第07章AWL电喷2

- 格式:doc

- 大小:3.41 MB

- 文档页数:29

奇瑞QQ3维修手册(372+MT玛瑞利电喷系统)目录第一章电喷控制和执行元件工作原理 (1)1、进气压力和进气温度传感器 (1)2、节气门位置传感器 (2)3、冷却液温度传感器 (3)4、爆震传感器KS (4)5、前氧传感器 (5)6、电子控制单元ECU (6)7、电动燃油泵 (8)8、电磁喷油器 (9)9、怠速执行器步进电机 (10)10、点火线圈 (11)11、碳罐控制阀 (12)12、燃油压力调节器 (13)13、钢制燃油分配管总成 (14)14、凸轮轴位置传感器 (15)15、曲轴位置传感器 (16)16、风扇控制 (17)第二章电喷系统故障诊断基本原理 (18)1、故障信息记录 (18)2、故障状态 (18)3、故障类型 (18)4、故障频度计数器 (18)5、跛行回家 (18)6、故障报警 (19)7、故障读出 (19)8、故障信息记录的清除 (19)9、故障查找 (19)10、根据故障信息记录实施故障诊断的步骤 (20)10.1、空调蒸发器出口温度传感器故障 (20)10.2、爆震传感器故障 (21)10.3、进气压力温度传感器的压力传感器部分故障 (22)10.4、前氧传感器故障 (23)10.5、进气压力温度传感器的温度传感器部分故障 (24)10.6、冷却液温度传感器故障 (25)10.7、喷油器驱动级故障 (26)10.8、碳罐控制阀驱动级 (28)10.9、故障指示灯(MIL)驱动级 (29)11、诊断仪故障码定义 (30)第三章、372马瑞利电喷控制原理图 (31)第一章电喷控制和执行元件工作原理1、进气压力和进气温度传感器用途:测量0.1bar左右的进气歧管绝对压力及进气气流的温度,为发动机提供负荷信息,可根据容积效应自动判断海拔高度。

组成和原理:这个传感器由两个传感器即进气歧管绝对压力传感器和进气温度传感器组合而成,装在进气歧管上。

进气压力传感器是用一个螺栓直接固定到进气管上,并通过两个密封圈来防止漏气。

《火焰之纹章:封印之剑》攻略第1章運命の息吹胜利条件:主角去“压制”上边的城堡。

攻略:GBA上的封印之剑系统与以前的纹章之谜很相似呢,也糅合了776的不少特点,相信玩过前两作的朋友会很容易上手。

另外它也没忘记系谱,高级职业的不同能力上限也不同,历代纹章中人物的支援关系仿照了系谱的恋爱特色,也需要慢慢培养才会使支援升级,而支援大大强化了,不仅仅是以前单纯的加命中率和回避率,而是能力真正上升,并且有着类似特技的设定。

虽然本作没有个人技能了,但是实际上还是有隐藏的技能存在的。

当然,追击和必杀已经是所有人物都能具备的共通技的^^好了,简单介绍了。

开始正题。

第一章,总是为了给玩的人上手练习用的^^,只要稍微注意,那就很轻松了。

查看人员,依然有两个护卫骑士,他们一般就要充当本章战斗主力喽~,アレン(阿伦)与ランス(兰斯)俗称为小红和小绿^^,前面是几个斧战士挡着,他们上去战时尽量使用剑进行攻击,武器相克性剑克斧,能够让自己多一分安全。

已经转职成圣骑士的老头マ-カス(马卡斯)一看就知道没什么用,是个快速移动的肉盾,先让他把铁剑交给主角,银枪也给小红或者小绿吧。

主角的西洋剑现在比较珍贵,尽量节省吧。

重骑士ボールス(波鲁斯)防御力很高,不过他是用枪的,容易被敌人的斧克制,用他挡一挡敌人到还可以,弓手ウォルト(沃尔特)一开始比较弱,他和主角应该尽量得到经验升级。

一开始,自身实力还不算厉害,所有人尽量聚集在一起,单打独斗一旦被围攻,很容易死亡的。

要小心敌人里的弓手,一开始还是有些棘手的。

注意上方村庄废墟前的山贼,这个职业的敌人是会破坏村子的,一定要抢先狙击了,不要让他破坏村子。

大家联手把冲下来的敌人解决了,只要相互协调好问题不会麻烦的,派个人去右边的村子里访问,可以得到5000G 的金钱,一开始我方还是比较穷的。

然后可以组织力量去进攻上方城堡了~将敌人一个个引下来,利用重骑士ボールス(波鲁斯)和マ-カス(马卡斯),让ボールス(波鲁斯)耗去敌人一些HP,然后其他人就容易对付了,当自己HP危险时,不要犹豫,使用伤药回复吧。

