传感器英文课件

- 格式:ppt

- 大小:8.81 MB

- 文档页数:44

传感器中英文介绍(总5页) -CAL-FENGHAI.-(YICAI)-Company One1-CAL-本页仅作为文档封面,使用请直接删除. sensorssensors(English name: transducer/sensor) is a kind of detection device, can feel the measured information, and will feel information transformation according to certain rule become electrical signal output, or other form of information needed to satisfy theinformation transmission, processing, storage, display, record and control requirements.Sensor's features include: miniaturization, digital, intelligent, multi-functional, systematic and network. It is the first step of automatic detection and automatic control. The existence and development of the sensor, let objects have sensory, such as touch, taste and smell let objects become live up slowly. Usually accordingto its basic cognitive functions are divided into temperature sensor, light sensor, gas sensor, force sensor, magnetic sensor, moisture sensor, acoustic sensor, radiation sensitive element, color sensorand sensor etc. 10 major categories.temperature transducerTemperature sensors (temperature transducer) refers to can feel temperature translates into usable output signal of the sensor. The temperature sensor is the core part of the temperature measuring instrument, wide variety. According to measuring methods could be divided into two types: contact and non-contact, according to the sensor material and electronic component features divided into two categories, thermal resistance and thermocouple.1 principle of thermocoupleThermocouple is composed of two different materials of metal wire, the welded together at the end. To measure the heating part of the environment temperature, can accurately know the temperature of the hot spots. Because it must have two different material of the conductor, so called the thermocouple. Different material to make the thermocouple used in different temperature range, their sensitivityis also each are not identical. The sensitivity of thermocouplerefers to add 1 ℃ hot spot temperature changes, the output variation of potential difference. For most of the metal material supportther mocouple, this value about between 5 ~ 40 microvolt / ℃.As a result of the thermocouple temperature sensor sensitivityhas nothing to do with the thickness of material, use very fine material also can make the temperature sensor. Also due to the production of thermocouple metal materials have good ductility, the slight temperature measuring element has high response speed, can measure the process of rapid change.Its advantages are:(1)high precision measurement. Because of thermocouple direct contact with the object being measured, not affected by intermediate medium.(2)the measurement range. Commonly used thermocouple from1600 ℃ to 50 ℃ ~ + sustainable measurement, some special thermocouple minimum measurable to - 269 ℃ (e.g., gold iron nickel chrome), the h ighest measurable to + 2800 ℃ (such as tungsten rhenium).(3) simple structure, easy to use. Thermocouple is usually composed of two different kinds of metal wire, but is not limited by the size and the beginning of, outside has protective casing, so very convenient to use. The thermocouple type and structure of the form.2. The thermocouple type and structure formation(1)the types of thermocoupleThe commonly used thermocouple could be divided into two types: standard thermocouple and non-standard thermocouple. Standard thermocouple refers to the national standard specifies its thermoelectric potential and the relationship between temperature, permissible error, and a unified standard score table of thermocouple, it has with matching display instrument to choose from. Rather than a standard thermocouple or on the order of magnitude less than therange to use standardized thermocouple, in general, there is no uniform standard, it is mainly used for measurement of some special occasions.Standardized thermocouple is our country from January 1, 1988, thermocouple and thermal resistance of all production according toIEC international standard, and specify the S, B, E, K, R, J, T sevenstandardization thermocouple type thermocouple for our countryunified design.(2)to ensure that the thermocouple is reliable, steady work, the structure of thermocouple requirements are as follows:①of the two thermocouple thermal electrode welding must be strong;②two hot electrode should be well insulated between each other, in case of short circuit;③compensation wires connected to the free cod of a thermocouple to convenient and reliable;④protect casing thermal electrodes should be able to make sufficient isolation and harmful medium.3.The thermocouple cold end temperature compensationDue to the thermocouple materials are generally more expensive (especially when using precious metals), and the temperature measurement points are generally more far, the distance to the instrument in order to save materials, reduce cost, usually adopt the compensating conductor) (the free end of the cold junction of the thermocouple to the steady control of indoor temperature, connectedto the meter terminals. It must be pointed out that the role of the thermocouple compensation wire extension hot electrode, so that only moved to the control room of the cold junction of the thermocouple instrument on the terminal, it itself does not eliminate the cold end temperature change on the influence of temperature, cannot have the compensation effect. So, still need to take some of the other correction method to compensate of the cold end temperatureespecially when t0 indicates influence on measuring temperature 0 ℃.Must pay attention to when using thermocouple compensating conductor model match, cannot be wrong polarity, compensation conductor should be connected to the thermocouple temperature should not exceed 100 ℃.传感器传感器(英文名称:transducer/sensor)是一种检测装置,能感受到被测量的信息,并能将感受到的信息,按一定规律变换成为电信号或其他所需形式的信息输出,以满足信息的传输、处理、存储、显示、记录和控制等要求。

