blow molding

- 格式:pdf

- 大小:404.37 KB

- 文档页数:7

资料范本本资料为word版本,可以直接编辑和打印,感谢您的下载模具注塑术语中英文对照地点:__________________时间:__________________说明:本资料适用于约定双方经过谈判,协商而共同承认,共同遵守的责任与义务,仅供参考,文档可直接下载或修改,不需要的部分可直接删除,使用时请详细阅读内容根据国家标准,以下为部分塑料模具成形术语的标准翻译。

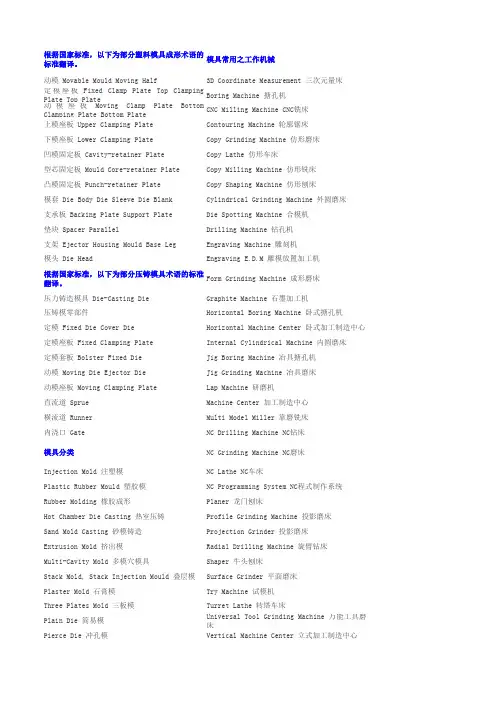

# q# [& x+ L, `动模 Movable Mould Moving Half4 E. u* i; o. U2 C. j- Z: H定模座板 Fixed Clamp Plate Top Clamping Plate Top Plate 0 \" s* Q8 W3 _% e] r动模座板 Moving Clamp Plate Bottom Clamping Plate Bottom Plate 9 ]上模座板 Upper Clamping Plate: _% |6 K d0 {8 w下模座板 Lower Clamping Plate 2 X: H: [- i. v0 R3 k1 d6 E凹模固定板 Cavity-retainer Plate 6 m3 o+ A% k. l8 Y" W! P型芯固定板 Mould Core-retainer Plate 0 V; tb凸模固定板 Punch-retainer Plate模套 Die Body Die Sleeve Die Blank. l支承板 Backing Plate Support Plate( I4 b; D& j6 f' r8 n垫块 Spacer Parallel R支架 Ejector Housing Mould Base Leg: p模头Die Head 3 ~% T] L6 d1 D} c模具分类8 a- ]8 V5 ^7 ]6 p m+ V5 J/ q- iInjection Mold 注塑模 Plastic Rubber Mould 塑胶模 4 Rubber Molding 橡胶成形Hot Chamber Die Casting 热室压铸 : Sand Mold Casting 砂模铸造Extrusion Mold 挤出模 #Multi-Cavity Mold 多模穴模具Palletizing Die 叠层模Plaster Mold 石膏模 Three Plates Mold 三板模 Plain Die 简易模 Pierce Die 冲孔模Forming Die 成型模 Progressive Die 连续模Gang Dies 复合模 Shearing Die 剪边模) Cavity Die 型腔模Riveting Die 铆合模 Compression Molding 压缩成型 " Flash Mold 溢流式模具Extrusion Mold 挤压式模具 .Split Mold 分割式模具 Mould Cavity 型腔母模 $Mold Core 模芯公模 Large Die Mold 大型模具, Precise Die Mold 精密模具Complex Die Mold 复杂模具) a! t: n2 p/ O-s a7 qFoaming Mould 发泡模具Metal Die 金属模具9Plastic Mold 塑料模具 Tool Stamping Die Punch Die 冲压模具9 l; ]( [! X; i5 h* LExtrusion Die 挤压模具 Graphite Die 石墨模具' h& n) b1 H% z- c流道浇口部分4 e9 ` c: `# T. X1 {3 p+ f8 FRunner System 浇道系统Sprue Cold Material Trap 浇道冷料井Sprue Puller 拉杆Runner Design 流道设计 & _$ G. i+ X1 I2 I! k5 X; vMain Runner 主流道Secondary Runner 次流道 tMould Gate Design 浇口设计Submarine Gate 潜伏浇口 3 P( L( r' E5 I& y6 w8 @Tunnel Gate 隧道式浇口 Pinpoint Gate 点浇口 , Fan Gate 扇形浇口Side Gate 侧浇口 4 j+ z3 v2 @: w. F' eEdge Gate 侧缘浇口Tab Gate 搭接浇口Film Gate 薄膜浇口Flash Gate 闸门浇口 ! r6 w+ w. @( @7 v- N% y! r8 `Slit Gate 缝隙浇口Dish Gate 盘形浇口 'Diaphragm Gate 隔膜浇口Ring Gate 环形浇口 Runnerless 无浇道Sprueless 无射料管方式Long Nozzle延长喷嘴方式Sprue 浇口,溶渣 9Insulated/ Hot Runner 热浇道 Runner Plat 浇道模块 ; Valve Gate阀门浇口 Slag Well冷料井 % V% @, i# J" m9 C' [Cold Slag 冷料渣Sprue Gate 射料浇口Nozzle 射嘴Sprue Lock Pin 料头钩销(拉料杆)注塑缺陷: x, a! ~8 U+ s+ zFlash 飞边 ) E9 V/ I5 E+ a& V9 oWarpage 翘曲8Air Trap 积风 - I) P! H$ @4 K# }Blush 发赤 $Flow Line 流痕 , S!U$ m# V, i& b; c% M$ gSplay 银纹 9 ~8 Z/ J! M. E( J$ Short Shot 短射(Sink Mark 缩痕 !Streak 条纹m: p( K- t5 |: c# E$ Y: KVoid 缩孔$Weld Line 熔接线 : w$ x8 |/ W! s1 m5 p; XGas Mark 烧焦 5 w6 P' U/ H8 h+ @/ |Cold Slug 冷斑 $Delamination 起皮 5 {, y* z" U% d' c, C% Y$ sBurr 毛刺 8 m+ x; d. x8 ? h. @* zFlaw Scratch 刮伤 - n2 ~* G* J3 {5 ZGloss 光泽3 c# s. z5 M% }0 C6 i- H4 s$ N" F6 eGlazing 光滑 8 N8 A4 s; x& z2 E; K; HSurface Check 表面裂痕Hesitation 迟滞. q; S; g; )2 I ) 注塑工艺$ c- Y$ F* Q. L# ~6 X2 ]* {* p( qMolding Conditions 成型条件Drying 烘干 * Z8 S1 p N4 \) }' L" y- HBarrel Temperature 料筒温度( B8 p: n) \: \+ f5 I2 YMelt Temperature 熔化温度4 W: b1 V; r2 |1 ) M ^2 X$ qMold Temperature 模具温度Injection Pressure 注塑压力Back Pressure 背压 5Injection Speed 注塑速度 ( j9 Screw Speed 螺杆转速 ' {% B& }+ `, zTensile Strength 抗拉强度Tensile Elongation 延伸率 /Flexural Modulus 弯曲模FlexuralStrength 抗弯强度Shrinkage 收缩率 9 t9 D2 J; M2 s7 ~( h4 U9 ?/ lRegrind Usage 次料使用Moulding 模塑机械设备8 [) C, u3 q5 OLathe 车床 9 M) f* H% u1 k3 d3 WPlaner 刨床 5 h.H' O/ O7 p1 ~Miller / Milling Machine 铣床 Grinder 磨床 Driller 钻床$ [# J* V$ l9 c$ U0 b: g: NLinear Cutting 线切割Electrical Sparkle电火花 , Welder 电焊机 Punching Machine 冲床 ! s) ]+ ]) t2 L3 n0 g: R. C0 LRobot 机械手 2 J" c0 e" ~+ \Common Equipment 常用设备 - `( [$ i*i8 _' k9 e- T8 ]$ N* hEDM Electron Discharge Machining 放电加工3D Coordinate Measurement 三次元量床 Boring Machine 搪孔机5 A: ?; r# i: d @Contouring Machine 轮廓锯床Copy Grinding Machine 仿形磨床 !N( e2 K, e4 K& P' Cylindrical Grinding Machine 外圆磨床 8 |' m8 g, X9 O; t0 G- O& r) hDie Spotting Machine 合模机Engraving Machine 雕刻机}+ L# L: d) IEngraving E.D.M 雕模放置加工机) O( P# l/ L. ^* x5j A" m- }! HForm Grinding Machine 成形磨床 Graphite Machine 石墨加工机 * hHorizontal Boring Machine 卧式搪孔机 8Horizontal Machine Center 卧式加工制造中心 + |# j x* F0 A; t2 F, LInternalCylindrical Machine 内圆磨床. W" e& c, B0 {模具零件* ]0 S9 G) fTop Plate 上托板(顶板) 2 r6 E* [5 N% R6 ?9 o! B- p& TTop Block 上垫脚 : k4 _1 J. r* f; }. L$ lPunch Set 上模座 2 v1 a) G+ ]# j% PPunch Pad 上垫板 0Punch Holder 上夹板 Stripper Pad 脱料背板 * t; ~/U2 {; gUp Stripper 上脱料板}/ s2 l9 R! m1 vMale Die 公模(凸模)Feature Die 公母模 / @6 _4 _$ l( E: ?% ^! x/ Z: OFemale Die 母模(凹模) , `( x6 U$ x' y$ L) j- rUpper Mold Plate 上模板 Lower Mold Plate 下模板 + s: K$ F/ x- q z! q$ J% u5 @Die Pad 下垫板 Die Holder 下夹板# U( l+ m% ~5 F3 uDie Set 下模座 3 L7 E3 b! `- ~- o) ^6 hBottom Block 下垫脚 1 U- z! ~1 x0 x! P" wBottom Plate下托板(底板)Stripping Plate 内外打(脱料板) " q+ EOuter Stripper 外脱料板 9 t3C/ k/ {8 u: A2 D( XInner Stripper 内脱料板Lower Stripper 下脱料板 5`6 Y8 S; ^8 I/ g! G2 h* ]; sInner Guiding Post 内导柱9 S- N! U+ ^6 Q1 l! o$ R, { D6 YInner Hexagon Screw 内六角螺钉Dowel Pin 固定销 7 ~$ Z5 o; S% y* N* q& y. G* AMould Coil Spring 模具弹簧 !Lifter Pin 顶料销 / F+ Isoheight Sleeve 等高套筒 Pin 销 .Lifter Guide Pin 浮升导料销 + o; c) m* d0 n8 l( L ]4 ]Guide Pin 导正销 ) h" C5 F) K, t9 aWire Spring 圆线弹簧# v; R* \! Z2 K5 ~; ]& X% [5 BOuter Guiding Post 外导柱 , u+ b&`- k+ AStop Screw 止付螺丝Located Pin 定位销 0 g) R( q- j4 [ y4O1 C bOuter Bush 外导套 - a0 y+ Q7 p, e'Punch 冲头 Insert 入块(嵌入件)Deburring Punch 压毛边冲子 " j+ u- W/ u! P% zGroove Punch 压线冲子G5 H/ C/ n) {/ P. bStamped Punch 字模冲子 * |0 O/ z) ^+ r; B, pRound Punch 圆冲子 " T8 A' ?$ h4 f3 U# ?# A# [Special Shape Punch 异形冲子 5OBending Block 折刀 Roller 滚轴 # l7 u6 T- |5 I$ Y% l I% nBaffle Plate 挡块Located Block 定位块 8 l% M4 c# g3 [- [% T2 gSupporting Block for Location 定位支承块 Air Cushion Plate 气垫板Air-Cushion Eject-rod 气垫顶杆Trimming Punch 切边冲子 -Stiffening Rib Punch Stinger 加强筋冲子9 L9 z; ?