德固赛炭黑介绍

- 格式:ppt

- 大小:6.43 MB

- 文档页数:49

什么是炭黑?橡胶用炭黑详解展开全文什么是炭黑?炭黑(也称碳黑)是由烃类化合物(液态或气态)经过不完全燃烧或热裂解形成的近似于球体的胶体粒子,以聚集体形式存在,表观呈纯黑色粉状或者粒状。

产品的粒径、结构和表面活性根据原料、制造方法和生产工艺的不同而有很大差异。

炭黑的主要成分是碳,同时包含微量氢、氧、灰份和水份。

炭黑的历史是什么?炭黑的历史由来已久,中国是世界上最早发现并生产炭黑的国家,距今已有三千多年的历史。

最开始炭黑这种物质只用于制墨。

随着工业的快速发展,炭黑也被应用到其他的领域当中,同时也在不断改善炭黑的生产技术。

从20世纪50年代初,先后成功研发了槽法炭黑、滚筒法炭黑、混气炭黑和气炉法炭黑,炭黑的生产技术越来越成熟,近年来更是得到了飞跃的发展。

我国古代就在炭黑的提取技术上有了不小的成就,制墨工艺更是为世界文化做出了贡献。

国外炭黑的制造,是由我国传入日本、东方各国,然后传到希腊、罗马,最后传入欧洲的。

我国的炭黑产量一直居于世界先进水平,基本满足了各个行业的需求,还出口日本、韩国、东南亚等国。

我们更是吸取国外的先进技术,增加了炭黑的品种,在质量和环保问题上都取得了突破。

随着各种技术的不断完善,目前的炭黑品种主要有导电炭黑、橡胶炭黑、色素炭黑、乙炔炭黑、喷雾炭黑、水泥砂浆炭黑、热裂解炭黑、半补强炭黑以及特种炭黑,这些炭黑的特性各不相同,所应用到的领域也不同。

