SBI转盘轴承样本

- 格式:pdf

- 大小:2.13 MB

- 文档页数:61

岗位训练手册轴承手册B E A R I N G H A N D B O O K目录第一章滚动轴承知识··············································································错误!未定义书签。

第一节滚动轴承分类和特性(GB/T-271-1997)······································错误!未定义书签。

一、滚动轴承构造类型分类····························································错误!未定义书签。

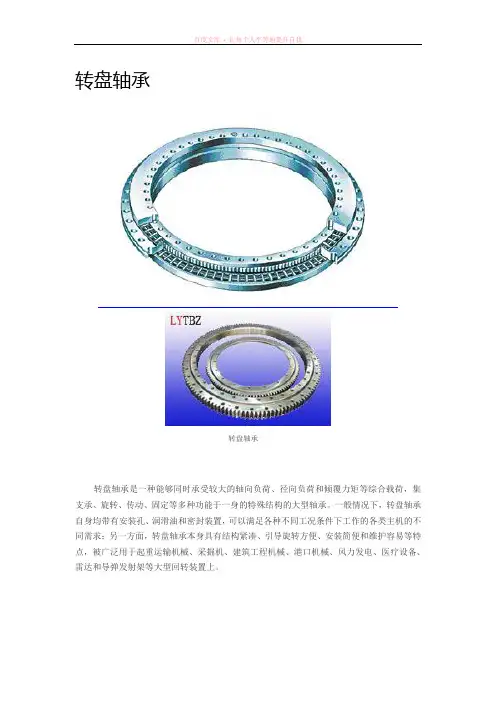

转盘轴承转盘轴承转盘轴承是一种能够同时承受较大的轴向负荷、径向负荷和倾覆力矩等综合载荷,集支承、旋转、传动、固定等多种功能于一身的特殊结构的大型轴承。

一般情况下,转盘轴承自身均带有安装孔、润滑油和密封装置,可以满足各种不同工况条件下工作的各类主机的不同需求;另一方面,转盘轴承本身具有结构紧凑、引导旋转方便、安装简便和维护容易等特点,被广泛用于起重运输机械、采掘机、建筑工程机械、港口机械、风力发电、医疗设备、雷达和导弹发射架等大型回转装置上。

概述转盘轴承是一种能够同时承受较大的轴向负荷、径向负荷和倾覆力矩等综合载荷,集支承、旋转、传动、固定等多种功能于一身的特殊结构的大型轴承。

[1]基本结构(交叉滚子轴承)回转支承的基本结构[2]转盘轴承通常由内圈、外圈、滚动体、隔离块等四大部件构成。

由于核心部件采用回转支承,因此可以同时承受轴向力、径向力。

其形式很多,但结构组成基本大同小异。

由左及右分别是(上部分): 1.外圈(有齿或无齿)2.密封带3.滚动体(滚球或滚柱)4.加油嘴由左及右分别是(下部分): 1.塞子2.锥销3.内圈(有齿或无齿)4.隔离块或保持架5.安装孔(丝孔或光孔)01系列转盘轴承单排四点接触球式单排四点接触球式转盘轴承由内圈、外圈、钢球、隔离块四大部分组成,结构紧凑、重量轻、钢球与圆弧滚道四点接触,能同时承受轴向力、径向力。

回转式输送机、焊接操作机、中小型起重机和挖掘机等工程机械均可选用。

02系列转盘轴承双排异径球式双排球式转盘轴承有三个座圈,钢球和隔离块可直接排入上下滚道,根据受力状况,安排了上下两排直径不同的钢球。

这种开式装配非常方便,上下圆弧滚道的承载角都为90°,能承受很大的轴向力和倾翻力矩。

当径向力大于0.1倍的轴向力时,滚道须特殊设计。

双排异径球式回转支承的轴向、径向尺寸都比较大,结构紧固。

特别适用于要求中等以上直径的塔式起重机,汽车起重机等装卸机械上。

系列转盘轴承-交叉滚子轴承单排交叉滚柱式单排交叉滚柱式转盘轴承简称交叉滚子轴承,由两个座圈组成,结构紧凑、重量轻、制造精度高,装配间隙小,对安装精度要求高,滚柱为1:1交叉排列,能同时承受轴向力、倾翻力矩和较大的径向力,被广泛地用于起重运输,工程机械和军工产品上。

SBI回转支承轴承SLEWING BEARINGSCAT-121洛阳世必爱特种轴承有限公司Luoyang SBI Special Bearing Co., Ltd.转盘轴承Slewing Bearings转盘轴承除承受推力负荷外,还可承受力矩和径向负荷,其类型有球轴承、滚子轴承及球-滚子轴承。

在结构上有单列、双列和三列型式;在传导方面有带齿(内圈或外圈)型,也有无齿型;在防尘和防漏脂方面有密封型,也有不带密封的结构;在安装方面有挡边(外圈或内圈上)和紧固螺孔,也有无挡边的结构。

