服装检验报告中英文电子版

- 格式:xls

- 大小:35.50 KB

- 文档页数:2

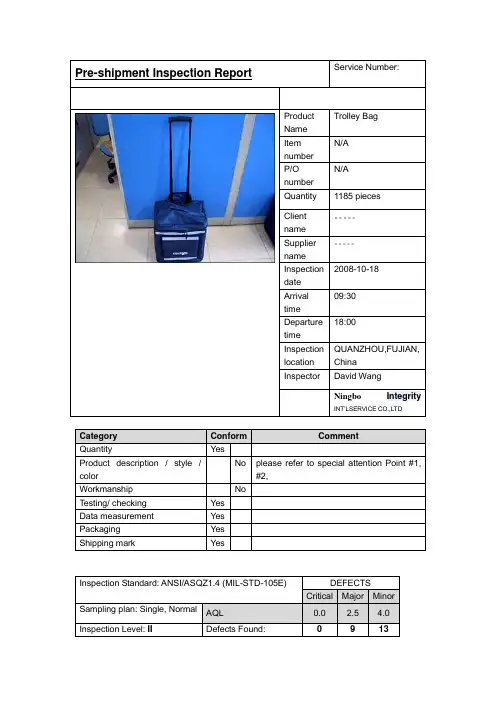

Pre-shipment Inspection Report Service Number: Summary SectionProductNameTrolley BagItemnumberN/AP/OnumberN/AQuantity 1185 piecesClientname。

Suppliername。

Inspectiondate2008-10-18Arrivaltime09:30Departuretime18:00Inspection location QUANZHOU,FUJIAN, ChinaInspector David WangNingbo IntegrityINT’LSERVICE CO.,LTDCategory Conform CommentQuantity YesProduct description / style / color No please refer to special attention Point #1, #2,Workmanship NoTesting/ checking YesData measurement YesPackaging YesShipping mark YesInspection Standard: ANSI/ASQZ1.4 (MIL-STD-105E) DEFECTSCritical Major Minor Sampling plan: Single, Normal AQL 0.0 2.5 4.0Inspection Level: II Defects Found: 0 9 13QuantityProduct description / style / colorspecificationCheck against sample submitted by client:Discrepancy was found on inspection samples, please refer to Special Attention point # 1 & #2.WorkmanshipDefectives ListDefectivesListDefectivesCRI MAJ MIN PictureDescription0 0 8Wrinkle markon fabricDirty stains 0 0 5DefectivesListDefectives ListDefectivesDescriptionCRI MAJ MIN PictureHandle standslant ( can beused)0 9 0TESTING /CHECKINGFunction test on handle, wheel, zip and Velcro.Performed on all seletced samples, the result was passed.Function checking for Velcro tape/zip Performed all selected samples, the result was acceptablePull test at handle strap by hand normal force Performed on S-3 samples, the result was passed.Adhesive test by tapes Performed on S-3 samples, Noprinting peel off, the result waspassedSize measure performed on 5 pcs samples,result is below measurement table.Internal Check performed on 5 pcs samples,Discrepancy was found oninspection samples, please refer toSpecial Attention point # 1 & # 2.(Page 2).Mass productions Approved sampleGap locationCarton Drop Test from 76cmheight, drop 10 times at 1 corner, 3edges and 6 faces.Performed on 3 cartons, the resultwas passedDATA MEASUREMENTSize MeasurementItems Spec.(cm)Samples1 2 3 4 5Product size (L * W * H) N/A 36 * 26.5* 4036 * 26.5* 4036 * 26.5* 4036 * 26.5* 4036 * 26.5* 40Side pocket23*25 23*24.5 23*24.5 23*24.5 23*24.5 23*24.5 Logo printing(L * W)N/A 11 * 2.6 11 * 2.6 11 * 2.6 11 * 2.6 11 * 2.6PE boardthickness onbottom and backpart4.0mm 4.0mm 4.0mm 4.0mm 4.0mm 4.0mmPE boardthickness around3 sides3.0mm 3.0mm 3.0mm 3.0mm 3.0mm 3.0mmGross Weight ofexport cartonN/A 5.0 KGS 5.1 KGS 5.2 KGS 5.0 KGS 5.0 KGSSize of Export carton N/A 39 * 32 *44cm39 * 32 *44cm39 * 32 *44cm39 * 32 *44cm39 * 32 *44cmPackagingUnit packingEach product was packed into anindividual poly bag ,sealed onopeningOuter packing Carton size: 39 * 32 * 44cm1 pc with an instruction sheet packed ina carton which fixed by 1 nylon strap.Shipping markShipping MarkFront mark Side markOther markingBar code label on CartonPrinting logo on bag Other PicturesSewn label Sewn label (back)Instruction sheet Bottom viewString on zipper puller Compare with approved sample (rightside one)CartonsTotal cartons Inspected cartons。

