001新一代控制系统OC 6000e Nexus介绍

- 格式:pdf

- 大小:3.19 MB

- 文档页数:41

警示TJNR6000系列在线运行微功耗电机软起动产品的安装、使用、维护过程中必须注意以下事项:※安装前请务必详细阅读本操作说明。

※必须由专业技术人员安装本软起动器。

※严禁在软起动器输出端(U、V、W)接电容器。

※检修软起动器下口线路时,必须切断输入电源。

※带金属外壳的软起动器在安装和使用时必须保证外壳可靠接地。

※不得私自拆卸、改装、维修本产品。

※电动机的规格与软起动器的规格要相匹配。

1、TJNR6000系列软起动器概述TJNR6000系列智能式在线运行微功耗电动机电子软起动器,适用于交流380V(其他电压等级参见型号说明,定货时应提前说明),50/60Hz,额定电流800A及以下的三相交流异步电动机。

软起动装置本体为模块型,需装在柜体或箱体内与开关配合使用组成电动机的控制电路,不需要加装旁路接触器和热过载继电器,即能起到电动机的起动控制和过载、缺相、三相不平衡、过电压、欠压保护。

2、产品型号说明与开箱检查2.1型号说明2.2开箱检查步骤每台TJNR6000系列软起动器在出厂前均进行了严格的检验和性能测试。

用户在收到产品并拆封后,请按下列步骤检查。

如发现问题,请及时与供货商联系或拨打公司的热线电话。

2.2.1检查产品的型号核对产品外壳上的规格标牌,确认您收到的货物与您所订购的产品相符。

产品表面右上角最右边的3为数字代表本软起动器的适配电机功率(还可以通过键盘查询此数,见操作说明),此数值不能小于电动机额定功率。

2.2.2检查其他物品每台软起动器包装箱内除了产品本身外,还应有配套的产品检验合格证,操作说明及产品保修单各一份。

2.2.3 产品保修期产品自开具发票或收货单之日起一年。

3、使用条件与安装要求TJNR6000系列软起动器应符合下述使用条件与安装方法要求,否则性能将不予保证,严重时甚至会造成软起动器寿命缩短甚至损坏。

3.1软起动器的使用条件✓执行标准:IEC 60947-4-2:2002;GB14048.6-2008✓进线电压(额定工作电压):交流220V/380V/440V/660V,50/60H Z。

G E N E R A L I N F O R M A T I O NIon Xe 20 provides complete control of conventional and moving lights, LEDs and media servers. It supports multiple users with partitioned parameter control and full backup, multiple playback faders and cue lists in a tracking, move-fade environment. The desk includes backlit buttons and 20 45mm non-motorized faders with associated displays.FEATURES• 2,048 or 12,288 outputs• 32,768 control channels (any number from 1 - 99,999)• Up to 99 discrete users• Partitioned control• Master playback pair with 100mm faders• 20 45mm faders x 100 pages for configurable faders,submasters, masters and grandmaster control with twoassociated high-contrast monochrome LCD displays• User-definable direct selects• Four discrete palette types (IFCB)• Presets function as “all palette”• E ffects provide dynamic relational and absolute progressivebehavior• C entral information area (CIA) accesses the browser andother controls• F our pageable encoders for non-intensity parameter control• C onfigurable high-density channel display, with format andflexi-channel modes• U p to six abstract color spaces, tinting, spectrum and fadepath tools.• User configurable, interactive Magic Sheets• E TCNet2™ and Net3™ (powered by ACN), ArtNet and Avab®UDP network output protocols• S how import from Obsession, Express™, Expression®,Emphasis®, Congo®, Cobalt®, Grand MA1, Grand MA2, Safariand Strand 500/300 Series• T wo individually configurable Ethernet ports• M ultiple MIDI and/or SMPTE TimeCode Inputs, Analog/SerialInputs, OSC transmit/recieve• V irtual Media Server function for pixel mapped effects,images, animations• S upport for multiple languages, including English, German,Spanish, French, Italian, Japanese, Korean, Russian andChinese (Simplified and Traditional)O R D E R I N G I N F O R M A T I O NIon Xe 20MODEL DESCRIPTIONIon Xe 20 - 2K Ion Xe 20, 2,048 outputs (minimum)Ion Xe 20 - 12K Ion Xe 20, 12,288 outputs (maximum)Ion Xe RPU - 2K Ion Xe Remote Processor, 2,048 outputsIon Xe RPU - 12K Ion Xe Remote Processor, 12,288 outputs Ion Xe 10K After-sale 10K upgradeETCnomad 512Client for Mac/PCO utput protocols are distributed using ETCNet2 DMX Nodes or Net3 DMX/RDM Gateways. I/O Gateways and Show Control Gateways provide switch closure functionality, MIDI and SMPTE TimeCode.Ion Xe 20 AccessoriesMODEL DESCRIPTIONEos MFW 10Eos Motorized Fader Wing 10Eos MFW 20Eos Motorized Fader Wing 20Eos FW 20Eos Standard Fader Wing 20Eos FW 40Eos Standard Fader Wing 40Net3 RVI3Net3 Remote Video InterfaceETCpad ETC Portable Access DeviceIon Xe - FC Ion Xe FlightcaseEos Family Offline Editor software for Mac and PC platforms is called ETCnomad and is available for download from Ion Xe 20 requires Windows 7 compatible external monitors,1280x1024 minimum resolution, standard, touch or multi-touch SHIPS WITH:• Dust cover• One Littlite• Mouse and mousepad• External alphanumeric keyboard• Two active display-port to DVI adapters•One locking IEC power cordS P E C I F I C A T I O N SSYSTEM CAPACITY• 2,048 or 12,288 Outputs• 32,768 Control Channels (devices)• 10,000 Cues• 999 Cue Lists• 200 Active Playbacks• 999 Submasters• 100 Fader Pages• 4 x 1,000 Palettes (Intensity, Focus, Color, Beam)• 1,000 Presets (all palette)• 1,000 Groups• 1,000 Effects (relative, absolute or step)• 99,999 Macros• 1,000 Snapshots• 1,000 Curves• 1,000 Color Paths• S upports two external display-port monitors at 1280x1024minimum resolution, with optional touch or multi-touchcontrol• Solid-state hard drive• Five USB ports for flashdrives, pointing devices, keyboards DISPLAY FUNCTIONS• A ll show data may be viewed on a single external monitor.External views may be posted separately or expanded acrossa maximum of two monitors. Three user-configurableworkspaces per display, with split-screen/sizing controls.• The Central Information Area accesses:-Browser-File Management-System Defaults-Show Defaults-Desk Defaults-Partition Definitions-Network Configuration-Show Data Utilities-Print to PDF-Record Target Lists-Patch functions-Help-Electronic alpha-numeric keyboard-Command Line-Selected Cue-Error messages-Context-Sensitive Control-Parameter Categories and individual parameters-Filters• Channel Displays-Live channel or table view-B lind cue, palette, preset and group views, in list, channel,table and spreadsheet formats-U ser-configurable to show required parameters and/orparameter categories (IFCB)-Flexi-channel to determine which channels to display-Zoom allows user to define how many channels are viewed-Color-coded intensity levels indicate direction of move S P E C I F I C A T I O N S-C olor-coded non-intensity levels indicate change fromprevious state-G raphic differentiation of moving lights, single parameterdevices and unpatched channels• Magic Sheets-User-defined interactive display layouts-O bjects and images may be imported• Patch Views-Patch by channel-Patch by address-Patch by Device List (RDM)-A ssign proportional patch value, curve and, preheat valuefor intensity-Swap pan and tilt-Invert pan and tilt-Custom fixture editor-User configurable shutter order• Playback Status Display-Accesses status of 100 fader pages-E xpanded cue list for selected cue, optional dynamiccountdown of active cues• Cue List Index• Effect Editor• Group Editor• Park Display• Dimmer Monitoring• Submaster List• Fader Config DisplayPLAYBACK CONTROLS• M aster Playback crossfade pair with two 100mmpotentiometers, Go, Stop/Back and Load• 50 pages of 20 45mm faders, each configurable as:-IFCB Palette/Preset Lists or single instances-Cue Playback, with user-configurable button/slider behavior-Grand Master with Blackout-A dditive or Inhibitive Submaster, with user-configurablebutton/slider behavior-Filtered Manual Timing Master• Rate Controller• Playback fader controls include:-Load to assign cue lists-Timing Disable-Off/On-Release-Freeze-Assert-Manual Override-Rate-Go To Cue 0-Spread-Background Enable/Disable-10 Priority States-10 Background Priority States-Parameter and channel filters• Macros-May be set to play background or foreground-Startup and Shutdown Macros-Disconnect MacrosS P E C I F I C A T I O N SMANUAL CONTROL• C hannel selection from keypad and/or multi-touchdirect selects• Lists constructed with +, -, thru• I ntensity set with level wheel, keypad, level button, fulland out• Select Last recalls last sequential channel selection set• Select Manual selects all channels with manual values• Select Active selects all channels with intensity above zero• Ordered groups• Offset; including even, odd, random and reverse• Fan• Sneak• User-definable home• H ome by parameter, parameter category or all non-intensityparameters• Capture• Park at level• Scaled park for temporary percentage adjustment• Recall-from and Copy-to commands• A bout provides detailed view of selected channels orrecord targets• Undo• Highlight and Lowlight, with optional user-definable Rem Dim • L amp controls to strike and douse arc sources,calibrate devicesPROGRAMMING FEATURES• Channel Functions-N on-intensity parameters set via numeric entry orpageable encoders-Encoders support software-controlled tactile response-Local display of color and gobo images-C olor matching to gel selector-Color Path, color tinting and color spectrum tools.-Apply discrete time and delay per channel parameter• Palette and Preset Functions-Record and Update-Toggle display to absolute data-U p to 999 decimal values may be inserted between anytwo whole numbers• Effects-Create live or blind-Pattern-based relative dynamic effects-Absolute effects-Step effects-Channel level overrides-Cue level overrides-Entry mode determines how parameters enter effects-Exit mode determines how parameters depart effects• Cue Recording-Cue List HTP/LTP Intensity-Cue List Priority and Background Priority-Cue List Assert-Fader as progress controller, manual or intensity master-Record manual values or channels in use-Auto playback of recorded cues-Referenced or auto-mark instructions-Block at cue or parameter level-Assert at cue or parameter level-All-fade flag S P E C I F I C A T I O N S-Follow or hang times-Out of sequence link-Loop functions-Cue level parameter category timing-20-part multi-part cues-Cue-level rate override-M ark flags for Auto or Referenced and Referenced PriorityMarks-U p to 999 decimal cues between each twowhole-numbered cues-Execute List·Triggers snapshot·Triggers macros·Triggers go of other cues·Syncs go to multiple cue lists·Show-control triggers·Analog triggers-Update and Update Trace functions-Undo record and delete• Submaster Recording and Playback-999 additive or inhibitive submasters-Bump button timing for fade up/dwell/fade out-Assert/Channel select button-Exclusive or Shielded Mode-Background enable/disable-Restore to background or minimum value-LTP/HTP intensity-Fader as progress controller or intensity master-Bump button to mark NPs-Priority and Background Priority status-M otorized faders match level across all devices andwhen paging-Submaster mapping on the fly• Curves-Assignable in patch to modify dimmer output ramp-A ssignable at cue or cue part level to modify intensitycrossfade profile or non-intensity parameter ramping INTERFACES• T wo individually configurable ethernet ports• E TCNet2, Net3 (powered by ACN), ArtNet and Avab UDPoutput protocols• Four DMX/RDM ports• Contact-closure triggers via D-Sub connector• T wo video connectors support display-port external displays(1280x1024) with optional single-touch or multi-touch screencontrol• USB multipurpose (five ports)• OSC Transmit/Receive• UDP Transmit/Receive• MIDI TimeCode, MIDI Show Control through Gateway• SMPTE TimeCode through Gateway• C ontact closure (12 analog inputs, 12 SPDT contact outputs,RS-232) through GatewayELECTRICAL• AC input (100 - 240V at 50/60 Hz)• P ower consumption (less external monitors) approximately 1amp at 120V or 230/240VP H Y S I C A LIon Xe 20 Dimensions*MODEL HEIGHT WIDTH DEPTHinches mm inches mm inches mm Ion Xe 20 4.1010429.3074414.24362 Ion Xe 20in shippingcontainer7.7519736.5092718.50470Ion Xe 20 in roadcase 8.3421245.121,14619.45494Ion Xe 20 Weights*MODEL WEIGHTlbs kgsIon Xe 20 console16.67.35Ion Xe 20 in shipping container22.59.98Ion Xe 20 in roadcase46.7TBD*Weight and dimensions typicalCorporate Headquarters 3031 Pleasant View Rd, PO Box 620979, Middleton WI 53562 0979 USA +1 608 831 4116London, UK Unit 26-28, Victoria Industrial Estate, Victoria Road, London W3 6UU, UK +44 (0) 20 8896 1000Rome, IT Via Pieve Torina, 48, 00156 Rome, Italy +39 (06) 32 111 683Holzkirchen, DE Ohmstrasse 3, 83607 Holzkirchen, Germany +49 (80 24) 47 00-0Hong Kong Room 1801, 18/F, Tower 1 Phase 1, Enterprise Square, 9 Sheung Yuet Road, Kowloon Bay, Kowloon, Hong Kong +852 2799 1220Web Copyright©2018 ETC. All Rights Reserved. All product information and specifications subject to change. 4311L1002 Rev C 02/18。

