,L32/44CR 共轨系统中没有独立机械油泵,只有通过柴油机凸轮驱动的高压油泵。

共轨高压油泵与传统机械控制式柴油机高压油泵不同之处在于没有齿条,通过高压油泵自带的由电子控制的节流阀实现单缸油量控制。

低压系统燃油经节流阀进入高压油泵后排入串联的共轨桶,通过高压油管可以将所有的共轨桶串联。

在共轨桶2端或1端装有阀组,通过安装在下部的1个单向溢流阀至低压系统,该单向溢流阀可以将喷油器喷射完成后的管内余压进行卸压,单缸燃油喷射的时间及油量可以通过电子控制阀组完成。

L32/44CR 柴油机燃油共轨系统简介盛卫明(中港疏浚有限公司,上海 200120)摘要:L32/44CR 柴油机是一款新型共轨电喷直立式四冲程柴油机,采用共轨式电子喷射系统,可对燃油喷射进行优化从而降低燃油消耗、减少氮氧化物排放。

控制系统采用曼恩自主研发的SaCoSone 系统,该系统集安全、监测和速度控制功能于一体,系统采用CAN 冗余总线方式与柴油机上控制单元进行通讯连接,完成信息交互。

现就该机型的燃油共轨系统和SaCoSone 控制系统进行简单介绍,使轮机管理人员加深对设备认识,增强管理经验,提升设备管理水平,保证船舶正常使用。

SXD-MAN B&W L32/40 柴油机技术介绍1、柴油机主要性能/技术数据:1.11.21.31.4 柴油机旋转方向:曲轴顺时针或逆时针旋转(从输出端看)注:根据AMN最新技术要求通知,用于固定桨的柴油机功率由500kW/缸改为450kW/缸2柴油机运行区域曲线2.1固定桨()2.2 变距桨()3、柴油机加减负荷时间曲线4、排放指标:满足IMO关于Nox的排放要求()5、柴油机外形尺寸和重量()6、总体布置图:增压器位于输出端或自由端()7、柴油机系统原理图7.1 燃油系统原理图()燃油品质:轻柴油: 在环境温度不低于0℃的地方, 可采用GB252-2000中0#、10#柴油;在环境温度低于0℃的地方,可采用-10#柴油.重油(低质油): 可燃用雷氏1号粘度≤7000秒/100°F(≤700 cSt/50℃)的重油(在具备完善的预热和分离、过滤条件下) ,但在柴油机启动后和停机前, 必须燃用轻柴油运转不少于30分钟.出厂试验时用MDO(0#或-10#轻柴油)柴油机燃油消耗率:()燃用重油时,进机燃油的粘度保持在12mm2/s~14mm2/s,为避免燃油加热时系统产生放气,燃油供给为加压系统。

7.2滑油系统原理图()滑油牌号: SAE40,总碱值由燃油含硫量而定()柴油机滑油消耗率:()油底壳为干式润滑泵可采用电动齿轮滑油泵或机带齿轮滑油泵气缸润滑采用机带专用气缸电动润滑泵(380 V/50 Hz 或440 V/60 Hz 、三相)。

曲轴、凸轮轴、定时传动装置、摇臂、增压器等采用强制压力润滑。

滑油预热方式为蒸气加热,滑油预热温度≥40℃预润滑说明()7.3中央冷却水系统原理图()中央冷却水系统由低温冷却水、高温冷却水和海水系统组成。

低温冷却水流经低温水泵、两级空冷器的第2级、滑油冷却器、喷油冷却器、低温冷却器、高温冷却器;高温冷却水流经高温水泵、高温冷却水预热单元、两级空冷器的第1级、柴油机(缸套、缸盖)、高温冷却器;海水系统流经海水泵、低温冷却器。

L+V32/40四冲程柴油机简介中国石油集团济柴动力总厂目录前言 (3)32/40系列柴油机主要技术参数 (4)产品特点 (10)产品应用 (17)服务 (21)前言2009年9月,中国石油集团济柴动力总厂与世界最大船用柴油机品牌之一的德国MAN柴油机公司签订了32/40柴油机的许可证生产协议,产品分为直列6、7、8、9缸和V 型12、14、16及18缸,转速分为720和750r/min两种,功率覆盖范围:3000kW~9000kW。

MAN公司产品可靠,技术领先,是世界上中低速柴油机的领先设计商和制造商,来自MAN公司的柴油机约覆盖了全世界贸易所需功率的近50%。

MAN柴油机公司研发柴油机尤其注重发动机的环保性能。

采用了独一无二的大型发动机技术,旨在逐步制造出排放性更低、动力性更强、经济型更好的发动机。

在优化功率和燃油消耗率的同时减少排放。

始终遵循排放法规,无论加工制造,还是发动机的出厂试验调试等,其产品可以说是内燃机中的理想动力。

32/40系列柴油机主要技术参数一、工作环境1、根据ISO 30461/1-2002,柴油机的工作条件:空气温度:298K(25℃)空气压力:1bar中冷器进水温度:298K(25℃)相对湿度:30%2、对于船用机,无功率损失的工作环境条件要求如下:空气温度:318K(45℃)空气压力:1bar中冷器进水水温度:311K(38℃)3、IMO要求:发动机可满足IMO TierII排放限值要求。

