多孔氧化铝模板的制备及应用

- 格式:pdf

- 大小:225.06 KB

- 文档页数:3

氧化铝自牺牲模板法氧化铝自牺牲模板法(Alumina Sacrificial Template Method)是一种通过利用氧化铝模板制备材料的方法。

该方法适用于制备各种纳米结构材料,如纳米线、纳米孔等。

本文将详细介绍氧化铝自牺牲模板法的原理和应用,并探讨其在材料科学领域中的潜在应用价值。

氧化铝自牺牲模板法的原理基于氧化铝的特殊性质。

氧化铝是一种常见的无机化合物,具有高热稳定性和耐蚀性。

在制备纳米结构材料时,首先需要制备氧化铝模板。

可以通过电化学沉积、溶液浸渍等方法制备均匀的氧化铝薄膜。

然后,在模板表面沉积所需的材料,如金属或半导体。

在制备过程中,氧化铝模板起到了“牺牲剂”的作用。

通过控制制备条件和材料沉积速率,可以最终得到所需的纳米结构材料。

制备完成后,可以通过酸性溶液溶解氧化铝模板,释放所得材料。

氧化铝自牺牲模板法具有以下几个优点。

首先,制备过程简单,不需要复杂的操作步骤和昂贵的设备。

其次,可以得到高纯度、高质量的纳米结构材料。

第三,可以灵活调控材料的形貌和尺寸。

最后,该方法可应用于多种不同材料的制备,如金属、半导体、陶瓷等。

在材料科学领域中,氧化铝自牺牲模板法已经得到广泛应用。

例如,在能源储存领域,可以利用该方法制备纳米多孔金属氧化物电极材料,用于超级电容器和锂离子电池。

在催化剂领域,可以利用该方法制备纳米多孔金属催化剂,提高催化活性和选择性。

此外,该方法还可用于制备纳米传感器、纳米电子器件等。

尽管氧化铝自牺牲模板法在材料科学领域有着广泛的应用,但仍存在一些挑战和局限性。

首先,氧化铝模板的制备需要一定的时间和成本。

其次,模板的尺寸和形貌的控制比较困难,会对最终制备的材料产生一定的影响。

此外,模板的溶解过程需要一定时间,可能对制备周期造成一定限制。

综上所述,氧化铝自牺牲模板法是一种简便、经济且有效的纳米结构材料制备方法。

该方法在能源储存、催化剂以及传感器等领域具有广泛的应用前景。

未来,随着材料科学的发展,相信氧化铝自牺牲模板法将为我们提供更多的制备途径和应用机会。

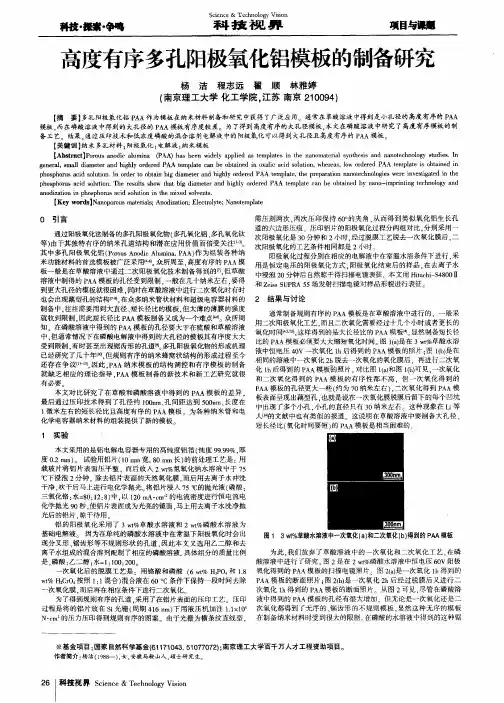

80材料导报2008年8月第22卷专辑ⅪA A O模板的制备及其应用*李晓洁,张海明,胡国锋,李育洁(天津工业大学理学院,天津300160)摘要阳极氧化铝模板由于其价廉,制备工艺简单,以及特殊的结构和多样的组装方法得到了广泛的研究和应用。

主要阐述了A A O模板的制备、影响因素,及其在纳米组装体系中的应用,包括量子点、纳米线、纳米管和“同轴电缆式”层状纳米材料等,介绍了A A O组装体系的应用,最后提出了A A O模板的潜在发展。

