船用救生艇柴油机BUKHDV29RME用户手册

- 格式:pdf

- 大小:911.24 KB

- 文档页数:34

船舶救生设备操作规程1.救生(助)艇及其降落设备操作规程本船左右舷各配备一艘救生艇,救生艇生产厂家为船艇制造有限公司,型号为22TECB。

定员28人,尺寸为L6.5m X B 2.3m X D 1.2m.其中左舷的2号救生艇兼做救助艇。

1.1救生艇释放操作方法如下(正常释放):1)拔出充电插头。

2)拔出索紧销(刹车销)。

3)带好艇艏缆。

4)松开艇架夹箍。

5)人员登艇。

6)拉遥控拉索,下降艇身至水面(注意在旋出本艇时,不可以做细微调整。

)7)启动艇机(在落水之前启动艇机)。

8)拉下自动脱钩装置脱钩。

9)脱掉艇艏缆,驶离大船。

1.2救生艇自动脱钩操作方法:1)救生艇降至水面后通过防护罩“A”观察,确认旋纽“C”处于打开位置;2)从释放手柄上拔出安全销“B”;3)将释放手柄从“D”位置向后拉至位置“E”,吊钩被自动释放。

1.3如果救生艇不能到达水面,驾驶员可以进行应急操作,操作方法如下:1)驾驶员下发进行释放指示;2)警告乘员必须扶好和抓牢;3)从释放手柄上拔出安全销“B”;4)除去防护罩“A”,在紧急状态下打破玻璃罩;5)用左手将旋纽“C”逆时针方向旋转至开启,右手将释放手柄从“D”位置向后拉至位置“E”,吊钩被释放。

1.4救生艇吊钩复位方法如下:1)将前后钩头转动至关闭位置,可通过前后挂钩锁紧指示指针观察确认锁紧;2)将旋纽“C”顺时针方向旋转只关闭位置;3)将释放手柄从“E”位置向后拉至“D”位置;4)插上安全销“B”;5)前后艇员用力拨动钩头确认已吊钩已复位。

1.5救生艇回收方法如下;1)乘员转动吊钩钩头到完全关闭的位置,使钩头完全复位2)驾驶员根据“吊钩复位说明”进行复位。

3)驾驶员检查释放手柄在锁紧位置并且安全销已经插好。

4)驾驶员发出信号,缓慢提升救生艇。

5)当救生艇被刚好离开水面时,驾驶员发出信号停止提升。

6)驾驶员检查确认拉杆已经复位,乘员检查确认每个吊钩尾端与半圆柱销正确贴和。

7)如果一切正常,驾驶员发出信号将救生艇提升至安放位置绑牢。

救生艇机操作规程文件编号:2120-E-0029

救生艇机操作规程

一. 启动前的准备

1. 检查柴油油位、机油油位和油质是否处于正常状态。

2 .艇机油门杆、离合器,应处于中间(空挡)位置。

3. 打开气门,手动盘车数转,对各运动部件进行活动,关闭气门。

4. 清理检查机器周围有无妨碍机器运动的障碍物。

5. 检查电启动是否正常。

6. 检查停机拉杆是否按到最低位置。

二、启动及运转

1. 启动

A.手摇启动:打开气门,摇动摇把,当转速达到时,关上气门,艇机启动。

B.电动启动:按下启动按钮约1-2秒钟,艇机启动。

2. 运转

A.艇机正式运转后,应及时检查各运动部件的运动情况,压力、温度是否正常。

B.加减油门测试机器及螺旋桨的运动情况。

C.当艇机在艇架上测试时,由于没有冷水,螺旋桨不可运动时间过长,避免螺旋桨轴承烧坏。

三、停机

1. 将油门减到最低(中间)此时螺旋桨应处于空挡位置。

2. 拉起停机拉杆,当机器停止运转后打开气门,手摇盘车数转后,关闭气门按下停机拉杆。

——————————————————————————————————————————————

次页:1/1。

救生艇与救助艇操作管理实验指导书周文烈 编写船艺实验室1救生艇筏操纵工作程序1.1救生艇的吊放和固定(重力式艇架)1)艇长站在艇舷边指挥,先取下艇罩;接着两人登艇,解开救生索,塞牢艇底塞,检查稳艇索是否解开,带好首尾缆绳,送出止荡索,拔去安全销,解脱安全钩,检查短拉索是否系牢,卸下梁木。