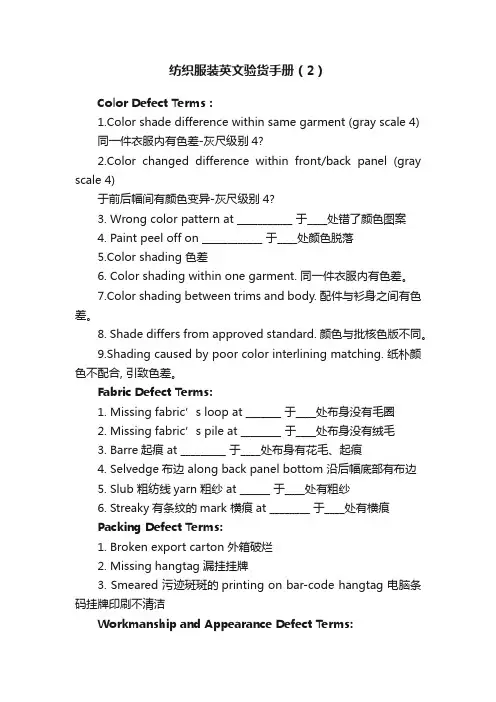

纺织服装英文验货手册(2)Color Defect Terms :1.Color shade difference within same garment (gray scale 4)同一件衣服内有色差-灰尺级别4?2.Color changed difference within front/back panel (gray scale 4)于前后幅间有颜色变异-灰尺级别4?3. Wrong color pattern at ___________ 于____处错了颜色图案4. Paint peel off on ____________ 于____处颜色脱落5.Color shading 色差6. Color shading within one garment. 同一件衣服内有色差。

7.Color shading between trims and body. 配件与衫身之间有色差。

8. Shade differs from approved standard. 颜色与批核色版不同。

9.Shading caused by poor color interlining matching. 纸朴颜色不配合, 引致色差。

Fabric Defect Terms:1. Missing fabric’s loop at _______ 于____处布身没有毛圈2. Missing fabric’s pile at ________ 于____处布身没有绒毛3. Barre起痕 at _________ 于____处布身有花毛、起痕4. Selvedge布边 along back panel bottom 沿后幅底部有布边5. Slub 粗纺线yarn 粗纱 at ______ 于____处有粗纱6. Streaky有条纹的mark 横痕at ________ 于____处有横痕Packing Defect Terms:1. Broken export carton 外箱破烂2. Missing hangtag 漏挂挂牌3. Smeared 污迹斑斑的printing on bar-code hangtag 电脑条码挂牌印刷不清洁Workmanship and Appearance Defect Terms:( Defect on Appearance外观缺陷)1. Asymmetric collar in size 、shape and length 衣领不对称2. Deformed 畸形的shell neck shape 领型不正3. Exceed shell mesh at ______ 于____处之面布网布过多4. Exposed under placket at top after button fasten 于扣扭处露底贴5. High-low pocket top 高低袋顶6. High-low sleeve slit 高低袖叉7. Missing a part of embroidery 没有了部分绣花8. Non-center embroidery 绣花不居中9. Pleat at _______ 于____处打死褶10. Poor pressing at ________ 于____处熨工差11. Puckering at ________ 于____处打褶12. Slant bottom 斜衫脚13. Slant embroidery pattern at right and left bottom/under armhole于衣脚及夹底处车花斜了14. Slant pocket 斜袋15. Slant shoulder seam to front panel 膊骨斜向前幅16. Slant sleeve placket/slit/vent 袖叉歪斜17. Twisted hem at ______ 于____处起豆角边18. Twisted seam at _____ 于____处扭骨19. Twisted sleeve/body at side seam 于袖子或衫身侧骨处扭骨20. Twisted tape/stripe/ strap 扭带21. Uneven side slit /vent at front and back side 于前后幅间的脚叉不对称22. Wavy at _______ 于____处起波浪23.Hiking at front, CF facing too short 吊襟 =ride up24.Hiking at back, lining too short 吊里25.Curve at CF zip(too much fullness at CF zip) 前中拉链溶位太多26.Curve at CF zip because of no easing of zipper. 前中拉链无溶位(引致纽曲)27.Hiking at back / Hiking at front 后幅吊起 / 前幅吊起:28.Front panel is bigger than under panel(lining) 前幅底幅细面幅松29.Lining too big, too short, too small, too long 里布太大, 太短, 太小, 太长30.Grain lines are not match at front & back panel 前后幅布纹不相称31.Front length uneven 左右前长不一致;32.Too loose at shell, Too loose at back/lining, turn insider out 底松, 面松, 向外反33.Seam binding stitch tension is too tight, causing bottom not smooth. 下摆丝带过紧, 使下摆不平顺34.Bottom hem is not in line / not straight. 下脚不够不平(直). =uneven/misaligned35.Twisting hem, puckering at hem 下脚纽纹起豆角.36.Uneven hem 左右下摆高低不一37.Vent length uneven 左右开叉长短不一马甲vest38.Uneven leg length 长短脚39.Uneven hem line 衫脚不平均 / 不对称40.bottom hem is not in line / not straight. 下脚不够不平(直)41.Twisting hem, puckering at hem 下脚纽纹起豆角..https://www./。