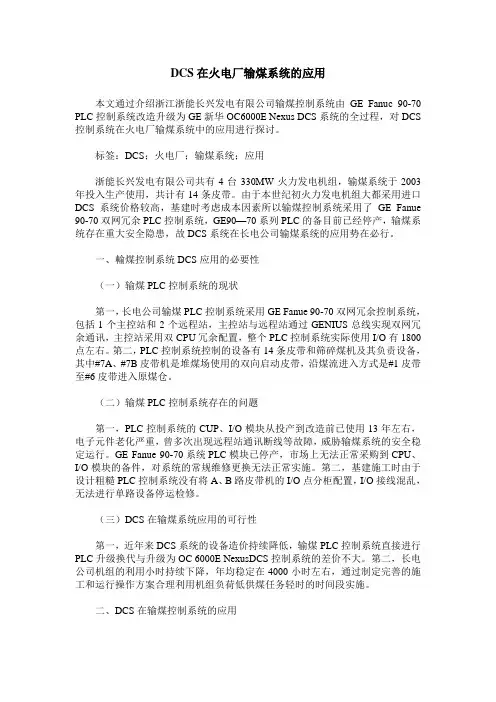

DCS在火电厂输煤系统的应用本文通过介绍浙江浙能长兴发电有限公司输煤控制系统由GE Fanuc 90-70 PLC控制系统改造升级为GE新华OC6000E Nexus DCS系统的全过程,对DCS 控制系统在火电厂输煤系统中的应用进行探讨。

标签:DCS;火电厂;输煤系统;应用浙能长兴发电有限公司共有4台330MW火力发电机组,输煤系统于2003年投入生产使用,共计有14条皮带。

由于本世纪初火力发电机组大都采用进口DCS系统价格较高,基建时考虑成本因素所以输煤控制系统采用了GE Fanue 90-70双网冗余PLC控制系统,GE90—70系列PLC的备目前已经停产,输煤系统存在重大安全隐患,故DCS系统在长电公司输煤系统的应用势在必行。

一、輸煤控制系统DCS应用的必要性(一)输煤PLC控制系统的现状第一,长电公司输煤PLC控制系统采用GE Fanue 90-70双网冗余控制系统,包括1个主控站和2个远程站,主控站与远程站通过GENIUS总线实现双网冗余通讯,主控站采用双CPU冗余配置,整个PLC控制系统实际使用I/O有1800点左右。

第二,PLC控制系统控制的设备有14条皮带和筛碎煤机及其负责设备,其中#7A、#7B皮带机是堆煤场使用的双向启动皮带,沿煤流进入方式是#1皮带至#6皮带进入原煤仓。