2)听到艇长口气后,副艇长提起艇机制动杆,将艇降至登艇甲板,艇员登艇。

3)人员登艇完毕后,松掉止荡索和短拉索,将艇继续降至水面,保持吊艇索有一定的受力,艇上人员向上拉起联动脱钩操纵环,使艇脱钩。

4)放艇人员利用绳梯或救生索下艇。

5)装上舵柄,解脱首尾缆,撑开并迅速划离大船约1/4里处待援。

6)机动艇降落水面之前即应把艇机发动好,以便艇落水后即可动车驶离。

1.2吊艇及固定1)吊艇前,艇上除留2名技术熟练的挂钩艇员外,其余人员从舷锑或绳梯登上大船。

2)由大船调整好艇首尾缆使艇处于吊艇滑车的下方,尽量做到既易于挂钩又勿使吊艇索挂钩过于松驰。

3)前后吊艇钩一旦挂上后,应立即将艇吊离水面。

横摇时应选择大船自另一舷回变到正浮位置时迅速挂钩,然后尽可能在大船向另一舷横倾时将艇吊离水面。

4)将艇吊至艇甲板时暂停,装上短拉索,收进艇的首尾缆绳并盘好,打开艇底塞放净积水,将止荡索滑车组收进艇内,最后两名挂钩艇员离艇。

5)继续吊艇至存放位置,然后将稳艇索系牢。

插好安全销,切断艇机电源,艇长检查确认妥当后宣布解散艇员。

2气胀式救生筏的投放2.1检查充气拉索是否牢固系结于筏架上,解去存放筒上系绳。

2.2拔去筏架上的保险插销,板动投放手柄,气胀式筏存放筒则靠自重滚出舷外。

2.3气胀筏充气后将其拉靠大船舷边。

2.4人员从绳梯或舷梯处登筏,如高度不超过4.5米,可直接从船上跳人筏内,如筏倾覆,应先予以扶正。

;3救生艇艇机操纵工作程序3.1操作规程1)检查燃油箱燃油是否足够,检查机油量。

2)将调速操纵杆手柄放在 "慢"与"快"的中间,离合器操纵杆应处于"停车" 位置。

船用柴油机组使用维修说明书江苏科技大学镇江四洋柴油机制造有限公司目录1.注意事项 (1)2.前言 (2)图380J-3船用柴油机组外型安装图 (4)3.机组主要技术参数 (6)4.机组分类 (7)4.1按救生艇释放形式分类 (7)4.2、按冷起动辅助装置分类 (7)5.机组主要结构 (8)5.1燃油系统 (8)5.2润滑系统 (7)5.3冷却系统 (9)5.4电器系统 (10)5.5齿轮箱 (10)5.6电器线路图 (11)5.6.1、常规配置电器系统(配进气火焰预热器) (11)5.6.1.1、电器系统图及仪表板 (11)5.6.1.2、电器系统部件说明 (13)5.6.2、特殊配置电器系统 (13)5.6.2.1、电器系统图及仪表板 (13)5.6.2.2、电器系统部件说明 (16)5.7起动前注意事项 (17)6.机组基本操作 (17)6.1起动 (17)6.1.1弹簧起动器起动(若用户选配) (19)6.1.2手摇起动(若用户选配) (20)6.2运行 (20)6.3停车 (21)7.机组日常维护保养 (21)7.1基本注意事项 (21)7.2常规保养时间 (22)7.3润滑油规格 (22)7.4齿轮箱润滑油规格 (23)7.5主要零部件拧紧力矩 (23)7.6气缸盖螺栓拧紧顺序图 (23)7.7润滑油位检查 (24)7.8更换润滑油 (24)7.9充电发电机皮带张紧 (24)7.10更换齿轮箱润滑油 (24)7.11燃油系统放气 (24)7.12放冷却液 (25)7.13更换柴油滤芯 (25)7.14气门间隙调整 (25)7.15装在吊艇架或自由抛三落救生艇的柴油机组的起动与运行 (25)7.16电器系统的注意事项 (25)7.17机组贮存 (26)8.常见故障及处理方法 (27)8.1柴油机机起动困难 (27)8.2机组输出功率不足 (27)8.3柴油机排气冒黑烟 (28)8.4柴油机机油压力太低(油压报警) (28)8.5柴油机敲缸 (28)8.6柴油机过热 (29)8.7柴油机过速或飞车 (29)附录1:380J-3机组交货清单 (30)附录2:380J-3机组随机工具清单 (30)附录3:380J-3机组随机备件清单 (31)欢迎您选择四洋牌船用柴油机组1、注意事项1)确保正确地安装柴油机组。

1.锚缆机操作规程----------------------------------------------------------------4 2.首尖舱污水遥控排水系统操作规程-----------------------------------------6 3.压载控制台操作规程-----------------------------------------------------------74. 货舱进水检测装置操作规程--------------------------------------------------95. 货舱污水处理操作规程--------------------------------------------------------116.报警监视系统操作规程--------------------------------------------------------127. 和面机/电炒锅操作规程------------------------------------------------------ 148. 电灶的使用与保养--------------------------------------------------------------159.粉碎机操作规程-----------------------------------------------------------------1610.烤箱的操作规程-----------------------------------------------------------------1711. 蒸馒头/蒸饭机的操作规程------------------------------------------------------1812. 货舱作业的安全规定----------------------------------------------------------1913. 甲板作业的安全规定---------------------------------------------------------2014. 开关舱作业的安全规定------------------------------------------------------2115. 系解缆作业的安全规定------------------------------------------------------2216. 舷外、水上作业的安全规定------------------------------------------------2417. AIS操作规程-------------------------------------------------------------------2518. C站操作规程-----------------------------------------------------------------2719. EPIRB 操作规程---------------------------------------------------------------2820. F站操作规程-----------------------------------------------------------------2921. GPS NAVIGATOR操作规程--------------------------------------------------3022. NAVTEX 操作规程-------------------------------------------------------------3323. NBDP 操作规程----------------------------------------------------------------3424. VDR 操作规程------------------------------------------------------------------3625. VHF 操作规程------------------------------------------------------------------3726. 电子海图操作规程------------------------------------------------------------3827. 雷达使用操作规程------------------------------------------------------------3928. 气象传真机操作规程---------------------------------------------------------4429. 自动舵操作规程---------------------------------------------------------------4730. 驾机联系制度------------------------------------------------------------------4831. 驾驶台规则---------------------------------------------------------------------5132. EEBD 操作规程----------------------------------------------------------------5233. 火警控制面板操作规程-----------------------------------------------------5334. 机舱大型二氧化碳灭火系统操作规程-----------------------------------5435. 机舱水雾灭火系统操作规程-----------------------------------------------5536. 救生筏释放程序--------------------------------------------------------------5637. 救生艇操作规程--------------------------------------------------------------5738. 消防员装备操作规程--------------------------------------------------------5839. 机炉舱规则--------------------------------------------------------------------6040. 机舱值班制度-----------------------------------------------------------------6241. 检修作业注意事项-----------------------------------------------------------6642. 主机操作规程-----------------------------------------------------------------6743. 副机操作规程-----------------------------------------------------------------6944. 燃油锅炉操作规程-----------------------------------------------------------7045. 主空压机操作规程-----------------------------------------------------------7246. 空调装置操作规程-----------------------------------------------------------7347.燃油分油机操作规程--------------------------------------------------------7448. 滑油分油机操作规程--------------------------------------------------------7549. 主机滑油泵操作规程--------------------------------------------------------7650. 主机缸套水泵操作规程-----------------------------------------------------7751. 主海水泵操作规程-----------------------------------------------------------7852. 重油驳运泵操作规程--------------------------------------------------------7953. 造水机操作规程--------------------------------------------------------------8054. 油水分离器操作规程--------------------------------------------------------8155. 生活污水处理装置操作规程-----------------------------------------------8256. 应急发电机操作规程--------------------------------------------------------8357. 应急救火泵操作规程--------------------------------------------------------8458. 应急空压机操作规程--------------------------------------------------------8559. 冰机操作规程-----------------------------------------------------------------8660. 焚烧炉操作规程--------------------------------------------------------------8764. 主配电板操作规程-----------------------------------------------------------8865. 应急配电板操作规程--------------------------------------------------------89 63. 压载泵操作规程--------------------------------------------------------------90目录64. 消防通用泵操作规程---------------------------------------------------------9165. 污水泵操作规程---------------------------------------------------------------9266. 机舱电力中断应急操作------------------------------------------------------9367. 触电的预防和急救------------------------------------------------------------9568. 总用电瓶及充放电板操作规程---------------------------------------------9669. 机舱报警检测系统操作规程------------------------------------------------9770. 机舱局部灭火系统操作规程------------------------------------------------9871. 机舱水雾灭火系统高压泵操作规程---------------------------------------9972. 主机机侧应急操作规程------------------------------------------------------10073. 主机盘车机操作规程---------------------------------------------------------10174. 饮水消毒柜操作规程---------------------------------------------------------10275. 砂轮机操作规程---------------------------------------------------------------10376. 气焊作业安全规定------------------------------------------------------------10477. 电焊作业安全规定------------------------------------------------------------10578. 车床作业安全规定----------------------------------------------------------10679. 救生艇机操作规程------------------------------------------------------------10780. 油渣泵操作规程---------------------------------------------------------------10881. 钻床作业操作规程------------------------------------------------------------10982. 火警T1016控制面板操作规程---------------------------------------------11083. 舵机操作规程------------------------------------------------------------------112锚缆机操作规程O P E R A T I O N I N S T R U C T I O N S F O R M O O R I N G W I N C H&W I N D L A S S 一、绞缆机操作的注意事项1)操作前必须要检查以下事项:●离合器的位置,齿轮箱上档位杆的位置,传感器上的指示灯,●检查刹车杆及刹车带是否完好,工作是否正常,●缆绳的出绳方向是否与刹车带底部连接块侧一致,●检查滚筒转动方向是否与操作杆指令方向一致,●检查所有的油脂润滑点,油位是否符合要求。