传感器中英文介绍Company Document number:WTUT-WT88Y-W8BBGB-BWYTT-19998. sensorssensors(English name: transducer/sensor) is a kind of detection device, can feel the measured information, and will feel information transformation according to certain rule become electrical signal output, or other form of information needed to satisfy the information transmission, processing, storage, display, record and control requirements.Sensor's features include: miniaturization, digital, intelligent, multi-functional, systematic and network. It is the first step of automatic detection and automatic control. The existence and development of the sensor, let objects have sensory, such as touch, taste and smell let objects become live up slowly. Usually according to its basic cognitive functions are divided into temperature sensor, light sensor, gas sensor, force sensor, magnetic sensor, moisture sensor, acoustic sensor, radiation sensitive element, color sensor and sensor etc. 10 major categories.temperature transducerTemperature sensors (temperature transducer) refers to can feel temperature translates into usable output signal of the sensor. The temperature sensor is the core part of the temperature measuring instrument, wide variety. According to measuring methods could be divided into two types: contact and non-contact, according to the sensor material and electronic component features divided into two categories, thermal resistance and thermocouple.1 principle of thermocoupleThermocouple is composed of two different materials of metal wire, the welded together at the end. To measure the heating part of the environment temperature, can accurately know the temperature of the hot spots. Because it must have two different material of the conductor, so called the thermocouple. Different material to make the thermocouple used in different temperature range, their sensitivity is also each are not identical. The sensitivity of thermocouple refers to add 1 ℃ hot spot temperature changes, the output variation of potential difference. For most of the metal material support thermocouple, this value about between 5 ~ 40 microvolt / ℃.As a result of the thermocouple temperature sensor sensitivity has nothing to do with the thickness of material, use very fine material also can make the temperature sensor. Also due to the production of thermocouple metal materials have good ductility, the slight temperature measuring element has high response speed, can measure the process of rapid change.Its advantages are:(1)high precision measurement. Because of thermocouple direct contact with the object being measured, not affected by intermediate medium.(2)the measurement range. Commonly used thermocouple from 1600 ℃ to50 ℃ ~ + sustainable measurement, some special thermocouple minimum measurable to - 269 ℃ ., gold iron nickel chrome), the highest measurable to + 2800 ℃ (such as tungsten rhenium).(3) simple structure, easy to use. Thermocouple is usually composed of two different kinds of metal wire, but is not limited by the size and the beginning of, outside has protective casing, so very convenient to use. The thermocouple type and structure of the form.2. The thermocouple type and structure formation(1)the types of thermocoupleThe commonly used thermocouple could be divided into two types: standard thermocouple and non-standard thermocouple. Standard thermocouple refers to the national standard specifies its thermoelectric potential and the relationship between temperature, permissible error, and a unified standard score table of thermocouple, it has with matching display instrument to choose from. Rather than a standard thermocouple or on the order of magnitude less than the range to use standardized thermocouple, in general, there is no uniform standard, it is mainly used for measurement of some special occasions.Standardized thermocouple is our country from January 1, 1988, thermocouple and thermal resistance of all production according to IEC international standard, and specify the S, B, E, K, R, J, T seven standardization thermocouple type thermocouple for our country unified design.(2)to ensure that the thermocouple is reliable, steady work, the structure of thermocouple requirements are as follows:①of the two thermocouple thermal electrode welding must be strong;②two hot electrode should be well insulated between each other, in case of short circuit;③compensation wires connected to the free cod of a thermocouple to convenient and reliable;④protect casing thermal electrodes should be able to make sufficient isolation and harmful medium.3.The thermocouple cold end temperature compensationDue to the thermocouple materials are generally more expensive (especially when using precious metals), and the temperature measurement points are generally more far, the distance to the instrument in order to save materials, reduce cost, usually adopt the compensating conductor) (the free end of the cold junction of the thermocouple to the steady control of indoor temperature, connected to the meter terminals. It must be pointed out that the role of the thermocouple compensation wire extension hot electrode, so that only moved to the control room of the cold junction of the thermocouple instrument on the terminal, it itself does not eliminate the cold end temperature change on the influence of temperature, cannot have the compensation effect. So, still need to take some of the other correction method to compensate of the cold end temperature especially when t0 indicates influence on measuring temperature 0 ℃.Must pay attention to when using thermocouple compensating conductor model match, cannot be wrong polarity, compensation conductor should be connected to the thermocouple temperature should not exceed 100 ℃.传感器传感器(名称:transducer/sensor)是一种检测装置,能感受到被测量的信息,并能将感受到的信息,按一定规律变换成为电信号或其他所需形式的信息输出,以满足信息的传输、处理、存储、显示、记录和控制等要求。

