LEC-7920桌面型嵌入式工业控制器

- 格式:pdf

- 大小:347.86 KB

- 文档页数:2

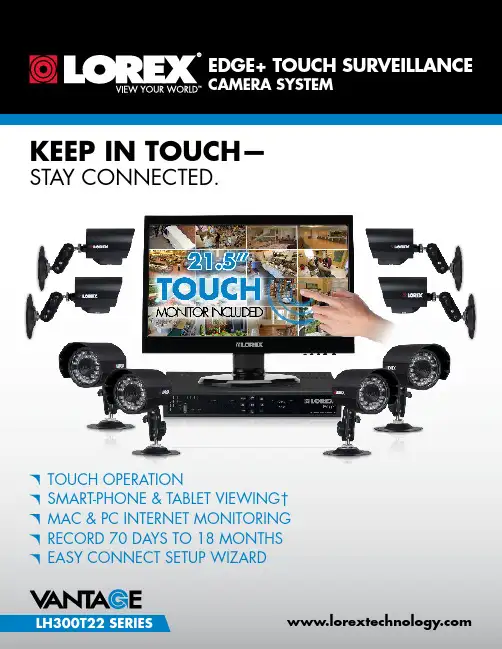

KEEP IN TOUCH—STAY CONNECTED.TOUCH OPERATIONSMART-PHONE & TABLET VIEWING†MAC & PC INTERNET MONITORING RECORD 70 DAYS TO 18 MONTHS EASY CONNECT SETUP WIZARDINTUITIVE TOUCH NAVIGATIONHigh resolution viewing and exceptional playback.PROFESSIONAL-GRADE VIDEO SURVEILLANCEAn expandable system that you can depend on.SLIM DESIGN AND SILENT OPERATIONYou can easily conceal you DVR.ANTI-GLARE TECHNOLOGYGet clear images under any lighting conditions.ULTIMATE CONNECTIVITYKeep in touch using any device from anywhere in the world.* For the latest smart phone compatibility list & free Appdownload† check •H.264 video compression.¹ DVI/VGA, HDMI compatible••Pentaplex operation - View, Record, Playback, Back Up & Remotely Control the system simultaneously •Recording options : Motion, schedule or continuous•Small form factor (7.0x11.5x1.5”)•“Flex” IR controller (line-of-sight not required)•USB: backup, image transfer, firmware upgrade, mouse & Touch operation•PTZ cameras supported (RS485)CONNECTIVITY•Instant Mobile Viewing on compatible Smart phones†•Exclusive LOREX Easy Connect Internet Set-up Wizard²•PC (Microsoft Windows™ 7/Vista/XP compatible) using Internet Explorer®•Mac™ compatible using Safari browser•Free LOREX DDNS (Dynamic Domain Name Service) for advanced remote connectivity at all times •Instant e-mail alertsTOUCH SCREEN MONITOR•21.5” Touch Screen LCD, 1920x1080 resolution•Optical, multi-touch technologyWHAT’S INSIDE IN THE BOX:•21.5” LED Touch Screen Monitor•DVR with pre-installed HDD*•High-resolution cameras*•Easy-to-follow setup instruction guide and manual•ALSO INCLUDES: Remote Control, Power Adapters, Mouse, Ethernet Cable, DVI to VGA •Converter, 60ft Camera Extension Cables per camera, USB, VGA, DVI Cables.VESA MOUNTEasily mounts to the back of an LCD monitor†† (Requires clear access tothe VESA mounting holes). DIGITAL VIDEO RECORDER:•High resolution AIS (Advanced Image Sensor) 480 TV lines •Lorex Pure Flat lens eliminates image curving•Exclusive infrared filter achieves accurate color reproduction in lighting conditions •Advanced day/night mode - picture automatically switches to B&W delivering better clarity in all low light conditions •Night vision range up to 75 ft. (25 m)** •Install indoors or outdoors (IP66)*** •Ceiling, counter or wall mountableCAMERAS (CVC6996):MOUNTING OPTIONSWall mountCeiling mountTable mountAIS IMAGE SENSOR + EXCLUSIVE INFRARED FILTER TECHNOLOGYAccurate color reproduction in varying lighting conditionsPURE FLAT™ LENSANTI-GLARE TECHNOLOGYEliminates image curving for an undistorted viewClear images under strong lighting conditions180mm/7.0”Dimensions:DISCLAIMERS:1. Recording time may vary based on recording resolution & quality, lighting conditions and movement in the scene.2. Requires a high speed internet connection and a router (not included).