关键词二次阳极氧化氧化铝模板纳米材料中图分类号:0611Fa br i c at i on a nd A ppl i ca t i on of A A O Tem pl at eLI X i aoj i e,Z H A N G H ai m i ng,H U G uof eng,L I Y uj i e(Col l ege of Sci e nce,Ti an j i n Po l yt e chni c U ni ver si t y,T i anj i n300160)A bs t ractB ec a u s e of i t s l ow cost,si m pl e pr epa r at i on t ec hnol o gy,as w el l as i t s s peci al s t r uct u r e and va r i ousa ss em bl y m e t hods.t he A A O t e m pl at e ha s been w i de l y r e sear che d and use d.T h i s paper m ai nl y el a bor at es t he pr epar a—t i on,i nf l uenc i ng f act or s of t he A A O t em pl at e,a nd i t s appl i cat i on i n t he nano-a ss e m bl y sys t em,i nc l udi ng quant um dot,na now i r e,na not ube,and coaxi a l cab l e l a m i na r na no-m a t er i al s and SO O i l,T h i s ar ti cl e al s o i n t r o duce s t he appl i cat i on ofA A O a ss em bl y s ys t em and f i nal l y pr opos e s t he pot en t i al deve l opm e nt of t he A A O t em pl at e.K ey w or ds t w o-st e ps a nodi za t i on,al um i num oxi de t e m pl a t e,nano m at e r i al s0引言1953年K el l er等首先报道了用电化学的方法制备多孔氧化铝膜,此后这种具有独特结构的模板被广泛用于各种纳米结构材料的制备。

