林巴赫L275&L550E发动机问答

- 格式:pdf

- 大小:19.30 KB

- 文档页数:5

•New Castle, DE USA +1-302-427-4000•Lindon, UT USA+1-801-763-1500•Hialeah, FL USA+1-305-828-4700•Crawley, United Kingdom +44-1293-658900•Shanghai, China +86-21-64956999•Taipei, Taiwan +88-62-25638880•Tokyo, Japan +81-3-5759-8500•Seoul, Korea +82-2-3415-1500•Bangalore, India +91-80-2319-4177-79•Paris, France +33-1-30-48-94-60•Eschborn, Germany +49-6196-400-600•Brussels, Belgium +32-2-706-0080•Etten-Leur, Netherlands +31-76-508-7270•Sollentuna, Sweden +46-8-555-11-521•Milano, Italy +39-02-265-0983•Barcelona, Spain +34-93-600-93-32•Melbourne, Australia +61-3-9553-0813•Mexico City, Mexico +52-55-52-00-18-60L OCAL O FFICES0000ARES-G 21235711143541AR R HEOMETERS15161718192021TM 27354112Test stationTransducer Force/Torque Rebalance Minimum Torque in Oscillation 0.05 μN.m Minimum Torque in Steady Shear 0.1μN.m Maximum Torque 200 mN.m Torque Resolution 1nN.m Normal/Axial Force Range 0.001to 20 N Motor Brushless DC Motor Bearings Jeweled Air Strain Resolution 0.04 μrad Min Angular Displacement in Oscillation 1 μrad Max Angular Displacement in Steady Shear UnlimitedAngular Velocity Range 1 x 10-6rad/s to 300 rad/s Angular Frequency Range 1 x 10-7to 628 rad/s Step Change in Velocity 5 ms Step Change in Strain 10 ms Temperature SystemsSmart Swap Standard Force Convection Oven, FCO -150 to 600˚C FCO Camera Viewer Optional Peltier Plate -40 to 180˚C Sealed Bath -10 to 150˚CT ECHNICAL SPECIFICATIONSARES-G2 T ECHNOLOGYTorque and Normal Force Transducer34F ORCE R EBALANCE M OTOR ANDM AGNETIC S USPENSIONN ON -C ONTACT T EMPERATURES ENSOR E LECTRONICST ORQUE R EBALANCE M OTORT ORQUE /N ORMAL F ORCER EBALANCE E LECTRONICSR ADIAL A IR B EARINGU PPER G EOMETRY MOUNT5ARES-G2 T ECHNOLOGY Advanced Brushless DC Drive MotorA high-resolution optical encoder measures and controls angular deflection over exceptionally wide rangesgreatly improving traditional oscillation and transient strain-controlled testing performance. The opticalencoder allows testing to be started in any position for all test modes, and with no preferred homeposition in oscillation, tests are seamlessly combined with smooth transition and timely response.T HRUST A IR B EARINGR ADIAL A IR B EARINGB RUSHLESS DC M OTORO PTICAL E NCODERN ON -C ONTACTT EMPERATURE S ENSORE LECTRONICSL OWER G EOMETRY MOUNTD UCTILE I RON FA CTIVE T EMPERATURE C ONTROLThe ARES-G2 incorporates our newly-patented, non-contact temperature sensor technology for active measurement and control of both the upper and lower plate temperature. Platinum Resistance Thermometers (PRT) can be installed into the shaft ofboth the motor and transducer. When installed, the PRTconnector engages a micro printed circuit board (PCB) on the rotating shaft. The tip of the PRT is placed in intimate contact with the center of an upper cone or plate and/or lower plate geometry. The PRT senses the temperature and transmits the signal to a secondary coil housed in the stationary part of the transducer and/or motor assemblies. The ability to measure and control temperature at the surface of both plates is unique patented technology. This frictionless technology enables temperature sensing on the transducer side with no impact on sensitivity, and on the motor assembly, allows for greater accuracy in small amplitude oscillation testing. Temperature control and measurements are made at the testing surface, which is in intimate contact with thesample, without impacting the measurement.TRIOS S OFTWARE AND E XTREME T ESTING F LEXIBILITYAn important new feature of the ARES-G2 is a new level of testing freedom and flexibility. All key components of the rheometer (motor, transducer, data acquisition, environmental controls, axial slide etc.) are independent units with their own intelligence, all of which are orchestrated by test instructions programmed with new TRIOS software interface. While this versatile and intuitive software interface provides fast and simple programming of well known general procedures for traditional testing, (eg. strain/frequency sweeps, stepwell-known strain, etc.), rigid limitations of pre-programmed test modes at the instrument level no longer exist. Instead, test or test sequencespecific instrument instructions are easily programmed in countless combinations and d ownloaded prior to the start of the experiment.F ULLY I NTEGRATED F AST D ATA A CQUISITIONThe ARES-G2 provides fully integrated fast data acquisition for transient and oscillatory testing using 5 fast data channels. This allows simultaneous collection of angular displacement, torque and normal force in all test modes. The high data sampling rate of 8kHz in oscillation mode provides better resolution of both the magnitude and phase of the measured signals and allows better harmonic resolutionwith accurate evaluation up to the 10th harmonic.T OUCH S CREEN AND K EY P ADThe ARES-G2 features a color touch screen userinterface mounted on the front of the test station.This graphical interface adds a new dimensionin ease-of-use. Interactive activities such as gapzeroing, sample loading and setting temperature canbe conveniently performed at the test station. It alsodisplays instrument status and test information (torque,normal force, sample temperature) and provides easyaccess to system information such as settings anddiagnostic reporting.P ELTIER P LATEThe Peltier Plate is a smart swap temperature control option providinga temperature range of –40 to 180 °C, with a maximum heating rate of30 °C/min, and temperature accuracy of +/- 0.1 °C. A platinum resistance thermometer (PRT) sensor is positioned in the middle of the lower sample plate and ensures accurate measurement and control of sample temperature. It is the most common system for standard parallel plate and cone and plate testing of structured fluids. The open design facilitates easy sample loading and cleaning of geometries. A new optional Solvent Trap and Purge Cover accessory is available for use with the Peltier plate. When used as a solvent trap, (to keep samples from volatilizing (drying) during experiments), the sample is fully isolated from the surrounding atmosphere by a fluid seal at the top (transducer side) and permanent seal at the bottom (motor side). A circular well containing solvent can also be attached and placed in contact with the Peltier plate surface. This allows the solvent to evaporate and create a saturated atmosphere inside the enclosure. Gases can be introduced through the purge ports. For example a dry air or nitrogen purge keeps moisture from condensing around the sample while testing below room temperature.R ECIRCULATING F LUID B ATHThe Recirculating Fluid Bath option can be used with parallel plate, cone and plate, and concentric cylinder geometries. Concentric cylinders are especially useful for very low viscosity fluids, dispersions of limited stability and for applications where fluid/solventevaporation may be a concern. The option requires a computer-controlled fluid circulator for automated temperature control operation. The temperature range is –10 to 150 °C with appropriate circulator and circulating fluid.ARES-G2 A CCESSORIESMinimum Torque Oscillation CR 0.003 μN.mMinimum Torque Oscillation CS 0.003 μN.mMinimum Torque Steady CR 0.01 μN.mMinimum Torque Steady CS 0.01 μN.mMaximum Torque 200 mN.mTorque Resolution 0.1 nN.m [1]Motor Inertia 18 μN.m.sAngular Velocity Range CS 0 to 300 rad/sAngular Velocity Range CR 1.4E -9to 300 rad/sFrequency Range 7.5E -7to 628 rad/sDisplacement Resolution 25 nradStep Change in Velocity 7 msStep Change in Strain 30 msDirect Strain Control Standard [2]Thrust Bearing MagneticNormal/Axial Force Range 0.005 to 50 NSmart Swap™StandardSmart Swap Geometry StandardPeltier Plate -40 to 200 °C [3]Environmental Test Chamber (ETC)-160 to 600 °CETC Camera Viewer OptionalConcentric Cylinder -20 to 150 °C [3]Peltier ControlUpper Heated Plate -30 to 150 °C [3]Electrically Heated Plate (EHP)-70 to 400 °C Camera Option with StreamingVideo and Image Capture OptionalT ECHNICAL S PECIFICATIONSCR - Controlled Rate Mode CS - Controlled Stress Mode [1] Internal Resolution for D to A converter at torque of 0.1 µN.m [2] Direct Strain Control provides single cycle oscillation and continuous oscillations during experiments.[3] Lower temperature limits require use of a suitable fluid in an external circulator.Minimum Torque Oscillation CR 0.03 μN.mMinimum Torque Oscillation CS 0.1 μN.mMinimum Torque Steady CR 0.05 μN.mMinimum Torque Steady CS 0.1 μN.mMaximum Torque 200 mN.mTorque Resolution 1 nN.m [1]Motor Inertia 15 μN.m.sAngular Velocity Range CS 0 to 300 rad/sAngular Velocity Range CR 1E -8to 300 rad/sFrequency Range 7.5E -7to 628 rad/sDisplacement Resolution 40 nradStep Change in Velocity 25 msStep Change in Strain 60 msDirect Strain Control Standard [2]Thrust Bearing Porous Carbon AirNormal/Axial Force Range 0.005 to 50 NSmart Swap™StandardPeltier Plate -40 to 200 °C [3]Environmental Test Chamber (ETC)-160 to 600 °CConcentric Cylinder -20 to 150 °C [3]Peltier ControlUpper Heated Plate -30 to 150 °C [3]Electrically Heated Plate (EHP)-70 to 400 °CT ECHNICAL S PECIFICATIONSCR - Controlled Rate Mode CS - Controlled Stress Mode [1] Internal Resolution for D to A converter at torque of 0.1 µN.m [2] Direct Strain Control provides single cycle oscillation and continuous oscillations during experiments.[3] Lower temperature limits require use of a suitable fluid in an external circulator.Minimum Torque 0.1 μN.m Maximum Torque 150 mN.m Torque Resolution 1 nN.m [1]Motor Inertia 15 μN.m.s Angular Velocity Range CS 0 to 300 rad/s Angular Velocity Range CR 1.00E -7to 300 rad/s Frequency Range 7.50E -7to 628 rad/s Displacement Resolution 40 nrad Step Change in Velocity 25ms Step Change in Strain 6 0ms Thrust Air Bearing Porous Carbon Smart Swap TM Standard Peltier Plate -40 to 200 °C [2]Peltier Plate Camera Optional Peltier Concentric Cylinder -20 to 150 °C [2]Upper Heated Plate -30 to 150 °C [2]Electrical Heated Plates -70 to 400 °C[1] Internal Resolution for D to A converter at torque of 1 µN.m [2] Lower temperature limits require use of a suitable fluid in an external circulator.T ECHNICAL SPECIFICATIONSAR T ECHNOLOGY The AR series represents a family of rheometers uniquely designed to deliver optimum system performance.6 R IGID O NE-P IECE A LUMINUM C ASTING& L INEAR B ALL S LIDEAR-G2 T ECHNOLOGYM AGNETIC T HRUST B EARINGWhy a magnetic bearing? Larger gaps in the absence of a continuous flow of pressurized air translates to unprecedented low levels of friction in the bearing. More importantly, the ability to control and measure torques in the nN.m range. No other rheometer can boast such low-end torque sensitivity. The larger gap in the thrust bearing is robust and not susceptible to contamination. The additional benefits of the magnetic bearing over traditional air bearing designs are the following:• Ultra low torques applied to the sample• Smaller sample volumes can be used• Ability to probe delicate material structures• Study of low viscosity materials over abroad range of conditionsP ATENTED D RAG C UP M OTOROur new patented advanced drag cup motor is designedto further reduce system friction by increasing the motor gap by 100%. Dramatic improvements in low end torque performance are realized without compromising high-end performance. The motor delivers enhanced transient response and an extended angular velocity control range. The motor incorporates a patented drag cup temperature sensor. For the first time in any rheometer design, the temperature of the drag cup is measured, ensuring the mostaccurate torque output.ACTIVE T EMPERATURE C ONTROL(ATC)The AR-G2 Electrically Heated Plate (EHP), Upper Heated Plate (UHP),and Dry Asphalt System all incorporate our new patented(1)non-con-tact temperature sensor for active measurement and control of theupper plate temperature, using a special draw rod. The draw rodhouses a micro PCB and Platinum Resistance Thermometer. AR-G2 T ECHNOLOGYICRO PCBP RIMARY CS ECONDARY C OIL HS SaS MART S WAP TM A CCESSORIESC ONCENTRIC C YLINDERConcentric Cylinders are commonly used for very low viscosity fluids,dispersions of limited stability, and applications where fluid/solventevaporation may be a problem. The Smart Swap Concentric Cylindersystem features Peltier temperature control and provides a temperaturerange of -20 to 150 °C with heating rates up to 15 °C/min.PPER H EATED P LATE(UHP)S MART S WAP TM A CCESSORIESE LECTRICALLY H EATED P LATES(EHP)The EHP is a Smart Swap TM temperature option that provides active heating and cooling of parallel plate and cone and plate geometries. The EHP is perfect for rheological characterization of polymer melts up to a maximum temperature of 400 °C. Otherfeatures include an environmental cover and heated purge gasand an optional Gas Cooling Accessory for temperature controlto -70˚C. An optional clear purge cover is available for sampleviewing and integration with camera viewer. Additionally, for theAR-G2, the EHP offers patented Smart Swap G eometries andnewly patented Active Temperature Control, ATC. ATC makes theAR-G2 EHP the only electrically heated plate system capable ofdirect temperature control of both the upper and lower plates.S MART S WAP TM A CCESSORIESD YNAMIC I NTERFACIAL S HEARR HEOLOGY U SING THE AR-G2The dynamic interfacial shear moduli G’ and G” are used tomonitor the network structure build-up, resulting from the adsorption of proteins at the interface. Proteins unfold at the interface and, therefore, are crucial to the stability of emulsions and foams. The measurement is done with a Du Noüy Ring, positioned at the interface of two liquids, or a liquid and air in a circular glass dish. The ultra-sensitive,nano-torque range of the AR-G2 rheometer is required to make these measurements. Figure 1 shows the dynamic storage modulus of this material continuously increases as the protein migrates to the surface and forms a network structure.0.030.025 0.02 0.0150.01 0.005 050100 150time (minutes)G ‘, G ’’ (N /m )34F LOW C URVE FOR D ISPERSIONS F LOW C URVE FOR P OLYMERSV ISCOELASTIC P ROPERTIES S TRAIN S WEEPD YNAMIC M ECHANICAL P ROPERTIES OF S OLIDS IN T ORSION T RANSIENT T ESTS(C REEP AND S TRESS R ELAXATION)D YNAMIC O SCILLATION ON L OW V ISCOSITY F LUIDS U SING ARES AR-G2 N ANO-T ORQUEM EASUREMENTS IN S TRESS& S TRAIN C ONTROL O SCILLATIONS TRESS AND S HEAR R ATE R AMPSE XTENSIONAL V ISCOSITYM EASUREMENTS ON ARESC REEP AND R ECOVERY OF A V ISCOELASTIC F LUIDS TRESS G ROWTH IN A T RANSIENT S TEP R ATE E XPERIMENT41© 2009 TA Instruments. All rights reserved.。