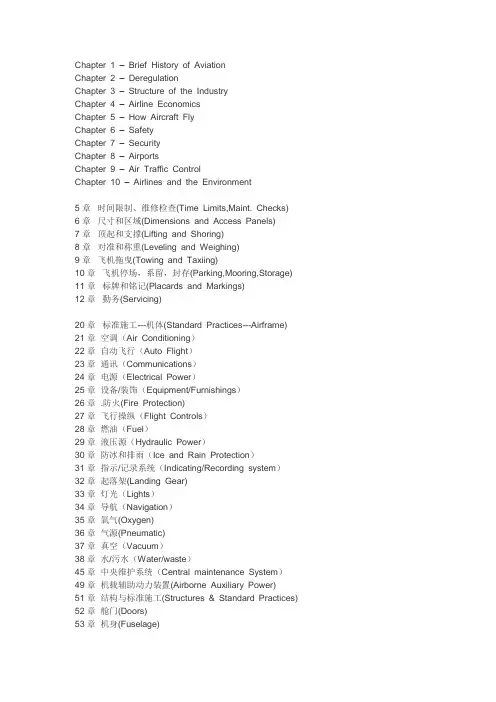

Chapter 1 –Brief History of AviationChapter 2 –DeregulationChapter 3 –Structure of the IndustryChapter 4 –Airline EconomicsChapter 5 –How Aircraft FlyChapter 6 –SafetyChapter 7 –SecurityChapter 8 –AirportsChapter 9 –Air Traffic ControlChapter 10 –Airlines and the Environment5章时间限制、维修检查(Time Limits,Maint. Checks) 6章尺寸和区域(Dimensions and Access Panels)7章顶起和支撑(Lifting and Shoring)8章对准和称重(Leveling and Weighing)9章飞机拖曳(Towing and Taxiing)10章飞机停场,系留,封存(Parking,Mooring,Storage) 11章标牌和铭记(Placards and Markings)12章勤务(Servicing)20章标准施工---机体(Standard Practices---Airframe) 21章空调(Air Conditioning)22章自动飞行(Auto Flight)23章通讯(Communications)24章电源(Electrical Power)25章设备/装饰(Equipment/Furnishings)26章 .防火(Fire Protection)27章飞行操纵(Flight Controls)28章燃油(Fuel)29章液压源(Hydraulic Power)30章防冰和排雨(Ice and Rain Protection)31章指示/记录系统(Indicating/Recording system)32章起落架(Landing Gear)33章灯光(Lights)34章导航(Navigation)35章氧气(Oxygen)36章气源(Pneumatic)37章真空(Vacuum)38章水/污水(Water/waste)45章中央维护系统(Central maintenance System)49章机载辅助动力装置(Airborne Auxiliary Power)51章结构与标准施工(Structures & Standard Practices) 52章舱门(Doors)53章机身(Fuselage)54章发动机吊舱/吊架(Nacelles/Pylons)55章稳定装置 (Stabilizers)安定面56章窗户(Windows)57章机翼(Wings)70章标准施工—发动机(Standard Practices—Engines)71章动力装置(Power Plant( Package))72章发动机(内部)(Engine (Internals))73章发动机燃油和控制(Engine Fuel and Control)74章点火装置(Ignition)75章发动机空气(Air)76章发动机操纵(Engine Controls)77章发动机指示(Engine Indicating)78章排气系统(Exhaust)79章发动机滑油系统(Oil)80章发动机起动(Starting)82章注水(Water Injecting)91章图表(不同性质的)(Charts (Miscellaneous))01 INTRODUCTION05 PERIODIC INSPECTIONS06 DIMENSIONS AND AREAS07 LIFTING AND SHORING08 LEVELING AND WEIGHING09 TOWING AND TAXIING10 PARKING, MOORING, STORAGE AND RETURN TO SERVICE11 PLACARDS AND MARKINGS12 SERVICING - ROUTINE MAINTENANCE18 VIBRATION AND NOISE ANALYSIS (HELICOPTER ONLY)20 STANDARD PRACTICES - AIRFRAME21 AIR CONDITIONING22 AUTO FLIGHT23 COMMUNICATIONS24 ELECTRICAL POWER25 EQUIPMENT / FURNISHINGS26 FIRE PROTECTION27 FLIGHT CONTROLS28 FUEL29 HYDRAULIC POWER30 ICE AND RAIN PROTECTION31 INDICATING / RECORDING SYSTEMS32 LANDING GEAR33 LIGHTS34 NAVIGATION35 OXYGEN36 PNEUMATIC37 VACUUM38 WATER / WASTE39 ELECTRICAL - ELECTRONIC PANELS AND MULTIPURPOSE COMPONENTS 41 WATER BALLAST45 CENTRAL MAINTENANCE SYSTEM (CMS)46 INFORMATION SYSTEMS49 AIRBORNE AUXILIARY POWER51 STANDARD PRACTICES AND STRUCTURES - GENERAL52 DOORS53 FUSELAGE54 NACELLES / PYLONS55 STABILIZERS56 WINDOWS57 WINGS60 STANDARD PRACTICES - PROPELLER / ROTOR61 PROPELLERS / PROPULSORS62 MAIN ROTOR(S)63 MAIN ROTOR DRIVE(S)64 TAIL ROTOR65 TAIL ROTOR DRIVE66 ROTOR BLADE AND TAIL PYLON FOLDING67 ROTORS FLIGHT CONTROL70 STANDARD PRACTICES - ENGINE71 POWER PLANT - GENERAL72 ENGINE72(T) ENGINE - TURBINE / TURBOPROP, DUCTED FAN / UNDUCTED FAN72(R) ENGINE - RECIPROCATING73 ENGINE - FUEL AND CONTROL74 IGNITION75 BLEED AIR76 ENGINE CONTROLS77 ENGINE INDICATING78 EXHAUST79 OIL80 STARTING81 TURBINES (RECIPROCATING ENGINES)82 WATER INJECTION83 ACCESSORY GEAR BOXES (ENGINE DRIVEN)84 PROPULSION AUGMENTATION91 CHARTS5章时间限制、维修检查(Time Limits,Maint. Checks)6章尺寸和区域(Dimensions and Access Panels)7章顶起和支撑(Lifting and Shoring)8章对准和称重(Leveling and Weighing)9章飞机拖曳(Towing and Taxiing)10章飞机停场,系留,封存(Parking,Mooring,Storage)11章标牌和铭记(Placards and Markings)12章勤务(Servicing)BMS3-33润滑脂的介绍/posts/35/topic-0045-359438.html20章标准施工---机体(Standard Practices---Airframe)21章空调(Air Conditioning)空调出口温度高/posts/35/topic-0045-359394.html[原创]关于737-300/500的空调/posts/35/topic-0045-356247.htmlPACK空中超温,会有那些原因引起呢?(专业贴)/posts/35/topic-0045 -359163.html22章自动飞行(Auto Flight)737NG的Y/D故障分析供大家参考/posts/72/topic-0045-729542.html 23章通讯(Communications)24章电源(Electrical Power)IDG和GEN /posts/35/topic-0045-358102.html737-300 B2972电源及APU自动关车排故思路之分析/posts/182/topic-0 045-1827865.html25章设备/装饰(Equipment/Furnishings)26章防火(Fire Protection)有关737灭火瓶...... /posts/35/topic-0045-357937.htmlAPU火警探测/posts/35/topic-0045-357662.html27章飞行操纵(Flight Controls)28章燃油(Fuel)737飞机燃油浮子电门/posts/35/topic-0045-359544.html29章液压源(Hydraulic Power)液压问题/posts/35/topic-0045-359382.html关于液压保险在液压管路的作用和位置?请教/posts/35/topic-0045-3592 99.html液压系统故障/posts/35/topic-0045-359411.html30章防冰和排雨(Ice and Rain Protection)31章指示/记录系统(Indicating/Recording system)32章起落架(Landing Gear)如何延长飞机轮胎的使用寿命/posts/35/topic-0045-358979.html前轮磨损/posts/35/topic-0045-359232.html谁能说说金属刹车片和碳刹车片的优缺点?/posts/35/topic-0045-358669. html请问哪位对防滞刹车结构熟悉的,简单介绍一下,谢谢那里有资料,网上有吗?http://bbs. /posts/35/topic-0045-359091.html请教:飞机换轮子的时候为什么要转动轮子? /posts/177/topic-0045-177 5484.html一起B737-300飞机使用自动速度刹车时,AUTO SPEED BRAKE 跳开关跳开http://bbs.fee /posts/103/topic-0045-1038900.html33章灯光(Lights)34章导航(Navigation)35章氧气(Oxygen)36章气源(Pneumatic)一起引气故障导致的增压故障(B737NG)/posts/103/topic-0045-1035067. html37章真空(Vacuum)38章水/污水(Water/waste)45章中央维护系统(Central maintenance System)49章机载辅助动力装置(Airborne Auxiliary Power)APU启动不起来了! /posts/35/topic-0045-357370.htmlAPU维护灯亮/posts/35/topic-0045-357331.html51章结构与标准施工(Structures & Standard Practices)52章舱门(Doors)53章机身(Fuselage)54章发动机短舱/吊架(Nacelles/Pylons)55章稳定装置(Stabilizers)56章窗户(windows)[讨论]玻璃上裂纹深度的测量??/posts/35/topic-0045-350765.html57章机翼(wings)70章标准施工---发动机(Standard Practices---Engines)71章动力装置(Power Plant (Package))IAEV2500系列发动机试车总结/posts/85/topic-0045-850361.html72章发动机(内部)(Engine (Internals))73章发动机燃油和控制(Engine Fuel and Control)74章点火装置(Ignition)75章发动机空气(Air)76章发动机操纵(Engine Controls)77章发动机指示(Engine Indicating)78章排气系统(Exhaust)737反推故障/posts/35/topic-0045-357397.html79章发动机滑油系统(Oil)80章发动机起动(Starting)82章注水(Water Injecting)91章图表(不同性质的)(Charts (Miscellaneous))ATA Specification 22001 *Reserved for Airline Use2 *Reserved for Airline Use3 *Reserved for Airline Use4 *Reserved for Airline Use5 TIME LIMITS/ MAINTENANCE CHECKS-00 General-10 Time Limits-20 Scheduled Maintenance Checks-30 & -40 Reserved-50 Unscheduled Maintenance checks6 DIMENSIONS AND AREAS7 LIFTING & SHORING-00 General-10 Jacking-20 Shoring8 LEVELING & WEIGHING-00 General-10 Weighing and Balancing-20 Leveling9 TOWING & TAXIING-00 General-10 Towing-20 Taxiing10 PARKING, MOORING, STORAGE & RETURN TO SERVICE -00 General-10 Parking/Storage-20 Mooring-30 Return to Service11 PLACARDS AND MARKINGS-00 General-10 Exterior Color Schemes and Markings-20 Exterior Placards and Markings-30 Interior Placards12 SERVICING-00 General-10 Replenishing-20 Scheduled Servicing-30 Unscheduled Servicing13 *Unassigned14 *Unassigned15 *Unassigned16 *Unassigned17 *Unassigned18 VIBRATION AND NOISE ANALYSIS (HELICOPTER ONLY) -00 GENERAL --10 VIBRATION ANALYSIS-20 NOISE ANALYSIS19 *Unassigned20 STANDARD PRACTICES-AIRFRAME-90 *Reserved for Airline Use21 AIR CONDITIONING-00 General-10 Compression-20 Distribution-30 Pressurization Control-40 Heating-50 Cooling-60 Temperature Control-70 Moisture/Air Contaminant22 AUTO FLIGHT-00 General-10 Autopilot-20 Speed-Attitude Correction-30 Auto Throttle-40 System Monitor-50 Aerodynamic Load Alleviating23 COMMUNICATIONS-00 General-10 Speech Communications-15 SATCOM-20 Data Transmission and Automatic Calling -30 Comfort-40 Interphone-50 Audio Integrating-60 Static Discharging-70 Audio & Video Monitoring-80 Integrated Automatic24 ELECTRICAL POWER-00 General-10 Generator Drive-20 AC Generation-30 DC Generation-40 External Power-50 AC Electrical Load Distribution-60 DC Electrical Load Distribution25 EQUIPMENT/FURNISHINGS-00 General-10 Flight Compartment-20 Passenger Compartment-30 Galley-40 Lavatories-50 Additional Compartments-60 Emergency-70 Available-80 Insulation26 FIRE PROTECTION-00 General-10 Detection-20 Extinguishing-30 Explosion Suppression27 FLIGHT CONTROLS-00 General-10 Aileron & Tab-20 Rudder & Tab-30 Elevator & Tab-40 Horizontal Stabilizer-50 Flaps-60 Spoiler, Drag Devices and Variable Aerodynamic Fairings -70 Gust Lock & Dampener-80 Lift Augmenting28 FUEL-00 General-10 Storage-20 Distribution-30 Dump-40 Indicating29 HYDRAULIC POWER-00 General-10 Main-20 Auxiliary-30 Indicating30 ICE AND RAIN PROTECTION-00 General-10 Airfoil-20 Air Intakes-30 Pitot and Static-40 Windows, Windshields and Doors-50 Antennas and Radomes-60 Propellers/Rotors-70 Water Lines-80 Detection31 INDICATING/RECORDING SYSTEMS-00 General-10 Instrument & Control Panels-20 Independent Instruments-30 Recorders-40 Central Computers-50 Central Warning Systems-60 Central Display Systems-70 Automatic Data Reporting Systems 32 LANDING GEAR-00 General-10 Main Gear and Doors-20 Nose Gear and Doors-30 Extension and Retraction-40 Wheels and Brakes-50 Steering-60 Position and Warning-70 Supplementary Gear33 LIGHTS-00 General-10 Flight Compartment-20 Passenger Compartment-30 Cargo and Service Compartments -40 Exterior-50 Emergency Lighting34 NAVIGATION-00 General-10 Flight Environment-20 Attitude & Direction-30 Landing and Taxiing Aids-40 Independent Position Determining -50 Dependent Position Determining -60 Flight Management Computing35 OXYGEN-00 General-10 Crew-20 Passenger-20 Passenger-30 Portable36 PNEUMATIC-00 General-10 Distribution-20 Indicating37 VACUUM-00 General-10 Distribution-20 Indicating38 WATER/WASTE-00 General-10 Potable-20 Wash-30 Waste Disposal-40 Air Supply39 *Unassigned40 *Unassigned41 WATER BALLAST-00 General-10 Storage-20 Dump-30 Indication42 *Unassigned43 *Unassigned44 CABIN SYSTEMS-00 General-10 Cabin Core System-20 Inflight Entertainment System-30 External Communication System-40 Cabin Mass Memory System-50 Cabin Monitoring System-60 Miscellaneous Cabin System45 CENTRAL MAINTENANCE SYSTEM-00 General-5 thru -19 CMS/Aircraft General-20 thru -49 CMS/Airframe Systems-45 Central Maintenance System-50 thru -59 CMS/Structures-60 thru -69 CMS/Propellers-70 thru -89 CMS/Power Plant45INFORMATION SYSTEMS-00 General-10 Airplane General Information Systems -20 Flight Deck Information Systems-30 Maintenance Information Systems-40 Passenger Cabin Information Systems -50 Miscellaneous Information Systems47 *Unassigned48 *Unassigned49 AIRBORNE AUXILIARY POWER-00 General-10 Power Plant-20 Engine-30 Engine Fuel and Control-40 Ignition/Starting-50 Air-60 Engine Controls .-70 Indicating-80 Exhaust-90 Oil50 Cargo and Accessory Compartments-00 General-10 Cargo Compartments-20 Cargo Loading Systems-30 Cargo Related Systems-40 Available-50 Accessory-60 Insulation51 Standard Practices, General-00 General-10 Investigation, Cleanup and Aerodynamic Smoothness-20 Processes-30 Materials-40 Fasteners-50 Support of Airplane for Repair and Alignment Check Procedures -60 Control-Surface Balancing-70 Repairs-80 Electrical Bonding52 DOORS-00 General-10 Passenger/Crew-20 Emergency Exit-30 Cargo-40 Service and Miscellaneous-50 Fixed Interior-60 Entrance Stairs-70 Monitoring and Operation-80 Landing Gear53 FUSELAGE-00 General-10 thru -90 (As Required) Fuselage Sections54 NACELLES/PYLONS-00 General-10 thru -40 (As Required) Nacelle Section-50 thru -80 (As Required) Pylon55 STABILIZERS-00 General-10 Horizontal Stabilizer or Canard-20 Elevator-30 Vertical Stabilizer-40 Rudder56 WINDOWS-00 General-10 Flight Compartment-20 Passenger Compartment-30 Door-40 Inspection and Observation57 WINGS-00 General-10 Center Wing-20 Outer Wing-30 Wing Tip-40 Leading Edge and Leading Edge Devices -50 Trailing Edge Trailing Edge Devices -60 Ailerons and Elevons-70 Spoilers-80 (as required)-90 Wing Folding System58 *Unassigned59 *Reserved for Airline Use60 STANDARD PRACTICES - PROPELLER/ROTOR61 PROPELLERS/PROPULSION-00 General-10 Propeller Assembly-20 Controlling-30 Braking-40 Indicating-50 Propulsor Duct62 ROTOR(S)-00 General-10 Rotor blades-20 Rotor head(s)-30 Rotor Shaft(s)/Swashplate Assy(ies) -4063 ROTOR DRIVE(S)-00 General-10 Engine/Gearbox couplings-20 Gearbox(es)-30 Mounts, attachments-40 Indicating64 TAIL ROTOR-00 General-10* Rotor blades-20* Rotor head-30 Available-40 Indicating65 TAIL ROTOR DRIVE-00 General-10 Shafts-20 Gearboxes-30 Available-40 Indicating66 FOLDING BLADES/PYLON-00 General-10 Rotor blades-20 Tail pylon-30 Controls and Indicating67 ROTORS FLIGHT CONTROL-00 General-10 Rotor-20 Anti-torque Rotor control (Yaw control)-30 Servo-control System68 *Unassigned69*Unassigned70 STANDARD PRACTICES - ENGINES71 POWER PLANT-00 General-10 Cowling-30 Fireseals-40 Attach Fittings-50 Electrical Harness-60 Air Intakes-70 Engine Drains72 ENGINE TURBINE/TURBO PROP DUCTED FAN/UNDUCTED FAN-00 General-10 Reduction Gear, Shaft Section (Turbo-Prop and/or Front Mounted Gear Driven Propulsor)-20 Air Inlet Section-30 Compressor Section-40 Combustion Section-50 Turbine Section-60 Accessory Drives-70 By-pass Section-80 Propulsor Section (Rear Mounted)73 ENGINE FUEL AND CONTROL-00 General-10 Distribution-20 Controlling-30 Indicating74 IGNITION-00 General-10 Electrical Power-20 Distribution-30 Switching75 AIR-00 General-10 Engine Anti-Icing-20 Cooling-30 Compressor Control-40 Indicating76 ENGINE CONTROLS-00 General-10 Power Control-20 Emergency Shutdown77 ENGINE INDICATING-00 General-10 Power-20 Temperature-30 Analyzers That-40 Integrated Engine Instrument Systems 78 EXHAUST-00 General-10 Collector/Nozzle-20 Noise Suppressor-30 Thrust Reverser-40 Supplementary Air79 OIL-00 General-10 Storage-20 Distribution-30 Indicating80 STARTING-00 General-10 Cranking81 TURBINES-00 General-10 Power Recovery-20 Turbo-Supercharger82 WATER INJECTION-00 General-10 Storage-20 Distribution-30 Dumping and Purging-40 Indicating83 ACCESSORY GEAR-BOXES-00 General-10 Drive Shaft Section-20 Gearbox Section84 Propulsion Augmentation-00 General-10 Jet Assist Takeoff85 *Unassigned86 *Unassigned87 *Unassigned88 *Unassigned89 *Unassigned90 *Unassigned91 CHARTS92 *Unassigned93 *Unassigned94 *Unassigned95 *Reserved for Airline Use96 *Reserved for Airline Use97 WIRING REPORTING-00-00 General-01-00 Zone 100 Fuselage Lower-02-00 Zone 200 Fuselage Top-03-00 Zone 300 Stabilizers-04-00 Zone 400 Nacelles-Pylons-05-00 Zone 500 Left Wing-06-00 Zone 600 Right Wing-07-00 Zone 700 Landing Gear Compartment -08-00 Zone 800 Doors-09-00 Zone 900 Lavatories & Galleys-20-00 Electrical Standard Items/Practices -21-00 Air Conditioning - General-21-10 Compression-21-20 Distribution-21-30 Pressurization Control-21-40 Heating-21-50 Cooling-21-60 Temperature Control-21-70 Moisture/Air Contaminant Control-22-00 Auto Flight - General-22-10 Autopilot-22-20 Speed - Attitude Correction-22-30 Auto Throttle-22-40 System Monitors-22-50 Aerodynamic Load Alleviating-23-00 Communications - General-23-10 Speech Communications-23-15 SATCOM-23-20 Data Transmission and Automatic Calling-23-30 Passenger Address, Entertainment and Comfort-23-40 Interphone-23-50 Audio Integrating-23-60 Static Discharging-23-70 Audio and Video Monitoring-23-80 Integrated Automatic Tuning-24-00 Electrical Power - General-24-10 Generator Drive-24-20 AC Generation-24-30 DC Generation-24-40 External Power-24-50 AC Electrical Load Distribution-24-60 DC Electrical Load Distribution-25-00 Equipment/Furnishings - General-25-10 Flight Compartment-25-20 Passenger Compartment-25-30 Galley-25-40 Lavatories-25-60 Emergency-25-80 Insulation-26-00 Fire Protection - General-26-10 Detection-26-20 Extinguishing-26-30 Explosion Suppression-27-00 Flight Controls - General-27-10 Aileron & Tab-27-20 Rudder & Tab-27-30 Elevator & Tab-27-40 Horizontal Stabilizer-27-50 Flaps-27-60 Spoiler, Drag Devices and Variable Aerodynamic Fairings -27-70 Gust Lock & Dampener-27-80 Lift Augmenting-28-00 Fuel - General-28-10 Storage-28-20 Distribution-28-30 Dump-28-40 Indicating-29-00 Hydraulic Power - General-29-10 Main-29-20 Auxiliary-29-30 Indicating-30-00 Ice and Rain Protection - General-30-10 Airfoil-30-20 Air Intakes-30-30 Pitot and Static-30-40 Windows, Windshields and Doors-30-50 Antennas And Radomes-30-60 Propellers/Rotors-30-70 Water Lines-30-80 Detection-31-00 Indicating/Recording Systems - General -31-10 Instrument and Control Panels-31-20 Independent Instruments-31-30 Recorders-31-40 Central Computers-31-50 Central Warning Systems-31-60 Central Display Systems-31-70 Automatic Data Reporting Systems-32-00 Landing Gear- General-32-10 Main Gear and Doors-32-20 Nose Gear and Doors-32-30 Extension and Retraction-32-40 Wheels and Brakes-32-50 Steering-32-60 Position And Warning-32-70 Supplementary Gear-33-00 Lights - General-33-10 Flight Compartment-33-20 Passenger Compartment-33-30 Cargo and Service Compartments-33-40 Exterior-33-50 Emergency Lighting-34-00 Navigation - General-34-10 Flight Environment Data-34-20 Attitude & Direction-34-30 Landing and Taxiing Aids-34-40 Independent Position Determining-34-50 Dependent Position Determining-34-60 Flight Management Computing-35-00 Oxygen - General-35-10 Crew-35-20 Passenger-35-30 Portable-36-00 Pneumatic - General-36-10 Distribution-36-20 Indicating-37-00 Vacuum - General-37-10 Distribution-37-20 Indicating-38-00 Water/Waste - General-38-10 Potable-38-20 Wash-38-30 Waste Disposal-38-40 Air Supply-44-00 Cabin Systems - General-44-10 Cabin Core System-44-20 In-flight Entertainment System-44-30 External Communication System-44-40 Cabin Mass Memory System-44-50 Cabin Monitoring System-44-60 Miscellaneous Cabin System-45-00 Central Maintenance System (CMS) General -45-05 CMS/Aircraft General-45-20 CMS/Airframe Systems-45-45 Central Maintenance System-45-50 CMS/Structures-45-60 CMS/Propellers-45-70 CMS/Power Plant-46-00 Information Systems - General-46-10 Airplane General Information Systems-46-20 Flight Deck Information Systems-46-30 Maintenance Information Systems-46-40 Passenger Cabin Information Systems-46-50 Miscellaneous Information Systems-49-00 Airborne Auxiliary Power - General-49-10 Power Plant-49-20 Engine-49-30 Engine Fuel And Control-49-40 Ignition And Starting-49-50 Air-49-60 Engine Controls-49-70 Indicating-49-80 Exhaust-49-90 Oil-50-00 Cargo And Accessory Compartments General -50-10 Cargo Compartments-50-20 Cargo Loading Systems-50-30 Cargo Related Systems-50-40 Available-50-50 Accessory Compartments-50-60 Insulation-52-00 Doors - General-52-10 Passenger/Crew-52-20 Emergency Exit-52-30 Cargo-52-40 Service-52-50 Fixed Interior-52-60 Entrance Stairs-52-70 Door Warning-52-80 Landing Gear-53-00 Fuselage - General-54-00 Nacelles/Pylons - General-54-10 Nacelle Section-54-50 Pylon-55-00 Stabilizers - General-55-10 Horizontal Stabilizer or Canard-55-20 Elevator-55-30 Vertical Stabilizer-55-40 Rudder-56-00 Windows - General-56-10 Flight Compartment-56-20 Passenger Compartment-56-30 Door-56-40 Inspection and Observation-57-00 Wings - General-57-10 Center Wing-57-20 Outer Wing-57-30 Wing Tip-57-40 Leading Edge and Leading Edge Devices-57-50 Trailing Edge and Trailing Edge Devices -57-60 Ailerons-57-70 Spoilers-57-90 Wing Folding System-61-00 Propellers/Propulsors - General-61-10 Propeller Assembly-61-20 Controlling-61-30 Braking-61-40 Indicating-61-50 Propulsor Duct-62-00 Rotors-63-00 Rotor Drives-64-00 Tail Rotor-65-00 Tail Rotor Drive-66-00 Folding Blades/Pylon-67-00 Rotors Flight Control-71-00 Power Plant - General-71-10 Cowling-71-20 Mounts-71-30 Fire seals-71-40 Attach Fittings-71-50 Electrical Harness-71-60 Air Intakes-71-70 Engine Drains-72-00 Engine Turbine/Turbo Prop Ducted Fan/Unducted Fan-72-10 Reduction Gear, Shaft Section (Turbo-Prop and/or Front Mounted GearDriven Propulsor)-72-20 Air Inlet Section-72-30 Compressor Section-72-40 Combustion Section-72-50 Turbine Section-72-60 Accessory Drives-72-70 By-pass Section-72-80 Propulsor Section (Rear Mounted)-73-00 Engine Fuel And Control - General-73-10 Distribution-73-20 Controlling-73-30 Indicating-74-00 Ignition - General-74-10 Electrical Power Supply-74-20 Distribution-74-30 Switching-75-00 Air - General-75-10 Engine Anti-Icing-75-20 Cooling-75-30 Compressor Control-75-40 Indicating-76-00 Engine Controls - General-76-10 Power Control-76-20 Emergency Shutdown-77-00 Engine Indicating - General-77-10 Power-77-20 Temperature-77-30 Analyzers-77-40 Integrated Engine Instrument Systems -78-00 Exhaust - General-78-10 Collector/Nozzle-78-20 Noise Suppressor-78-30 Thrust Reverser-78-40 Supplementary Air-79-00 Oil - General-79-10 Storage-79-30 Indicating-80-00 Starting - General-80-10 Cranking98 *Reserved for Airline Use99 *Unassigned100 *Do not use101 *Do not use102 *Do not use103 *Do not use104 *Do not use105 *Do not use106 *Do not use107 *Do not use108 *Do not use109 *Do not use110 *Do not use111 *Do not use112 *Do not use113 *Do not use114 *Do not use115 Flight Simulator Systems。

