水压试验检验报告中英文修订稿

- 格式:docx

- 大小:44.15 KB

- 文档页数:3

HYDROSTATIC PRESSURE TESTINGPROCEDURE水压试验程序Prepared By编制: Date日期:Reviewed By审核: Date日期:Approved By批准: Date日期:CONTENT目录1.0General综述2.0Test Preparation试验准备3.0Hydrostatic Pressure Test of Pipeline管线水压试验4.0Inspection Requirements检验要求5.0Reporting报告6.0Report Form报告表格1.0General综述1.1Piping hydrostatic testing should be performed in accordance with ASME B31.3.管线水压试验依照ASME B31.3。

1.1.1All fabrication/repair have been completed, except for operations which could notbe performed prior to the pressure test such as cosmetic grinding on the basematerial which does not affect the required thickness.除了不影响母材厚度的一些整修工作,所有制造和维修在水压试验之前完成。

1.1.2All examinations have been performed, except those required after the test.所有检验已完成,需要试验后的检验例外。

1.2Test gages used in pressure testing shall meet the following requirements.压力试验用表应满足如下要求。

Hydrostatic Test Control Procedure□Controlled□UncontrolledDalian Deep Blue Pump Co., Ltd.1.PurposeThis procedure is to control the process of hydrostatic test and provide hydrostatic test sequence and requirements making the hydrostatic test conform to requirements of ASME Section Ⅲ, Division 1, NB and QA Manual (DBP/NQA-SC-10)2.ScopeThis procedure is applicable to all the pressure retaining items, appurtenance and material to be hydrostatic tested.3.Terms3.1 Hydrostatic test: apply test pressure to the item under prescribed condition.水3.2 Holding time: the time of hydrostatic test pressure maintained4.Responsibility4.1 Technical department shall be responsible for preparing of hydrostatic test instruction anddesigning of test clamping fixture.4.2 Fabrication department shall be responsible for preparing technical requirements , performinghydrostatic test in accordance with requirements of drawing, Technical Procedure, traveler and instructions and recording test results on the test report.4.3 QA Departmenta) organize to train, examine and qualify the hydrostatic test operator and examiner.b) analyze the test water and record the water analysis results on the analysis report.c) supervise and notice customer and ANI to come for witness.5. Pre-work of hydrostatic test5.1 The pressure gauge shall be indicating pressure gauge and be connected to the item to betested directly. The pressure gauge shall be installed on the position easy to watch in accordance with technical requirements.5.2 Indicating pressure gaugea) analog type indicating pressure gage used in testing shall be graduated over a range notless than 1.5 times nor more than 4 times the test pressure. It is best to select 2 timestest pressure.b) digital pressure gauge may be also used without range restriction provided the combinederror due to calibration and readability does not exceed 1% of the test pressure..5.3 Calibrate all the pressure gages against standard dead weight tester or a calibrated mastergage. All the pressure gauges shall be calibrated before each test or series test. A series of test is that group of tests using the same pressure test gage or gages which is conducted at the same site within a period not exceeding 2 weeks.5.4 Perform the hydrostatic test after all the inspections finished. For the item need to be heattreatment, perform the hydrostatic test after heat treatment.5.5 The hydrostatic test operator shall be trained and familiar with materials related to item to betested.( such as, drawing and requirements about hydrostatic test operation)5.6 The examiner shall be qualified to verify the pump, piping, valve, pressure gage andclamping fixture used in test.5.7 The test equipment shall be examined before pressure is applied to ensure that it is tight andthat all low pressure filling lines and other items that should not be subjected to the test have been disconnected or isolated.6. Hydrostatic test6.1 The test medium shall be water or other liquid permitted by Design Specification. The testmedium temperature shall conform to requirements of drawing or instruction.6.2 Inject the test medium after the tested item being discharged air to the lest content.6.3 The test pressure, holding time and acceptance criteria shall conform to requirements ofdrawing or customer documents.6.4 Increase the test pressure slowly to 0.8 times test pressure to check test equipment, each areaand pressure value, and then increase the pressure to test pressure if no leakage or abnormalphenomena.6.5 Keep on venting of the test area to prevent overpressure resulting from abnormal testmedium temperature increasing during holding time.6.6 The holding time shall conform to requirements of technical and drawing. Check thepressure within prescribed time to ensure the pressure stable.6.7 Examination for leakage after application of pressurea) holding the test pressure at least 10 min before examining leakage.b) examine the leakage under test pressure with the witness of ANIc) the test operator shall not be absent from his position during hydrostatic test.7. After hydrostatic testa) the hydrostatic test operator shall dry the item with clean compressed air or nitrogenafter hydrostatic test.b) the test result shall be recorded on 《Hydrostatic Test Report》by hydrostatic testoperator, signed by examiner and reviewed by ANI..8. RecordHydrostatic Test Report( Exhibit 11-1 )。

