米顿罗三柱塞高压往复泵中文版

- 格式:pdf

- 大小:4.14 MB

- 文档页数:16

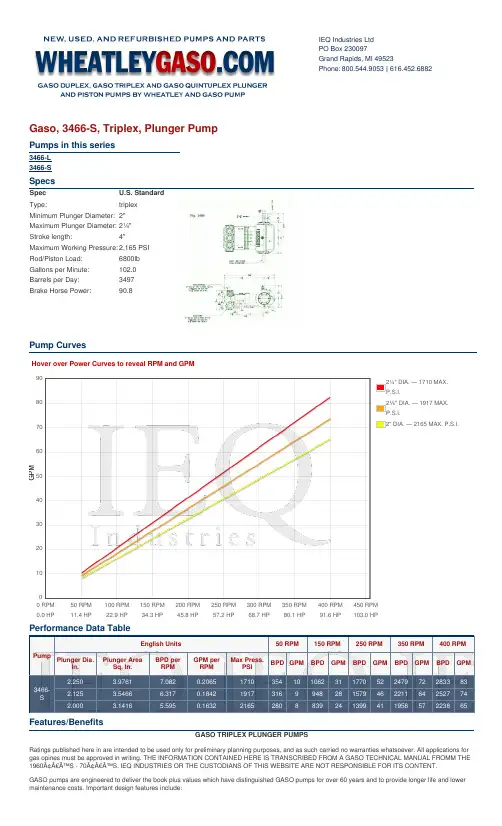

Spec U.S. Standard Type:triplexMinimum Plunger Diameter:2"Maximum Plunger Diameter:2¼"Stroke length:4"Maximum Working Pressure:2,165 PSIRod/Piston Load:6800lb Gallons per Minute:102.0Barrels per Day:3497Brake Horse Power:90.8Gaso, 3466-S, Triplex, Plunger PumpPumps in this series3466-L 3466-SSpecsPump CurvesHover over Power Curves to reveal RPM and GPMFeatures/BenefitsGASO TRIPLEX PLUNGER PUMPSRatings published here in are intended to be used only for preliminary planning purposes, and as such carried no warranties whatsoever. All applications for gas opines must be approved in writing. THE INFORMATION CONTAINED HERE IS TRANSCRIBED FROM A GASO TECHNICAL MANUAL FROMM THE 1960’S - 70’S. IEQ INDUSTRIES OR THE CUSTODIANS OF THIS WEBSITE ARE NOT RESPONSIBLE FOR ITS CONTENT.GASO pumps are engineered to deliver the book plus values which have distinguished GASO pumps for over 60 years and to provide longer life and lowermaintenance costs. Important design features include:0 RPM 0.0 HP50 RPM 11.4 HP100 RPM 22.9 HP150 RPM 34.3 HP200 RPM 45.8 HP250 RPM 57.2 HP300 RPM 68.7 HP350 RPM 80.1 HP400 RPM 91.6 HP450 RPM 103.0 HP1020304050607080902¼" DIA. — 1710 MAX.P.S.I.2⅛" DIA. — 1917 MAX.P.S.I.2" DIA. — 2165 MAX. P.S.I.Phone:IEQ Industries Ltd PO Box 230097Grand Rapids, MI 49523800.544.9053 |616.452.6882Power End SpecificationsPower Frame. High-strength gray iron alloy casting with heavy wall sections well written to ensure rigid construction.Crankshaft. Mounted with centerline of shaft on centerline of cross heads. Crankshaft may extend from either side of the pump.Crankshaft Bearings. Interchangeable heavy-duty roller bearings.Connecting Rods. All triplex plunger pumps are equipped with H type construction rods, with renewable Babbit lined steel backed shell bearings at the crank end and bronze bushings at crosshead end.Crossheads. Figures 3088, and series 3200, 3300, 313, 3400, 3800, 3900, 3600 and 3700 pumps are furnished with cylindrical type high-strength alloy castings. Series 3500 pumps are furnished with semi-cylindrical typecasting. Cross head tends are hardened and ground steel.Lubrication. All power and parts are lubricated by splash system from oil in the crankcase reservoir. Power frame has an oil return channel, from front of the cross heads back to the crankcase, to permit constant circulation of oil and to help keep oil cool. Positive power and lubrication is optional for series 3700 pumps.Stuffing Boxes. Figures 3088 and series 3200, 3300, 3400, 3500, 3800, and 3900 pumps are furnished with double lip “Uâ€Âcup packings. Series 3630 700 pumps are furnished with a set of four non-crushable lip type packing rings.Fluid End SpecificationsFLUID END BODY. Alloys which are stocked our