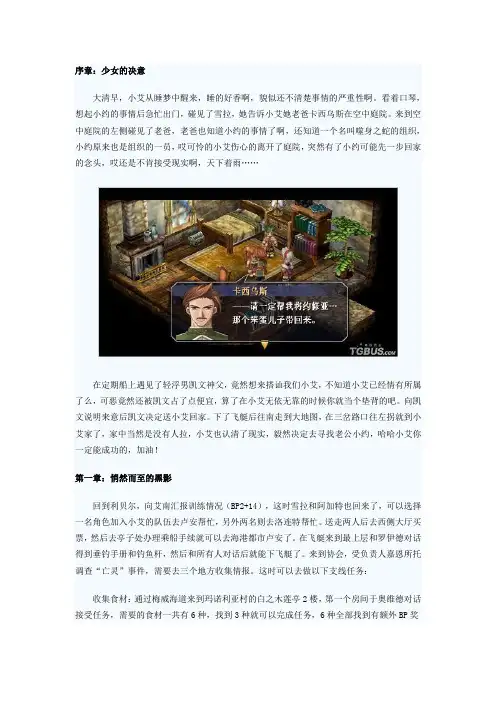

序章:少女的决意大清早,小艾从睡梦中醒来,睡的好香啊,貌似还不清楚事情的严重性啊。

看着口琴,想起小约的事情后急忙出门,碰见了雪拉,她告诉小艾她老爸卡西乌斯在空中庭院。

来到空中庭院的左侧碰见了老爸,老爸也知道小约的事情了啊,还知道一个名叫噬身之蛇的组织,小约原来也是组织的一员,哎可怜的小艾伤心的离开了庭院,突然有了小约可能先一步回家的念头,哎还是不肯接受现实啊,天下着雨……在定期船上遇见了轻浮男凯文神父,竟然想来搭讪我们小艾,不知道小艾已经情有所属了么,可恶竟然还被凯文占了点便宜,算了在小艾无依无靠的时候你就当个垫背的吧。

向凯文说明来意后凯文决定送小艾回家。

下了飞艇后往南走到大地图,在三岔路口往左拐就到小艾家了,家中当然是没有人拉,小艾也认清了现实,毅然决定去寻找老公小约,哈哈小艾你一定能成功的,加油!第一章:悄然而至的黑影回到利贝尔,向艾南汇报训练情况(BP2+14),这时雪拉和阿加特也回来了,可以选择一名角色加入小艾的队伍去卢安帮忙,另外两名则去洛连特帮忙。

送走两人后去西侧大厅买票,然后去亭子处办理乘船手续就可以去海港都市卢安了。

在飞艇来到最上层和罗伊德对话得到垂钓手册和钓鱼杆,然后和所有人对话后就能下飞艇了。

来到协会,受负责人嘉恩所托调查“亡灵”事件,需要去三个地方收集情报。

这时可以去做以下支线任务:收集食材:通过梅威海道来到玛诺利亚村的白之木莲亭2楼,第一个房间于奥维德对话接受任务,需要的食材一共有6种,找到3种就可以完成任务,6种全部找到有额外BP奖励,食材分别是魔兽之骨,魔兽之牙,魔兽之角,魔兽鸟肉,魔兽鱼卵,魔兽鸟蛋。

多打打怪兽吧不难凑齐的(BP2+1)紺碧之塔的照片拍摄:此任务建议在三个地点都调查完在去学院前完成,因为如果朵洛希在队伍中会有额外BP奖励。

去酒店1层房间于森特对话接受任务,穿过南面的阿伊纳街道来到紺碧之塔,2楼往左走,右边是死路,在塔顶选择朵洛希来拍摄,OK后回去和森特对话完成任务(BP1+2)别忘了去赌场用100代币换牌技师杰克2卷哦。

比亚迪F0电喷系统维修手册-图文发动机管理系统F0轿车维修手册发动机管理系统维修手册第一节电喷系统维修须知1.1一般维修须知1.1.1只允许使用数字万用表对电喷系统进行检查工作。

1.1.2维修作业请使用正品零部件,否则无法保证电喷系统的正常工作。

1.1.3维修过程中,只能使用无铅汽油。

1.1.4请遵守规范的维修诊断流程进行维修作业。

1.1.5维修过程中禁止对电喷系统的零部件进行分解拆卸作业。

1.1.6维修过程中,拿电子元件(电子控制单元、传感器等)时,要非常小心,不能让它们掉到地上。

1.1.7树立环境保护意识,对维修过程中产生的废弃物进行有效地处理。

1.2维修过程注意事项1.2.1不要随意将电喷系统的任何零部件或其接插件从其安装位置上拆下,以免意外损坏或水份、油污等异物进入接插件内,影响电喷系统的正常工作。

1.2.2当断开和接上接插件时,一定要将点火开关置于关闭位置,否则会损坏电器元件。

1.2.3在进行故障的热态工况模拟和其它有可能使温度上升的维修作业时,决不要使电子控制单元的温度超过80℃。

1.2.4电喷系统的供油压力较高(300kPa左右),所有燃油管路都是采用耐高压燃油管。

即使发动机没有运转,油路中也保持较高的燃油压力。

所以在维修过程中要注意不要轻易拆卸油管,在需对燃油系统进行维修的场合时,拆卸油管前应对燃油系统进行卸压处理,卸压方法如下:拆下燃油泵继电器,启动发动机使其怠速运转,直到发动机自行熄灭。

油管的拆卸和燃油滤清器的更换应在通风良好的地方由专业维修人员进行。

1.2.5从燃油箱中取下电动燃油泵时不要给油泵通电,以免产生电火花,引起火灾。

1.2.6燃油泵不允许在干态下或水里进行运转试验,否则会缩减其使用寿命,另外燃油泵的正负极切不可接反。

1.2.7对点火系统进行检查时,只有在必要的时候才进行跳火花检测,并且时间要尽可能短,检测时不能打开节气门,否则会导致发动机管理系统F0轿车维修手册大量未燃烧的汽油进入排气管,损坏三元催化器。