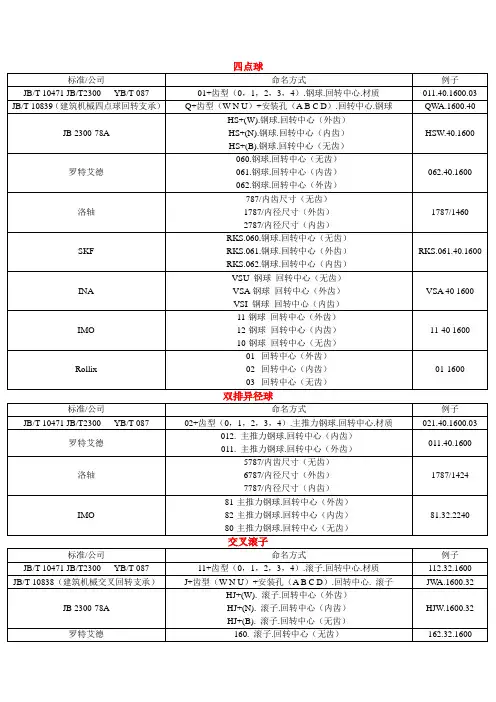

Slewing bearings (slewing rings) can take thrust load, moment load and radial load. SBI slewing bearings can be divided into three types: ball type, roller type and ball-roller type. In structure, the bearings can be single-row, double-row or triple-row. Type of structure, There are single-row, double-rows and three-rows. In power transmission, the bearings can be with gear teeth (on outer ring or inner ring) and without gear teeth. In dust and grease proof, they can be with seals or without seals. In mounting convenience, they can be with flange or bolt bores or without.本公司转盘轴承标准系列的代号方法同国家标准JB/T2300-1999之规定。