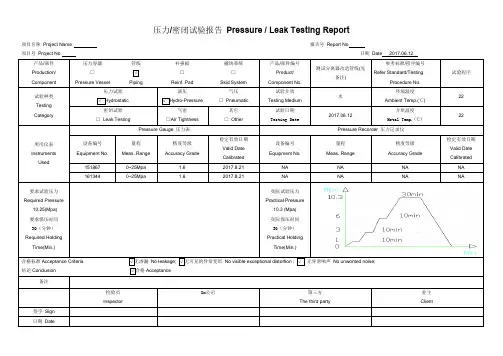

压力管道水压试验报告范文Pressure Piping Water Test Report.Test Information.Project Name: [Enter Project Name]Location: [Enter Location]Test Date: [Enter Test Date]Witness: [Enter Witness Name]Test Pressure: [Enter Test Pressure]Test Duration: [Enter Test Duration]Scope of Test.This test was conducted to verify the integrity of thepressure piping system and its components. The test included all piping, valves, fittings, and other components within the system.Test Procedure.The test was conducted in accordance with the following standards:ASME B31.1, Power Piping.ANSI/AWWA C600, Installation of Ductile-Iron Water Mains and Their Appurtenances.The test procedure involved the following steps:1. The system was isolated from all sources of water.2. The test pressure was applied to the system using a calibrated hydraulic pump.3. The system was held at the test pressure for thespecified duration.4. The system was inspected for leaks and other signs of failure.Test Results.The system held the test pressure for the entire duration of the test without any signs of failure. No leaks or other indications of system damage were observed.Conclusions.Based on the test results, it is concluded that the pressure piping system is capable of withstanding the specified test pressure. The system is therefore considered to be fit for service.Recommendations.No recommendations are required at this time.Attachments.Test data sheets.Inspection reports.中文回答:压力管道水压试验报告。

CONTENT 目录1 Scope 范围2 Reference 参考文件3 Personnel Safety 人身安全4 General Requirements 一般要求5 Record 记录6 Revision 修订1 Scope 范围This work details the method of hydrotesting for the CSPC Nanhai Petrochemical Project HDPE/PP Pipes above /under ground to be tested.本程序叙述了南海石化项目HDPE+PP装置管线系统进行水压试验及冲洗的一般要求。

该试验程序适用于所有地上和地下管线的试验和冲洗。

2 References 参考文件2.1 NH-HDPE+PP-WPR-208 PREFAB.&ERECTION PROCEDURE FOR PROCESSPIPING工艺管线施工程序2.2 PR-8710-0000-0067-CSPC 管道工程试压试漏2.3 PR-8130-0000-0007-CSPC FLUSHING AND BLOWING OF LINES ANDEQUIPMENT管道和设备的冲洗与吹扫2.4 ASME B31.3 Process pipeline工艺管道3 Personnel Safety人生安全Personnel Safety refer to the section 14 of PROCEDURE FOR PROCESS PIPING CONSTRUCTION- NH-HDPE+PP-WPR-208.人生安全要求见“工艺管线施工程序”,文件号为NH-HDPE+PP-WPR-208中第14节。

4General Requirements 一般要求4.1 This procedure applies to a range of different type of tests for different combinations ofassemblies and pipe.本程序适用于对组件与管子的不同组合所进行的各种不同类型的水压试验及冲洗要求。

