常用中英文缩写对照表

- 格式:xls

- 大小:80.00 KB

- 文档页数:2

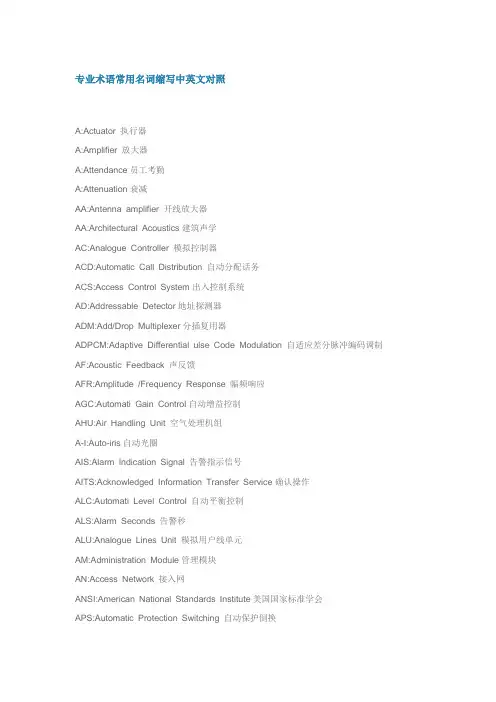

专业术语常用名词缩写中英文对照A:Actuator 执行器A:Amplifier 放大器A:Attendance员工考勤A:Attenuation衰减AA:Antenna amplifier 开线放大器AA:Architectural Acoustics建筑声学AC:Analogue Controller 模拟控制器ACD:Automatic Call Distribution 自动分配话务ACS:Access Control System出入控制系统AD:Addressable Detector地址探测器ADM:Add/Drop Multiplexer分插复用器ADPCM:Adaptive Differential ulse Code Modulation 自适应差分脉冲编码调制AF:Acoustic Feedback 声反馈AFR:Amplitude /Frequency Response 幅频响应AGC:Automati Gain Control自动增益控制AHU:Air Handling Unit 空气处理机组A-I:Auto-iris自动光圈AIS:Alarm Indication Signal 告警指示信号AITS:Acknowledged Information Transfer Service确认操作ALC:Automati Level Control 自动平衡控制ALS:Alarm Seconds 告警秒ALU:Analogue Lines Unit 模拟用户线单元AM:Administration Module管理模块AN:Access Network 接入网ANSI:American National Standards Institute美国国家标准学会APS:Automatic Protection Switching 自动保护倒换ASC:Automati Slope Control 自动斜率控制ATH:Analogue Trunk Unit 模拟中继单元ATM:Asynchrous Transfer Mode 异步传送方式AU- PPJE:AU Pointer Positive Justification 管理单元正指针调整AU:Administration Unit 管理单元AU-AIS:Administrative Unit Alarm Indication SignalAU告警指示信号AUG:Administration Unit Group 管理单元组AU-LOP:Loss of Administrative Unit Pointer AU指针丢失AU-NPJE:AU Pointer Negative Justification管理单元负指针调整AUP:Administration Unit Pointer管理单元指针AVCD:Auchio &Video Control Device 音像控制装置AWG:American Wire Gauge美国线缆规格BA:Bridge Amplifier桥接放大器BAC:Building Automation & Control net建筑物自动化和控制网络BAM:Background Administration Module后管理模块BBER:Background Block Error Ratio背景块误码比BCC:B-channel Connect ControlB通路连接控制BD:Building DistributorBEF:Buiding Entrance Facilities 建筑物入口设施BFOC:Bayonet Fibre Optic Connector大口式光纤连接器BGN:Background Noise背景噪声BGS: Background Sound 背景音响BIP-N:Bit Interleaved Parity N code 比特间插奇偶校验N位码B-ISDN:Brand band ISDN 宽带综合业务数字网B-ISDN:Broad band -Integrated Services Digital Network 宽带综合业务数字网BMC:Burst Mode Controller 突发模式控制器BMS:Building Management System 智能建筑管理系统BRI:Basic Rate ISDN 基本速率的综合业务数字网BS:Base Station基站BSC:Base Station Controller基站控制器BUL:Back up lighting备用照明C/S: Client/Server客户机/服务器C:Combines 混合器C:Container 容器CA:Call Accounting电话自动计费系统CATV:Cable Television 有线电视CC:Call Control 呼叫控制CC:Coax cable 同轴电缆CCD:Charge coupled devices 电荷耦合器件CCF:Cluster Contril Function 簇控制功能CD:Campus Distributor 建筑群配线架CD:Combination detector 感温,感烟复合探测器CDCA:Continuous Dynamic Channel Assign 连续的动态信道分配CDDI:Copper Distributed Data 合同缆分布式数据接口CDES:Carbon dioxide extinguisbing system 二氧化碳系统CDMA:Code Division Multiplex Access 码分多址CF:Core Function 核心功能CFM:Compounded Frequency Modulation 压扩调频繁CIS:Call Information System 呼叫信息系统CISPR:Internation Special Conmittee On Radio Interference 国际无线电干扰专门委员会CLNP:Connectionless Network Protocol 无连接模式网络层协议CLP:Cell Loss Priority信元丢失优先权CM:Communication Module 通信模块CM:Configuration Management 配置管理CM:Cross-connect Matrix交叉连接矩阵CMI:Coded Mark Inversion传号反转码CMISE:Common Management Information Service公用管理信息协议服务单元CPE:Convergence protocol entity 会聚协议实体CR/E:card reader /Encoder (Ticket reader )卡读写器/编码器CRC:Cyclic Redundancy Check 循环冗佘校验CRT:Cathode Ray Tabe 显示器,监视器,阴极射线管CS: Convergence service 会聚服务CS:Cableron Spectrum 旧纳档块化技术CS:Ceiling Screen 挡烟垂壁CS:Convergence Sublayer合聚子层CSC:Combined Speaker Cabinet 组合音响CSCW:Computer supported collaborative work 计算机支持的协同工作CSES:Continuius Severely Errored Second 连续严重误码秒CSF:Cell Site Function 单基站功能控制CTB:Composite Triple Beat 复合三价差拍CTD:Cable Thermal Detector 缆式线型感温探测器CTNR:carrier to noise ratio 载波比CW:Control Word 控制字D:Directional 指向性D:Distortion 失真度D:Distributive 分布式DA:Distribution Amplifier 分配的大器DBA:Database Administrator数据库管理者DBCSN:Database Control System Nucleus数据库控制系统核心DBOS:Database Organizing System 数据库组织系统DBSS:Database Security System 数据库安全系统DC:Door Contacts大门传感器DCC:Digital Communication Channel数字通信通路DCN:Data Communication Network 数据通信网DCP-I:Distributed Control Panel -Intelligent智能型分散控制器DCS:Distributed Control System集散型控制系统DDN:Digital Data Network 数字数据网DDS:Direct Dignital Controller直接数字控制器DDW:Data Describing Word 数据描述字DECT:Digital Enhanced Cordless Telecommunication增强数字无绳通讯DFB:Distributed Feedback 分布反馈DID:Direct Inward Dialing 直接中继方式,呼入直拨到分机用户DLC:Data Link Control Layer 数据链路层DLI:DECT Line InterfaceDODI:Direct Outward Dialing One 一次拨号音DPH:DECT PhoneDRC:Directional Response Cahracteristics 指向性响应DS:Direct Sound 直正声DSP:Digital signal Processing 数字信号处理DSS:Deiision Support System 决策支持系统DTMF:Dual Tone Multi-Frequency 双音多频DTS:Dual -Technology Sensor 双鉴传感器DWDM:Dense Wave-length Division Multiplexing 密集波分复用DXC:Digital Cross-Connect 数字交叉连接E:Emergency lighting照明设备E:Equalizer 均衡器E:Expander 扩展器EA-DFB:Electricity Absorb-Distributed Feedback 电吸收分布反馈ECC:Embedded Control Channel 嵌入或控制通道EDFA:Erbium-Doped Fiber Amplifier掺饵光纤放大器EDI:Electronic Data Interexchange 电子数据交换EIC:Electrical Impedance Characteristics 电阻抗特性EMC:Electro Magnetic Compatibiloty 电磁兼容性EMI:Electro Magnetic Interference 电磁干扰EMS:Electromagnetic Sensitibility 电磁敏感性EN:Equivalent Noise 等效噪声EP:Emergency Power 应急电源ES:Emergency Sooket 应急插座ES:Evacuation Sigvial疏散照明ESA:Error SecondA 误码秒类型AESB:ErrorSecondB 误码秒类型BESD:Electrostatic Discharge静电放电ESR:Errored Second Ratio 误码秒比率ETDM:Electrical Time Division Multiplexing电时分复用ETSI:European Telecommunication Standards Institute欧洲电信标准协会F:Filter 滤波器FAB:Fire Alarm Bell 火警警铃FACU:Fire Alarm Contrlol Unit 火灾自动报警控制装置FC:Failure Count 失效次数FC:Frequency Converter 频率变换器FCC:Fire Alarm System 火灾报警系统FCS:Field Control System 现场总线FCU:Favn Coil Unit风机盘管FD:Fire Door 防火门FD:Flame Detector 火焰探测器FD:Floor DistributorFD:Frequency Dirsder 分频器FDD:Frequency Division Dual 频分双工FDDI:Fiberdistributed Data Interface光纤缆分布式数据接口。