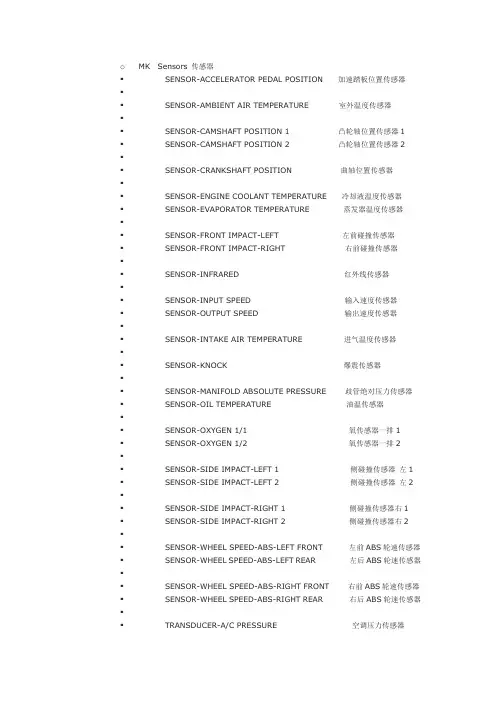

o MK Sensors 传感器▪SENSOR-ACCELERATOR PEDAL POSITION 加速踏板位置传感器▪▪SENSOR-AMBIENT AIR TEMPERATURE 室外温度传感器▪▪SENSOR-CAMSHAFT POSITION 1 凸轮轴位置传感器1▪SENSOR-CAMSHAFT POSITION 2 凸轮轴位置传感器2▪▪SENSOR-CRANKSHAFT POSITION 曲轴位置传感器▪▪SENSOR-ENGINE COOLANT TEMPERATURE 冷却液温度传感器▪SENSOR-EVAPORATOR TEMPERATURE 蒸发器温度传感器▪▪SENSOR-FRONT IMPACT-LEFT 左前碰撞传感器▪SENSOR-FRONT IMPACT-RIGHT 右前碰撞传感器▪▪SENSOR-INFRARED 红外线传感器▪▪SENSOR-INPUT SPEED 输入速度传感器▪SENSOR-OUTPUT SPEED 输出速度传感器▪▪SENSOR-INTAKE AIR TEMPERATURE 进气温度传感器▪▪SENSOR-KNOCK 爆震传感器▪▪SENSOR-MANIFOLD ABSOLUTE PRESSURE 歧管绝对压力传感器▪SENSOR-OIL TEMPERATURE 油温传感器▪▪SENSOR-OXYGEN 1/1 氧传感器一排1▪SENSOR-OXYGEN 1/2 氧传感器一排2▪▪SENSOR-SIDE IMPACT-LEFT 1 侧碰撞传感器左1 ▪SENSOR-SIDE IMPACT-LEFT 2 侧碰撞传感器左2 ▪▪SENSOR-SIDE IMPACT-RIGHT 1 侧碰撞传感器右1 ▪SENSOR-SIDE IMPACT-RIGHT 2 侧碰撞传感器右2 ▪▪SENSOR-WHEEL SPEED-ABS-LEFT FRONT 左前ABS轮速传感器▪SENSOR-WHEEL SPEED-ABS-LEFT REAR 左后ABS轮速传感器▪▪SENSOR-WHEEL SPEED-ABS-RIGHT FRONT 右前ABS轮速传感器▪SENSOR-WHEEL SPEED-ABS-RIGHT REAR 右后ABS轮速传感器▪▪TRANSDUCER-A/C PRESSURE 空调压力传感器。