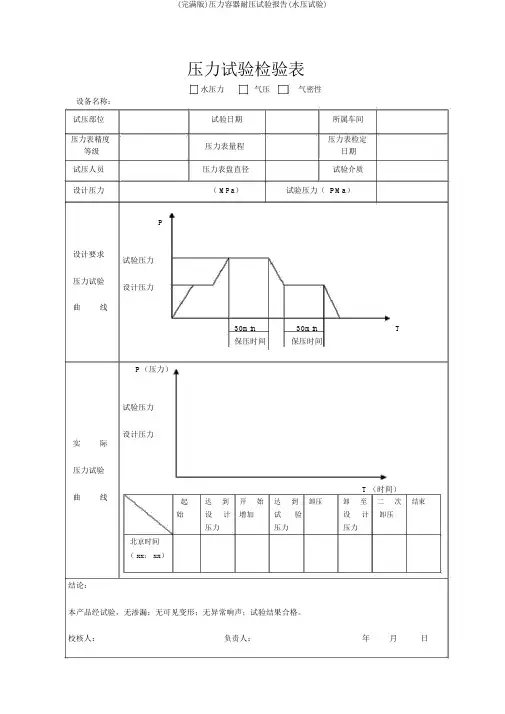

(完满版)压力容器耐压试验报告(水压试验)

压力试验检验表

水压力气压气密性

设备名称:

试压部位试验日期所属车间

压力表精度

压力表量程压力表检定

等级日期

试压人员压力表盘直径试验介质

设计压力( MPa)试验压力( PMa)

P

设计要求

试验压力

压力试验

设计压力

曲线

30min 30min T

保压时间保压时间

P(压力)

试验压力

实际

设计压力

压力试验

曲线

T (时间)

起达到开始达到卸压卸至二次结束

始设计增加试验设计卸压

压力压力压力

北京时间

( xx: xx)

结论:

本产品经试验,无渗漏;无可见变形;无异常响声;试验结果合格。

校核人:负责人:年月日。

w水压爆破试验规程英文Hydraulic Burst Test Procedure1. ObjectiveThe objective of this test is to determine the maximum pressure that a material or component can withstand before failure occurs. This information is crucial for ensuring the safety and reliability of the material or component in its intended application.2. Apparatus- Hydraulic testing machine capable of generating and controlling high-pressure water- Pressure gauge with high accuracy and range appropriate for the expected burst pressure- Specimen holder or fixture to secure the material or component during the test- Safety barrier or shielding to protect operators and spectators from potential hazards3. Test Preparation- Prepare the specimen by following the appropriate standard for sampling and preparation.- Inspect the hydraulic testing machine and pressure gauge to ensure they are in proper working condition.- Set up the specimen holder or fixture in a secure and stable manner.- Ensure the safety barrier or shielding is properly installed to prevent potential injuries.4. Test Procedure- Connect the hydraulic testing machine to the pressure source and ensure all connections are tight and sealed.- Slowly increase the pressure on the specimen using the hydraulic testing machine while monitoring the pressure gauge.- Gradually increase the pressure until the specimen fails or until the desired burst pressure is reached.- Record the maximum pressure at which the specimen failed or burst.- If multiple tests are to be conducted, repeat the procedure for each specimen.5. Data Analysis and Reporting- Analyze the test data to determine the burst pressure of the material or component.- Calculate the average burst pressure if multiple tests were conducted.- Report the maximum burst pressure, along with any relevant observations or notes, in the test report.- Compare the obtained burst pressure with the specified requirements and standards for the material or component. Note: This procedure is a general guideline for conducting a hydraulic burst test. The specific requirements and details may vary depending on the material or component being tested. It is important to refer to the appropriate standard or specification for detailed instructions.。