二、柴油机参数1、一般参数:发动机循环:四冲程增压器系统:恒压气缸数:直列6、7、8、9气缸数:V型12、14、16、18缸径:320mm冲程:400mm单缸扫气容积:32.2L 2、功率和重量比值(MCR ): 直列机:11.3-12.7kg/kW V 型机:9.4-10.2kg/kW3、单缸输出功率(MCR ):750/720rpm :500kW4、冷却:气缸冷却:淡水 中冷器(两级):淡水燃油喷嘴冷却:淡水,只用于HFO 运行 起动方法:压缩气体 三、主要技术规格 1、系列技术规格船用燃油消耗率100%负荷 85%负荷 L+V32/40 181g/kWh179 g/kWh机油消耗g/kWh L+V32/40船机 0.5 g/kWh功率输出MCR (最大持续功率)发动机转速 750rpm 720*)rpm 平均活塞转速 10.0m/s 9.6m/s 平均有效压力24.9bar25.9bar*)只用于电机驱动2、L32/40柴油机参数两个发动机安装的最小中心距离:2,500mm前端带增压器的两发动机安装的最小中心距离:3,000mm 720r/min 转速的柴油机仅用于发电机设备用于定距螺旋推进器时柴油机单缸功率:480kw/cyl缸径:320mm ,行程400mmISO 标准工况下的比燃油消耗(SFOC)尺寸润滑油消耗率0.5g/kwh3、V32/40柴油机参赛润滑油消耗率0.5g/kwh 缸径:320mm ,行程400mmISO 标准工况下的比燃油消耗(SFOC)尺寸两个发动机安装的最小中心距离:4,000mm 720r/min 转速的柴油机仅用于发电机设备用于定距螺旋推进器时柴油机单缸功率:480kw/cyl4、L32/40柴油机机组参数缸径:320mm行程:400mm尺寸净重发电机效率为96.5%P为发动机之间的空间要求,宽600mm,高2,000mm。

DF4D型内燃机车主要技术参数一、机车主要技术参数传动方式交-直流电传动轨距 1435mm轮径 1050 mm轴重 23±3%T计算整备重量 138T±3%T标称功率 3240kW运用功率 2940kW机车速度(按动轮直径半磨耗计算)最大速度 100km/h持续速度 24。

5km/h机车轮周牵引力(轮箍半磨耗状态)最大起动牵引力 480。

48kN持续牵引力 341。

15kN通过最小曲线半径 145m轴距 1800mm转向架全轴距 3600mm机车全轴距 15900mm机车外形尺寸长 21100mm(两车钩中心距)宽 mm高 mm燃油箱容积 9000L机油装载量1200kg水装载量 1200kg砂装载量 800kg车钩中心线高度 880±10mm二、机车主要部件技术参数1.柴油机型号 16V280ZJD形式四冲程、废气涡轮增压、增压空气中冷、直接喷射燃烧室缸径 240mm行程 275mm气缸数及排列 16缸 V型排列 50°夹角标定功率 3240Kw标定转速 1000r/min最低空载稳定转速 430r/min燃油消耗率 208g /(kW.h)机油消耗率〈2.04g /(kW。

h)重量 22790kg2.同步主发电机型号 JF204D额定容量 2911kVA额定电压 425/770V额定电流 3955/2183A额定转速 1000r/min励磁方式他励冷却方式径向自通风额定频率 116.7Hz绝缘等级 H/H额定励磁电压 92/105V(DC)额定励磁电流 255/285A(DC)额定效率 95-96%3。

牵引电机型号 ZD109B额定功率 530kW额定电压 670/980V额定电流 845/575A最大电流 1100A额定转速 745r/min通风量≥110m3/min绝缘等级 H/H通风方式强迫外通风工作制连续励磁方式串励3。

主硅整流柜型号 GTF—5100/12500硅整流元件型号 ZP2000—28 12个额定交流输入电压 1000V额定交流输入电流 3980A最大直流输出电压 1250V额定直流输出电流 5100A额定功率 530kW5。