/ a6 O, s' dRibbon Punch 压筋冲子 Reel-stretch Punch 卷圆压平冲子 'Guide Plate 定位板 / L0 F; r1J/ ) ?Sliding Block 滑块0 M! u% L3 {( T2 h# WSliding Dowel Block滑块固定块 + |2 C) c* F' f, d6 v; YActive Plate 活动板 8 h5 u* S$ a7 JLower Sliding Plate 下滑块板 Upper Holder Block 上压块Upper MidPlate 上中间板Spring Box 弹簧箱 Spring-Box Eject-rod 弹簧箱顶杆Spring-Box Ejec模具技术用语7 D+ l$ ?4 l2 Q各种常用模具成形方式& O+ x; `5 v o- P" KAccurate Die Casting 精密压铸Powder Forming 粉末成形# w: j%_$ i0 ZCalendaring Molding 压延成形 ) @6 I( c" @8 V. h- j9 uPowder Metal Forging 粉末锻造+ R# C! t( I: h" F1 r; sCold Chamber Die Casting 冷式压铸 8 \. d( o/ X+ L+ l3 A" j/ A2 mPrecision Forging 精密锻造"Cold Forging 冷锻 Press Forging stamp forging冲锻6 m$ q. @( ]) C' ZCompacting Molding 粉末压出成形 : Rocking Die Forging 摇动锻造Compound Molding 复合成形 ! N/ q% {1 L, ^) \" GRotary Forging 回转锻造' V9 g( j* }' T$ YCompression Molding 压缩成形 % {( g y7 U" Q8 f4 r+ wRotational Molding 离心成形$ Dip Mold 浸渍成形 2 u( e. c2 L5d( U2 K& IRubber Molding 橡胶成形" q- m4 s9 x9 M; O' oEncapsulation Molding 注入成形 3Sand Mold Casting 砂模铸造Extrusion Molding 挤出成形 Shell Casting 壳模铸造- Foam Forming 发泡成形 ' I5 o, _0 v/ v8 l4 V% t9 vSinter Forging 烧结锻造9 V" _0 B3 f/ s7 J7 O, LForging Roll轧锻Six Sides Forging 六面锻造2 l3 S( W- D) nGravity Casting 重力铸造" l) R/ ]" |, N" D7 Y, HSlush Molding 凝塑成形\% J4 \% c; L1 KHollow Blow Molding 中空(吹出)成形 Squeeze Casting 高压铸造8 P* d( s2 u5 F# F h5 }# BHot Chamber Die Casting 热室压铸 0Swaging 挤锻; j" w" c9 S4 N5 tHot Forging 热锻 ;Transfer Molding 转送成形$ Injection Molding 射出成形 " U3 {- C+ d m/ Warm Forging 温锻- G8 n3 j2 {; O1 KInvestment Casting 精密铸造Matched Die Method 对模成形法* z6 w' w# e" B2 s. Laminating Method 被覆淋膜成形 % m; O9 r( Q( o# d8 z* h( O) cLow Pressure Casting 低压铸造1 ^- z7 `# z, d$ JLost Wax Casting 脱蜡铸造 ; [3VMatched Mould Thermal Forming 对模热成形模8 |9 _7 \- _; Q+ f; K& X/ Z0 Q! bClose Mold 合模 Demould 脱模脱模剂/ O, [9 v% H- B1 DMould Unloading 开模8 Tool Change Retooling Die Changing 换模% Mould Clamping 锁模3 }$ N. {# K: D6 [+ R! C! s) r各式模具分类用语# b' k3 _3 M4 T.i/ U8 @( q1 MBismuth Mold 铋铸模 Landed Plunger Mold 有肩柱塞式模具- b9 M$ o* m( M0 |& x0 LBurnishing Die 挤光模 7 |- f: J" P. w1 S, B' Landed Positive Mold 有肩全压式模具.Button Die 镶入式圆形凹模 ! [% ?9 \$ ]6 n$ BLoading Shoe Mold 料套式模具$ B9 v; I; [4 b* v6 e6 E$ r. CCenter-Gated Mold 中心浇口式模具 .D) g' y" c2 _0 L1 cLoose Detail Mold 活零件模具Chill Mold 冷硬用铸模' D$ C5 m) S }2 t5 l* v+ {+ `; gLoose Mold 活动式模具/ Cold Hobbing 冷挤压制模法 4 @3 N3 w9 |. H7 h& WLouvering Die 百叶窗冲切模7 d+ t: E5 _" F9 e# H; iComposite Dies 复合模具 . t; p" F+ n! w, K8 s3 Q) _Manifold Die 分歧管模具6Counter Punch 反凸模7 S3 R5 J6 R! j7 P$ {Modular Mold 组合模具4Double Stack Mold 双层模具 ! k0 {$ ]8 l/ sMulti-Cavity Mold 多模穴模具% `" E8 g. w/ c Electroformed Mold 电铸成形模 & Multi-Gate Mold 复式浇口模具Expander Die 扩径模% a+ n1 u% E& c1 D# q7 f( G# D" Z AOffset Cold Bending Die 双折冷弯模具' n+ p1 p: Q2 z& ~/ C8 E. w& M1 wExtrusion Die 挤出模 8 IPalletizing Die 叠层模9 i* ^6 G: w% {5 J7 l" D( u) [& w# uFamily Mold 反套制品模具 7 [& G" K, S" Z; uPlaster Mold 石膏模2 I! L! [; B. g" Q2 J4 zBlank Through Dies 漏件式落料模! ?/ A. _* ]. D( pPorous Mold 通气性模具' d: hDuplicated Cavity Plate 复板模 , E& i, ]. d% x3 e( l' ?Positive Mold 全压式模具; g Q1 r/ E5 e* I& M4 s5 }Fantail Die 扇尾形模具 / F, }/ x. X9 `; X& H( R6 h9 x( M& x9 `Pressure Die 压紧模: a7Fishtail Die 鱼尾形模具 ( |$ V) s( t* d9 \Profile Die 轮廓模6 { v: G! E/ J" i8 p9 E5u5 ^4 |Flash Mold 溢料式模具 # H. r6 ^; z0 [7 ]! F2 Q3 WProgressive Die 顺序模9 z: G1 X, O/ oGypsum Mold 石膏铸模 5 y0 _& ~* C/ S% Y7 B4 k! c1 MPortable Mold 手提式模具, r( Y' L/ o4 ]/ Y! u( gHot-Runner Mold 热流道模具 Prototype Mold 雏形试验模具原型模具5 B$ w p: n" ?& iIngot Mold 钢锭模' J* ]1 [6 ^$ T& c9 o, D {; NPunching Die 落料模1 Lancing Die 切口模切缝模2 r6 g4 \' m5 l* T# P, K- ]0 v' WRaising(Embossing)压花起伏成形+ ~7 k) O5 Q0 g1 d% V# ?Re-entrant Mold 倒角式模具 2 `$ k2 A+ I/ z- |# O. ~Sectional Die 拼合模c! \1 N# m: X- sRunless Injection Mold 无流道冷料模具A4 f0 ?8 V+ q l& s8 F% x& kSectional Die 对合模具Segment Mold 组合模 + B: f; T: ^* G4 V* p: i6 ?Semi-Positive Mold 半全压式模具- l9 O& r. k# }% Z$ q$ x' Shaper 定型模套 1 P, I g; F' i6 y! M( ?Single Cavity Mold 单腔模具3 v+ M$ M, a) J) mSolid Forging Die 整体锻模 '~& j, e0 m7 v2 z: Q7 nSplit Forging Die 拼合锻模$ g.Split Mold 双并式模具 * m4 ]6 a& b8 }9 ySprueless Mold 无注道残料模具5 j: d& F! G; Z, k6 i$ pSqueezing Die 挤压模 0 W8 Z' I4 @: P: {4 pStretch Form Die 拉伸成形模4Sweeping Mold 平刮铸模 ; f9 L' \4 D8 r1 G9 c4 d- lSwing Die 振动模具%Three Plates Mold 三片式模具 9 Trimming Die 切边模4Unit Mold 单元式模具 $ Universal Mold 通用模具) Q: H2 d) R, x8 I2 fUnscrewing Mold 退扣式模具 / Q1 K5 \6 t0 ]* E Q4 Y' [6 H% sYoke Type Die 轭型模t-Plate 弹簧箱顶板 # c9 C2 \, R: Q3 I9 A4 rBushing Block Liner Bushing 衬套 , m4 p& y/ Q: x) TCover Plate 盖板 & _2 p6 m# {- hGuide Pad 导料块模具厂常用之标准零配件 I8 p1 L G- S( t1 M: y# )6 lAir Vent Valve 通气阀 $ V, i; S( c0 d xAnchor Pin 锚梢7Angular Pin 角梢 9 _8 `! H5 U+ q2 P3 R8 oBaffle 调节阻板( L, J3 i2l4 B7 ^' N& lAngular Pin 倾斜梢6 r j, m2 u6 ?, T" @- Q. fBaffle Plate 折流档板$ Ball Button球塞套 5 f2 s6 ]4 y8 ~) J, a, r& \! w% EBall Plunger 定位球塞 B w- `; n L$ c/ {3 c2 UBall Slider 球塞滑块 % v3 @+ c: o* fBinder Plate 压板6Blank Holder 防皱压板 . J4 n7 [0 Q& {# _0 B6 N9^Blanking Die 落料冲头. `.Bolster 上下模板m3 B- p% E! V/ c0 DBottom board 浇注底板7Bolster 垫板 $ Bottom Plate 下固定板*Bracket 托架 / ^' u2 K% d6 }# h: L1 Z i6 |Bumper Block 缓冲块: h/ D; \0 ]5 V1 C$ K; A9 Y rBuster 堵口 2 z: ?: Z, {( b* _" k& ACasting Ladle 浇注包4 l* w: G7 U: v! f t: rCastinglug 铸耳 % O. _+ [; x: z3 a; e" `Cavity 模穴(模仁)* e7 |5 n" g$ ], GCavity Retainer Plate 模穴托板 Center Pin 中心梢1 Clamping Block 锁定块2 L7 b+ }1 s2 I7 _" ]- XCoil Spring 螺旋弹簧% Z( r4 }% `- e3 W+ \! U+ HCold Punched Nut 冷冲螺母 !Cooling Spiral 螺旋冷却栓1 Core 心型 3Core Pin 心型梢0 k, X/ o# U8 Z% u Cotter 开口梢 Cross 十字接头 1 Cushion Pin 缓冲梢 8 j' Y* z1 m/ I. W( l( m" G: R: ~Diaphragm Gate 盘形浇口Die Approach 模头料道, d* {3 ^ n8 y3 n$ n4 YDie Bed 型底Die Block 块形模体 . |! O1 U: E% m3 M( wDie Body 铸模座8 |7 V' x1 q* f- [) W! w( r0 dDie Bush合模衬套 ;Die Button 冲模母模3 K, }$ J; K+ qDie Clamper 夹模器 8 T* W4 ~) b% Q: R6 [7f aDie Fastener 模具固定用零Die Holder 母模固定板 * a% @% C/ R, {/ Y1 FDie Lip 模唇: [3 f8 Y- N* q2 V, iDie Plate 冲模板Die Set 冲压模座5 u* q. V8 ?. qDirect Gate 直接浇口Dog Chuck 爪牙夹头$Dowel 定位梢 ,Dowel Hole 导套孔. x+ ]6 W/ x, S/ l9 ?