(二)输煤PLC控制系统存在的问题第一,PLC控制系统的CUP、I/O模块从投产到改造前已使用13年左右,电子元件老化严重,曾多次出现远程站通讯断线等故障,威胁输煤系统的安全稳定运行。

GE Fanue 90-70系统PLC模块已停产,市场上无法正常采购到CPU、I/O模块的备件,对系统的常规维修更换无法正常实施。

第二,基建施工时由于设计粗糙PLC控制系统没有将A、B路皮带机的I/O点分柜配置,I/O接线混乱,无法进行单路设备停运检修。

(三)DCS在输煤系统应用的可行性第一,近年来DCS系统的设备造价持续降低,输煤PLC控制系统直接进行PLC升级换代与升级为OC 6000E NexusDCS控制系统的差价不大。

G R O C E R Y D A I H .B ELECTRONIC CASH REGISTERCE -6000USER'S MANUALF R O F O O D EL I C A T E S S E N Casio CE-6000 users and programming ManualIntroduction & ContentsIntroduction & Contents (2)Getting Started (8)Remove the cash register from its box (8)Remove the tape holding parts of the cash register in place (8)Plug the cash register into a wall outlet (8)Insert the mode key marked “PGM” into the mode switch (8)Install receipt/journal paper (9)Set the date (11)Set the time (11)Tax table programming (11)Introducing CE-6000 (16)General guide (16)Display (18)Keyboard (20)Basic Operations and Setups (22)How to read the printouts (22)How to use your cash register (23)Assigning a clerk (24)Clerk secret number key (24)Displaying the time and date (25)To display and clear the time (25)To display and clear the date (25)Preparing coins for change (25)Preparing and using department keys (26)Registering department keys (26)Programming department keys (27)To program a unit price for each department (27)To program the tax calculation status for each department (27)To program high amount limit for each department (28)Registering department keys by programming data (29)Preset price (29)Preset tax status (29)Locking out high amount limitation (29)Preparing and using PLUs (30)Programming PLUs (30)To program a unit price for each PLU (30)To program tax calculation status for each PLU (30)Registering PLUs (31)Shifting the taxable status of an item (32)Calculation merchandise subtotal (32)Preparing and using discounts (33)Programming discounts (33)Registering discounts (33)Discount for items and subtotals (33)Preparing and using reductions (34)Programming for reductions (34)Registering reductions (34)Reduction for items (34)45In t r o d u c t i o n & C o n t e n t s CE-6000 User's Manual Registering credit and check payments (35)Check (35)Credit (35)Mixed tender (cash, credit and check) (36)Validation printing (36)Registering returned goods in the REG mode (37)Registering returned goods in the RF mode (38)Normal refund transaction (38)Reduction of amounts paid on refund (38)Registering money received on account (39)Registering money paid out (39)Making corrections in a registration (40)To correct an item you input but not yet registered (40)To correct an item you input and registered (41)To cancel all items in a transaction (42)No sale registration (42)Printing the daily sales reset report (43)Advanced Operations and Setups (44)Clerk interrupt function (44)Single item cash sales (45)Addition (46)Addition (plus) (46)Premium (%+) (46)Coupon transactions (47)Coupon registration using <COUPON> (coupon key) (47)Coupon registration using <COUPON2> (coupon 2 key) (47)Arrangement key registrations (48)Arrangement programming (48)Currency exchange function (49)Registering foreign currency (49)Full amount tender in foreign currency (49)Partial tender in a foreign currency (50)Currency exchange programming (50)Food stamp function (51)Food stamp key programming (51)Food stamp registration (51)No change due (51)Mixed food stamp/cash change (52)Food stamp registration (Illinois rule) (54)No change due (54)Mixed food stamp/cash change (56)Electronic benefits transfer (60)About mixed EBT card tenders (60)T emporarily releasing compulsion (62)Introduction & ContentsProgramming to clerk (63)Programming clerk number (63)Programming trainee status (63)Programming commission rate (63)Programming machine features (64)Programming to general control file (64)Programming department/PLU (71)Batch feature programming to department/PLU (71)Individual feature programming to department/PLU (72)Programming to transaction keys (73)<CASH>, <CHARGE>, <CHECK> (73)<CREDIT> (74)<RECEIVED ON ACCOUNT>, <PAID OUT> (74)<FOOD STAMP TENDER>, <EBT> (75)<#/NO SALE> (75)<%+>, <%–> (76)<+>, <–>, <COUPON> (77)<ARRANGEMENT> (78)<CURRENCY EXCHANGE> (78)<POST RECEIPT> (79)<MULTIPLICATION>, <QUANTITY/FOR>, <SQUARE>, <CUBE> (79)Programming descriptors and messages (80)Programming clerk name and messages (80)Programming department/transaction key descriptor (84)Programming PLU descriptor (85)Entering characters (86)Using character keyboard (86)Entering characters by code (87)Character code list (87)Keyboard layout change (88)Configuration of the physical key layout (88)Programming procedure (88)The outline of functions (89)Printing read/reset reports (90)To print the individual department, PLU read report (90)To print the financial read report (91)To print the individual clerk read/reset report (91)To print the daily sales read/reset report (92)To print the PLU read/reset report (93)To print the hourly sales read/reset report (93)To print the monthly sales read/reset report (94)To print the group read/reset report (94)To print the periodic 1/2 sales read/reset reports (95)Reading the cash register's program (96)To print unit price/rate program (except PLU) (96)To print key descriptor, name, message program (except PLU) (97)To print the general control program, compulsory and key program (98)To print the keyboard layout program (99)To print the PLU program (99)67In t r o d u c t i o n & C o n t e n t s CE-6000 User's Manual Troubleshooting.....................................................................................................................100When an error occurs...................................................................................................................100When the register does not operate at all ....................................................................................101Clearing a machine lock up..........................................................................................................102In case of power failure ................................................................................................................102User Maintenance and Options ............................................................................................103T o replace the ink ribbon ..............................................................................................................103T o replace journal paper...............................................................................................................104T o replace receipt paper...............................................................................................................105Options .........................................................................................................................................105Specifications.........................................................................................................................106Index. (107)。