船用柴油机操作流程

船用柴油机操作流程如下:

1、把操纵盘(或手柄)转至停车位置上,同时使冷却水在冷却腔内继续循环5至10分钟,此时还要开启独立水泵向主机泵水循环。

2、开启示功阀,将燃油控制手柄调至零位。

3、冲车吹出气缸内的残留油气等杂质,并向气缸内壁手摇气缸注油器润滑,接上盘车机盘车。

当接到完车指令后说明船舶已停泊结束,此时轮机员应关闭相应阀件,并进入主机完车操作,程序如下:

1、车钟放至完车位置,检查并确认主机燃油操纵杆在停车位置上。

2、闭起动空气系统的主停气阀、主起动阀和空气瓶出口阀。

3、燃油系统低压燃油输送泵。

4、关停主机海水泵、关闭主机海水泵进出口控制阀及冷却器的进口阀。

5、检查各缸示功发是否全开,盘车10至15分钟,需要注入润滑油润滑。

6、将扫气箱、涡轮端排出管登出放残考克全开,进行放残。

7、关掉机舱温度、压力报警器及其他不使用的开关。

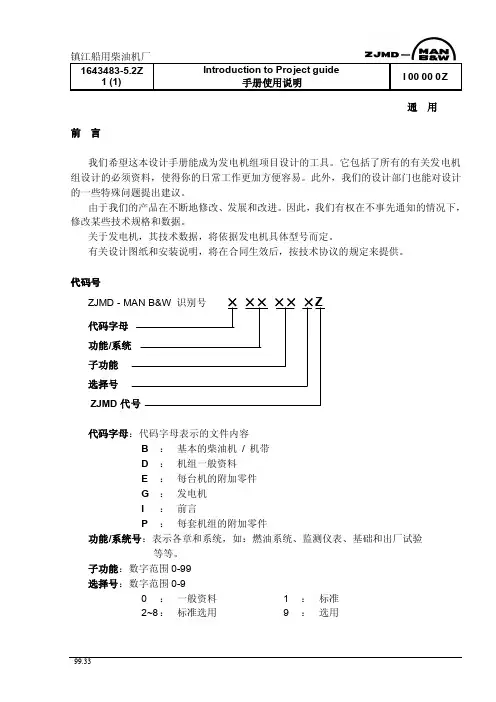

通 用

99.33 前 言

我们希望这本设计手册能成为发电机组项目设计的工具。

它包括了所有的有关发电机组设计的必须资料,使得你的日常工作更加方便容易。

此外,我们的设计部门也能对设计的一些特殊问题提出建议。

由于我们的产品在不断地修改、发展和改进。

因此,我们有权在不事先通知的情况下,修改某些技术规格和数据。

关于发电机,其技术数据,将依据发电机具体型号而定。

有关设计图纸和安装说明,将在合同生效后,按技术协议的规定来提供。

代码号

ZJMD - MAN B&W 识别号 × ×× ×× ×Z

代码字母

功能/系统

子功能 选择号

ZJMD 代号

代码字母:代码字母表示的文件内容

B : 基本的柴油机 / 机带

D : 机组一般资料

E : 每台机的附加零件

G : 发电机

I : 前言 P : 每套机组的附加零件

功能/系统号:表示各章和系统,如:燃油系统、监测仪表、基础和出厂试验

等等。

子功能:数字范围0-99

选择号:数字范围0-9

0 : 一般资料 1 : 标准

2~8 : 标准选用 9 : 选用。

柴油船外机的操作方法柴油船外机是一种常用于船只的动力设备,它通过柴油燃料产生燃烧来驱动船只前行。

以下是柴油船外机的操作方法:1. 准备:在操作柴油船外机之前,首先需要确保良好的通风和安全环境。

检查排气管是否畅通,并确保没有泄漏或磨损的部件。

检查燃油供应系统和液位计,确保燃油充足。

同时,检查船只电池是否充电充足,以供启动使用。

2. 启动:打开柴油船外机的机械引擎开始启动。

在启动之前,确保刹车和离合器处于释放状态。

然后打开燃油阀门,启动机械引擎。

启动后,保持引擎自行运转一段时间,以确保机械部件顺利工作。

3. 加速:一旦机械引擎顺利运转,可以轻轻转动油门,逐渐增加油门的打开程度。

此时,应注意船只的反应,并根据需要适时调整油门的打开程度,以控制船只的速度和方向。

应保持油门操作平稳,避免突然加速或减速。

4. 转向:柴油船外机的转向通常通过操控舵轮来实现。

当需要转向时,向左或向右转动舵轮,以改变船只的航向。

需要注意的是,舵轮转动的力度和速度应适中,以避免急转弯或转动过度,对船只造成不必要的压力和损伤。

5. 停止:当需要停止柴油船外机时,首先减小油门的打开程度,使船只逐渐减速。

然后将油门转向最低档位,使机械引擎停止运转。

同时关闭燃油阀门和其他相关开关,确保安全停机。

6. 维护:柴油船外机的正常运行需要定期保养和维护。

包括更换燃油和空气滤清器,定期检查和清洁散热器和冷却系统,检查并更换机油和机油滤清器,以及检查和调整传动零件等。

同时,定期检查和清洁电池,以确保良好的电力系统运行。

7. 安全注意事项:在操作柴油船外机时,需要注意一些安全事项。

确保操作者熟悉操作手册和安全规程,了解机械部件的安全操作方式。

同时,佩戴合适的个人防护装备,如耳塞、手套、护目镜等。

在操作过程中,禁止穿戴宽松衣物或长发等易被卷入机械部件的物品,避免发生意外事故。

总之,柴油船外机的操作方法需要注意安全、规范和维护,以确保船只的正常运行和乘员的安全。

救助艇发动机启动和操作须知1.启动前的准备工作注意:如果是在船上进行艇机的日常启动检查,而不是将艇放至水面。

启动前应将艇机螺旋桨浸没在一装有淡水的桶里,水位应至少淹没艇机进水孔。

如无冷却水禁止启动机器。