• DVI to HDMI converter cable required. (not included).† Instant Mobile Viewing on iPad™, iPhone™ , BlackBerry (supported model numbers: 9700, 9800, 9000, 8900), Android (version 1.5 & above) and Window Mobile (6.0 & above). Selectable one channel live viewing. Mobile phone data plan is required (not included). Router port forwarding required. For the latest smart phone compatibility list check as new smart phone models become available in the market.†† Easily mounts to the back of an LCD monitor with VESA standard mounting holes and an independent stand. Requires clear access to the 100 x100 mm VESA mounting holes.* Number of Channels/ Cameras/ Accessories/ HDD (hard disk drive) capacity may vary by model. Check your package label for specific content information.** Night vision range up to 75 ft. (23 m) in ideal conditions. Objects at or beyond this range may be partially or completely obscured, depending on the camera application.*** Not intended for submersion in water. Installation in a sheltered location recommended.All trademarks belong to their respective owners. No claim is made to the exclusive right to use the trademarks listed, other than the trademarks owned by Lorex Technology Inc. We reserve the right to change models, configurations or specifications without notice or liability. Product may not be exactly as shown. Images are simulated.SYSTEMOperating System: Linux (embedded)Pentaplex: Simultaneous View, Record, Playback, Backup & Remote MonitoringNumber of Channels: 8/16 ChannelInputs/OutputsVideo In: 8/16 x 1Vp-p, 75ohms, BNCDVI Out : DVI compatible. DVI to VGA Converter includedAudio In: 2 Line in(RCA)Audio Out: 2 line out(RCA)USB Port: 2 front & backAlarm In: 4 x TTL, programmable as NC/NOAlarm Out: 1 x Relay with NO/NC contactPTZ Control: By T erminal connector (RS485)DisplayLive Display: 1 or 4 or 9 (8ch)1 or 4 or 9 or 16 (16ch)Live Display Speed: 240 (8ch)/ 240 (16ch) NTSC, 200 (8ch)/ 200 (16ch) P ALOSD: ON/OFFOSD Navigation: USB Mouse, IR Remote Controller, Front Panel ControlsActivity Detection: 6 x 8 gridSensitivity Levels: 100System Control: USB Mouse, Front Panel Controls, Handheld Remote ControlFirmware Upgrade: Via USB deviceUser Authority: ADMIN/USER/GUESTRECORDINGVideo Compression: H.264Audio Compression: ADPCMRecording Speed & Resolution: 8/16 Channel: 240 fps (NTSC), 200 fps (P AL) @ 320 x 240 NTSC / 320 x 256 P AL120 fps (NTSC), 200 fps (P AL) @ 640 x 240 NTSC / 640 x 256 P AL60 fps (NTSC), 100 fps (P AL) @ 640 x 480 NTSC / 640 x 512 P ALRecording Resolution Setting: Programmable per cameraRecording Quality Control: 5 levelsImage Size: 8.51 Kbyte (640x480,640x512), 11.2 Kbyte (640x240, 640x256) 14.13 Kbyte (320x240, 320x256)Recording Modes: Continuous, motion, alarmPre Recording: Max. 10 secondsPost Recording: Max. 255 secondsAlarm Recording: Programmable per cameraReliability: W atch-Dog, Auto-recovery after power failure PLA