Molybnenum alloy iron for crude oil and freshwater service, and steel for pumping petroleum products in hazardous locations. Aluminum bronze alloys are used for salt water and other corrosive liquids. Special alloys such as Hastalloy C, Inconel or stainless steel can be furnished upon request.VALVES. Figure 3211 and 3364 pumps are furnished standard with wing guided type valves and seats. Figures 3365, 3088 and series 3113, 3400, 3500, 3800, 3900, 3630 700 pumps are furnished with stem guided disk type valve assemblies.CYLINDER HEADS AND VALVE COVERS. 3211 and 3364 pumps with aluminum bronze and Molybdenum alloy fluid ends have threaded valve covers and cylinder heads, all other our bolt on type.PLUNGERS. Plunger materials are available in: file hard steel,colmonoy's surfaced steel, solid ceramic, and chrome plated steel.STUFFING BOXES. All triplex pump boxes, with the exception of figures 3088, 3583, and series 3900, 3630 3700 pumps, are board directly into the fluid body. Stuffing boxes are for figures 3088, nerdy 3583 and series 3800, 3900, 3630 and 3700 pumps are replaceable type.PACKING. Standard packing is a set of non-crushable lid tight packing rings. Other packing can be furnished for special applications.PlLUNGER LUBRICATION. Furnished by use of grip oilers or regulated flow of oil from a force-feed's lubricator. Lubricate or is mounted on the pump with separate oil lines to each plunger.Disclaimer IThis website is intended as a reference tool only. It has been constructed from published data that is based on manufacturer's sales and engineering documents that are either current, historical and obsolete. Much of the machinery data contained herein has been re-rated through the years with different engineering criteria which maybe in conflict with legacy data. Much of the content published here is calculated online with the use of dynamic data using formulas and extrapolations considered to be sound engineering formulas and are correct to the degree that the data used is accurate. We have done our best to be as precise as as possible in this posting but do not represent any of the calculations or performance data to be entirely accurate. The data published here is intended to be general information rather than actual and to serve as a reference rather than a technical absolute. The user of such data should confirm such information independently.Copyright and Disclaimers is your resource for Gaso pumps, Gaso pump parts and a supplier of ORIGINAL GASO PARTS and equipment, new used and remanufactured Wheatley, GASO andWheatley/GASO plunger and piston pumps and pump parts and is not affiliated with Wheatley/GASO Inc. or its parent company, National Oilwell Varco,p Copyright ©2017, IntelleQ Holdings, LLC. All rights reserved, *Used under license from IntelleQ Holdings, LLC.。