1)将燃油软管与油箱连接好,并通过油量表检查油箱中燃油量;2)将燃油软管的另一端与舷外机供油系统连接;3)逆时针旋松油箱盖上的放气螺钉2-3圈,使油箱通气;4)利用燃油软管中的软气囊将燃油泵入化油器,直到感觉到软气囊内部充满燃油为止;5)将启动档位处于空挡位置,将空挡节流杆开启,将应急制动开关的锁定扳与制动开关牢固连接好。

2.电动启动1)断开电池充电线路,否者易对电池造成损害;2)将电池选择开关钥匙插入,选择启动机器所需的电池,一般只需要一个电池启动(配备有两组电池),钥匙柄所指的位置即是电池所处的状态;3)将发动机钥匙插入,并将应急制动开关拉线系在操作者手腕上,或系在牢固的衣服上或操作者其它部位;4)将启动钥匙开关由“ON”位置顺时针方向转至“START”位置,最多不超过五秒,转动的同时按压钥匙,会触发遥控阻气风门控制系统,将阻气风门关闭;5)发动机启动后,松开主开关钥匙,使其自动回转到“ON”位置,不可以取下钥匙,然后将中位节流杆拉至原来关闭位置。

3.手动启动手动启动前的准备工作和电动启动前的准备工作是一致的。

1)拉出阻气门钮;2)快速拉动启动绳拉绳,将机器启动运转,如不能启动,可重复几次;3)机器启动运转后将阻气门钮推入。

4.启动后检查事项1)启动后立即检查冷却水是否从冷却水出水孔持续流出,如果发动机运转没有水从出水孔流出,应立即停止发动机运转,检查进水和出水孔是否堵塞,再次进行启动;2)在开始航行操作前,应使发动机以慢速状态预热运转3分钟;3)检查发动机各系统,操纵构件各部位是否正常;4)当有关人员登艇后,注意观察一下艇,纵倾横倾是否正常,应该基本上保持正常漂浮状态;5)在发动机正常运行过程中,不可将钥匙转动或拔出,否则将会损坏启动马达及飞轮(运行中将钥匙转START位置)或造成紧急停车(运行中将钥匙转到OFF,或者拔出)。

救生艇艇机的操作程序

一、启动程序

1、打开机器冷却水的海水阀和燃油箱的燃油阀;

2、将离合器操纵手柄处于停车位置;

3、将调速器操纵手柄放在中速位置;

4、接通电启动按钮与蓄电池之间的线路;

5、盘车,使艇机活动部件运转一下,检查有无异响;

6、使减压阀处于减压位置,按启动按钮,当启动马达带动飞轮且有适当

转速时,关闭减压阀,艇机即启动完毕。

7、如用手摇把起动时,应装上手摇把,由慢而快的转动机器,当转到适

当的转速时,关闭减压阀,并继续快速转动机器,直到马达启动为止。

手摇把应尽快拿下。

另:低温启动艇机有困难时, 可将低温起动液按规定量倒入柴油机进液口, 再按上述方式启动艇机。

二、停机的程序

1、停车前先逐渐减小油门,使转速缓慢地降下来。

待其运转3—5分

钟后,再将离合器的操纵手柄扳至“停车”位置。

2、关闭燃油阀,然后切断电源,最后关闭冷却水的海底阀。

3、如环境温度在零度或零度以下时,停机后应使柴油机冷却水温度降

至30—40度后再打开放水开关,且冷却水要放净。

船用发电机组的说明书船用发电机组说明书本说明书是针对船用发电机组的操作、维护和保养等方面的详细说明。

在操作前请仔细阅读本手册并按照说明进行操作。

1. 概述本船用发电机组是为满足船舶电力系统需求而开发的,其特点为高性能、节能、环保、可靠性强、维护简便等优势。

2. 功能介绍本船用发电机组主要由以下几部分组成:(1)柴油机:采用先进设计理念的四冲程柴油机,能够满足高效率、低燃油消耗的要求;(2)发电机:具有高度稳定性和电气转换效率;(3)控制系统:实现对发电机组稳定运行的控制和监测,能够实时检测机组性能,保护机组安全运行;(4)散热系统:采用先进的空气散热技术,可为机组提供优良的散热性能,确保机组长期安全运行。

3. 操作要点(1)发电机组应设在通风、干燥、防尘、防雨及防盐雾的室内;(2)发电机组应按照说明书的要求,正确接线,以确保机组安全运行;(3)运行前应检查机组各项功能是否正常;(4)运行中应及时检查机组运行状态,如发现异常应及时停止机组并检查;(5)停机前应先关闭负荷,然后再关闭机组。

4. 维护与保养为确保机组的长期稳定运行,应按照以下维护和保养要点开展管理:(1)发电机组应按照规定进行定期保养;(2)机组运行轨迹和状态应进行跟踪监控,及时发现并解决问题;(3)机组应保持清洁状态,定期清洗机组外观及引擎表面的油污;(4)机组存放时应注意室内通风干燥,定期打开机组运行五分钟左右,以保持机组性能;(5)机组长期停放时应进行润滑及防锈处理。