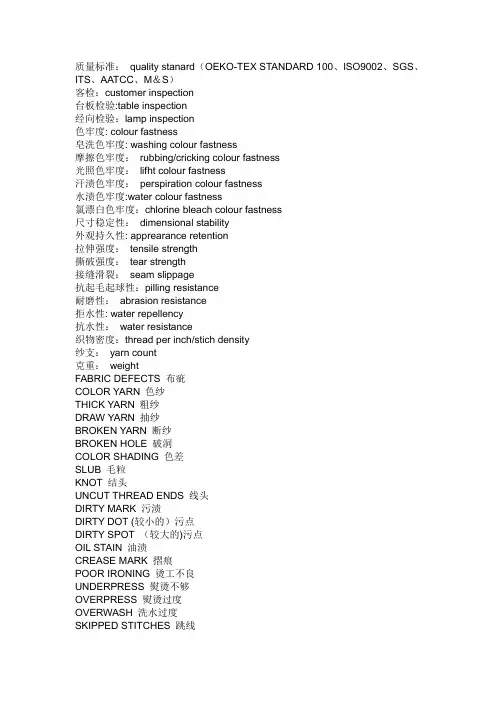

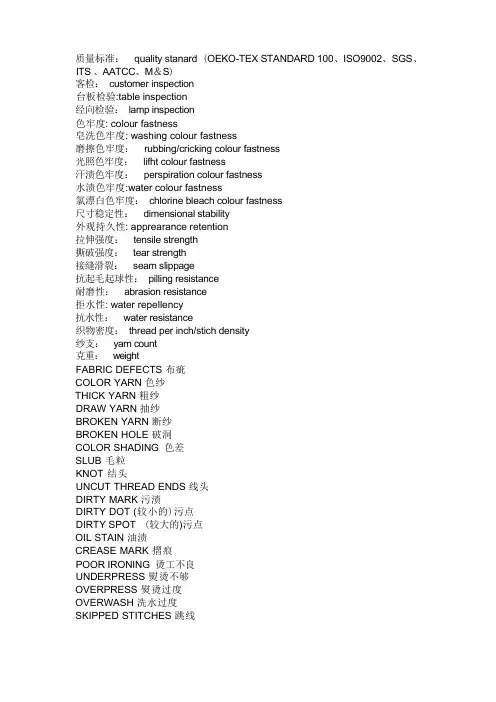

质量标准:quality stanard(OEKO-TEX STANDARD 100、ISO9002、SGS、ITS、AATCC、M&S)客检:customer inspection台板检验:table inspection经向检验:lamp inspection色牢度: colour fastness皂洗色牢度: washing colour fastness摩擦色牢度:rubbing/cricking colour fastness光照色牢度:lifht colour fastness汗渍色牢度:perspiration colour fastness水渍色牢度:water colour fastness氯漂白色牢度:chlorine bleach colour fastness尺寸稳定性:dimensional stability外观持久性: apprearance retention拉伸强度:tensile strength撕破强度:tear strength接缝滑裂:seam slippage抗起毛起球性:pilling resistance耐磨性:abrasion resistance拒水性: water repellency抗水性:water resistance织物密度:thread per inch/stich density纱支:yarn count克重:weightFABRIC DEFECTS 布疵COLOR YARN 色纱THICK YARN 粗纱DRAW YARN 抽纱BROKEN YARN 断纱BROKEN HOLE 破洞COLOR SHADING 色差SLUB 毛粒KNOT 结头UNCUT THREAD ENDS 线头DIRTY MARK 污渍DIRTY DOT (较小的)污点DIRTY SPOT (较大的)污点OIL STAIN 油渍CREASE MARK 摺痕POOR IRONING 烫工不良UNDERPRESS 熨烫不够OVERPRESS 熨烫过度OVERWASH 洗水过度SKIPPED STITCHES 跳线BROKEN STITCHES 断线BAD JOIN STITCHES 驳线不良POOR BACK—STITCHES 回针不佳RUN OFF STITCHES 落坑HI/LOW POCKET 高低袋HIKING AT BOTTOM OF PLACKET 前筒吊脚HIKING UP 起吊OPEN SEAM 爆口PUCKER 起皱PLEATED 打褶SLEEVE LENGTH UNEVEN 长短袖SHADING GARMENT TO GARMENT 衫与衫之间色差SHADING WITHIN 1PCS GARMENT 衣服裁片色差TWIST 扭BIG EYELID 大眼皮CENTER BACK RIDES UP 后幅起吊COLLAR POINT HI/LOW 领尖高低COLOR THREAD LEFT INSIDE 藏色线CROSSED BACK VENT 背*搅CUFF FACING VISIBLE 介英反光EXCESS EXTENSION 突咀FLAP STRICKING UP 袋盖反翘FRONT HORIZONTAL SEAM NOT LEVEL 前幅水平缝骨不对称IMPROPER CROSS SEAM AT JOINING SIDE SEAM 袖底十字骨不对LINING TOO FULL/TIGHT 里布太多/太紧MISMATCH CHECKS/STRIPES 格仔/条子不对称NEEDLE HOLE 针孔OFF GRAIN 布纹歪OVERLAPPED COLLAR 叠领OVERLAPPED LIPS 叠唇PULLING AT INSIDE/OUTSIDE SEAM 吊脚RAW EDGE 散口RUBBLING 起泡SCRIMP 印花裂痕SEAM OVERTURN 止口反骨SMILING POCHET 袋“笑口”STRIPES/CHECKS NOT MATCHING 不对条/格THREAD VISIBLE OUTSIDE 缝线外露TWIST LEG 扭髀UNDER THREAD VISIBLE 底线露出UNDERPLY TURN OUT 反光UNDERPLY VISIBLE OUTSIDE 反光UNEVEN COLOR 深浅色UNEVEN LIPS 大小唇UNEVEN SLEEVE LENGTH 长短袖UNEVEN STITCHING DENSITY 针步密度不均匀UNMATCHED CROTCH CROSS 下裆十字骨错位UNMEET BACK VENT 背*豁WAVY AT PLACKET 前筒起蛇(皱)WRONG COMBO 颜色组合错误WRONG PATTERN 图案错误WRONG SIZE INDICATED 错码品质英语—服装质量检验英语FABRIC DEFECTS 