米顿罗隔膜式化学计量泵安全操作规程范文一、引言米顿罗隔膜式化学计量泵是一种用于输送各种化学液体的设备,其操作涉及到泵的运行、维护和安全。

为了确保操作人员和设备的安全,制定了本安全操作规程。

二、安全设备1. 在操作过程中,必须戴上合适的防护眼镜,防止泵液喷溅到眼睛。

2. 在操作过程中,应穿戴适当的防护服,确保皮肤不直接接触到泵液。

3. 在操作过程中,要轻拿轻放工具,避免工具落地造成伤害。

4. 在操作过程中,确保有充足的通风,避免吸入有害气体。

三、安全操作步骤1. 检查泵的工作环境是否安全,确保没有明火、易燃易爆物品等危险物。

2. 检查泵的供电是否正常,确保电源稳定。

3. 在操作泵之前,确保操作人员已经接受相关培训,了解泵的工作原理和操作要点。

4. 打开泵的主电源开关,确保电机运行正常。

5. 检查泵的各个连接部位是否密封良好,确保没有泄漏。

6. 通过观察显示屏或仪表,确保泵的运行参数正常。

7. 在操作泵之前,确保操作人员将注意力集中在泵上,避免分散注意力造成安全隐患。

8. 在操作过程中,严禁将手伸入泵内或近距离接近泵口。

9. 在操作过程中,严禁将泵液直接倾倒入污水或其他泄露处,应采取相应的密闭方式进行处理。

10. 在操作过程中,如发现异常情况,应立即停止泵的运行,并采取相应的紧急措施。

四、泵的维护1. 定期检查泵的密封件,如发现损坏应及时更换。

2. 定期清洗泵的过滤网,确保通畅。

3. 定期检查并紧固泵的连接螺丝,确保泵的连接牢固。

4. 定期检查并清理泵的出口管道,确保畅通。

5. 定期检查泵的电气设备,如有异常应及时处理。

6. 定期对泵进行润滑,确保泵的运转顺畅。

五、应急措施1. 如发生泵故障、泵液泄漏等紧急情况,应立即切断泵的电源,并采取相应的应急措施。

2. 如泵液误入眼睛或皮肤,应立即用大量清水冲洗,并及时就医。

六、总结通过本安全操作规程,能够有效地提高操作人员的安全意识和操作水平,减少事故的发生,确保泵的正常运行和设备的安全。

米顿罗计量泵使用及技术说明米顿罗计量泵可以对许多液体进行输送,尤其是具有腐蚀性的液体,作为一种特殊的容积泵,其在现代工业与技术的不断发展中而不断的进步,不断的满足着生产工作的需求,对于泵这种机械产品来说,对冲程的调节是非常重要的,米顿罗计量泵也是一样,那么,在输送过程中,米顿罗计量泵是如何对冲程进行调节的,其调节冲程的方式都有哪些?接下来就让我们一起来看看吧。

米顿罗计量泵在输送过程中,冲程的调节方式有很多种,而比较常用的应该就是以下这三种了。

第一种方法是在输出管路系统设置旁通回路,然后对旁通阀进行调节,并控制回冲程这样就达到了对系统的输出冲程进行调节的目的,但是,通过这种方法来对冲程进行调节,会加大能量的损耗,这也是这种冲程调节方式的一大缺点。

第二种方法是通过对泵转速的改变来对冲程进行调节,这种方法需要在泵的平均冲程与转速成正比的情况下进行,而往复泵正好有这个特性,所以,可以通过这种方式来看对冲程进行调节;此外,通过改变转速调节冲程的方法还需要对装置或电动机进行调速,但是,在小冲程的时候,冲程数太小而导致排液时间过长,这对于某些化学反应是不允许的,所以还需要多多的注意。

第三种方法是一种比较常用的方法了,其是通过对泵活塞(柱塞)的行程长度的调节来对冲程进行调节,这种方法的一大优点是计量精度高,而且即使是在小冲程的情况下,仍然可以满足线性要求,可以说是比较有效的一种方法。

米顿罗计量泵调节冲程的方法还有很多,需要操作人员根据实际的运作情况来对方法进行选择,从而选择到合适的冲程调节方法来促进泵的正常、顺利的运作。

米顿罗计量泵设备说明与使用特点性能隔膜泵头使用米顿罗公司的专利MARS技术(自动机械补油系统),综合了各种传统泵头的优点。

高性能隔膜泵头取消了传统液压隔膜泵头所需的物料端的圆盘隔膜护盘,从而使泵头既具有管式隔膜的“直接通过性”和柱塞泵的低NPSH(净正吸入压头)要求等性能,又能有效的保护隔膜,延长隔膜寿命,且避免了传统计量泵头精度可能随使用时间变化的弱点。