YBACKPlayback Display: 1,4,9 (8ch), 1,4,9,16 (16ch)Playback Speed: V ariable up to 60xPlayback Players: Apple QuickTime PlayerSearch: By time & eventSTORAGE & ARCHIVEStorage: Up to 1 HDD’s (SA T A)Maximum Capacity: Up to 2TBBackup Media: USB Flash Drive (max 4GB)Backup File Format: MOV file (Codec included)Bookmark Archiving: SupportedCONNECTIVITYEasy Connect: 1. Y oics Enabled (registration required)2. Lorex Auto Port Forward WizardSoftware: W eb browserSupported Operating Systems: Windows™ XP, Vista, 7 and Apple Mac (via Safaribrowser)Browsers: Internet Explorer, SafariEmail Notification: Snap Shot attachment (8/16ch)Mobile Connectivity: iPad™ , iPhone™ - 3.1.2 and above, Blackberry™ -(supported model numbers: 9700, 9800, 9000, 8900),Android (version 1.5 & above), Windows Mobile™ smartphones – 6.0 and above touch screen smart phones DDNS: Free Lorex DDNSW eb Server Port: Programmable by UserNetwork Protocol: LAN, DHCP, Dynamic IP, DDNSNetwork Interface: 10/100-Base-TX, RJ-45Network Speed Control: 10 levels (28.8Kb ~ 1.5MB)/sec.GENERALPower Consumption: Approx. 30 wattsSupply V oltage: 120V AC-240V AC, 12VDC, 2.5A(4ch) 3A(8/16ch), 50/60Hz Unit Dimensions (W x D x H): 11.6” x 7.2” x 1.67”290mm x 180mm x 41.8mmUnit W eight: 3.2±0.22 lbs / 1.45±0.1 kg (8/16ch)Operating T emperature: 41° ~ 104° F / 5° ~ 40° CHumidity: 10 ~ 75% NCDVR, TOUCH MONITOR & CAMERA SPECIFICATIONS DVR:Image Sensor: 1/4” Advanced ColorVideo Format/Pixels: NTSC: 656(H) x 492 (V)Horizontal Resolution: 480 TVLSync. & Scan. Systems: Internal; 2:1 InterlaceS/N Ratio: > 48dBIris & Shutter Speed AES; 1/60 - 1/50,000 sec.Minimum Illumination: ***********(IRoff),0LUX(IRLEDson) Video Output: Comp. 1.0 Vpp @ 75ohmLens/Lens Mount: 5.0mm F2.8/FixedFOV (diagonal): 50 degreesT ermination: Video: BNC Female, Power: Barrel FemaleIR / Night Vision Range: 30 IR LEDs/850nm/75’ (23m)Power Requirement: 12V DV ±10%Power Consumption: 220 mA or 3W maxOperating T emp.: 14°F ~ 122°F (-10°C ~ 50°C)W eight (with stand): 0.66 lb / 0.3 kgDimensions L x W x H(with sunshade): 5.1” x 3” x 5.1” / 130mm x 75mm x 129mm LCD Panel Size: 21.5” / 54.61 cmDCR: 10000:1 (typical)Viewing Angle: Horizontal 170°, vertical 160° (typical) Response Time: 5 ms (typical)Brightness: 265 cd/m2 (typical)Input Signal: Analog signal (D-sub); digital signal (DVI) Display Color: 16.7 M colorsFrequency: 24 ~ 83 kHz Horizontal, 50 ~ 76 Hz V ertical Optimum Graphic Resolution: 1920 x 1080 (60Hz)Max Pixel Clock: 180 MHZTilt: -5° ~ 20°Audio Output: 1W X 2Power Supply: AC: 100-240V ~ 50-60Hz;Power Consumption: Display mode: Max 48W; LED color: Blue Sleeping mode: Less than 1W, LED color: OrangeSize (W x H x D): 20” x 15.8” x 7.9” / 507mm x 402 mm x 200 mm W eight: 11lbs / 5 KgEnvironmental conditions: Operating temperature/humidity: 5 ~ 35°C,Relative humidity: 10-85%CAMERA (CVC6996):21.5” TOUCH SCREEN LCD MONITOR:MODELCONFIGURATIONPACKAGEW x D x H in & mmWEIGHTCUBEUPC