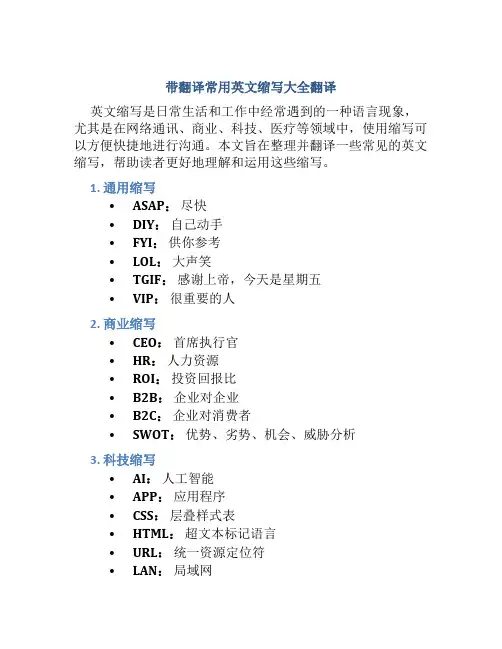

带翻译常用英文缩写大全翻译

英文缩写是日常生活和工作中经常遇到的一种语言现象,尤其是在网络通讯、商业、科技、医疗等领域中,使用缩写可以方便快捷地进行沟通。

本文旨在整理并翻译一些常见的英文缩写,帮助读者更好地理解和运用这些缩写。

1. 通用缩写

•ASAP:尽快

•DIY:自己动手

•FYI:供你参考

•LOL:大声笑

•TGIF:感谢上帝,今天是星期五

•VIP:很重要的人

2. 商业缩写

•CEO:首席执行官

•HR:人力资源

•ROI:投资回报比

•B2B:企业对企业

•B2C:企业对消费者

•SWOT:优势、劣势、机会、威胁分析

3. 科技缩写

•AI:人工智能

•APP:应用程序

•CSS:层叠样式表

•HTML:超文本标记语言

•URL:统一资源定位符

•LAN:局域网

4. 医疗缩写

•MRI:磁共振成像

•CT:计算机断层扫描

•AIDS:艾滋病

•CDC:美国疾病控制和预防中心

•LMP:最后月经期

5. 教育缩写

•SAT:学术能力评估测试

•ACT:美国高中学考

•STEM:科学、技术、工程、数学

•GPA:平均绩点

•TOEFL:托福考试

•IELTS:雅思考试

通过学习和掌握这些常用英文缩写的翻译,我们可以更好地融入不同领域的交流中,提高自己的工作效率和沟通能力。

掌握这些缩写是现代社会中一种基本的语言能力,希望读者能够从中受益并运用到实际生活和工作中。

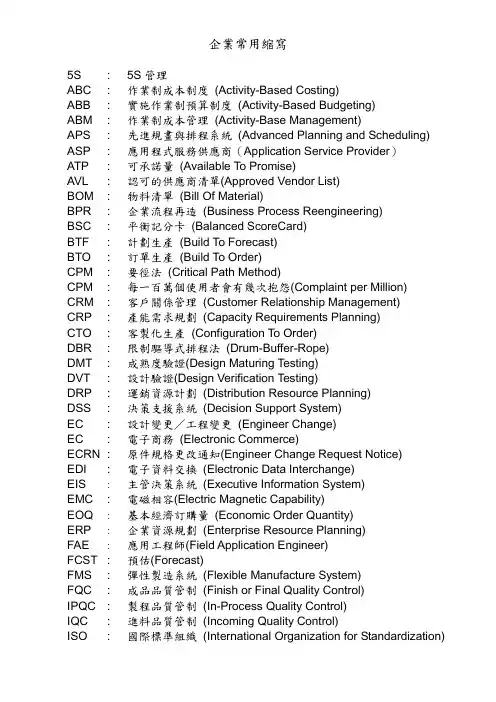

企業常用縮寫5S : 5S管理ABC : 作業制成本制度(Activity-Based Costing)ABB : 實施作業制預算制度(Activity-Based Budgeting)ABM : 作業制成本管理(Activity-Base Management)APS : 先進規畫與排程系統(Advanced Planning and Scheduling) ASP : 應用程式服務供應商(Application Service Provider)ATP : 可承諾量(Available To Promise)AVL : 認可的供應商清單(Approved Vendor List)BOM : 物料清單(Bill Of Material)BPR : 企業流程再造(Business Process Reengineering)BSC : 平衡記分卡(Balanced ScoreCard)BTF : 計劃生產(Build To Forecast)BTO : 訂單生產(Build To Order)CPM : 要徑法(Critical Path Method)CPM : 每一百萬個使用者會有幾次抱怨(Complaint per Million) CRM : 客戶關係管理(Customer Relationship Management) CRP : 產能需求規劃(Capacity Requirements Planning)CTO : 客製化生產(Configuration To Order)DBR : 限制驅導式排程法(Drum-Buffer-Rope)DMT : 成熟度驗證(Design Maturing Testing)DVT : 設計驗證(Design Verification Testing)DRP : 運銷資源計劃(Distribution Resource Planning)DSS : 決策支援系統(Decision Support System)EC : 設計變更/工程變更(Engineer Change)EC : 電子商務(Electronic Commerce)ECRN : 原件規格更改通知(Engineer Change Request Notice)EDI : 電子資料交換(Electronic Data Interchange)EIS : 主管決策系統(Executive Information System)EMC : 電磁相容(Electric Magnetic Capability)EOQ : 基本經濟訂購量(Economic Order Quantity)ERP: 企業資源規劃(Enterprise Resource Planning)FAE: 應用工程師(Field Application Engineer)FCST : 預估(Forecast)FMS : 彈性製造系統(Flexible Manufacture System)FQC : 成品品質管制(Finish or Final Quality Control)IPQC : 製程品質管制(In-Process Quality Control)IQC : 進料品質管制(Incoming Quality Control)ISO : 國際標準組織(International Organization for Standardization) ISAR : 首批樣品認可(Initial Sample Approval Request)JIT : 即時管理(Just In Time)KM :知識管理(Knowledge Management)L4L : 逐批訂購法(Lot-for-Lot)LTC : 最小總成本法(Least Total Cost)LUC : 最小單位成本(Least Unit Cost)MES : 製造執行系統(Manufacturing Execution System)MO : 製令(Manufacture Order)MPS : 主生產排程(Master Production Schedule)MRO : 請修(購)單(Maintenance Repair Operation)MRP : 物料需求規劃(Material Requirement Planning)MRPII : 製造資源計劃(Manufacturing Resource Planning)NFCF : 更改預估量的通知Notice for Changing ForecastOEM : 委託代工(Original Equipment Manufacture)ODM : 委託設計與製造(Original Design & Manufacture)OLAP : 線上分析處理(On-Line Analytical Processing)OLTP : 線上交易處理(On-Line Transaction Processing)OPT : 最佳生產技術(Optimized Production T echnology)OQC : 出貨品質管制(Out-going Quality Control)PDCA : PDCA管理循環(Plan-Do-Check-Action)PDM : 產品資料管理系統(Product Data Management)PERT : 計畫評核術(Program Evaluation and Review Technique)PO : 訂單(Purchase Order)POH : 預估在手量(Product on Hand)PR : 採購申請Purchase RequestQA : 品質保證(Quality Assurance)QC : 品質管制(Quality Control)QCC : 品管圈(Quality Control Circle)QE : 品質工程(Quality Engineering)RCCP : 粗略產能規劃(Rough Cut Capacity Planning)RMA : 退貨驗收Returned Material ApprovalROP : 再訂購點(Re-Order Point)SCM : 供應鏈管理(Supply Chain Management)SFC : 現場控制(Shop Floor Control)SIS : 策略資訊系統(Strategic Information System)SO : 訂單(Sales Order)SOR : 特殊訂單需求(Special Order Request)SPC : 統計製程管制(Statistic Process Control)TOC : 限制理論(Theory of Constraints)TPM : 全面生產管理Total Production ManagementTQC : 全面品質管制(Total Quality Control)TQM : 全面品質管理(Total Quality Management)WIP : 在製品(Work In Process)5S管理5S是由日本企業研究出來的一種環境塑造方案,其目的在藉由整理(SEIRI)、整頓(SEITON)、清掃(SEISO)、清潔(SEIKETSU)及身美(SHITSUKE)五種行為來創造清潔、明朗、活潑化之環境,以提高效率、品質及顧客滿意度。