Why a smartfactory?Because this is the future.In the smart factory, state-of-the-artsoftware provides real-time data fromconnected devices enabling them tolearn and adapt to changing demandson the production lines.The technology contributes tomanaging the entire productionprocess and enables continuousimprovements in productivity andend-product quality.How Atlas Copco cantake you one step closerAtlas Copco has the technology to solve yourproduction challenges. Technology that can operateseveral tools using only one physical controller, predicttool failures, and suggest maintenance schedules.Technology that gives valuable insights into the data it generates from previous production programs. The data continuously created by Atlas Copco smart tools and solutions can be used to maximize uptime and quality in your operation and cut yourWe present our Power Focus Offering. It's smart!What do you need in order to create a smart assembly?Power up your tightening stationsTurboTight for STR tools and TensorPulse and TurboTight for SRB tools help minimize Improves ergonomics by eliminating reaction force; increased productivity due to faster tightening time TBP SRB ST WrenchTensor STRQST Tensor SLMWR-TA MWR-STensor STB Tensor ES Tensor SBTBP-S BCP-REIAM Power Focus Power Focus 6000Fieldbus modulesController accessoriesElectronic deliveryPhysical deliveryItemOrder nr.Hardware Power Focus 60008436 1800 02Power Focus 6000 LV8436 1800 11ItemOrder nr.Profibus 8436 0940 05DeviceNet8436 0940 10Ethernet/IP 2 PORT 8436 0940 15ProfiNet I/O 2 PORT 8436 0940 20Anybus CC – CC Link 8436 0940 25Anybus CC – CC Link IE8436 0940 30Open Protocol Extension Open Protocol Extension 1 pcs 8436 1950 20TrueAngle TrueAngle 1 pcs8436 1910 03StepSync StepSync 1 pcs8436 1950 00Industrial Location Guidance Industrial Location Guidance 1 pcs8436 1950 10 SoftPLC SoftPLC 1 pcs 8436 1910 04Yield Control Yield Control 1 pcs8436 1910 06ItemOrder nr.Low Reaction Strategies Low Reaction Strategies 1 pcs 8436 1910 80Electronic deliveryJoint ControlJoint Control Virtual Station 1 pcs 8436 1960 20Station ControlStation Control Virtual Station 1 pcs 8436 1960 30Critical ControlCritical Control Virtual Station 1 pcs 8436 1960 40Process ControlProcess Control Virtual Station 1 pcs8436 1960 50ItemOrder nr.Batch ControlBatch Control Virtual Station 1 pcs 8436 1960 10Physical deliveryItemOrder nr.Batch ControlBatch Control Virtual Stations 1 pcs 8436 1960 11Batch Control Virtual Stations 2 pcs 8436 1960 12Batch Control Virtual Stations 5 pcs 8436 1960 15Batch Control Virtual Stations 10 pcs 8436 1960 16Joint ControlJoint Control Virtual Station 1 pcs 8436 1960 21Joint Control Virtual Station 2 pcs 8436 1960 22Joint Control Virtual Station 5 pcs 8436 1960 25Joint Control Virtual Station 10 pcs 8436 1960 26Station ControlStation Control Virtual Station 1 pcs 8436 1960 31Station Control Virtual Station 2 pcs 8436 1960 32Station Control Virtual Station 5 pcs 8436 1960 35Station Control Virtual Station 10 pcs 8436 1960 36Critical ControlCritical Control Virtual Station 1 pcs 8436 1960 41Critical Control Virtual Station 2 pcs 8436 1960 42Critical Control Virtual Station 5 pcs 8436 1960 45Critical Control Virtual Station 10 pcs 8436 1960 46Process ControlProcess Control Virtual Station 1 pcs 8436 1960 51Process Control Virtual Station 2 pcs 8436 1960 52Process Control Virtual Station 5 pcs 8436 1960 55Process Control Virtual Station 10 pcs8436 1960 56ItemOrder nr.Low Reaction Strategies Low Reaction Strategies 1 pcs 8436 1910 81Low Reaction Strategies 2 pcs 8436 1910 82Low Reaction Strategies 5 pcs 8436 1910 85Low Reaction Strategies 10 pcs 8436 1910 86TrueAngle TrueAngle 1 pcs 8436 1910 31TrueAngle 2 pcs 8436 1910 32TrueAngle 5 pcs 8436 1910 35TrueAngle 10 pcs 8436 1910 36SoftPLC SoftPLC 1 pcs 8436 1910 41SoftPLC 2 pcs 8436 1910 42SoftPLC 5 pcs8436 1910 45SoftPLC 10 pcs 8436 1910 46Yield ControlYield 1 pcs 8436 1910 61Yield 2 pcs8436 1910 62Yield 5 pcs 8436 1910 65Yield 10 pcs8436 1910 66Open Protocol Extension OP Extension 1 pcs 8436 1950 21OP Extension 2 pcs 8436 1950 22OP Extension 5 pcs 8436 1950 25OP Extension 10 pcs 8436 1950 26Industrial Location Guidance Industrial Location Guidance 1 pcs8436 1950 11 StepSync StepSync 1 pcs8436 1950 01ItemOrder nr.PF6000 Mounting Stand 4222 1736 80PF6000 Adapter Plate 4222 1783 80PF6000 Security Seal4222 1736 03PF6000 Communication Cable 1M 4222 1721 01PF6000 Communication Cable 3M 4222 1721 03PF6000 Communication Cable 5M4222 1721 05ItemOrder nr.Power Focus IAM8436 0910 00ItemOrder nr.Line Configurator – Electronic Delivery ToolsTalk 2 Line Configurator 1 pcs 8092 1714 02Line Configurator – Physical Delivery ToolsTalk 2 Line Configurator 1 pcs 8092 1714 03ToolsTalk 2 Line Configurator 5 pcs 8092 1714 04ToolsTalk 2 Line Configurator 10 pcs8092 1714 05Line Manager – Electronic Delivery ToolsTalk 2 Line Manager 1 pcs 8092 1714 06Line Manager – Physical Delivery ToolsTalk 2 Line Manager 1 pcs 8092 1714 07ToolsTalk 2 Line Manager 5 pcs 8092 1714 08ToolsTalk 2 Line Manager 10 pcs8092 1714 09ItemOrder nr.Electronic DeliveryManual Tightening Control 1 pcs 8436 1970 20Physical DeliveryManual Tightening Control 1 pcs 8436 1970 21Manual Tightening Control 2 pcs 8436 1970 22Manual Tightening Control 5 pcs 8436 1970 25Manual Tightening Control 10 pcs8436 1970 26FMS PortableThe FMS Portable is a great option for you who does not have the controllers networked.With the Atlas Copco FMS Portable it is possible to load and distribute virtual stations and features to individual controllers.Total Workstation SolutionsIn the Smart Connected Ecosystem, Atlas Copco offers Total WorkstationSolutions with reaction supports, including arms, visualization equipment, positioning solutions, and error proofing accessories. Atlas Copco also offers an assembly software suite for collecting and analyzing tightening data and managing quality assurance. In addition, Atlas Copco can provide station control and work guidance solutions ItemOrder nr.FMS Portable8436 1910 99At Atlas Copco service, we create the best value from your investmentsEvery production line and industrial site is unique and has its own challenges. With that in mind, our service solutions are designed to help you get the most out of your industrial equipment. We combine analysis of production data with know-how and expertise to enhance your productivity and quality, while maximizing the cost efficiency of your maintenance.Service solutions from Atlas CopcoFor Power Focus 6000, tools and software, we can provide a wide range of services■Startup, calibration and programing of the tightening system. ■Optimized maintenance solutions for cost savings and higher uptime.■Operator training on systems and products.■Tightening Services – a consultancy service for optimized tightening results.Atlas Copco offers worldwide service■We have a global presence and can support you at every step of the assembly production process.■Standard service products and tailor-made solutions are available.Contact us!As your dedicated assembly partner, Atlas Copco has the technology you need to handle today’s and future production challenges.Our Smart Connected Ecosystem will meet all your needs and keep your operation ahead of the game in a sustainable way.Atlas Copco Industrial Technique AB (publ) SE-105 23 Stockholm, Sweden Phone: +46 8 743 80 00Reg. no: 556014-27209 8 3 3 2 2 1 9 0 1–E N ©A t l a s C o p c o I n d u s t r i a l T e c h n i q u e A B , S t o c k h o l m , S w e d e n . P r o d u c t i o n。