% t, m2 [Dowel Pin 合模梢 3 R8 y7 m5 K" K5 {- nDozzle 辅助浇口)Dowel Pin 定位梢 # Draft 拔模锥度. t. h; F) o# W0 N" l8 oDraw Bead 张力调整杆 6 \, M' z/ Drive Bearing 传动轴承. ]0 \3O% O1 m) D DEjection Pad 顶出衬垫 2 m4 z( v/ T* A+ B KEjector脱模器+ L6 [. V" ^- x/ _$ YEjector Guide Pin 顶出导梢6 p) H; x4 m& M2 Q) H# K$ [Ejector Leader Bush 顶出导梢衬套. EEjector Pad 顶出垫7 Ejector Pin 顶出梢9 K9 E% e% C' kEjector Plate 顶出板) |4 A( C, m7 i) [/ m* u5 }# l$ aEjector Rod 顶出杆9 Ejector Sleeve 顶出衬套[6 t. Y8 f9 X& \Ejector Valve 顶出阀: q# n$ B- o& K4 W7 _$ I/ v" M. P! aEye Bolt 环首螺栓 * c6 T0 w/ c6 M0 Filling Core 填充型芯椿入蕊: Film Gate 薄膜形浇口 / D$ n* l! J' ^9 ^. L% I6 JFinger Pin 指形梢6 Finish Machined Plate 角形模板% Q x2 I0 Q) w5 {Finish Machined Round Plate 圆形模板) s7 d3H/ V$ KFixed Bolster Plate 固定侧模板 , T2 m) T5 x$ t( zFlanged Pin带凸缘针. D( y' J6 E7 {Flash Gate 毛边形浇口 -Flask 上箱Floating Punch 浮动冲头 +Gate 浇口3 _-Gate Land 浇口面9 Q& Y' q8 Y# q7 j. FGib 凹形拉紧楔/ s;Goose Neck 鹅颈管 $ K& Y"r! X8 {/ V1 C3 O$ wGuide Bushing 引导衬套& Guide Pin 导梢 Guide Post 引导柱+ G: Guide Plate 导板 9Guide Rail 导轨, L5 w s6 Z& E2 k3j$ H0 C7 QHead Punch 顶头冲孔}( a: _ Z& Z5 W( |. W9 J+ tHeadless Punch 直柄冲头+ w; ]* L0 P; B2 N$ t(Heavily Tapered Solid整体模蕊盒 2 H# E2 A- {$ E1 u2 H, @Hose Nippler 管接头. Impact Damper 缓冲器 5Injection Ram 压射柱Inlay Bush 嵌入衬套8 W1 |0 }, U+ q;b _+ i" vInner Plunger 内柱塞' ]- P+ {* R0 P8 v% K+ T" `+ YInner Punch 内冲头 # }! G7 a4 [+ _ L) A$ IInsert 嵌件 4 h1 ]3 H( G* T- F: m' m; LInsert Pin 嵌件梢 1 E/ D9 E" l5 R7 c- L6 f1 PKing Pin 转向梢- King Pin Bush 主梢衬套 , s0 |6 g7 w* B' _. rKnockout Bar 脱模杵8 W.B+ {5 \. v( h0 tLand 合模平坦面 #Land Area 合模面1 Q5 r. e& H( b3 fLeader Bush 导梢衬套 6 `+ n3 A) b' S: _Lifting Pin 起模顶针起模杆! J; K9 L K6 P/ [, S" A# lLining 内衬Locating Center Punch 定位中心冲头4 F# m+ s) D' a3 {Locating Pilot Pin 定位导梢 $ x8 P4 ~6 a" x* }9 a# T& n6 sLocating Ring 定位环8Lock Block 压块 3Locking Block 定位块% Y# s) u! E* KLocking Plate 定位板 ; v3 @2 S8 |& } \# P- t'|Loose Bush 活动衬套1 X8 s' C4 _ t5 K' bMaking Die 打印冲子4Manifold Block 歧管档块" Z6 z0 J. F2 G/ u1 O6 lMaster Plate 靠模样板 * ]" S# Q5 z, b1 p0 d: c B, qMatch Plate 分型板1Mold Base 塑胶模座 & Q$ A! ^- f( s' v, w' s% C6 v! I- ~Mold Clamp 铸模紧固夹: L9 k/ H* Y" wMold Platen 模用板p7 l% p: U$ a* e: JMoving Bolster 换模保持装置+ r! o5 @. P7 S4 H `- DMoving Bolster Plate 可动侧模板, r8 u2 q$ O# U2 Z, FOne Piece Casting 整体铸件9 Parallel Block平行垫块 + |Parting Line 分模线6 s% t! x- m& tParting Lock Set 合模定位器Pass Guide 穴型导板- C Y$ R% d8 Y: f( MPeened Head Punch 镶入式冲头锤击强化冲头钻杆凸模' j3 J* r8 N/ g- a( x; y% \Pilot Pin 定位销导向销子6 n8 m9 B; K; c" O& D r; VPin Gate 针尖浇口 # _3 u r" w$ J2 z5 { B4 L0 ^Plate 衬板0 a5 v b0 ?1 I5 _1 e( ]8 ~Pre Extrusion Punch 顶挤冲头5 P1 F2 b. Y& d* b8 \) S, H( UPunch 冲头1 H+ ^6 p( v, b bPuncher 推杆4 Z' I% e, X* g% ]4 R' c/ WPusher Pin 衬套梢 4 x3 {" D+ X S3 c. O# ~Rack 机架 4 u' }) F z6 y& }% |5 g' V- pRapping Rod 起模杆! _4 ^# Z! [# {% X! p C* MRe-entrant Mold 凹入模1 D( N4 D) S& z3 M; n1 | V. qRetainer Pin 嵌件梢& p! l! H+ x8 a( xRetainer Plate 托料板 $ R4 z% x, H4 x0 z6 V0 [- NReturn Pin 回位梢/ Q, g5 s- s/ W# kRiding Stripper 浮动脱模器8 ?4 ?9 t9 p( @) \. z0 Z3 ^6 b7 kRing Gate 环型浇口0 z7 o6 E( d/ j/ r: K" i! R. {Roller 滚筒 " o5 k' z( E3 k. LRunner 流道& z- O4 _* f" g2 x6 xRunner Ejector Set 流道顶出器 + O. F/ `:_( \4 b6 jRunner Lock Pin 流道拉梢8 w$ s! X# m3 I0 \7 yScrew Plug 头塞3 z# l9 G/ |5 i m5 v8 o% PSet Screw 固定螺丝+ N$ X# C7 x" xShedder 脱模装置; I0 C" N* D" e ^ Y; o1 oShim 分隔片/ x) Y1 U' C0 o L/ m Shoe 模座之上下模板" g- O) O# _! ~7 n$ L; w- Q; t7 zShoot 流道1 X0 F( v7 E" |( m" ` Shoulder Bolt 肩部螺丝`2 l- Y& o# j p; X# U+ bSkeleton 骨架. X) T# B# t3 f+ g/ A- q4 `9 DSlag Riser 冒渣口 ' _3 l8 m3 G, v3 g- ySlide(Slide Core)滑块- r* {" r+ l' U v5 fSlip Joint 滑配接头: G8 g7 F) J; o/ ]Spacer Block 间隔块& m0 L/ w: z# q8 s3 q) v: OSpacer Ring 间隔环 ! ^, e/ U6 U$ j4X O1 E8 J% m2 f+ xSpider 模蕊支架; l: a6 i# w1 P" FSpindle 主轴( {4 G' @% B6 u' g3 j/ f3 sSprue 注道2 C$ q B$ d' g4 uSprue Bushing 注道衬套 / i- y- Q/ V$ f8 L; S; ^' VSprue Bushing Guide 注道导套. c5 @# o& T; }Sprue Lock Bushing 注道定位衬套 2 ?* ~5 C, M+ L [Sprue Puller 注道拉料浇道推出杆注道残料顶销; k9 |: U+ k) P! E6 Q( @6 ]Spew Line 合模线 6 T0 P: [' w8 Q JSquare Key 方键& `8 o o8 q/ e7 F* C* iSquare Nut 方螺帽- u* Z7 ~0 S0 @. dSquare Thread 方螺纹* L7 T9 v: E9 ]6 Y2 O3 WLimit Stop Collar 限位套 5 b9 m" ^6 o( \5 k, a- ZStop Pin 止动梢' d ^' w& X; U) _! JStop Ring 止动环 6 m4 b1 p- e6 ~- UStopper 定位停止梢' o; G, @- `" EStraight Pin 圆柱销# G. B: F8 m k6 lStripper Bolt 脱料螺栓2 J0 G/ g& W; p; l2 P" pStripper Bushing 脱模衬套' ), T, o" n' m0 V3 X2 ?Stripper Plate 剥料板& D* {: a0 w%X R2 aStroke End Block 行程止梢- r$ \: Z! @: t+ ^! G% o, } {Submarine Gate 潜入式浇口8 s# Y* E, ~9 R' Q3 oSupport Pillar 支撑支柱顶出支柱 * Z" l6A( @$ N8 )2 BSupport Pin 支撑梢2 F& L9 y1 `# i; k9 oSupporting Plate 托板9 e* y9 r9 ?/ C* e4 JSweep Template 造模刮板5 e} n8 X, J; f$ F# b5 r& hTab Gate 辅助浇口 } } [; [' J1 l" v: PTaper Key 推拔键, k] ^0 A. o# {* p; w @: G. h( s' s0 eTaper Pin 拔锥梢锥形梢& _+ Y) T! m4 u} q& u9 XTeeming Pouring 浇注: t2 c/ ~/ F- ]Three Start Screw 三条螺纹 7 D7 x6 N1 x1 Q% B& RThrust Pin 推力销: z- S0 I ^$ n+ KTie Bar 拉杵 ! S8 _9 g& W9 F$ bTunnel Gate 隧道形浇口- R* M! T& D8 e" T! U+ h7 zVent 通气孔$ S5 s' V0 ~9 hWortle Plate 拉丝模板模具常用之工作机械5 U9 q2 r/ G" J9 o4 n7 _3D Coordinate Measurement 三次元量床0 A+ w* K' ~' Y, `" E; HBoring Machine 搪孔机: g* k1 ?5 r$ e, G1 Y ~CNC Milling Machine CNC铣床# g0 B n& Z# r- W" x3 BContouring Machine 轮廓锯床5 b& J- `6 L! v& ]- ICopy Grinding Machine 仿形磨床* ?! @" s& S' ~5 r9 m! LCopy Lathe 仿形车床, R6 z7 E/ R8 S9 ] n0 eCopy Milling Machine 仿形铣床! |8 ~8 w. _* u3 }5 ICopy Shaping Machine 仿形刨床6 G) ?" V! [& {) NCylindrical Grinding Machine 外圆磨床* f6 [( `8 p: S) [7 CDie Spotting Machine 合模机6 v5 j9 H$ m4 p1 P6 ~Drilling Machine 钻孔机2 Q0 F/ J8 L# \( I. yEngraving Machine 雕刻机! L% j; j9 x9 g* U. H3 MEngraving E.D.M 雕模放置加工机! N- ?+ J( l/ c, y3 \Form Grinding Machine 成形磨床: a1 p' B3 ~5 S: k p, I' GGraphite Machine 石墨加工机! o9 N3 c" N8 X9 dHorizontal Boring Machine 卧式搪孔机5 O! s4 N5 t5 q4 z( [' NHorizontal Machine Center 卧式加工制造中心 - N4 P. g$ H6 y7 P; _Internal Cylindrical Machine 内圆磨床4 N7 I4 ]$ O+ f- Z+ NJig Boring Machine 冶具搪孔机 8 w+ `) y5 c ^- wJig Grinding Machine 冶具磨床: Q, U7 g& Q! Y2 T( r: ?( [4 qLap Machine 研磨机) U' V2 t# g2 T5 _+ p5 @0 YMachine Center 加工制造中心# v, s7 b5 d5 I9 XMulti Model Miller 靠磨铣床 3 w1 P [- ]3 ~' J8 ^5 i. VNC Drilling Machine NC钻床: ^( {# {; x6 b( X* b* ] Z: NNC Grinding Machine NC磨床$ ^3 }9 w2 U+ M6 eNC Lathe NC车床! o) d* ]7 W% h5 [% B3 ^NC Programming System NC程式制作系统# {+ c$ @9 @' a- TPlaner 龙门刨床4 a3 x2 L( |" i' ]" kProfile Grinding Machine 投影磨床5 u) S, Z. q, {0 ]! {& ZProjection Grinder 投影磨床( Z% u+ M/ P7 VRadial Drilling Machine 旋臂钻床1 m- c/ [) }! g4 F$ M* }Shaper 牛头刨床+ `9 B% w7 Y$ y+ X8 Y) u. d8 wSurface Grinder 平面磨床$ P0 K8 I2 ~; _. d& l1 BTry Machine 试模机6 u( ?1 a8 @# v0 T5j$ jTurret Lathe 转塔车床" h; ?' H5 C9 [8 [Universal Tool Grinding Machine 万能工具磨床|- X9 s4 ]+ `Vertical Machine Center 立式加工制造中心+ X( f( e h- j4 H9 l( c9 F- S5 {) kWire E.D.M 线割放电加工机?# A7 n8 c/ c* @: I5 p入水 Gate % D* I+ l; y0 B" H ~+ u' J) I进入位 Gate Location 9 O7 c% a7 l0 J水口形式 Gate Type / h7 @! x/ _ U2 _ t0 u大水口 Edge Gate ) g+ c+ E/ X2 u; a- y细水口 Pin-point Gate % K8 [( g1 p( K& n3 B ~: T水口大小 Gate Size 5 ?