家里水管打压测试标准英文回答:Water Pipe Pressure Testing Standards for Residential Buildings.Water pipe pressure testing is a crucial step in ensuring the integrity and reliability of a residential plumbing system. It involves applying pressurized water to the pipes to identify and fix any potential leaks, weak points, or other issues. The pressure testing standards for residential water pipes vary depending on the specific region, building codes, and industry practices.General Pressure Testing Procedure.The general procedure for water pipe pressure testingin residential buildings involves the following steps:1. Isolating the Water Supply: The first step is toisolate the water supply to the area being tested. This is typically done by closing the main water valve.2. Filling the System with Water: The pipes are then filled with water from a controlled source, such as a pump or a pressurized water tank.3. Applying Pressure: Once the system is filled with water, pressure is applied using a pressure gauge or a pressure testing pump. The specific pressure applied will depend on the local building codes and industry standards.4. Holding the Pressure: The pressure is held for a specified period, usually 15-30 minutes, to allow for any potential leaks or weak points to manifest.5. Monitoring for Leaks: During the pressure hold period, the system is carefully monitored for any signs of leaks or water seepage. Any detected leaks or pressure drops indicate a problem that needs to be investigated and repaired.6. Releasing the Pressure: After the pressure hold period, the pressure is slowly released from the system.7. Final Inspection: Once the pressure has been released, a final inspection of the system is conducted to ensure there are no visible leaks or damage.Pressure Testing Standards.The specific pressure testing standards for residential water pipes may vary depending on local building codes and industry practices. However, the following general guidelines are commonly used:Initial Pressure: The initial pressure applied to the system is typically between 50 and 100 psi (pounds per square inch).Hold Pressure: The pressure is held at the initial pressure for 15-30 minutes.Final Pressure: After the hold period, the pressure isgradually reduced to a final pressure of 30-50 psi. This final pressure is typically maintained for the remainder of the inspection period.Importance of Pressure Testing.Water pipe pressure testing is an essential part of ensuring the safety and reliability of a residential plumbing system. It helps to identify and fix potential problems before they become major issues, such as leaks, pipe bursts, or water damage. Regular pressure testing is recommended to maintain the integrity of the system and prevent costly repairs or emergencies.中文回答:住宅水管打压测试标准。