非道路用系列柴油机主要特点:工程机械用系列柴油机秉承车用系列柴油机的一贯优良品质,采用直喷式燃烧室,易启动,油耗低,经济性好。

结构紧凑、重量轻,便于安装布置。

具有扭矩储备大、振动小、噪声低等性能优点。

关键零部件均采用经过优化的高速车用柴油机零部件,使柴油机具有良好的可靠性,市场互换性和通用性好。

二、叉车用系列柴油机主要技术参数主要特点:叉车用系列柴油机秉承车用系列柴油机的一贯优良品质,采用直喷式燃烧室,易启动,油耗低,经济性好。

结构紧凑、重量轻,便于安装布置。

具有扭矩储备大、振动小、噪声低等性能优点。

齿轮系经过优化设计,液压动力输出更加稳定。

其它关键零部件均采用经过优化的高速车用柴油机零部件,使柴油机具有良好的可靠性,市场互换性和通用性好。

主要特点:拖拉机用系列柴油机秉承车用系列柴油机的一贯优良品质,采用直喷式燃烧室,易启动,油耗低,经济性好。

结构紧凑、重量轻,便于安装布置。

具有扭矩储备大、振动小、噪声低、调速率低等性能优点。

关键零部件均采用经过优化的高速车用柴油机零部件,使柴油机具有良好的可靠性,市场互换性和通用性好。

主要特点:收割机用系列柴油机秉承车用系列柴油机的一贯优良品质,采用直喷式燃烧室,易启动,油耗低,经济性好。

结构紧凑、重量轻,便于安装布置。

具有动力强劲、振动小、噪声低、调速率低等性能优点。

关键零部件均采用经过优化的高速车用柴油机零部件,使柴油机具有良好的可靠性,市场互换性和通用性好。

主要特点:发电机组用系列柴油机秉承车用系列柴油机的一贯优良品质,采用直喷式燃烧室,易启动,油耗低,经济性好。

结构紧凑、重量轻,便于安装布置。

具有动力强劲、振动小、噪声低、调速率低等性能优点。

关键零部件均采用经过优化的高速车用柴油机零部件,使柴油机具有良好的可靠性。

动力接口符合SAE标准,市场互换性和通用性好。

主要特点:水泵机组用系列柴油机秉承车用系列柴油机的一贯优良品质,采用直喷式燃烧室,易启动,油耗低,经济性好。

柴油发电机组简介作用:保证机组的安全停机,当电厂正常电源失去时向机组的保安负荷供电,因此该设备的快速启动和快速带负荷能力以及可靠性是柴油发电机组的重要性指标。

组成:柴油发电机组由一台柴油机和一台柴油机驱动的同步发电机、成套配电柜、控制盘、蓄电池以及继电保护系统和所有的辅助设备组成。

柴油发电机组简介•我厂柴油发电机组为英国进口的柴油机和美国马拉松技术无刷、自励磁、水平轴、自行散热同步型柴油发电机组。

本机型具有结构紧凑,系统简单、启动方便、维护量小等优点。

冷却系统有自带的风机和水泵完成,采用电子打火和电子调速系统,启动快捷,运行稳定。

具备自动和手动启动功能。

柴油发电机组保证在火电厂全厂停电事故中,快速自启动带载运行,在无人值守的情况下,接到启动指令后在15秒内一次启动成功,在60秒内实现一个自启动的循环(即三次试启动),若自起动连续三次失败, 则发出停机信号, 并闭锁自起动回路。

柴油发电机组自启动成功率不小于99%。

自启动成功的定义是:柴油发电机组在额定转速,发电机在额定电压下稳定运行2-3秒,并具备首次加载条件。

柴油发电机组简介•带负载稳定运行功能•柴油发电机组自启动成功后,允许首次加载不低于50%额定负载,在首次加载后的60秒内带满负载运行,并在负载额定容量不低于20%,允许长期稳定运行。

•柴油发电机组应能在功率因数为0.8的额定负载下,稳定运行12小时中,应允许有1小时1.1倍的过载运行,并在24小时内,允许出现上述过载运行两次。

发电机尚应允许15秒的1.6倍过载运行(过载:额定电压下的过电流)。

•柴油发电机组允许全电压直接启动的空载四极速鼠笼式异步电动机的容量不小于200kW。

柴油发电机组简介•自动调节功能•柴油发电机组的空载电压整定范围为95-105%,线电压波形正弦性畸变率不大于5%。

•柴油发电机组在带功率因数为0.8-1.0的负载,负载功率在0-100%内渐变时应能达到:稳态电压调整率≤±0.5%、稳态频率调整率±2%可调、•电压、频率波动率:≤±0.15%、≤0.5%(负载功率在0-25%内渐变时)•自动控制功能:保安段母线电压自动连续监测;柴油发电机组简介•机组在空载状态,突加功率因数<0.4(滞后)额定容量为0.2Pe的三相对称负载或在已带80%Pe 的稳定负载再突加上述负载时,发电机的母线电压0.2秒后应不低于75%Ue,发电机瞬态电压调整率δu≤+20~-15%,电压恢复到最后稳定电压的±3%•以内所需时间不超过1秒,瞬态频率调整率≤5%(电子调整器),频率稳定时间<3秒,突减额定功率容量为0.2Pe的负载时,柴油发电机组升速不超过额定转速的10%。