瓦锡兰电喷机fcm-20工作原理瓦锡兰电喷机FCM-20工作原理电喷机是指使用电场加速离子的喷嘴,将离子加速并射出的一种设备。

瓦锡兰电喷机FCM-20是一种高端电喷机,工作原理详细说明如下。

1. 喷嘴结构瓦锡兰电喷机FCM-20的喷嘴是一个复杂的结构,由多层组成。

首先是出口,它是一个细长的椭圆形板状物体,通过出口喷射离子。

在出口的上游位置是推力环,它是一个环状结构,负责产生推力和离子荷电。

在推力环的上游是阳极,它是一个高电压的电极,负责接通电源和控制电场分布。

在阳极的上游是阴极,它是一个产生电子的结构,为离子注入电荷。

2. 构成电场FCM-20的电场是由阳极、推力环和喷嘴出口组成。

阳极和推力环具有不同电势,形成了一个高电压区域。

离子在这个区域中感受到了电场力,并逐渐加速。

在喷嘴的出口处,电场达到了最大值,将离子加速到了几百m/s的速度,然后喷射出去。

离子进入大气层后,与分子相互碰撞,从而实现了推进目标的作用。

3. 离子产生离子产生有两种方式:化学反应和电离。

在FCM-20中,电离方式是首选。

阴极通过加热或光电效应,产生高速电子。

这些电子与气体分子相互碰撞,使得分子产生电离。

离子在中性气体中将继续扩散,并在极电场的作用下被加速。

加速之后,离子进入冷却通道,并注入到出口区域的离子束中。

4. 离子束流控制离子束流是由喷嘴出口发射的离子流,它对电喷机的性能和推力十分关键。

在FCM-20中,离子束流的控制主要依靠电场控制。

通过调节阳极和推力环的电势差,可以控制离子束流的速度和形状。

还可以通过调节离子注入的速度和时间来控制离子束流的强度和分布。

总结瓦锡兰电喷机FCM-20是一种高精度的电喷机,它采用电离的方式产生离子,并通过复杂的结构和电场控制,在推进轨道上实现高效的推力。

了解FCM-20的工作原理,可以帮助我们更好地理解电喷机的技术和应用。

瓦锡兰电喷机FCM-20是一种适用于微小驱动航天器的推进系统。

它使用离子作为推进介质,提供了比传统燃料更高的比冲和比推力。

Chapter 1 –Brief History of AviationChapter 2 –DeregulationChapter 3 –Structure of the IndustryChapter 4 –Airline EconomicsChapter 5 –How Aircraft FlyChapter 6 –SafetyChapter 7 –SecurityChapter 8 –AirportsChapter 9 –Air Traffic ControlChapter 10 –Airlines and the Environment5章时间限制、维修检查(Time Limits,Maint. Checks) 6章尺寸和区域(Dimensions and Access Panels)7章顶起和支撑(Lifting and Shoring)8章对准和称重(Leveling and Weighing)9章飞机拖曳(Towing and Taxiing)10章飞机停场,系留,封存(Parking,Mooring,Storage) 11章标牌和铭记(Placards and Markings)12章勤务(Servicing)20章标准施工---机体(Standard Practices---Airframe) 21章空调(Air Conditioning)22章自动飞行(Auto Flight)23章通讯(Communications)24章电源(Electrical Power)25章设备/装饰(Equipment/Furnishings)26章 .防火(Fire Protection)27章飞行操纵(Flight Controls)28章燃油(Fuel)29章液压源(Hydraulic Power)30章防冰和排雨(Ice and Rain Protection)31章指示/记录系统(Indicating/Recording system)32章起落架(Landing Gear)33章灯光(Lights)34章导航(Navigation)35章氧气(Oxygen)36章气源(Pneumatic)37章真空(Vacuum)38章水/污水(Water/waste)45章中央维护系统(Central maintenance System)49章机载辅助动力装置(Airborne Auxiliary Power)51章结构与标准施工(Structures & Standard Practices) 52章舱门(Doors)53章机身(Fuselage)54章发动机吊舱/吊架(Nacelles/Pylons)55章稳定装置 (Stabilizers)安定面56章窗户(Windows)57章机翼(Wings)70章标准施工—发动机(Standard Practices—Engines)71章动力装置(Power Plant( Package))72章发动机(内部)(Engine (Internals))73章发动机燃油和控制(Engine Fuel and Control)74章点火装置(Ignition)75章发动机空气(Air)76章发动机操纵(Engine Controls)77章发动机指示(Engine Indicating)78章排气系统(Exhaust)79章发动机滑油系统(Oil)80章发动机起动(Starting)82章注水(Water Injecting)91章图表(不同性质的)(Charts (Miscellaneous))01 INTRODUCTION05 PERIODIC INSPECTIONS06 DIMENSIONS AND AREAS07 LIFTING AND SHORING08 LEVELING AND WEIGHING09 TOWING AND TAXIING10 PARKING, MOORING, STORAGE AND RETURN TO SERVICE11 PLACARDS AND MARKINGS12 SERVICING - ROUTINE MAINTENANCE18 VIBRATION AND NOISE ANALYSIS (HELICOPTER ONLY)20 STANDARD PRACTICES - AIRFRAME21 AIR CONDITIONING22 AUTO FLIGHT23 COMMUNICATIONS24 ELECTRICAL POWER25 EQUIPMENT / FURNISHINGS26 FIRE PROTECTION27 FLIGHT CONTROLS28 FUEL29 HYDRAULIC POWER30 ICE AND RAIN PROTECTION31 INDICATING / RECORDING SYSTEMS32 LANDING GEAR33 LIGHTS34 NAVIGATION35 OXYGEN36 PNEUMATIC37 VACUUM38 WATER / WASTE39 ELECTRICAL - ELECTRONIC PANELS AND MULTIPURPOSE COMPONENTS 41 WATER BALLAST45 CENTRAL MAINTENANCE SYSTEM (CMS)46 INFORMATION SYSTEMS49 AIRBORNE AUXILIARY POWER51 STANDARD PRACTICES AND STRUCTURES - GENERAL52 DOORS53 FUSELAGE54 NACELLES / PYLONS55 STABILIZERS56 WINDOWS57 WINGS60 STANDARD PRACTICES - PROPELLER / ROTOR61 PROPELLERS / PROPULSORS62 MAIN ROTOR(S)63 MAIN ROTOR DRIVE(S)64 TAIL ROTOR65 TAIL ROTOR DRIVE66 ROTOR BLADE AND TAIL PYLON FOLDING67 ROTORS FLIGHT CONTROL70 STANDARD PRACTICES - ENGINE71 POWER PLANT - GENERAL72 ENGINE72(T) ENGINE - TURBINE / TURBOPROP, DUCTED FAN / UNDUCTED FAN72(R) ENGINE - RECIPROCATING73 ENGINE - FUEL AND CONTROL74 IGNITION75 BLEED AIR76 ENGINE CONTROLS77 ENGINE INDICATING78 EXHAUST79 OIL80 STARTING81 TURBINES (RECIPROCATING ENGINES)82 WATER INJECTION83 ACCESSORY GEAR BOXES (ENGINE DRIVEN)84 PROPULSION AUGMENTATION91 CHARTS5章时间限制、维修检查(Time Limits,Maint. Checks)6章尺寸和区域(Dimensions and Access Panels)7章顶起和支撑(Lifting and Shoring)8章对准和称重(Leveling and Weighing)9章飞机拖曳(Towing and Taxiing)10章飞机停场,系留,封存(Parking,Mooring,Storage)11章标牌和铭记(Placards and Markings)12章勤务(Servicing)BMS3-33润滑脂的介绍/posts/35/topic-0045-359438.html20章标准施工---机体(Standard Practices---Airframe)21章空调(Air Conditioning)空调出口温度高/posts/35/topic-0045-359394.html[原创]关于737-300/500的空调/posts/35/topic-0045-356247.htmlPACK空中超温,会有那些原因引起呢?(专业贴)/posts/35/topic-0045 -359163.html22章自动飞行(Auto Flight)737NG的Y/D故障分析供大家参考/posts/72/topic-0045-729542.html 23章通讯(Communications)24章电源(Electrical Power)IDG和GEN /posts/35/topic-0045-358102.html737-300 B2972电源及APU自动关车排故思路之分析/posts/182/topic-0 045-1827865.html25章设备/装饰(Equipment/Furnishings)26章防火(Fire Protection)有关737灭火瓶...... /posts/35/topic-0045-357937.htmlAPU火警探测/posts/35/topic-0045-357662.html27章飞行操纵(Flight Controls)28章燃油(Fuel)737飞机燃油浮子电门/posts/35/topic-0045-359544.html29章液压源(Hydraulic Power)液压问题/posts/35/topic-0045-359382.html关于液压保险在液压管路的作用和位置?请教/posts/35/topic-0045-3592 99.html液压系统故障/posts/35/topic-0045-359411.html30章防冰和排雨(Ice and Rain Protection)31章指示/记录系统(Indicating/Recording system)32章起落架(Landing Gear)如何延长飞机轮胎的使用寿命/posts/35/topic-0045-358979.html前轮磨损/posts/35/topic-0045-359232.html谁能说说金属刹车片和碳刹车片的优缺点?/posts/35/topic-0045-358669. html请问哪位对防滞刹车结构熟悉的,简单介绍一下,谢谢那里有资料,网上有吗?http://bbs. /posts/35/topic-0045-359091.html请教:飞机换轮子的时候为什么要转动轮子? /posts/177/topic-0045-177 5484.html一起B737-300飞机使用自动速度刹车时,AUTO SPEED BRAKE 跳开关跳开http://bbs.fee /posts/103/topic-0045-1038900.html33章灯光(Lights)34章导航(Navigation)35章氧气(Oxygen)36章气源(Pneumatic)一起引气故障导致的增压故障(B737NG)/posts/103/topic-0045-1035067. html37章真空(Vacuum)38章水/污水(Water/waste)45章中央维护系统(Central maintenance System)49章机载辅助动力装置(Airborne Auxiliary Power)APU启动不起来了! /posts/35/topic-0045-357370.htmlAPU维护灯亮/posts/35/topic-0045-357331.html51章结构与标准施工(Structures & Standard Practices)52章舱门(Doors)53章机身(Fuselage)54章发动机短舱/吊架(Nacelles/Pylons)55章稳定装置(Stabilizers)56章窗户(windows)[讨论]玻璃上裂纹深度的测量??/posts/35/topic-0045-350765.html57章机翼(wings)70章标准施工---发动机(Standard Practices---Engines)71章动力装置(Power Plant (Package))IAEV2500系列发动机试车总结/posts/85/topic-0045-850361.html72章发动机(内部)(Engine (Internals))73章发动机燃油和控制(Engine Fuel and Control)74章点火装置(Ignition)75章发动机空气(Air)76章发动机操纵(Engine Controls)77章发动机指示(Engine Indicating)78章排气系统(Exhaust)737反推故障/posts/35/topic-0045-357397.html79章发动机滑油系统(Oil)80章发动机起动(Starting)82章注水(Water Injecting)91章图表(不同性质的)(Charts (Miscellaneous))ATA Specification 22001 *Reserved for Airline Use2 *Reserved for Airline Use3 *Reserved for Airline Use4 *Reserved for Airline Use5 TIME LIMITS/ MAINTENANCE CHECKS-00 General-10 Time Limits-20 Scheduled Maintenance Checks-30 & -40 Reserved-50 Unscheduled Maintenance checks6 DIMENSIONS AND AREAS7 LIFTING & SHORING-00 General-10 Jacking-20 Shoring8 LEVELING & WEIGHING-00 General-10 Weighing and Balancing-20 Leveling9 TOWING & TAXIING-00 General-10 Towing-20 Taxiing10 PARKING, MOORING, STORAGE & RETURN TO SERVICE -00 General-10 Parking/Storage-20 Mooring-30 Return to Service11 PLACARDS AND MARKINGS-00 General-10 Exterior Color Schemes and Markings-20 Exterior Placards and Markings-30 Interior Placards12 SERVICING-00 General-10 Replenishing-20 Scheduled Servicing-30 Unscheduled Servicing13 *Unassigned14 *Unassigned15 *Unassigned16 *Unassigned17 *Unassigned18 VIBRATION AND NOISE ANALYSIS (HELICOPTER ONLY) -00 GENERAL --10 VIBRATION ANALYSIS-20 NOISE ANALYSIS19 *Unassigned20 STANDARD PRACTICES-AIRFRAME-90 *Reserved for Airline Use21 AIR CONDITIONING-00 General-10 Compression-20 Distribution-30 Pressurization Control-40 Heating-50 Cooling-60 Temperature Control-70 Moisture/Air Contaminant22 AUTO FLIGHT-00 General-10 Autopilot-20 Speed-Attitude Correction-30 Auto Throttle-40 System Monitor-50 Aerodynamic Load Alleviating23 COMMUNICATIONS-00 General-10 Speech Communications-15 SATCOM-20 Data Transmission and Automatic Calling -30 Comfort-40 Interphone-50 Audio Integrating-60 Static Discharging-70 Audio & Video Monitoring-80 Integrated Automatic24 ELECTRICAL POWER-00 General-10 Generator Drive-20 AC Generation-30 DC Generation-40 External Power-50 AC Electrical Load Distribution-60 DC Electrical Load Distribution25 EQUIPMENT/FURNISHINGS-00 General-10 Flight Compartment-20 Passenger Compartment-30 Galley-40 Lavatories-50 Additional Compartments-60 Emergency-70 Available-80 Insulation26 FIRE PROTECTION-00 General-10 Detection-20 Extinguishing-30 Explosion Suppression27 FLIGHT CONTROLS-00 General-10 Aileron & Tab-20 Rudder & Tab-30 Elevator & Tab-40 Horizontal Stabilizer-50 Flaps-60 Spoiler, Drag Devices and Variable Aerodynamic Fairings -70 Gust Lock & Dampener-80 Lift Augmenting28 FUEL-00 General-10 Storage-20 Distribution-30 Dump-40 Indicating29 HYDRAULIC POWER-00 General-10 Main-20 Auxiliary-30 Indicating30 ICE AND RAIN PROTECTION-00 General-10 Airfoil-20 Air Intakes-30 Pitot and Static-40 Windows, Windshields and Doors-50 Antennas and Radomes-60 Propellers/Rotors-70 Water Lines-80 Detection31 INDICATING/RECORDING SYSTEMS-00 General-10 Instrument & Control Panels-20 Independent Instruments-30 Recorders-40 Central Computers-50 Central Warning Systems-60 Central Display Systems-70 Automatic Data Reporting Systems 32 LANDING GEAR-00 General-10 Main Gear and Doors-20 Nose Gear and Doors-30 Extension and Retraction-40 Wheels and Brakes-50 Steering-60 Position and Warning-70 Supplementary Gear33 LIGHTS-00 General-10 Flight Compartment-20 Passenger Compartment-30 Cargo and Service Compartments -40 Exterior-50 Emergency Lighting34 NAVIGATION-00 General-10 Flight Environment-20 Attitude & Direction-30 Landing and Taxiing Aids-40 Independent Position Determining -50 Dependent Position Determining -60 Flight Management Computing35 OXYGEN-00 General-10 Crew-20 Passenger-20 Passenger-30 Portable36 PNEUMATIC-00 General-10 Distribution-20 Indicating37 VACUUM-00 General-10 Distribution-20 Indicating38 WATER/WASTE-00 General-10 Potable-20 Wash-30 Waste Disposal-40 Air Supply39 *Unassigned40 *Unassigned41 WATER BALLAST-00 General-10 Storage-20 Dump-30 Indication42 *Unassigned43 *Unassigned44 CABIN SYSTEMS-00 General-10 Cabin Core System-20 Inflight Entertainment System-30 External Communication System-40 Cabin Mass Memory System-50 Cabin Monitoring System-60 Miscellaneous Cabin System45 CENTRAL MAINTENANCE SYSTEM-00 General-5 thru -19 CMS/Aircraft General-20 thru -49 CMS/Airframe Systems-45 Central Maintenance System-50 thru -59 CMS/Structures-60 thru -69 CMS/Propellers-70 thru -89 CMS/Power Plant45INFORMATION SYSTEMS-00 General-10 Airplane General Information Systems -20 Flight Deck Information Systems-30 Maintenance Information Systems-40 Passenger Cabin Information Systems -50 Miscellaneous Information Systems47 *Unassigned48 *Unassigned49 AIRBORNE AUXILIARY POWER-00 General-10 Power Plant-20 Engine-30 Engine Fuel and Control-40 Ignition/Starting-50 Air-60 Engine Controls .-70 Indicating-80 Exhaust-90 Oil50 Cargo and Accessory Compartments-00 General-10 Cargo Compartments-20 Cargo Loading Systems-30 Cargo Related Systems-40 Available-50 Accessory-60 Insulation51 Standard Practices, General-00 General-10 Investigation, Cleanup and Aerodynamic Smoothness-20 Processes-30 Materials-40 Fasteners-50 Support of Airplane for Repair and Alignment Check Procedures -60 Control-Surface Balancing-70 Repairs-80 Electrical Bonding52 DOORS-00 General-10 Passenger/Crew-20 Emergency Exit-30 Cargo-40 Service and Miscellaneous-50 Fixed Interior-60 Entrance Stairs-70 Monitoring and Operation-80 Landing Gear53 FUSELAGE-00 General-10 thru -90 (As Required) Fuselage Sections54 NACELLES/PYLONS-00 General-10 thru -40 (As Required) Nacelle Section-50 thru -80 (As Required) Pylon55 STABILIZERS-00 General-10 Horizontal Stabilizer or Canard-20 Elevator-30 Vertical Stabilizer-40 Rudder56 WINDOWS-00 General-10 Flight Compartment-20 Passenger Compartment-30 Door-40 Inspection and Observation57 WINGS-00 General-10 Center Wing-20 Outer Wing-30 Wing Tip-40 Leading Edge and Leading Edge Devices -50 Trailing Edge Trailing Edge Devices -60 Ailerons and Elevons-70 Spoilers-80 (as required)-90 Wing Folding System58 *Unassigned59 *Reserved for Airline Use60 STANDARD PRACTICES - PROPELLER/ROTOR61 PROPELLERS/PROPULSION-00 General-10 Propeller Assembly-20 Controlling-30 Braking-40 Indicating-50 Propulsor Duct62 ROTOR(S)-00 General-10 Rotor blades-20 Rotor head(s)-30 Rotor Shaft(s)/Swashplate Assy(ies) -4063 ROTOR DRIVE(S)-00 General-10 Engine/Gearbox couplings-20 Gearbox(es)-30 Mounts, attachments-40 Indicating64 TAIL ROTOR-00 General-10* Rotor blades-20* Rotor head-30 Available-40 Indicating65 TAIL ROTOR DRIVE-00 General-10 Shafts-20 Gearboxes-30 Available-40 Indicating66 FOLDING BLADES/PYLON-00 General-10 Rotor blades-20 Tail pylon-30 Controls and Indicating67 ROTORS FLIGHT CONTROL-00 General-10 Rotor-20 Anti-torque Rotor control (Yaw control)-30 Servo-control System68 *Unassigned69*Unassigned70 STANDARD PRACTICES - ENGINES71 POWER PLANT-00 General-10 Cowling-30 Fireseals-40 Attach Fittings-50 Electrical Harness-60 Air Intakes-70 Engine Drains72 ENGINE TURBINE/TURBO PROP DUCTED FAN/UNDUCTED FAN-00 General-10 Reduction Gear, Shaft Section (Turbo-Prop and/or Front Mounted Gear Driven Propulsor)-20 Air Inlet Section-30 Compressor Section-40 Combustion Section-50 Turbine Section-60 Accessory Drives-70 By-pass Section-80 Propulsor Section (Rear Mounted)73 ENGINE FUEL AND CONTROL-00 General-10 Distribution-20 Controlling-30 Indicating74 IGNITION-00 General-10 Electrical Power-20 Distribution-30 Switching75 AIR-00 General-10 Engine Anti-Icing-20 Cooling-30 Compressor Control-40 Indicating76 ENGINE CONTROLS-00 General-10 Power Control-20 Emergency Shutdown77 ENGINE INDICATING-00 General-10 Power-20 Temperature-30 Analyzers That-40 Integrated Engine Instrument Systems 78 EXHAUST-00 General-10 Collector/Nozzle-20 Noise Suppressor-30 Thrust Reverser-40 Supplementary Air79 OIL-00 General-10 Storage-20 Distribution-30 Indicating80 STARTING-00 General-10 Cranking81 TURBINES-00 General-10 Power Recovery-20 Turbo-Supercharger82 WATER INJECTION-00 General-10 Storage-20 Distribution-30 Dumping and Purging-40 Indicating83 ACCESSORY GEAR-BOXES-00 General-10 Drive Shaft Section-20 Gearbox Section84 Propulsion Augmentation-00 General-10 Jet Assist Takeoff85 *Unassigned86 *Unassigned87 *Unassigned88 *Unassigned89 *Unassigned90 *Unassigned91 CHARTS92 *Unassigned93 *Unassigned94 *Unassigned95 *Reserved for Airline Use96 *Reserved for Airline Use97 WIRING REPORTING-00-00 General-01-00 Zone 100 Fuselage Lower-02-00 Zone 200 Fuselage Top-03-00 Zone 300 Stabilizers-04-00 Zone 400 Nacelles-Pylons-05-00 Zone 500 Left Wing-06-00 Zone 600 Right Wing-07-00 Zone 700 Landing Gear Compartment -08-00 Zone 800 Doors-09-00 Zone 900 Lavatories & Galleys-20-00 Electrical Standard Items/Practices -21-00 Air Conditioning - General-21-10 Compression-21-20 Distribution-21-30 Pressurization Control-21-40 Heating-21-50 Cooling-21-60 Temperature Control-21-70 Moisture/Air Contaminant Control-22-00 Auto Flight - General-22-10 Autopilot-22-20 Speed - Attitude Correction-22-30 Auto Throttle-22-40 System Monitors-22-50 Aerodynamic Load Alleviating-23-00 Communications - General-23-10 Speech Communications-23-15 SATCOM-23-20 Data Transmission and Automatic Calling-23-30 Passenger Address, Entertainment and Comfort-23-40 Interphone-23-50 Audio Integrating-23-60 Static Discharging-23-70 Audio and Video Monitoring-23-80 Integrated Automatic Tuning-24-00 Electrical Power - General-24-10 Generator Drive-24-20 AC Generation-24-30 DC Generation-24-40 External Power-24-50 AC Electrical Load Distribution-24-60 DC Electrical Load Distribution-25-00 Equipment/Furnishings - General-25-10 Flight Compartment-25-20 Passenger Compartment-25-30 Galley-25-40 Lavatories-25-60 Emergency-25-80 Insulation-26-00 Fire Protection - General-26-10 Detection-26-20 Extinguishing-26-30 Explosion Suppression-27-00 Flight Controls - General-27-10 Aileron & Tab-27-20 Rudder & Tab-27-30 Elevator & Tab-27-40 Horizontal Stabilizer-27-50 Flaps-27-60 Spoiler, Drag Devices and Variable Aerodynamic Fairings -27-70 Gust Lock & Dampener-27-80 Lift Augmenting-28-00 Fuel - General-28-10 Storage-28-20 Distribution-28-30 Dump-28-40 Indicating-29-00 Hydraulic Power - General-29-10 Main-29-20 Auxiliary-29-30 Indicating-30-00 Ice and Rain Protection - General-30-10 Airfoil-30-20 Air Intakes-30-30 Pitot and Static-30-40 Windows, Windshields and Doors-30-50 Antennas And Radomes-30-60 Propellers/Rotors-30-70 Water Lines-30-80 Detection-31-00 Indicating/Recording Systems - General -31-10 Instrument and Control Panels-31-20 Independent Instruments-31-30 Recorders-31-40 Central Computers-31-50 Central Warning Systems-31-60 Central Display Systems-31-70 Automatic Data Reporting Systems-32-00 Landing Gear- General-32-10 Main Gear and Doors-32-20 Nose Gear and Doors-32-30 Extension and Retraction-32-40 Wheels and Brakes-32-50 Steering-32-60 Position And Warning-32-70 Supplementary Gear-33-00 Lights - General-33-10 Flight Compartment-33-20 Passenger Compartment-33-30 Cargo and Service Compartments-33-40 Exterior-33-50 Emergency Lighting-34-00 Navigation - General-34-10 Flight Environment Data-34-20 Attitude & Direction-34-30 Landing and Taxiing Aids-34-40 Independent Position Determining-34-50 Dependent Position Determining-34-60 Flight Management Computing-35-00 Oxygen - General-35-10 Crew-35-20 Passenger-35-30 Portable-36-00 Pneumatic - General-36-10 Distribution-36-20 Indicating-37-00 Vacuum - General-37-10 Distribution-37-20 Indicating-38-00 Water/Waste - General-38-10 Potable-38-20 Wash-38-30 Waste Disposal-38-40 Air Supply-44-00 Cabin Systems - General-44-10 Cabin Core System-44-20 In-flight Entertainment System-44-30 External Communication System-44-40 Cabin Mass Memory System-44-50 Cabin Monitoring System-44-60 Miscellaneous Cabin System-45-00 Central Maintenance System (CMS) General -45-05 CMS/Aircraft General-45-20 CMS/Airframe Systems-45-45 Central Maintenance System-45-50 CMS/Structures-45-60 CMS/Propellers-45-70 CMS/Power Plant-46-00 Information Systems - General-46-10 Airplane General Information Systems-46-20 Flight Deck Information Systems-46-30 Maintenance Information Systems-46-40 Passenger Cabin Information Systems-46-50 Miscellaneous Information Systems-49-00 Airborne Auxiliary Power - General-49-10 Power Plant-49-20 Engine-49-30 Engine Fuel And Control-49-40 Ignition And Starting-49-50 Air-49-60 Engine Controls-49-70 Indicating-49-80 Exhaust-49-90 Oil-50-00 Cargo And Accessory Compartments General -50-10 Cargo Compartments-50-20 Cargo Loading Systems-50-30 Cargo Related Systems-50-40 Available-50-50 Accessory Compartments-50-60 Insulation-52-00 Doors - General-52-10 Passenger/Crew-52-20 Emergency Exit-52-30 Cargo-52-40 Service-52-50 Fixed Interior-52-60 Entrance Stairs-52-70 Door Warning-52-80 Landing Gear-53-00 Fuselage - General-54-00 Nacelles/Pylons - General-54-10 Nacelle Section-54-50 Pylon-55-00 Stabilizers - General-55-10 Horizontal Stabilizer or Canard-55-20 Elevator-55-30 Vertical Stabilizer-55-40 Rudder-56-00 Windows - General-56-10 Flight Compartment-56-20 Passenger Compartment-56-30 Door-56-40 Inspection and Observation-57-00 Wings - General-57-10 Center Wing-57-20 Outer Wing-57-30 Wing Tip-57-40 Leading Edge and Leading Edge Devices-57-50 Trailing Edge and Trailing Edge Devices -57-60 Ailerons-57-70 Spoilers-57-90 Wing Folding System-61-00 Propellers/Propulsors - General-61-10 Propeller Assembly-61-20 Controlling-61-30 Braking-61-40 Indicating-61-50 Propulsor Duct-62-00 Rotors-63-00 Rotor Drives-64-00 Tail Rotor-65-00 Tail Rotor Drive-66-00 Folding Blades/Pylon-67-00 Rotors Flight Control-71-00 Power Plant - General-71-10 Cowling-71-20 Mounts-71-30 Fire seals-71-40 Attach Fittings-71-50 Electrical Harness-71-60 Air Intakes-71-70 Engine Drains-72-00 Engine Turbine/Turbo Prop Ducted Fan/Unducted Fan-72-10 Reduction Gear, Shaft Section (Turbo-Prop and/or Front Mounted GearDriven Propulsor)-72-20 Air Inlet Section-72-30 Compressor Section-72-40 Combustion Section-72-50 Turbine Section-72-60 Accessory Drives-72-70 By-pass Section-72-80 Propulsor Section (Rear Mounted)-73-00 Engine Fuel And Control - General-73-10 Distribution-73-20 Controlling-73-30 Indicating-74-00 Ignition - General-74-10 Electrical Power Supply-74-20 Distribution-74-30 Switching-75-00 Air - General-75-10 Engine Anti-Icing-75-20 Cooling-75-30 Compressor Control-75-40 Indicating-76-00 Engine Controls - General-76-10 Power Control-76-20 Emergency Shutdown-77-00 Engine Indicating - General-77-10 Power-77-20 Temperature-77-30 Analyzers-77-40 Integrated Engine Instrument Systems -78-00 Exhaust - General-78-10 Collector/Nozzle-78-20 Noise Suppressor-78-30 Thrust Reverser-78-40 Supplementary Air-79-00 Oil - General-79-10 Storage-79-30 Indicating-80-00 Starting - General-80-10 Cranking98 *Reserved for Airline Use99 *Unassigned100 *Do not use101 *Do not use102 *Do not use103 *Do not use104 *Do not use105 *Do not use106 *Do not use107 *Do not use108 *Do not use109 *Do not use110 *Do not use111 *Do not use112 *Do not use113 *Do not use114 *Do not use115 Flight Simulator Systems。