* h7 q7 a# v, _转水口 Switching Runner Gate0 j R: I3 ]. G& [1 N; H# p唧嘴口径 Sprue Diameter# |6 k1 ]1 j @+ _流道 Mold Runner , L" y% Z5 N+ [ n- m' H( Y- d热流道 Hot Runner Hot Manifold8 \2 W/ P! D" H4 A0 W' |- d, U. ?8 e2 S温度控制器温控器Thermostat Thermoregulators Temperature Controller% H$ q2 @$ i5 K" S5 I B% f热嘴冷流道 Hot Sprue Cold Runner 9D- ?& H( ]9 j# S! r! D' P, B4 J唧嘴直流 Direct Sprue Gate, [/ U) x. D/ u- c ^: a圆形流道 Round Full Half Runner $ ]/ t.D. v: o& I流道电脑分析 Mold Flow Analysis % N( T, \. K' H% m2 ?流道平衡 Runner Balance5 V5 t) a# M( R7 [+ o0 r: \9 z热嘴 Hot Sprue) N$ _; }$ d, y& p0 ]7 c, W- p热流道板 Hot Manifold & k4 g) C;o# h# d: a& T3 e% X发热管 Cartridge Heater ; P$ f4 I3 G# O& N4 t! D6 `% I探针 Thermocouples2 u1 @ Z: p; `8 B4 L. c- L插头 Connector Plug / J. i2 |7 a7o+ G7 b/ o插座 Connector Socket ! V2 l* {% W- @3 |密封封料 Seal& s% ~3 ?" x: s4 M) d% w5 |运水 Water Line " ^) U2 Y0 B1 Q5 m* s' t9 U喉塞 Line Plug Throat Taps, n5 n5 P* [% B6 n% S E# A喉管 Tube + V% n I2 f% ]2 F' ]+ c; Q1 [& t塑胶管 Plastic Tube ; V% z7 b5 [$ o8 i) r& J快速接头 Jiffy Quick Connector Quick Disconnect Coupling* ^; ?)S9 l: b3 R模具零件 Mold Components 3 V+ N8 j0 E* Y' d* B三板模 3-Plate Mold 3 w( `6 l& Y6 K2 y: `, I二板模 2-Plate Mold, c% I- H& E. t2 |9 K1 z$ M. |8 ?! d; t边钉导边 Leader Pin Guide Pin' s" j3 G/ O2 w$ L边司导套 Bushing Guide Bushing" O5 @8 i: {. m9 j# Y8 W中托司 Shoulder Guide Bushing ( j. k5 ]5 X3 f0 W- V9 h6 w中托边 Guide Pin 1 d; v4 I8 {& Y1 u' @0 J顶针板 Ejector Retainner Plate% \3 b# @- b1 \. Y托板 Support Plate 6 z5 T* ^( u+ s) }/ { c 螺丝 Screw / Y* m/ B' t& p2 I$ P* O) G* [. r管钉 Dowel Pin$ d- ^" v0 c" C+ R/ o6 A. o开模槽 Ply Bar Scot 6 f! u' s4 W1 V0 c内模管位 Core Cavity inter-Lock2 K0 n3 w; {- ^" M# D2 @, N" L& K顶针 Ejector Pin % a, r6 m" [. A2 i/ r0 C, ]司筒 Ejector Sleeve3 g7 R8 Z2 ?: Y司筒针 Ejector Pin ' ~, F: x# j% j* e推板 Eject Plate Push Plate Stripper Plate $ F2 w, z# y- f9 K0 ?, |' r. G缩呵 Movable Core Return Core Puller v+ `4 p& D8 {7 _5 k扣机(尼龙拉勾) Nylon Latch Lock ' W, i1 Y$ ` r( G$ X斜顶 Lifter ! M% v6 @% ^: }, ^$ w- |9 h模胚(架) Mold Base) N& j3 @1 u; z4 X8 ~- [! C上内模 Cavity Insert 0 K/ K* z* T: L9 [) X0 a& Q5 v; p下内模 Core Insert+ t( o( m$ k, _ U$ P* L$ O& R行位(滑块) Slide 8 T1 k4 t$ C+ G2 H; f2 a镶件 Insert/ o9 B3 R8 d# L压座 Wedge2 q3 ?+ E' W) C6 \- u) ^3 M耐磨板油板 Wedge Wear Plate6 f, D, B. b' m( g压条 Plate ) Y+ J# n$ e9 y! o7 _撑头 Support Pillar 0 f0 Z1 @2 @/ X# a5 t( D唧嘴 Sprue Bushing7 e/ G+ ~1 v# A9 F# D* ]挡板 Stop Plate' Q" X% V/ R7 p定位圈 Locating Ring : \# n$ }! g; E2 v3 e7A Y锁扣 Latch 7 A; E" Y0 r9 f' Z Y: X0 [. x扣机 Parting Lock Setz$ v' s/ k: p9 n推杆 Push Bar( s& c3 G- k8 n2 t栓打螺丝 S.H.S.B: ?/ ` Z% r$ M4 L z/ G顶板 Ejector Plate0 E) X& W! ?' u+ n$ Y+ M5 l! H- u活动臂 Lever Arm , ~6 y8 m, w" |分流锥 Sprue Spreader" ^+ A8 K) r' c( c- f6 P分流板 Spreader Plate* F& a `" w* l) S% B- [/ `水口司 Bush : D" ]; k9 ~: K3 i垃圾钉 Stop Pin2 ^# m# C" i& i: u隔片 Buffle8 y1 N# ` E& _/ v* R- @2 @弹弓柱 Spring Rod$ R5 e( _, G/ W3 P弹弓 Die Spring& W) l j6 P, N8 Z2 p$ S. w: z8 o中托司 Ejector Guide Bush 0 M! _! {, V" \) u中托边 Ejector Guide Pin- q# Q+ b" S! C' |' v; u0 x5 _ d镶针 Pin* o/ f9 j( I9 o9 V A! [4 Z销子 Dowel Pin" f& E/ R% ` ~波子弹弓 Ball catch: N0 @! L$ l, W: i: G3 f9 [* \3 h喉塞 Pipe Plug 9 Q8 U9 {2 c/ f+ s3 L5 f* h( |锁模块 Lock Plate9 o4 @3 d: J2 _+ ?& \! }, M斜顶 Angle from Pin* E9 I4 R0 o# V6 C' ]斜顶杆 Angle Ejector Rod 2 F3 w3 c: l( b4 t! X/ U8 Z! I尼龙拉勾 Parting Locks/ E) J& t+ I; s: G" y8 X+ i- p活动臂 Lever Arm/ s0 V' f r4 l, e1 ~& T! g0 b& A复位键提前回杆 Early Return Bar 3 e2 c9 @5 f* O: v+ i2 a气阀 Valves2 o, b% V- M0 s6 Y( J o$ c斜导边 Angle Pin 9 o& w! O/ F) j,Z0 N" t$ z术语 Terms0 \) p' Y4 `( ~! H9 m7 S/ d承压平面平衡 Parting Surface Support Balance * J6 Z9 Q- z, |# K+ a" ^: p模排气 Parting Line Venting % c+ Q5 e8 J0 m; S- ~回针碰料位 Return Pin and Cavity Interference& Z" L& C9 S$ \$ Q! Q0 U- Q顶针碰运水 Water Line Interferes with Ejector Pin4 B! t \1 }8 k料位出上下模 Part from Cavith (Core) Side2 A0 ]9 r4 w: Y$ ~不准用镶件 Do Not Use (Core Cavity) Insert 7 k, ^5 s# ^9 O' y& N用铍铜做镶件 Use Beryllium Copper Insert % I* k) R' E) E* ~4 v8I q- O( q# I初步模图设计 Preliminary Mold Design 0 P# Z9 k7 Z, T3 Z9 J% u0 L 正式模图设计 Final Mold Design- p1 k# ^! N4 c% [( Z `3 q弹弓压缩量 Spring Compressed length9 P& J% P9 A7 R. _* Y" r5 w" ?稳定性好 Good Stability Stable ' K.h) O7 H/ v% @+ t! S强度不够 Insufficient Rigidity $ r5 A, t/ E+ l$ h# f' C均匀冷却 Even Cooling% X! Y( |4 A& `) h( @" P% w1 S0 X3 W2 w扣模 Sticking' D+ I1 L4 ^8 d( o% H. k热膨胀 Thermal Expansion 2 t+ V& h4 m. J: ]7 f$ V, _2 r公差 Tolerance 6 ?7 D" K& Q9 _, ^5 ?6 I% }5 T( l铜公(电极) Copper Electrode, Z; E4 L6 B7 @2 }2 MAir Vent Valve 通气阀$ e( w p/ g# f- P% a( J! o, qAnchor Pin 锚梢. w: K' U; e7 }Angular Pin 角梢 6 k: Q$ ^ [' n# @; \Baffle 调节阻板 6 g! ^7 A, P2 G1 I6 [Angular Pin 倾斜梢% d3 ?2 C3 y/ S8 L' t% w* c/ gBaffle Plate 折流挡板7 F! X: @" G0 V: ~: }1 [Ball Button 球塞套, |! y1 K6 ]9 a* N# C% m) YBall Plunger 定位球塞 3 t1 S- [" N' S0 t" DBall Slider 球塞滑块 7 a2 \; [1 m. x5 H0 S% bBinder Plate 压板5 R+ I, C4 Q8 f. Y6 W' YBlank Holder 防皱压板 * C& _9 ~# X' G9 t6 p4 ~. pBlanking Die 落料冲头5 v% f% @% {/ [Bolster 上下模板% f" b+ S9 ]/ a" g6 ], sBottom Board 浇注底板 1 e" } R+ C2 ]' q$ t" ~Bolster 垫板 : a: P- i; m% E4 ^/ m% G0 CBottom Plate 下固定板 % P* b' v9 S ~Bracket 托架% Z" u1 K6 o. G5 NBumper Block 缓冲块 7 i! r: [' K1 Y+ CBuster 堵口8 N) \' K+ e* q; x5 wCasting Ladle 浇注包: ]3 j. ~* k3 N4 a LCasting Lug 铸耳 , l* Y( V/ L/ Z, I: N$ P Cavity 模腔模穴(模仁) , I- k ?# z8 d" QCavity Retainer Plate 模穴托板0 H N* [* d; s z$ dCenter Pin 中心梢. ?$ n. x% B! o9 A0 O4 bClamping Block 锁定块5 f, F& d: `) I- OCoil Spring 螺旋弹簧2 X1 e+ V, T- u/ y$ t+ H5 sCold Punched Nut 冷冲螺母 & P3 |2 g6 E) [% ?! m5 y% aCooling Spiral 螺旋冷却栓 $ u2 V4 z" h9 E. i2 dCore 心型+ @3 O; l, u8 i9 F: iCore Pin 心型梢 1 W" {& B7 {" s6 |$ sCotter 开口梢 8 r( Q( i2 Q( Q; ]* A0 L" r9 ]Cross 十字接头" w/ {; L9 y6 W' Y. L# X( }6 N. h( WCushion Pin 缓冲梢 1 r. o) w8 z( d' W: P" {* YDiaphragm Gate 盘形浇口 3 Y9 t! z' p4 u1 h, j+ tDie Approach 模头料道 ) H# {6 C9 a+ Q% Q/ r! w: LDie Bed 型底 " x, X0 Q( U# z- X2 J+ a F$ EDie Block 块形模体n' J0 T5 p! L# p% i1 a( ]6 ADie Body 模体$ A4 n3 b; c7 e8 H' W! l$ zDie Body 铸模座{: }# N( g$ o7 {4 | ^Die Bush 合模衬套. `+ q4 L. ^ R. `% P9 A0 L. BDie Button 冲模母模3 J5 _7 H1 [$ x1 C% DDie Clamper 夹模器: a: Z4 }- d5 CDie Fastener 模具固定用零件 0 b2 O3 z& ?& _+ yDie Holder 母模固定板) n- v3 n+ E0 D- J t. n# @ \Die Lip 模唇1 G1 E y, ]/ [. H! gDie Plate 冲模板9 B# f4 w9 t* G+ M) p" ]7 XDie Set 冲压模座 + k5 t3 _8 E3 ^, q6 yDirect Gate 直接浇口 1 W3 j, W! ]: i5 F+ b: C. aDog Chuck 爪牙夹头 ' M. S, w% Z- a$ q9 P。