纳米多孔材料的制备与应用指南纳米多孔材料是一类具有多个纳米级孔洞的材料,其孔径通常在1到100纳米之间。

这些孔洞结构可以提供材料更大的比表面积和更丰富的孔隙容积,从而赋予材料更多优异的性能。

纳米多孔材料在各个领域都有广泛的应用,包括催化、气体吸附、分离纯化、药物输送等。

在本文中,我们将探讨纳米多孔材料的制备技术和应用指南。

一、纳米多孔材料的制备技术1. 模板法制备模板法制备纳米多孔材料是一种常用的方法。

该方法通常涉及两个步骤:首先,在一个较大的模板上形成原位孔洞阵列;然后,通过沉积材料或化学反应来填充或取代模板中的孔洞。

模板的选择非常关键,常见的模板包括硅胶、聚合物微球等。

此外,可通过自组装、硅烷化等方法对模板进行表面处理,以控制孔洞结构和孔径大小。

2. 溶剂挥发法制备溶剂挥发法制备纳米多孔材料的过程中,通过选择合适的溶剂和溶质,利用挥发性溶剂的挥发来形成孔洞结构。

这种方法简单易行,成本较低。

常用的溶剂挥发法包括溶胶-凝胶法、模板溶剂挥发法等。

溶剂挥发法制备的纳米多孔材料结构相对较简单,孔径大小可调控性较差。

3. 硬模板法制备硬模板法是在模板材料(如氧化铝、二氧化硅)的辅助下制备纳米多孔材料的方法。

该方法常与溶胶-凝胶法或沉积法结合使用。

首先,在硬模板孔洞中进行前驱体的沉积;然后,通过化学反应或热处理来脱除硬模板材料。

硬模板法制备的纳米多孔材料具有良好的孔洞结构和较高的孔隙度,但受限于模板材料的形状和制备过程相对复杂。

4. 气相沉积法制备气相沉积法利用气相反应物沉积在基底上形成纳米多孔材料。

常见的气相沉积法有化学气相沉积(CVD)和物理气相沉积(PVD)。

这种方法在制备过程中可以通过调控温度、反应气体流量等参数来控制纳米多孔材料的孔径和结构。

然而,气相沉积法通常需要较高的设备成本和复杂的操作。

二、纳米多孔材料的应用指南1. 催化应用纳米多孔材料具有较大的比表面积和丰富的孔隙结构,这使得它们在催化反应中具有显著优势。

不同孔径的氧化铝陶瓷英文回答:Aluminum Oxide Ceramic with Different Pore Sizes.Aluminum oxide ceramic, also known as alumina ceramic, is a type of advanced ceramic material that is composed primarily of aluminum oxide (Al2O3). It is characterized by its high strength, hardness, wear resistance, and thermal stability. One of the key properties of alumina ceramic is its porosity, which refers to the presence of pores or voids within the material. The pore size of alumina ceramic can vary significantly, depending on the manufacturing process and the intended application.Alumina ceramics with different pore sizes exhibit distinct properties and are used in a wide range of applications. Some of the most common types of alumina ceramics include:Dense alumina ceramic: This type of alumina ceramic has a very low porosity, typically less than 1%. It is characterized by its high strength, hardness, and wear resistance. Dense alumina ceramics are often used in applications where these properties are critical, such as in cutting tools, wear plates, and armor.Porous alumina ceramic: This type of alumina ceramic has a higher porosity, typically between 1% and 50%. It is characterized by its high surface area and permeability. Porous alumina ceramics are often used in applications where these properties are important, such as in filters, catalysts, and membranes.Ultraporous alumina ceramic: This type of alumina ceramic has a very high porosity, typically greater than 50%. It is characterized by its low density and high surface area. Ultraporous alumina ceramics are often used in applications where these properties are critical, such as in thermal insulation, sound absorption, and catalysis.The pore size of alumina ceramic can be controlled byadjusting the manufacturing process. Some of the methods used to control pore size include:Sintering temperature: The sintering temperature affects the grain size and pore size of alumina ceramic. Higher sintering temperatures typically result in larger grain sizes and pores.Doping: Doping alumina ceramic with certain elements, such as magnesium or zirconium, can affect the pore size. Doping can lead to the formation of new phases that have different pore structures.Templating: Templating is a process that uses a sacrificial template to create pores of a specific size and shape. The template is removed after sintering, leaving behind pores with the desired characteristics.The pore size of alumina ceramic has a significant impact on its properties and applications. Some of the key factors that are affected by pore size include:Strength: In general, the strength of alumina ceramic decreases with increasing pore size. This is because pores act as stress concentrators, which can lead to failure under load.Hardness: The hardness of alumina ceramic also decreases with increasing pore size. This is because pores provide a path for crack propagation.Wear resistance: The wear resistance of alumina ceramic decreases with increasing pore size. This is because pores provide a surface for wear particles to lodge and abrade.Thermal conductivity: The thermal conductivity of alumina ceramic decreases with increasing pore size. Thisis because pores act as thermal insulators.Electrical conductivity: The electrical conductivity of alumina ceramic decreases with increasing pore size. This is because pores act as electrical insulators.Due to their unique properties, alumina ceramics with different pore sizes are used in a wide range of applications, including:Cutting tools: Dense alumina ceramics are used in cutting tools because of their high strength, hardness, and wear resistance.Wear plates: Dense alumina ceramics are also used in wear plates to protect surfaces from wear and abrasion.Armor: Dense alumina ceramics are used in armor to provide protection against ballistic impact.Filters: Porous alumina ceramics are used in filters to remove particles from fluids.Catalysts: Porous alumina ceramics are used as catalysts to support catalytic reactions.Membranes: Porous alumina ceramics are used as membranes to separate different components of a fluidmixture.Thermal insulation: Ultraporous alumina ceramics are used in thermal insulation to reduce heat transfer.Sound absorption: Ultraporous alumina ceramics areused in sound absorption to reduce noise levels.Catalysis: Ultraporous alumina ceramics are used as catalysts to support catalytic reactions.中文回答:不同孔径氧化铝陶瓷。

阳极氧化铝膜

阳极氧化铝膜(Anodic Aluminum Oxide, 简称AAO)是通过

在铝材料上进行电化学氧化处理而形成的具有多孔结构的氧化铝膜。

阳极氧化铝膜的制备过程一般包括以下步骤:首先将铝材料作为阳极,与阴极(一般为不锈钢)一起通过电解液(如硫酸或草酸溶液)连接在一起,施加一定的电压和电流关系,使铝材料表面氧化生成铝氧化物。

在此过程中,阴极上的氢气析出,而形成的铝氧化物在阳极表面生成均匀且致密的氧化铝膜。

具体的氧化膜结构和孔径大小,可以通过调整电解液成分、温度、电压和电流密度等控制因素来调节。

阳极氧化铝膜具有一定的物理和化学稳定性,并且具有高度有序的多孔结构。

其孔径大小可调节,并且具有均匀的孔径分布。

AAO膜的孔径一般在纳米到微米级别之间,常见范围为几十

纳米到几百纳米。

这种多孔结构的氧化铝膜能够在许多应用中发挥重要作用,例如作为模板用于生长纳米线、纳米颗粒等纳米材料,还可用作支撑材料、滤膜、光学薄膜、催化剂载体等领域。

总的来说,阳极氧化铝膜具有丰富的应用潜力,并且其制备过程相对简单,因此在纳米技术和材料科学领域引起了广泛的关注。