炭黑的作用有哪些?主要用作橡胶的补强剂和填料,其消耗量约为橡胶消耗量的一半,橡胶用炭黑占炭黑总量的94%,其中约60%用于轮胎制造。

此外,也用作油墨、涂料和塑料的着色剂以及塑料制品的紫外光屏蔽剂。

许多其他制品,如电极、干电池、电阻器、炸药、化妆品及抛光膏中,也是重要的助剂。

橡胶用炭黑如轮胎行业,橡胶密封件,减震件等等,橡胶制品中配合一定量的炭黑可以起到补强和填充作用以改善橡胶制品的性能。

炭黑的性能指标有哪些?1. 粒径炭黑的粒径是表示碳黑原生粒径,它是通过电子显微镜测试的,是一定颗数粒径的平均值。

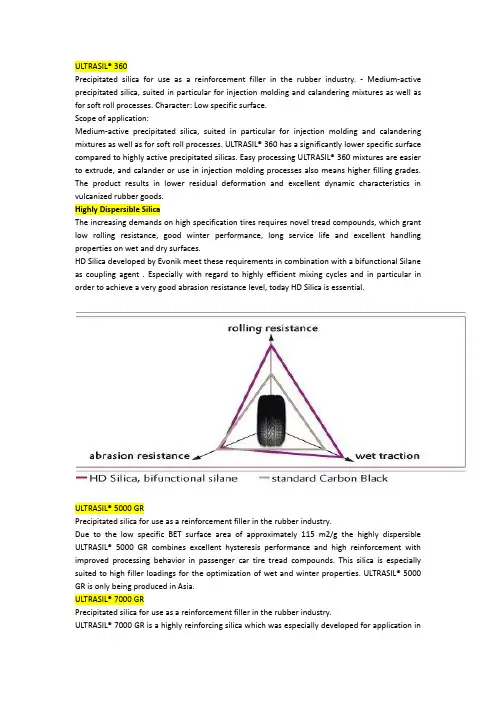

ULTRASIL® 360Precipitated silica for use as a reinforcement filler in the rubber industry. - Medium-active precipitated silica, suited in particular for injection molding and calandering mixtures as well as for soft roll processes. Character: Low specific surface.Scope of application:Medium-active precipitated silica, suited in particular for injection molding and calandering mixtures as well as for soft roll processes. ULTRASIL® 360 has a significantly lower specific surface compared to highly active precipitated silicas. Easy processing ULTRASIL® 360 mixtures are easier to extrude, and calander or use in injection molding processes also means higher filling grades. The product results in lower residual deformation and excellent dynamic characteristics in vulcanized rubber goods.Highly Dispersible SilicaThe increasing demands on high specification tires requires novel tread compounds, which grant low rolling resistance, good winter performance, long service life and excellent handling properties on wet and dry surfaces.HD Silica developed by Evonik meet these requirements in combination with a bifunctional Silane as coupling agent . Especially with regard to highly efficient mixing cycles and in particular in order to achieve a very good abrasion resistance level, today HD Silica is essential.ULTRASIL® 5000 GRPrecipitated silica for use as a reinforcement filler in the rubber industry.Due to the low specific BET surface area of approximately 115 m2/g the highly dispersible ULTRASIL® 5000 GR combines excellent hysteresis performance and high reinforcement with improved processing behavior in passenger car tire tread compounds. This silica is especially suited to high filler loadings for the optimization of wet and winter properties. ULTRASIL® 5000 GR is only being produced in Asia.ULTRASIL® 7000 GRPrecipitated silica for use as a reinforcement filler in the rubber industry.ULTRASIL® 7000 GR is a highly reinforcing silica which was especially developed for application inlow rolling resistant passenger car tire tread compounds, so called “Green Tire”. With a specific BET surface area of approximately 170 m2/g this silica imparts to tread compounds in combination with bifunctional silanes high abrasion resistance combined with excellent rolling resistance and wet traction.Conventional SilicateMetal Silicates are obtained by replacing a part of the acid used during the precipitation by metallic salts. In rubber mixtures these silicates offer processing and product properties which could only hardly be achieved by pure Silica.ULTRASIL® 880Precipitated silica for use as reinforcement filler in the rubber industry.ULTRASIL® 880 is a precipitated silica with a Calcium admixture and a very low specific BET surface area of approximately 35 m2/g. It gives rubber mixtures excellent residual deformation and extrusion characteristics. ULTRASIL® 880 allows profiles with virtually no swelling and a very smooth surface. Even EPDM mixtures with extremely high filling grades (up to 200 parts per hundred rubber) can still be easily processed. In white mixtures, ULTRASIL® 880 can partially be substituted for titanium dioxide. The effect of sulfur adsorption is negligible.ULTRASIL® AS 7Precipitated sodium aluminum silicate for use as a reinforcement filler in the rubber industry.ULTRASIL® AS 7 is a precipitated aluminum silicate with a low specific BET surface area of approximately 60 m2/g. It combines medium reinforcement properties with particularlytrouble-free handling and processing. The latter allows for higher filler parts than would be possible with highly active precipitated silica. Blending with ULTRASIL® VN 3 or inactive fillers makes it possible to adjust the reinforcement effect within a wide range.ULTRASIL® VN 2Precipitated silica for use as reinforcement filler in the rubber industry. - Ultrasil VN 2 significantly enhances rubber mixtures in terms of Shore hardness, tensile strength, tear resistance and abrasion resistance.Scope of application:ULTRASIL® VN 2 has a reinforcement potential that is only marginally lower than that of ULTRASIL® 3, which has a higher surface. It significantly enhances rubber mixtures in terms of Shore hardness, tensile strength, tear resistance and abrasion resistance. Activators must be added to achieve optimum rubber properties, e.g. glycols, amine or other base accelerators. ULTRASIL® VN 2 GRUltrasil® VN 2 GR significantly enhances rubber mixtures in terms of Shore hardness, tensile strength, tear resistance and abrasion resistance, while preserving mixture viscosity and processing benefits.Scope of application:ULTRASIL® VN 2 GR has a reinforcement potential that is only marginally lower than that of ULTRASIL® VN 3, which has a higher surface. It significantly enhances rubber mixtures in terms of Shore hardness, tensile strength, tear resistance and abrasion resistance, while preserving mixture viscosity and processing benefits. Activators must be added to achieve optimum rubber properties, e.g. glycols, amine or other base accelerators.ULTRASIL® VN 3Precipitated silica for use as reinforcement filler in the rubber industry.Ultrasil® VN 3 has a high reinforcement potential and significantly enhances rubber mixtures in terms of Shore hardness, tensile strength, tear resistance and abrasion resistance.Scope of application:ULTRASIL® VN 3 has a high reinforcement potential and significantly enhances rubber mixtures in terms of Shore hardness, tensile strength, tear resistance and abrasion resistance. Activators must be added to achieve optimum rubber properties, e.g. glycols, amine or other base accelerators. With the appropriate mixture composition, ULTRASIL® VN 3's higher surface means vulcanized goods have greater transparency.ULTRASIL® VN 3 GRPrecipitated silica for use as reinforcement filler in the rubber industry. Granulation means less dust build-up during processing as well as a higher compression density versus powdered forms. Scope of application:ULTRASIL® VN 3 GR has a high reinforcement potential and significantly enhances rubber mixtures in terms of Shore hardness, tensile strength, tear resistance and abrasion resistance. Activators must be added to achieve optimum rubber properties, e.g. glycols, amine or other base accelerators. With the appropriate mixture composition, ULTRASIL® VN 3 GRS's higher surface means vulcanized goods have greater transparency.。