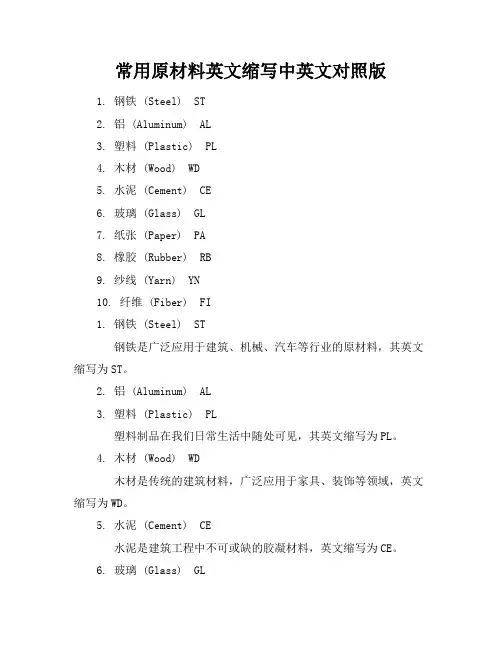

常用原材料英文缩写中英文对照版1. 钢铁 (Steel) ST2. 铝 (Aluminum) AL3. 塑料 (Plastic) PL4. 木材 (Wood) WD5. 水泥 (Cement) CE6. 玻璃 (Glass) GL7. 纸张 (Paper) PA8. 橡胶 (Rubber) RB9. 纱线 (Yarn) YN10. 纤维 (Fiber) FI1. 钢铁 (Steel) ST钢铁是广泛应用于建筑、机械、汽车等行业的原材料,其英文缩写为ST。

2. 铝 (Aluminum) AL3. 塑料 (Plastic) PL塑料制品在我们日常生活中随处可见,其英文缩写为PL。

4. 木材 (Wood) WD木材是传统的建筑材料,广泛应用于家具、装饰等领域,英文缩写为WD。

5. 水泥 (Cement) CE水泥是建筑工程中不可或缺的胶凝材料,英文缩写为CE。

6. 玻璃 (Glass) GL7. 纸张 (Paper) PA纸张是日常生活中常见的文具用品,英文缩写为PA。

8. 橡胶 (Rubber) RB9. 纱线 (Yarn) YN纱线是纺织品的原材料,英文缩写为YN。

10. 纤维 (Fiber) FI纤维是构成纱线的基本单元,广泛应用于纺织、非织造布等领域,英文缩写为FI。

当然,让我们继续丰富这份常用原材料英文缩写的中英文对照版:11. 铜 (Copper) CU铜是一种具有优良导电性和导热性的金属,常用于电线、电缆和管道制造,其英文缩写为CU。