CodeLH38410T228 ch Edge+ DVR x 4 (480) TVL Cameras x 1TB HDD x 21.5” Touch Monitor Retail English 658mm x 320mm x 470mm/ 25.9” x 12.6” x 18.5”13.8 kg/30.5 lb0.09786 CBM / 3.49486 CBF7-78597-38410-9LH38410T22F 8 ch Edge+ DVR x 4 (480) TVL Cameras x 1TB HDD x 21.5” Touch Monitor Retail Universal 658mm x 320mm x 470mm/ 25.9” x 12.6” x 18.5”13.8 kg/30.5 lb 0.09786 CBM / 3.49486 CBF 7-78597-38411-6LH328501C4T228 ch Edge+ DVR x 4(480) TVL Cameras x 500 GB HDD x 21.5” Touch MonitorRetail English658mm x 320mm x 470mm/ 25.9” x 12.6” x 18.5”13.8 kg/30.5 lb 0.09786 CBM / 3.49486 CBF 7-78597-32806-6LH3281001C4T228 ch Edge+ DVR x 4(480) TVL Cameras x 1TB HDD x 21.5” Touch MonitorRetail English658mm x 320mm x 470mm/ 25.9” x 12.6” x 18.5”13.8 kg/30.5 lb 0.09786 CBM / 3.49486 CBF 7-78597-32817-2LH328501C4T22FMX8 ch Edge+ DVR x 4(480) TVL Cameras x 500 GB HDD x 21.5” Touch MonitorRetail Universal658mm x 320mm x 470mm/ 25.9” x 12.6” x 18.5”13.8 kg/30.5 lb 0.09786 CBM / 3.49486 CBF 7-78597-32806-6LH328501C4T22B 8 ch Edge+ DVR x 4(480) TVL Cameras x 500 GB HDD x 21.5” Touch MonitorBrown 650mm x 365mm x 560mm/ 25.6” x 14.4” x 22.2”13.8 kg/30.5 lb 0.09786 CBM / 3.49486 CBF 7-78597-32805-9LH3281001C4T22B 8 ch Edge+ DVR x 4(480) TVL Cameras x 1 TB HDD x 21.5” Touch MonitorBrown 650mm x 365mm x 560mm/ 25.6” x 14.4” x 22.2”13.8 kg/30.5 lb 0.09786 CBM / 3.49486 CBF 7-78597-32815-8LH318501C8T22B 8 ch Edge DVR x 8 (480) TVL Cameras x 500 GB HDD x 21.5” Touch MonitorBrown 650mm x 365mm x 560mm/ 25.6” x 14.4” x 22.2”15.9 kg/35.1 lb 0.1329 CBM / 4.692 CBF 7-78597-31812-8LH328501C8T22B 8 ch Edge+ DVR x 8(480) TVL Cameras x 500 GB HDD x 21.5” Touch MonitorBrown 650mm x 365mm x 560mm/ 25.6” x 14.4” x 22.2”15.9 kg/35.1 lb 0.1329 CBM / 4.692 CBF 7-78597-32809-7LH3281001C8T22B 8 ch Edge+ DVR x 8 (480) TVL Cameras x 1TB HDD x 21.5” Touch Monitor Brown 650mm x 365mm x 560mm/ 25.6” x 14.4” x 22.2”15.9 kg/35.1 lb 0.1329 CBM / 4.692 CBF 7-78597-32816-5LH326501C8T22B 16 ch Edge+ DVR x 8 (480) TVL Cameras x 500 GB HDD x 21.5” Touch MonitorBrown 650mm x 365mm x 560mm/ 25.6” x 14.4” x 22.2”15.9 kg/35.1 lb 0.1329 CBM / 4.692 CBF 7-78597-32606-2LH3261001C8T22B 16 ch Edge+ DVR x 8 (480) TVL Cameras x 1 TB HDD x 21.5” Touch MonitorBrown 658mm x 320mm x 470mm/ 25.9” x 12.6” x 18.5”15.9 kg/35.1 lb 0.09786 CBM / 3.49486 CBF 7-78597-32611-6LH36810T22B 16 ch Edge+ DVR x 8 (480) TVL Cameras x 1TB HDD x 21.5” Touch MonitorBrown 658mm x 320mm x 470mm/ 25.9” x 12.6” x 18.5”15.9 kg/35.1 lb 0.09786 CBM / 3.49486 CBF 7-78597-32610-9LH361610T22B 16 ch Edge+ DVR x 16 (480) TVL Cameras x 1TB HDD x 21.5” Touch MonitorBrown 622mm x 495mm x 444mm/ 24.5” x 19.5” x 17.5”23.3 kg/51.5 lb 0.136770 CBM / 4.83 CBF 7-78597-32614-7Includes 8 or 16 Channel DVR, HDD Pre-Installed, Remote Control & “Flex” IR controller, Power adaptor for DVR, Mouse, Ethernet Cable, DVI to VGA Converter, 4 or 8 x Cameras, 4 or 8 x Camera Stands, 4 or 8 x 60ft BNC Extension Cables, 1 or 2 x 4 in 1 camera power adaptors, 2 screws (for key-hole style VESA mounting), 21.5” LCD Touch Screen Monitor, power cord for Monitor, audio cable, USB cable, VGA cable, DVI cable.