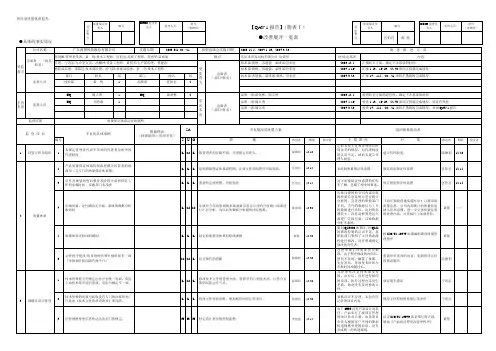

kaizen改善登记表

- 格式:xls

- 大小:23.50 KB

- 文档页数:2

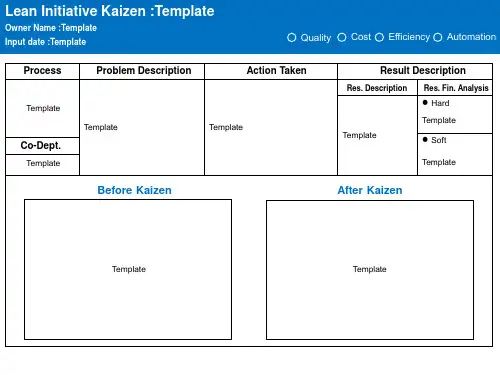

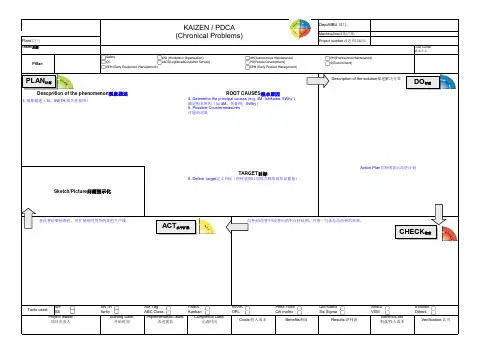

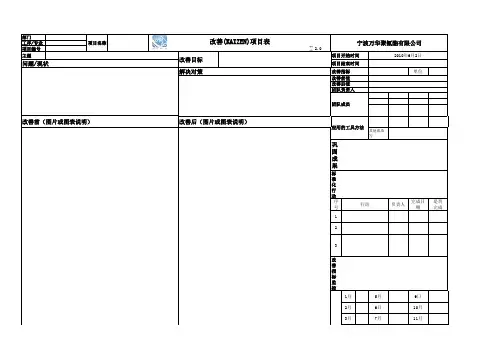

Dept/MBU 部门:Machine/line 设备/产线:Project number.改进项目编号:Cost Center 成本中心Pillar:4M 5W1H AM Tag FMEA NVAAPoka Yoke QM Matrix SMED X Matrix 5S5whyABC Class.Kanban OPLQA matrixSix SigmaVSMOthersStarting Date:开始时间Implementation team:改进团队Completion Date:完成时间Costs:投入成本Benefits 利益Results:净利润Benefit/Cost 利益/投入成本Verification:认可Tools used:Sketch/Picture 问题图示化改善前/改善中/改善后的不良柱状图,并用一句话总结改善的效果。

将改善结果标准化,并扩展到同类型的其他生产线Project leader 项目负责人KAIZEN / PDCA (Chronical Problems)Plant 工厂:Theme 主题:Action Plan 甘特图表示改进计划Description of the solution 描述解决方案Descprition of the phenomenon 现象描述ROOT CAUSES 根本原因6. Define target 定义目标(用柱状图计划每月降低的坏品数量)TARGET 目标1. 现象描述(如:5W1H,损失柱状图)4. Determine the principal causes (e.g. 4M, Ishikawa, 5Why )确定根本原因(如 4M ,鱼骨图,5Why )5. Possible Countermeasures 可能的对策3 DM10h PLAN DO 行动CHECK 检查ACT 水平扩展PLAN 计划SafetyWO (Workplace Organisation)AM(Autonomous Maintenance)PM(Professional Maintenance)QCL&CS(Logistica&Customer Service)EEM (Early Equipment Management)PD(People Development)E(Environment)EPM (Early Product Management)。