Evonik_Degussa特种炭黑介绍Evonik DegussaSpeciality CarbonBlacksfor MRG Industry德固赛用于橡胶制品的特殊碳黑J. C. Nian & Dr. W. Wolff粘志成先生 & 伍福博士Applied Technology Rubber Reinforcement橡胶补强应用技术| Evonik Degussa Speciality Carbon Black for MRG Industry Page | 2 Content 内容Introduction介绍Purex? grades and Durex?0 for extrusion applications应用于挤出制品的 Purex?碳黑和 Durex?0Carbon blacks for molding applications应用于模制成型的碳黑Handling properties操作性能Summary总结| Evonik Degussa Speciality Carbon Black for MRG Industry Page | 3 MRG Industry Mechanical Rubber Goods Industry 工业用橡胶制品Printing Rolls印刷滚筒 Windshield wipers雨刷Profiles挤出制品Hoses软管Molded goods模制物品Introduction - The MRG Industry简介 -橡胶制品工业| Evonik Degussa Speciality Carbon Black for MRG Industry Page | 4 Different application fields different technical requirements不同的应用领域不同的技术需求Large number of recipes大量的配方large number of rubber grades mechanical resistance, oil resistance, heat ageing...多样的橡胶等级机械抗力、耐油、热老化…等。

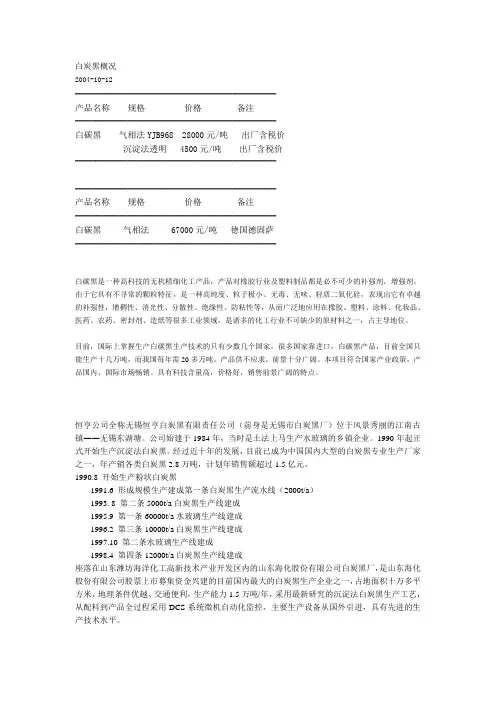

白炭黑概况2004-10-12━━━━━━━━━━━━━━━━━━━━━━━产品名称规格价格备注━━━━━━━━━━━━━━━━━━━━━━━白碳黑气相法YJB968 28000元/吨出厂含税价沉淀法透明 4500元/吨出厂含税价━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━产品名称规格价格备注━━━━━━━━━━━━━━━━━━━━━━━白碳黑气相法 67000元/吨德国德固萨━━━━━━━━━━━━━━━━━━━━━━━白碳黑是一种高科技的无机精细化工产品,产品对橡胶行业及塑料制品都是必不可少的补强剂,增强剂。