根据国家标准,以下为部分塑料模具成形术语的标准翻译。

模具常用之工作机械动模 Movable Mould Moving Half3D Coordinate Measurement 三次元量床定模座板Fixed Clamp Plate Top Clamping Plate Top Plate Boring Machine 搪孔机动模座板Moving Clamp Plate BottomClamping Plate Bottom PlateCNC Milling Machine CNC铣床上模座板 Upper Clamping Plate Contouring Machine 轮廓锯床下模座板 Lower Clamping Plate Copy Grinding Machine 仿形磨床凹模固定板 Cavity-retainer Plate Copy Lathe 仿形车床型芯固定板 Mould Core-retainer Plate Copy Milling Machine 仿形铣床凸模固定板 Punch-retainer Plate Copy Shaping Machine 仿形刨床模套 Die Body Die Sleeve Die Blank Cylindrical Grinding Machine 外圆磨床支承板 Backing Plate Support Plate Die Spotting Machine 合模机垫块 Spacer Parallel Drilling Machine 钻孔机支架 Ejector Housing Mould Base Leg Engraving Machine 雕刻机模头 Die Head Engraving E.D.M 雕模放置加工机根据国家标准,以下为部分压铸模具术语的标准翻译。

Form Grinding Machine 成形磨床压力铸造模具 Die-Casting Die Graphite Machine 石墨加工机压铸模零部件Horizontal Boring Machine 卧式搪孔机定模 Fixed Die Cover Die Horizontal Machine Center卧式加工制造中心定模座板 Fixed Clamping Plate Internal Cylindrical Machine 内圆磨床定模套板 Bolster Fixed Die Jig Boring Machine 冶具搪孔机动模 Moving Die Ejector Die Jig Grinding Machine 冶具磨床动模座板 Moving Clamping Plate Lap Machine 研磨机直流道 Sprue Machine Center 加工制造中心横流道 Runner Multi Model Miller 靠磨铣床内浇口 Gate NC Drilling Machine NC钻床模具分类NC Grinding Machine NC磨床Injection Mold 注塑模NC Lathe NC车床Plastic Rubber Mould 塑胶模NC Programming System NC程式制作系统Rubber Molding 橡胶成形Planer 龙门刨床Hot Chamber Die Casting 热室压铸Profile Grinding Machine 投影磨床Sand Mold Casting 砂模铸造Projection Grinder 投影磨床Extrusion Mold 挤出模Radial Drilling Machine 旋臂钻床Multi-Cavity Mold 多模穴模具Shaper 牛头刨床Stack Mold, Stack Injection Mould 叠层模Surface Grinder 平面磨床Plaster Mold 石膏模Try Machine 试模机Three Plates Mold 三板模Turret Lathe 转塔车床Plain Die 简易模Universal Tool Grinding Machine万能工具磨床Pierce Die 冲孔模Vertical Machine Center 立式加工制造中心Forming Die 成型模Wire E.D.M 线割放电加工机Progressive Die 连续模入水 GateGang Dies 复合模进入位 Gate LocationShearing Die 剪边模水口形式 Gate TypeCavity Die 型腔模大水口 Edge GateRiveting Die 铆合模细水口 Pin-point GateCompression Molding 压缩成型水口大小 Gate SizeFlash Mold 溢流式模具转水口 Switching Runner GateExtrusion Mold 挤压式模具唧嘴口径 Sprue DiameterSplit Mold 分割式模具流道 Mold RunnerMould Cavity 型腔 母模热流道 Hot Runner Hot ManifoldMold Core 模芯 公模温度控制器温控器ThermostatThermoregulators Temperature Controller Large Die Mold 大型模具热嘴冷流道 Hot Sprue Cold RunnerPrecise Die Mold 精密模具唧嘴直流 Direct Sprue GateComplex Die Mold 复杂模具圆形流道 Round Full Half RunnerFoaming Mould 发泡模具流道电脑分析 Mold Flow AnalysisMetal Die 金属模具流道平衡 Runner BalancePlastic Mold 塑料模具热嘴 Hot SpruePress Tool Stamping Die Punch Die冲压模具热流道板 Hot ManifoldExtrusion Die 挤压模具发热管 Cartridge HeaterGraphite Die 石墨模具探针 Thermocouples流道浇口部分插头 Connector PlugRunner System 浇道系统插座 Connector SocketSprue Cold Material Trap 浇道 冷料井密封 封料 SealSprue Puller 拉杆运水 Water LineRunner Design 流道设计喉塞 Line Plug Throat TapsMain Runner 主流道喉管 TubeSecondary Runner 次流道塑胶管 Plastic TubeMould Gate Design 浇口设计快速接头Jiffy Quick Connector QuickDisconnect CouplingSubmarine Gate 潜伏浇口模具零件 Mold ComponentsTunnel Gate 隧道式浇口三板模 3-Plate MoldPinpoint Gate 点浇口二板模 2-Plate MoldFan Gate 扇形浇口边钉 导边 Leader Pin Guide PinSide Gate 侧浇口边司 导套 Bushing Guide BushingEdge Gate 侧缘浇口中托司 Shoulder Guide BushingTab Gate 搭接浇口中托边 Guide PinFilm Gate 薄膜浇口顶针板 Ejector Retainner PlateFlash Gate 闸门浇口托板 Support PlateSlit Gate 缝隙浇口螺丝 ScrewDish Gate 盘形浇口管钉 Dowel PinDiaphragm Gate 隔膜浇口开模槽 Ply Bar ScotRing Gate 环形浇口内模管位 Core Cavity inter-LockRunnerless 无浇道顶针 Ejector PinSprueless 无射料管方式司筒 Ejector SleeveLong Nozzle 延长喷嘴方式司筒针 Ejector PinSprue 浇口,溶渣推板Eject Plate Push Plate StripperPlateInsulated Runner Hot Runner 热浇道缩呵 Movable Core Return Core Puller Runner Plat 浇道模块扣机(尼龙拉勾) Nylon Latch LockValve Gate阀门浇口斜顶 LifterSlag Well 冷料井模胚(架) Mold BaseCold Slag 冷料渣上内模 Cavity InsertSprue Gate 射料浇口,直浇口下内模 Core InsertNozzle 射嘴行位(滑块) SlideSprue Lock Pin 料头钩销(拉料杆)镶件 Insert注塑缺陷压座 WedgeFlash 飞边耐磨板 油板 Wedge Wear PlateWarpage 翘曲压条 PlateAir Trap 积风撑头 Support PillarBlush 发赤唧嘴 Sprue BushingFlow Line 流痕挡板 Stop PlateSplay 银纹定位圈 Locating RingShort Shot 短射锁扣 LatchSink Mark 缩痕扣机 Parting Lock SetStreak 条纹推杆 Push BarVoid 缩孔栓打螺丝 S.H.S.BWeld Line 熔接线顶板 Ejector PlateGas Mark 烧焦活动臂 Lever ArmCold Slug 冷斑分流锥 Sprue SpreaderDelamination 起皮分流板 Spreader PlateBurr 毛刺水口司 BushFlaw Scratch 刮伤垃圾钉 Stop PinGloss 光泽隔片 BuffleGlazing 光滑弹弓柱 Spring RodSurface Check 表面裂痕弹弓 Die SpringHesitation 迟滞中托司 Ejector Guide Bush注塑工艺中托边 Ejector Guide PinMolding Conditions 成型条件镶针 PinDrying 烘干销子 Dowel PinBarrel Temperature 料筒温度波子弹弓 Ball catchMelt Temperature 熔化温度喉塞 Pipe PlugMold Temperature 模具温度锁模块 Lock PlateInjection Pressure 注塑压力斜顶 Angle from PinBack Pressure 背压斜顶杆 Angle Ejector RodInjection Speed 注塑速度尼龙拉勾 Parting LocksScrew Speed 螺杆转速活动臂 Lever ArmTensile Strength 抗拉强度复位键 提前回杆 Early Return BarTensile Elongation 延伸率气阀 ValvesFlexural Modulus 弯曲模数斜导边 Angle PinFlexural Strength 抗弯强度术语 TermsShrinkage 收缩率承压平面平衡Parting Surface SupportBalanceRegrind Usage 次料使用模排气 Parting Line VentingMoulding 模塑回针碰料位Return Pin and CavityInterference机械设备顶针碰运水Water Line Interferes withEjector PinLathe 车床料位出上下模Part from Cavith(Core)SidePlaner 刨床不准用镶件Do Not Use(Core Cavity)InsertMiller Milling Machine 铣床用铍铜做镶件 Use Beryllium Copper Insert Grinder 磨床初步模图设计 Preliminary Mold Design Driller 钻床正式模图设计 Final Mold DesignLinear Cutting 线切割弹弓压缩量 Spring Compressed length Electrical Sparkle 电火花稳定性好 Good Stability StableWelder 电焊机强度不够 Insufficient RigidityPunching Machine 冲床均匀冷却 Even CoolingRobot 机械手扣模 StickingCommon Equipment 常用设备热膨胀 Thermal ExpansionEDM Electron Discharge Machining放电加工公差 Tolerance3D Coordinate Measurement 三次元量床铜公(电极) Copper Electrode Boring Machine 搪孔机Air Vent Valve 通气阀Contouring Machine 轮廓锯床Anchor Pin 锚梢Copy Grinding Machine 仿形磨床Angular Pin 角梢Cylindrical Grinding Machine 外圆磨床Baffle 调节阻板Die Spotting Machine 合模机Angular Pin 倾斜梢Engraving Machine 雕刻机Baffle Plate 折流挡板Engraving E.D.M 雕模放置加工机Ball Button 球塞套Form Grinding Machine 成形磨床Ball Plunger 定位球塞Graphite Machine 石墨加工机Ball Slider 球塞滑块Horizontal Boring Machine 卧式搪孔机Binder Plate 压板Horizontal Machine Center卧式加工制造中心Blank Holder 防皱压板Internal Cylindrical Machine 内圆磨床Blanking Die 落料冲头模具零件Bolster 上下模板Top Plate 上托板(顶板)Bottom Board 浇注底板Top Block 上垫脚Bolster 垫板Punch Set 上模座Bottom Plate 下固定板Punch Pad 上垫板Bracket 托架Punch Holder 上夹板Bumper Block 缓冲块Stripper Pad 脱料背板Buster 堵口Up Stripper 上脱料板Casting Ladle 浇注包Male Die 公模(凸模)Casting Lug 铸耳Feature Die 公母模Cavity 模腔 模穴(模仁)Female Die 母模(凹模)Cavity Retainer Plate 模穴托板Upper Mold Plate 上模板Center Pin 中心梢Lower Mold Plate 下模板Clamping Block 锁定块Die Pad 下垫板Coil Spring 螺旋弹簧Die Holder 下夹板Cold Punched Nut 冷冲螺母Die Set 下模座Cooling Spiral 螺旋冷却栓Bottom Block 下垫脚Core 心型Bottom Plate下托板(底板)Core Pin 心型梢Stripping Plate 内外打(脱料板)Cotter 开口梢Outer Stripper 外脱料板Cross 十字接头Inner Stripper 内脱料板Cushion Pin 缓冲梢Lower Stripper 下脱料板Diaphragm Gate 盘形浇口Inner Guiding Post 内导柱Die Approach 模头料道Inner Hexagon Screw 内六角螺钉Die Bed 型底Dowel Pin 固定销Die Block 块形模体Mould Coil Spring 模具弹簧Die Body 模体Lifter Pin 顶料销Die Body 铸模座Isoheight Sleeve 等高套筒Die Bush 合模衬套Pin 销Die Button 冲模母模Lifter Guide Pin 浮升导料销Die Clamper 夹模器Guide Pin 导正销Die Fastener 模具固定用零件Wire Spring 圆线弹簧Die Holder 母模固定板Outer Guiding Post 外导柱Die Lip 模唇Stop Screw 止付螺丝Die Plate 冲模板Located