布疵COLOR YARN 色纱THICK YARN 粗纱DRAW YARN 抽纱BROKEN YARN 断纱BROKEN HOLE 破洞POOR IRONING 烫工不良UNDERPRESS 熨烫不够OVERPRESS 熨烫过度OVERWASH 洗水过度COLOR SHADING 色差SLUB 毛粒KNOT 结头UNCUT THREAD ENDS 线头DIRTY MARK 污渍DIRTY DOT (较小的)污点DIRTY SPOT (较大的)污点OIL STAIN 油渍CREASE MARK 摺痕SKIPPED STITCHES 跳线BROKEN STITCHES 断线BAD JOIN STITCHES 驳线不良POOR BACK—STITCHES 回针不佳RUN OFF STITCHES 落坑HI/LOW POCKET 高低袋HIKING AT BOTTOM OF PLACKET 前筒吊脚HIKING UP 起吊OPEN SEAM 爆口PUCKER 起皱PLEATED 打褶SLEEVE LENGTH UNEVEN 长短袖SHADING GARMENT TO GARMENT 衫与衫之间色差SHADING WITHIN 1PCS GARMENT 衣服裁片色差TWIST 扭CENTER BACK RIDES UP 后幅起吊COLLAR POINT HI/LOW 领尖高低COLOR THREAD LEFT INSIDE 藏色线CROSSED BACK VENT 背*搅CUFF FACING VISIBLE 介英反光EXCESS EXTENSION 突咀FLAP STRICKING UP 袋盖反翘FRONT HORIZONTAL SEAM NOT LEVEL 前幅水平缝骨不对称IMPROPER CROSS SEAM AT JOINING SIDE SEAM 袖底十字骨不对LINING TOO FULL/TIGHT 里布太多/太紧MISMATCH CHECKS/STRIPES 格仔/条子不对称NEEDLE HOLE 针孔OFF GRAIN 布纹歪OVERLAPPED COLLAR 叠领OVERLAPPED LIPS 叠唇PULLING AT INSIDE/OUTSIDE SEAM 吊脚RAW EDGE 散口RUBBLING 起泡SCRIMP 印花裂痕SEAM OVERTURN 止口反骨SMILING POCHET 袋“笑口”STRIPES/CHECKS NOT MATCHING 不对条/格THREAD VISIBLE OUTSIDE 缝线外露TWIST LEG 扭髀UNDER THREAD VISIBLE 底线露出UNDERPLY TURN OUT 反光UNDERPLY VISIBLE OUTSIDE 反光UNEVEN COLOR 深浅色UNEVEN LIPS 大小唇UNEVEN SLEEVE LENGTH 长短袖UNEVEN STITCHING DENSITY 针步密度不均匀UNMATCHED CROTCH CROSS 下裆十字骨错位UNMEET BACK VENT 背*豁WAVY AT PLACKET 前筒起蛇(皱)WRONG COMBO 颜色组合错误WRONG PATTERN 图案错误WRONG SIZE INDICATED 错码质量标准: quality stanard(OEKO—TEX STANDARD 100、ISO9002、SGS、ITS、AATCC、M&S)客检:customer inspection台板检验:table inspection经向检验:lamp inspection色牢度: colour fastness皂洗色牢度: washing colour fastness摩擦色牢度: rubbing/cricking colour fastness光照色牢度: lifht colour fastness汗渍色牢度: perspiration colour fastness水渍色牢度:water colour fastness氯漂白色牢度:chlorine bleach colour fastness尺寸稳定性: dimensional stability外观持久性: apprearance retention拉伸强度: tensile strength撕破强度: tear strength接缝滑裂: seam slippage抗起毛起球性:pilling resistance耐磨性: abrasion resistance拒水性: water repellency抗水性: water resistance织物密度:thread per inch/stich density纱支: yarn count克重: weightFABRIC DEFECTS 布疵COLOR YARN 色纱THICK YARN 粗纱DRAW YARN 抽纱THREAD VISIBLE OUTSIDE 缝线外露WAVY AT PLACKET 前筒起蛇(皱)APPROVED SWATCH 已批的布办ART. NO。