SpecU.S. Standard Type:triplexMinimum Plunger Diameter:Maximum Plunger Diameter:Stroke length:4"Maximum Working Pressure:PSI Rod/Piston Load:6800lb Gallons per Minute:Barrels per Day:Brake Horse Power:90.8Gaso, 3467, Triplex, Plunger PumpPumps in this series 3467SpecsPump CurvesHover over Power Curves to reveal RPM and GPMFeatures/BenefitsGASO TRIPLEX PLUNGER PUMPSRatings published here in are intended to be used only for preliminary planning purposes, and as such carried no warranties whatsoever. All applications for gas opines must be approved in writing. THE INFORMATION CONTAINED HERE IS TRANSCRIBED FROM A GASO TECHNICAL MANUAL FROMM THE 1960’S - 70’S. IEQ INDUSTRIES OR THE CUSTODIANS OF THIS WEBSITE ARE NOT RESPONSIBLE FOR ITS CONTENT.GASO pumps are engineered to deliver the book plus values which have distinguished GASO pumps for over 60 years and to provide longer life and lower maintenance costs. Important design features include:Power End SpecificationsPower Frame. High-strength gray iron alloy casting with heavy wall sections well written to ensure rigid construction.Crankshaft. Mounted with centerline of shaft on centerline of cross heads. Crankshaft may extend from either side of the pump.Crankshaft Bearings.Interchangeable heavy-duty roller bearings.Phone:IEQ Industries LtdPO Box 230097Grand Rapids, MI 49523800.544.9053 |616.452.6882Connecting Rods. All triplex plunger pumps are equipped with H type construction rods, with renewable Babbit lined steel backed shell bearings at the crank end and bronze bushings at crosshead end.Crossheads. Figures 3088, and series 3200, 3300, 313, 3400, 3800, 3900, 3600 and 3700 pumps are furnished with cylindrical type high-strength alloy castings. Series 3500 pumps are furnished with semi-cylindrical typecasting. Cross head tends are hardened and ground steel.Lubrication. All power and parts are lubricated by splash system from oil in the crankcase reservoir. Power frame has an oil return channel, from front of the cross heads back to the crankcase, to permit constant circulation of oil and to help keep oil cool. Positive power and lubrication is optional for series 3700 pumps.Stuffing Boxes. Figures 3088 and series 3200, 3300, 3400, 3500, 3800, and 3900 pumps are furnished with double lip “Uâ€Âcup packings. Series 3630 700 pumps are furnished with a set of four non-crushable lip type packing rings.Fluid End SpecificationsFLUID END BODY. Alloys which are stocked our Molybnenum alloy iron for crude oil and freshwater service, and steel for pumping petroleum products in hazardous locations. Aluminum bronze alloys are used for salt water and other corrosive liquids. Special alloys such as Hastalloy C, Inconel or stainless steel can be furnished upon request.VALVES. Figure 3211 and 3364 pumps are furnished standard with wing guided type valves and seats. Figures 3365, 3088 and series 3113, 3400, 3500, 3800, 3900, 3630 700 pumps are furnished with stem guided disk type valve assemblies.CYLINDER HEADS AND VALVE COVERS. 3211 and 3364 pumps with aluminum bronze and Molybdenum alloy fluid ends have threaded valve covers and cylinder heads, all other our bolt on type.PLUNGERS. Plunger materials are available in: file hard steel,colmonoy's surfaced steel, solid ceramic, and chrome plated steel.STUFFING BOXES. All triplex pump boxes, with the exception of figures 3088, 3583, and series 3900, 3630 3700 pumps, are board directly into the fluid body. Stuffing boxes are for figures 3088, nerdy 3583 and series 3800, 3900, 3630 and 3700 pumps are replaceable type.PACKING. Standard packing is a set of non-crushable lid tight packing rings. Other packing can be furnished for special applications.PlLUNGER LUBRICATION. Furnished by use of grip oilers or regulated flow of oil from a force-feed's lubricator. Lubricate or is mounted on the pump with separate oil lines to each plunger.Disclaimer IThis website is intended as a reference tool only. It has been constructed from published data that is based on manufacturer's sales and engineering documents that are either current, historical and obsolete. Much of the machinery data contained herein has been re-rated through the years with different engineering criteria which maybe in conflict with legacy data. Much of the content published here is calculated online with the use of dynamic data using formulas and extrapolations considered to be sound engineering formulas and are correct to the degree that the data used is accurate. We have done our best to be as precise as as possible in this posting but do not represent any of the calculations or performance data to be entirely accurate. The data published here is intended to be general information rather than actual and to serve as a reference rather than a technical absolute. The user of such data should confirm such information independently.Copyright and Disclaimers is your resource for Gaso pumps, Gaso pump parts and a supplier of ORIGINAL GASO PARTS and equipment, new used and remanufactured Wheatley, GASO andWheatley/GASO plunger and piston pumps and pump parts and is not affiliated with Wheatley/GASO Inc. or its parent company, National Oilwell Varco,p Copyright ©2017, IntelleQ Holdings, LLC. All rights reserved, *Used under license from IntelleQ Holdings, LLC.。