2 The construction of temperature sensorTemperature is a fundamental physical quantity. In the nature all processes are closely related to temperature. According to the law of wave interaction with matter. Successively developed Acoustic temperature sensor, infrared sensor and microwave sensor. The four main types: thermocouples, thermistors, resistance temperature detector (RTD) and IC temperature sensor temperature sensor. IC temperature sensors, including two types of analog output and digital output.5 Teomatic of temperature sensor-------ThermocoupleA thermocouple consists of two conductors of different materials (usually metal alloys) that produce a voltage in the vicinity of the point where the two conductors are in contact. The voltage produced is dependent on, but not necessarily proportional to, the difference of temperature of the junction to other parts of those conductors. Thermocouples are a widely used type of temperature sensor for measurement and control [1] and can also be used to convert a temperature gradient into electricity. Commercial thermocouples are inexpensive,[2] interchangeable, are supplied with standard connectors, and can measure a wide range of temperatures. In contrast to most other methods of temperature measurement, thermocouples are self powered and require no external form of excitation. The main limitation with thermocouples is accuracy; system errors of less than one degree Celsius (C) can be difficult to achieve3 the Classification of temperature sensorContact temperature sensor:The contact temperature sensor detecting section have good contact with the measured object. Also known as a thermometer.Non-contact temperature sensor:Its sensitive element and the object to be measured is not in contact with each other. Also known as non-contact Thermometer. This instrument is used to measure moving objects, small targets, a small thermal capacity or rapid temperature changes in the surface temperature of the (transient) objects. Can also be used to measure the temperature of the temperature field distribution.4 The type of temperature sensorInfrared temperature sensor:Infrared (IR) radiation is part of the electromagnetic spectrum,which includes radio waves, microwaves, visible light, and ultraviolet light, as well as gamma rays and X-rays. Analog temperature sensor:Traditional analog temperature sensors such as thermocouples, the thermistor and RTDS temperature monitoring. Linearity is not good in some temperature range. The need for cold junction compensation or lead compensation, thermal inertia, slow response times. Integrated analog temperature sensor compared. With the advantages of high sensitivity, good linearity, fast response. And it will also drive the circuit, the signal processing circuit, as well as the necessary logic control circuits are integrated on a monolithic IC, a small actual size, ease of useLogic output temperature sensor:In many applications. We do not need to strictly measure the temperature value. Only care about whether the temperature is beyond the scope of a set. Once the temperature exceeds the specified range, the alarm signal. Start or turn off fans, air conditioners, heaters, or other control devices. The optional logic output temperature sensor.6 select the right temperature sensorIf you want to make reliable temperature measurements. First you need to select the correct temperature meter. Also is a temperature sensor. The thermocouples, thermistors, platinum resistance (RTD), and the temperature IC is the most commonly used temperature sensor in the test.Thermocouples are the simplest and most common temperature sensor. But the thermocouple is not suitable for high-precision measurement applications.The Thermistor have its measurement techniques. The size of thermistor is small. Can stabilize soon, will not cause the heat load. But it is fragile. If Large current across will cause self-heating. The thermistor is a resistive device. Any current source will power on fever. Power is equal to the square of the current resistance plot. So to use a small current source. If the thermistor is exposed in the heat. Will lead to permanent damage.7 Development trendsAfter entering the 21st century. Smart temperature sensor is moving in high-precision, multi-function bus standardization, high reliability and security, the development of a virtual sensor and network sensor developed single-chip temperature measurement system and other high-tech direction rapidly. Smart temperature sensor bus technology to achieve standardization and normalization. Single line (1-Wire) bus, I2C bus, SMBus bus and spI bus in the bus. Temperature sensor as a slave by the dedicated bus interface with the host communications.。