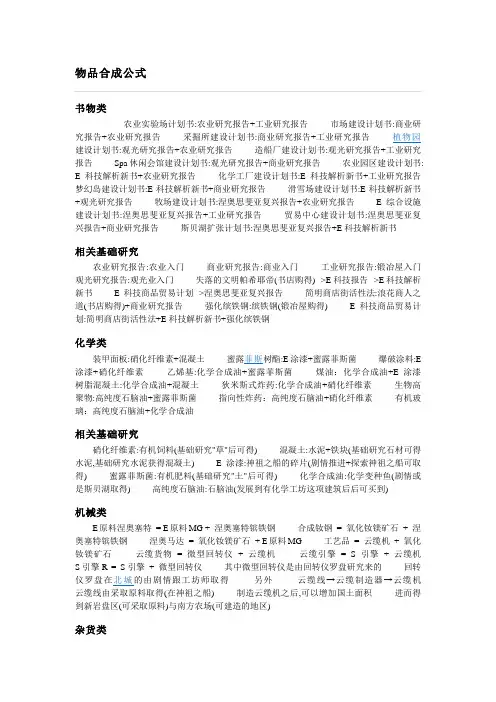

物品合成公式书物类农业实验场计划书:农业研究报告+工业研究报告市场建设计划书:商业研究报告+农业研究报告采掘所建设计划书:商业研究报告+工业研究报告植物园建设计划书:观光研究报告+农业研究报告造船厂建设计划书:观光研究报告+工业研究报告Spa休闲会馆建设计划书:观光研究报告+商业研究报告农业园区建设计划书: E科技解析新书+农业研究报告化学工厂建设计划书:E科技解析新书+工业研究报告梦幻岛建设计划书:E科技解析新书+商业研究报告滑雪场建设计划书:E科技解析新书+观光研究报告牧场建设计划书:涅奥思斐亚复兴报告+农业研究报告E综合设施建设计划书:涅奥思斐亚复兴报告+工业研究报告贸易中心建设计划书:涅奥思斐亚复兴报告+商业研究报告斯贝湖扩张计划书:涅奥思斐亚复兴报告+E科技解析新书相关基础研究农业研究报告:农业入门商业研究报告:商业入门工业研究报告:锻冶屋入门观光研究报告:观光业入门失落的文明帕希耶帝(书店购得)-->E科技报告-->E科技解析新书E科技商品贸易计划-->涅奥思斐亚复兴报告简明商店街活性法:浪花商人之道(书店购得)+商业研究报告强化缤铁钢:缤铁钢(锻冶屋购得) E科技商品贸易计划:简明商店街活性法+E科技解析新书+强化缤铁钢化学类装甲面板:硝化纤维素+混凝土蜜露菲斯树酯:E涂漆+蜜露菲斯菌爆破涂料:E 涂漆+硝化纤维素乙烯基:化学合成油+蜜露菲斯菌煤油:化学合成油+E涂漆树脂混凝土:化学合成油+混凝土狄米斯式炸药:化学合成油+硝化纤维素生物高聚物:高纯度石脑油+蜜露菲斯菌指向性炸药:高纯度石脑油+硝化纤维素有机玻璃:高纯度石脑油+化学合成油相关基础研究硝化纤维素:有机饲料(基础研究"草"后可得) 混凝土:水泥+铁块(基础研究石材可得水泥,基础研究水泥获得混凝土) E涂漆:神祖之船的碎片(剧情推进+探索神祖之船可取得) 蜜露菲斯菌:有机肥料(基础研究"土"后可得) 化学合成油:化学变种鱼(剧情或是斯贝湖取得) 高纯度石脑油:石脑油(发展到有化学工坊这项建筑后后可买到)机械类E原料涅奥塞特= E原料MG + 涅奥塞特镔铁钢合成钕钢= 氧化钕镁矿石+ 涅奥塞特镔铁钢涅奥马达= 氧化钕镁矿石+ E原料MG 工艺品= 云缆机+ 氧化钕镁矿石云缆货物= 微型回转仪+ 云缆机云缆引擎= S引擎+ 云缆机S引擎R = S引擎+ 微型回转仪其中微型回转仪是由回转仪罗盘研究来的回转仪罗盘在北城的由剧情跟工坊师取得另外云缆线→云缆制造器→云缆机云缆线由采取原料取得(在神祖之船) 制造云缆机之后,可以增加国土面积进而得到新岩盘区(可采取原料)与南方农场(可建造的地区)杂货类组合研究皇家香皂:玫瑰香精+香精油精油蜡烛:石蜡+香精油急救箱:微型E纤维+香精油保水贴布:微型E纤维+石蜡E金属线:探测棒+微型E 纤维玫瑰水晶:艾梅渥姆水晶+玫瑰香精探色炼锤:艾梅渥姆水晶+探测棒E 蠕虫:农业试验所建造后取得涅奥思斐亚蚕宝宝后基础研究而得(农业园区也可)相关基础研究玫瑰香精:玫瑰计时芳香剂香精油:万能软膏药微型E纤维:强化E纤维强化E纤维:E纤维(E纤维:卖过E蠕虫后可到杂货店买到) 探测棒:风水盘(风水盘:在杂货店可买到) 艾梅渥姆水晶:琢磨过的艾梅渥姆琢磨过的艾梅渥姆:艾梅渥姆原石(E工坊可买到)食物类咖哩面包= 巴哈涅罗咖哩+ 特制美味面包哈密瓜面包= 公主哈密瓜+ 特制美味面包热狗堡= 香肠+ 特制美味面包香肠咖哩= 香肠+ 巴哈涅罗咖哩优酪面包= 高原优酪+ 特制美味面包水果优酪= 高原优酪+ 公主哈密瓜鱼肉三明治= 生鱼片组合+ 特制美味面包蟳肉棒= 生鱼片组合+ 香肠生鱼片的优酪凉拌= 生鱼片组合+ 高原优酪研发篇食物篇蔬菜> 泡菜牛乳> 起司鸡肉> 鸡肉盖饭猪肉> 猪肉盖肉> 香肠五花肉> 五花肉盖饭葡萄酒> 美味葡萄酒香辛科> 巴哈涅罗> 巴哈涅罗咖哩面包> 松软面包> 特制美味面包汉堡> 羊肉炉高原牛乳> 高原优酪高原哈密瓜>麝香哈密瓜> 公主哈密瓜东洋的鱼> 生鱼片组化学篇土> 有机肥料> 蜜露菲斯菌草> 有机饲料> 硝化纤维素野鸡> 涅奥交趾鸡野牛> 铿锵牛化学变种鱼> 化学合成油石材> 水泥> 混疑土石脑油> 高纯度石脑油神祖之船碎片> E 涂漆涅奥斯斐亚蚕宝宝>E蠕虫螺旋蝇> 变种螺旋蝇E蠕虫病病毒>E蠕虫病疫苗机械篇铁块>强化钢铁镔铁钢>强化镔铁钢>涅奥塞特镔铁钢E原料>E原料改造>E原料MG氧化镁矿石>精练氧化镁>氧化钕镁矿石云缆线>云缆线制造器>云缆机次元精工表>时光精工表闪烁的热水壶>蒸气式轿车>S引擎多哥步枪>多哥步枪娜诺卡SP高产出核反应堆>增值炉太阳炉>高速炉回转仪罗盘>微型回转仪杂物篇盆栽> 室内盆栽组玫瑰> 玫瑰时芳香剂> 玫瑰香精香草> 万能软膏药> 香精油蜜蜡> 蜡萤烛> 石蜡毛纤品> 耐水纤维风水盘> 探测器美诺时相机> 微型天文台艾梅渥姆原石>琢磨过的艾梅渥姆>艾梅渥姆水晶E纤维>强化E纤维>微型E纤维高空弹跳绳>高空弹跳组合坏掉的E套装>E套装.GG专用简谍之耳>微型扩音器书物篇农业心得>农业入门>农业研究报告锻治屋心得>锻治屋入门>工业研究报告商业心得>商业入门>商业研究报告观光心得>观光业入门>观光研究报告观光导览手册>涅奥斯斐亚走透透涅奥斯斐亚ND政策企划书>商店街繁荣计画失落的文明帕希耶帝>E科技报告>E科技解析新书以土维生的日子>娜诺卡式E科技农法蓝色的时代>软式采堀工法浪花商人之道>简明商店街活性法东方见闻录>涅奥斯斐亚美食地图E科技商品贸易计画>涅奥斯斐亚复兴报告编辑本段事件一览2/5早王宫去王宫见女王陛下3/5早港口看到一对要离国的母子5/5早元老院士兵的恐吓,初遇哈利5/5早北城市民的搭讪6/5早改装工坊,初遇珞琪,接受玫瑰计时芳香剂的委托南城区政府开放10/5早和元老院议员的对话10/5早港口得到商业心得12/5早南城与元老院士兵纠缠,被珞琪救回(这里超级搞笑)中到北城的哈利家13/5早接受哈利的E填料委托(需要E原料改造,研究E原料得)15/5早南城得到娜诺卡特制咖啡19/5早北城区政府开放20/5早到王宫见女王,接受经济政策计划书委托(需要商业入门,研究商业心得)20/5早北城发生E原料矿洞意外28/5晚法萨来访1/6早马特奈送王宫补助资金1/6早北城得到锻冶屋心得2/6早见女皇,得到神祖之船出入许可证2/6早或中神祖之船在神祖之船会遇到哈利,哈利会滔滔说起神祖之船过往的历史迹。