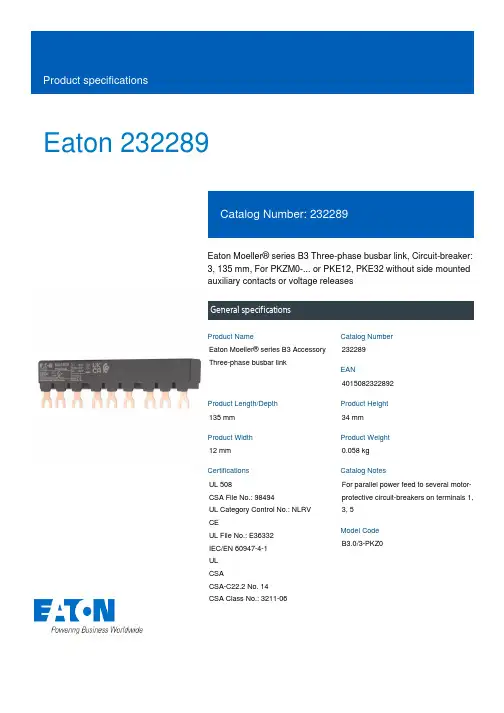

Eaton 232289Eaton Moeller® series B3 Three-phase busbar link, Circuit-breaker:3, 135 mm, For PKZM0-... or PKE12, PKE32 without side mountedauxiliary contacts or voltage releasesGeneral specificationsEaton Moeller® series B3 AccessoryThree-phase busbar link2322894015082322892135 mm34 mm12 mm0.058 kgUL 508CSA File No.: 98494UL Category Control No.: NLRV CEUL File No.: E36332IEC/EN 60947-4-1ULCSACSA-C22.2 No. 14CSA Class No.: 3211-06For parallel power feed to several motor-protective circuit-breakers on terminals 1, 3, 5B3.0/3-PKZ0Product Name Catalog NumberEANProduct Length/Depth Product Height Product Width Product Weight Certifications Catalog NotesModel CodeBlackForkInsulatedCan be extended by rotating installation 3Three-pole 45 mmIII3Accessories 6000 V AC3 Circuit-breakersPKZ0PKE12PKE32-25 °C 55 °C 690 V 690 V 63 A0 kA 0 kA 4.5 W0 W1.5 W 63 AColorElectric connection type FeaturesFunctionsNumber of phases Number of poles Mounting widthOvervoltage categoryPollution degreeProduct categoryRated impulse withstand voltage (Uimp) Suitable forUsed withAmbient operating temperature - min Ambient operating temperature - max Rated operational voltage (Ue) - max Rated operational voltage (Ue) at AC - max Rated uninterrupted current (Iu)Rated conditional short-circuit current (Iq) Rated short-time withstand current (Icw)Equipment heat dissipation, current-dependent PvidHeat dissipation capacity PdissHeat dissipation per pole, current-dependent PvidRated operational current for specified heat dissipation (In)0 WMeets the product standard's requirements.Meets the product standard's requirements.Meets the product standard's requirements.Meets the product standard's requirements.Meets the product standard's requirements.Does not apply, since the entire switchgear needs to be evaluated.Does not apply, since the entire switchgear needs to be evaluated.Meets the product standard's requirements.Does not apply, since the entire switchgear needs to be evaluated.Meets the product standard's requirements.Does not apply, since the entire switchgear needs to be evaluated.Does not apply, since the entire switchgear needs to be evaluated.Is the panel builder's responsibility.Is the panel builder's responsibility.Is the panel builder's responsibility.Save time and space thanks to the new link module PKZM0-XDM32ME Motor Starters in System xStart - brochureSwitching