12. 石油 (Petroleum) PT石油是现代工业的重要能源和原料,用于生产汽油、柴油、塑料等多种化学品,英文缩写为PT。

13. 天然气 (Natural Gas) NG天然气作为一种清洁能源,广泛应用于供暖、发电和工业生产,英文缩写为NG。

14. 棉花 (Cotton) CT棉花是纺织业的重要原料,用于制作衣物和家居用品,英文缩写为CT。

15. 尼龙 (Nylon) NY尼龙是一种合成纤维,以其耐磨性和强度著称,广泛应用于服装和工业领域,英文缩写为NY。

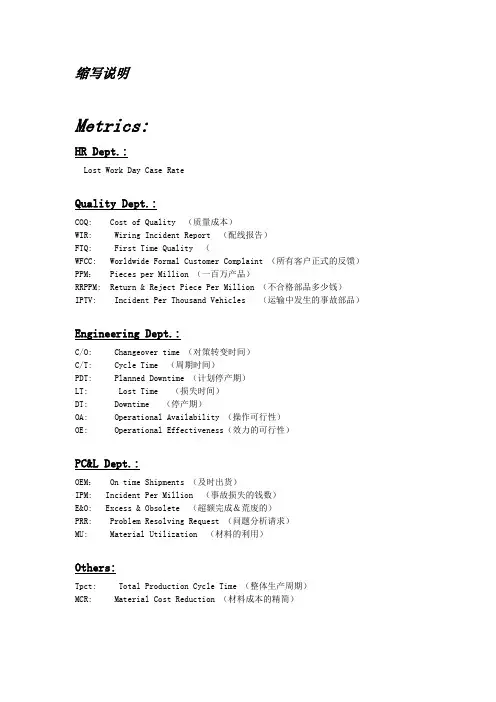

缩写说明Metrics:HR Dept.:Lost Work Day Case RateQuality Dept.:COQ: Cost of Quality (质量成本)WIR: Wiring Incident Report (配线报告)FTQ: First Time Quality (WFCC: Worldwide Formal Customer Complaint (所有客户正式的反馈)PPM: Pieces per Million (一百万产品)RRPPM: Return & Reject Piece Per Million (不合格部品多少钱)IPTV: Incident Per Thousand Vehicles (运输中发生的事故部品)Engineering Dept.:C/O: Changeover time (对策转变时间)C/T: Cycle Time (周期时间)PDT: Planned Downtime (计划停产期)LT: Lost Time (损失时间)DT: Downtime (停产期)OA: Operational Availability (操作可行性)OE: Operational Effectiveness(效力的可行性)PC&L Dept.:OEM:On time Shipments (及时出货)IPM: Incident Per Million (事故损失的钱数)E&O: Excess & Obsolete (超额完成&荒废的)PRR: Problem Resolving Request (问题分析请求)MU: Material Utilization (材料的利用)Others:Tpct: Total Production Cycle Time (整体生产周期)MCR: Material Cost Reduction (材料成本的精简)6SIGMADMAIC: Define, Measure, Analysis, Improve, ControlVOC: Voice of CustomerCTQ: Critical to QualitySIPOC: Supplier, Input, Process, Output, CustomerI&CIM: Innovation, & Continuos ImprovementTMAP: Though MapPMAP: Process MapMSE: Measure System EvaluationFMEA: Failure Modes and Effects AnalysisNEM: Numerical Evaluation of MetricsANOVA: Analysis of VarianceDOE : Design of ExperimentsLEAN1.DMS -- Delphi Manufacturing systemEEI : Employee Environment & InvolvementWPO: Workplace OrganizationQS: Quality SystemOA: Operational AvailabilityMM: material movementMSD: Manufacturing System Design2.KMS -- Kaizen Manufacturing system3.OSKKK -- Observation, Standardization, Kaizen, Kaizen, Kaizen ……4.PFP -- People Focus practice5.VSM— Value Stream Mapping6.TPM: Total Production Maintenance7.PMP: Production Maintenance Partnership8.PM: Planned Maintenance9.TPS: Toyota Production System10. SMED: Single Minutes of Exchange Die12. FIFO: First In First Out13.5S: Clear (Sort), Organize ( Straighten), Clean(Sweep), Maintain(Standardize), Continuous Improvement ( Sustain)14.NWG: Natural Work Group15.WIP: Work In Process16.PFEP: Plant For Every Part17.JIT: Just in Time18.PDCA: Plan – Do – Check – Action19.SQIP: Supplier Quality Improvement Process20.VOC: Voice of Customer21.MSDS: Material Safety Date Sheets22.PDP: Product Development Process23.PTC: Protect The Customer24.APQP: Advanced Product Quality Planning25.SPDP: Supplier Performance Development Process26.QSA: Quality System Assessment27.SPC: Statistic Process Control28.PDAP: Production Part Approval29.DBS: Delphi Business System30.MSA: Measurement System Analysis31.FMEA: Failure Mode and Effects Analysis32.TLCC: Total Life Cycle CostEach FunctionHR Dept:HR: Human ResourcePBP: People Business PlanNWG: Natural Work GroupPPI: People Performance IndexMSDS: Material Safety Data SheetsOSHA : Occupational Safety and Health AdministrationIS&S Dept.IS&S: Information System and ServiceIT: Information TechnologyFS: Fourth ShiftMRP: Material Requirement PlanERP: Enterprise Resource PlanSAP: System, Application & ProductsJIT: Just – In – TimeSILS: Supply in Line SequenceOA: Office AutomationISP: Information Security PolicyFIS: An information System Supporting Audi A4 Production in FAW-VW BF: Back FlushOS: Operation SystemIP: Internet ProtocolPC& L:PC& L: Production Control & LogisticE & O: Excess and ObsoletePFEP: Plan For Every PartsTOR: Turn Over RateIPM: Incident Per MillionMPS: Master Production SchedulePO: Purchasing OrderMOQ: Minim Order QualityPPQ: Part Packing QualityL/T: Lead-TimeBOM: Bill of MaterialsWIP: Work In ProcessFIFO: First