Pro 6000E GenSetGasoline 6 kW 60 Hz• Onan Portable GenSet® EliteTM14 hp Overhead Valve Engine• Full-Featured Control Panel • Electric Start• Low Oil Pressure Shutdown with Indicator Light • 9-gal, 10-hr Fuel Tank • Idlematic with SwitchModels and RatingsModel Starter Hz Voltage MaxWatts Max Amps Rated Watts RatedAmpsAC Receptacles 6.0 EGHEB/38018* Electric/Recoil60120/240600050/25 550045.8/22.9 (1) Duplex 120V/15A GFI(2) Duplex 120V/30A TL (1) Duplex 120V/30A TL*CSA-approved.Ratings apply to altitudes up to 500 ft (152.4 m), 85o F (29.4oC).Derating: Power output will decrease 3.5% for each 1000 ft (305 m) above sea level and 1% for each 10oF(5.5o C) increase in ambient temperature about 85o F (29oC).Weight, Size and Sound Level• Dry Weight: 205 lb (94 kg)• Length: 29.2 in (743 mm); Width: 22.5 in (572 mm); Height: 28.0 in (711 mm) • Sound Levels- Idlematic:, 65 dB(A) at 7 m, 79 dB(A) at 1 m- Full Load, 60Hz: 79 dB(A) at 7 m, 92 dB(A) at 1 m© 2003 Cummins Power Generation Specifications subject to change without notice A-1398a (10/03)Standard Features • Onan® Elite TM 14-hp overhead valveengine• Low oil pressure shutdown• Electronic ignition• AC and DC manual reset circuitbreakers• Dual element air cleaner• Wrap-around protective cradle of 1-in steel tubing• USDA spark-arresting muffler• Vibration isolator frame mountings• Electric and recoil start• 9-gal, 10-hr fuel tank at rated load• Solid state automatic voltageregulator• Full-featured control panel• Idlematic with switch• Full-flow oil filter• VoltmeterReceptacles• 6.0 EGHEB/38018, (CSA-approved)(60 Hz)- (1) Duplex, 120V/15A GFI (AC),(NEMA 5-15R)- (2) 120V/30A Twistlock (AC),(NEMA L5-30R)- (1) 120/240V/20A Twistlock (AC)(NEMA L14-30R- (1) 12V/10A, 120W (DC)• Full-power switch• Simultaneous AC and 12 VDC• 12 VDC battery charging with cables• Battery tray (battery not included.Recommended 180 cca minimum @40o F, 300 cca @ -20o FAccessories • Two wheel dolly kit - (part #410-1166)• Twistlock plug 120 V/30 A, NEMAL5-30P (part #323-0862)• Twistlock plug 120/240 V/20 A,NEMA L14-20P (part #323-0857)Engine and Performance Detail Design: 4-cycle gasolineCylinders: 1Bore: 3.31 in (84.2 mm)Stroke: 2.76 in (70 mm)Displacement: 23.8 in3 (390 cm3)Power: 14 bhp maxCylinder liner: Cast ironValves: Overhead valve configuration.Premium valve materials, replaceableguides and seats and intake stem seals.Lubrication system: Positivedisplacement oil pump (full-pressurelubrication) with filterLube oil capacity: 1.0 qt (0.9 L) withfilterStarting system: Electric/recoilApproximate run time: 10 hr at ratedloadFuel tank capacity: 9 gal (34 L)Automatic decompression releasesystemTypical fuel consumptionGasoline, gph (Lph)No load Half load Full load60 Hz (est.) NA 0.51 (1.9) 0.92 (3.5)Alternator Detail Design: 2-pole AC alternatorExciter system: Self-excited, permanentmagnet provides instant voltage build up.Cooling: Air-cooledVoltage regulator: AutomaticNo load to full load Constant loadGenSetDetail Voltage regulationFrequency regulation ±3%±4%±2%±2%BasicDimensionsThis outline drawing is provided for general reference only and is not intended for design or installation. See installation manual and obtian outline drawing 500-2653 for more information (available from you Distributor/Dealer).Warranty Policy Onan Pro Series Portable GenSets are backed by Onan's standard three-year limited warranty, with an optional five-year extended warranty. See your local Distributor/Dealer for details.After Sale SupportGENUINE ONAN MAINTENANCE PARTS AND PRODUCTSFor your ongoing satisfaction and the dependability of your Onan genset, Onan offers a complete line of replacement and tune-up parts, oil and maintenance chemicals specifically designed for gensets. Easy to find at Onan service and parts dealers coast-to-coast, Onan Green Label TM parts are packaged for correct selection and convenient storage.EASY TO LOCATE CERTIFIED ONAN SERVICE AND PARTS DEALERS Onan has over 400 certified commercial service dealers covering most majormetropolitan areas in the U.S. and Canada. To locate Onan service dealers in your area, call 1-800-888-ONAN and request a commercial service and parts dealer directory (F-1060).Standards and TestingTested at extremes of temperature -20o F to +120o F for starting and operation.60 Hz models (120/240V only) listed by Nationwide Consumer Testing Institute, Inc. per ANSI/EGS-1 and CSA certified per electrical Bulletin 946. Tested in high humidity conditions. Tested in salt spray conditions.Tested in heavy air borne dust conditions. Field Test Program.This product meets US. EPA Phase 1 and 1995-1999 California Regulations for utility and lawn and garden equipment engines.Do not use this genset on a boat. Such use may violate U.S. Coast Guardregulations, and can result in severe personal injury or death from fire, explosion, electrocution, or carbon monoxide poisoning.Contact your Distributor/Dealer for more information:To easily locate the nearest Onan Distributor/Dealer, or for more information, contact Onan at 1-800-888-ONAN or 763-574-5000; 1400 73rd Avenue N.E., Minneapolis, MN 55432 U.S.A.;fax 763-574-5298; .Onan is a subsidiary of Cummins Engine Company. Onan is a registered trademark of Onan Corporation.Cummins is a registered trademark of Cummins Engine Company.WARNING: Backfeed to utility systems can cause electrocution or property damage. Do not connect to building electrical except through approved device and after building main breaker is opened.。

GE检测控制技术新一代控制系统OC 6000e Nexus介绍GE检测控制技术新华控制工程有限公司总工白强OC 6000e Nexus Overview for DCS EUC 201129概述GE DCS 发展历程OC 6000e 系统架构及产品系列OC 6000e Nexus 客户价值9OC 6000e Nexus 特点9OC 6000e Nexus 系统介绍OC 6000e Nexus 系统网络 OC 6000e Nexus 硬件OC 6000e Nexus 测试及认证9OC 6000e 控制软件9问答目录概述IGCC ESBWR35,000+ I/O~10,000+ I/OOC 6000e Nexus Overview for MC EUC 20114OC 6000e Nexus Overview for MC EUC 20115设备控制层(现场总线、Modus 接口等)机组控制层(常规/高级控制器、通用/专用IO 等)机组运行与优化层(监视、控制、仿真、参数与过程优化等)厂级运行与优化层(厂级监视、性能分析、负荷分配、远程诊断等)集团信息管理层OC 6000e 一体化控制系统架构OC 6000e Nexus Overview for MC EUC 20116状态检测闭环优化过程仿真模型预测控制“一键启停”远程诊断TMR ETS 模块Profibus DP 模块HART IO 模块Nexus IOMCI 通讯模块Cimplicity HMI XDPS HMI UCSA DPU/eDPU Mark series IOXDPS IOOC 6000e HMIUCSAClassic IOMark 系列XDPS 系列软件功能扩展硬件功能扩展OC 6000e 系列iDPUOC 6000e 系统平台的技术路线OC6000e Classic /MK VIe/ Hart IO 优化/管理iLINKOC4000 IOMCI/MDPiDPUOC4000 IOOC 6000e Nexus Overview for MC EUC 20118OC 6000e Nexus客户价值最大程度地保护客户已有投资-完整的系统兼容性:设备控制层,机组控制层,应用软件组态便于实施-完备的部署、升级方案,最少的现场实施周期持续的系统性能扩展-优化的系统软件平台,丰富的现场控制层接口,高级应用软件包及控制解决方案OC 6000e NEXUS 特点OC 6000e Nexus Overview for MC EUC 201110精简的架构•简单、高效•集成运输•最小化的安装空间•无专门的接地要求•极少的备件种类•高可靠性、避免电缆连接故障•可维护性高基于国际/国家标准的设计•安全标准•电气标准•机械标准•软件标准•测试标准安全与环境•内嵌的安全机制,只接受合格的预定义的网络数据包•禁止未授权的控制器连接•SELV机柜设计•WEEE/ROHS (2005.8.13, EU)不间断的可靠性•供电系统的鲁棒性•低功耗设计•冗余容错控制器•冗余电源/网络•同时在线,无需切换时间•产品验证和可靠性测试•抗震、抗雷击•EMC 设计OC 6000e Nexus 系统特点OC 6000e Nexus Overview for MC EUC 201111可控的实时性能•高性能、低功耗的控制器•QNX 实时操作系统(控制器)•冗余的100Mbps 控制网络•快速控制回路运行周期•固定时帧的过程输入/输出,保证周期控制的精确性•1ms 精度的SOE时钟同步•快速的HMI 响应时间便利性设计、易操作性和维护性•系统容量>20万点标签量•灵活的系统配置规模500-60000个I/O 点•友好的运行和维护人机界面•易用的硬件配置和软件组态配置•系统所有的软硬件应用配置均可存档管理•虚拟控制器仿真技术•多语言界面在线切换OC 6000e Nexus Overview for MC EUC 201112基于GE 专业领域技术的控制解决方案•一体化的控制解决方案•支持Modbus, Profibus DP 等现场总线协议•提供多样的软硬件升级方案,支持现有XDPS 系统的逐步升级,充分保护客户已有的控制系统投资全面提升控制、运行和管理水平的应用方案•一键启停系统(APS )•仿真与优化系统(SIMPANEL )•控制优化解决方案(COP )•过程优化解决方案(POP )•热工监督辅助系统(CISP)OC 6000e NEXUS 系统介绍优化通讯接口过程I/O过程I/O第三方设备OC 6000e Nexus Overview for MC EUC 2011DPS DPS DPS DPS DPS DPS DPS DPS DPS网络时间服务器DPSDPS分散控制站OC 6000e NEXUS 系统硬件OC 6000e Nexus Overview for MC EUC 201118整体化设计,单板结构,工业级防护外壳。