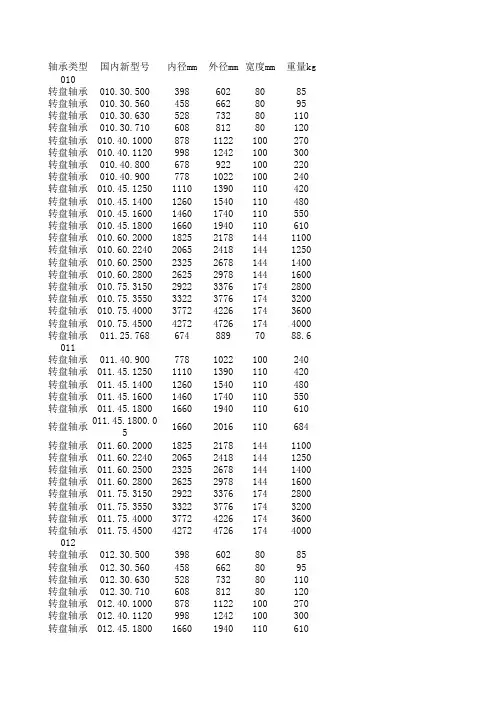

轴承类型国内新型号内径mm外径mm宽度mm重量kg 010转盘轴承010.30.5003986028085转盘轴承010.30.5604586628095转盘轴承010.30.63052873280110转盘轴承010.30.71060881280120转盘轴承010.40.10008781122100270转盘轴承010.40.11209981242100300转盘轴承010.40.800678922100220转盘轴承010.40.9007781022100240转盘轴承010.45.125011101390110420转盘轴承010.45.140012601540110480转盘轴承010.45.160014601740110550转盘轴承010.45.180016601940110610转盘轴承010.60.2000182521781441100转盘轴承010.60.2240206524181441250转盘轴承010.60.2500232526781441400转盘轴承010.60.2800262529781441600转盘轴承010.75.3150292233761742800转盘轴承010.75.3550332237761743200转盘轴承010.75.4000377242261743600转盘轴承010.75.4500427247261744000转盘轴承011.25.7686748897088.6 011转盘轴承011.40.9007781022100240转盘轴承011.45.125011101390110420转盘轴承011.45.140012601540110480转盘轴承011.45.160014601740110550转盘轴承011.45.180016601940110610转盘轴承011.45.1800.0516602016110684转盘轴承011.60.2000182521781441100转盘轴承011.60.2240206524181441250转盘轴承011.60.2500232526781441400转盘轴承011.60.2800262529781441600转盘轴承011.75.3150292233761742800转盘轴承011.75.3550332237761743200转盘轴承011.75.4000377242261743600转盘轴承011.75.4500427247261744000 012转盘轴承012.30.5003986028085转盘轴承012.30.5604586628095转盘轴承012.30.63052873280110转盘轴承012.30.71060881280120转盘轴承012.40.10008781122100270转盘轴承012.40.11209981242100300转盘轴承012.45.180016601940110610转盘轴承012.60.2000182521781441100转盘轴承012.60.2240206524181441250转盘轴承012.60.2500232526781441400转盘轴承012.60.2800262529781441600转盘轴承012.75.3150292233761742800转盘轴承012.75.3550332237761743200转盘轴承012.75.4000377242261743600转盘轴承012.75.4500427247261744000 013转盘轴承013.30.5003986028085转盘轴承013.30.5604586628095转盘轴承013.30.63052873280110转盘轴承013.30.71060881280120转盘轴承013.40.10008781122100270转盘轴承013.40.800678922100220转盘轴承013.40.9007781022100240转盘轴承013.45.125011101390110420转盘轴承013.45.140012601540110480转盘轴承013.45.1400D1192.81540110502转盘轴承013.45.160014601740110550特重轴承国内新型号内径mm外径mm宽度mm重量kg 类型转盘轴承013.45.180016601940110610转盘轴承013.60.2000182521781441100转盘轴承013.60.2240206524181441250转盘轴承013.60.2500232526781441400转盘轴承013.60.2800262529781441600转盘轴承013.75.3150292233761742800转盘轴承013.75.3550332237761743200转盘轴承013.75.4000377242261743600转盘轴承013.75.4500427247261744000 014转盘轴承014.30.5003986028085转盘轴承014.30.5604586628095转盘轴承014.30.560.12426.326628094转盘轴承014.30.63052873280110转盘轴承014.30.71060881280120转盘轴承014.40.10008781122100270转盘轴承014.40.11209981242100300转盘轴承014.40.800678922100220转盘轴承014.40.9007781022100240转盘轴承014.60.2000182521781441100转盘轴承014.60.2240206524181441250转盘轴承014.60.2500232526781441400转盘轴承014.60.2800262529781441600转盘轴承014.75.3150292233761742800转盘轴承014.75.3550332237761743200转盘轴承014.75.4000377242261743600转盘轴承014.75.4500427247261744000 114转盘轴承114.25.5003986027580转盘轴承114.25.5604586627590转盘轴承114.25.63052873275100转盘轴承114.25.71060881275110转盘轴承114.28.1000878112282210转盘轴承114.28.1120998124282230转盘轴承114.28.80067892282170转盘轴承114.28.900778102282190转盘轴承114.32.12501110139091350转盘轴承114.32.14001260154091400转盘轴承114.32.16001460174091440转盘轴承114.32.18001660194091500转盘轴承114.40.200018252178112900转盘轴承114.40.2240206524181121000转盘轴承114.40.2500232526781121100转盘轴承114.40.2800262529781121250转盘轴承114.50.3150292233761342150转盘轴承114.50.3550332237761342470转盘轴承114.50.4000377242261342800转盘轴承114.50.4500427247261343100 110转盘轴承110.25.5003986027580转盘轴承110.25.5604586627590转盘轴承110.25.63052873275100转盘轴承110.25.71060881275110转盘轴承110.28.1000878112282210转盘轴承110.28.1120998124282230转盘轴承110.28.80067892282170转盘轴承110.28.900778102282190转盘轴承110.32.12501110139091350转盘轴承110.32.14001260154091400转盘轴承110.32.16001460174091440转盘轴承110.32.18001660194091500转盘轴承110.40.200018252178112773转盘轴承110.40.2240206524181121000转盘轴承110.40.2500232526781121100转盘轴承110.40.2800262529781121250转盘轴承110.50.3150292233761342150转盘轴承110.50.3550332237761342470转盘轴承110.50.4500427247261343100 