Pin 定位销Die Set 冲压模座Outer Bush 外导套Direct Gate 直接浇口Punch 冲头Dog Chuck 爪牙夹头Insert 入块(嵌入件)Dowel 定位梢Deburring Punch 压毛边冲子Dowel Hole 导套孔Groove Punch 压线冲子Dowel Pin 合模梢Stamped Punch 字模冲子Dozzle 辅助浇口Round Punch 圆冲子Dowel Pin 定位梢Special Shape Punch 异形冲子Draft 拔模锥度Bending Block 折刀Draw Bead 张力调整杆Roller 滚轴Drive Bearing 传动轴承Baffle Plate 挡块Ejection Pad 顶出衬垫Located Block 定位块Ejector 脱模器Supporting Block for Location 定位支承块Ejector Guide Pin 顶出导梢Air Cushion Plate 气垫板Ejector Leader Bush 顶出导梢衬套Air-Cushion Eject-rod 气垫顶杆Ejector Pad 顶出垫Trimming Punch 切边冲子Ejector Pin 顶出梢Stiffening Rib Punch Stinger 加强筋冲子Ejector Plate 顶出板Ribbon Punch 压筋冲子Ejector Rod 顶出杆Reel-stretch Punch 卷圆压平冲子Ejector Sleeve 顶出衬套Guide Plate 定位板Ejector Valve 顶出阀Sliding Block 滑块Eye Bolt 环首螺栓Sliding Dowel Block 滑块固定块Filling Core 填充型芯 椿入蕊Active Plate 活动板Film Gate 薄膜形浇口Lower Sliding Plate 下滑块板Finger Pin 指形梢Upper Holder Block 上压块Finish Machined Plate 角形模板Upper Mid Plate 上中间板Finish Machined Round Plate 圆形模板Spring Box 弹簧箱Fixed Bolster Plate 固定侧模板Spring-Box Eject-rod 弹簧箱顶杆Flanged Pin 带凸缘针Spring-Box Eject-Plate 弹簧箱顶板Flash Gate 毛边形浇口Bushing Block Liner Bushing 衬套Flask 上箱Cover Plate 盖板Floating Punch 浮动冲头Guide Pad 导料块Gate 浇口模具技术用语Gate Land 浇口面各种常用模具成形方式Gib 凹形拉紧楔Accurate Die Casting 精密压铸Goose Neck 鹅颈管Powder Forming 粉末成形Guide Bushing 引导衬套Calendaring Molding 压延成形Guide Pin 导梢Powder Metal Forging 粉末锻造Guide Post 引导柱Cold Chamber Die Casting 冷式压铸Guide Plate 导板Precision Forging 精密锻造Guide Rail 导轨Cold Forging 冷锻Head Punch 顶头冲孔Press Forging 冲锻Headless Punch 直柄冲头Compacting Molding 粉末压出成形Heavily Tapered Solid 整体模蕊盒Rocking Die Forging 摇动锻造Hose Joint Pipe Coupler 管接头Compound Molding 复合成形Impact Damper 缓冲器Rotary Forging 回转锻造Injection Ram 压射柱塞Compression Molding 压缩成形Inlay Bush 嵌入衬套Rotational Molding 离心成形Inner Plunger 内柱塞Dip Mold 浸渍成形Inner Punch 内冲头Rubber Molding 橡胶成形Inserts 嵌件Encapsulation Molding 注入成形Insert Pin 嵌件梢Sand Mold Casting 砂模铸造King Pin 转向梢Extrusion Molding 挤出成形King Pin Bush 主梢衬套Shell Casting 壳模铸造Knockout Bar 脱模杵Foam Forming 发泡成形Land 合模平坦面Sinter Forging 烧结锻造Land Area 合模面Forging Roll 轧锻Leader Bush 导梢衬套Six Sides Forging 六面锻造Lifting Pin 起模顶针Gravity Casting 重力铸造Lining 内衬Slush Molding 凝塑成形Locating Center Punch 定位中心冲头Hollow Blow Molding 中空(吹出)成形Locating Pilot Pin 定位导梢Squeeze Casting 高压铸造Locating Ring 定位环Hot Chamber Die Casting 热室压铸Lock Block 压块Swaging 挤锻Locking Block 定位块Hot Forging 热锻Locking Plate 定位板Transfer Molding 转送成形Loose Bush 活动衬套Injection Molding 射出成形Making Die 打印冲子Warm Forging 温锻Manifold Block 歧管档块Investment Casting 精密铸造Master Plate 靠模样板Matched Die Method 对模成形法Match Plate 分型板Laminating Method 被覆淋膜成形Mold Base 塑胶模座Low Pressure Casting 低压铸造Mold Clamp 铸模紧固夹Lost Wax Casting 脱蜡铸造Mold Platen 模用板Matched Mould Thermal Forming对模热成形Moving Bolster 换模保持装置模Close Mold 合模Moving Bolster Plate 可动侧模板Demould 脱模 脱模剂One Piece Casting 整体铸件Mould Unloading 开模Parallel Block 平行垫块Eject 顶出Parting Line 分模线Tool Change Retooling Die Changing 换模Parting Lock Set 合模定位器Mould Clamping 锁模Pass Guide 穴型导板各式模具分类用语Peened Head Punch 镶入式冲头 钻杆凸模Bismuth Mold 铋铸模Pilot Pin 定位销 导向销子Landed Plunger Mold 有肩柱塞式模具Pin Gate 针尖浇口Burnishing Die 挤光模Plate 衬板Landed Positive Mold 有肩全压式模具Pre Extrusion Punch 顶挤冲头Button Die 镶入式圆形凹模Punch 冲头Loading Shoe Mold 料套式模具Puncher 推杆Center-Gated Mold 中心浇口式模具Pusher Pin 衬套梢Loose Detail Mold 活零件模具Rack 机架Chill Mold 冷硬用铸模Rapping Rod 起模杆Loose Mold 活动式模具Re-entrant Mold 凹入模Cold Hobbing 冷挤压制模法Retainer Pin 嵌件梢Louvering Die 百叶窗冲切模Retainer Plate 托料板Composite Dies 复合模具Return Pin 回位梢Manifold Die 分歧管模具Riding Stripper 浮动脱模器Counter Punch 反凸模Ring Gate 环型浇口Modular Mold 组合模具Roller 滚筒Double Stack Mold 双层模具Runner 流道Multi-Cavity Mold 多模穴模具Runner Ejector Set 流道顶出器Electroformed Mold 电铸成形模Runner Lock Pin 流道拉梢Multi-Gate Mold 复式浇口模具Screw Plug 头塞Expander Die 扩径模Set Screw 固定螺丝Offset Cold Bending Die 双折冷弯模具Shedder 脱模装置Extrusion Die 挤出模Shim 分隔片Stack Mold, Stack Injection Mould 叠层模Shoe 模座之上下模板Family Mold 反套制品模具Shoot 流道Plaster Mold 石膏模Shoulder Bolt 肩部螺丝Blank Through Dies 漏件式落料模Skeleton Frameworks 骨架Porous Mold 通气性模具Slag Riser 冒渣口Duplicated Cavity Plate 复板模Slide(Slide Core) 滑块Positive Mold 全压式模具Slip Joint 滑配接头Fantail Die 扇尾形模具Spacer Block 间隔块Pressure Die 压紧模Spacer Ring 间隔环Fishtail Die 鱼尾形模具Spider 模蕊支架Profile Die 轮廓模Spindle 主轴Flash Mold 溢料式模具Sprue 注道Progressive Die 顺序模Sprue Bushing 注道衬套Gypsum Mold 石膏铸模Sprue Bushing Guide 注道导套Portable Mold 手提式模具Sprue Lock Bushing 注道定位衬套Hot-Runner Mold 热流道模具Sprue Puller 注道残料顶销 浇道推出杆Prototype Mold 雏形试验模具 原型模具Sprue Line 合模线Ingot Mold 钢锭模Square Key 方键Punching Die 落料模Square Nut 方螺帽Lancing Die 切口模 切缝模Square Thread 方螺纹Raising(Embossing) 压花起伏成形Stop Collar 限位套Re-entrant Mold 倒角式模具Stop Pin 止动梢Sectional Die 拼合模Stop Ring 止动环Runless Injection Mold 无流道冷料模具Stopper 定位停止梢Sectional Die 对合模具Straight Pin 圆柱销Segment Mold 组合模Stripper Bolt 脱料螺栓Semi-Positive Mold 半全压式模具Stripper Bushing 脱模衬套Shaper 定型模套Stripper Plate 剥料板Single Cavity Mold 单腔模具Stroke End Block 行程止梢Solid Forging Die 整体锻模Submarine Gate 潜入式浇口Split Forging Die 拼合锻模Support Pillar 支撑支柱 顶出支柱Split Mold 双并式模具Support Pin 支撑梢Sprueless Mold 无注道残料模具Supporting Plate 托板Squeezing Die 挤压模Sweep Template 造模刮板Stretch Form Die 拉伸成形模Tab Gate 辅助浇口Sweeping Mold 平刮铸模Taper Key 推拔键Swing Die 振动模具Taper Pin 拔锥梢 锥形梢Three Plates Mold 三片式模具Teeming 浇注Trimming Die 切边模Three Start Screw 三条螺纹Unit Mold 单元式模具Thrust Pin 推力销Universal Mold 通用模具Tie Bar 拉杵Unscrewing Mold 退扣式模具Tunnel Gate 隧道形浇口Yoke Type Die 轭型模Vent 通气孔模具厂常用之标准零配件Wortle Plate 拉丝模板Air Vent Valve 通气阀Pierce 冲孔Anchor Pin 锚梢Forming 成型(抽凸 冲凸)Angular Pin 角梢Draw Hole 抽孔Baffle 调节阻板Bending 折弯Angular Pin 倾斜梢Trim 切边Baffle Plate 折流档板Emboss 凸点Ball Button 球塞套Dome 凸圆Ball Plunger 定位球塞Semi-Shearing 半剪Ball Slider 球塞滑块Stamp Mark 冲记号Binder Plate 压板Deburr or Coin 压毛边Blank Holder 防皱压板Punch Riveting 冲压铆合Blanking Die 落料冲头Side Stretch 侧冲压平Bolster 上下模板Reel Stretch 卷圆压平Bottom board 浇注底板Groove 压线Bolster 垫板Blanking 下料Bottom Plate 下固定板Stamp Letter 冲字(料号)Bracket 托架Shearing 剪断Bumper Block 缓冲块Tick-Mark Nearside 正面压印Buster 堵口Tick-Mark Farside 反面压印Casting Ladle 浇注包Extension Drawing 展开图Casting lug 铸耳procedure Drawing 工程图Cavity 模穴(模仁)Die Structure Drawing 模具结构图Cavity Retainer Plate 模穴托板Material 材质Center Pin 中心梢Material Thickness 料片厚度Clamping Block 锁定块Factor 系数Coil Spring 螺旋弹簧Upward 向上Cold Punched Nut 冷冲螺母Downward 向下Cooling Spiral 螺旋冷却栓Press Specification 冲床规格Core 心型Die Height Range 适用模高Core Pin 心型梢Die Height 闭模高度Cotter 开口梢Burr 毛边Cross 十字接头Gap 间隙Cushion Pin 缓冲梢Weight 重量Diaphragm Gate 盘形浇口Total Weight 总重量Die Approach 模头料道Punch Weight 上模重量Die Bed 型底Compression Molding 压缩成型Die Block 块形模体Flash Mold 溢流式模具Die Body 铸模座Extrusion Mold 挤压式模具Die Bush 合模衬套Split Mold 分割式模具Die Button 冲模母模Cavity 型腔 母模Die Clamper 夹模器Mold Core 模芯 公模Die Fastener 模具固定用零件Taper 锥拔Die Holder 母模固定板Leather Cloak 仿皮革Die Lip 模唇Shiver 饰纹Die Plate 冲模板Flow Mark 流痕Die Set 冲压模座Welding Mark 溶合痕Direct Gate 直接浇口Post Screw Insert 螺纹套筒埋值Dog Chuck 爪牙夹头Self Tapping Screw 自攻螺丝Dowel 定位梢Striper Plate 脱料板Dowel Hole 导套孔Piston 活塞Dowel Pin 合模梢Cylinder 汽缸套Dozzle 辅助浇口Chip 细碎物Dowel Pin 定位梢Handle Mold 手持式模具Draft 拔模锥度Encapsulation Molding 低压封装成型Draw Bead 张力调整杆Two Plate 两极式(模具)Drive Bearing 传动轴承Well Type 蓄料井Ejection Pad 顶出衬垫Insulated Runner 绝缘浇道方式Ejector 脱模器Hot Runner 