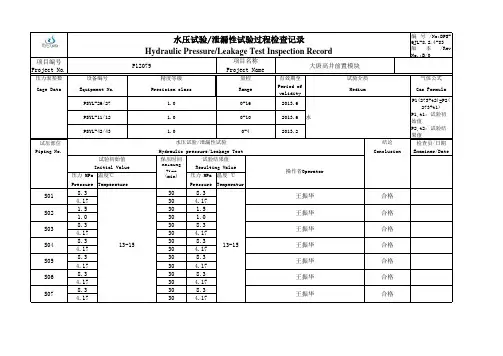

QJL-8.2.4-83版本/Rev No.:B/0项目编号Project No.压力表参数有效期至气体公式Gage DataPeriod of validity Gas Formula 2013.6P1(273+t2)=P2(273+t1)2013.6P1,t1:试验初始值2013.2P2,t2:试验结果值试压部位检查员/日期Piping No.Examiner/Date保压时间Holding Time 压力 MPa(min)压力 MPa 温度℃Pressure Pressure Temperature 8.3308.34.1730 4.171.530 1.51.030 1.08.3308.34.1730 4.178.3308.34.1730 4.178.3308.34.1730 4.178.3308.34.1730 4.178.3308.34.1730 4.17Hydraulic Pressure/Leakage Test Inspection RecordP12079项目名称Project Name大唐高井前置模块水压试验/泄漏性试验Hydraulic pressure/Leakage Test结论Conclusion试验介质Medium水PSYL-42/431.00-4设备编号Equipment No.精度等级Precision class量程Range PSYL-26/27PSYL-11/12 1.01.0温度℃Temperature试验初始值Initial Value试验结果值Resulting Value 操作者Operator王振华合格S03S02王振华合格S01王振华合格合格0-160-10S0713-1513-15王振华S06王振华合格S05王振华合格S04王振华合格QJL-8.2.4-83版本/Rev No.:B/0项目编号Project No.压力表参数有效期至气体公式Gage DataPeriod of validity Gas Formula 2013.6P1(273+t2)=P2(273+t1)2013.6P1,t1:试验初始值2013.2P2,t2:试验结果值试压部位检查员/日期Piping No.Examiner/Date保压时间Holding Time 压力 MPa(min)压力 MPa 温度℃Pressure Pressure Temperature 6.330 6.34.1730 4.176.330 6.34.1730 4.176.330 6.34.1730 4.176.330 6.34.1730 4.176.330 6.34.1730 4.176.330 6.34.1730 4.176.330 6.34.1730 4.17Hydraulic Pressure/Leakage Test Inspection Record设备编号精度等级量程试验介质Equipment No.Precision classRange MediumP12079项目名称大唐高井前置模块Project Name水压试验/泄漏性试验结论Hydraulic pressure/Leakage TestConclusionPSYL-26/27 1.00-16水PSYL-11/12 1.00-10PSYL-42/431.00-4Initial ValueResulting Value Operator温度℃Temperature试验初始值试验结果值操作者F05王振华合格合格合格F03王振华合格F0213-1513-15王振华F04王振华F06王振华F08王振华合格合格F07王振华合格QJL-8.2.4-83版本/Rev No.:B/0项目编号Project No.压力表参数有效期至气体公式Gage DataPeriod of validity Gas Formula 2013.6P1(273+t2)=P2(273+t1)2013.6P1,t1:试验初始值2013.2P2,t2:试验结果值试压部位检查员/日期Piping No.Examiner/Date保压时间Holding Time 压力 MPa(min)压力 MPa 温度℃Pressure Pressure Temperature 6.330 6.34.1730 4.176.330 6.34.1730 4.176.330 6.34.1730 4.176.331 6.34.1732 4.176.333 6.34.1734 4.171.535 1.51.036 1.06.337 6.34.1738 4.17Hydraulic Pressure/Leakage Test Inspection Record设备编号精度等级量程试验介质Equipment No.Precision classRange MediumP12079项目名称大唐高井前置模块Project Name水压试验/泄漏性试验结论Hydraulic pressure/Leakage TestConclusionPSYL-26/27 1.00-16水PSYL-11/12 1.00-10PSYL-42/431.00-4合格合格Initial ValueResulting Value Operator温度℃Temperature试验初始值试验结果值操作者合格F14王振华合格合格F10王振华合格F0913-1513-15王振华F11王振华F13王振华F15王振华合格F12王振华QJL-8.2.4-83版本/Rev No.:B/0项目编号Project No.压力表参数有效期至气体公式Gage DataPeriod of validity Gas Formula 2013.6P1(273+t2)=P2(273+t1)2013.6P1,t1:试验初始值2013.2P2,t2:试验结果值试压部位检查员/日期Piping No.Examiner/Date保压时间Holding Time 压力 MPa(min)压力 MPa 温度℃Pressure Pressure Temperature 6.330 6.34.1730 4.176.330 6.34.1730 4.176.330 6.34.1730 4.176.331 6.34.1732 4.176.333 6.34.1734 4.176.335 6.34.1736 4.176.337 6.34.1738 4.17Hydraulic Pressure/Leakage Test Inspection RecordP12079项目名称大唐高井前置模块Project Name设备编号精度等级量程试验介质Equipment No.Precision classRange MediumPSYL-26/27 1.00-16水PSYL-11/12 1.00-10PSYL-42/431.00-4水压试验/泄漏性试验结论Hydraulic pressure/Leakage TestConclusion试验初始值试验结果值操作者Initial ValueResulting Value Operator温度℃TemperatureF1613-1513-15王振华合格F17王振华合格F18王振华合格F19王振华合格F20王振华合格F21王振华合格F22王振华合格QJL-8.2.4-83版本/Rev No.:B/0项目编号Project No.压力表参数有效期至气体公式Gage DataPeriod of validity Gas Formula 2013.6P1(273+t2)=P2(273+t1)2013.6P1,t1:试验初始值2013.2P2,t2:试验结果值试压部位检查员/日期Piping No.Examiner/Date保压时间Holding Time 压力 MPa(min)压力 MPa 温度℃Pressure Pressure Temperature 6.330 6.34.1730 4.178.3308.34.1730 4.178.3308.34.1730 4.178.3308.34.1730 4.17Hydraulic Pressure/Leakage Test Inspection RecordP12079项目名称大唐高井前置模块Project Name设备编号精度等级量程试验介质Equipment No.Precision classRange MediumPSYL-26/27 1.00-16水PSYL-11/12 1.00-10PSYL-42/431.00-4水压试验/泄漏性试验结论Hydraulic pressure/Leakage TestConclusion试验初始值试验结果值操作者Initial ValueResulting Value Operator温度℃TemperatureF2313-1513-15王振华合格E01王振华合格E02王振华合格E03王振华合格。