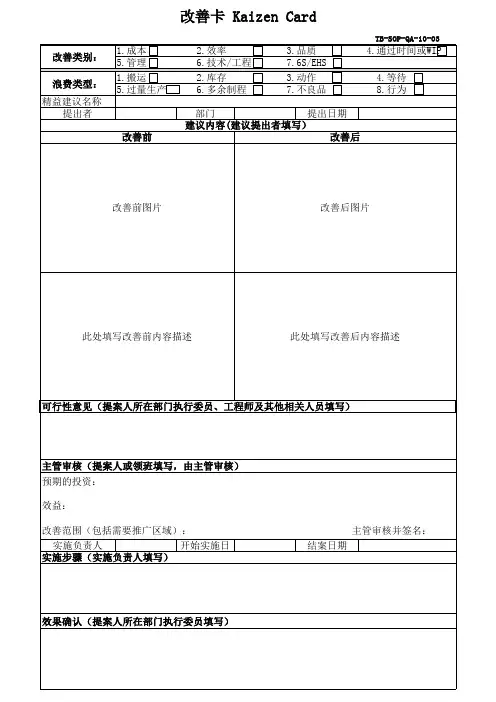

Kaizen活动管理办法(节选)1 目的为了深入推进精益生产管理活动,规范、鼓励员工对工作现场点点滴滴的改善活动,持续不断地开展改善工作,特修订Kaizen活动管理办法。

2 适用范围本办法适用于全公司。

3 定义3.1 Kaizen:是一个日语词汇,意指小的、连续的、渐进的改进。

企业通过改进一系列生产经营过程中的细节活动,如持续减少非增值活动、消除原材料浪费、改进操作程序、提高产品质量、缩短产品生产时间、不断地激励员工。

它要求每一位管理人员及作业人员,要以相对较少的费用来持续不断地改进工作。

3.2 Kaizen改善项目:员工在工作中发现有浪费现象,并实施改进,同时突出持续改善的项目。

3.3 优秀Kaizen项目:是指完成难度较大,安全及经济效果较为明显的改善项目,可以是独立完成,也可以是他人或多人完成。

3.4 改善之星:指对公司Kaizen活动有突出贡献的先进个人(或班组),评选依据是员工(或班组)在评审时段内提出并已得到落实的Kaizen改善项目的总数量和总积分。

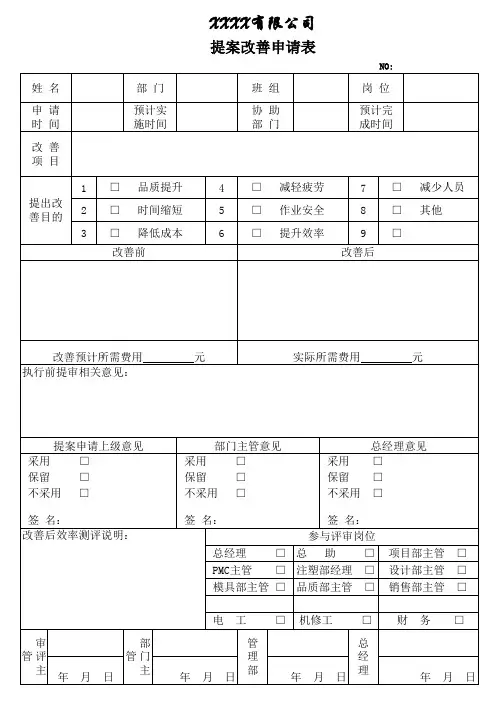

5 工作程序员工提出改善建议,经主管线长(室主任、科长)或厂长(部长)确认后,才可执行。

执行后,填写“Kaizen项目登记表”(见原制度附表1),在本部门Kaizen管理员处登记,并由Kaizen管理员每月5日前汇总后报推进办公室,汇总内容包括“部门Kaizen项目汇总表”(见原制度附表2),“部门员工Kaizen数量积分统计表”(见原制度附表3),“Kaizen优秀项目登记表”(见原制度附表4)。