5. 故障处理发现机组故障时应及时采取以下措施:(1)确认故障现象是否正确;(2)检查故障的程度,并及时采取相应的措施;(3)严格按照故障排除步骤,进行清洗或更换部件等维修措施;(4)清除故障后,应进行试运转。

6. 安全提示为确保机组的安全使用,请务必注意以下安全提示:(1)禁止在机组运行时进入机组内部,以确保人员安全;(2)在机组工作过程中,严禁使用金属、绝缘性能不佳的工具和手套,以避免引起电击事故;(3)在机组运行过程中,不得私自拆卸机组或更换部件;(4)在机组清洗和检查过程中,必须切断电源,以确保人员安全。

Quality Craftsmanship Since 1958TABLE OF CONTENTSTable Of Contents (2)Congratulations (3)Safety (3)Symbol Glossary (4)Specifications (Subject To Change Without Notice) (5)Equipment Location (6)Starboard Fittings (6)Port Fittings (7)Main Cabin Top Deck Components (8)Stern Components (9)Main Cabin And Cockpit Lights (10)Fuel System, Engine, Generator & Webasto Furnace (11)Closed Engine Cooling System (12)Raw Water / Sea Strainer System (13)Fresh Water Plumbing System (14)Shower Sump (15)Bilge Pump System (16)Waste System With Macerator Pump (17)Electric Pumps Onboard (18)Air Conditioning (19)Webasto Furnace (20)Solar Panel (21)Battery Configuration (22)Fuse Location & Values (23)Fuse Location & Values (24)Power Panel And Solar Panel Control Box (25)Ac Distribution Panel & Rotary Switch (26)12V Helm Control Operation (27)Ranger Tug R-29 Wiring Schematic (Acc. 1) (28)Ranger Tug R-29 Wiring Schematic (Acc. 2) (29)Ranger Tug R-29 Wiring Schematic (Acc. 3) (30)Ranger Tug R-29 Wiring Schematic (Lighting) (31)Ranger Tug R-29 Wiring Schematic (P.D.P.) (32)Ranger Tug R-29 Working Deck (33)Mast Set Up And Takedown (34)Care And Maintenance (35)Example Of A Preparation For The Road Checklist (35)Example Of A Spring Pre-Launch Checklist (36)Example Of Winter Storage Checklist (37)Warning Label Locations (38)Notes (39)CONGRATULATIONSThe Ranger Tug family has a passion for boating. We are committed to continuous process improvement in all areas that affect our customer’s satisfaction with our products and providing great customer service.SAFETYSafety is always a concern at Ranger Tugs. Please read all manuals to ensure that equipment is used in a safe manner. We highly recommend attendance in a Coast Guard approved boating safety course. Such courses are available from the Coast Guard directly or from boating organizations. Owners should have annual inspec-tions to ensure that all safety equipment is current.STEOPTSYMBOL GLOSSARYAttention! – Important Operating or Maintenance InstructionsAttention! – Electrical Shock HazardFresh WaterBlack WaterFuelStandard EquipmentOptional EquipmentHintsSPECIFICATIONS(Subject to Change Without Notice)R-29 SLength .......................................................................................... 28' 10" 8.79 m Length Overall (w/swim step) ........................................................ 33' 4" 10.16 m Beam ............................................................................................ 10' 0" 3.05 m Draft ............................................................................................. 30".76 m Weight, Dry .................................................................................. 10,500 lbs 4,762 kg Water Bridge Clearance (mast up) ................................................. 13' 11" 4.24 m Water Bridge Clearance (mast down) ............................................ 9' 11" 3.02 m Height on Trailer (mast down) ....................................................... 13' 3" 4.04 m Fuel Capacity ................................................................................ 145 gal 548.89 L Water Capacity (fresh) ................................................................... 45 gal 170.34 L Holding Tank Capacity .................................................................. 40 gal 151.42 L Hot Water Tank Capacity .............................................................. 8 gal 30.28 L Length Overall on Trailer with no dinghy (RIB) ............................... 39' 6"12.04 LR-29 CBLength .......................................................................................... 28' 10" 8.79 m Length Overall (w/swim step) ........................................................ 33' 4" 10.16 m Beam ............................................................................................ 10' 0" 3.05 m Draft ............................................................................................. 30".76 m Weight, Dry .................................................................................. 10,800 lbs 4,899 kg Water Bridge Clearance (mast up) ................................................. 13' 11" 4.24 m Water Bridge Clearance (mast down) ............................................ 9' 11" 3.02 m Height on Trailer ........................................................................... 13' 3" 4.04 m Fuel Capacity ................................................................................ 145 gal 548.89 L Water Capacity (fresh) ................................................................... 45 gal 170.34 L Holding Tank Capacity .................................................................. 40 gal 151.42 L Hot Water Tank Capacity .............................................................. 8 gal 30.28 L Length Overall on Trailer with no dinghy (RIB) ............................... 39’ 6”12.04 L➊ Bow Ladder➋ Shore Power Inlet(s)➌ Diesel Fill On Deck ➍ Fuel Tank Vent➎ Waste Outlet On Deck ➏ Holding Tank Vent➐ Foredeck Anchor Windlass Switches➑ Aft Bilge➒ Forward Bilge ➓ Boarding LadderRudder Keel Drain Plug Bow ThrusterKeelProp Water Fill On DeckStern ThrusterMaceratorShower Sump Sink Drain AC AftEQUIPMENT LOCATIONSTARBOARD FITTINGS1 2 3 4 5 6 7 8 9 10 11 12 13D EKeep all vents, drains and exhausts clear of any obstructions to ensure proper performance of each system.STE111312141516A B C D 17➊ Water Tank Vent ➋ Anchor Locker Drain ➌ Galley Sink Drain ➍ Bow Thruster➎ Generator Vent Cover ➏ Generator Exhaust➐ Engine Exhaust ➑ Keel ➒ Prop ➓ RudderWebasto Diesel Heater ExhaustStern ThrusterSTEPORT FITTINGS1 25 6Keep all vents, drains and exhausts clear of any obstructions to ensure proper performance of each system.1112MAIN CABIN TOP DECK COMPONENTS STE1 3 5 6 7 82 4➊ Anchor Light ➋ Running Light ➌ TV Antenna ➍ Radar ➎ Searchlight➏ Horn➐ Navigation Light(RED Port, GREEN Starboard)➊ Flagstaff Mount➋ Deck Shower➌ Amber Courtesy Lights ➍ Swim Platform Struts ➎ Cockpit Drain with Flap ➏ Towing Strapdown Eye ➐ Trim Tab Ram➑ Trim Tab ➒ Under Water Lights➓ Stern ThrusterPropRudderProp ZincTransom ZincSwim PlatformSwim Platform FendersRail Chain or Chain GatePropane LockerDinghy CleatsTrim Tab ZincsThruster ZincPatio RailingStand Off MountsDinghy DavitSTERN COMPONENTSSTE1 2 3 4 5 6 7 8 10 11 12 13 14 15 169 18 1911 12 13 14 15 1617 18 19 20 21 22 23 24MAIN CABIN AND COCKPIT LIGHTS STEMain Cabin SwitchDashSwitchForwardCabin SwitchHeadSwitchCockpitSwitch PanelSwitch OnFixture➊V-Berth Cabin Lights✓➋ Head Lights✓➌Under Bed Lighting✓➍Indirect Cabin Lights✓➎Cockpit & Transom Lights✓➏Red