锂离子电解液的介绍英文PPT

- 格式:ppt

- 大小:1.91 MB

- 文档页数:45

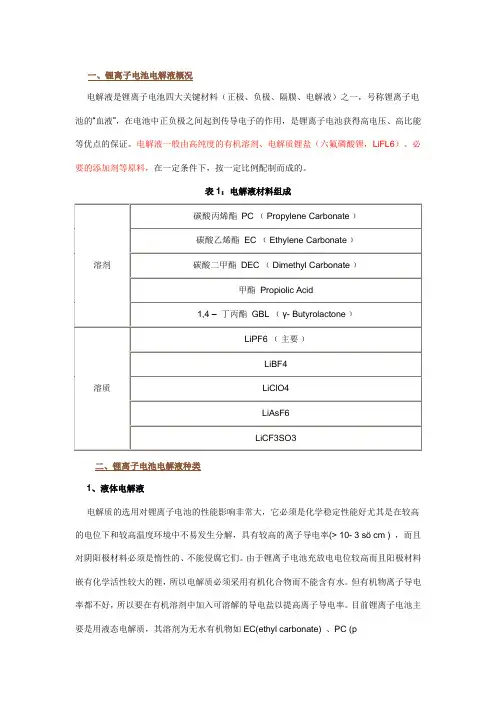

ropylenecarbonate)、DMC(dim ethyl carbonate)、DEC (diethyl carbonate),多数采用混合溶剂,如EC2DMC 和PC2DMC 等。

导电盐有L iClO 4、L iPF6、L iBF6、L iA sF6 和L iO SO 2CF3,它们导电率大小依次为L iA sF6> L iPF6> L iClO 4>L iBF6> L iO SO 2CF3。

L iClO4因具有较高的氧化性容易出现爆炸等安全性问题,一般只局限于实验研究中;L iAsF6离子导电率较高易纯化且稳定性较好,但含有有毒的A s,使用受到限制;L iBF6化学及热稳定性不好且导电率不高,LiO SO2CF3导电率差且对电极有腐蚀作用,较少使用;虽然LiPF6会发生分解反应,但具有较高的离子导电率,因此目前锂离子电池基本上是使用L iPF6。

目前商用锂离子电池所用的电解液大部分采用L iPF6 的EC2DMC,它具有较高的离子导电率与较好的电化学稳定性。

2、固体电解液用金属锂直接用作阳极材料具有很高的可逆容量,其理论容量高达3862mAh·g-1,是石墨材料的十几倍,价格也较低,被看作新一代锂离子电池最有吸引力的阳极材料,但会产生枝晶锂。

采用固体电解质作为离子的传导可抑制枝晶锂的生长,使得金属锂用作阳极材料成为可能。

此外使用固体电解质可避免液态电解液漏液的缺点,还可把电池做成更薄(厚度仅为0.1mm )、能量密度更高、体积更小的高能电池。

破坏性实验表明固态锂离子电池使用安全性能很高,经钉穿、加热( 200℃)、短路和过充(600%) 等破坏性实验,液态电解质锂离子电池会发生漏液、爆炸等安全性问题,而固态电池除内温略有升高外(<20℃)并无任何其它安全性问题出现。

固体聚合物电解质具有良好的柔韧性、成膜性、稳定性、成本低等特点,既可作为正负电极间隔膜用又可作为传递离子的电解质用。

锂离子电池电解液英文资料Lithium-ion Battery ElectrolyteElectrolyte is a key component of lithium-ion batteries, which are widely used in portable electronic devices and electric vehicles. It plays a critical role in the overall performance and safety of the battery system. The electrolyte serves as a medium for lithium ions to shuttle between the positive and negative electrodes during charge and discharge cycles.The electrolyte commonly used in lithium-ion batteries is a mixture of organic solvents, lithium salts, and additives. Organic solvents provide high conductivity and dissolve lithium salts to form ionic solutions. The most commonly used solvents include ethylene carbonate (EC), dimethyl carbonate (DMC), and diethyl carbonate (DEC).Lithium salts, such as lithium hexafluorophosphate (LiPF6), lithium perchlorate (LiClO4), and lithium trifluoromethanesulfonate (LiCF3SO3), provide the necessary lithium ions for electrochemical reactions. These salts are usually added to the electrolyte in a concentration of 0.5-1.5 M.Additives are used to improve the performance and safety of the lithium-ion battery. They can enhance the stability and cycling life of the electrode-electrolyte interface, suppress the formation of lithium dendrites, and improve the thermal stability of the electrolyte. Common additives include vinylene carbonate (VC), fluoroethylene carbonate (FEC), and lithium salt complexes.The electrolyte composition and properties are carefully designed to optimize the performance and safety of thelithium-ion battery. High ionic conductivity is essential for efficient charge and discharge processes. However, excessive conductivity can lead to side reactions, increased battery self-discharge, and thermal instability. Therefore, electrolytes with a balance between conductivity andstability are desired.In recent years, researchers have been actively developing new electrolytes with improved properties, such as high voltage stability, wide temperature range operation, and enhanced safety. Solid-state electrolytes, which eliminate the use of flammable organic solvents, are also being explored as a potential replacement for liquid electrolytes.Overall, the electrolyte is a crucial component of lithium-ion batteries, ensuring the efficient and safe operation of the battery system. Ongoing research and development efforts are focused on advancing electrolyte technology to enable the next generation of high-performance lithium-ion batteries.。