新华XDPS-400系统升级至OC6000E的介绍及注意事项摘要:详细的介绍了由新华公司XDPS-400系统升级至OC6000E的过程,包括硬件布置、软件组态、网络连接、接口通讯等。

同时分析了系统设计、设备拆装及软件组态的工作过程中遇到的问题并制定了解决方案,总结了升级过程中每个步骤的注意事项,对计划进行XDPS-400系统升级至OC6000E的公司具有一定的参考指导意义。

关键词:分散控制系统(DCS);分散处理单元;I\O总线一、概述:我公司#7、#8机组的分散控制系统(Distributed Control System,简称DCS)均采用上海新华公司的XDPS-400系统。

由于此两台机组的分散控制系统分别于2002年、2004年投产,系统各硬件及网络均已老化、性能不稳定,影响机组的安全可靠运行,我公司决定对其进行升级改造,升级为GE新华的OC6000E系统。

OC6000E系统平台及NEXUS系列I\O采用兼容性设计,为XDPS-400系统提供了一种高效的升级方案。

二、DPS-400系统与OC6000E系统的比较及升级思路:1、机柜布置比较DPS-400系统机柜分为控制柜、端子柜、配电柜、继电器柜和交换机柜(采用同轴电缆网络结构的无交换机柜)。

OC6000E系统的配电柜、继电器柜和交换机柜与原系统一致,控制柜和端子柜分为一体设计(新上系统时一般采用此机柜)和分开设计(适合升级项目)。

升级设计思路:保持DCS小间机柜布局不变,仍采用控制柜与端子柜分开的结构。

升级前后的对照图如下:2、卡件类型比较XDPS-400系统卡件分为:DI、DO、AI、AO、LC-S、SMC、BZT、LPC卡等OC6000E系统没有设置LC-S、BZT及普通转速卡,AO卡为8通道。

升级设计思路:①由于卡件的尺寸与原端子板的大小一致,卡件与原型号的通道数量也相同,DI、DO、AI卡件可以在原位置进行更换,接线电缆无需变动;②由于原系统AO端子板为16通道(左侧8通道与1块卡件连接,右侧8通道与1块卡件连接),新系统的AO卡只能接入8通道(均在左侧),所以两侧均有接线的端子板,应升级为2块AO卡,为减少接线的改动量,所增加的AO卡应尽量就近安装。

Stulz C6000控制器第52索引精密空调机组微处理控制器操作手册目录页码简介 (3)安全须知 (3)页码代号 (3)控制器说明 (4)操作界面 (6)控制器操作 (7)菜单对话框和参数说明启动窗口.............................................................................. .. (8)标准窗口 (9)“信息”菜单..................................................................... ......... .. 10 “控制”菜单................................................................................. .... .12 “服务”菜单................................................................................. . (17)功能说明监控器操作.................................................................................... (26)GE操作 (27)干冷器操作 (28)两套系统的顺序控制 (29)总线顺序控制 (31)数字自控连接 (32)备份运行 (34)传感器的故障 (36)信号....................................................................................... (37)控制器出厂时的设........................................................................ (40)控制图....................................................................................... (42)硬件说明控制器.......... .. (44)下载新软件 (45)标准I/O板 (48)扩展I/O板 (52)温度/湿度传感器 (54)系统配置带I/O板的C6000的电路图 (55)第一模块带监控器的C6000的电路图 (55)第二模块带监控器的C6000的电路图 (56)打印机连接 (57)电脑连接 (57)故障排除 (58)信息水平概述 (59)控制水平概述 (60)服务水平概述 (61)简介本手册对控制器的操作和设计进行了说明,控制器组成了空调单元的中央控制站,整个空调都是由控制器控制和检测的。

火电厂热控自动化控制设备的调试与安装分析摘要:为满足各界持续提升的电力需求,近年来我国电力领域进步迅速,热控自动化便属于其中代表。

基于此,本文简单介绍火电厂热控自动化控制设备的调试与安装要点,并结合实例开展深入探讨,以供参考。

关键词:火电厂;热控自动化控制设备;安装;调试引言:在先进的设备和技术支持下,火电厂的供电持续性和稳定性得到较好保障,热控自动化控制设备在其中发挥着重要作用。

热控自动化控制设备存在自动化程度高、运行成本低等优点,为保证这类设备较好服务于火电厂,正是本文围绕设备调试与安装开展具体研究的原因所在。

1.调试与安装要点1.1安装要点在安装火电厂热控自动化控制设备的过程中,可从以下几方面入手:第一,环境选择。

在设备安装前,需优选安装环境,充分考虑环境对设备使用效果和使用寿命的影响,安装环境控制也需要得到重视。

在具体安装过程中,需保证土建与安装的协调,同时做好对安装环境中粉尘、空气的控制,保证存在处于合理标准内的粉尘,现代化除尘技术的科学应用也需要得到重视,进而更好为设备安装提供支持[1];第二,硬件安装。

为保证热控自动化控制设备的智能化、信息化水平,硬件设备安装需要聚焦除尘、防潮等物理特性,设法提升硬件安装水平,这对设备使用寿命和运转效率带来的影响较为深远。

值得注意的是,硬件安装需要远离磁场区域,避免设备正常运行受到电磁信号干扰;第三,规范接地。

为保证热控自动化控制设备安全稳定运行,接地的规范性控制极为关键,在线路连接过程中,接地人员需要参考大地零基准带压点,针对性进行接地模式选择。

火电厂热控自动化控制设备一般选择单独式接地,接地独立性需要严格控制,进而预防电流过载,保证设备安全运行,接地过程需要重点关注过程控制单元、管理计算机及操作管理站;第四,敷设电缆。

由于存在较高的运行功率,热控自动化控制设备同时存在较高电能消耗,因此需要选择负载能力较强的电缆,这一过程需要对设备的屏蔽及非屏蔽信号进行区分,最大程度控制信号源在系统内的相互干扰。

关于ETS结构的比较分析摘要随着电力行业的发展,发电厂的ETS架构出现了越来越多的形式,本文比较了两个主流结构的优缺点,并给出相应的评估。

关键词发电厂;Ets;Dcs;Plc1 ETS的作用ETS应能接受接受来自就地、TSI、锅炉侧、电气侧及DEH侧所发出的跳机信号,其中就地的信号居多,一般包括但不限于EH油压低、润滑油压低、凝汽器真空低,个别机组甚至有润滑油油位低。

当ETS判断汽机需要跳闸,则让四个AST电磁阀失电打开,卸掉安全油,汽机主汽阀关闭,同时,ETS通过硬接线将汽机跳闸信号送至DEH、电气侧、锅炉侧。

当故障解除,或者机组正常汽机时,则需要接受来自DEH的复位信号,清除首出,并配合让AST电磁阀带电,进行挂闸。

除了危机停机功能外,ETS还能通过控制相关的试验电磁阀从而进行EH油压低、真空低、润滑油压低等在线试验功能。

以上功能即为ETS的基本功能。

现有流行的ETS结构有两种,分别是以PLC为控制核心的和以DPU为控制核心,下文将对这两种结构进行介绍,并比较两者的优劣性。

2 以DPU为控制核心的ETS广州协鑫2x180MW燃气-蒸汽联合循环机组,1、2号机组DCS是美国GE 公司新华控制工程有限公司生产的OC6000e Nexus分散控制系统,如图1.1所示,其ETS系统直接挂在其UDH高速网络上,其控制器配备为与DCS一样的DPU,假如有需要,DCS、DEH都可以对其进行网络访问,即工程师站、操作员站等UDH用户直接对ETS的DPU进行数据读取和实时操作,而不需要通过硬接线或网络量转接进DCS或者DEH。