112转盘轴承112.28.1000878112282210转盘轴承112.28.1120998124282230转盘轴承112.28.80067892282170转盘轴承112.28.900778102282190转盘轴承112.32.12501110139091350转盘轴承112.32.14001260154091400转盘轴承112.32.16001460174091440转盘轴承112.32.18001660194091500转盘轴承112.40.200018252178112900转盘轴承112.40.2240206524181121000转盘轴承112.40.2500232526781121100转盘轴承112.40.2800262529781121250转盘轴承112.50.3150292233761342150转盘轴承112.50.3550332237761342470转盘轴承112.50.4000377242261342800转盘轴承112.50.4500427247261343100 120转盘轴承120.25.5003986027580转盘轴承120.25.5604586627590转盘轴承120.25.63052873275100转盘轴承120.25.71060881275110转盘轴承120.28.1000878112282210转盘轴承120.28.1120998124282230转盘轴承120.28.80067892282170转盘轴承120.28.900778102282190转盘轴承120.32.12501110139091350转盘轴承120.32.14001260154091400转盘轴承120.32.16001460174091400转盘轴承120.32.1600.03K14601740100429转盘轴承120.32.18001660194091500转盘轴承120.40.200018252178112900转盘轴承120.40.2240206524181121000转盘轴承120.40.2500232526781121100转盘轴承120.40.2800262529781121250转盘轴承120.50.3150292233761342150转盘轴承120.50.3550332237761342470转盘轴承120.50.4000377242261342800转盘轴承120.50.4500427247261343100 121转盘轴承121.25.5003986027580转盘轴承121.25.5604586627590转盘轴承121.25.63052873275100转盘轴承121.25.71060881275110转盘轴承121.28.1000878112282210转盘轴承121.28.1120998124282230转盘轴承121.28.80067892282170转盘轴承121.28.900778102282190转盘轴承121.32.12501110139091350020转盘轴承020.25.500384616106100转盘轴承020.25.560444676106115转盘轴承020.25.630514746106130转盘轴承020.25.710594826106140转盘轴承020.30.10008581142124300转盘轴承020.30.11209781262124340转盘轴承020.30.800658942124200转盘轴承020.30.9007581042124250转盘轴承020.40.125010741426160580转盘轴承020.40.140012241576160650转盘轴承020.40.160014241776160750转盘轴承020.40.180016241976160820转盘轴承020.50.2000178522151901150转盘轴承020.50.2240202524551901500转盘轴承020.50.2500228527151901700转盘轴承020.50.2800258530151901900转盘轴承020.60.3150287234282263300转盘轴承020.60.3550327238282263700转盘轴承020.60.4000372242782264200转盘轴承020.60.4500422247782264700 021转盘轴承021.25.500384616106100转盘轴承021.25.560444676106115转盘轴承021.25.630514746106130转盘轴承021.25.710594826106140转盘轴承021.30.10008581142124300转盘轴承021.30.800658942124200转盘轴承021.30.9007581042124250转盘轴承021.40.125010741426160580转盘轴承021.40.140012241576160650转盘轴承021.40.160014241776160750转盘轴承021.40.180016241976160820转盘轴承021.50.2000178522151901150转盘轴承021.50.2240202524551901500转盘轴承021.50.2500228527151901700转盘轴承021.50.2800258530151901900转盘轴承021.60.3150287234282263300转盘轴承021.60.3550327238282263700转盘轴承021.60.4000372242782264200转盘轴承021.60.4500422247782264700 022转盘轴承022.25.500384616106100转盘轴承022.25.560444676106115转盘轴承022.25.630514746106130转盘轴承022.25.710594826106140转盘轴承022.30.10008581142124300转盘轴承022.30.11209781262124340转盘轴承022.30.800658942124200转盘轴承022.30.9007581042124250转盘轴承022.40.125010741426160580转盘轴承022.40.140012241576160650转盘轴承022.40.160014241776160750转盘轴承022.40.180016241976160820转盘轴承022.50.2000178522151901150转盘轴承022.50.2240202524551901500转盘轴承022.50.2500228527151901700转盘轴承022.50.2800258530151901900转盘轴承022.60.3150287234282263300转盘轴承022.60.3550327238282263700转盘轴承022.60.4000372242782264200转盘轴承022.60.4500422247782264700 023转盘轴承023.25.500384616106100转盘轴承023.25.560444676106115转盘轴承023.25.630514746106130转盘轴承023.25.710594826106140转盘轴承023.30.10008581142124300转盘轴承023.30.800658942124200转盘轴承023.30.9007581042124250转盘轴承023.40.125010741426160580转盘轴承023.40.140012241576160650转盘轴承023.40.160014241776160750转盘轴承023.40.180016241976160820转盘轴承023.50.2000178522151901150转盘轴承023.50.2240202524551901500转盘轴承023.50.2500228527151901700转盘轴承023.50.2800258530151901900转盘轴承023.60.3150287234282263300转盘轴承023.60.3550327238282263700转盘轴承023.60.4000372242782264200转盘轴承023.60.4500422247782264700 024转盘轴承024.25.500384616106100转盘轴承024.25.560444676106115转盘轴承024.25.630514746106130转盘轴承024.25.710594826106140转盘轴承024.30.10008581142124300转盘轴承024.30.11209781262124340转盘轴承024.30.800658942124200转盘轴承024.30.9007581042124250转盘轴承024.40.125010741426160580转盘轴承024.40.160014241776160750转盘轴承024.40.180016241976160820转盘轴承024.50.2000178522151901150。