美国海军舰载机联队大西洋舰队NS Norfolk, VA NS 诺福克,VAPacific Fleet 太平洋舰队NS Pearl Habor, HI NS珍珠哈伯,您好CVN-65 USS Enterprise CVN - 65企业号航空母舰Enterprise-class 企业级Norfo lk, VA弗吉尼亚州诺福克CVN-68 USS Nimitz CVN - 68“号尼米兹Nimitz-class 尼米兹级San Diego, CA 加利福尼亚州圣迭戈CVN-69 USS Dwight D. Eisenhower CVN- 69“号艾森豪威尔 Nimitz-class 尼米兹级Norfo lk, VA弗吉尼亚州诺福克CVN-72 USS Abraham Lincoln “亚伯拉罕林肯”号CVN - 72 Nimitz-class 尼米兹级Ev erett, WA 埃弗雷特,WACVN-70 USS Carl Vinson CVN - 70“卡尔文森 “号Nimitz-class 尼米兹级 Norfo lk, VA 弗吉尼亚州诺福克CVN-73 USS George Washington CVN - 73“乔治华盛顿 “号 Nimitz-class 尼米兹级 Yokosuka, Japan日本横须贺CVN-71 USS Theodore Roosevelt CVN -71“西奥多罗斯福 “号 Nimitz-class 尼米兹级 Norfo lk, VA 弗吉尼亚州诺福克CVN-76 USS Ronald Reagan CVN - 76“里根“号Nimitz-class 尼米兹级San Diego, CA 加利福尼亚州圣迭戈CVN-75 USS Harry S. Truman CVN -75“号杜鲁门 Nimitz-class 尼米兹级Norfo lk, VA 弗吉尼亚州诺福克CVN-74 USS John C. Stennis 美国海军CVN -74斯坦尼斯 Nimitz-class 尼米兹级Bremeton, WA Bremeton ,WACVN-77 USS George HW Bush 美国海军CVN - 77乔治HW 布什Nimitz-class 尼米兹级Norfo lk, VA 弗吉尼亚州诺福克CVW -1 CVW - 1CVN-65CVN - 65 USS Enterprise企业号航空母舰VFA-11VFA - 11Red Rippers红松土F/A-18F Super HornetF/A-18F超级大黄蜂NAS Oceana, VANAS Oceana的,VAVFA-211VFA - 211Checkmates走投无路F/A-18F Super HornetF/A-18F超级大黄蜂NAS Oceana, VANAS Oceana的,VAVFA-136VFA - 136KnighthawksKnighthawksF/A-18C HornetF/A-18C“大黄蜂”NAS Oceana, VANAS Oceana的,VAVMFA-251ThunderboltsVMFAF/A-18C HornetF/A-18C“大黄蜂”USMC海军陆战队MCAS Beaufort,- 251 雷电SC MCAS 博福特,资深大律师VAQ-137 VAQ - 137 Rooks 鲁克斯EA-6B Prowler EA -6B “徘徊者”NAS Whidbey Island, WA NAS惠德贝岛,西澳VAW-123 VAW - 123Screwtops ScrewtopsE-2C Hawkeye E - 2C 鹰眼NS Norfolk, VA NS 诺福克,VAHS-11 HS - 11 DragonslayersDragonslayersSH-60F/HH-60H SeahawkSH-60F/HH-60H海鹰NASJacksonville, FL NAS 佛罗里达州杰克逊维尔VRC-40 Det IIVRCC-2A Greyhound C - 2A灰狗NAS Norfolk, VA NAS 弗吉尼亚州- 40侦探II诺福克CVW - 2CVN-72CVN - 72 USS Abraham Lincoln“亚伯拉罕林肯“号VFA-2VFA - 2Bounty Hunters赏金猎人F/A-18F Super HornetF/A-18F超级大黄蜂NAS Lemoore, CANAS勒穆尔,CAVFA-137VFA -137Kestrels红隼F/A-18E Super HornetF/A-18E“超级大黄蜂”NAS Lemoore, CANAS勒穆尔,CAVFA-151VFA -151Vigilantes治安维持会F/A-18C HornetF/A-18C“大黄蜂”NAS Lemoore, CANAS勒穆尔,CAVFA-34VFA - 34Blue Blasters蓝历险F/A-18C HornetF/A-18C“大黄蜂”NAS Oceana, VANAS Oceana的,VAVAQ-131 VAQ - 131Lancers 枪骑兵EA-6B Prowler EA - 6B “徘徊者”NAS Whidbey Island, WA NAS 惠德贝岛,西澳VAW-116 VAW -116 Sunkings SunkingsE-2C Hawkeye E - 2C 鹰眼NAS Point Mugu, CA NAS 点木谷,CAHS-2 HS - 2 Golden Falcons 黄金猎鹰SH-60F/HH-60HSeahawkSH-60F/HH-60H 海鹰NAS North Island, CA NAS 北岛,CAHSM-77 HSM -77MH-60R Seahawk MH -60R 海鹰NAS North Island, CA NAS 北岛,CASabrehawksSabrehawksVRC-30 Det II VRC - 30侦探II Providers供应商C-2A Greyhound C - 2A灰狗NAS North Island,CA NAS北岛,CACVW - 3CVN-75CVN - 75 USS Harry S. Truman USS哈里杜鲁门VFA-32VFA -32Swordsmen剑士F/A-18F Super HornetF/A-18F超级大黄蜂NAS Oceana, VANAS Oceana的,VAVMFA-312VMFA - 312Checkerboards棋盘F/A-18C HornetF/A-18C“大黄蜂”USMC海军陆战队MCAS Beaufort, SCMCAS博福特F/A-18C HornetF/A-18C“大黄蜂”VFA-37 VFA - 37 Ragin' Bulls Ragin “公牛NAS Oceana, VA NAS Oceana 的,VAVFA-105 VFA - 105Gunslingers 枪手F/A-18E Super Hornet F/A-18E “超级大黄蜂”NAS Oceana, VA NAS Oceana 的,VAVAQ-130 VAQ -130 Zappers ZappersEA-6B Prowler EA -6B “徘徊者”NAS Whidbey Island, WA NAS 惠德贝岛,西澳VAW-126 VAW -126Seahawks海鹰E-2C Hawkeye E - 2C 鹰眼NS Norfolk, VA NS诺福克,VAHS-7 HS - 7 Dusty Dogs尘SH-60F/HH-60HSeahawkSH-60F/HH-60H海鹰NAS Jacksonville, FL NAS 佛罗里达州杰克逊维尔土飞扬的狗VRC-40 Det I VRC - 40侦探我 RawhidesRawhidesC-2A Greyhound C - 2A灰狗NAS Norfolk, VA NAS 弗吉尼亚州诺福克CVW- 5CVN-73 CVN - 73 USS George Washington “乔治华盛顿 “号 (Japan) (日本)VFA-102 VFA -102Diamondbacks响尾蛇F/A-18F Super Hornet F/A-18F 超级大黄蜂NAF Atsugi NAF厚木VFA-27 VFA - 27 Royal Maces 皇家锤F/A-18E Super Hornet F/A-18E “超级大黄蜂”NAF Atsugi NAF厚木F/A-18C Hornet F/A-18C “大黄蜂”NAF Atsugi NAF 厚木VFA-192 VFA -192Golden Dragons金龙VFA-195 VFA - 195 DambustersDambustersF/A-18C Hornet F/A-18C “大黄蜂”NAF Atsugi NAF厚木VAQ-136 VAQ -136Gauntlets 护手EA-6B Prowler EA - 6B “徘徊者”NAF Atsugi NAF 厚木VAW-115 VAW - 115Liberty Bells 自由钟声E-2C Hawkeye E - 2C 鹰眼NAF Atsugi NAF 厚木HS-14HS - 14 Chargers充电器SH-60F/HH-60H SeahawkSH-60F/HH-60H海鹰NAF AtsugiNAF厚木HSL-51HSL - 51 Warlords军阀SH-60B Seahawk SH - 60B海鹰NAF AtsugiNAF厚木VRC-30 Det V VRC - 30侦探V Providers供应商C-2A Greyhound C - 2A灰狗NAF AtsugiNAF厚木CVW- 7VFA-143VFA -143Pukin' DogsPukin“狗F/A-18E Super HornetF/A-18E“超级大黄蜂”NAS Oceana, VANAS Oceana的,VACVN-69CVN - 69USS Dwight D.Eisenhower USS艾森豪威尔VFA-103VFA -103Jolly Rogers乔利罗杰斯F/A-18F Super HornetF/A-18F超级大黄蜂NAS Oceana, VANAS Oceana的,VAVFA-83VFA - 83 RampagersRampagersF/A-18C HornetF/A-18C“大黄蜂”NAS Oceana, VANAS Oceana的,VAVFA-131VFA -131 Wildcats野猫F/A-18C HornetF/A-18C“大黄蜂”NAS Oceana, VANAS Oceana的,VAVAQ-140VAQ -140 Patriots爱国者EA-6B Prowler EA -6B“徘徊者”NAS WhidbeyIsland, WA NAS惠德贝岛,西澳VAW-125VAW -125TigertailsTigertailsE-2C Hawkeye E - 2C鹰眼NS Norfolk, VA NS诺福克,VAHS-5HS - 5 Nightdippers NightdippersSH-60F/HH-60HSeahawkSH-60F/HH-60H海鹰NAS Jacksonville,FL NAS佛罗里达州杰克逊维尔VRC-40 Det III VRC - 40侦探III RawhidesRawhidesC-2A Greyhound C - 2A灰狗NAS Norfolk, VANAS弗吉尼亚州诺福克CVW -8 CVW - 8VFA-31VFA -31TomcattersTomcattersF/A-18E SuperHornet F/A-18E“超级大黄蜂”NAS Oceana, VA NASOceana的,VACVN-71CVN - 71 USS Theodore