由于它具有不寻常的颗粒特征,是一种高纯度、粒子极小、无毒、无味、轻质二氧化硅,表现出它有卓越的补强性,增稠性、消光性、分散性、绝缘性、防粘性等,从而广泛地应用在橡胶、塑料、涂料、化妆品、医药、农药、密封剂、造纸等很多工业领域,是诸多的化工行业不可缺少的原材料之一,占主导地位。

目前,国际上掌握生产白碳黑生产技术的只有少数几个国家,很多国家靠进口,白碳黑产品,目前全国只能生产十几万吨,而我国每年需20多万吨。

产品供不应求,前景十分广阔。

本项目符合国家产业政策,产品国内、国际市场畅销。

具有科技含量高,价格好,销售前景广阔的特点。

恒亨公司全称无锡恒亨白炭黑有限责任公司(前身是无锡市白炭黑厂)位于风景秀丽的江南古镇――无锡东湖塘。

公司始建于1984年,当时是土法上马生产水玻璃的乡镇企业。

1990年起正式开始生产沉淀法白炭黑。

经过近十年的发展,目前已成为中国国内大型的白炭黑专业生产厂家之一,年产销各类白炭黑2.8万吨,计划年销售额超过1.5亿元。

1990.8 开始生产粉状白炭黑1991.6 形成规模生产建成第一条白炭黑生产流水线(2000t/a)1993. 8 第二条5000t/a白炭黑生产线建成1995.9 第一条60000t/a水玻璃生产线建成1996.2 第三条10000t/a白炭黑生产线建成1997.10 第二条水玻璃生产线建成1998.4 第四条12000t/a白炭黑生产线建成座落在山东潍坊海洋化工高新技术产业开发区内的山东海化股份有限公司白炭黑厂,是山东海化股份有限公司股票上市募集资金兴建的目前国内最大的白炭黑生产企业之一,占地面积十万多平方米,地理条件优越、交通便利,生产能力1.5万吨/年,采用最新研究的沉淀法白炭黑生产工艺,从配料到产品全过程采用DCS系统微机自动化监控,主要生产设备从国外引进,具有先进的生产技术水平。

Evonik Degussa Speciality Carbon Blacksfor MRG Industry德固德固赛赛用于橡用于橡胶胶制品的特殊碳黑J. C. Nian & Dr. W. Wolff 粘志成先生& & 伍福伍福博士Applied Technology Rubber Reinforcement 橡胶补强应胶补强应用技用技用技术术Content 内容Introduction介绍Purex®grades and Durex®0 for extrusion applications 挤出制品的Purex®碳黑和Durex®0用于挤应用于Carbon blacks for molding applications应用于模制成型的碳黑Handling properties操作性能Summary总结MRG Industry (= Mechanical Rubber Goods Industry 工业用橡用橡胶胶制品)Printing Rolls 印刷印刷滚滚筒Windshield wipers 雨刷Profiles 挤出制品Hoses 软管Molded goods模制物品Introduction -The MRG Industry 简介-橡胶制品工制品工业业Different application fields different technical requirements 不同的不同的应应用领域 不同的技不同的技术术需求Large number of recipes 大量的配方•large number of rubber grades (mechanical resistance, oil resistance, heat ageing...)多样的橡的橡胶胶等级(机械抗力机械抗力、、耐油耐油、、热老化…等)。

•different reinforcing/filling systems (soft carbon blacks, clays, silica...),不同的不同的补强补强/ 填充系填充系统统(软质软质碳黑碳黑碳黑、、黏土黏土、、白碳黑…等)。

炭黑工艺及分析炭黑工艺及分析一、概述炭黑是气态或液态的碳氢化合物在空气不足的条件下进行不完全燃烧或热裂分解所生成的无定形碳,为疏松、质轻而极细的黑色粉末物质,具有高度分散性。