d BrrD d11DF圆柱滚子轴承带保持架的圆柱滚子轴承带盘式保持架或隔片的圆柱滚子轴承单列满装圆柱滚子轴承双列满装圆柱滚子轴承高精密圆柱滚子轴承圆柱滚子轴承带保持架的圆柱滚子轴承 (394)带保持架的单列圆柱滚子轴承具有很高的径向承载能力,与满装滚子轴承相比,适用于较高的转速。

滚动体由内圈或外圈的两个挡边引导,通过保持架和这个套圈组成一个单元。

这种轴承的一个套圈可拆下,因此内外圈可分别安装。

这类轴承可作为浮动、半定位及定位轴承。

带盘式保持架或隔片的圆柱滚子轴承 (446)这类轴承的黄铜盘式保持架或塑料隔片防止了滚动体间的相互接触。

此类轴承是介于满装轴承与带保持架轴承之间的一种设计。

滚动体由外圈的刚性挡边引导。

内圈可拆分,因此内外圈可以分开安装。

此类轴承专门用作半定位轴承。

单列满装圆柱滚子轴承 (460)此类轴承带有满装圆柱滚子组。

滚动体由套圈挡边引导。

由于具有尽可能多的滚子,满装圆柱滚子轴承具有极高的承载能力和高刚性。

限于运动学条件,此类轴承没有带保持架的圆柱滚子轴承那样高的极限转速。

此类轴承专门用作半定位轴承。

双列满装圆柱滚子轴承 (478)滚动体由套圈挡边引导。

轴承具有极高的承载能力和高刚性。

限于运动学条件,该类轴承没有带保持架的圆柱滚子轴承那样高的极限转速。

索轮轴承(轴承外圈带有止动槽)通过止动环可以很方便地进行轴向定位。

双列满装圆柱滚子轴承可用作浮动、半定位及定位轴承。

高精密圆柱滚子轴承 (500)这类双列高精密圆柱滚子轴承(浮动轴承)主要应用于机床,精度等级为SP。

可为主轴提供径向支撑。

此类轴承外圈可拆分,因而便于安装与拆卸。

内圈带有圆锥内孔,用于轴承内部游隙的优化设置。

392HR 1Schaeffler Group IndustrialSchaeffler Group Industrial HR 1393FE Br r1d D带保持架的圆柱滚子轴承页带保持架的圆柱滚子轴承产品概览带保持架的圆柱滚子轴承 (396)特性 (397)浮动轴承 (397)半定位轴承 (397)定位轴承 (398)密封 (398)润滑 (398)工作温度 (398)保持架 (398)后缀 (399)设计与安全指南容许的倾斜角度 (400)轴向承载能力 (400)最小径向载荷 (401)轴承当量动载荷 (402)轴承当量静载荷 (402)轴承布置设计 (402)精度内部径向游隙 (403)尺寸表带保持架的圆柱滚子轴承,浮动轴承 (404)带保持架的圆柱滚子轴承,半定位轴承与定位轴承..............420Schaeffler Group Industrial HR 1395396HR 1Schaeffler Group Industrial 产品概览带保持架的圆柱滚子轴承浮动轴承NU10、NU19、NU2..-E 、NU4、NU3..-E 、NU22..-E 、NU23..-E N2..-E 、N3..-E113 437a 113 439a半定位轴承NJ2..-E 、NJ3..-E 、NJ4、NJ22..-E 、NJ23..-E113 430a 定位轴承带平挡圈NUP2..-E 、NUP3..-E 、NUP22..-E 、NUP23..-E113 438a 带L 型斜挡圈NJ2..-E+HJ 、NJ3..-E +HJ 、NJ4+HJ 、NJ22..-E +HJ 、NJ23..-E +HJ00014089Schaeffler Group Industrial HR 1397特性带保持架的单列圆柱滚子轴承由内圈、外圈、圆柱滚子及保持架组件构成。