In First OutDOH: Day On HandPR/R: Problem Resolution and ReportingI/E DeptI/E: Import & ExportLMC: Logistic Management CompanyP/A: Public AffairsRDC: Regional Distribution Center: Consolidation CenterCCIB: China Commodity Inspection BranchCD: Customs DutyVAT: Value Added TaxPR/R: Problem Resolution and ReportingQuality Dept.QC: Quality ControlQSA: Quality System AssessmentDBS: Delphi Business SystemPDP: Product Development ProcessAPQP: Advanced Product Quality Planning and Control Plan PPAP: Production Part ApprovalSPDP: Supplier Performance Development ProcessMSA: Measurement System AnalysisSPC: Statistic Process ControlFMEA: Failure Mode And Effects AnalysisCSE: Customer Support EngineerIP: Improvement PlanDOE : Design of ExperimentsGage R&R : Gage Repeatability and Reproducibility SQIP: Supplier Quality Improvement Process GD&T : Geometric Dimensioning and Tolerancing PR/R : Problem Resolution and ReportingAE Dept.PDP: Product Development Process--PI: Product Initiation--CD: Concept Direction--CA: Concept Approval--PA: Product ApprovalAE: Application EngineeringOTS: Off- Tool- SamplesSOP: Start of ProductionOS: Start null seriesCKD: Comletely Knocked DownMPI: Muli Point InjectionPDM: Product Description ManualABS: Anti-Blacker- SystemEOP: End of ProductionCES: CATIA Electric SystemGPS: Global Positioning SystemAT: Automatic TransmissionAC: Air ConditionTDI: Turbo direction injectionSDI: Suck Diesel InjectionCAN: Controller Area NetworkSKD: Semi Knocked DownCVT: Continuously Variable TransmissionDUM: Digital Mock UpADP: Delphi Advanced Development ProcessEngineering Dept.M & TD: Machine & Tool DesignPCT: Planned Cycle TimeSWIP: Standard Work In ProcessCAD: Computer Aided DesignCAE: Computer Aided EngineeringCAM: Computer Aided ManufacturingCIP: Continuous Improvement ProcessDFA: Design for AssemblyDFE: Design for EnvironmentDFM: Define for ManufacturabilityDFMEA: Design Failure Mode and Effects AnalysisEBOM: Engineering Bill of MaterialEWO: Engineering Work OrderFM : Flow ManufacturingM-BOM: Manufacturing Bill of MaterialFinance Dept.ICRQ: Internal Control Review QuestionnairesTTM: Total travel managementABC: Analysis based on costFARS: Financial Accounting and Reporting StaffCFPR: Corporate Financial Policy & ReportingD-CAP: Delphi Corporate Accounting PoliciesOthersE/EDS: Electric/Electronic Distribution SystemDCS: Delphi Connection SystemDMS: Delphi Mechtronic SystemOCM: Organizational change ManagementAIAG: Automotive Industries Action GroupAPP: Advance Purchasing ProcessAR: Appropriation RequestASQC: American Society for Quality ControlCAMIP: Continuous Automotive Marketing Information Program CAPPLAN : Capacity Planning SystemCMVSS : Canadian Motor Vehicle Safety StandardsCP: Critical PathCPM : Critical Path MethodDD: Design and DevelopmentDV: Design ValidationFEA: Finite Element AnalysisIDR: Interim Design ReviewKCC: Key Control CharacteristicKCDS: Key Characteristic Designation SystemKPC: Key Product CharacteristicMRD: Material Required DateMVSS: Motor Vehicle Safety StandardsP-BOM: Product Bill of MaterialPC: Problem CommunicationPDR: Preliminary Design ReviewPL: Project LaunchPM: Project ManagementPR: Performance ReviewPRR: Production Readiness ReviewPV: Product ValidationPVR: Process Validation ReviewQFD: Quality Function DeploymentQRDP: quality, reliability, durability, and performance RASI: responsibility matrixRC: Requirements and ConceptsRR: Requirements ReviewSORP: Start of Regular ProductionSOW: Statement of WorkTALC: Trim-Appearance-Lighting-ColorTDP: Delphi Technology Development ProcessTIR: Test Incident ReportTSM: Trade Study MethodologyVSM: Variation Simulation ModelingWBS: Work Breakdown Structure。