300MW机组汽轮机检修规程目录第一篇汽轮机本体 (1)第一章结构概述和技术规范 (1)1.1结构概述 (1)1.2主要技术规范 (1)第二章汽缸 (5)2.1汽缸结构 (5)2.2汽缸解体前工作 (6)2.3高中压缸的解体 (6)2.4低压缸的解体 (7)2.5翻缸 (8)2.6汽缸的检修工艺及质量标准 (9)2.7汽缸的组装、保温及化妆板安装 (10)第三章转子 (12)3.1结构概述 (12)3.2检修工艺 (13)3.3质量标准 (18)第四章喷咀、隔板和隔板套 (18)4.1结构概述 (18)4.2静叶持环及隔板的检修 (30)4.3质量标准 (31)第五章汽封 (44)5.1结构概述 (44)5.2检修工艺 (48)5.3质量标准 (50)第六章滑销系统 (57)6.1结构概述 (57)第七章汽轮机找中心 (61)7.1找中心的目的 (61)7.2转子根据联轴器找中心 (61)7.3转子在汽缸内找中心 (61)7.4转子根据联轴器找中心 (61)7.5找中心 (62)7.6轴瓦调整量计算 (62)7.7对轮找中心的质量标准 (64)7.8转子对汽缸前后轴封凹窝中心的测量 (64)第八章盘车装置 (65)8.1结构概述 (65)8.2检修工艺及质量标准 (68)第九章中低压连通管 (68)9.1结构概述 (68)9.2检修工艺 (70)第十章轴承 (70)10.1结构概述 (70)10.2检修内容及工艺 (71)第十一章冷水塔 (75)11.1结构概述 (75)11.2技术规范 (75)11.3检修工艺及要求 (75)11.4大小修项目 (76)第二篇汽轮机调速 (77)第一章调速系统检修通则 (77)第二章配汽机构 (77)2.3再热主汽门 (84)2.4再热调节汽门 (87)第三章液压调节控制系统 (89)3.1油动机 (89)3.2快速卸荷阀 (90)3.3电液转换器 (96)3.4隔绝阀 (97)3.5逆止阀 (97)3.6滤网 (98)3.7线性位移差动变送器 (98)第四章保安系统 (99)4.1危急遮断器 (99)4.2危急遮断油门 (101)4.3危急试验油门 (103)4.4就地手动脱扣及复位装置 (103)4.5摇控复位装置 (104)4.6充油试验 (105)4.7隔膜阀 (105)第五章润滑油系统 (106)5.1主油泵 (107)5.2润滑油箱 (109)5.3冷油器 (109)5.4换向阀 (111)5.5排烟风机 (114)5.6辅助油泵 (115)5.7高压密封备用油泵 (116)第六章 EH油系统 (120)6.1E H油箱 (120)6.2E H系统供油泵 (122)6.3卸荷阀 (122)6.4溢流阀 (123)6.5蓄能器 (123)6.6大修后EH系统冲洗 (125)第七章密封油系统 (127)7.1系统中的主要技术参数 (128)7.2空侧滤油器 (128)7.3密封油泵 (129)7.4减压阀 (130)7.5差压调节阀 (130)第三篇给水泵汽轮机检修规程 (133)第一章给水泵汽轮机本体部分 (133)1.1概述 (133)1.2技术规范 (134)1.3 小汽轮机本体检修工艺质量标准 (135)第二章调节系统 (147)2.1放大器 (148)2.2启动装置 (148)2.3传动机构 (149)2.4调节汽阀 (150)2.5油动机 (152)2.6管道调节阀 (154)第三章保安系统 (155)3.3速关阀 (158)第四章油系统 (160)4.1主油泵 (161)4.2冷油器 (162)4.3滤油器 (162)4.4油箱 (163)4.5阀门 (164)4.6排烟机 (165)第四篇汽轮机辅机 (165)第一章除氧器及水箱检修规程 (165)1.1设备概述及主要技术规范 (165)1.2检修工艺及要求 (168)第二章压加热器设备检修 (171)2.1概述 (171)2.2技术规范 (171)2.3检修工艺及标准 (173)2.3.1水室密封面的维修 (173)2.3.2密封部件的清理及检查 (174)2.3.3密封件的组装 (174)2.3.4水室隔板的检修处理 (174)2.3.5管束及管端部件的检漏 (175)2.3.6检漏后的修理与要求 (175)2.3.7管束破裂的测定 (178)2.3.8壳体检修 (178)2.3.9传热管的更换 (181)2.3.10水压试验 (182)2.3.12大修间隔 (183)第三章低压加热器 (183)3.1概述 (183)3.2主要技术规范 (184)3.3检修工艺及标准 (185)3.3.1水室隔板的拆卸 (185)3.3.2检查与修理 (185)3.3.3通流隔板与水室大盖复位 (185)3.3.4检漏与处理方法 (186)3.3.5壳体的检修与要求 (186)3.3.6检查 (187)3.3.7修复 (187)3.3.8壳体芯子的装复 (187)3.3.9水压试验 (188)3.3.10检修项目 (188)第四章凝结器设备检修 (190)4.4设备概述及技术规范 (190)4.2设备结构及检修工艺 (190)4.3结构及用途 (191)4.3.1接颈 (192)4.3.2水室 (192)4.3.3热水井 (192)4.3.4检修工艺及要求 (192)4.3.5排气伸缩节的检修 (194)4.3.6接颈部分的检查与修理 (194)4.3.7三级减温减压装置的检修 (194)4.3.8铜管检漏后的处理方法与要求 (194)4.3.10大修项目及特殊项目 (197)4.3.11特殊项目 (197)4.3.12备品备件、专用工具及紧固件一览表 (197)第五章胶球冲洗装置检修 (198)5.1胶球冲洗装置概述 (198)5.2主要技术规范 (198)5.3胶球清洗装置的结构及作用 (198)5.3.1收球网示意图 (198)5.3.2检修内容 (200)5.3.3胶球装置检修 (200)5.3.4检修工具一览表 (201)5.3.5单项检修耗工量 (201)5.3.6检修材料定额表 (202)5.3.7备品配件一览表 (202)第五篇汽轮机管阀 (203)第一章阀门管道概述 (203)第二章高、低压旁路系统阀门检修 (208)2.1高压旁路阀检修 (208)2.2低压旁路阀检修 (214)2.3油缸检修 (215)第三章主、再热蒸汽系统阀门检修 (220)3.1冷再逆止阀检修 (221)3.2主汽疏水阀隔离阀检修 (224)3.3主汽疏水阀检修 (225)3.4热段疏水阀检修 (227)3.5抽汽电动门检修 (229)第五章安全阀检修 (232)第六章循环水蝶阀检修 (235)第七章高压截止阀检修 (236)第八章管道的检查与检修 (239)8.1 管道检查 (239)8.2 管道检修 (240)8.3 管道的连接 (240)8.4 管道附件 (242)8.5 管道法兰及垫片 (244)8.6 管道金属监督的主要内容 (247)8.7 汽机部分主要汽水管道管径计算结果 (248)第九章各类水箱检查与检修 (251)第六篇汽轮机水泵 (254)第一章电动给水泵检修工艺规程 (254)1.1设备概述及规范 (254)1.2检修工艺及标准 (258)第二章电动给水泵前置泵检修规程 (272)2.1设备规范及结构说明 (272)2.2检修工艺及标准 (274)第三章循环水泵检修规程 (281)3.1设备规范及结构概述 (281)3.2检修前的准备工作 (282)3.3检修工艺及标准 (284)第四章 IS型水泵检修工艺规程 (286)4.1设备规范 (286)4.2检修工艺及标准 (287)第五章 SA型泵检修规程 (287)5.2检修工艺及质量标准 (289)5.3结构概述 (289)5.4检修工艺及质量标准 (289)第六章液力耦合器 (291)6.1结构概述及规范 (291)6.2运行参数 (293)6.3检修工艺 (294)第七章凝结水泵检修规程 (296)7.1设备概述及规范 (296)7.2检修工艺 (296)7.3各零件的清理检查 (298)7.4泵的组装与调整 (300)7.5检修质量标准 (301)第八章汽动给水泵 (302)8.1设备概述及规范 (302)8.2检修工艺及标准 (306)第九章汽动给水泵前置泵 (321)9.1设备概述及规范 (321)9.2检修工艺及标准 (322)第一篇汽轮机本体第一章结构概述和技术规范1.1结构概述N300-16.7/537/537型汽轮机是上海汽轮机厂引进美国西屋公司技术制造的,为亚临界、一次中间再热、高中压合缸、双缸双排汽、单轴、冷凝式汽轮机。

豪爵电喷系统维修手册摘要:一、引言二、豪爵电喷系统的概述1.系统组成2.系统工作原理三、豪爵电喷系统的维修流程1.维修前的准备工作2.故障诊断3.零部件更换与维修4.系统调试与检测四、豪爵电喷系统的常见故障及处理方法1.无法启动2.启动困难3.发动机运行不稳4.油耗过高5.其他故障五、豪爵电喷系统的维护与保养1.定期检查2.零部件更换建议3.使用与储存注意事项六、结论正文:【引言】豪爵电喷系统维修手册,旨在为广大摩托车维修人员提供一套详细的维修指南,以便于快速、准确地解决豪爵电喷系统在运行过程中可能出现的各种问题。