轴承样本

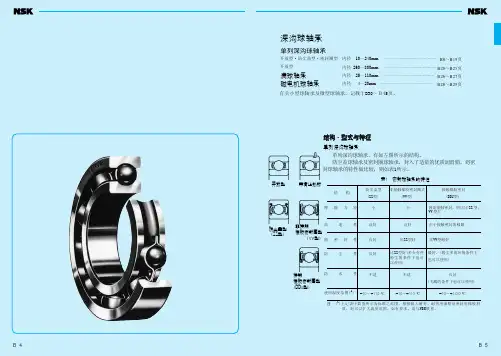

深沟球轴承

调心球轴承

圆柱滚子轴承

调心滚子轴承

滚针轴承

螺旋滚子轴承

角接触球轴承

圆锥滚子轴承

推力球轴承

推力角接触球轴承

推力滚子轴承

推力圆锥滚子轴承

推力调心滚子轴承

组合轴承

外球面球轴承

带座外球面球轴承

水泵轴连轴承

转盘轴承

关节轴承

微型轴承

英制轴承

法兰轴承

陶瓷轴承

不锈钢轴承

薄壁轴承

平面轴承

滚针轴承

调心轴承

单向轴承

电主轴轴承

角接触轴承

塑料轴承

高速涡轮牙钻手机轴承

牙钻轴承

手术动力装置轴承

/zcmulu/index.asp?style=pic&id=1。

额定负荷重量型 号Basic Loads Mass DesignationsD d H D1D2φ1φ2D3d1H1h φ3Coa mm 104 N kg 116752480260604442961616141436038060---75.455116752K48026060------36038060---75.458.617679259046045570488812M101051854245---62.635.9176792K590460455704881212101051854245---62.636176792K2M59046045570488128101052653445---94.430.81167/530780530607405602020171364566535---1121031167/5607205603669059012121412638.5641.5333-70.840.31167/560K720560366905901232M1216634646363-70.839.21167/560M7205603669059012121412638.5641.5363-70.838.11168/56078056060------645668603-22410311768/63078063069------71872269---11179.41167/700900700368607401212M1617796804363--17960E787/760G295076080915795242418M16853.5856.57194M10×12031383 - 6401000775649488022412/12M1213 / M1287888249152M8×11961123 - 640K1000775649488022412/12M1212 / M1287888249152M8196112787/800G10508009010128383030202092392776163M10×121519271769/850Y11208508510749241212M2022995101085---15l 24871769/850G2K112085085107492412121722999l00385---210257787/932G212009321201148984404026M2410641068100204G1 / 4in 349328787/960G211659609011351040363618M161073107778146M10×1249202787/1000G21250100010012061044121218M161123112790103M10×1540283787/1260G2150912609014651315363622M201386138970142ZGL / 8in 37827471169/1400Y18201400136175014702424353516081612136-4M10×1611111471169/1400Y118201400136175014702424353516081612136-4M10×110701120787/1440G21780144010017301494484822M201618162285154M12×1.25503533787/1628G21927162813018751680363626M2417741778115156G1 / 4in 692732787/1700KM20001700150195017502424212118421858130204M10×1684826KDL900—610508325610208621212181894294645-4M622752.5LD—Q00748527555453307161618M163813865054M10×187.243.7LD—QOO7K48527555453307161618183813865054M10×187.243.7LD—Q020440240554002801818M20-7H 223403425053M10×178.234.74 point contact ball bearing slewing ring (without gear)四点接触球式转盘轴承(无齿式)n1n2n3mm mm mm mm 外 形 尺 寸安 装 孔 尺 寸结 构 尺 寸Boundary Dimensions Bolt Hole Diameter Structure Dimensions额定负荷重量型 号Basic Loads Mass DesignationsD d H D1D2φ1φ2D3d1H1h φ3Da b Coa mm mm mm 104 N kg D178794694470776305001818M1618567.5564.564136M10 x1669611460015793.11787/600G786600727406362024 2.5196896916074n 678913150010794.11787/674G285367470825709342320M2076476859102n 78891255001838911787/674G2K853674708257093424181876476859102n 788912550018388.61787/710G28947106784574488M10M107988065893M10×l 69241525501791071787/710G2K89471067875760812M10M127988065893M10×169241525501791071787/710G2Kl89471067865744202013137988065894M10 x169241525501791071787/800G 10508009010128383030202092392776163M10×1610921806002152171787/800GK 10508009010128383030202092392776163M10×1610921806002152171788/1040G2 -104080122010803030M1617.5115311577010--10131412570029725l 1787/1060G 13351060109129511052424M20221198120210094M8×110138813880-0.65014071787/107513651075120131011303636262612181222105154M8×1814241769004634631787/1075K 1365107513013101130363624241218122210510--10142014012004635501787/1075G21365107512013lO 11303636242412181222105154M10 x110142513890 1.44634631787/1075G2K 1365107512013lO 11303636M242612181222105154M8×1814241'769004634631787/1330G21475133082.415101362242418.518.5143914457012.46M10×1915841747003532803 — 647G 14071352100137014041813M8M101390139463-86 4.514493206002161431788/1410G2-141085159014543636M1617.51524.61528.67015--1016761607003953121787/1640G 20501640160199017103030282818441856140202 1.5102108210105-0.6111812641787/170019451700120190017502424M182118251845110104M10×1519703923504055161789/1700GM 2052170010019801780242420M181878188290104 1.5520804145005516781787/2650G228852650100285027004848 M20M202777278180106n 122950244800913751Z x mm mm mm mm n1n2n3m Boundary Dimensions Bolt Hole Diameter Structure Dimensions Gear Parameters 外 形 尺 寸安 装 孔 尺 寸结 构 尺 寸齿 轮 参 数额定负荷重量型 号Basic Loads Mass DesignationsD d H D1D2φ1φ2D3d1H1h φ3da b Coa mm mm mm 104 N kg 2788/850K97685080------91691980---29164562001741173-646G21200-5611701044162417.510.51088109246124M8 x1698516644021084.12782/1000GK127010001001220105024/2×224/2×217/M1217/M121133113785152M10×16972.61647003843222787/1210G215301210122148012604040262613681372108124M10 x11011641188007135402787/1400GK17151400110166014602424M20M201558156295152M121.256136523077-0.353655452787/1400GK11715140011016601460242423231558156295152M10x16136523077-0.353655452787/14401780144010017301494484822M201618162285104M121.25814001775005035542787/1440G1780144010017301494484822M201618162285104M121.25814001775005785542768/1440G1780144010417301494484822M201613162787106M121.25814001775205785552787/1525G218751525140181515854242292916981702122174M121.25161452921100.3587310192788/171220501790112200618473672222219251926921218M10x1161712108100-0.56046632789/223024882230160244522754848M20M222337.52342.513558ZG1/4in 1821441211450124711142789/2240G225002240140245422805656M24M242357.52362.511558M14x1.5182146121125085611612789/273529902735160295427704848M20M242835284513558ZG1/4in 222625121144015591457Z x mm mm mm mm n1n2n3m Boundary Dimensions Bolt Hole Diameter Structure Dimensions Gear Parameters 外 形 尺 寸安 装 孔 尺 寸结 构 尺 寸齿 轮 参 数50Ball and roller combined slewing bearing (external gear)球柱组合转盘轴承重量De D d H D1D2фMD3d1H1hb 正常最大mm mm mm mmmm mm mm mm mm mm mm mm KN KN 221.32.3550.**3772.83358159363834187630271035913509143501091623210.11603202028221.32.3750.**3980.8355815938463618803027103791370914350109162460.50.11603202186221.32.4000.**4220.8380815940863868843027124041395914350109162610.50.11603202278221.32.4250.**4476.84058159434241189030271242914209143501091627610.11603202455221.36.4000.**4244.43792175409538587633301240453955159501251823210.11963912792221.36.4250.**4496.4404217543474108803330124295420515950125182470.50.11963912981221.36.4500.**4748.4429217545994358843330144545445515950125182610.50.11963913171221.36.4750.**5000.4454217548514608903330144795470515950125182750.50.11963913363221.40.4500.**4776427618346124348723633144550445016750133202360.50.12314633673221.40.4750.**5016452618348524598763633144800470016750133202480.50.12314633796轴 承 型 号 (外齿式)n n1m Z x k kg 外 形 尺 寸安 装 尺 寸结 构 尺 寸齿 轮 参 数齿轮圆周力Boundary dimensions Installation dimesnions Fabrication dimensionsGear data。