Roosevelt“西奥多罗斯福“号VFA-213VFA- 213Black Lions黑狮子F/A-18F SuperHornet F/A-18F超级大黄蜂NAS Oceana, VA NASOceana的,VAVFA-15VFA -15ValionsValionsF/A-18C HornetF/A-18C“大黄蜂”NAS Oceana, VA NASOceana的,VAVFA-87VFA -87GoldenWarriors黄金战士F/A-18A+ HornetF/A-18A +“大黄蜂”NAS Oceana, VA NASOceana的,VAVAQ-141VAQ- 141ShadowhawksShadowhawksEA-6B Prowler EA -6B“徘徊者”NAS Whidbey Island, WANAS惠德贝岛,西澳VAW-124 VAW - 124 Bear Aces熊王牌E-2C Hawkeye E - 2C鹰眼NS Norfolk, VA NS诺福克,VAHS-3HS - 3 Tridents三叉戟SH-60F/HH-60HSeahawkSH-60F/HH-60H海鹰NAS Jacksonville, FL NAS佛罗里达州杰克逊维尔VRC-40 Det V VRC - 40侦探V Rawhides RawhidesC-2A Greyhound C -2A灰狗NAS Norfolk, VA NAS弗吉尼亚州诺福克CVW- 9VFA-154VFA -154Black Knights黑骑士F/A-18F Super HornetF/A-18F超级大黄蜂NAS Lemoore, CANAS勒穆尔,CACVN-74CVN - 74USS John C.Stennis USS斯坦尼斯VMFA-323VMFA- 323Death Rattlers死亡嘎声F/A-18C HornetF/A-18C“大黄蜂”USMC海军陆战队MCAS Miramar , CAMCAS美丽华VFA-146VFA -146 Blue Diamonds蓝彩钻F/A-18C HornetF/A-18C“大黄蜂”NAS Lemoore, CANAS勒穆尔,CAVFA-147VFA -147 Argonauts淘金F/A-18C HornetF/A-18C“大黄蜂”NAS Lemoore, CANAS勒穆尔,CAVAQ-138VAQ -EA-6B Prowler EA -6B“徘徊者”NAS Whidbey138Yellowjackets 黄衫Island, WA NAS 惠德贝岛,西澳VAW-112 VAW -112 Golden Hawks 金老鹰E-2C Hawkeye E - 2C 鹰眼NAS Point Mugu, CANAS 点木谷,CAHSC-8 HSC - 8 EightballersEightballersMH-60S KnighthawkMH - 60S KnighthawkNAS North Island, CA NAS 北岛,CAHSM-71 HSM - 71 Raptors 猛龙队MH-60R Seahawk MH- 60R海鹰NAS North Island, CA NAS 北岛,CAVRC-30 Det IV VRC - 30侦探四 Providers供应商C-2A Greyhound C - 2A灰狗NAS North Island, CA NAS 北岛,CACVW -11 CVW - 11CVN-68CVN - 68 USS Nimitz美国海军尼米兹号VFA-41VFA - 41Black Aces黑色王牌F/A-18F Super HornetF/A-18F超级大黄蜂NAS Lemoore,CA NAS勒穆尔,CAVFA-14VFA - 14TophattersTophattersF/A-18E Super HornetF/A-18E“超级大黄蜂”NAS Lemoore,CA NAS勒穆尔,CAVFA-97VFA - 97WarhawksWarhawksF/A-18C HornetF/A-18C“大黄蜂”NAS Lemoore,CA NAS勒穆尔,CAVFA-86VFA - 86Sidewinders“响尾蛇”F/A-18C HornetF/A-18C“大黄蜂”MCAS Beaufort,SC MCAS博福特,资深大律师VAQ-135VAQ - 135 Black Ravens黑乌鸦EA-6B Prowler EA - 6B“徘徊者”NAS WhidbeyIsland, WA NAS惠德贝岛,西澳VAW-117VAW -117 Wallbangers WallbangersE-2C Hawkeye E - 2C鹰眼NAS Point Mugu,CA NAS点木谷,CAHS-6HS - 6 Screamin' Indians Screamin“印第安人SH-60F/HH-60HSeahawkSH-60F/HH-60H海鹰NAS NorthIsland, CA NAS北岛,CAVRC-30 Det III VRC - 30侦探III Providers供应商C-2A Greyhound C - 2A灰狗NAS NorthIsland, CA NAS北岛,CACVW- 14CVN-76 CVN - 76 USS Ronald Reagan “罗纳德里根 “号VFA-22 VFA -22Redcocks RedcocksF/A-18F Super Hornet F/A-18F 超级大黄蜂NAS Lemoore, CA NAS 勒穆尔,CAVFA-115 VFA -115Eagles 老鹰F/A-18E Super Hornet F/A-18E “超级大黄蜂”NAS Lemoore, CA NAS 勒穆尔,CAVFA-113 VFA - 113Stingers 毒刺F/A-18C Hornet F/A-18C “大黄蜂”NAS Lemoore, CA NAS 勒穆尔,CAF/A-18C Hornet F/A-18C “大黄蜂”VFA-25 VFA - 25Fist of the Fleet 舰队之拳NAS Lemoore, CA NAS 勒穆尔,CAVAQ-139 VAQ - 139Cougars美洲狮EA-6B Prowler EA - 6B “徘徊者”NAS Whidbey Island, WA NAS 惠德贝岛,西澳VAW-113 VAW -113Black Eagles 黑鹰E-2C Hawkeye E - 2C 鹰眼NAS Point Mugu,CA NAS 点木谷,CAHS-4 HS - 4 Black Knights黑骑士SH-60F/HH-60H SeahawkSH-60F/HH-60H海鹰NAS North Island, CA NAS 北岛,CAVRC-30 Det I VRC - 30侦探我Providers供应商C-2A Greyhound C - 2A灰狗NAS North Island,CA NAS北岛,CACVW - 17VFA-81VFA -81SunlinersSunlinersF/A-18C HornetF/A-18C“大黄蜂”NAS Oceana, VA NASOceana的,VAVAQ-132VAQ- 132Scorpions蝎子EA-6B Prowler EA -6B“徘徊者”NAS Whidbey Island, WANAS惠德贝岛,西澳VAW-121VAW - 121BluetailsBluetailsE-2C Hawkeye E - 2C鹰眼NS Norfolk, VA NS诺福克,VAHS-15HS - 15 Red Lions红狮子SH-60F/HH-60HSeahawkSH-60F/HH-60H海鹰NAS Jacksonville, FL NAS佛罗里达州杰克逊维尔VRC-40 Det IV VRC - 40侦探四RawhidesC-2A Greyhound C -2A灰狗NAS Norfolk, VA NAS弗吉尼亚州诺福克TACTI CAL战术SUPPO RT支VFA-204VFA -204River Rattlers河嘎声F/A-18A+ HornetF/A-18A +“大黄蜂”NAS JRB NewOrleans, LA NAS JRB新奥尔良,洛杉矶VFC-12VFC - 12Fighting Omars战斗OmarsF/A-18C/B HornetF/A-18C/B“大黄蜂”NAS Oceana, VA NASOceana的,VA持 WINGVFC-13 VFC - 13 Fighting Saints 战斗的圣徒F-5E/F/N Tiger II F-5E/F/N 虎IINAS Fallon, NV NAS伦,内华达州VFC-111 VFC - 111Sundowners SundownersF-5N Tiger II F - 5N 老虎IINAS Key West, FL NAS 基韦斯特,佛罗里达州VAQ-209 VAQ -209 Star Warriors星勇士EA-6B Prowler EA -6B “徘徊者”NAF Washington, DC NAF 的华盛顿,DCVAW-77 VAW -77Night Wolves夜E-2C Hawkeye E - 2C 鹰眼狼NAS JRB NewOrleans, LA NAS JRB新奥尔良,洛杉矶CVW 3CVW 3CVW 7CVW 7CVW 8CVW 8 CVW 1CVW 1VFA-11 "Red Rippers"VFA - 11“红松土”VFA-32"Swordsmen"VFA - 32“剑客”VFA-143 "Pukin'Dogs"VFA -143“Pukin”狗“VFA-31"T omcatters"VFA- 31“T omcatters”VFA-211 "Fighting Checkmates"VFA - 211“战斗走投无路”VMFA-312"Checkerboards"VMFA - 312“棋盘”VFA-103 "JollyRogers"VFA -103“乔利罗杰斯”VFA-213 "BlackLions"VFA -213“黑狮子”VFA-136 "Knighthawks"VFA-136“Knighthawks”VFA-37 "RaginBulls"VFA - 37的“Ragin公牛“VFA-83"Rampagers"VFA -83“Rampagers”VFA-15 "Valions"VFA -15“Valions”VMFA-251 "Thunderbolts" VMFA - 251“雷电”VFA-105"Gunslingers"VFA - 105“枪手”VFA-131"Wildcats"VFA -131“野猫”VFA-87 "GoldenWarriors"VFA -87“黄金战士”VAQ-137 "Rooks" VAQ - 137“白嘴鸦”VAQ-130"Zappers"VAQ -130“Zappers”VAQ-140"Patriots"VAQ -140“爱国者”VAQ-141"Shadowhawks"VAQ -141“Shadowhawks”VAW-123 "Screwtops"VAW - 123“Screwtops”VAW-126"Seahawks"VAW - 126“海鹰”VAW-121"Bluetails"VAW- 121“Bluetails”VAW-124 "BearAces"VAW -124“熊王牌”HS-11 "Dragonslayers"HS -11“Dragonslayers”HSC-7 "DustyDogs"HSC -7“尘埃狗”HS-5"Nightdippers"HS -5“Nightdippers”HSM-70"Spartans"HSM -70“斯巴达”VRC-40 Det.VRC - 40侦探。