工作流程如下:6 控制要求6.1 Kaizen活动主要强调:全员参与,着重身边微小的浪费,每天都改善(持续改善)。

改善尽量为自己工作范围内,可由自己完成,或由自己部门内同事帮助即可完成。

员工开展改善前必须经直属基层领导同意后方可行动,涉及安全、环保、产品质量方面的改善项目必须经主管单位部级以上领导同意。

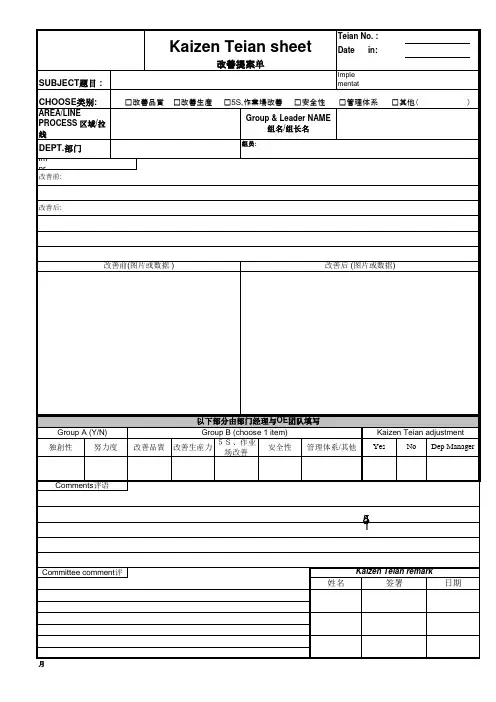

6.2 实施改善项目,应及时填报“Kaizen项目登记表”,描述改善前后的内容和工作重点,尽量附改善活动实施前后的照片,经直接主管审核后交本单位Kaizen管理员汇总和评分、积分。

KAIZEN表格(PDCA循环)Dept/MBU 部门:Machine/line 设备/产线:Project number.改进项目编号:Cost Center 成本中心Pillar:4M 5W1H AM Tag FMEA NVAAPoka Yoke QM Matrix SMED X Matrix 5S5whyABC Class.Kanban OPLQA matrixSix SigmaVSMOthersStarting Date:开始时间Implementation team:改进团队Completion Date:完成时间Costs:投入成本Benefits 利益Results:净利润Benefit/Cost 利益/投入成本Verification:认可Tools used:Sketch/Picture 问题图示化改善前/改善中/改善后的不良柱状图,并用一句话总结改善的效果。

将改善结果标准化,并扩展到同类型的其他生产线Project leader 项目负责人KAIZEN / PDCA (Chronical Problems)Plant 工厂:Theme 主题:Action Plan 甘特图表示改进计划Description of the solution 描述解决方案Descprition of the phenomenon 现象描述ROOT CAUSES 根本原因6. Define target 定义目标(用柱状图计划每月降低的坏品数量)TARGET 目标1. 现象描述(如:5W1H,损失柱状图)4. Determine the principal causes (e.g. 4M, Ishikawa, 5Why )确定根本原因(如4M ,鱼骨图,5Why )5. Possible Countermeasures 可能的对策3 DM10h PLAN DO 行动CHECK 检查ACT 水平扩展PLAN 计划SafetyWO (Workplace Organisation)AM(Autonomous Maintenance)PM(Professional Maintenance)QCL&CS(Logistica&Customer Service)EEM (Early Equipment Management)PD(People Development)E(Environment)EPM (Early Product Management)。

注:改善之星改善项目未全部列出,详请查看kaizen登记表

制度说明

制度是以执行力为保障的。

“制度”之所以可以对个人行为起到约束的作用,是以有效的执行力为前提的,即有强制力保证其执行和实施,否则制度的约束力将无从实现,对人们的行为也将起不到任何的规范作用。

只有通过执行的过程制度才成为现实的制度,就像是一把标尺,如果没有被用来划线、测量,它将无异于普通的木条或钢板,只能是可能性的标尺,而不是现实的标尺。

制度亦并非单纯的规则条文,规则条文是死板的,静态的,而制度是对人们的行为发生作用的,动态的,而且是操作灵活,时常变化的。

是执行力将规则条文由静态转变为了动态,赋予了其能动性,使其在执行中得以实现其约束作用,证明了自己的规范、调节能力,从而得以被人们遵守,才真正成为了制度。