Rolling Element BearingsFigure 11-1, Mechanical Engineering Design, Juvinall& MarshekBearing Terminology•Tapered Bore:Seat the bearing onto a tapered shaft or to accommodatea tapered sleeve which can be used to fix a bearing to a shaft.•Shields or Seals:Between the inner and outer rings to capture lubricating grease around the balls and prevent intrusion ofcontaminants.( Z-shield ,RS-seal)-eg-61814-2RS1-two contact seals(NRB)•Self Aligning:The inner ring can pivot so that the bore of the inner ring is not aligned with that of the outer ring, this accommodates shaftswhich are not perfectly aligned (concentric) with the outer ring of thebearing.Bearing Terminology•Pure Radial and Pure Axial Loads:This indicates a bearing’s ability to sustain each of these kinds of loads in isolation.•Combined Loads:Ability to sustain a radial and an axial load at the same time.•Moment Load:This indicates a bearing’s ability to support a moment at right angles to the longitudinal shaft axis.•High Running Accuracy and High Stiffness: Some applications require a bearing which maintains the center of rotation of the shaft with extreme accuracy even when large loads are applied.Bearing Terminology•Locating:If the inner ring of a bearing is axially “locked” to the shaft and the outer ring is axially “locked” to the housing, then the bearing is said to be locating since it prevents the shaft from moving axially w.r.t.the housing.•Non-Locating:If either the inner or outer ring is not axially locked, the bearing cannot prevent the axial movement of the shaft.•Axial Displacement:In some bearings, the inner and outer races are free to move axially w.r.t. each other. This kind of bearing cannot be used in a locating arrangement.Bearing TerminologyFig 122-124, Ball andRoller BearingsAngle Of Contact•Figure 122a,bBearing Classification Bearing ClassificationBearing Types & LoadsDeep Groove Ball Bearing Pictures Courtesy of SKF General Catalogue, and SKF Rolling Bearings in Industrial GearboxesDeep Groove Ball BearingsMax axial load =.25*C o --.5*C0Bearing Types & LoadsCylindrical Roller Bearing Pictures Courtesy of SKF General Catalogue, and SKF Rolling Bearings in Industrial GearboxesCylindrical Roller BearingAxial load is governed by load capabilityOf sliding contact on flange –function oflubricant, operating temp. and heatremoval.Bearing Types & LoadsSpherical Roller Bearing Pictures Courtesy of SKF General Catalogue, and SKF Rolling Bearings in Industrial GearboxesBearing Types & LoadsTapered Roller Bearing Pictures Courtesy of SKF General Catalogue, and SKF Rolling Bearings in Industrial GearboxesBearing Types & LoadsAngular Contact Ball Bearing Pictures Courtesy of SKF General Catalogue, and SKF Rolling Bearings in Industrial GearboxesBearing Types & LoadsThrust Taper Roller BearingPictures Courtesy of SKF General Catalogue, and SKF Rolling Bearings in Industrial GearboxesBearing Types & LoadsDouble-Row Angular ContactBall BearingPictures Courtesy of SKF General Catalogue, and SKF Rolling Bearings in Industrial GearboxesBearing Types & LoadsFour-Point Angular ContactBall BearingPictures Courtesy of SKF General Catalogue, and SKF Rolling Bearings in Industrial GearboxesBearing Types & LoadsCARB Bearing•Very high radial load carryingcapacity•No axial load carrying capacity•Accommodates both axial motion andangular misalignmentPictures Courtesy of SKF General Catalogue, and SKF Rolling Bearings in Industrial GearboxesLBasic Bearing Life Rating 10•Norton fig 10-22(10^6 revolutions)LBasic Bearing Life Rating10•The L10rating life of a sufficiently large number of dimensionally identical bearings is expressed by the number of revolutions or number of hours at constant speed reached or exceeded by 90% of this bearing group before the firstsigns of material fatigue appear.If design on L10life chance of 10% failure at design life.Can one do better.a 99% life rating =.21*L10 LifeThe Life EquationL 10= Basic Life Rating in [revolutions x 106]C = Basic Dynamic Load Rating . This is the max. load at which 90% of the tested bearings will show no fatigue damage after 106revolutions. This value is given in the bearing catalogue for every bearing type.Note:If a bearing is subjected to a basic dynamic load of “C” then there is a 90% confidence that it will survive to 106cycles (L 10=1)P (upper-case) = Equivalent Dynamic Bearing Load . This is a measure of the combined radial and axial load on the bearing.p (lower-case) = Exponent for Life Equation . 