林巴赫发动机操作手册是一份详细说明林巴赫发动机的安装、调试、操作和维护的指南。

以下是关于林巴赫发动机操作手册的详细介绍:

1. 安装与调试:手册首先介绍了林巴赫发动机的安装与调试步骤。

包括发动机的搬运、安装位置的选择、连接油路和电气系统等。

在安装过程中,要确保发动机与设备的连接正确,并遵循相关的安全规范。

2. 操作方法:手册详细介绍了林巴赫发动机的操作方法。

包括启动发动机、调整发动机转速、控制油门等。

在操作过程中,要遵循正确的操作流程,确保发动机的安全运行。

3. 维护保养:手册强调了林巴赫发动机的定期维护保养的重要性。

包括更换机油、空气滤清器、燃油滤清器等。

定期维护保养可以确保发动机的正常运行,延长发动机的使用寿命。

4. 故障排除:手册提供了林巴赫发动机常见的故障排除方法。

包括发动机无法启动、发动机过热、发动机异响等。

在遇到故障时,可以根据手册提供的故障排除方法进行排查和修复。

5. 安全注意事项:手册还列出了林巴赫发动机操作过程中的安全注意事项。

包括穿戴适当的个人防护装备、避免接触高温部件、避免在发动机运行时进行维修等。

遵循这些安全注意事项可以确保操作人员的人身安全。

6. 技术参数:手册提供了林巴赫发动机的技术参数,包括发动机型号、功率、转速、燃油消耗率等。

这些参数可以帮助用户了解发动机的性能特点,选择合适的发动机型号。

7. 附件与工具:手册还介绍了林巴赫发动机所需的附件与工具,包括油管、油泵、油嘴等。

在操作发动机时,要确保所有的附件和工具都已准备齐全。

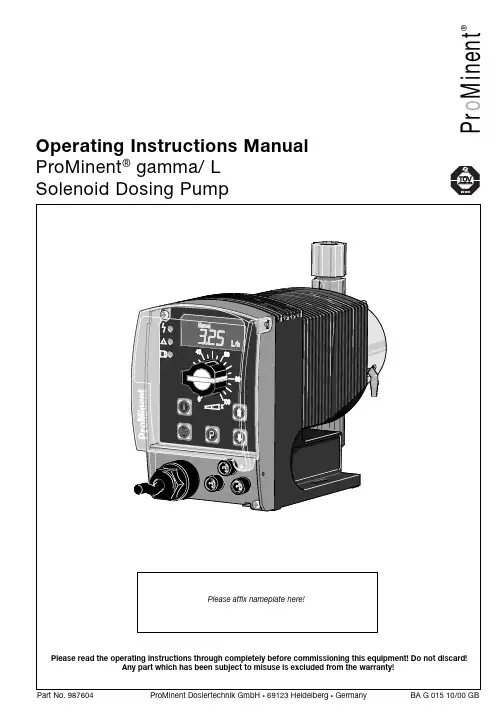

P r o M i n e n t®Operating Instructions Manual ProMinent ® gamma/ L Solenoid Dosing PumpPrintingPrinting:Operating Instructions ProMinent® gamma/ L© ProMinent Dosiertechnik GmbH, 1999Address:ProMinent Dosiertechnik GmbHIm Schuhmachergewann 5-11D-69123 HeidelbergPostfach 101760D-69007 Heidelberg*****************www.prominent.deSubject to technical alteration.Please fold out this page! ÈOperating-/Settings DiagramContinuous displayFunction DescriptionOperating modes Operating modes are selected using the MODE menu (depending upon identity code, someoperating modes may be absent)..“Analogue” operating mode: (Identity code, control variant: analogue current)The stroke rate is controlled via an analogue electrical signal via the “external control” terminal.Signal processing is pre-selected at the controller.“Manual” operating mode: (Identity code, control variant: manual, standard function)The stroke rate is controlled manually via the controller.“Contact” operating mode: (Identity code, control variant: external 1:1 / external with pulsecontrol)This operating mode offers the opportunity to make fine adjustments with small increase/decrease factors. Dosing can be activated by a pulse via the “external control” terminal or by asemiconductor element. With the “pulse control” option it is possible to pre-set a feed quantity(batch) or number of strokes (factor 0.01 to 99.99) via the control unit.“Batch” operating function: (identity code, control variant, external 1:1 / external with pulsecontrol)This operating mode offers the option of working with larger transfer factors (up to 65535).Metering can be triggered by pressing the P key or a pulse from the “external control” terminalvia a contact or semiconductor element. A batching quantity or number of strokes can be pre-selected via the control unit.Functions The following functions can be selected using the SET menu:“Calibrate” function:The gamma/ L can be operated in all operating modes including in calibrating mode. Thecorresponding continuous displays can show the actual feed quantity or the feed rate.Calibration is maintained within the stroke frequency range 0 - 180 strokes/ min. Calibration isalso maintained when a stroke frequency is altered up to ± 10 %.“Pressure level” function:It is possible to set different pressure levels.“Auxiliary frequency” function:It is possible to set a stroke rate in the SET menu, which may be activated via the “externalcontrol” terminal. This auxiliary frequency overrides all other pre-set stroke rate frequencies.“Flow” function:Stops the gamma/ L when the flow is insufficient. In the SET menu, the number of failed strokesis entered after which the pump will be turned off.The following functions are available as standard:“Float switch” function:Information on the liquid level in the feed chemical container is transmitted to the gamma/ L.This option requires the installation of a 2-stage float switch. This is connected to the “floatswitch” terminal.“Pause” function:The gamma/ L can be stopped by remote control via the “external control” terminal. The “pau-se” function operates only via the “external control” terminal.The following functions are activated by keystrokes:“Stop” function:The gamma/ L can be stopped by pressing the STOP/START key without disconnecting fromthe mains power supply.Function Description“Prime” function:Priming (short term feed at maximum frequency) is activated by pressing both arrow keys at thesame time.Optional relay The gamma/ L has two connection options.“Fault indicating relay” option:In the event of fault signals, warning signals or float switch activation signals, connects anelectrical circuit to trigger alarm sirens etc. The relay is retrofitted via an aperture in the powerend.“Fault indicating and pacing relay” option:Along with the fault indicating relay, the pacing relay produces an electrical impulse for everystroke. The relay is retrofitted via an aperture in the power end.Function and errorindicators The operating and error status is shown via the three LEDs and the “error” indicator on the LCD (see also section 12):LCD indicator If a fault occurs “error” will appear along with an additional fault warning.LED indicator Operating indicator (green)This indicator is lit as long as the gamma/ L is operating correctly.Warning indicator (yellow)This warning light appears if the gamma/ L electronics detect a situation that could lead to afault, e.g. “liquid levels low 1st stage”.Warning indicator (red)This warning light appears if a fault occurs, e.g. “liquid levels low 2nd stage”.Hierarchy of operating modes, functions and fault statusesThe different operating modes, functions and fault statuses each have a differing effect onwhether and how the gamma/ L functions. These effects are given below:1.Prime2.Fault, stop, pause3.Auxiliary frequency4.Manual, analogue, contact, batchto:1.“Prime” can be activated in any pump status (as long as it is operable)2.“Fault”, “stop” and “pause” stop all system parts up to “prime”.3.The stroke rate of the “auxiliary frequency” always overrides the existing operating strokerate.Commissioning / Operating8.2Diagrams for setting feed capacityGeneralS Open out the page showing the diagram of your pump type (see appendix).S Calculate the correction factor. Mark the operating pressure for your application in the dia-gram “correction factor depending upon operating pressure”.S Trace a line from this value vertically up to the curve and then horizontally left. Read off thecorrection factor.S Divide the required feed rate by the correction factor determined as above. Mark this value(l/h) on the “l/h” axis in the diagram “feed rate depending upon stroke length and strokerate”.S Trace a line horizontally from this value to the left. Trace a line from the intersection with thestraight line for the adjustable stroke frequencies vertically downwards to the “strokelength” axis.S Set the gamma/ L to one of the stroke frequencies determined in this way, and thecorresponding stroke length.The measurements for determining the feed rate for the following diagrams were carried outusing water and the correction factor was determined at a 70 % stroke length. Distribution ofthe feed rate across all material versions: -5 to +15 %.9OperatingThis section describes all operating options available to you when the gamma/ L is incontinuous display mode (no P key symbol in the LCD display).GUIDELINE•Open out the fold-out page following the title page fully! There you will find theoverviews “control elements and key functions” and “operating settings dia-gram”.•Look at the overview “continuous displays”. This page shows you which displaysare available in which operating mode, and which values are directly alterable inthe corresponding continuous displays.9.1Manual operationSet stroke length Stroke length is continually adjustable within a range of 0 - 100 %. The recommended strokelength range, which will practically guarantee technical reproducibility, is 30 - 100 % (SEK type:50 - 100 %).The following operating options are available via the different keys (see also figure on the nextpage):Stop/Start gamma/ L To stop gamma/ L: press STOP/START key.To start gamma/ L: press STOP/START key.Start batch Press the P key briefly in “batch” operating mode.Load factory settings Press the P key for 15 s to load factory calibration settings!Current settings will be deleted.Change to settings mode WeIf you press the P key for 2 s in any continuous display the gamma/ L will change to settingsmode (see section 7).If CODE 1 is set, the code must be entered after pressing the P key.Check adjustable values Each time you press the i key you will see a different continuous display. The number ofcontinuous displays depends upon the identity code, the selected operating mode and theconnected accessories.Change directlyalterable values To change a value (see below) directly in the corresponding continuous display, press one of thearrow keys until “set” appears in the LCD display. The delay has been programmed in to preventinadvertent changing of values.If CODE 2 has been set, this code must be entered after pressing the arrow key.Directly alterable values are as follows:。