SXD-MAN B&W L32/40 柴油机技术介绍1、柴油机主要性能/技术数据:1.11.21.31.4 柴油机旋转方向:曲轴顺时针或逆时针旋转(从输出端看)注:根据AMN最新技术要求通知,用于固定桨的柴油机功率由500kW/缸改为450kW/缸2柴油机运行区域曲线2.1固定桨()2.2 变距桨()3、柴油机加减负荷时间曲线4、排放指标:满足IMO关于Nox的排放要求()5、柴油机外形尺寸和重量()6、总体布置图:增压器位于输出端或自由端()7、柴油机系统原理图7.1 燃油系统原理图()燃油品质:轻柴油: 在环境温度不低于0℃的地方, 可采用GB252-2000中0#、10#柴油;在环境温度低于0℃的地方,可采用-10#柴油.重油(低质油): 可燃用雷氏1号粘度≤7000秒/100°F(≤700 cSt/50℃)的重油(在具备完善的预热和分离、过滤条件下) ,但在柴油机启动后和停机前, 必须燃用轻柴油运转不少于30分钟.出厂试验时用MDO(0#或-10#轻柴油)柴油机燃油消耗率:()燃用重油时,进机燃油的粘度保持在12mm2/s~14mm2/s,为避免燃油加热时系统产生放气,燃油供给为加压系统。

7.2滑油系统原理图()滑油牌号: SAE40,总碱值由燃油含硫量而定()柴油机滑油消耗率:()油底壳为干式润滑泵可采用电动齿轮滑油泵或机带齿轮滑油泵气缸润滑采用机带专用气缸电动润滑泵(380 V/50 Hz 或440 V/60 Hz 、三相)。

曲轴、凸轮轴、定时传动装置、摇臂、增压器等采用强制压力润滑。

滑油预热方式为蒸气加热,滑油预热温度≥40℃预润滑说明()7.3中央冷却水系统原理图()中央冷却水系统由低温冷却水、高温冷却水和海水系统组成。

低温冷却水流经低温水泵、两级空冷器的第2级、滑油冷却器、喷油冷却器、低温冷却器、高温冷却器;高温冷却水流经高温水泵、高温冷却水预热单元、两级空冷器的第1级、柴油机(缸套、缸盖)、高温冷却器;海水系统流经海水泵、低温冷却器。

MAN V32/40系列柴油机曲轴TR镦锻工艺开发李恩轩;杜绍贵;李六如【摘要】V32/40系列柴油机是MAN公司研发的四冲程中速船用柴油机。

主要用于船舶推进主机和辅机,可在无限航区运用,并满足IMO和NOx排放要求。

极佳的经济性与高寿命使V32/40系列机广泛用于全球船舶领域中,市场前景广阔。

【期刊名称】《金属加工:热加工》【年(卷),期】2012(000)021【总页数】4页(P59-62)【关键词】柴油机曲轴;工艺开发;镦锻;船舶领域;船用柴油机;MAN公司;推进主机;无限航区【作者】李恩轩;杜绍贵;李六如【作者单位】南车资阳机车有限公司曲轴事业部,四川641301;南车资阳机车有限公司曲轴事业部,四川641301;南车资阳机车有限公司曲轴事业部,四川641301【正文语种】中文【中图分类】U675.96V32/40系列柴油机是MAN公司研发的四冲程中速船用柴油机。

主要用于船舶推进主机和辅机,可在无限航区运用,并满足IMO和NOx排放要求。

极佳的经济性与高寿命使V32/40系列机广泛用于全球船舶领域中,市场前景广阔。

MAN V32/40系列柴油机包括18V32/40、16V32/40、14V32/40、12V32/40共4种机型,单缸功率为500kW,因此该系列柴油机的额定功率范围为6000~9000kW。

截止2011年底,国内已经有潍柴、陕柴、镇柴、杭州中高、石油济柴及南车资阳等公司获得了MAN V32/40柴油机的生产许可证。

这种状况无疑会加剧主机厂间的竞争,但是对曲轴制造业来说则是一种利好。

南车资阳公司2008年获得MAN V32/40系列柴油机生产许可证后,凭借雄厚的实力全力推进MAN机国产化。

2009年公司获得孟加拉电站项目,以18V32/40柴油机为主发电机,公司以孟加拉电站项目为载体开始强力推进18V32/40柴油机样机试制及核心零部件的国产化工作。

曲轴作为发动机的核心部件之一,是首批要求进行国产化的零部件。