质量标准:quality stanard (OEKO-TEX STANDARD 100、ISO9002、SGS、ITS 、AATCC、M&S)客检:customer inspection台板检验:table inspection经向检验:lamp inspection色牢度: colour fastness皂洗色牢度: washing colour fastness磨擦色牢度:rubbing/cricking colour fastness光照色牢度:lifht colour fastness汗渍色牢度:perspiration colour fastness水渍色牢度:water colour fastness氯漂白色牢度:chlorine bleach colour fastness尺寸稳定性:dimensional stability外观持久性: apprearance retention拉伸强度:tensile strength撕破强度:tear strength接缝滑裂:seam slippage抗起毛起球性:pilling resistance耐磨性:abrasion resistance拒水性: water repellency抗水性:water resistance织物密度:thread per inch/stich density纱支:yarn count克重:weightFABRIC DEFECTS 布疵COLOR YARN 色纱THICK YARN 粗纱DRAW YARN 抽纱BROKEN YARN 断纱BROKEN HOLE 破洞COLOR SHADING 色差SLUB 毛粒KNOT 结头UNCUT THREAD ENDS 线头DIRTY MARK 污渍DIRTY DOT (较小的)污点DIRTY SPOT (较大的)污点OIL STAIN 油渍CREASE MARK 摺痕POOR IRONING 烫工不良UNDERPRESS 熨烫不够OVERPRESS 熨烫过度OVERWASH 洗水过度SKIPPED STITCHES 跳线BROKEN STITCHES 断线BAD JOIN STITCHES 驳线不良POOR BACK—STITCHES 回针不佳RUN OFF STITCHES 落坑HI/LOW POCKET 高低袋HIKING AT BOTTOM OF PLACKET 前筒吊脚HIKING UP 起吊OPEN SEAM 爆口PUCKER 起皱PLEATED 打褶SLEEVE LENGTH UNEVEN 长短袖SHADING GARMENT TO GARMENT 衫与衫之间色差SHADING WITHIN 1PCS GARMENT 衣服裁片色差TWIST 扭BIG EYELID 大眼皮CENTER BACK RIDES UP 后幅起吊COLLAR POINT HI/LOW 领尖高低COLOR THREAD LEFT INSIDE 藏色线CROSSED BACK VENT 背*搅CUFF FACING VISIBLE 介英反光EXCESS EXTENSION 突咀FLAP STRICKING UP 袋盖反翘FRONT HORIZONTAL SEAM NOT LEVEL 前幅水平缝骨不对称IMPROPER CROSS SEAM AT JOINING SIDE SEAM 袖底十字骨不对LINING TOO FULL/TIGHT 里布太多/太紧MISMATCH CHECKS/STRIPES 格仔/条子不对称NEEDLE HOLE 针孔OFF GRAIN 布纹歪OVERLAPPED COLLAR 叠领OVERLAPPED LIPS 叠唇PULLING AT INSIDE/OUTSIDE SEAM 吊脚RAW EDGE 散口RUBBLING 起泡SCRIMP 印花裂痕SEAM OVERTURN 止口反骨SMILING POCHET 袋“笑口”STRIPES/CHECKS NOT MATCHING 不对条/格THREAD VISIBLE OUTSIDE 缝线外露TWIST LEG 扭髀UNDER THREAD VISIBLE 底线露出UNDERPLY TURN OUT 反光UNDERPLY VISIBLE OUTSIDE 反光UNEVEN COLOR 深浅色UNEVEN LIPS 大小唇UNEVEN SLEEVE LENGTH 长短袖UNEVEN STITCHING DENSITY 针步密度不均匀UNMATCHED CROTCH CROSS 下裆十字骨错位UNMEET BACK VENT 背*豁WAVY AT PLACKET 前筒起蛇(皱)WRONG COMBO 颜色组合错误WRONG PATTERN 图案错误WRONG SIZE INDICATED 错码品质英语—服装质量检验英语FABRIC DEFECTS 布疵COLOR YARN 色纱THICK YARN 粗纱DRAW YARN 