Parker Hannifin Manufacturing Germany GmbH &Co.KG Registered office:Bielefeld District Court:Bielefeld HRA 15699Branch office Kelsterbachpersonally liable partner:Parker Hannifin GmbHFasanenweg 5,65451Kelsterbach,Germany Registered office:Bielefeld District Court:Bielefeld HRB 35489Tel.:+4961079039-0,Fax:+496107-64162Managing directors of Parker Hannifin GmbH:Dr.-Ing.Hans-Jürgen Haas,E-Mail:**********************Ellen Raahede Secher,Kees VeraartInternet:Chairman of the Supervisory Board:HansgeorgGreunerInstallation InstructionsHydrant Pit BoxWL5917©2017-This documentation is copyrightprotected.History of document versionsRevision Date Author Reason for change/commentsR0010.08.2017Documentation First creationTable of contentsHistory of document versions (2)Table of contents (2)1Introduction (3)1.1General information (3)1.1.1Purpose and aim of this document (3)1.1.2Abbreviations (3)1.1.3Glossary (3)1.1.4Literature and bibliography (3)1.2Description of the hydrant pit box (4)2Assembly of the hydrant pit box (4)2.1Procedure (4)2.1.1General information (4)2.1.2Welding on the inner housing (5)2.1.3Installation of the outer hydrant housing (5)2.1.4Integration of external hydrant housing in concrete (5)2.1.5Installation of the cover (5)3Assembling the hydrant pit valve (6)3.1Procedure (6)3.1.1General information (6)3.1.2Finish of flange sealing surfaces (6)3.1.3Visual inspection prior to installation (6)3.1.4Lubrication and lubricants (7)3.1.5Mounting and centering the seal (7)3.1.6Applying the required tightening torques (8)3.1.7Use of DIN flanges (9)3.1.8System for the tightening of screws (9)3.1.9Quality assurance and documentation of installation (10)3.1.10Pressure and leak testing (11)4Drawing E-5917-00Rev.3 (12)5Parts list E-5917-00Rev.3 (13)1Introduction1.1General information1.1.1Purpose and aim of this documentThe manual describes the operation of the hydrant pit box and aims to provide an overview of the activities for installation,risks,and workflows with any appropriate release procedures for all partici-pants.Wearing PPE,local policies and in particular the safety regulations,laws,and specifications must continue to be observed.1.1.2Abbreviationsbar Pressure unitBetrSichV Operational safety ordinance(replacement for VbF)DN Nominal diameterEx-R Explosion protection directives(ATEX)HSSE Health,Safety,Security and EnvironmentHSEQ Health,Safety,Environment and QualityPSA,PPE Personal Protective EquipmentSiGe Safety and health protection1.1.3GlossaryDispenser Tanker vehicle with hose,filter water separators and counters for the refuelling of aircraft on the apronFlusher Cleaning vehicle for cleaning the underground hydrant systemHydrant Connection point for the removal of fluids from pressure pipe systems.With avi-ation fuel systems,the refuelling of aircraft is effected via an underground kero-sene pipeline network and hydrants.Kerosene Fuel for jet engines and propeller turbines;very similar to paraffin.Kerosene is obtained by distillation of petroleum,similar to diesel and gasoline,but differentto these,can function without halogenated additives.The technical term is TurboFuel Jet A-1.Pit pipeline Underground pipeline from the distributor shaft to the underground hydrant pit valveTransfer station Structural equipment at the end of the transmission lineUndergroundhydrant pitvalveConnection point for the refuelling of aircraft by means of a dispenser1.1.4Literature and bibliography∙Relevant DIN,DIN EN and ISO standards∙DIN EN1591-1Tightening torques∙MIL-PRF-4556F1.2Description of the hydrant pit boxThe hydrant pit box is intended for the installation of API/IP-hydrant pit valves.It consists of an inner housing made of a steel welded construction and an outer housing made of spheroidal cast iron.To maintain cleanliness of the product and to protect against corrosion both housings are coated as follows:the inner sides are coated with Interline850according to MIL-PRF-4556F,and the outer sides with Poxitar F(epoxy black).To transfer vertical loads to the surroundings-concrete-the outer housing can slide vertically relative to the inner housing.To prevent the leakage of the product and of any contaminated surface water into the ground,a seal in the form of a bellows is fitted between the outer and inner housing.In the inner housing there is a welded-on6”riser flange,on which the hydrant pit valve and if required an isolating ball valve are mounted.A pipe is welded onto the outer side of the hydrant inner housing, which is welded to the pipes of the hydrant system by a certified specialist company.The hydrant pit box has a cover made of an aluminium alloy.It has a non-slip surface,a Buna"N"cover seal,and a nylon tether and is delivered depending on the required certification of the airport in the respective load class.The design of the underside of the cover allows rotation of the cover without twisting and buckling of the nylon tether.The nylon tether is attached to the hydrant pit box using the provided screw lugs at the inside of the hydrant pit box.Screw lugs for secure transport are located inside the hydrant pit box.2Assembly of the hydrant pit box2.1Procedure2.1.1General information2.1.1.1Regulations and work instructionsBetrSichV,HSSE,HSSQ,SiGe and internal work instructions and requirements are to be observed and adhered to,if applicable.2.1.1.2Transport-loading and unloadingThe hydrant pit box is delivered by a logistics company.The hydrant cabinet comes lashed,packed in shrink wrap on a wooden pallet.The offloading must be done professionally and properly with suitable loading and unloading equipment.The outer housing is placed onto the inner housing for transport purposes and secured with three(3) transport locks.2.1.2Welding on the inner housingTo weld on the inner housing to the piping system the three transport locks must be demounted,and then the outer housing can be removed.The welding on is done in accordance with the specifications and requirements for the pipework sys-tem to be connected.After welding,the coating of the pipe must be applied in accordance with the applicable requirements for the pipework system.Note:A blind flange must be installed on the riser flange for the pressure test of the complete system.2.1.3Installation of the outer hydrant housingBefore installing the outer hydrant housing the cover must be removed,and the outer housing is lifted up using suitable loading and unloading equipment on slings and hooks,so that it hangs freely and can be moved.Note:The outer casing must be aligned so that the distance between the sealing surface of the6"ANSI300 lbs riser flange and the top of the hydrant pit box respectively the surrounding concrete surface of the airfield is545mm.The three(3)transport locks are screwed to the screw lugs inside at the top of the pit box to fix the housing.Fine alignment of the housing to the surrounding concrete surface of the airfield is done by turning the nuts under the mounting flanges.2.1.4Integration of outer hydrant housing in concreteDuring the concrete work the following points must be observed:∙The concrete thickness around the hydrant cabinet must not be more than350mm,so that a vertical movement relative to the inner housing is ensured.∙The inner housing must be not set in concrete to avoid stress in the piping system.∙The transition between the outer and inner housing must remain free to ensure the vertical mobility.∙The top of the outer housing of the hydrant pit box should be aligned to the surrounding con-crete floor in a way that it stands slightly proud with a slight slope in the concrete around the pit box.This will prevent that surface water runs into the hydrant pit box as soon as the cover is removed.∙If the cover is mounted during the concrete works the cover seal must be protected so that it is not damaged.2.1.5Installation of the coverAfter the installation of the hydrant pit box the transport locking devices are removed first.∙The nylon tether of the cover is attached to one of the3lugs in the housing and secured witha cable clamp.