带翻译常用英文缩写词带翻译

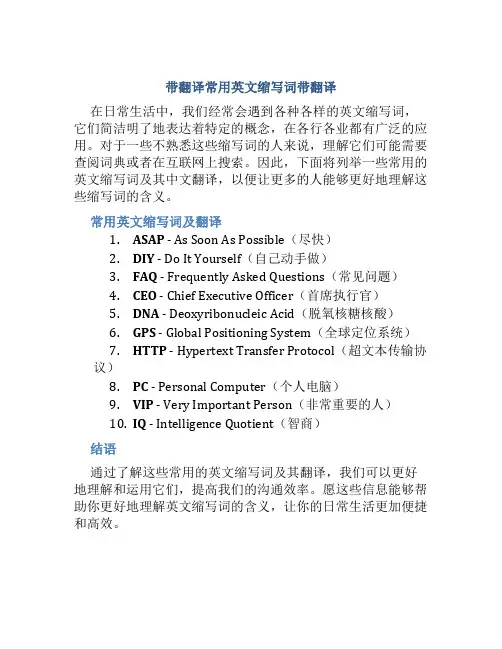

在日常生活中,我们经常会遇到各种各样的英文缩写词,它们简洁明了地表达着特定的概念,在各行各业都有广泛的应用。

对于一些不熟悉这些缩写词的人来说,理解它们可能需要查阅词典或者在互联网上搜索。

因此,下面将列举一些常用的英文缩写词及其中文翻译,以便让更多的人能够更好地理解这些缩写词的含义。

常用英文缩写词及翻译

1.ASAP - As Soon As Possible(尽快)

2.DIY - Do It Yourself(自己动手做)

3.FAQ - Frequently Asked Questions(常见问题)

4.CEO - Chief Executive Officer(首席执行官)

5.DNA - Deoxyribonucleic Acid(脱氧核糖核酸)

6.GPS - Global Positioning System(全球定位系统)

7.HTTP - Hypertext Transfer Protocol(超文本传输协

议)

8.PC - Personal Computer(个人电脑)

9.VIP - Very Important Person(非常重要的人)

10.IQ - Intelligence Quotient(智商)

结语

通过了解这些常用的英文缩写词及其翻译,我们可以更好地理解和运用它们,提高我们的沟通效率。

愿这些信息能够帮助你更好地理解英文缩写词的含义,让你的日常生活更加便捷和高效。

常用英文缩写(英语星期月份等)星期星期一:Mon.=Monday星期二:Tues.=Tuesday星期三:Wed.=Wednesday星期四:Thur.=Thurday星期五:Fri.=Friday星期六:Sat.=Saturday星期天:Sun.=Sunday月份一月份=JAN. Jan.=January二月份=FEB. Feb.=February三月份=MAR. Mar.=March四月份=APR. Apr.=April五月份=MAY May=May六月份=JUN. Jun.=June七月份=JUL. Jul.=July八月份=AUG. Aug.=August九月份=SEP. Sept.=September十月份=OCT. Oct.=October十一月份=NOV. Nov.=November十二月份=DEC. Dec.=December注意:“.”不能省略!!!这里给大家个例子,比如今天2007年3月20日Mar.20,2007写日期时,可以用基数词(避免出现不必要的失误)1,2,3,4,5,。

28,29,30,31等。

怎样用英语表达年、月、日一、年份在英语中,年份一般用阿拉伯数字写出,其读。

写方法有以下几种:1、四位数的年份,一般前两个数为一个单位,后两个数为一个单位,依次按基数词读出。

如:1763年写作:1763读作:seventeen sixty-three或seventeen hundred and sixty-three2006年写作:2006。

读作:two thousand and six2063年写作:2063。

读作:twenty sixtythree或twenty hundred and sixty-three1050年写作:1050。

读作:ten fifty或ten hundred and fifty 海量范文写作/2、三位数的年份,可以按基数词读出,或者第一个数字为一个单位,后两个数字为一个单位,按基数词读出。