热浇道Ejector Guide Pin 顶出导梢Runner Plat 浇道模块Ejector Leader Bush 顶出导梢衬套Valve Gate 阀门浇口Ejector Pad 顶出垫Band Heater 环带状的电热器Ejector Pin 顶出梢Spindle 阀针Ejector Plate 顶出板Spear Head 刨尖头Ejector Rod 顶出杆Slag Well 冷料井Ejector Sleeve 顶出衬套Cold Slag 冷料渣Ejector Valve 顶出阀Air Vent 排气道Eye Bolt 环首螺栓Welding Line 熔合痕Filling Core 填充型芯 椿入蕊Eject Pin 顶出针Film Gate 薄膜形浇口Knock Pin 顶出销Finger Pin 指形梢Return Pin 回位销反顶针Finish Machined Plate 角形模板Sleeve 套筒Finish Machined Round Plate 圆形模板Stripper Plate 脱料板Fixed Bolster Plate 固定侧模板Insert Core 放置入子Flanged Pin 带凸缘针Runner Stripper Plate 浇道脱料板Flash Gate 毛边形浇口Guide Pin 导销Flask 上箱Eject Rod (Bar)(成型机)顶业捧Floating Punch 浮动冲头Subzero 深冷处理Gate 浇口Three Plate 三极式模具Gate Land 浇口面Runner System 浇道系统Gib 凹形拉紧楔Stress Crack 应力电裂Goose Neck 鹅颈管Orientation 定向Guide Bushing 引导衬套Sprue Gate 射料浇口,直浇口Guide Pin 导梢Nozzle 射嘴Guide Post 引导柱Sprue Lock Pin 料头钩销(拉料杆)Guide Plate 导板Slag Well 冷料井Guide Rail 导轨Side Gate 侧浇口Head Punch 顶头冲孔Edge Gate 侧缘浇口Headless Punch 直柄冲头Tab Gate 搭接浇口Heavily Tapered Solid 整体模蕊盒Film Gate 薄膜浇口Hose Nippler 管接头Flash Gate 闸门浇口Impact Damper 缓冲器Slit Gate 缝隙浇口Injection Ram 压射柱塞Fan Gate 扇形浇口Inlay Bush 嵌入衬套Dish Gate 因盘形浇口Inner Plunger 内柱塞Diaphragm Gate 隔膜浇口Inner Punch 内冲头Ring Gate 环形浇口Insert 嵌件Submarine Gate 潜入式浇口Insert Pin 嵌件梢Tunnel Gate 隧道式浇口King Pin 转向梢Pin Gate 针点浇口King Pin Bush 主梢衬套Runnerless 无浇道Knockout Bar 脱模杵Sprueless 无射料管方式Land 合模平坦面Long Nozzle 延长喷嘴方式Land Area 合模面Sprue 浇口 溶渣Leader Bush 导梢衬套Landed Plunger Mold 有肩柱塞式模具Lifting Pin 起模顶针 起模杆Burnishing Die 挤光模Lining 内衬Landed Positive Mold 有肩全压式模具Locating Center Punch 定位中心冲头Button Die 镶入式圆形凹模Locating Pilot Pin 定位导梢Loading Shoe Mold 料套式模具Locating Ring 定位环Center-Gated Mold 中心浇口式模具Lock Block 压块Loose Detail Mold 活零件模具Locking Plate 定位板Loose Mold 活动式模具Loose Bush 活动衬套Cold Hobbing 冷挤压制模Making Die 打印冲子Louvering Die 百叶窗冲切模Manifold Block 歧管档块Composite Dies 复合模具Master Plate 靠模样板Manifold Die 分歧管模具Match Plate 分型板Counter Punch 反凸模Mold Base 塑胶模座Modular Mold 组合式模具Mold Clamp 铸模紧固夹Double Stack Mold 双层模具Mold Platen 模用板Multi-Cavity Mold 多模穴模具Moving Bolster 换模保持装置Electroformed Mold 电铸成形模Moving Bolster Plate 可动侧模板Multi-Gate Mold 复式浇口模具One Piece Casting 整体铸件Expander Die 扩径模Parallel Block 平行垫块Offset Bending Die双折冷弯模具偏移弯曲模Parting Line 分模线Extrusion Die 挤出模Parting Lock Set 合模定位器Palletizing Die 叠层模Pass Guide 穴型导板Family Mold 反套制品模具Peened Head Punch镶入式冲头锤击强化冲头Plaster Mold 石膏模钻杆凸模Pilot Pin 定位销 导向销子Blank Through Dies 漏件式落料模Pin Gate 针尖浇口Porous Mold 通气性模具Plate 衬板Duplicated Cavity Plate 复板模Pre Extrusion Punch 顶挤冲头Positive Mold 全压式模具Punch 冲头Fantail Die 扇尾形模具Puncher 推杆Pressure Die 压紧模Pusher Pin 衬套梢Fishtail Die 鱼尾形模具Rack 机架Profile Die 轮廓模Rapping Rod 起模杆Flash Mold 溢料式模具Re-entrant Mold 凹入模Progressive Die 顺序模Retainer Pin 嵌件梢Gypsum Mold 石膏铸模Retainer Plate 托料板Portable Mold 手提式模具Return Pin 回位梢Hot-Runner Mold 热流道模具Riding Stripper 浮动脱模器Prototype Mold 雏形试验模具Ring Gate 环型浇口Ingot Mold 钢锭模Roller 滚筒Punching Die 落料模Runner 流道Lancing Die 切口模Runner Ejector Set 流道顶出器Raising(Embossing) 压花起伏成形Runner Lock Pin 流道拉梢Re-entrant Mold 倒角式模具Screw Plug 头塞Sectional Die 拼合模Set Screw 固定螺丝Runnerless Injection Mold 无流道冷料模具Shedder 脱模装置Sectional Die 对合模具Shim 分隔片Segment Mold 组合模Shoot 流道Shaper 定型模套Shoulder Bolt 肩部螺丝Single Cavity Mold 单腔模具Skeleton 骨架Solid Forging Die 整体锻模Slag Riser 冒渣口Split Forging Die 拼合锻模Slide(Slide Core) 滑块Split Mold 双并式模具Slip Joint 滑配接头Sprueless Mold 无注道残料模具Spacer Block 间隔块Squeezing Die 挤压模Spacer Ring 间隔环Stretch Form Die 拉伸成形模Spider 模蕊支架Sweeping Mold 平刮铸模Spindle 主轴Swing Die 振动模具Sprue 注道Three Plates Mold 三片式模具Sprue Bushing 注道衬套Trimming Die 切边模Sprue Bushing Guide 注道导套Unit Mold 单元式模具Sprue Lock Bushing 注道定位衬套Universal Mold 通用模具Sprue Puller注道拉料浇道推出杆注道残料Unscrewing Mold 退扣式模具顶销Spew Line 合模线Yoke Type Die 轭型模Square Key 方键Accurate Die Casting 精密压铸Square Nut 方螺帽Powder Forming 粉末成形Square Thread 方螺纹Calendaring Molding 压延成形Limit Stop Collar 限位套Powder Metal Forging 粉末锻造Stop Pin 止动梢Cold Chamber Die Casting 冷式压铸Stop Ring 止动环Precision Forging 精密锻造Stopper 定位停止梢Cold Forging 冷锻Straight Pin 圆柱销Press Forging 冲锻Stripper Bolt 脱料螺栓Compacting Molding 粉末压出成形Stripper Bushing 脱模衬套Rocking Die Forging 摇动锻造Stripper Plate 剥料板Compound Molding 复合成形Stroke End Block 行程止梢Rotary Forging 回转锻造Submarine Gate 潜入式浇口Compression Molding 压缩成形Support Pillar 支撑支柱 顶出支柱Rotational Molding 离心成形Support Pin 支撑梢Dip Mold 浸渍成形Supporting Plate 托板Rubber Molding 橡胶成形Sweep Template 造模刮板Encapsulation Molding 注入成形Tab Gate 辅助浇口Sand Mold Casting 砂模铸造Taper Key 推拔键Extrusion Molding 挤出成形Taper Pin 拔锥梢 锥形梢Shell Casting 壳模铸造Teeming Pouring 浇注Foam Forming 发泡成形Three Start Screw 三条螺纹Sinter Forging 烧结锻造Thrust Pin 推力销Forging Roll 轧锻Tie Bar 拉杵Six Sides Forging 六面锻造Vent 通气孔Slush Molding 凝塑成形Wortle Plate 拉丝模板Hollow(Blow) Molding 中空(吹出)成形Squeeze Casting 高压铸造Hot Chamber Die Casting 热室压铸Swaging 挤锻Hot Forging 热锻Transfer Molding 转送成形Injection Molding 射出成形Warm Forging 温锻Investment Casting 精密铸造Matched Die Method 对模成形法Laminating Method 被覆淋膜成形Low Pressure Casting 低压铸造Lost Wax Casting 脱蜡铸造Matched Mould Thermal Forming对模热成形模Barreling 滚光加工Belling 压凸加工Bending 弯曲加工Blanking 下料加工Bulging 撑压加工Burring 冲缘加工Cam Die Bending 凸轮弯曲加工Caulking 压合加工Coining 压印加工Compressing 压缩加工Compression Bending 押弯曲加工Crowning 凸面加工Curl Bending 卷边弯曲加工Curling 卷曲加工Cutting 切削加工Dinking 切断蕊骨Double Shearing 叠板裁断Drawing 引伸加工Drawing with Ironing 抽引光滑加工Embossing 浮花压制加工Extrusion 挤制加工Filing 锉削加工Fine Blanking 精密下料加工Finish Blanking 光制下料加工Finishing 精整加工Folding 折边弯曲加工Folding 折叠加工Forming 成形加工Impact Extrusion 冲击挤压加工Indenting 压痕加工Ironing 引缩加工Knurling 滚花Lock Seaming 固定接合Louvering 百叶窗板加工MarKing 刻印加工Necking 颈缩加工Notching 冲口加工Parting 分断加工Piercing 冲孔加工Progressive Bending 连续弯曲加工Progressive Blanking 连续下料加工Progressive Drawing 连续引伸加工Progressive Forming 连续成形加工Reaming 铰孔加工Restriking 二次精冲加工 矫形锻压Riveting 铆接加工Roll Bending 滚筒弯曲加工Roll Finishing 滚压加工Rolling 压延加工Roughing 粗加工Scrapless Machining 无废料加工Seaming 折弯重叠加工Shaving 缺口修整加工Shearing 切断加工Sizing 精压加工 矫正加工Slitting 割缝加工Spinning 卷边旋接Staking 铆固Stamping 锻压加工Swaging 挤锻压加工Trimming 整缘加工Upsetting 锻粗加工 顶锻镦粗Wiring 抽线加工Aberration 色差Atomization 雾化Bite 咬入Blacking Hole 涂料孔(铸疵)Blacking Scab 涂料疤Blister 起泡Blooming 起霜Blow Hole 破孔Blushing 泛白Body Wrinkle 侧壁皱纹Breaking-in 冒口带肉Bubble 膜泡Burn Mark 糊斑Flash Burr 毛边Camber Warpage 翘曲Cell 气泡Center Buckle 表面中部波皱Check 细裂痕Checking 龟裂Chipping 修整表面缺陷Clamp-off 铸件凹痕Collapse 塌陷Color Mottle 色斑Corrosion 腐蚀Crackle 裂痕 裂纹Crazing 碎裂Crazing 龟裂Distortion Deformation 变形Edge 切边碎片Edge Crack 裂边Fading 退色Filler Speak 填充料斑Fissure 裂纹Flange Wrinkle 凸缘起皱Flaw 刮伤Flow Mark 流痕Galling 毛边Glazing 光滑Gloss 光泽Grease Pits 污斑Grinding Defect 磨痕Haircrack 发裂Incrustation 水锈Indentation 压痕Internal Porosity 内部气孔Mismatch 偏模Mottle 斑点Necking 缩颈Nick 割痕Orange peel 橘皮状表面缺陷Overflow 溢流Peeling 剥离Pit 坑Pitting Corrosion 点状腐蚀Plate Mark 模板印痕Pock 麻点Pock Mark 痘斑Resin Streak 树脂流纹Resin Wear 树脂脱落Riding 凹陷Sagging 松垂Saponification 皂化Scar 疤痕Scrap 废料Scrap Jam 废料阻塞Scratch 刮伤 划痕Scuffing 深冲表面划伤Seam 裂痕Shock Line 模口挤痕Short Shot 充填不足Shrinkage Pool 凹孔Sink Mark 凹痕Skin Inclusion 表皮折叠Straightening 矫直Streak 条状痕Surface Check 表面裂痕Surface Roughening 橘皮状表皮皱折Surging 波动Sweat Out 冒汗Torsion Distortion 扭曲Warpage 翘曲Waviness 波痕Weld Mark 焊痕Whitening 白化Wrinkle 皱纹Gas Aassisted Technology 气辅Bottle Cap Mold 瓶盖模具。