∙Before inserting the cover the Buna"N"(O-ring)seal has to be checked,then the cover can be used.The cover must stand not more than1mm proud of the hydrant cabinet.To set the cover height,seals are available in different thicknesses.3Assembling the hydrant pit valve3.1Procedure3.1.1General informationBefore installation of the hydrant pit valve the distance between the surface of the riser flange and the top of the housing(equal to top of the housing cover)must be checked.Note:The distance must be545±5mm.If it is larger,it may be necessary to install an intermediate ring between riser flange and hydrant valve,to bridge the distance.The supplied seal must be fitted between riser flange and hydrant valve.The nuts are tightened with the specified torque.3.1.2Finish of flange sealing surfacesIf the flange sealing surfaces are supplied with a temporary coating,e.g.as corrosion protection,then this must be removed without residues prior to installation(e.g.with detergent and a suitable wire brush).Note:When exchanging seals,it must be ensured that the old seal is removed completely from the flange sealing surface,without the sealing surface being damaged.Note:Remnants of corrosion inhibitors on the flange sealing surfaces(with new flanges)adversely affect the leak tightness of flange connections as well as the removal of the seal remains in a subsequent ex-change of seals.3.1.3Visual inspection prior to installationMake sure that the flange sealing surfaces are clean,undamaged and flat.In particular,no radially running surface damages such as scratches or points of impact must be present.In case of doubt the damage must be examined by an expert on-site and the flange if necessary re-placed or refinished.Screws,nuts,and washers must be clean and undamaged.Pay particular attention to the threads and contact surfaces.Screws,nuts,and if necessary washers removed during assembly work are to be replaced with new according to the risk assessment or after testing in the event of ed screws,nuts,and wash-ers are allowed only to be reinstalled in the"as new"condition.The seal must be clean,undamaged and dry.The use of adhesives and assembly pastes is not allowed for ed seals must not be used again.In particular,seals with kinks should never be used,be-cause they pose a safety risk.Ensure that only seals which are free of defects and faults are provided to the assembly personnel.The manufacturer's instructions must be observed.3.1.4Lubrication and lubricantsTo minimise friction forces the sliding surfaces of the screws,nuts,and washers are to be treated with suitable lubricants before tightening.Optimal lubrication is given when all sliding surfaces such as the thread,the nut contact surface,and if necessary with moving screw head also the head contact surface is lubricated(see Figure1).Only in this way the required screw preload can be reached at the specified torque,and after exposure to temperature easy loosening of the screw connections is possible.All lubricants should be applied only as a thin film,but across complete surfaces.Excess lubrication has no advantages,neither with respect to friction reduction.The application can be done with a medium hard,non-shedding brush or a sponge.3.1.5Mounting and centering the sealThe correct mounting of the flange connections relies on matching flange plates without centre offset, which allow correct positioning of the seal without damage.Centering bolts should be used especially for stretch bolts as a mounting aid.Recommendation:Use centering bolts made of plastic,so that gap or misalignment cannot be levered with the bolt. The gap(non-parallelism of the sealing surfaces)before tightening of the screws can be regarded as of no consequence,as long as the permitted gap according to figure2is not exceeded.The gap has to be eliminated from the gaping side (a).NutNutWasherThreadThreadWasherWasherNutFigure1–Flange connection elements to be lubricated(left version with screw,right version with threaded bar)3.1.6Applying the required tightening torquesTo achieve the tightness class of L0,01,tightening torques were determined according to DIN EN1591-1(table1).For simplification,for a group of seals,nominal sizes,and PN-classes the calculation of the tightening torques has been optimised,so that for one screw size in conjunction with the seal group only one tightening torque can be set.In most cases,the permissible stresses for at least one part of the flange connection have been exhausted.The simplification achieved with this approach for practical applica-tion compensates the few cases of non-maximum load stresses.Note:Flanges made of austenitic steel and ferrite according to DIN EN1092-1are dimensionally the same. Table1-required tightening torques for mounting of flanges according to DIN EN1092-1type11and fasteners(such as screws,threaded rods)of25CrMo4/A2-70or comparable strength Figure2–Flange opening gaps and guideline values for permissible gap=a-bThreadTorqueTightening processSeal groupWith manual wrenchor if req.with exten-sionSeal groupWith torque wrenchor other torque-con-trolled processThese tightening torques were calculated by BASF SE and confirmed on occasion by cooperating companies.Recommended lever length300mmRecommended lever length550mm3.1.7Use of DIN flangesAlso for DIN flanges,whose sizes are identical to DIN EN1092-1,the tightening torques in table1apply for the nominal sizes and PN-classes shown in table2.Table2–nominal sizes and PN-classes of the previous DIN flangesThe smaller flange thickness of DIN flanges<DN50compared with EN flanges has no influence on the tightening torques.Austenitic weld neck flanges for machine welding according to PAS1057-6with reduced s-dimension (base wall thickness)are covered by the DIN flanges.3.1.8System for the tightening of screws3.1.8.1General informationThe order in which the nuts and bolts are tightened has a significant impact on the distribution of forces acting on the seal(surface pressure).Improper tightening leads to a high variation of bolt loads and can lead to falling below the required minimum surface pressure and to leaks.After tightening the nut at least two,but no more than five threads should protrude at the end of the screw(see also DIN78).Threaded rods are to be mounted so that the overhangs on both sides are about equal.Screw heads,nuts,and washers must have smooth contact.The screws are to be pre-assembled by hand,when doing so∙hardened washers according to DIN EN ISO7089with minimum hardness class200HV are to be placed under the nuts∙the screws are to be installed so that all screw heads are arranged on one side of the flange ∙with bolt connections where the screw head is turned(blind hole),put the washers under the bolt heads∙for horizontally arranged flanges place the screws from above∙stiff bolts should be replaced by smooth running ones∙it is possible to simultaneously use multiple tightening toolsPressure class Standard Nominal size3.1.8.2Tightening procedureThe screws are1.to be tightened cross-wise,as shown in figure3,with30%of the nominal torque2.to be tightened same as1.,with60%of the nominal torque3.to be tightened same as1.,with100%of the nominal torque4.tightend once more with full nominal torque around the circumference This process is to berepeated so often until the nuts no longer turn on applying the full torque.3.1.9Quality assurance and documentation of installation3.1.9.1Quality assuranceThe assembly class determines what measures are required for quality assurance,including the related documentation,see table3.Table3-measures for quality assurance by assembly class8screws12screws16screws20screws24screwsFigure3–Tightening process1:cross-wise tightening of the screwsAssembly class Quality assurance measuresNo continuous inspectionsSampling inspection-By assembly personnel(by a second technician)-Scope:2%of the flange connections-If deviations from the torque range are found the inspection scope is to be extended-DocumentationSampling inspection-By assembly personnel(by a second technician)-Scope:10%of the flange connections-If deviations from the torque range are found the inspection scope is to be extended-DocumentationCross-check-By an independent person-Scope:2%of the flange connections-Documentation-If deviations from the torque range are found the inspection scope is to be extended-11 Due to the settling behaviour of the seal,the check of the torque should be done4hours after instal-lation at the earliest.To determine the test torque,the torque is multiplied with the PQR value of the seal at the QA value of30MPa at room temperature taking into consideration the variation when tightening the screws.If the flange connection is checked immediately after installation,the tightening torques are to be used as test torques.The check of the tightening torque is done at the location where the screw connection was tightened. Usually,the nut is tightened.For this reason,here also the washer is installed.For the test,the torque wrench is set to the test torque.If the nut cannot be turned further,the required tightening torque has been applied.3.1.9.2DocumentationThe nature and extent of the documentation must be consistent with the respective operational man-agement system.The following list is an example.∙New creation:o Planning documentationo Isometricso Workshop drawingso Specificationso Schematic sketches∙Inspection or minor repairs:o Work cardso Repair specificationso Plant-specific opening and closing of flange connectionso Shift logo Repair bookFor the documentation of the assembly,for example the manufacturer certification including naming the participating installation technicians is sufficient.It is not necessary that the flange connection is associated with a specific technician.Thus,it would be sufficient for the documentation of the assem-bly for example that the staff involved in the assembly are named on the manufacturing and inspection certificates for pipes.An individual marking of flange connections can be useful.3.1.10Pressure and tightness testingPressure test(according to BetrSichV:Strength testing)and leakage tests(according to BetrSichV:ex-ternal examination)are to be carried out according to the assembly quality assurance.Montageanl_Hydrgeh_WL6576_E_201708R00.docx11of。