不溶于各种溶剂,相对密度1.8~2.1。

其成分主要是元素碳,并含有少量氧、氢和硫以及其他杂质和水分等,其微晶具有准石墨结构。

炭黑的主要物理性质有比表面积、密度、结构性、表面性质、导热性、导电性和光学性质等;主要化学性质有氧化、接枝和磺化等反应性以及催化作用、消除自由基作用和抗老化性作用等。

各种炭黑的差异主要在表面积(或粒子大小)、聚集体形态、粒子和聚集体的质量分布和化学组成等方面。

炭黑主要用作橡胶的补强剂和填料,其消耗量约为橡胶消耗量的一半,橡胶用炭黑占炭黑总量的94%,其中约60%用于制造。

此外,也用作油墨、和的着色剂以及塑料制品的紫外光屏蔽剂。

在许多其他制品,如电极、干电池、电阻器、炸药、化妆品及抛光膏中,它也是重要的助剂。

二、市场分析炭黑系芳族石油或煤焦油等原料不完全燃烧的产物,作为重要的填充补强剂和优良的着色或调色剂,目前广泛应用于橡胶及塑料加工、油墨、涂料、化纤、制革、电子,冶金等行业.橡胶用炭黑约占炭黑总耗用量的90%,其使用不仅能提高橡胶制品的强度,而且能改进胶料的工艺性能,赋予制品耐磨、耐撕。

耐热等多种性能,延长制品的使用寿命,适量填充炭黑还可以降低生产成本.据不完全统计,根据轮胎和橡胶加工的发展,以及炭黑相关应用领域的需求,据统计,全球工业企业每年消耗800万~900万吨炭黑,中国的炭黑年消费量为110万吨,是仅次于美国的全球第二大炭黑消费国。

目前国内炭黑生产能力为200万吨,2004年总产量为138万吨,表现消费量已达到140万吨.2006年我国炭黑产量为182.5万吨。

预计2010年全国炭黑的需求量将达到200-220万吨.中国汽车制造业及轮胎制造业的迅猛发展导致近年来对炭黑的需求量急剧提高。

我国高速公路近年来取得了快速发展,轮胎对高品质的新工艺炭黑、及新工艺低滞后,低滚动阻力炭黑的需求日益增多.目前,中国汽车工业发展迅猛,已经是世界第二大汽车产销国;汽车工业的快速发展又带动了轮胎工业的发展,中国目前已成为世界第一大轮胎生产国;而炭黑作为轮胎生产中的第二大原材料,也充分受益于轮胎工业的发展,轮胎工业担当了炭黑行业发展的催化剂。

关于德固赛

佚名

【期刊名称】《上海化工》

【年(卷),期】2006(31)12

【摘要】德固赛集团是世界领先的特种化工公司。

2005财年,集团的四万四千名员工创造了一百一十八亿欧元的销售额,公司息税前利润(EBIT)达到九亿四千万欧元。

这一成绩使德固赛成为德国第三大化工企业,同时也位居全球特种化工行业之首。

创新性的产品和系统解决方案使德固赛为客户的成功作出有价值的、不可或缺的贡献。

德固赛已成为客户成功的“创新原动力”。

【总页数】1页(PI0004-I0004)

【关键词】化工公司;化工企业;化工行业;销售额;系统解;原动力;集团;客户

【正文语种】中文

【中图分类】F407.7

【相关文献】

1.德固赛正式更名为赢创德固赛 [J], 扬子江

2.德固赛(中国)投资有限公司高性能聚合物业务部用于激光标记的德固赛专利添加剂 [J],

3.致力于健康事业的德固赛(degussa)--德固赛生物活性物质部亚洲区域经理王正平博士访谈 [J], 李玉

4.德固赛:不断创新,为中国提供量身定制的解决方案——访德固赛(中国)投资有限公司涂料原料及色浆业务部亚太区销售副总裁艾瑞仕博士 [J], 樊森

5.赢创德固赛:新技术的传播者——记赢创德固赛·益生菌应用及饲料氨基酸新技术研讨会 [J], 周会会

因版权原因,仅展示原文概要,查看原文内容请购买。