© 2011 Lorex Technology Inc.As our product is subject to continuous improvement, Lorex T echnology & subsidiaries reserve the right to modify product design, specifications & prices without notice and3700 Koppers StreetBaltimore, Maryland 21227,Lorex Technology Inc.250 Royal Crest CourtMarkham, Ontario, CanadaBack Panel - 8 & 16 Channel DVRsPRODUCT INFORMATIONProduct Information:。

Eaton Logic Controller (ELC)The Eaton Logic Controller.Compact, modular, and ready tocommunicate. It’s the cost-effectivesolution to machine control.The right amount of I/O.Why pay for functionality you don’t need? Why be trapped with functionality you can’t scale to meet changing needs? Eaton is changing everything with the ELC.At less than half the size of most PLCs, the ELC is an ideal solution when space is at a premium and specialized I/O needs present themselves.Space saving. Cost saving.This space-saving design is as perfectly at home in asmall machine control station as it is in an MCC and other enclosed applications where space is critical. Reduced space also means smaller control cabinets and panels, or more capability in the same amount of space. However you look at it, the ELC means value.Half the size of most PLCs, the ELC puts the right amount of I/O right where you need it.ELC Controller and Expansion Modules.ELC Programming SoftwareProgram on your PC and download to the ELC through a serial cable or over Ethernet. Make online changes, monitor and remote control the run/stop operation. Software wizards simplify the programming process.eaton corporation Programmable Logic Controller 3Machine spaceis measured in inches.The ELC is measuredthe same way.eaton corporation Programmable Logic Controller 5ELC’s value added differences 5 controller styles: •PB Base Model— 14 I/O (8i/6o)Over 130 instructions provide all the power you need. Two serial ports for master/slave communications.•PC Clock/Calendar Model— 12 I/O (8i/4o)Same as the PB model, plus clock/calendar, twice theprogram steps, distributed I/O, and retentive data storage.•PA Analog Model— 10 I/O (6i/4o)Same as the PC model, plus embedded analog I/O.•PH High-Speed Model— 12 I/O (8i/4o)Same as the PC model, plus the ability to capture or output 100 kHz pulses.•PV Advanced Model— 28 I/O (16i/12o)Almost 10 times faster than the other ELC controllers, high speed I/O to 200 kHz, and additional advanced features. Add left side expansion modules for master communicationson networks such as Ethernet and DeviceNet ™.More Controller Features•High-speed pulse capture and high-speed pulse output on all controllers.•Broad selection of AC/DC in, relay/transistor and high current output modules.•Large selection of analog In/Out in various I/O counts per module.