抽纱BROKEN YARN 断纱BROKEN HOLE 破洞POOR IRONING 烫工不良UNDERPRESS 熨烫不够OVERPRESS 熨烫过度OVERWASH 洗水过度COLOR SHADING 色差SLUB 毛粒KNOT 结头UNCUT THREAD ENDS 线头DIRTY MARK 污渍DIRTY DOT (较小的)污点DIRTY SPOT (较大的)污点OIL STAIN 油渍CREASE MARK 摺痕SKIPPED STITCHES 跳线BROKEN STITCHES 断线BAD JOIN STITCHES 驳线不良POOR BACK —STITCHES 回针不佳RUN OFF STITCHES 落坑HI/LOW POCKET 高低袋HIKING AT BOTTOM OF PLACKET 前筒吊脚HIKING UP 起吊OPEN SEAM 爆口PUCKER 起皱PLEATED 打褶SLEEVE LENGTH UNEVEN 长短袖SHADING GARMENT TO GARMENT 衫与衫之间色差SHADING WITHIN 1PCS GARMENT 衣服裁片色差TWIST 扭CENTER BACK RIDES UP 后幅起吊COLLAR POINT HI/LOW 领尖高低COLOR THREAD LEFT INSIDE 藏色线CROSSED BACK VENT 背*搅CUFF FACING VISIBLE 介英反光EXCESS EXTENSION 突咀FLAP STRICKING UP 袋盖反翘FRONT HORIZONTAL SEAM NOT LEVEL 前幅水平缝骨不对称IMPROPER CROSS SEAM AT JOINING SIDE SEAM 袖底十字骨不对LINING TOO FULL/TIGHT 里布太多/太紧MISMATCH CHECKS/STRIPES 格仔/条子不对称NEEDLE HOLE 针孔OFF GRAIN 布纹歪OVERLAPPED COLLAR 叠领OVERLAPPED LIPS 叠唇PULLING AT INSIDE/OUTSIDE SEAM 吊脚RAW EDGE 散口RUBBLING 起泡SCRIMP 印花裂痕SEAM OVERTURN 止口反骨SMILING POCHET 袋“笑口”STRIPES/CHECKS NOT MATCHING 不对条/格THREAD VISIBLE OUTSIDE 缝线外露TWIST LEG 扭髀UNDER THREAD VISIBLE 底线露出UNDERPLY TURN OUT 反光UNDERPLY VISIBLE OUTSIDE 反光UNEVEN COLOR 深浅色UNEVEN LIPS 大小唇UNEVEN SLEEVE LENGTH 长短袖UNEVEN STITCHING DENSITY 针步密度不均匀UNMATCHED CROTCH CROSS 下裆十字骨错位UNMEET BACK VENT 背*豁WAVY AT PLACKET 前筒起蛇(皱)WRONG COMBO 颜色组合错误WRONG PATTERN 图案错误WRONG SIZE INDICATED 错码质量标准:quality stanard(OEKO —TEX STANDARD 100、ISO9002、SGS、ITS 、AATCC、M&S)客检:customer inspection台板检验:table inspection经向检验:lamp inspection色牢度:colour fastness皂洗色牢度:washing colour fastness磨擦色牢度:rubbing/cricking colour fastness光照色牢度:lifht colour fastness汗渍色牢度: perspiration colour fastness水渍色牢度:water colour fastness氯漂白色牢度:chlorine bleach colour fastness尺寸稳定性:dimensional stability外观持久性:apprearance retention拉伸强度:tensile strength撕破强度:tear strength接缝滑裂:seam slippage抗起毛起球性:pilling resistance耐磨性:abrasion resistance拒水性: water repellency抗水性: water resistance织物密度:thread per inch/stich density纱支:yarn count克重: weightFABRIC DEFECTS 布疵COLOR YARN 色纱THICK YARN 粗纱DRAW YARN 抽纱THREAD VISIBLE OUTSIDE 缝线外露WAVY AT PLACKET前筒起蛇(皱)APPROVED SWATCH 已批的布办ART. NO。