吹瓶机的专业术语1. 吹瓶机 (Blow Molding Machine):也叫注塑吹塑机,是一种用于制造塑料瓶、桶、容器等物品的专业机器设备,通过吹塑(Blow Molding)工艺制造。

2. 锥杆模具(Conical die mould):也叫做锥度模具,是一种塑料注塑模具。

它的结构与注塑机的注射过程相关联。

它的形状特别设计,允许塑料熔体在流动过程中得到平稳的流动,并且形成一定的速度梯度,从而避免塑料熔体振动和产生空气泡。

5. 无人操作吹瓶机(Automatic Blow Molding Machine):是一种目前应用最广泛的吹瓶机,它具有自动化程度高、操作简便等优点,能够满足对生产效率和质量要求较高的用户需求。

6. 梯级式吹瓶机(Cascade Blow Molding Machine):是一种连续式吹瓶机,它具有高度自动化和高精度的生产能力。

它通过梯级式火焰伴热炉加热塑料坯料,使其熔化并流动,从而形成所需的瓶子。

9. 真空吸模机(Vacuum-suction Molding Machine):是一种用于制造贴合包装的专业机器设备。

在制造过程中,将塑料片材通过吸塑技术,形成凸凹不平的贴合形状,从而形成所需的包装容器。

10. 压痕机(Creasing Machine):是一种用于制造塑料盒的专业设备。

它可以将塑料片材纵向折叠并进行凹凸加工,从而形成所需的盒体形状。

12. 拉伸吹塑机(Stretch Blow Molding Machine):是一种同时具备拉伸和吹塑功能的生产设备,可以生产出高质量的塑料瓶、桶等容器。

它的生产过程结合了吹塑和拉伸两种成型方式,能够形成质量更优良的塑料制品。

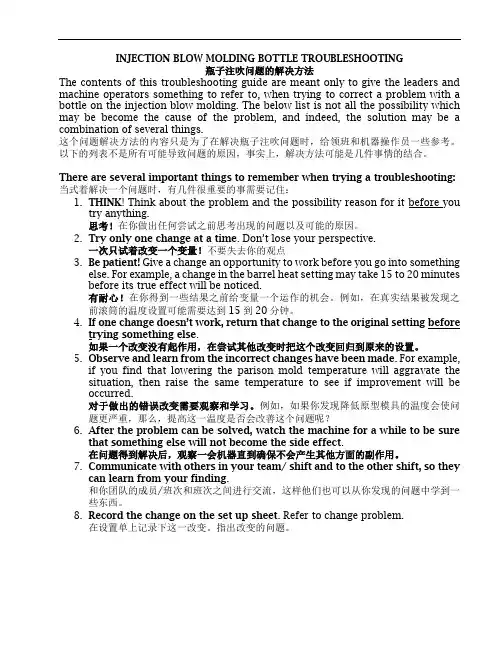

INJECTION BLOW MOLDING BOTTLE TROUBLESHOOTING瓶子注吹问题的解决方法The contents of this troubleshooting guide are meant only to give the leaders andmachine operators something to refer to, when trying to correct a problem with abottle on the injection blow molding. The below list is not all the possibility which may be become the cause of the problem, and indeed, the solution may be acombination of several things.这个问题解决方法的内容只是为了在解决瓶子注吹问题时,给领班和机器操作员一些参考。

以下的列表不是所有可能导致问题的原因,事实上,解决方法可能是几件事情的结合。

There are several important things to remember when trying a troubleshooting: 当式着解决一个问题时,有几件很重要的事需要记住:1.THINK! Think about the problem and the possibility reason for it before youtry anything.思考!在你做出任何尝试之前思考出现的问题以及可能的原因。

2.Try only one change at a time. Don’t lose your p erspective.一次只试着改变一个变量!不要失去你的观点3.Be patient! Give a change an opportunity to work before you go into somethingelse. For example, a change in the barrel heat setting may take 15 to 20 minutes before its true effect will be noticed.有耐心!在你得到一些结果之前给变量一个运作的机会。

主要塑料成型方法

主要塑料成型方法包括以下几种:

1. 注塑成型(Injection Molding):将熔化的塑料通过高压注入到模具中,冷却后形成所需的塑件。

2. 吹塑成型(Blow Molding):将熔化的塑料放在膨胀模具中,在内部加气压力,使塑料贴合模具壁冷却,形成薄壁容器。

3. 挤出成型(Extrusion):将熔化的塑料通过挤压机的螺杆,通过挤出口挤压成带孔的连续型塑料制品。

4. 压塑成型(Compression Molding):将熔化的塑料放入加热后的模具中,然后通过压力使塑料填充模具,冷却后形成塑件。

5. 真空成型(Vacuum Forming):将热塑性塑料片加热软化,放在模具上方,然后用真空吸引将塑料吸附到模具上的负模形状上,形成塑件。

6. 旋转成型(Rotational Molding):将粉末或液态塑料放入旋转模具中,通过旋转模具使塑料均匀粘附于模具内壁,冷却后形成产品。

7. 压膜成型(Thermoforming):将热塑性塑料片加热软化,放在模具上方,

然后用压力将塑料与模具上的正模形状贴合,冷却后形成塑件。

这些塑料成型方法在不同的应用领域有着各自特点和适用性,被广泛应用于塑料制品的生产中。

模具专业英文术语大全1. Die - 模具2. Mold - 模具3. Cavity - 型腔4. Core - 芯子5. Ejector pin - 顶杆6. Land - 分型面7. Gate - 浇口8. Filleting - 去毛刺9. Trim - 修整10. Draft - 拔模斜度11. Undercut - 底切12. Flash - 飞边13. Warpage - 翘曲14. Shrinkage - 收缩15. Melt flow rate - 熔融指数16. Injection molding - 注塑成型17. Blow molding - 吹塑成型18. Compression molding - 压缩成型19. Vacuum molding - 真空成型20. Overmolding - 包覆成型21. Co-injection molding - 双色注塑成型22. Gas assist injection molding - 气体辅助注塑成型23. Rotational molding - 旋转成型24. Injection compression molding - 注射压缩成型25. Injection blow molding - 注射吹塑成型26. Injection stretch blow molding - 注射拉伸吹塑成型27. Injection transfer molding - 注射传递成型28. Injection foam molding - 注射发泡成型29. Injection gas assisted rotational molding - 注射气体辅助旋转成型30. Injection compression blow molding - 注射压缩吹塑成型31. Injection stretch blow molding - 注射拉伸吹塑成型32. Injection transfer blow molding - 注射传递吹塑成型33. Injection foam blow molding - 注射发泡吹塑成型34. Injection gas assisted transfer molding - 注射气体辅助传递成型35. Injection compression foam molding - 注射压缩发泡成型36. Injection stretch foam molding - 注射拉伸发泡成型37. Injection transfer foam molding - 注射传递发泡成型38. Injection gas assisted foam blow molding - 注射气体辅助发泡吹塑成型39. Injection compression foam blow molding - 注射压缩发泡吹塑成型40. Injection stretch foam blow molding - 注射拉伸发泡吹塑成型41. Injection transfer foam blow molding - 注射传递发泡吹塑成型42. Injection gas assisted compression molding - 注射气体辅助压缩成型43. Injection gas assisted stretch blow molding - 注射气体辅助拉伸吹塑成型44. Injection gas assisted transfer blow molding - 注射气体辅助传递吹塑成型45. Injection gas assisted foam compression molding - 注射气体辅助发泡压缩成型46. Injection gas assisted foam stretch blow molding - 注射气体辅助发泡拉伸吹塑成型47. Injection gas assisted foam transfer blow molding - 注射气体辅助发泡传递吹塑成型48. Injection gas assisted compression foam molding - 注射气体辅助压缩发泡成型49. Injection gas assisted stretch foam blow molding - 注射气体辅助拉伸发泡吹塑成型50. Injection gas assisted transfer foam blow molding - 注射气体辅助传递发泡吹塑成型51. Mold temperature control system - 模具温度控制系统52. Coolant system - 冷却系统53. Ejector system - 顶出系统54. Feed system - 喂料系统55. Packaging machine - 包装机56. Automated guided vehicle (AGV) - 自动导引车(AGV)57. Robotic arm - 机械臂58. Computer numerical control (CNC) machine - 计算机数控(CNC)机床59. Plastics injection machine - 塑料注塑机60. Plastics extruder - 塑料挤出机61. Plastics blow molding machine - 塑料吹塑机62. Plastics injection compression molding machine -塑料注塑压缩成型机63. Plastics injection stretch blow molding machine - 塑料注塑拉伸吹塑成型机64. Plastics injection transfer molding machine - 塑料注塑传递成型机65. Plastics injection foam molding machine - 塑料注塑发泡成型机66. Plastics injection gas assisted rotational molding machine - 塑料注塑气体辅助旋转成型机67. Plastics injection compression foam molding machine - 塑料注塑压缩发泡成型机68. Plastics injection stretch foam molding machine - 塑料注塑拉伸发泡成型机69. Plastics injection transfer foam molding machine - 塑料注塑传递发泡成型机70. Plastics injection gas assisted foam blow molding machine - 塑料注塑气体辅助发泡吹塑成型机71. Plastics injection compression foam blow molding machine - 塑料注塑压缩发泡吹塑成型机72. Plastics injection stretch foam blow molding machine - 塑料注塑拉伸发泡吹塑成型机73. Plastics injection transfer foam blow moldingmachine - 塑料注塑传递发泡吹塑成型机74. Plastics injection molding machine with movable platen - 带活动模板的塑料注塑机75. Plastics injection molding machine with fixed platen - 带固定模板的塑料注塑机76. Plastics injection molding machine with hot runner system - 带热流道系统的塑料注塑机77. Plastics injection molding machine with cold runner system - 带冷流道系统的塑料注塑机78. Plastics injection molding machine with multi-cavity design - 带多腔设计的塑料注塑机79. Plastics injection molding machine with clamping force control - 带夹紧力控制的塑料注塑机80. Plastics injection molding machine with cycle time reduction - 带循环时间缩短的塑料注塑机81. Plastics injection molding machine with energy saving features - 带节能功能的塑料注塑机82. Plastics injection molding machine with high precision control - 带高精度控制的塑料注塑机83. Plastics injection molding machine with automatic tool changing system - 带自动换模系统的塑料注塑机84. Plastics injection molding machine with roboticautomation - 带机器人自动化的塑料注塑机85. Plastics injection molding machine with quality control system - 带质量管理系统的塑料注塑机86. Plastics injection molding machine with process monitoring system - 带工艺监控系统的塑料注塑机87. Plastics injection molding machine with maintenance reminder system - 带维护提醒系统的塑料注塑机88. Plastics injection molding machine with data logging and analysis - 带数据记录和分析的塑料注塑机89. Plastics injection molding machine with remote control and monitoring - 带远程控制和监控的塑料注塑机90. Plastics injection molding machine with safety features - 带安全功能的塑料注塑机91. Plastics injection molding machine with operator interface - 带操作员界面的塑料注塑机92. Plastics injection molding machine with easy cleaning system - 带易清洁系统的塑料注塑机93. Plastics injection molding machine with quick change tooling - 带快速换模装置的塑料注塑机94. Plastics injection molding machine with low noiseoperation - 带低噪音运行的塑料注塑机95. Plastics injection molding machine with high throughput capacity - 带高产量能力的塑料注塑机96. Plastics injection molding machine with energy recovery system - 带能量回收系统的塑料注塑机97. Plastics injection molding machine with environmental protection features - 带环保功能的塑料注塑机98. Plastics injection molding machine with advanced materials compatibility - 带先进材料兼容性的塑料注塑机99. Plastics injection molding machine with customizable options - 可定制选项的塑料注塑机100. Plastics injection molding machine with reliable performance and durability - 具有可靠性能和耐用性的塑料注塑机。

注拉吹成型工艺

注拉吹成型(Blow Molding)是一种常用的塑料制造工艺,用于制造中空容器或零件,如瓶子、桶、容器等。

该工艺结合了注塑成型和吹塑成型的特点,可以生产出具有复杂形状和中空结构的塑料制品。

注拉吹成型的基本步骤如下:

注塑(Injection Molding):在注拉吹成型机上,将熔化的塑料通过螺杆注射进注射腔体中。

注塑腔体通常具有与最终产品相似的外形,但内部为空心。

拉伸吹塑(Stretch Blow Molding):在注塑后,注射腔体会移动到吹塑腔体中。

在吹塑腔体中,通过先对塑料进行拉伸,然后再用气压吹塑,使塑料与腔体壁紧密贴合,形成中空的产品形状。

冷却与固化:在吹塑完成后,用冷却系统迅速冷却塑料,使其固化。

取出产品:一旦塑料完全固化,打开模具,取出成品。

注拉吹成型工艺具有以下优点:

高效生产:相对于传统的吹塑成型工艺,注拉吹成型速度更快,生产效率更高。

灵活性:可以制造出多种形状和尺寸的中空产品,适用于不同的应用领域。

产品质量:注拉吹成型制造的产品具有较好的密封性和均匀的壁厚,表面光滑,质量稳定。

成本效益:注拉吹成型相对于其他成型工艺来说,模具制造成本较低,适用于大规模生产。

注拉吹成型广泛应用于食品和饮料包装、化妆品容器、医疗器械、汽车零件等领域。