• 2 Modbus ®(ASCII / RTU) serial ports: 1 slave only, 1 master/slave.•Over 200 instructions to choose from: Floating point math, communications, 16- and 32-bit math, logical, blockmove, block compare, retentive data storage, conversion, time base from clock/calendar.ELC benefits solve applications:Size —large PLC features in a 1" package. Half the size of competitive offerings. ELC can retrofit more I/O in the same space or allow more costsavings by reducing cabinet size.Flexibility —ELC controllers expand from 10 to hundreds of I/O points. Expand with up to 16 modules (no more than 8 analog/specialty modules).•Add only the amount of I/O you need. Choose I/O counts as small as 2 points and as large as 16 points per module.•DIN-rail mounting lets you add as many modules as needed by snapping them into mating connectors.Large PLC Features —Multiple communications ports,distributed I/O capability, high speed counters, high speed pulse outputs, interrupts, timer resolution to 1ms, PIDs, plus much more.Software —ELCSoft programs in standard ladder or sequential function chart programming.•Display registers “in use” and modules attached to the ELC.•Monitor runtime applications and enter/modify register values.•Wizards aid programming of ELC Link for distributed I/O, standard communications, high speed counters,pulse outputs, positioning, interrupts, PIDs, and extension module setup.Communications —Connecting to networks is easy on Modbus ®, Modbus TCP , DeviceNet ™, and Profibus.No racks requiredA DIN-rail lets you add as many modules as desired. Just snap on, and slide into place. All connections are done automatically. Built-in displayAn integral LED display on some models provides user-assigned process monitoring, error messages, alarms, display counts and more.ELC Features and SpecificationsELC Controller Features and Specificationscontroller eLc-pB14nnDr/Dt eLc-pa10aaDr/Dt eLc-pc12nnar/Dr/Dt eLc-pH12nnDt eLc-pV28nnDr/Dt Dimensions WxHxD (mm) 25.2 x 90 x 60 37.4 x 90 x 60 70 x 90 x 60 Maximum I/O—Expandable up to 16 expansion modules (maximum of 8 analog/specialty modules)I/O Type—Embedded 14 (8 DI/6DO) 10 (4DI/2DO/2AI/2AO) 12 (8 DI/4 DO) 28 (16DI/12DO) DC In Sink/Source YesExecution Speed Basic instructions—2 µs minimum 0.24 µs minimum Program Language Instructions + Ladder Logic + SFCProgram Capacity (steps) 3792792015,872Data Memory Capacity (bits) 12804096Data Memory Capacity (words) 744500010,000 Index Registers 2816File Memory Capacity (words) None1600 Words 10,000 Words Retentive Storage YesCommands Basic/Advanced 32/107 32/168 32/193 Floating Point YesSFC Commands (steps) 1281024Timers Qty 128244 standard with additional timers for subroutine and retentive applicationsTimers Resolution1–100msCounters Qty 128 250 253High Speed Counters (See Note)Up to 4Up to 6Up to 8Up to 8Max High Speed Counting (See Note) 2 at 20 kHz 1 at 30 