1*TD-000150-Cinema Loudspeaker Systems User ManualSB-5218 and SB-7218 Dual-18” SubwoofersIntroductionThe SB-5218 and SB-7218 are specially designed cinema subwoofers, featuring dual 500 and 700 watt, respectively, 18” (460mm) low-frequency transducers mounted in ported enclosures. The enclosures are tuned to 25 hertz and use a B6 alignment. These should be used with the B6 boost filter option provided by the QSC SF-1 or SF-3 Subwoofer Filter mod-ules or the QSC Digital Cinema Monitor to ensure extended response to the lowest audible frequencies.Meeting cinema requirements for the extended low frequency response differentiates the SB-5218 and SB-7218 from more conventional “rock-and-roll” subwoofer systems. Their fre-quency range extends to below 25 hertz when used with the correct B6 filter.The two custom 500 watt (700 watt, SB-7218), 18” transducers were developed especially for cinema use. The woofers feature 4” (100mm) voice coils and vented pole pieces to ensure cool operation, even at high power levels. Cooler temperatures increase driver lifespan and decrease problematic power compression at high drive levels. Undercut pole pieces provides a Symmetrical Magnetic Gap (SMG), reducing second harmonic distortion.Enclosures are constructed of high quality MDF panels and feature Single Woofer Chambers (SWC). The separate chamber for each transducer makes the enclosure stronger, provides rigidity, and prevents cone over-excursion in the rare event of a driver failure (enclosure “loading” is not lost for the remaining transducer).Large, Fully Radiused Ports (FRP) ensure smooth air flow through the ports, especially at higher drive levels. This prevents potentially audible port turbulence noise. Both internal and external port openings are fully radiused.With Symmetrical Port Loading (SPL) bass ports are evenly spaced on each side of the trans-ducers, making internal pressure more uniform across the back surface of the transducer. This prevents the cone from being displaced to one side or another by unbalanced air pres-sure, reducing the chance of driving the voice coil out of the center of the gap at high drive levels.Enclosure is not designed to be suspended, flown, or rigged. Do not sus-pend, fly, or rig this enclosure.This product is capable of producing sound pressure levels that can perma-nently damage human hearing. Always keep sound pressure levels in the listening area below levels that can damage human hearing.Install in accordance with QSC Audio Product’s instructions and alicensed, professional engineer. Only use attachments, mounts, accesso-ries, or brackets specified by QSC Audio Products, Inc. Refer all servicing to qualified personnel. Servicing is required when the apparatus has been damaged in any way.WARNING! Before placing, installing, rigging, or suspending any speaker product, inspect all hardware, suspension, cabinets, transducers, brackets and associated equipment for damage. Any missing, corroded, deformed or non-load rated component could significantly reduce the strength of the installation, placement, or array. Any such condition severely reduces the safety of the installation and should be immediately corrected. Use only hardware which is rated for the loading conditions of the installation and any possible short-term unexpected overloading. Never exceed the rating of the hardware or equipment. Consult a licensed, professional engineer when any doubt or questions arise regarding a physical equipment installa-tion.TD-000150-00 rev.C© Copyright 2003, 2004, QSC Audio Products, Inc.QSC® is a registered trademark of QSC Audio Products, Inc.“QSC” and the QSC logo are registered with the U.S. Patent and Trademark Office1675 MacArthur Blvd., Costa Mesa, CA, 92626 USAMain Number (714) 754-6175 Sales & Marketing (714) 957-7100 or toll free (USA only) (800) 854-4079Customer Service(714) 957-7150 or toll free (USA only) (800) 772-28342ConnectionsNormal Connection The SB-5218/7218 has barrier strip screw ter-minals for connection. The terminals accept up to #10 AWG stranded loudspeaker wiring. Use the largest wire size and shortest wire length possible for a given installation. Observe the polarity markings and keep polarity consistent throughout the system for best performance.Parallel Connection of Second SB-5218/7218The terminals marker SPK2 may be used to con-nect another SB-5218/7218 in parallel. Connect the wires as shown in the illustration, at right. Note: If the SB-5218/7218’s internal wiring has been modified in any way, this may not func-tion. If this is the case, remove the terminal cup and verify the presence of the factory yellow jumper and blue jumper wires; remedy as required or have the loudspeaker serviced.Individual Transducer Connection (requires modification)The transducers are wired in parallel inside the enclosure. If individual transducer connection is required, remove the terminal cup and remove the yellow and the blue jumper wires that are connected between the SPK1 and SPK2 termi-nals. Replace the terminal cup and mark the enclosure with a note of the modification.Normal Connection Example:Parallel Connection Example:Individual TransducerConnection Example:3Specifications (subject to change without notice)SB-5218SB-7218Frequency Range:24 - 100 Hz (±3 dB)22 - 100 Hertz (±3 dB)19 - 250 Hz useable range (-10 dB)19 - 250 Hertz useable range (-10 dB)Maximum Output:135 dB SPL calculated peak137 dB SPL calculated peak1 meter, half space, at rated rms power with 6 dB crest factor pink noise input, 25 - 250 Hertz.129 dBA SPL calculated maximum continuous 130.5 dBA SPL calculated maximum continuous1 meter. The dBA scale is typically used to identify sound sources which can cause permanent hearing loss.Impedance:4 ohms, nom. (3.2 @ 25 Hz., 62 @ 50 Hz.) 4 ohms, nom. (3.2 @ 27 Hz., 28 @ 48 Hz.)Maximum Input Power:100 hours of 6 dB crest factor 800 watts rms1200 watts rmspink noise, 25 - 250 Hertz2 hours of 6 dB crest factor1000 watts rms1500 watts rmspink noise, 25 - 250 Hertz, AES methodRecommended Amp Power:1600 watts rms maximum 2600 watts rms maximum Sensitivity:99.5 dB half space 101.0 dB half space (25 - 100 Hz, 1 watt, 1 m.)93.5 dB full space95.0 dB full spaceWeight:225 lbs. shipping, 205 lbs. net (102/93 kg.)230 lbs. shipping, 210 lbs. net (104/95 kg.)Both Models-Nominal Coverage:Omnidirectional (80 Hz)Recommended Processing:LF boost- freq.= 25 Hz, Q=2.0, gain= +6 dB. QSC DSP configurations are available at . Parameters for alternative processing hardware are available upon request.Connectors:Barrier strip screw terminals accept up to #10 AWG stranded wire. Four terminals: (two INPUT and two PARALLEL OUT). Drivers are internally wired in parallel. For independent transducer connection, remove blue jumper wire and yellow jumper wire on internal-side of terminal cup and mark enclosure accordingly.Transducers:Two 18” (457mm) high efficiency subwoofer transducers featuring vented 4” (100mm) copper voice coils on Kapton® formers. High excursion/low distortion design, with extremely high power handling, and low thermal and port com-pression.Enclosure:B6 alignment, vented enclosure with symmetrical port design, tuned to 25 Hz, constructed of medium density fibre-board and heavily braced. Features vandal resistant woofer mounting bolts.Size:30” wide X 48” high X 24” deep (762 mm X 1220 mm X 610 mm)4Warranty (USA only; other countries, see your dealer or distributor)DisclaimerQSC Audio Products, Inc. is not liable for any damage to amplifiers, or any other equipment that is caused by negligence or improper installation and/or use of this loudspeaker product. QSC Audio Products 3 Year Limited WarrantyQSC Audio Products, Inc. (“QSC”) guarantees its products to be free from defective material and / or workmanship for a period of three (3) years from date of sale, and will replace defective parts and repair malfunctioning products under this warranty when the defect occurs under normal installation and use - provided the unit is returned to our factory or one of our authorized service stations via pre-paid transportation with a copy of proof of purchase (i.e., sales receipt).This warranty provides that the examination of the return product must indicate, in our judgment, a manufacturing defect.This warranty does not extend to any product which has been subjected to misuse, neglect, accident, improper installation, or where the date code has been removed or defaced. QSC shall not be liable for incidental and/or consequential damages.This warranty gives you specific legal rights. This limited warranty is freely transferable during the term of the warranty period.Customer may have additional rights, which vary from state to state.In the event that this product was manufactured for export and sale outside of the United States or its territories, then this lim-ited warranty shall not apply. Removal of the serial number on this product, or purchase of this product from an unauthorized dealer, will void this limited warranty. Periodically, this warranty is updated. To obtain the most recent version of QSC’s war-ranty statement, please visit . Contact us at 800-854-4079 or visit our website at .Contacting QSC Audio ProductsMailing address:QSC Audio Products, Inc.1675 MacArthur BoulevardCosta Mesa, CA 92626-1468 USATelephone Numbers:Main Number (714) 754-6175Sales & Marketing (714) 957-7100 or toll free (USA only) (800) 854-4079Customer Service(714) 957-7150 or toll free (USA only) (800) 772-2834Facsimile Numbers:Sales & Marketing Fax(714) 754-6174Customer Service Fax(714) 754-6173World Wide Web: E-mail:*************************************QSC Audio Products, Inc. 1675 MacArthur Boulevard Costa Mesa, California 92626 USA ©2003, 2004 “QSC” and the QSC logo are registered with the U.S. Patent and Trademark Office.Kapton® is a registered trademark of E.I. du Pont de Nemours and Company.5Manual del usuario de los sistemas de altavoces para salas de cineSubwoofers dobles de 18"SB-5218 y SB-7218IntroducciónLos subwoofers SB-5218 y SB-7218 están especialmente diseñados para salas de cine, cuentan con dos transductores de baja frecuencia de 18” (460mm), de 500 y de 700 vatios,respectivamente, montados en cajas con puertos. Las cajas están afinadas a 25 hertz y usan una alineación B6. Deben usarse con la opción de filtro intensificador B6 proporcionada por los módulos de filtro de subwoofer QSC SF-1 o SF-3 o por el monitor de cine digital QSC para asegurar la respuesta extendida a las frecuencias audibles más bajas.El cumplimiento de los requisitos de salas de cine respecto a la respuesta extendida de baja frecuencia distingue a los subwoofers SB-5218 y SB-7218 de los sistemas de subwoofers tipo “rock-and-roll” más convencionales. Su intervalo de frecuencia se extiende por debajo de los 25 hertz cuando se usan con el filtro B6 correcto.Los dos transductores de 18", de 500 vatios (700 vatios para el SB-7218) se desarrollaronespecíficamente para su uso en salas de cine. Los woofers tienen bobinas de voz de 4” (100 mm) y polos ventilados para asegurar una operación fría, incluso a niveles de alta potencia. Lastemperaturas más frías aumentan la vida útil del excitador y reducen la problemática compresión de la potencia a niveles altos de excitación. El polo proyectado proporciona un campo magnético simétrico (Symmetrical Magnetic Gap, SMG), reduciendo la segunda deformación armós cajas están construidas con paneles MDF (cartón duro de densidad media) y tienen cámaras de woofer sencillo (Woofer Chambers, SWC). La cámara separada para cada transductorproporciona a la caja resistencia, rigidez, y evita la excursión excesiva del cono en el raro evento de una falla del excitador (la "carga" de la caja no se pierde para el transductor restante).Los grandes puertos totalmente redondeados (Fully Radiused Ports, FRP) aseguran un flujo de aire uniforme a su través, especialmente a niveles mayores de excitación. Esto evita ruido de turbulencia en el puerto potencialmente audible. Ambas aberturas del puerto, la interna y la externa, están totalmente redondeadas.Con la carga simétrica de los puertos (Symmetrical Port Loading, SPL), los puertos de bajos están igualmente separados a cada lado de los transductores, haciendo que la presión interna sea más uniforme a través de la superficie posterior del transductor. Esto evita que el cono sea desplazado de un lado a otro por la presión no equilibrada del aire, reduciendo la probabilidad de impulsar la bobina de voz fuera del centro del espacio a altos niveles de excitación.La caja no está diseñada para montarse suspendida, en voladizo ni sobre arneses. No suspenda esta caja, no la monte en voladizo ni sobre arneses.Este producto es capaz de producir niveles de presión del sonido que pueden causar daños permanentes al oído humano. Siempre mantenga los niveles de presión del sonido en un área de audición con un nivel menor que el que provoca daños al oído humano.Instale de acuerdo con las instrucciones de QSC Audio Products y de un ingeniero profesional con la debida licencia. Sólo use piezas, montajes,accesorios y soportes especificados por QSC Audio Products, Inc. Refiera todo el servicio a personal calificado. Cuando el aparato haya sido dañado de alguna manera, es necesario proporcionarle servicio.