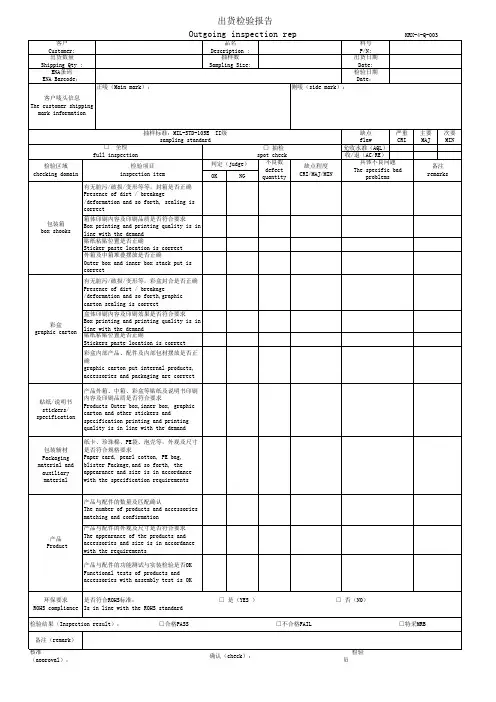

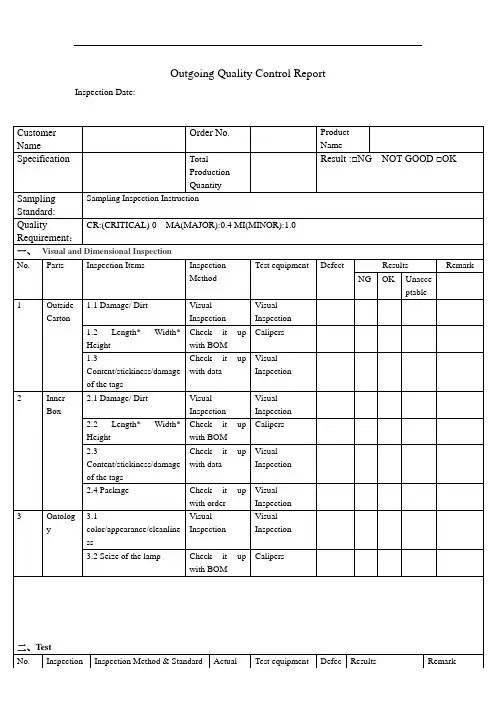

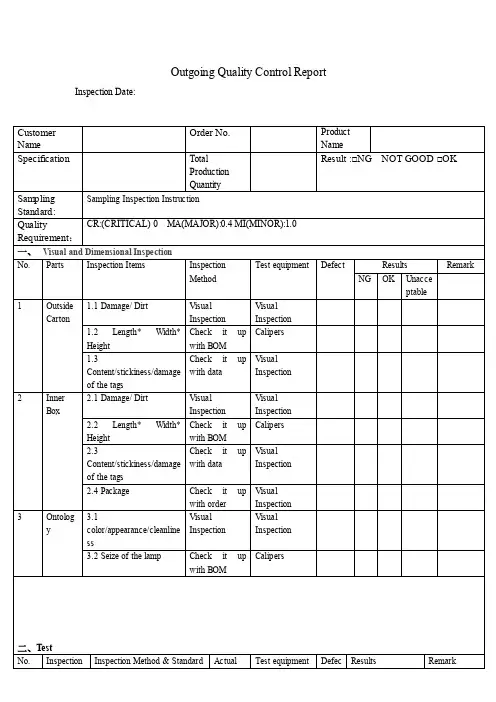

Outgoing Quality Control Report Inspection Date:Inspector:出货检验报告检验日期:检验员QC:下面红色部分是赠送的总结计划,不需要的可以下载后编辑删除!2014年工作总结及2015年工作计划(精选)XX年,我工区安全生产工作始终坚持“安全第一,预防为主,综合治理”的方针,以落实安全生产责任制为核心,积极开展安全生产大检查、事故隐患整改、安全生产宣传教育以及安全生产专项整治等活动,一年来,在工区全员的共同努力下,工区安全生产局面良好,总体安全生产形势持续稳定并更加牢固可靠。

一、主要工作开展情况(一)认真开展安全生产大检查,加大安全整治力度。

在今年的安全生产检查活动中,工区始终认真开展月度安全检查和日常性安全巡视检查记录,同时顺利完成公司组织的XX年春、秋季安全生产大检查和国家电网公司组织的专项隐患排查工作。

截止日前,工区先后共开展各类安全检查71次,查出事故隐患点22处,均进行了闭环处理。

通过检查活动,进一步夯实了工区的安全生产基础。

(二)顺利完成保电专项工作。

本年度工区共进行专项保电工作10次,累计保电天数达到90余天,通过工区全员的共同努力,顺利完成春节保电、国庆保电、七一保电、特高压投送电保电、500kv沁博线保电等一批重要节假日的保电工作。

(四)工作票统计及其他工作情况。

截止11月15日,我工区连续实现安全生产1780天;全年共办理工作票50张,其中第一种工作票24张,含基建单位8张;第二种工作票26张。

工作票合格率100%,执行情况较好。

全年工区所辖线路跳闸次数共计0次,线路跳闸率为0次/(百公里·年)。

(四)安环体系标准化建设本年度在公司统一的部署下,工区积极参与安环体系标准化建设工作,先后派员参加安环体系标准化培训2次,迎接公司开展安环体系内审工作三次,先后审查出问题共计20余处,先后进行了闭环整改。