同时,工程师站可以通过验证电子狗后,获得组态软件的更高权限,对ETS的逻辑进行修改,而普通工程师权限对于ETS的DPU只有只读权限。

由于用户可以直接访问其DPU,则EH油压低、润滑油压低、凝汽器真空等在线实验可以方便快捷地完成,而不用再通过DCS作为中转站。

DPU采用三冗余结构,每个就地测点分别进入三个DPU后,三个DPU会进行表决才会得出最终结论,同理逻辑判断也是如此。

GE检测控制技术新一代控制系统OC 6000e Nexus介绍GE检测控制技术新华控制工程有限公司总工白强OC 6000e Nexus Overview for DCS EUC 201129概述GE DCS 发展历程OC 6000e 系统架构及产品系列OC 6000e Nexus 客户价值9OC 6000e Nexus 特点9OC 6000e Nexus 系统介绍OC 6000e Nexus 系统网络 OC 6000e Nexus 硬件OC 6000e Nexus 测试及认证9OC 6000e 控制软件9问答目录概述IGCC ESBWR35,000+ I/O~10,000+ I/OOC 6000e Nexus Overview for MC EUC 20114OC 6000e Nexus Overview for MC EUC 20115设备控制层(现场总线、Modus 接口等)机组控制层(常规/高级控制器、通用/专用IO 等)机组运行与优化层(监视、控制、仿真、参数与过程优化等)厂级运行与优化层(厂级监视、性能分析、负荷分配、远程诊断等)集团信息管理层OC 6000e 一体化控制系统架构OC 6000e Nexus Overview for MC EUC 20116状态检测闭环优化过程仿真模型预测控制“一键启停”远程诊断TMR ETS 模块Profibus DP 模块HART IO 模块Nexus IOMCI 通讯模块Cimplicity HMI XDPS HMI UCSA DPU/eDPU Mark series IOXDPS IOOC 6000e HMIUCSAClassic IOMark 系列XDPS 系列软件功能扩展硬件功能扩展OC 6000e 系列iDPUOC 6000e 系统平台的技术路线OC6000e Classic /MK VIe/ Hart IO 优化/管理iLINKOC4000 IOMCI/MDPiDPUOC4000 IOOC 6000e Nexus Overview for MC EUC 20118OC 6000e Nexus客户价值最大程度地保护客户已有投资-完整的系统兼容性:设备控制层,机组控制层,应用软件组态便于实施-完备的部署、升级方案,最少的现场实施周期持续的系统性能扩展-优化的系统软件平台,丰富的现场控制层接口,高级应用软件包及控制解决方案OC 6000e NEXUS 特点OC 6000e Nexus Overview for MC EUC 201110精简的架构•简单、高效•集成运输•最小化的安装空间•无专门的接地要求•极少的备件种类•高可靠性、避免电缆连接故障•可维护性高基于国际/国家标准的设计•安全标准•电气标准•机械标准•软件标准•测试标准安全与环境•内嵌的安全机制,只接受合格的预定义的网络数据包•禁止未授权的控制器连接•SELV机柜设计•WEEE/ROHS (2005.8.13, EU)不间断的可靠性•供电系统的鲁棒性•低功耗设计•冗余容错控制器•冗余电源/网络•同时在线,无需切换时间•产品验证和可靠性测试•抗震、抗雷击•EMC 设计OC 6000e Nexus 系统特点OC 6000e Nexus Overview for MC EUC 201111可控的实时性能•高性能、低功耗的控制器•QNX 实时操作系统(控制器)•冗余的100Mbps 控制网络•快速控制回路运行周期•固定时帧的过程输入/输出,保证周期控制的精确性•1ms 精度的SOE时钟同步•快速的HMI 响应时间便利性设计、易操作性和维护性•系统容量>20万点标签量•灵活的系统配置规模500-60000个I/O 点•友好的运行和维护人机界面•易用的硬件配置和软件组态配置•系统所有的软硬件应用配置均可存档管理•虚拟控制器仿真技术•多语言界面在线切换OC 6000e Nexus Overview for MC EUC 201112基于GE 专业领域技术的控制解决方案•一体化的控制解决方案•支持Modbus, Profibus DP 等现场总线协议•提供多样的软硬件升级方案,支持现有XDPS 系统的逐步升级,充分保护客户已有的控制系统投资全面提升控制、运行和管理水平的应用方案•一键启停系统(APS )•仿真与优化系统(SIMPANEL )•控制优化解决方案(COP )•过程优化解决方案(POP )•热工监督辅助系统(CISP)OC 6000e NEXUS 系统介绍优化通讯接口过程I/O过程I/O第三方设备OC 6000e Nexus Overview for MC EUC 2011DPS DPS DPS DPS DPS DPS DPS DPS DPS网络时间服务器DPSDPS分散控制站OC 6000e NEXUS 系统硬件OC 6000e Nexus Overview for MC EUC 201118整体化设计,单板结构,工业级防护外壳。