常用縮寫中英文對照表英文縮寫英文名稱中文名稱A/D analog to Digital Convert 模數轉換AD Administration Department 總管理處AFEP Analog Front-End Processor 模擬制程ALU Arithmetic Logic Unit 運算器算朮邏輯部件AMF Americas Manufacturing facilities 美制設備AO Actual Output 實際產出AO Audit Office 稽核室APC Auto-Power Control 自動功率控制AFCC Asia Pacific Customer Center 強大客服中心AQL Acceptable Quality Level 允收品質水準ASL Approved Supplier List 合格料件名錄ASP Analog Signal Processing 模擬信號處理ATER ATIP Error Rate ATIP錯誤率ATIP Absultc Time In Progroove 預刻溝橫槽的絕對時間AVL Approved Vendor List 合格供應商名錄BIOS Basic Input Output System 基本輸入輸出系統BLER Block Error Rate 塊錯誤率BOM Bill OF Material 物料清單CL Control Line 管制線CA Corrective Action 糾正措施CAD Computer Aided Design 電腦輔助設計CAR Corrective Action Request 糾正措施請求單CAV Corrective Action Velocity 角速度CC Computer Center 電腦中心CD Compact Disc 壓縮碟片CD-R CD Recordable 一次刻錄壓縮碟片CD-ROM CD Read Only Memory 壓縮碟片只讀存儲器CD-RW CD Rewritable 可重復燒錄壓縮碟片CESO Center Servo Output 中心伺服輸出CIFIR Combined Initial Field Incident Rate 試裝區異常率CIP Continuous Improvement Process 持續流程改善CKIN Clock In 時鐘輸入CLCA Closed Loop Corrective Action 糾正持續循環改善CLV Constant Linear Velocity 線速度CND Can Not Duplicate 不可重復COB Chip-on-board 電路板晶片線COE Charter Of Expectations 期望值CPK Process Capability 制程能力CPU Central Processing Unit 中央處理器常用縮寫中英文對照表英文縮寫英文名稱中文名稱CRP Capacity Requirement Plan 產能需求計劃CS Center Servo 中心伺服CSD Customer Service Delivery 客戶服務D/A Digital to Analog Contert 數模轉換DAC Disc Application Code 碟片申請代碼DAO Disc At Once 碟片方式一次刻錄DART Dell Acceptance Reliability Dell可接受可靠度測試DMEA Disk motor Servo Output 碟片馬達脈沖DMSO Disk Motor Enable 磁片馬達伺輸出DOW Disc Once Write 一次碟片刻錄DPMU Defects Per Hundred Units 不良百分比DPPM Defective Part Per Million 每百萬不良率DRAM Dynamic RAM 動態隨機存儲器DSP Dell Service Provider Dell 服務供應DSP Digital Signal Processing 數字信號處理DVD Digital Video Disc 數字視頻磁片ECC Error Correction Code 錯誤糾正碼ECD Error Detection Code 錯誤驗證碼ECN Engineering Change Notification 工程變更通知ECO Engineering Change Order 工程變更通知ECR Engineering Change Request 工程變更請求EEPROM Electrically EPROM 電可擦編程式只讀存儲器EMF European Manufacturing Facilities 制設備EMR Electromechanical Repair 電器設備維護EMS Expanded Memory Specification 擴充內存規範EMS Environment Management System 環境管理體系EPROM Eraseble Programmable ROM 可擦可編程式只讀存儲器ERP Enterprise Resource Planning 企業資源規則ESD Electronic Static Discharge 靜電防護ESG Enterprise Systems Group 企業系統FA Failure Analysis 不良分析FA Financial & Accounting Department 財會部FAI First Article Inspection 首件檢驗FAQ Frequently Asked Questions 常見問答FCS First Customer Ship 首家出貨FEO Focus Error Output 聚集誤差輸出FG Frequency Generalor 頻率發生器FIFO First-in –first-out 先進行出FM Factory Manager Office 廠長室常用縮寫中英文對照表英文縮寫英文名稱中文名稱FMSO Feed Motor Servo Output 遞給馬達伺服輸出FOSO Focusing Servo Output 聚集伺服輸出FR Forword Reverse 逆轉GA General Affairs 總務部GM General Manager Office 總經理室GR&R Gage Repeatability &Reproducibility 量具之再現性與重復性GSQE Global Supplier Quality Engineer 世界供應商品質工程H/I Hand Insert 手插HR Human Resources 人力資源部IC Integrated Circuit 集成電話IDE Interface Driver Electronic 電子設備介面IE Industrial Engineering 工業工程IFIR Initial Field Incident Rate 市場不良率IO Import/Export Department 進出口部IQA Incoming Quality Audit 內部稽核IQA Incoming Quality Assurance 進料品質保証IQC Incoming Quality Control 進料品質控制IRD Intergrated Receiver Decoder 整合收訊解碼器ISO International Organization For Standardization 國際標准組織ISRC International Standard Recording Code 國際標准化記錄代碼IT Information Technology 資訊技朮JQE Joint Quality Engineer 品質聯絡工程LBN Logical Block Control 邏輯塊序號LDC Laser Diode Control 雷射控制LDIN Loader IN 加戰LDO Laser Diode Output 雷射輸出LED Light Emitting Diode 發光二極管LIMIT Limit Switch 極限開關LOB Line Of Business 商業線LRCK Left Right Clock 左右聲道時種信號LRR Line Reject Rate 線上不良率LTPD Lot Tolerance Percent Defective 批次的容忍不良率MAD Mean Absolute Deviation 平均絕差ME Mechanics Engineering 機構工程MIS Management Information System 管理資訊系統MMC Multi Media Command 多媒體命令MPEG Motion Picture Experts Group 運動圖像專家組(圖聲標准) MPS Master Production Schedule 主生產排程MQE Manufacturing Quality Engineer 製造品質工程常用縮寫中英文對照表英文縮寫英文名稱中文名稱MRB Material Review Board 物料簽審辦法MRP Material Requirement Plan 物料需求計劃MSA Measurement System Analysis 測量系統分析MTBF Mean Time Between