Abstract:This report details the procedures and results of a water quality analysis experiment conducted to assess the chemical and biological characteristics of a given water sample. The experiment focused on determining the pH, dissolved oxygen (DO), turbidity, and total coliform bacteria levels in the water. The findings are discussed in relation to the potential impacts on aquatic life and human health.Introduction:Water quality is a critical factor in determining the suitability of water for various uses, including drinking, irrigation, and recreational activities. This experiment was designed to evaluate the chemical and biological parameters of water to ensure its safety and suitability for intended use. The primary objectives of the experiment were to measure the pH, dissolved oxygen (DO), turbidity, and total coliform bacteria levels in the water sample.Materials and Methods:1. Sample Collection:A water sample was collected from a local river using a sterile sampling bottle. The bottle was rinsed with the water to be sampled and thenfilled to the specified mark. The sample was immediately sealed and transported to the laboratory for analysis.2. pH Measurement:The pH of the water sample was measured using a digital pH meter. The meter was calibrated using standard buffer solutions before use. The pH probe was immersed in the water sample and the reading was recorded.3. Dissolved Oxygen (DO) Measurement:Dissolved oxygen levels were measured using a dissolved oxygen probe connected to a digital meter. The probe was calibrated using a saturated oxygen solution before use. The probe was submerged in the water sample, and the DO level was recorded.4. Turbidity Measurement:Turbidity was measured using a nephelometer. The water sample was poured into a cuvette, and the nephelometer was set to the appropriate wavelength. The turbidity reading was obtained by reading the intensity of light scattered by the sample.5. Total Coliform Bacteria Count:Total coliform bacteria were counted using the multiple tubefermentation (MTF) method. A sterile loop was used to transfer a small volume of the water sample to a series of tubes containing lactose broth. The tubes were incubated at 37°C for 48 hours. The presence of coliform bacteria was indicated by the appearance of gas production in the broth.Results:1. pH:The pH of the water sample was found to be 7.2, which is within the acceptable range for most aquatic organisms.2. Dissolved Oxygen (DO):The dissolved oxygen level in the water sample was measured to be 9.5mg/L, which is above the minimum required for most fish species.3. Turbidity:The turbidity of the water sample was determined to be 10 NTU (Nephelometric Turbidity Units), indicating a relatively clear water body.4. Total Coliform Bacteria Count:The total coliform bacteria count in the water sample was found to be100 colonies per 100 mL, which is within the acceptable range fordrinking water.Discussion:The pH level of the water sample is within the optimal range for most aquatic organisms, suggesting that it is suitable for fish and other aquatic life. The high dissolved oxygen levels indicate that the wateris well-oxygenated, which is essential for the survival of aerobic organisms. The relatively low turbidity level suggests that the water is clear and free from suspended particles that could hinder light penetration and reduce photosynthesis.The total coliform bacteria count in the water sample is within the acceptable range for drinking water, indicating that the water is relatively free from fecal contamination. However, it is important to note that the presence of coliform bacteria does not necessarilyindicate the presence of pathogenic organisms. Further analysis, such as the detection of specific pathogens, would be required to assess the water's safety for drinking purposes.The results of this experiment suggest that the water sample is generally of good quality, with no immediate concerns regarding its suitability for aquatic life or human use. However, regular monitoring and analysis should be conducted to ensure ongoing water quality and to detect any potential changes or contamination.Conclusion:The water quality analysis experiment conducted in this study has provided valuable insights into the chemical and biological characteristics of the water sample. The results indicate that the water is suitable for aquatic life and has the potential for various uses, although it is important to continue monitoring and maintaining its quality to ensure its safety and sustainability. Further research and analysis may be necessary to explore the long-term impacts of environmental factors on water quality and to develop strategies for water resource management.References:1. APHA, AWWA, WEF. Standard Methods for the Examination of Water and Wastewater. 22nd ed. Washington, DC: American Public Health Association; 2012.2. Colwell, R. R. (2006). Water quality: A guide to the uses and management of freshwater resources. Cambridge University Press.3. USEPA. Guidelines for Water Quality Monitoring. EPA 822-B-02-001. Washington, DC: United States Environmental Protection Agency; 2002.。