. sensorssensors(English name: transducer/sensor) is a kind of detection device, can feel the measured information, and will feel information transformation according to certain rule become electrical signal output, or other form of information needed to satisfy the information transmission, processing, storage, display, record and control requirements.Sensor's features include: miniaturization, digital, intelligent, multi-functional, systematic and network. It is the first step of automatic detection and automatic control. The existence and development of the sensor, let objects have sensory, such as touch, taste and smell let objects become live up slowly. Usually according to its basic cognitive functions are divided into temperature sensor, light sensor, gas sensor, force sensor, magnetic sensor, moisture sensor, acoustic sensor, radiation sensitive element, color sensor and sensor etc. 10 major categories.temperature transducerTemperature sensors (temperature transducer) refers to can feel temperature translates into usable output signal of the sensor. The temperature sensor is the core part of the temperature measuring instrument, wide variety. According to measuring methods could be divided into two types: contact and non-contact, according to the sensor material and electronic component features divided into two categories, thermal resistance and thermocouple.1 principle of thermocoupleThermocouple is composed of two different materials of metal wire, the welded together at the end. To measure the heating part of the environment temperature, can accurately know the temperature of the hot spots. Because it must have two different material of the conductor, so called the thermocouple. Different material to make the thermocouple used in different temperature range, their sensitivity is also each are not identical. The sensitivity of thermocouple refers to add 1 ℃hot spot temperature changes, the output variation of potential difference. For most of the metal material support thermocouple, this value about between 5 ~ 40 microvolt / ℃.As a result of the thermocouple temperature sensor sensitivity has nothing to do with the thickness of material, use very fine material also can make the temperature sensor. Also due to the production of thermocouple metal materials have good ductility, the slight temperature measuring element has high response speed, can measure the process of rapid change.Its advantages are:(1)high precision measurement. Because of thermocouple direct contact with the object being measured, not affected by intermediate medium.(2)the measurement range. Commonly used thermocouple from 1600 ℃to 50 ℃ ~ + sustainable measurement, some special thermocouple minimum measurable to - 269 ℃ (e.g., gold iron nickel chrome), the highest measurable to + 2800 ℃ (such as tungsten rhenium).(3) simple structure, easy to use. Thermocouple is usually composed of two different kinds of metal wire, but is not limited by the size and the beginning of, outside has protective casing, so very convenient to use. The thermocouple type and structure of the form.2. The thermocouple type and structure formation(1)the types of thermocoupleThe commonly used thermocouple could be divided into two types: standard thermocouple and non-standard thermocouple. Standard thermocouple refers to the national standard specifies its thermoelectric potential and the relationship between temperature, permissible error, and a unified standard score table of thermocouple, it has with matching display instrument to choose from. Rather than a standard thermocouple or on the order of magnitude less than the range to use standardized thermocouple, in general, there is no uniform standard, it is mainly used for measurement of some special occasions.Standardized thermocouple is our country from January 1, 1988, thermocouple and thermal resistance of all production according to IEC international standard, and specify the S, B, E, K, R, J, T seven standardization thermocouple type thermocouple for our country unified design.(2)to ensure that the thermocouple is reliable, steady work, the structure of thermocouple requirements are as follows:①of the two thermocouple thermal electrode welding must be strong;②two hot electrode should be well insulated between each other, in case of short circuit;③compensation wires connected to the free cod of a thermocouple to convenient and reliable;④protect casing thermal electrodes should be able to make sufficient isolation and harmful medium.3.The thermocouple cold end temperature compensationDue to the thermocouple materials are generally more expensive (especiallywhen using precious metals), and the temperature measurement points are generally more far, the distance to the instrument in order to save materials, reduce cost, usually adopt the compensating conductor) (the free end of the cold junction of the thermocouple to the steady control of indoor temperature, connected to the meter terminals. It must be pointed out that the role of the thermocouple compensation wire extension hot electrode, so that only moved to the control room of the cold junction of the thermocouple instrument on the terminal, it itself does not eliminate the cold end temperature change on the influence of temperature, cannot have the compensation effect. So, still need to take some of the other correction method to compensate of the cold end temperature especially when t0 indicates influence on measuring temperature 0 ℃.Must pay attention to when using thermocouple compensating conductor model match, cannot be wrong polarity, compensation conductor should be connected to the thermocouple temperature should not exceed 100 ℃.传感器传感器(英文名称:transducer/sensor)是一种检测装置,能感受到被测量的信息,并能将感受到的信息,按一定规律变换成为电信号或其他所需形式的信息输出,以满足信息的传输、处理、存储、显示、记录和控制等要求。