White Combo ✓➐Overhead White Lights✓➑Exterior Red/White✓➒Reading Lights✓➓Underwater Lights✓Engine GeneratorGenerator filters Fuel filter Fuel filterWebastoVentEngine return Engine supply Generator returnGenerator shut-off valveGenerator supplyFuel Tank Sender Engine shut-off valveFuel fillFUEL SYSTEM, ENGINE, GENERATOR & WEBASTO FURNACE STEVolvo D4 300hpThere is a secondary on-engine fuel filter that is not shown on this drawing. You will be able tofind information about this filter in the diesel engine manual supplied with your boat. The sec-ondary filter is where the water-in-fuel sensor is located.Main engine fuel shutoff is located underneath the forward engine hatch as you enter the maincabin. The primary fuel filter is mounted on the bulkhead in the engine compartment. There is adrain in the bottom of this filter for draining water.STERNCLOSED ENGINE COOLING SYSTEMSTE Provides an alternate heating system for the Fresh Water Heater and provides primary heating source for the Forced Air Cabin Heater. This system is also designed to provide cooling to the internal components of your engine. Please refer to your engine operations manual for more information.• Use only Volvo VCS coolant in this system. Do not mix coolant types.• Close black handled coolant valves on front of engine if a leak is suspected in either the fresh water heater or forced air cabin heater. This will keep coolant inside of the engine where it is needed most.EngineValvesHeaterSwitch at helm HotWaterHeaterCabin HeaterRAW WATER / SEA STRAINER SYSTEMSTE • Engine raw water thru-hull and strainer• Multi port sea strainer for head and raw water wash down pump.• Generator raw water thru-hull strainerGeneratorStrainerEngineEngineThru-hull/ValveGenerator Multi StrainerThru-hull/ValveMulti StrainerRaw Water WashdownA/C Raw Water (OPT)Head Raw WaterGeneratorThru-hull/ValveEngineStrainer• A/C Raw Water InputFRESH WATER PLUMBING SYSTEM60 Gallon Fresh Water Tank, 8 Gallon Hot Water Heater, 3.5 GPM Fresh Water Pump.STEGalley sink hotGalley sink coldWater tank sending unitFresh water pump/strainer(under removable teak panel)Water pump switch/gaugelocated in midberthSHOWER SUMPSTE12V , 800 GPH(This should be inspected for debris on a regular basis if shower is used frequently.)Shower drainThru-hull exhaustAft AC condensate drainForward AC condensate drainSump pumpThe shower sump box is located underneath a removable panel in the stateroom floor positioned just outside the head door.WASTE SYSTEM WITH MACERATOR PUMPSTESTE40 Gallon Tank with standard pump out, and ventWaste tank level can be checked by utilizing the head control panel. Please refer to your head operations manual.Waste tank pump out stations are widely available.Please follow the directions carefully for the pump out equipment you are using to avoid damage to the waste system.Boat owner is responsible forfollowing all applicable laws when using the macerator system to pump out into the surrounding waters.Overboard shutoff valve is accessed under berth inline with the macerator pump.Valve must remain either locked, or only able to be opened by using a tool when not using macerator. Example: zip tieMacerator pump outOverboard Shutoff ValveMaceratorELECTRIC PUMPS ONBOARDSTEFresh Water Pump(Under floor panel just inside cabin)Toilet Water Pump(Starboard lazerette forward)Forward Bilge PumpAft Bilge PumpA/C Pump (optional)(Engine room bulkhead forward)Washdown Raw Water Pump (Engine room bulkhead aft)AIR CONDITIONINGA/C VentWEBASTO FURNACEWebasto furnace is located under access panel below refrigerator.The control panel is located at the quarter berth power management center.The fuel pump is in the salon floor hatch compartment inside of the black box.Webasto FurnaceFuel Pump / Filter (inside black box)Interior Heat VentInterior Heat VentExhaust(keep unblocked/gets very warm)Exterior Heat VentSOLAR PANELSolar panel 160 watt, with display panel• The solar panel is designed to provide charging to the house & engine batteries. 90% of its charge is dedicated to the house battery and 10% is dedicated to the engine battery.• The green light on the solar display indicates proper operation.• The solar display is located in the mid-berth.• The controller is located in the port lazarette*Keep panel clean and completely uncovered for best resultsThruster BatterySolar PanelDisplayBatteriesController121113Battery Banks 1 = House 2 = Engine 3 = ThrusterBATTERY CONFIGURATIONSTE4 House Batteries, 1 Engine Battery, 1 Thruster Battery.3 Switches in cockpit behind circular access panelBatteriesSTERNMICRO-WAVE ACCESS-ORY CHART LIGHTSHORNHOUSEENGINEBATTERY PARALLELSTESTEHouse, engine, & battery parallel switches are located behind the port side circular access panel in the cockpit.Thruster battery switches located in the midberthOnce the EMERGENCY PARALLEL switch is placed in the on position the power from the HOUSE batteries will be transferred to the ENGINE battery. Use only for EMERGENCY starting of the engine.If the house bank drops below 10.8v you must reset the charging relay by switching on the parallel while the engine is running.TransducerFUSE LOCATION & VALUESSTE These DC fuse blocks are located behind the wood hatch in the midberth.Fuses are automotive blade type and all values shown below are in Amps.Bilge Pump #1Bilge Pump #2Bilge AlarmCO Monitor #1CO Monitor #2Volt Meter Battery #3Hot powered (always on)Hot powered (always on)LPG ControllerEngine Hatch (switch)Volt Meter Battery #2Downrigger (starboard) Downrigger (port) 12V Outlet (mid-berth)RefrigeratorRefrigerator (aft) Switch Panel (4 switch)Autopilot Pump Washdown Freshwater Pump Cabin Lights Misc. Lights SpotlightThis DC fuse block is mounted under the bridge dash.Fuses are automotive blade type and all values shown below are in Amps.Switch Panel (bridge)12V Outlet (bridge)Nav. Display (bridge)Located in the port side cockpit lazeretteSolar Panel Controller may be mounted forward of the power panel on boats with a generatorPOWER PANEL AND SOLAR PANEL CONTROLLER BOXCommand BridgeSedanSolar Panel Controller50 Amp Breaker50 Amp Breaker Automatic Charging Relay (ACR)Automatic ChargingRelay (ACR)300 Amp ANLBus Fuse300 Amp ANL Bus Fuse150 Amp Breaker• There are two more 250 amp ANL fuses for the Bow and Stern thruster located in the midship outboard of the thruster battery switches behind cabinet door.STEAC DISTRIBUTION PANEL & ROTARY SWITCHSTESTEAC Rotary Selector Switch (Available with Generator) AC Main Line 2 (with AC)The AC Rotary Switch Selector Switch will determine which source of incoming 120 Volt power to use for your AC Distribution Panel.A/C Main 1 must on in order for batteries to charge.AC Distribution PanelAC MAIN1AC MAIN2FWD AIR AFT AIR AFT RELAY ACCESS-ORYMICRO-WAVE ACCESS-ORY COOK TOP OVEN ICE MAKER WATER HEATERGALLEY OUTLETS OUTLETS FORWARD SALONOUTLETSMICRO-WAVE