and protecting motors - catalogProduct Range Catalog Switching and protecting motorsDA-DC-00004554.pdfDA-DC-00004601.pdfDA-DC-00004109.pdfDA-DC-00004245.pdfDA-DC-00004891.pdfDA-DC-00004918.pdfDA-DC-00004920.pdfDA-DC-00004917.pdfDA-DC-00004883.pdfDA-DC-00004945.pdfDA-DC-00004911.pdfDA-DC-00004879.pdfDA-DC-00004921.pdfDA-DC-00004884.pdfDA-DC-00004962.pdfDA-DC-00004890.pdfDA-DC-00004892.pdfDA-DC-00004888.pdfDA-DC-00004950.pdfDA-DC-00004914.pdfDA-DC-00004887.pdfDA-DC-00004944.pdfeaton-manual-motor-starters-busbar-b3-accessory-dimensions.eps eaton-manual-motor-starters-busbar-b3-accessory-3d-drawing-005.epsETN.B3.0_3-PKZ0Static heat dissipation, non-current-dependent Pvs10.2.2 Corrosion resistance10.2.3.1 Verification of thermal stability of enclosures10.2.3.2 Verification of resistance of insulating materials to normal heat10.2.3.3 Resist. of insul. mat. to abnormal heat/fire by internal elect. effects10.2.4 Resistance to ultra-violet (UV) radiation10.2.5 Lifting10.2.6 Mechanical impact10.2.7 Inscriptions10.3 Degree of protection of assemblies10.4 Clearances and creepage distances10.5 Protection against electric shock10.6 Incorporation of switching devices and components10.7 Internal electrical circuits and connections10.8 Connections for external conductors10.9.2 Power-frequency electric strength BrochuresCataloguesCertification reports Declarations of conformityDrawingseCAD modelInstallation instructionsEaton Corporation plc Eaton House30 Pembroke Road Dublin 4, Ireland © 2023 Eaton. All rights reserved. Eaton is a registered trademark.All other trademarks areproperty of their respectiveowners./socialmediaIs the panel builder's responsibility.Is the panel builder's responsibility.The panel builder is responsible for the temperature rise calculation. Eaton will provide heat dissipation data for the devices.Is the panel builder's responsibility. The specifications for the switchgear must be observed.Is the panel builder's responsibility. The specifications for the switchgear must be observed.The device meets the requirements, provided the information in the instruction leaflet (IL) is observed.IL122027ZUWIN-WIN with push-in technologyb3_0_3_pkz0b3_0_3_pkz0.stp10.9.3 Impulse withstand voltage10.9.4 Testing of enclosures made of insulating material 10.10 Temperature rise10.11 Short-circuit rating10.12 Electromagnetic compatibility10.13 Mechanical function Installation videos mCAD model。