本手册将从系统概述、维修流程、常见故障及处理方法、维护与保养等方面进行详细阐述。

【豪爵电喷系统的概述】豪爵电喷系统,作为摩托车发动机的核心部件,负责精确控制燃油喷射量和喷射时机,以保证发动机在各种工况下都能保持良好的燃烧状态。

系统主要由喷油器、燃油泵、节气门体、空气流量传感器、进气压力传感器、冷却液温度传感器、氧传感器等组成。

【豪爵电喷系统的维修流程】1.维修前的准备工作:了解摩托车型号及电喷系统型号,准备相应的维修工具和设备。

2.故障诊断:通过故障码读取、实地检测等方法,找出故障原因。

3.零部件更换与维修:根据诊断结果,更换或维修相应零部件。

4.系统调试与检测:修复后对系统进行调试和检测,确保故障排除。

【豪爵电喷系统的常见故障及处理方法】1.无法启动:检查燃油泵、喷油器、点火线圈等部件是否正常工作。

2.启动困难:检查空气流量传感器、冷却液温度传感器、进气压力传感器等是否故障。

3.发动机运行不稳:检查喷油器、燃油泵、节气门体等部件是否工作正常。

4.油耗过高:检查氧传感器、空气流量传感器等部件是否准确测量数据。

5.其他故障:根据具体现象,进行相应诊断和处理。

【豪爵电喷系统的维护与保养】1.定期检查:按照摩托车保养周期,定期检查电喷系统各部件的工作状态。

2.零部件更换建议:根据摩托车使用情况和厂家建议,及时更换磨损严重的零部件。

豪爵电喷系统维修手册尊敬的用户,感谢您选择豪爵电喷系统维修手册。

为了让您更好地了解和维修豪爵电喷系统,以下为您详细介绍豪爵电喷系统的相关内容。

一、豪爵电喷系统概述豪爵电喷系统作为我国一款优质摩托车产品,以其出色的性能和稳定的品质赢得了广大用户的喜爱。

本手册主要针对豪爵电喷摩托车的维修进行详细阐述,包括维修流程、操作步骤、故障排查与维修、保养与维护等方面。

二、维修手册的使用方法在开始维修前,请详细阅读本手册,了解豪爵电喷摩托车的基本结构和功能。

根据需要,您可以按照手册中的目录快速查找相关内容。

在维修过程中,请遵循手册中的操作步骤,确保维修过程的安全和顺利进行。

三、维修流程与操作步骤1.准备工作:检查工具和材料是否齐全,确保工作环境安全、干净。

2.故障排查:通过观察、询问等方式,了解摩托车故障现象,为后续维修提供依据。

3.拆卸:根据故障排查结果,逐步拆卸相关部件,以便进一步检查。

4.检查与诊断:检查拆卸下来的部件是否存在损坏或故障,对故障部件进行诊断。

5.更换与维修:根据诊断结果,更换损坏部件或对故障部件进行维修。

6.组装与调试:完成更换或维修后,重新组装摩托车,并进行调试,确保摩托车正常运行。

四、常见故障排查与维修1.发动机无法启动:检查电池电压、火花塞、点火线圈等部件,如有异常,进行更换或维修。

2.发动机抖动:检查燃油喷射系统、点火系统、供气系统等,调整或更换故障部件。

3.油耗过大:检查燃油泵、喷油器、空气流量计等,调整或更换故障部件。

4.发动机过热:检查水泵、风扇、散热器等,更换或维修故障部件。

五、保养与维护指南1.定期更换机油:每行驶5000公里,更换一次机油,确保发动机润滑良好。

2.定期更换空气滤清器:每行驶2000公里,更换一次空气滤清器,保证进气畅通。

3.检查刹车系统:定期检查刹车片、刹车油,确保刹车系统正常工作。

4.检查轮胎:定期检查轮胎胎压、花纹磨损情况,确保行车安全。

六、安全注意事项1.在进行维修作业时,务必断开电池负极,防止触电。

Chapter 1 –Brief History of AviationChapter 2 –DeregulationChapter 3 –Structure of the IndustryChapter 4 –Airline EconomicsChapter 5 –How Aircraft FlyChapter 6 –SafetyChapter 7 –SecurityChapter 8 –AirportsChapter 9 –Air Traffic ControlChapter 10 –Airlines and the Environment5章时间限制、维修检查(Time Limits,Maint. Checks) 6章尺寸和区域(Dimensions and Access Panels)7章顶起和支撑(Lifting and Shoring)8章对准和称重(Leveling and Weighing)9章飞机拖曳(Towing and Taxiing)10章飞机停场,系留,封存(Parking,Mooring,Storage) 11章标牌和铭记(Placards and Markings)12章勤务(Servicing)20章标准施工---机体(Standard Practices---Airframe) 21章空调(Air Conditioning)22章自动飞行(Auto Flight)23章通讯(Communications)24章电源(Electrical Power)25章设备/装饰(Equipment/Furnishings)26章 .防火(Fire Protection)27章飞行操纵(Flight Controls)28章燃油(Fuel)29章液压源(Hydraulic Power)30章防冰和排雨(Ice and Rain Protection)31章指示/记录系统(Indicating/Recording system)32章起落架(Landing Gear)33章灯光(Lights)34章导航(Navigation)35章氧气(Oxygen)36章气源(Pneumatic)37章真空(Vacuum)38章水/污水(Water/waste)45章中央维护系统(Central maintenance System)49章机载辅助动力装置(Airborne Auxiliary Power)51章结构与标准施工(Structures & Standard Practices) 52章舱门(Doors)53章机身(Fuselage)54章发动机吊舱/吊架(Nacelles/Pylons)55章稳定装置 (Stabilizers)安定面56章窗户(Windows)57章机翼(Wings)70章标准施工—发动机(Standard Practices—Engines)71章动力装置(Power Plant( Package))72章发动机(内部)(Engine (Internals))73章发动机燃油和控制(Engine Fuel and Control)74章点火装置(Ignition)75章发动机空气(Air)76章发动机操纵(Engine Controls)77章发动机指示(Engine Indicating)78章排气系统(Exhaust)79章发动机滑油系统(Oil)80章发动机起动(Starting)82章注水(Water Injecting)91章图表(不同性质的)(Charts (Miscellaneous))01 INTRODUCTION05 PERIODIC INSPECTIONS06 DIMENSIONS AND AREAS07 LIFTING AND SHORING08 LEVELING AND WEIGHING09 TOWING AND TAXIING10 PARKING, MOORING, STORAGE AND RETURN TO SERVICE11 PLACARDS AND MARKINGS12 SERVICING - ROUTINE MAINTENANCE18 VIBRATION AND NOISE ANALYSIS (HELICOPTER ONLY)20 STANDARD PRACTICES - AIRFRAME21 AIR CONDITIONING22 AUTO FLIGHT23 COMMUNICATIONS24 ELECTRICAL POWER25 EQUIPMENT / FURNISHINGS26 FIRE PROTECTION27 FLIGHT CONTROLS28 FUEL29 HYDRAULIC POWER30 ICE AND RAIN PROTECTION31 INDICATING / RECORDING SYSTEMS32 LANDING GEAR33 LIGHTS34 NAVIGATION35 OXYGEN36 PNEUMATIC37 VACUUM38 WATER / WASTE39 ELECTRICAL - ELECTRONIC PANELS AND MULTIPURPOSE COMPONENTS 41 WATER BALLAST45 CENTRAL MAINTENANCE SYSTEM (CMS)46 INFORMATION SYSTEMS49 AIRBORNE AUXILIARY POWER51 STANDARD PRACTICES AND STRUCTURES - GENERAL52 DOORS53 FUSELAGE54 NACELLES / PYLONS55 STABILIZERS56 WINDOWS57 WINGS60 STANDARD PRACTICES - PROPELLER / ROTOR61 PROPELLERS / PROPULSORS62 MAIN ROTOR(S)63 MAIN ROTOR DRIVE(S)64 TAIL ROTOR65 TAIL ROTOR DRIVE66 ROTOR BLADE AND TAIL PYLON FOLDING67 ROTORS FLIGHT CONTROL70 STANDARD PRACTICES - ENGINE71 POWER PLANT - GENERAL72 ENGINE72(T) ENGINE - TURBINE / TURBOPROP, DUCTED FAN / UNDUCTED FAN72(R) ENGINE - RECIPROCATING73 ENGINE - FUEL AND CONTROL74 IGNITION75 BLEED AIR76 ENGINE CONTROLS77 ENGINE INDICATING78 EXHAUST79 OIL80 STARTING81 TURBINES (RECIPROCATING ENGINES)82 WATER INJECTION83 ACCESSORY GEAR BOXES (ENGINE DRIVEN)84 PROPULSION AUGMENTATION91 CHARTS5章时间限制、维修检查(Time Limits,Maint. Checks)6章尺寸和区域(Dimensions and Access Panels)7章顶起和支撑(Lifting and Shoring)8章对准和称重(Leveling and Weighing)9章飞机拖曳(Towing and Taxiing)10章飞机停场,系留,封存(Parking,Mooring,Storage)11章标牌和铭记(Placards and Markings)12章勤务(Servicing)BMS3-33润滑脂的介绍/posts/35/topic-0045-359438.html20章标准施工---机体(Standard Practices---Airframe)21章空调(Air Conditioning)空调出口温度高/posts/35/topic-0045-359394.html[原创]关于737-300/500的空调/posts/35/topic-0045-356247.htmlPACK空中超温,会有那些原因引起呢?(专业贴)/posts/35/topic-0045 -359163.html22章自动飞行(Auto Flight)737NG的Y/D故障分析供大家参考/posts/72/topic-0045-729542.html 23章通讯(Communications)24章电源(Electrical Power)IDG和GEN /posts/35/topic-0045-358102.html737-300 B2972电源及APU自动关车排故思路之分析/posts/182/topic-0 045-1827865.html25章设备/装饰(Equipment/Furnishings)26章防火(Fire Protection)有关737灭火瓶...... /posts/35/topic-0045-357937.htmlAPU火警探测/posts/35/topic-0045-357662.html27章飞行操纵(Flight Controls)28章燃油(Fuel)737飞机燃油浮子电门/posts/35/topic-0045-359544.html29章液压源(Hydraulic Power)液压问题/posts/35/topic-0045-359382.html关于液压保险在液压管路的作用和位置?请教/posts/35/topic-0045-3592 99.html液压系统故障/posts/35/topic-0045-359411.html30章防冰和排雨(Ice and Rain Protection)31章指示/记录系统(Indicating/Recording system)32章起落架(Landing Gear)如何延长飞机轮胎的使用寿命/posts/35/topic-0045-358979.html前轮磨损/posts/35/topic-0045-359232.html谁能说说金属刹车片和碳刹车片的优缺点?/posts/35/topic-0045-358669. html请问哪位对防滞刹车结构熟悉的,简单介绍一下,谢谢那里有资料,网上有吗?http://bbs. /posts/35/topic-0045-359091.html请教:飞机换轮子的时候为什么要转动轮子? /posts/177/topic-0045-177 5484.html一起B737-300飞机使用自动速度刹车时,AUTO SPEED BRAKE 跳开关跳开http://bbs.fee /posts/103/topic-0045-1038900.html33章灯光(Lights)34章导航(Navigation)35章氧气(Oxygen)36章气源(Pneumatic)一起引气故障导致的增压故障(B737NG)/posts/103/topic-0045-1035067. html37章真空(Vacuum)38章水/污水(Water/waste)45章中央维护系统(Central maintenance System)49章机载辅助动力装置(Airborne Auxiliary Power)APU启动不起来了! /posts/35/topic-0045-357370.htmlAPU维护灯亮/posts/35/topic-0045-357331.html51章结构与标准施工(Structures & Standard Practices)52章舱门(Doors)53章机身(Fuselage)54章发动机短舱/吊架(Nacelles/Pylons)55章稳定装置(Stabilizers)56章窗户(windows)[讨论]玻璃上裂纹深度的测量??/posts/35/topic-0045-350765.html57章机翼(wings)70章标准施工---发动机(Standard Practices---Engines)71章动力装置(Power Plant (Package))IAEV2500系列发动机试车总结/posts/85/topic-0045-850361.html72章发动机(内部)(Engine (Internals))73章发动机燃油和控制(Engine Fuel and Control)74章点火装置(Ignition)75章发动机空气(Air)76章发动机操纵(Engine Controls)77章发动机指示(Engine Indicating)78章排气系统(Exhaust)737反推故障/posts/35/topic-0045-357397.html79章发动机滑油系统(Oil)80章发动机起动(Starting)82章注水(Water Injecting)91章图表(不同性质的)(Charts (Miscellaneous))ATA Specification 22001 *Reserved for Airline Use2 *Reserved for Airline Use3 *Reserved for Airline Use4 *Reserved for Airline Use5 TIME LIMITS/ MAINTENANCE CHECKS-00 General-10 Time Limits-20 Scheduled Maintenance Checks-30 & -40 Reserved-50 Unscheduled Maintenance checks6 DIMENSIONS AND AREAS7 LIFTING & SHORING-00 General-10 Jacking-20 Shoring8 LEVELING & WEIGHING-00 General-10 Weighing and Balancing-20 Leveling9 TOWING & TAXIING-00 General-10 Towing-20 Taxiing10 PARKING, MOORING, STORAGE & RETURN TO SERVICE -00 General-10 Parking/Storage-20 Mooring-30 Return to Service11 PLACARDS AND MARKINGS-00 General-10 Exterior Color Schemes and Markings-20 Exterior Placards and Markings-30 Interior Placards12 SERVICING-00 General-10 Replenishing-20 Scheduled Servicing-30 Unscheduled Servicing13 *Unassigned14 *Unassigned15 *Unassigned16 *Unassigned17 *Unassigned18 VIBRATION AND NOISE ANALYSIS (HELICOPTER ONLY) -00 GENERAL --10 VIBRATION ANALYSIS-20 NOISE ANALYSIS19 *Unassigned20 STANDARD PRACTICES-AIRFRAME-90 *Reserved for Airline Use21 AIR CONDITIONING-00 General-10 Compression-20 Distribution-30 Pressurization Control-40 Heating-50 Cooling-60 Temperature Control-70 Moisture/Air Contaminant22 AUTO FLIGHT-00 General-10 Autopilot-20 Speed-Attitude Correction-30 Auto Throttle-40 System Monitor-50 Aerodynamic Load Alleviating23 COMMUNICATIONS-00 General-10 Speech Communications-15 SATCOM-20 Data Transmission and Automatic Calling -30 Comfort-40 Interphone-50 Audio Integrating-60 Static Discharging-70 Audio & Video Monitoring-80 Integrated Automatic24 ELECTRICAL POWER-00 General-10 Generator Drive-20 AC Generation-30 DC Generation-40 External Power-50 AC Electrical Load Distribution-60 DC Electrical Load Distribution25 EQUIPMENT/FURNISHINGS-00 General-10 Flight Compartment-20 Passenger Compartment-30 Galley-40 Lavatories-50 Additional Compartments-60 Emergency-70 Available-80 Insulation26 FIRE PROTECTION-00 General-10 Detection-20 Extinguishing-30 Explosion Suppression27 FLIGHT CONTROLS-00 General-10 Aileron & Tab-20 Rudder & Tab-30 Elevator & Tab-40 Horizontal Stabilizer-50 Flaps-60 Spoiler, Drag Devices and Variable Aerodynamic Fairings -70 Gust Lock & Dampener-80 Lift Augmenting28 FUEL-00 General-10 Storage-20 Distribution-30 Dump-40 Indicating29 HYDRAULIC POWER-00 General-10 Main-20 Auxiliary-30 Indicating30 ICE AND RAIN PROTECTION-00 General-10 Airfoil-20 Air Intakes-30 Pitot and Static-40 Windows, Windshields and Doors-50 Antennas and Radomes-60 Propellers/Rotors-70 Water Lines-80 Detection31 INDICATING/RECORDING SYSTEMS-00 General-10 Instrument & Control Panels-20 Independent Instruments-30 Recorders-40 Central Computers-50 Central Warning Systems-60 Central Display Systems-70 Automatic Data Reporting Systems 32 LANDING GEAR-00 General-10 Main Gear and Doors-20 Nose Gear and Doors-30 Extension and Retraction-40 Wheels and Brakes-50 Steering-60 Position and Warning-70 Supplementary Gear33 LIGHTS-00 General-10 Flight Compartment-20 Passenger Compartment-30 Cargo and Service Compartments -40 Exterior-50 Emergency Lighting34 NAVIGATION-00 General-10 Flight Environment-20 Attitude & Direction-30 Landing and Taxiing Aids-40 Independent Position Determining -50 Dependent Position Determining -60 Flight Management Computing35 OXYGEN-00 General-10 Crew-20 Passenger-20 Passenger-30 Portable36 PNEUMATIC-00 General-10 Distribution-20 Indicating37 VACUUM-00 General-10 Distribution-20 Indicating38 WATER/WASTE-00 General-10 Potable-20 Wash-30 Waste Disposal-40 Air Supply39 *Unassigned40 *Unassigned41 WATER BALLAST-00 General-10 Storage-20 Dump-30 Indication42 *Unassigned43 *Unassigned44 CABIN SYSTEMS-00 General-10 Cabin Core System-20 Inflight Entertainment System-30 External Communication System-40 Cabin Mass Memory System-50 Cabin Monitoring System-60 Miscellaneous Cabin System45 CENTRAL MAINTENANCE SYSTEM-00 General-5 thru -19 CMS/Aircraft General-20 thru -49 CMS/Airframe Systems-45 Central Maintenance System-50 thru -59 CMS/Structures-60 thru -69 CMS/Propellers-70 thru -89 CMS/Power Plant45INFORMATION SYSTEMS-00 General-10 Airplane General Information Systems -20 Flight Deck Information Systems-30 Maintenance Information Systems-40 Passenger Cabin Information Systems -50 Miscellaneous Information Systems47 *Unassigned48 *Unassigned49 AIRBORNE AUXILIARY POWER-00 General-10 Power Plant-20 Engine-30 Engine Fuel and Control-40 Ignition/Starting-50 Air-60 Engine Controls .-70 Indicating-80 Exhaust-90 Oil50 Cargo and Accessory Compartments-00 General-10 Cargo Compartments-20 Cargo Loading Systems-30 Cargo Related Systems-40 Available-50 Accessory-60 Insulation51 Standard Practices, General-00 General-10 Investigation, Cleanup and Aerodynamic Smoothness-20 Processes-30 Materials-40 Fasteners-50 Support of Airplane for Repair and Alignment Check Procedures -60 Control-Surface Balancing-70 Repairs-80 Electrical Bonding52 DOORS-00 General-10 Passenger/Crew-20 Emergency Exit-30 Cargo-40 Service and Miscellaneous-50 Fixed Interior-60 Entrance Stairs-70 Monitoring and Operation-80 Landing Gear53 FUSELAGE-00 General-10 thru -90 (As Required) Fuselage Sections54 NACELLES/PYLONS-00 General-10 thru -40 (As Required) Nacelle Section-50 thru -80 (As Required) Pylon55 STABILIZERS-00 General-10 Horizontal Stabilizer or Canard-20 Elevator-30 Vertical Stabilizer-40 Rudder56 WINDOWS-00 General-10 Flight Compartment-20 Passenger Compartment-30 Door-40 Inspection and Observation57 WINGS-00 General-10 Center Wing-20 Outer Wing-30 Wing Tip-40 Leading Edge and Leading Edge Devices -50 Trailing Edge Trailing Edge Devices -60 Ailerons and Elevons-70 Spoilers-80 (as required)-90 Wing Folding System58 *Unassigned59 *Reserved for Airline Use60 STANDARD PRACTICES - PROPELLER/ROTOR61 PROPELLERS/PROPULSION-00 General-10 Propeller Assembly-20 Controlling-30 Braking-40 Indicating-50 Propulsor Duct62 ROTOR(S)-00 General-10 Rotor blades-20 Rotor head(s)-30 Rotor Shaft(s)/Swashplate Assy(ies) -4063 ROTOR DRIVE(S)-00 General-10 Engine/Gearbox couplings-20 Gearbox(es)-30 Mounts, attachments-40 Indicating64 TAIL ROTOR-00 General-10* Rotor blades-20* Rotor head-30 Available-40 Indicating65 TAIL ROTOR DRIVE-00 General-10 Shafts-20 Gearboxes-30 Available-40 Indicating66 FOLDING BLADES/PYLON-00 General-10 Rotor blades-20 Tail pylon-30 Controls and Indicating67 ROTORS FLIGHT CONTROL-00 General-10 Rotor-20 Anti-torque Rotor control (Yaw control)-30 Servo-control System68 *Unassigned69*Unassigned70 STANDARD PRACTICES - ENGINES71 POWER PLANT-00 General-10 Cowling-30 Fireseals-40 Attach Fittings-50 Electrical Harness-60 Air Intakes-70 Engine Drains72 ENGINE TURBINE/TURBO PROP DUCTED FAN/UNDUCTED FAN-00 General-10 Reduction Gear, Shaft Section (Turbo-Prop and/or Front Mounted Gear Driven Propulsor)-20 Air Inlet Section-30 Compressor Section-40 Combustion Section-50 Turbine Section-60 Accessory Drives-70 By-pass Section-80 Propulsor Section (Rear Mounted)73 ENGINE FUEL AND CONTROL-00 General-10 Distribution-20 Controlling-30 Indicating74 IGNITION-00 General-10 Electrical Power-20 Distribution-30 Switching75 AIR-00 General-10 Engine Anti-Icing-20 Cooling-30 Compressor Control-40 Indicating76 ENGINE CONTROLS-00 General-10 Power Control-20 Emergency Shutdown77 ENGINE INDICATING-00 General-10 Power-20 Temperature-30 Analyzers That-40 Integrated Engine Instrument Systems 78 EXHAUST-00 General-10 Collector/Nozzle-20 Noise Suppressor-30 Thrust Reverser-40 Supplementary Air79 OIL-00 General-10 Storage-20 Distribution-30 Indicating80 STARTING-00 General-10 Cranking81 TURBINES-00 General-10 Power Recovery-20 Turbo-Supercharger82 WATER INJECTION-00 General-10 Storage-20 Distribution-30 Dumping and Purging-40 Indicating83 ACCESSORY GEAR-BOXES-00 General-10 Drive Shaft Section-20 Gearbox Section84 Propulsion Augmentation-00 General-10 Jet Assist Takeoff85 *Unassigned86 *Unassigned87 *Unassigned88 *Unassigned89 *Unassigned90 *Unassigned91 CHARTS92 *Unassigned93 *Unassigned94 *Unassigned95 *Reserved for Airline Use96 *Reserved for Airline Use97 WIRING REPORTING-00-00 General-01-00 Zone 100 Fuselage Lower-02-00 Zone 200 Fuselage Top-03-00 Zone 300 Stabilizers-04-00 Zone 400 Nacelles-Pylons-05-00 Zone 500 Left Wing-06-00 Zone 600 Right Wing-07-00 Zone 700 Landing Gear Compartment -08-00 Zone 800 Doors-09-00 Zone 900 Lavatories & Galleys-20-00 Electrical Standard Items/Practices -21-00 Air Conditioning - General-21-10 Compression-21-20 Distribution-21-30 Pressurization Control-21-40 Heating-21-50 Cooling-21-60 Temperature Control-21-70 Moisture/Air Contaminant Control-22-00 Auto Flight - General-22-10 Autopilot-22-20 Speed - Attitude Correction-22-30 Auto Throttle-22-40 System Monitors-22-50 Aerodynamic Load Alleviating-23-00 Communications - General-23-10 Speech Communications-23-15 SATCOM-23-20 Data Transmission and Automatic Calling-23-30 Passenger Address, Entertainment and Comfort-23-40 Interphone-23-50 Audio Integrating-23-60 Static Discharging-23-70 Audio and Video Monitoring-23-80 Integrated Automatic Tuning-24-00 Electrical Power - General-24-10 Generator Drive-24-20 AC Generation-24-30 DC Generation-24-40 External Power-24-50 AC Electrical Load Distribution-24-60 DC Electrical Load Distribution-25-00 Equipment/Furnishings - General-25-10 Flight Compartment-25-20 Passenger Compartment-25-30 Galley-25-40 Lavatories-25-60 Emergency-25-80 Insulation-26-00 Fire Protection - General-26-10 Detection-26-20 Extinguishing-26-30 Explosion Suppression-27-00 Flight Controls - General-27-10 Aileron & Tab-27-20 Rudder & Tab-27-30 Elevator & Tab-27-40 Horizontal Stabilizer-27-50 Flaps-27-60 Spoiler, Drag Devices and Variable Aerodynamic Fairings -27-70 Gust Lock & Dampener-27-80 Lift Augmenting-28-00 Fuel - General-28-10 Storage-28-20 Distribution-28-30 Dump-28-40 Indicating-29-00 Hydraulic Power - General-29-10 Main-29-20 Auxiliary-29-30 Indicating-30-00 Ice and Rain Protection - General-30-10 Airfoil-30-20 Air Intakes-30-30 Pitot and Static-30-40 Windows, Windshields and Doors-30-50 Antennas And Radomes-30-60 Propellers/Rotors-30-70 Water Lines-30-80 Detection-31-00 Indicating/Recording Systems - General -31-10 Instrument and Control Panels-31-20 Independent Instruments-31-30 Recorders-31-40 Central Computers-31-50 Central Warning Systems-31-60 Central Display Systems-31-70 Automatic Data Reporting Systems-32-00 Landing Gear- General-32-10 Main Gear and Doors-32-20 Nose Gear and Doors-32-30 Extension and Retraction-32-40 Wheels and Brakes-32-50 Steering-32-60 Position And Warning-32-70 Supplementary Gear-33-00 Lights - General-33-10 Flight Compartment-33-20 Passenger Compartment-33-30 Cargo and Service Compartments-33-40 Exterior-33-50 Emergency Lighting-34-00 Navigation - General-34-10 Flight Environment Data-34-20 Attitude & Direction-34-30 Landing and Taxiing Aids-34-40 Independent Position Determining-34-50 Dependent Position Determining-34-60 Flight Management Computing-35-00 Oxygen - General-35-10 Crew-35-20 Passenger-35-30 Portable-36-00 Pneumatic - General-36-10 Distribution-36-20 Indicating-37-00 Vacuum - General-37-10 Distribution-37-20 Indicating-38-00 Water/Waste - General-38-10 Potable-38-20 Wash-38-30 Waste Disposal-38-40 Air Supply-44-00 Cabin Systems - General-44-10 Cabin Core System-44-20 In-flight Entertainment System-44-30 External Communication System-44-40 Cabin Mass Memory System-44-50 Cabin Monitoring System-44-60 Miscellaneous Cabin System-45-00 Central Maintenance System (CMS) General -45-05 CMS/Aircraft General-45-20 CMS/Airframe Systems-45-45 Central Maintenance System-45-50 CMS/Structures-45-60 CMS/Propellers-45-70 CMS/Power Plant-46-00 Information Systems - General-46-10 Airplane General Information Systems-46-20 Flight Deck Information Systems-46-30 Maintenance Information Systems-46-40 Passenger Cabin Information Systems-46-50 Miscellaneous Information Systems-49-00 Airborne Auxiliary Power - General-49-10 Power Plant-49-20 Engine-49-30 Engine Fuel And Control-49-40 Ignition And Starting-49-50 Air-49-60 Engine Controls-49-70 Indicating-49-80 Exhaust-49-90 Oil-50-00 Cargo And Accessory Compartments General -50-10 Cargo Compartments-50-20 Cargo Loading Systems-50-30 Cargo Related Systems-50-40 Available-50-50 Accessory Compartments-50-60 Insulation-52-00 Doors - General-52-10 Passenger/Crew-52-20 Emergency Exit-52-30 Cargo-52-40 Service-52-50 Fixed Interior-52-60 Entrance Stairs-52-70 Door Warning-52-80 Landing Gear-53-00 Fuselage - General-54-00 Nacelles/Pylons - General-54-10 Nacelle Section-54-50 Pylon-55-00 Stabilizers - General-55-10 Horizontal Stabilizer or Canard-55-20 Elevator-55-30 Vertical Stabilizer-55-40 Rudder-56-00 Windows - General-56-10 Flight Compartment-56-20 Passenger Compartment-56-30 Door-56-40 Inspection and Observation-57-00 Wings - General-57-10 Center Wing-57-20 Outer Wing-57-30 Wing Tip-57-40 Leading Edge and Leading Edge Devices-57-50 Trailing Edge and Trailing Edge Devices -57-60 Ailerons-57-70 Spoilers-57-90 Wing Folding System-61-00 Propellers/Propulsors - General-61-10 Propeller Assembly-61-20 Controlling-61-30 Braking-61-40 Indicating-61-50 Propulsor Duct-62-00 Rotors-63-00 Rotor Drives-64-00 Tail Rotor-65-00 Tail Rotor Drive-66-00 Folding Blades/Pylon-67-00 Rotors Flight Control-71-00 Power Plant - General-71-10 Cowling-71-20 Mounts-71-30 Fire seals-71-40 Attach Fittings-71-50 Electrical Harness-71-60 Air Intakes-71-70 Engine Drains-72-00 Engine Turbine/Turbo Prop Ducted Fan/Unducted Fan-72-10 Reduction Gear, Shaft Section (Turbo-Prop and/or Front Mounted GearDriven Propulsor)-72-20 Air Inlet Section-72-30 Compressor Section-72-40 Combustion Section-72-50 Turbine Section-72-60 Accessory Drives-72-70 By-pass Section-72-80 Propulsor Section (Rear Mounted)-73-00 Engine Fuel And Control - General-73-10 Distribution-73-20 Controlling-73-30 Indicating-74-00 Ignition - General-74-10 Electrical Power Supply-74-20 Distribution-74-30 Switching-75-00 Air - General-75-10 Engine Anti-Icing-75-20 Cooling-75-30 Compressor Control-75-40 Indicating-76-00 Engine Controls - General-76-10 Power Control-76-20 Emergency Shutdown-77-00 Engine Indicating - General-77-10 Power-77-20 Temperature-77-30 Analyzers-77-40 Integrated Engine Instrument Systems -78-00 Exhaust - General-78-10 Collector/Nozzle-78-20 Noise Suppressor-78-30 Thrust Reverser-78-40 Supplementary Air-79-00 Oil - General-79-10 Storage-79-30 Indicating-80-00 Starting - General-80-10 Cranking98 *Reserved for Airline Use99 *Unassigned100 *Do not use101 *Do not use102 *Do not use103 *Do not use104 *Do not use105 *Do not use106 *Do not use107 *Do not use108 *Do not use109 *Do not use110 *Do not use111 *Do not use112 *Do not use113 *Do not use114 *Do not use115 Flight Simulator Systems。