Failures 平均故障間隔時間MWD Missing,Wrong,Damaged性漏件,錯件,損傷NFF No Fault Found 無不良發現NIST National Instisute of Standards & Technology 國際工業標准工程NFPR Normalize Push-Pull Ration 標准推拉式配置NWS Normalized Wobble Signal 標准抖動信號OBA Out of Box Audit 開箱檢驗OCM Operational Commodity Manager 日常運作管理OEMA Optical Disc Manufacturers Associztion 光碟製造協會OEM Optical Equipment Manufacturing 代加工OIP Outgoing Inspection Plan 出貨檢驗計劃OPC Optical Power Control 鐳射能量控制OPU Optical Pick-up Unit 光學拾取器OQC Out-going Quality Control 出貨檢驗ORT Ongoing Reliability Testing 持續性可靠度試驗OSTA Optical Storage Technology Association 光學存儲技術協會OTETF On Time First Time Fix 及時整理PCA Power Calibration Area 能量校正區PCB Print Circuit Board 印刷電路板PD Purchasing Department 采購部PE Production Engineering 製造工程PG Product Group 製造部PIC Person in charge 負責人PLL Phase-Locked Loop 鎖相環PM Process Maintenance 保養PMA Process Management Area 能量儲存區PMP Process Management Plan 制程管理計劃PO Public Relation Office 公關室PP Production Planning Department 資材部PP Push-Pull 推拉式PPID Piece Part Indentification 零件標式PQC Process Quality Control 制程檢驗PRP Phase Review Process 相變過程PSG Personal Systems Group 個人系統PUH Pick-Up Head 拾取頭QBR Quality Business Review 每季商業評估常用縮寫中英文對照表英文縮寫英文名稱中文名稱QC Quality Control 品質控制QC Quality Control Department 品管部QCC Quality Control Circle 品管圈QE Quality Engineering 品質工程QMP Quality Control Plan 品質管理計劃QMS Quality Management System 品質管理體系QPA Quality Process Audit 制程品質稽核QSA Quality Systems Audit 品質系統稽核QSL Qualified Supplier List 料件承信廠商RAM Read Acess Memory 隨機存領儲器RF Radio Frequeney 高頻射頻RFGC RF Gain Control RF增益控制RFGO RF Gain Output RF增益輸出RFGS RF Gain Select RF增益選擇RFQ Request For Quote 提出請求RFRP RF Ripple 高頻波射頻波PFRST RF Reset RF 復位RFZC RF Zero Crossing RF零點交錯RMA Return Merechandise Authoriz 退貨處理RN Radial Noise 射線干擾ROM Read Only Memory 只讀存儲器ROPC Run OPC 啟動OPCRSQE Regional Supplier Quality Engineer 區域供應商品質工程RTS Ready to ship 准備出貨RTV Return To Vendor 退回供應商S/H Sample & Hold 樣品保留SAO Session At Once 節區方式一次燒錄SB Short Brake 剎車SBAD Sub Beam Adder 協累加器SBSY Sub Block Synochronization 塊同步SCAR Supplier Corrective Action Request 供應商糾正措施需求單SCM Strategic Commodity Manager 日常策劃管理SCSI Small Computer System Interface 小型計算機接口SCT Strategic Commodity Team 日常策劃小組SDRAM Synehronization DRAM 同步動態隨機存儲器SFCS Shop Floor Control System 現場管理系統SFSY Sub Frame SynchrenizationSIP Standard Inspection Plan 標准檢驗計劃SLD Start Leadin Diameter 導入區啟始之直徑常用縮寫中英文對照表英文縮寫英文名稱中文名稱SMC Surface Mount Component 無源表面貼片元件SMD Surface Mount Device 有源表面貼片技術SMT Surface Mount Technology 表面貼片技術SOP Standard Operation Procedure 標准作業程序SOSA Supplier Online Scorecard Application 供應商記錄請求SPC Statistic Process Control 統計制程管制SPD Start Program Diameter 程序區啟始之直徑SQE Supplier Quality Engineer 供應商品質工程SQS Supplier Quality Standard 供應商品質標准SRAM Static RAM 靜態隨機存儲器STR Shared Technology Resourece Groups 技術支援分享STS Ship-To-Stock 材料免檢STT Ship To Target 出貨至目的地TL Target Line 目標線TAO Track At Once 軌跡方式一次刻錄TE Testing Engineer 測試工程TEBC Tracking Error Balance ControlTEO Track Error OutputTOC Table Of ContentsTQC Total Quality ControlTRSO Tracking Servo Output 循跡誤差伺服輸出TTL Technical Transfer List 技術轉移清單TTR Technology Transtition Roamaps 技術轉移流程TVC Total Variable Cost 總變動成本UAL Use AS Is 特采UDF Universal Disk Format 通用碟片格式化UPC Universal Product Code 通用產品代碼VIFIR Verified Initial Field Incident Rate 驗證市場不良率VLRR Verified Line Refect Rate 指導驗證線上不良率W/I Working Instruction 作業說明書WCNR CNR Of Wobble CNR抖動WIP Work In Process 作業中WWP Worldwild Procurement 采購。

常见英语缩写词和翻译汇总表

在英语中,缩写词是经常出现的一种语言现象,它们可以

简化表达,提高交流效率。

有些常见的英语缩写词已经被广泛应用,但对于一些新手来说,这些缩写词可能会造成困惑。

本文将介绍一些常见的英语缩写词及其翻译,以帮助读者更好地理解和运用这些缩写词。

缩写词列表

以下是一些常见的英语缩写词及其对应的中文翻译:

1.ASAP:as soon as possible - 尽快

2.DIY:do it yourself - 自己动手做

3.FAQ:frequently asked questions - 常见问题

4.VIP:very important person - 极重要的人物

5.CEO:chief executive officer - 首席执行官

6.GPS:global positioning system - 全球定位系统

7.RSVP:répondez s’il vous plaît (French) - 请回复

8.FYI:for your information - 供您参考

9.TGIF:thank goodness it’s Friday - 感谢上帝,今天

是星期五

10.SOS:save our souls - 救命

缩写词的使用

这些缩写词通常用于书面或口语交流中,可以帮助简化表达,缩短句子长度,提高交流效率。

例如,在写邮件或聊天时,使用ASAP代替。