截止日前,工区已初步建立起了标准化安环工作体系,在今后工作中,工区将进一步完善各项工作流程,努力确保体系工作符合外审相关要求。

矿产资源开发利用方案编写内容要求及审查大纲

矿产资源开发利用方案编写内容要求及《矿产资源开发利用方案》审查大纲一、概述

㈠矿区位置、隶属关系和企业性质。

如为改扩建矿山, 应说明矿山现状、

特点及存在的主要问题。

㈡编制依据

(1简述项目前期工作进展情况及与有关方面对项目的意向性协议情况。

(2 列出开发利用方案编制所依据的主要基础性资料的名称。

如经储量管理部门认定的矿区地质勘探报告、选矿试验报告、加工利用试验报告、工程地质初评资料、矿区水文资料和供水资料等。

对改、扩建矿山应有生产实际资料, 如矿山总平面现状图、矿床开拓系统图、采场现状图和主要采选设备清单等。

二、矿产品需求现状和预测

㈠该矿产在国内需求情况和市场供应情况

1、矿产品现状及加工利用趋向。

2、国内近、远期的需求量及主要销向预测。

㈡产品价格分析

1、国内矿产品价格现状。

2、矿产品价格稳定性及变化趋势。

三、矿产资源概况

㈠矿区总体概况

1、矿区总体规划情况。

2、矿区矿产资源概况。

3、该设计与矿区总体开发的关系。

㈡该设计项目的资源概况

1、矿床地质及构造特征。

2、矿床开采技术条件及水文地质条件。

服装质量与跟单检验英语Quality Control and Inspection in Garment ManufacturingIntroductionIn garment manufacturing, ensuring high-quality products is crucial to meet customer expectations and maintain a good reputation in the market. One of the key aspects of quality control is the process of conducting inspections throughout the production cycle. This article aims to discuss the significance of garment quality and the role of follow-up inspections in ensuring standards are met.Importance of Garment Quality1. Customer Satisfaction: The foremost reason for focusing on garment quality is to ensure customer satisfaction. High-quality garments retain their shape, color, and functionality over time, meeting the expectations of consumers and enhancing their experience.2. Brand Reputation: Garment manufacturers with a reputation for producing high-quality products have an advantage in the market. Consistently delivering reliable and durable apparel helps in building a strong brand image and gaining customer loyalty.3. Compliance with Standards: Quality control in the garment industry ensures that products meet both national and international standards. Compliance with regulations and guidelines is essential to avoid legal issues, product recalls, and reputational damage.Quality Control Process1. Raw Material Inspection: The first step in ensuring garment quality is checking the incoming raw materials. Fabrics, trims, and accessories must be inspected for defects, color variations, and conformity to specifications before they are used in production.2. In-Process Inspection: Throughout the manufacturing process, inspections are conducted at various stages. This helps in identifying and rectifying any issues promptly, ensuring that the final product meets the required quality standards.3. Final Inspection: Before garments are packaged and prepared for shipping, a comprehensive final inspection is conducted. It includes checking for stitching defects, proper labeling, measurements, color consistency, and overall appearance.Follow-up Inspections1. Definition: Follow-up inspections, also known as pre-shipment inspections, are conducted after the production is completed but before the goods are shipped to the buyer. These inspections aim to ensure that the manufactured garments meet the buyer's requirements and the agreed-upon quality standards.2. Scope of Inspection: During a follow-up inspection, the inspector checks for visual defects, measurements, labeling, packaging, and any other specific requirements mentioned in the buyer's specifications. This helps in minimizing the risk of sending defective or non-compliant products to the market.3. Benefits of Follow-up Inspections:a) Identifying Defects: Follow-up inspections help in identifying any defects or non-conformities that may have been overlooked during the in-process inspections. This ensures that only high-quality garments are delivered to the buyers.b) Risk Mitigation: By conducting follow-up inspections, manufacturers can mitigate the risk of receiving a shipment of substandard garments, which could lead to financial losses and damage to the brand's reputation.c) Compliance Assurance: Follow-up inspections ensure that the manufactured garments comply with all the specified quality standards, labeling requirements, and safety regulations set by the buyer and relevant authorities.ConclusionIn the garment manufacturing industry, maintaining high-quality standards is crucial for success. Quality control processes, including follow-up inspections, play a vital role in ensuring that garments meet customer expectations, adhere to standards, and comply with regulations. By prioritizing garment quality and conducting thorough inspections, manufacturers can establish a strong brand reputation, enhance customer satisfaction, and ensure sustainable business growth.。