GALLEY OUTLETS OUTLETS FORWARDSALONOUTLETSBOW THRUSTERSTERNTHRUSTERBOW THRUSTERSTERN THRUSTERACCESS-ORYCOOK TOP OVEN ICE MAKER WATER HEATER ACCESS-ORY ACCESS-ORY ACCESS-ORY ACCESS-ORYAC Distribution Panel with GeneratorAC Distribution PanelAC Main 1AC Main 1AC Main 1AC Main 1AC Main 2AC Main 2Water Pump gauge/switchWater Pump gauge/switchAC Main 2 used for only FWD/AFT air and aft relay breakersBattery Banks 1 = House 2 = Engine3 = ThrusterAt HelmAt HelmIn CockpitACC is for overhead cockpit lightsResettable switchbreakersResettable switchbreakersHeater Control High Water Alarm12V HELM CONTROL OPERATIONSTEThe high bilge alarm should be set to the “armed” position for it to automatically operate. This is wired directly to the hot fuseblock. The high bilge alarm will still be active regardless of battery switch position.Armed = Red light/audible alarm Off = Red light only.The Heater Control will operate the fan speed of the Heater Craft Heater. The Heater Craft Cabin Heater will only warm as the engine reaches normal operating temperature.The bilge pumps operate automatically with electronic float switches regardless of battery switch position.However, the BILGE PUMP and BILGE PUMP2 will run continuously once their switches are placedin the on position. Monitor the outflow accordingly. Do not run when dry.RANGER TUG R-29 WIRING SCHEMATIC (ACC. 1)R-29 Accessories #1+12VELECTRICAL SCHEMATIC-12VRANGER TUG R-29 WIRING SCHEMATIC (ACC. 2)R-29 Accessories #2+12VELECTRICAL SCHEMATIC-12V Bilge PumpCO MonitorUNSWITCHED ALWAYS ON!RANGER TUG R-29 WIRING SCHEMATIC (ACC. 3)R-29 Accessories #3+12VPDPELECTRICAL SCHEMATIC-12V Breaker FuseHorn Prompt toSpeaker Switch DPSTUNSWITCHED ALWAYS ON!RANGER TUG R-29 WIRING SCHEMATIC (LIGHTING)+12VR-29 Lighting7-25-16-12V PDP All Switched w/ House Battery SwitchRANGER TUG R-29 WIRING SCHEMATIC (P.D.P.)HOUSEHOUSETHRUSTERSENGINE312111R-29 Power Distribution ELECTRICAL SCHEMATICRANGER TUG R-29 WORKING DECKSTER-29 CB R-29 SMAST SET UP AND TAKEDOWNMAST SET UP PROCEDURE1. Remove the three black plastic wing nuts from the mast base.2. Remove the two mast tie down cables from their storage positions in the roof clips.3. With the mast tie down cables still loose, remove pin, raise the mast off of the stainless steel support bar.4. Secure the stainless steel retaining bar in the appropriate clip attached, reinsert pin into mast fitting.5. Raise the mast to its full extension and ensure that it fits correctly over the mounting studs on the roofmounting plate.6. Attach the three black plastic wing nuts to the mounting studs and hand tighten securely.7. Attach the two mast tie down cables to their appropriate clips on the port and starboard side of the roof.8. Make sure the mast tie down cables are adjusted properly.MAST TAKE DOWN PROCEDURE1. Remove the mast tie down cables from their clips on the port and starboard side of the roof.2. Remove the three black plastic wing nuts from the mast base mounting studs.3. Carefully lower the mast onto the stainless steel support bar and insert pin.4. Attach the black plastic wing nuts back onto the screws on the mast mounting plate and secure themfor storage by hand tightening.5. Attach the two mast tie down cables to their storage positions in the roof clips.6. Secure the mast with a tie down.CARE AND MAINTENANCEPlease customize to your personal needs. Consult your engine and trailer user manuals for ad-ditional information.EXAMPLE OF A PREPARATION FOR THE ROAD CHECKLISTTOW VEHICLE – PRIOR TO USE£ Test Lights.£ Check brakes.£ Check tire pressure and condition.£ Check hitch related electrical connections.TRAILER – PRIOR TO USE£ Check registration£ Check rollers and bed rails.£ Check wheel bearings and lubricate as required.£ Check winch.£ Test electrical connection and lights.£ Check tire pressure and condition.£ Check safety chains.£ Check boat straps.£ Check braking system.£ Check hitch for proper connection and lock down.£ Install safety chains (cross under hitch).£ Remove tire blocks.BOAT – PRIOR TO USE WITH TRAILER£ Lower mast.£ Lower VHF antenna.£ Secure the Bimini awning frame.£ Raise and secure swim platform ladder.£ Set all switches and breakers to the OFF position, Including Thruster/Windlass cutoff switch£ Close and secure all windows, ports and vents.£ Lock cabin.£ Center rudder.£ Remove Drain Plug.£ Install windshield canvas to protect from rocks while traveling.EXAMPLE OF A SPRING PRE-LAUNCH CHECKLISTCLEANING£ Remove debris from scuppers and scupper drains.£ Clean hull using a mild biodegradable detergent and then wax.£ Clean topsides and decks using a mild biodegradable detergent and then wax.£ Clean and polish all bright work.£ Clean and oil teak.£ Clean windows, ports, and hatches.£ Clean bimini cover.£ Check and clean anchor, rode, and anchor storage compartment.INSPECTION£ Check Drain Plug£ Check spare parts and tools and replace as necessary.£ Check wiper blades.£ Check swim platform.£ Inspect and test trim tabs.£ Check condition of bottom paint.£ Check windlass.£ Verify electronics for correct operation.£ Check all inside and outside lights.£ Macerator Y-Valve in proper position and secured.£ Inspect and verify position of all sea cocks and shut off valves.£ Check alarms for proper operation.£ Check fluid levels.£ Inspect batteries / water level in batteries (if applicable).£ Check bilge pump operation / clean float switches.SAFETY EQUIPMENT£ Sound signaling device.£ Check flares and their expiration dates.£ Check personal flotation devices.£ Check fire extinguishers and their fill dates.£ First aid kits.GALLEY£ Check stove for proper operation.£ Check everyday utensil stock.DOCUMENTS£ Registration sticker.£ Insurance papers and Passports.£ Boat Inspection sticker.£ Charts and float plan forms.EXAMPLE OF WINTER STORAGE CHECKLISTGENERAL MAINTENANCE£ Fill Fuel Tank and add a fuel stabilizer.£ Empty and clean black water tank.£ Empty fresh water tank use a non-toxic antifreeze per manufacturer’s directions.£ Winterize black and fresh water tanks as necessary based on weather.£ Check bilge area for oil and for proper operation / Check bilge pump operation / clean float switches.£ Check zincs and replace as necessary.£ Check impeller.£ Check and clean water strainer.£ Clear barnacles and debris from hull fittings.£ Trickle charge batteries every 30-60 days.£ Vent boat to prevent mildew.£ Check trailer tire pressure and condition.£ Check trailer braking system.£ Check trailer bearings.£ Remove Drain Plug.£ Turn off all battery cutoff switches.ENGINE£ Flush sea strainer system with fresh water.£ Check all fluid levels.£ Check all hose fittings.£ Check engine maintenance requirements.£ Inspect and verify position of all sea cocks and shut off valves.GALLEY£ Empty, clean and freshen refrigerator.£ Remove all dry food from storage.WARNING LABEL LOCATIONSNOTESFax 253-839-5218 。