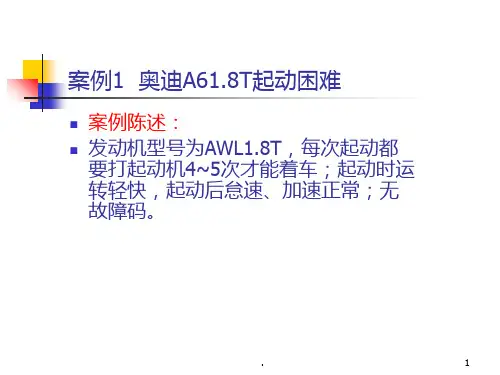

第二节A WL型发动机电喷系统的维修A WL型发动机电喷系统技术数据见表7-28。

一、A WL型发动机电控元件安装位置A WL型发动机电控元件的安装位置见图7-1所示。

图7-1 A WL型发动机电控元件安装位置1-催化净化器的λ传感器G39(55N²m) 2-催化净化器后的λ传感器G130(55N²m) 3-冷却液温度传感器G62 4-燃油压力调节器 5-发动机转速传感器G28 6-插头 7-3孔插头(用于爆震传感器1G61,绿色;发动机转速传感器G28,灰色;爆震传感器2G66,蓝色) 8-电子油门故障警报灯K132 9-油门踏板位置传感器G79和G185 10-制动灯开关F和制动踏板开关F47 11-Motronic供电继电器J271 12-离合器踏板开关F36 13-发动机控制单元J220 14-增压压力传感器G31 15-节气门控制单元J338 16-进气温度传感器G42 17-增压器空气再循环阀N249 18-爆震传感器1G61 19-爆震传感器2G66 20-霍尔传感器G40 21-喷油器N30~N33 22-点火线圈N、128、N158和N163 23-增压压力限制电磁阀N75 24-空气流量计G70 25-活性炭罐电磁阀1N80 在冷却液膨胀罐下部的插头及布置见图7-2所示。

燃油泵继电器J17在司机脚坑处中央电器盒的位置4,如图7-3所示。

制动灯开关F、制动踏板开关F47和离合器踏板开关F36安装位置如图7-4所示,为保证定位牢固,开关只能安装一次。

增压器空气再循环阀N249安装在进气歧管下,图7-5中所示为进气歧管拆下后,从下面看的状态。

油门踏板位置传感器G79和G185的安装位置如图7-6所示。

Motronic供电继电器J271安装在流水槽的电器盒内,如图7-7箭头所示。

增压压力传感器G31拧在增压空气冷却器的上部,如图7-8箭头所示。

图7-2 插头安装位置1-λ传感器G130及其加热器Z29,4孔插头(褐色) 2-λ传感器G39及其加热器Z19,6孔插头(黑色) 3-发动机转速传感器G28,3孔插头(灰色) 4-爆震传感器2 G66,3孔插头(兰色) 5-爆震传感器1 G61,3孔插头(绿色)图7-3 燃油泵继电器位置图7-4 制动灯开关、制动踏板开关和离合器踏板开关安装位置1-卡夹2-离合器踏板开关F36 3-制动灯开关F和制动踏板开关F47图7-5 增压器空气再循环阀的安装位置图7-6 油门踏板位置传感器的安装位置图7-7 Motronic供电继电器的安装位置图7-8 增压压力传感器的安装位置空气滤清器的分解见图7-9所示。

图7-9 空气滤清器分解图1-滤清器壳下体2-套管3-橡胶套管4-空气管5-密封圈6-空气流量计G70 7-空气管8-螺栓(6N²m) 9-滤清器壳上体 10-活性炭罐管路 11-螺栓(10 N²m)12-隔热板 13-滤芯 14-螺栓(10 N²m) 15-橡胶套管二、发动机控制单元的更换1、发动机控制单元的拆卸连接V AS5051或V.A.G1551,选择“01”发动机控制单元。

然后打开点火开关,显示屏显示控制单元识别码,将编码与编码表相对比。

关闭点火开关。

按图7-10箭头方向拔出流水槽盖的橡胶密封垫,向前取下流水槽盖。

拆下图7-11箭头所示流水槽内电器盒护板。

用螺丝刀小心撬下图7-12箭头所示固定卡夹。

松开图7-13所示插头定位(箭头),拔下控制单元插头,取下发动机控制单元。

注意拔下发动机控制单元插头后,自适应值将被清除,但故障存储器内的故障代码仍保留。

图7-10 拔出流水槽盖橡胶密封垫图7-11 拆卸流水槽内电器盒护板图7-12 撬下固定夹图7-13 拆卸发动机控制单元1、2-发动机控制单元插头2、发动机控制单元的安装发动机控制单元的安装按与拆卸相反顺序进行,安装发动机控制单元后,应进行下述工作:(1)查询并清除故障代码。

(2)进行节气门控制单元J338自适应。

(3)注意发动机控制单元编码说明。

(4)对于带车速控制装置的车(可从转向开关上识别出),要将其与发动机控制单元接通。

(5)对于带自动变速器的车,进行强制减档功能自适应。

(6)进行防盗器与发动机控制单元自适应,在自适应初始阶段,怠速可能不稳及行驶不平顺,这是正常现象。

三、电喷系统技术参数的检查(一)怠速转速的检查检查怠速转速时,要求:①排气系统无漏气;②冷却液温度不低于80℃;③关闭用电设备(检测时,散热器风扇不应转动);④关闭空调;⑤未接压力表;⑥对于自动变速器的车,变速杆在P或N位置。

怠速转速不可调,在发动机基本设定过程中可以检查怠速转速。

在发动机基本设定过程中,压缩机和活性炭罐电磁阀均应关闭。

怠速转速的检查步骤如下:查询故障代码,故障存储器不应存有故障,如需要,排除故障,清除故障代码,关闭并再次起动发动机。

试车后再次查询故障代码,使发动机继续怠速运转。

显示屏显示:输入显示组056,按Q键确认。

显示屏显示:检查显示区1的转速值(实际值)是否在允许的公差范围内。

显示区1的怠速转速就是发动机的实际转速,该值应在740~860r/min之间,显示区2的转速值是由发动机控制单元计算出的一个理论转速值,该值显示800r/min。

在怠速时,发动机控制单元一直在试图使实际转速与规定转速相适应,也就是说,怠速实际转速应与规定转速大致相等。

显示区3和4是一种信息,但与控制怠速转速无关。

如果达到规定值,结束检查。

如果未达到规定值,再次查询故障代码。

如果怠速转速过高或过低,且故障存储器中无故障代码,则检查进气系统是否漏气,检查节气门控制单元是否正常,检查活性炭罐电磁阀是否常开以及是否进行了节气门控制单元自适应。

(二)系统压力、燃油压力调节器及保持压力的检查燃油压力调节器按进气歧管压力来调节燃油压力,从而使喷油阀上的压力下降在任何转速及负荷范围内均相同。

检查燃油压力时要求①燃油泵继电器正常;②燃油泵正常;③燃油滤清器正常;④蓄电池电压不低于12.7V;⑤带自动变速器的车,变速杆应在P或N位置。

1、系统压力的检查短时打开油箱盖(以卸压),拆下发动机盖罩。

打开图7-14箭头所示接头,用抹布吸净溢出的燃油,用1318/11、1318/12及1318/13将V.A.G1318接到供油管上,如图7-15所示,打开压力测试仪上的锁栓,杆应指向燃油流动方向。

起动发动机,使之怠速运转,测量燃油压力,燃油压力值应为约350kPa。

拔下图7-16所示燃油压力调节器上的真空软管,燃油压力应升至约400kPa。

关闭点火开关,检查密封性和保持压力,注意表上压降,10min后,压力不应小于250kPa。

如果保持压力降至250kPa以下,起动发动机,使之怠速动转。

建立起压力后,关闭点火开关,同时关闭V.A.G1318上的锁栓(图7-17箭头所示的杆与油流成90°),注意表上压降。

图7-14 打开油管接头图7-15 安装压力测试仪图7-16 拔下燃油压力调节器上真空软管图7-17 关闭V.A.G1318上的锁栓如果压力未下降,检查燃油泵单向阀;如果压力又下降,打开V.A.G1318上锁栓,杆指向油流方向,起动发动机,使之怠速运转,建立起压力后,关闭点火开关,在棕色标记处封住回流软管。

如果压力不下降,更换燃油压力调节器;如果压力又下降,检查管路接头,燃油分配管上O形环及喷油阀是否漏泄并检查压力测试仪是否泄漏。

四、喷油系统部件的检查(一)喷油器的检查1、喷油器内阻的检查拆下发动机盖罩,拔下被检喷油器插头。

如图7-18所示,将万用表(电阻档)接到喷油器上。

室温时喷油器电阻值应为12~13Ω。

如果未达到规定值,更换喷油器。

如果达到规定值,检查喷油器供电电压。

图7-18 检查喷油器内阻2、喷油器供电电压的检查检查喷油器供电电压时要求喷油器保险丝正常以及燃油泵继电器正常。

拔下被检喷油器插头,利用V.A.G1527B将图7-19所示喷油器插头1接到发动机搭铁,打开点火开关,发光二极管应亮。

如果二极管不亮,检查触点1和喷油器保险丝间导线是否断路,如需要,排除导线断路故障。

如果二极管亮,则检查喷油器功能。

图7-19 喷油器插头3、喷油器功能的检查检查喷油器功能时要求喷油器内阻正常。

将喷油器插头套管向后推,但插头仍插着,如图7-20所示,将V.A.G1527B接到触点2(信号)和1(正极)之间,短时起动起动机(发动机可以起动),发光二极管应闪亮。

如果二极管不闪亮,将V.A.G1598/31接到发动机控制单元线束上,不接发动机控制单元,检查喷油器插头触点2的导线是否断路及对地/正极短路。

如需要,排除导线断路或短路故障。

如果导线正常,则更换发动机控制单元。

图7-20 连接V.A.G1527B到喷油器触点上(二)带喷油器的燃油分配管的分解和组装带喷油器的燃油分配管的分解和组装见图7-21所示。

图7-21 带喷油器的燃油分配管分解图1-喷油器接头(3N²m)2-O形环3-喷油器N30~N33 4-O形环5-燃油分配管6-供油管(25N²m)7-回油管8-喷油器插头(4个)9-内六角螺栓(10N²m)10-燃油压力调节器11-O形环12-O形环13-燃油压力调节器卡夹14-卡夹15-进气歧管(三)喷油器的拆装拆下发动机盖罩,拔下喷油器N30、N31、N32和N33的导线/插头,拔下进气温度传感器G42、霍尔传感器G40和节气门控制单元J338的导线/插头。

拧下图7-22箭头所示燃油分配管的固定螺栓,拔下燃油压力调节器上的真空管,从进气歧管上将燃油分配管连同喷油器一同拔出,将其放到发动机舱后部一块干净抹布上。

拔下卡夹并取下喷油器。

注意更换燃油分配管时,应先拆下燃油软管。

图7-22 拆卸燃油分配管固定螺栓喷油器的安装按与拆卸相反顺序进行,但应注意下述几点:(1)更换打开的连接处O形环(更换喷油器的前O形环时,不可拆下喷油器头部的塑料盖,O形环要从塑料盖上取下)。

(2)用干净的发动机机油浸润O形环。

(3)注意喷油器的正确安装位置。

(4)检查卡夹是否装好。

(5)将已装好喷油器的燃油分配管装到进气歧管上,均匀压入。

(6)燃油分配管与进气歧管的拧紧力矩为10N²m。

(四)喷油量、密封性及喷油型式的检查喷油量、密封性及喷油型式时要求燃油系统压力正常,从进气歧管上拆下带喷油器的燃油分配管,燃油软管不拆。

将V.A.G1598/31接到发动机控制单元线束上,不接发动机控制单元。

(1)检查喷油器密封性用V.A.G1594A中辅助接线跨接V.A.G1598/31上触点1和65,打开点火开关,燃油泵应运转。

检查喷油器密封性(目视检查),燃油泵运转时,每个喷油器每分钟漏油不应多于1~2滴。