3 for ball bearings, 10/3 for roller bearings.The Life EquationThe Basic Life Rating can also be expressed in hours of operation:where, n, is the rotational speed in rpmpP C L ⎟⎠⎞⎜⎝⎛=10ph P C n L ⎟⎠⎞⎜⎝⎛=6010610Dynamic Bearing LoadsP = Equivalent Dynamic Bearing LoadF r = the Actual Radial Load on the bearing F a = the Actual Axial Load on the bearingX = the Radial Load Factor for the bearing Y = the Axial Load Factor for the bearingar YF XF P +=Equivalent Dynamic Bearing Loads •Y will be LARGE for bearings which are unsuitable for axial loads. For example, SKF self-aligning ball bearings have values of Y as large as6.1•Y will be SMALL for bearings which are suited to carry axial loads. For example, SKF taper roller bearings usually have Y values of 1.0ar YF XF P +=Applicable Values of X and Y or Where, e, is a reference value which depends on bearing type and load magnitudes (see tables of specifications for bearings in SKF catalogue)e F F r a >e F Fra<Applicable Values of X and YExampleA self-aligning bearing is needed for a 20mm dia shaft. The shaft speedis 1200rpm and the bearing must operate for 3000hrs without maintenance. The radial load is 3000N and the axial load is 600N. Choose a bearing for this application.ExampleExampleSelf-Aligning Ball Bearings, (SKF Catalogue Pg. 155)Equivalent Dynamic Bearing Loadswhere when a r F Y F P 1+=eF F ra≤eF Fra>a r F Y F P 265.0+=ExampleExample ExampleExampleSpherical Roller Bearings, (SKF Catalogue Pg. 245)Equivalent Dynamic Bearing Loadswhere when a r F Y F P 1+=eF F ra≤eF Fra>a r F Y F P 267.0+=ExampleExample ExampleTo make copy of SKF catalogue.---open up“easy CD creator” on machine next to scanner in DAPR Lab.open file “SKFCAT” then click on directory “SKFIEC”Make sure you copy with “smart burn” presets .Note-don’t reconfigure each time if making more than1 copy.To run catalogue , go to SKFIEC directory and clickon SKFCD2 .NOTE –ALL THE FITS LISTED IN BEARING BOOKS ARE CALCULATED FROMCSA/ISO STANDARDS FOR “FITS OF MATING PARTS”Note-page 542 text-”rollingelement bearings are intended tohave inner and outer races pres-fitted to shaft and housing”page 9 SKF Cat.925—As ageneral rule ,ball bearings shouldhave an operational clearancewhich is virtually zero ,or theremay be a slight preload .Cylindricaland spherical rollers should alwayshave some residual clearance.-design-assembly –maintenance –life-runningaccuracy-all may result invaried clearance or pressfits.Snap RingsBearing ArrangementsFloating / Locating Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig. 295a-f, Pg. 250Picture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig. 295a-f, Pg. 250Floating / Locating Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig. 295a-f, Pg. 250Floating / Locating Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig. 295a-f, Pg. 250Floating / Locating Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig 295a-f, Pg. 250Floating / Locating Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig. 295a-f, Pg. 250Floating / Locating Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig. 296 -Fig 301, Pg. 250Adjustable Bearing ArrangementsExampleTaper rollersNote –these equations are only valid when Bearings are adjusted against each other with practically zero clearance , but without preload If you preload the bearings the axial forces will have to be determined. Best bet Call SKF To determine best coarse of action.Picture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig. 296 -Fig 301, Pg. 250Adjustable Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig. 296 -Fig 301, Pg. 250Adjustable Bearing ArrangementsAdjustable Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig 333, Pg. 294Floating Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig 302a-c, Pg. 254Floating Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig 302a-c, Pg. 254Floating Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig 302a-c, Pg. 254Floating Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig 334, Pg. 294Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig 396, Pg. 326 Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig 397, Pg. 326Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig 470, Pg. 374 Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig 477, Pg. 390Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig 499, Pg. 428 Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig 502, Pg. 433Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig 503, Pg. 433 Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig 503, Pg. 433Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig 503, Pg. 433 Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig 503, Pg. 433Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig 503, Pg. 433 Bearing ArrangementsPicture courtesy: Ball and Roller Bearing Arrangements, Theory Design and Application.Fig 503, Pg. 433。