多功能双体船舶操作手册船舶操作手册主机操作规程一、主机起动前检查备车准备:1.检查并开启燃油系统,冷却水系统进出口阀(一般为常开)。

2.检查艉轴油箱油位,并用手摇泵泵油至回油管油流出为止。

3.启动为主机服务的油泵和水泵,并确认其工况良好(特别是寒冷季节)4.检查冷却水已完全排到各排出点;检查各压力表读数;检查各管路是否泄漏。

5.加油润滑各必须手动加注润滑点。

6.检查滑油压力,检查各运动部件轴承及其他润滑点已充足供油与良好润滑。

7.检查燃油压力及燃油系统是否泄漏。

8.通知驾驶台:车备好。

二、主机起动操作:1.严格按照驾驶台发出的车钟指令,启动操作主机。

2.主机运转后,立即检查各参数,纠正异常参数,如必要停车检修。

3.如是冷车,输出功率慢慢增加。

三、主机换向操作:1.按要求,操纵手轮从“向前”到“停止”位置,手轮被啮合在“停止”位置,停止供油。

2.向逆时针倒车方向转动操纵手轮,直到换向指示灯和换向指示显示“倒车”位置,即换向结束。

3.由“倒车”到“正车”换向操作与上述操作相反。

四、主机运行:1.轮机员根据主机实际负荷参数,适当调整主机转速和气缸注油量。

2.主机正常运行期间,应在不超过30分钟内,必须作巡回检查,用手背触摸主机曲柄箱道门判断主轴承、连杆大端轴承的工作情况;应把主机各运行参数和曲拐箱油位与主机说明书所规定的参数做比较;如有异常,应适当调整;如遇紧急情况,可先行停车,再报告驾驶台/轮机长。

五、主机停车:1.逐渐减小负荷,主机在低负荷下继续运转一段时间。

2.转动手轮至“停止”位置。

发电机操作规程一、启动前的准备1.检查柴油机各部件是否正常,各附件连接是否牢靠,是否有漏油、漏水现象,并排除不正常现象。

2.检查海水泵进出口阀、柴油机进油阀是否打开。

3.检查柴油日用柜油位、淡水冷却水箱水位是否正常。

二、柴油机启动1.把起动手柄再次推倒起动位置,等到发火转速后,迅速把起动手柄推至运行位置,启动后检查各仪表参数是否符合说明书要求(特别是滑油压力)。

救生艇发动机操作须知

1起动前检查:

车叶及其轴系是否无障碍,换向齿轮箱及其滑油油位是否正常。

柴油机四周及曲轴箱油位是否正常。

柴油柜油位是否足够(一般用-10轻柴油),出口阀是否开启。

2起动

把换向杆置于空档位置,把高压油泵油门调节杆置于起动位置。

把气阀顶开杆板至顶开位置。

搭好摇动手柄,用力猛摇至高速转动后迅速把气阀顶开杆板至关闭位置,直至机器在柴油控制下运转。

在进行操作过程中,要注意调节油门,以防飞车或因低于稳定转速而自行停车。

3停机

油门减至零位。

要关好柴油柜进出口阀和加足柴油,以及盖好护机罩和护艇罩。