单板包括:•CPU•实时控制网络(UDH )•IO 网络(IOnet )及智能IO 总线(iLINK )•COM 配置接口瘦机身设计,更小的安装底脚全冗余的网络接口设计(UDH/IOnet/iLINK ) 专用的双机跟踪网络连接(T 网) 所有网口具有通讯状态指示 免风扇运行,很强的环境温度适应性 在板式非易失性闪存,防尘、防振,无需后备电池 LED 自诊断指示QNX ®实时多任务操作系统OC 6000e Nexus 一体化控制器iDPUOC 6000e Nexus Overview for MC EUC 201119iDPU 控制器技术参数•冗余24Vdc 电源输入•Intel ®1.66 GHz 嵌入式处理器•DDR2 667/800 MHz, 1GB 内存•2GB 在板非易失性闪存•1Gbps 冗余UDH 控制网连接(以太网)•1Gbps 冗余IO 网络连接(以太网)•4个智能高速冗余串行I/O 总线(1Mbps ),每根总线最多可接入12个Nexus I/O 模块•1Gbps 专用双机跟踪网络•最大I/O 模块接入能力:Nexus I/O –48块•QNX ® 实时多任务操作系统•最快40ms 循环运算周期•最多999个控制组态页•NTP 网络时钟同步,±1ms •0~60℃环境工作温度OC 6000e Nexus Overview for MC EUC 201120 OC 6000e Nexus I/O 模块智能模块设计集成化设计,单板包含:•高性能处理器子系统•冗余高速智能I/O通讯接口•I/O调理及数字化回路•接口保护电路可通过智能I/O总线(iLINK)更新模块固件及上装引导装载程序低功耗电路设计全隔离电路设计精确校时协议,时钟同步精度可达100us安装及接线可拆卸的欧式单排端子和OC 4000/XDPS高度兼容的模块安装尺寸及I/O接线定义电源管理冗余的24V dc供电与系统电源隔离的模块内部工作电源及I/O供电具备模块热插拔及限流功能诊断功能LED自诊断指示工作电源监视及报警模块温度监视及报警模块种类较少的模块种类显著地减少了备品备件的总量OC 6000e Nexus Overview for MC EUC 201121Nexus I/O 通用技术参数电源安装双路24V dc (±10%),1:1冗余螺钉安装处理器规范及标准高性能32位嵌入式处理器CFR 47 FCC Part 15:2009I/O 通讯ANSI C63.4-2003冗余高速智能串行总线EN 61326-1: 2006通讯速率:1MbpsCISPR 11: 2007DB-9连接器,孔型IEC 61000-4-2/3/4/5/6/8/11终端连接器环境单排欧式端子,脱卸式工作温度:0~60℃线规:2.5mm2,双线湿度:10~ 90%, 不结露外形尺寸振动:10-500Hz, 加速度不超过10m/s 2209x129.5x51mm (高x 宽x 深)污染物:粉尘颗粒尺寸大于0.5uis, 少于18,000颗/LOC 6000e Nexus Overview for MC EUC 201122特性MAI50MAI51通道数16信号范围±10V, ±5V, 0(4)-20mARTD(二线制/三线制): Pt10, Pt100, Cu10, Cu50; TC: E, J, K, N, R, S, T, B 超限报警±10%,软件判断报警*测量误差最大0.1%最大0.2%模数转换16位,8个通道一组LED 指示模块运行状态;通讯状态;故障报警隔离电压通道间250VAC,通道对地500VAC 通道与系统隔离电压1500VAC抗干扰能力共模抑制比>120dB ;差模抑制比>60dB 功耗典型3W,最大5W<2W认证随系统已通过CE 认证*注:±10V 输入无超限报警OC 6000e Nexus Overview for MC EUC 201123特性MAO50通道数8输出范围0(4)-20mA, 部分通道支持0(1)-5V 输出负载能力电流输出-最大1000Ω电压输出-最小500kΩ误差最大0.1%数模转换12位,每个通道单独D/ALED 指示模块运行状态;通讯状态;故障报警隔离电压通道间250VAC,通道对地500VAC 通道与系统隔离电压1500VAC 抗干扰能力共模抑制比>120dB 功耗<6.5W认证随系统已通过CE 认证特性MDI50通道数32输入信号干接点或沉电流信号查询电压48V dc SOE 功能具备SOE 精度1ms信号滤波固件,3~50ms 可调, 默认24ms 通道指示通道输入状态LED 指示模块运行状态;通讯状态;故障报警隔离电压通道对地500VAC通道与系统隔离电压1500VAC 功耗典型1.2W,最大8.5W认证随系统已通过CE 认证OC 6000e Nexus Overview for MC EUC 201124特性MDO53MDO54通道数16输出类型继电器输出,1NO/1NC24V dc/100mA触点容量•12A@250V AC(阻性);12A@30V dc(阻性);•7.5A@250V AC(感性);6A@30V dc(感性)N/A配合大容量继电器输出板, 可达:•10A@220V dc (阻性);16A@400V AC (阻性);•2A@220V dc (感性);3.6A@110V dc(感性)输出指示具备通道输出LED指示LED指示模块运行状态;通讯状态;故障报警隔离电压通道间1000VAC,通道对地2500VAC通道与系统隔离电压3000VAC功耗典型1.3W,最大11W典型1.3W,最大4W认证随系统已通过CE认证OC 6000e Nexus Overview for MC EUC 201125iDPU 控制器24V dc 电源Nexus I/O 模块(机柜正面)最多12块OC 6000e Nexus 标准控制柜前视图侧视图后视图交流电源开关箱Nexus I/O 模块(机柜背面)最多12块iLINK总线扩展板24V dc电源分配组件iLINK 总线OC 6000e Nexus Overview for MC EUC 201126Nexus 标准控制柜技术参数特性技术参数外形尺寸800x600x2200mm (宽x深x高)IP等级NEMA 1 (IP30)组件安装布置机柜前后开门,柜内组件螺钉安装方式I/O模块容量最多24个模块/机柜外部供电双路110V/220V AC (±10%)内部供电双路24V dc (±10%), 1:1冗余发热量典型值<200W(6AI/4AO/4DI/6DO/1对iDPU)散热方式风扇,前后柜门各一个机柜照明选配基座安装绝缘直接安装在机柜固定槽钢上,无需铺设专门的绝缘胶垫27OC 6000e Nexus Overview for MC EUC 2011OC 6000e Nexus 硬件工作环境测试应力破坏界限高可操作界限高高低低低破坏界限可操作界限规格规格增强应力以:•达到可操作界限•达到破坏界限应力测试:•热递增量: 在10℃步进下-100 ~ 200℃•快速热变量: -60 ~90℃•6轴随机振动:在10Grms 步进时振动10 ~50Grms •综合环境: -60 ~100℃快速变量及10Grms 步进高加速寿命试验(HALT)目标: 提高设计可靠性•应用于设计流程中,以确认设计限制因素•提高设计余量•成效: 提升了可靠性通过GE 及供应商设备验证温度测试范围: -50 ~ +126°CThermal ImagingR23R1Q1U2U1OC 6000e Nexus Overview for MC EUC 201128OC 6000e Nexus 认证测试CE,FCC29OC 6000e Nexus Overview for MC EUC 2011OC 6000e Nexus 控制操作台一个工作站的多重作用:•操作员•工程师•维护30OC 6000e Nexus Overview for MC EUC 2011OC 6000e 控制软件OC 6000e 系统软件和工具控制与监测•图表显示•控制面板•趋势图显示•报警管理•组图显示•条形统计图显示•点状态显示数据资料记录•报告•事故追踪记录•操作员动作记录•事件顺序记录•报警记录•系统状态记录•维护记录•历史数据记录电厂运行•启动/停机图表•性能计算•持续运行时间计算•应力计算•用户自定义计算•设备管理工程应用工具•创建图表•创建数据库•创建控制逻辑•创建报表•系统状态显示•电子指导•其它应用OC 6000e Nexus Overview for MC EUC 201132OC 6000e 配置工具系统集成配置工具MPC•集成配置工具,系统配置管理•一站式管理,可通过一台工程师站完成整个系统的远程配置和管理•多语言界面,在线切换•支持多种类型控制器、I/O•系统程序守护及自启动33OC 6000e Nexus Overview for MC EUC 2011OC 6000e 用户安全管理角色高级工程师工程师高级操作员操作员其他系统管理√用户管理√系统组态√√数据库管理√√应用组态√√控制组态√√图形组态√√√运行√√√√报警和事件√√√√报表√√√√监视√√√√√系统用户配置工具•多种用户类型,不同用户权限•用户对系统节点的权限分配管理OC 6000e Nexus Overview for MC EUC 201134OC 6000e 控制组态工具图形化组态工具SystCFG•丰富的控制算法库(基本控制/电厂专用/高级控制/诊断)•在线、自动维护系统数据库•增强的安全功能-逻辑加锁、口令保护•在线组态/调试,无需编译、重启控制器•支持虚拟控制器及IO通道的仿真过程画面制作工具FigEdit•丰富的过程控制预定义图库(静态/动态)•可从模板创建画面,界面风格统一、易于修改35OC 6000e Nexus Overview for MC EUC 2011OC 6000e 操作员软件过程画面显示工具FigView•人机工程学设计的过程显示元素•结构化的流程图框架设计及菜单系统•优化设计的设备操作面板,丰富的过程状态信息及操作指导趋势图显示工具Trend•历史、实时显示无缝衔接•多光标截取,最多4次•每个趋势曲线具有数字标号•可随时隐藏或显示某条曲线•趋势导出功能(excel或文本)•离线方式下的历史数据回放功能•追忆再现功能,方便检查设备跳闸原因36OC 6000e Nexus Overview for MC EUC 2011OC 6000e 历史收集及报表历史收集软件•无点数限制,可采集所有系统标识点•可定义的采集死区和周期,有效控制数据采集量•可选择抽取、生成数据文本文件•可抽取、生成原始数据文件•快速、高保真压缩存储,满足长时间历史数据收集需求报表工具•周期型、事件型、触发型•支持最多4个数据源•支持最多1000个用户自定义模板•图形界面组态37OC 6000e Nexus Overview for MC EUC 2011OC 6000e 报警管理•包括过程报警及I&C报警•实时、历史报警一览•报警显示过滤功能•按报警级别及到达时间先后主动上推•触发报警,主动推送相关报警画面•模拟软光字牌报警•按报警区域分布显示,相应的屏幕指示灯提示及画面索引功能•多种报警级别区分显示38OC 6000e Nexus Overview for MC EUC 2011OC 6000e Nexus Overview for MC EUC 201139OC 6000e系统诊断谢谢!敬请登录GE新华网站,了解更多信息: /xinhua。