¡ADVERTENCIA! Antes de colocar, instalar, montar o suspender cualquier producto de altavoz, inspeccione todo el herraje, la suspensión, los armarios, los transductores, los soportes y el equipo asociado para detectar laexistencia de daños. Cualquier componente faltante, corroído, deformado, o sin carga nominal podría reducir significativamente la resistencia de lainstalación, la colocación o la configuración. Cualquier condición de este tipo reduce gravemente la seguridad de la instalación y debe corregirse deinmediato. Use sólo herraje que esté clasificado para las condiciones de carga de la instalación y cualquier carga excesiva a corto plazo inesperada posible. Nunca exceda el valor nominal del herraje ni del dispositivo. Consulte a un ingeniero profesional con la debida licencia cuando surjan dudas o preguntas referentes a la instalación física del equipo.*TD-000150-TD-000150-00 rev.C© Derechos de autor 2003, 2004, QSC Audio Products, Inc.QSC® es una marca comercial registrada de QSC Audio Products, Inc.“QSC” y el logotipo de QSC están registrados con la Oficina de Patentes y MarcasComerciales de los Estados Unidos1675 MacArthur Blvd., Costa Mesa, CA, 92626 EE.UU.Número principal +1 (714) 754-6175 Ventas y Comercialización +1 (714) 957-7100 o línea sin costo (sólo para EE.UU.) +1 (800) 854-4079Servicio al cliente +1 (714) 957-7150 o línea sin costo (sólo en EE.UU.) +1 (800) 772-28346ConexionesConexión normalEl SB-5218/7218 tiene terminales de tornillo de barra protectora para su conexión. Losterminales aceptan cableado trenzado de hasta #10 AWG para altavoces. Use el alambre del calibre más grande y de la longitud más corta posible en cualquier instalación. Observe las marcas de polaridad y mantenga la polaridad uniforme en todo el sistema para permitir el mejor rendimiento.Conexión en paralelo de un segundo SB-5218/7218Los terminales marcadores SPK2 se pueden usar para conectar en paralelo otro SB-5218/7218. Conecte los cables como se como se muestra en la ilustración, a la derecha. Nota: si el cableado interno de SB-5218/7218 se ha modificado de alguna manera, es posible que no funcione. En este caso, quite la cúpula del terminal y verifique la presencia de alambres amarillos y azules de puentes instalados en fábrica; corrija el problema según se requiera, o solicite que den servicio al altavoz.Conexión del transductor individual(requiere modificación)Los transductores están conectados en paralelo dentro de la caja. Si se requiere la conexión del transductor individual, quite la cúpula del terminal y quite los alambres amarillo y azul del puente que están conectados entre los terminales SPK1 y SPK2. Vuelva a colocar la cúpula del terminal y marque la caja con una nota que indique la modificación.transductor individual:Ejemplo de una conexión normal:Ejemplo de conexiónen paralelo:7Especificaciones (sujetas a cambio sin previo aviso).SB-5218SB-7218Intervalo de frecuencia:24 - 100 Hz (±3 dB)22 - 100 Hertz (±3 dB)Intervalo útil de 19 - 250 Hz (-10 dB)Intervalo útil de 19 - 250 Hertz (-10 dB)Salida máxima:Pico calculado de SPL: 35 dBPico calculado de SPL: 137 dB1 metro, medio espacio, a una potencia rms nominal con entrada de ruido rosa con factor de cresta de 6 dB, 25 - 250 Hertz.Máximo calculado continuo de SPL: 129 dBA Máximo calculado continuo de SPL: 130.5 dBA1 metro. La escala de dBA típicamente se usa para identificar fuentes de sonido que pueden causar pérdida auditiva permanenteImpedancia:4 ohms, nom. (3.2 a 25 Hz., 62 a 50 Hz.) 4 ohmios, nom. (3.2 a 27 Hz., 28 a 48 Hz.)Potencia máxima de entrada:100 horas de factor de cresta de 6 dB 800 vatios rms 1200 vatios rmsruido rosa, 25 - 250 Hertz2 horas de factor de cresta de 6 dB 1000 vatios rms 1500 vatios rmsruido rosa, 25 - 250 Hertz, método AESPotencia de amperaje recomendada:1600 vatios rms como máximo 2600 vatios rms como máximo Sensibilidad:99.5 dB medio espacio 101.0 dB medio espacio (25 - 100 Hz, 1 vatio, 1 m.)93.5 dB espacio completo95.0 dB espacio completoPeso:225 libras envío, 205 libras neto (102/93 kg.)230 libras envío, 210 libras neto (104/95 kg.)Ambos modelos:Cobertura nominal:Omnidireccional (80 Hz)Procesamiento recomendado:Intensificador de baja frecuencia- frec.= 25 Hz, Q=2.0, ganancia +6 dB. Las configuraciones DSP de QSC estándisponibles en . Los parámetros para el herraje de procesamiento alternativo están disponibles si así se solicitan.Conectadores:Los terminales de tornillo de barra protectora aceptan alambre trenzado de hasta #10 AWG . Cuatro terminales: (dos de ENTRADA y dos de SALIDA PARALELA). Los excitadores están cableados internamente en paralelo. Para la conexión de un transductor independiente, quite los alambres azul y amarillo de los puentes que se encuentran en el lado interno de la cúpula del terminal y marque la caja de acuerdo con esto.Transductores:Dos transductores de subwoofer, de alta eficiencia, de 18” (457mm), con bobinas de voz de cobre de 4” (100mm) ventiladas, en soportes de Kapton®. Diseño de alta excursión/baja deformación, con un manejo de potencia extremadamente alta, y baja compresión térmica y de puerto.Caja:Alineación B6, caja ventilada con diseño de puertos simétricos, afinada a 25 Hz, construida con cartón duro de media densidad y fuertemente soportado. Tiene pernos de montaje del woofer resistentes al vandalismo.Tamaño:30” de ancho X 48” de alto X 24” de profundidad (762 mm X 1220 mm X 610 mm)8Garantía (sólo en EE.UU.; en otros países, consulte a su concesionario o distribuidor)RenunciaQSC Audio Products, Inc. no es responsable por ningún daño a los amplificadores, ni a ningún otro equipo que sea causado por negligencia o instalación y/o uso inadecuado de este altavoz. Garantía limitada de 3 años de QSC Audio ProductsQSC Audio Products, Inc. (“QSC”) garantiza que sus productos estarán libres de materiales y/o mano de obra defectuosos por un periodo de tres (3) años a partir de la fecha de la venta, y reemplazará las piezas defectuosas y reparará los productos que funcionen mal bajo esta garantía cuando el defecto ocurra bajo condiciones normales de instalación y uso, siempre y cuando la unidad se devuelva a nuestra fábrica o a una de nuestras estaciones autorizadas de servicio mediante transportación prepagada con una copia del comprobante de compra (por ejemplo, el recibo de la compra).Esta garantía requiere que el examen del producto devuelto indique, en nuestra opinión, un defecto de fabricación.Esta garantía no se extiende a ningún producto que hubiera estado sometido a uso indebido, negligencia, accidente, instalación incorrecta, o en el que se hubiera quitado o modificado el código de la fecha. QSC tampoco será responsable por daños incidentales y/o emergentes.Esta garantía le otorga derechos legales específicos. Esta garantía limitada es libremente transferible durante el período de la misma.El cliente podría gozar de derechos adicionales, que podrían variar de un estado a otro.En caso de que este producto fuera fabricado para exportación y venta fuera de los Estados Unidos o sus territorios, entonces no será aplicable esta garantía limitada. La eliminación del número de serie en este producto, o la compra de este producto de un distribuidor no autorizado, anularán esta garantía limitada. Esta garantía se actualiza periódicamente. Para obtener la versión más reciente de la declaración de garantía de QSC, visite . Comuníquese con nosotros llamando al 800-854-4079 o visite nuestro sitio en Internet en .Cómo comunicarse con QSC Audio ProductsDirección postal:QSC Audio Products, Inc.1675 MacArthur BoulevardCosta Mesa, CA 92626-1468 EE.UU.Números de teléfono:Número principal +1 (714) 754-6175Ventas y Comercialización +1 (714) 957-7100 o número sin costo (sólo EE.UU.) +1 (800) 854-4079Servicio al cliente +1 (714) 957-7150 o línea sin costo (sólo en EE.UU.) +1 (800) 772-2834Números de fax:Ventas y Comercialización Fax +1 (714) 754-6174Servicio al Cliente Fax +1 (714) 754-6173World Wide Web: Direcciónelectrónica:*************************************QSC Audio Products, Inc. 1675 MacArthur Boulevard Costa Mesa, California 92626 EE.UU.“QSC” y el logo QSC están registrados con la Oficina de Patentes y Marcas Comerciales de EE.UU.Kapton® es una marca comercial registrada de E.I. du Pont de Nemours and Company.9Manuel d'utilisation de systèmes de haut-parleurs de cinéma Doubles caisson d'extrêmes graves de 45,7cmSB-5218 etSB-7218IntroductionLes modèles SB-5218 et SB-7218 sont des caissons d'extrêmes graves spécialement conçus à partir de deux transducteurs basse fréquence de 460mm de 500 et 700W, respectivement enfermés dans des enceintes résonnantes. Les enceintes sont réglées à 25Hz et utilisent un alignement B6. Elles doivent être utilisées avec le filtre d'appoint B6 proposé avec les modules de filtres de caissons d'extrêmes graves QSC SF-1 ou SF-3 ou le moniteur de cinéma numérique QSC pour garantir une réponse étendue aux plus basses fréquences audibles.La satisfaction des exigences des salles de cinéma en matière de réponse basse fréquence étendue différencie les modèles SB-5218 et SB-7218 des systèmes de caissons d'extrêmes graves du type «rock-and-roll », plus conventionnels. Leur plage de fréquence atteint moins de 25 Hz lorsqu'ils sont utilisés avec le filtre B6 correct.Les deux transducteurs personnalisés de 45,7cm/500 W (700 W pour le modèle SB-7218) ont été spécialement développés pour les salles de cinéma. Les caissons d'extrêmes graves ont des bobines mobiles de 100mm et des sections de pôle à évents pour éviter la surchauffe, même à grande puissance. Les basses températures augmentent la durée de vie de l'étage d'attaque et diminuent la compression de puissance problématique à grande puissance. Les sections de pôle évidées assurent un espace magnétique symétrique (SMG), ce qui réduit la distorsion harmonique secondaire.Les enceintes sont faites de panneaux de MDF de haute qualité et ont des compartiments indépendants pour caissons d'extrêmes graves (SWC). Le compartiment séparé pour chaque transducteur rend l'enceinte plus solide, procure une certaine rigidité et empêche ledépassement de course du cône dans l'éventualité rarissime d'une panne d'étage d'attaque (le «chargement » de l'enceinte n'est pas interrompu pour l'autre transducteur).Les grands ports entièrement arrondis (FRP) garantissent la circulation d'air uniforme à travers les ports, surtout à haute puissance. Ceci empêche les interférences sonores. Les ouvertures internes et externes des ports sont entièrement arrondies.Grâce au chargement symétrique des ports (SPL), les ports à graves sont équidistants de part et d'autre des transducteurs, ce qui répartit uniformément la pression interne à travers la surface arrière du transducteur. Ceci empêche le déplacement du cône d'un côté ou de l'autre par un déséquilibre de la pression d'air, ce qui réduit le risque d'excentrage de la bobine mobile à haute puissance.L'enceinte n'a pas été conçue pour être suspendue, balancée ou montée. La suspension , le balancement ou le montage de l'enceinte sont interdits.Ce produit est capable de produire des niveaux de pression sonoresusceptibles d'endommager l'ouïe de manière irréversible. Toujours maintenir les niveaux de pression sonore dans la zone d'écoute en deçà de niveaux susceptibles de compromettre l'ouïe.Installer conformément aux instructions de QSC Audio Products et d’untechnicien professionnel diplômé. Utiliser uniquement des fixations, supports, accessoires ou équerres spécifiés par QSC Audio Products. Confier toutes les réparations à un personnel qualifié. Une réparation ou maintenance est requise lorsque l’appareil a été endommagé d’une manière quelconque.AVERTISSEMENT ! Avant de placer, installer, monter ou suspendre un haut-parleur, inspecter l’état de toute la visserie, du matériel de suspension, des armoires, des transducteurs, des supports et du matériel associé. Toutcomposant manquant, corrodé, déformé ou non adapté à la charge risque de réduire sensiblement la solidité de l’installation, sa mise en place ou sa portée. Une telle condition réduit sensiblement la sécurité de l’installation et doit être immédiatement corrigée. Utiliser uniquement du matériel de montage prévu pour les conditions de charge de l’installation et toute surcharge éventuelle à court terme imprévue. Ne jamais dépasser les spécifications nominales du matériel de montage ou de l’équipement. Consulter un technicienprofessionnel diplômé en cas de doute ou de question concernant l’installation physique de l’équipement.*TD-000150-TD-000150-00 rév. C© Copyright 2003, 2004, QSC Audio Products, Inc.QSC® est une marque déposée de QSC Audio Products, Inc.QSC et le logo QSC sont des marques déposées auprès de l'U.S. Patent andTrademark Office.1675 MacArthur Blvd., Costa Mesa, CA 92626Téléphone (standard)+1 (714) 754-6175 Ventes et Marketing +1 (714) 957-7100 ou +1 (800) 854-4079 (numéro vert valable aux États-Unis seulement)Service clientèle +1 (714) 957-7150 ou numéro vert (États-Unis seulement) +1 (800) 772-2834。