kHz 1 at 100 kHz 2 at 200 kHz Pulse Output 2 channels, 10 kHz Max 2 channels, 50 kHz Max 100 kHz 200 kHzPID YesMaster Control Loop 8 LoopsSubroutines 64 Subroutines 256 SubroutinesFor/Next Loops YesInterrupts 61522Real-time Clock / Calendar No Built-inPassword Security YesDiagnostic Relays YesDiagnostic Word Registers YesSpecialty Expansion Modules (Analog In/Analog Out/TC/RTD/PT) Up to a maximum of 8Serial Ports 2 Modbus (ASCII/RTU) 1=Slave (RS-232)/1=Master-Slave (RS-485)Remote I/O No With 16 other devices With 32 other devices Run Time Editing No YesRun / Stop Switch YesRemovable Terminal Strips YesSpecial Features —2, 7-Segment Displays 2 Potentiometers 2 PotentiometersHigh-speed, left side bus Note: High speed counter inputs can be used for different types of 32-bit counting, such as single-ended, single-phase two inputs, and quadrature.Therefore, all high speed counters may not be used at the same time. Please refer to the ELC Systems Manual, MN05003003E, for details.controller Module inputs outputs110 Vac 24 Vdcsink/sourceanalog relay24 Vdcsinking analogELC-PB14NNDR—8—6——ELC-PB14NNDT—8——6—ELC-PC12NNAR8——4——ELC-PC12NNDR—8—4——ELC-PC12NNDT—8——4—ELC-PA10AADR—422—2 ELC-PA10AADT—42—22 ELC-PH12NNDT—8——4—ELC-PV28NNDR—16—12——ELC-PV28NNDT—16——12—eaton corporation Programmable Logic Controller6ELC Expansion Module FeaturesDigital i/o Model power input Unit output Unitpoint type point typeDimensions WxHxD (mm) 25.2 x 90 x 60ELC-EX08NNAN24 Vdc 8110 Vac0—ELC-EX08NNDN8DC Sink or Source 0—ELC-EX08NNNR08Relay ELC-EX08NNNT08Transistor ELC-EX06NNNI06High Current Relay ELC-EX08NNDR44Relay ELC-EX16NNDR88ELC-EX08NNDT44Transistor ELC-EX16NNDT88analog i/o Model power input Unit output Unitpoint type point typeDimensions WxHxD (mm) 25.2 x 90 x 60ELC-AN02NANN24 Vdc 0—20~+20mA OV~+10VELC-AN04NANN04ELC-AN06AANN4–20mA~+20mA–10V~+10V 2ELC-AN04ANNN40—ELC-PT04ANNN4Platinum Temp.0ELC-TC04ANNN4Thermocouple0 Electrical SpecificationsInput Voltage Requirements ELC: 24 Vdc (–15%~+20%) (with DC input reverse polarity protection), Expansion Unit: supplied by the ELCPower Consumption Typically 3–6WInsulation Resistance>5 MΩ at 500 Vdc (Between all inputs/outputs and earth)Noise Immunity ESD: 8 kV Air Discharge EFT: Power Line 2 kV, Digital I/O: 1 kV, Analog & Communication I/O: 1 kV Damped-Oscillatory Wave: Power Line: 1 kV, Digital I/O: 1 kV RS: 26 MHz–1 GHz, 10 V/mTemperature Operation: 0ºC~55ºC (Temperature), 50~95% (Humidity), Pollution degree 2; Storage: –40ºC~70ºC (Temperature), 5~95% (Humidity)Vibration/ShockResistanceStandard: IEC1131-2, IEC 68-2-6 (TEST Fc)/IEC1131-2 & IEC 68-2-27 (TEST Ea)Certifications C-Tick, cULus, CE, Class I Div 2 Groups A, B, C, DELC Accessoriescatalog number DescriptionELC-PS0124 Watt, 1 Amp Power SupplyELC-PS0248 Watt, 2 Amp Power SupplyELC-HHP Hand-Held Programmer (includes cable)ELC-CBPCELC1Cable to connect a PC or ELC-GP unit to ELC, 1 meter with right angle connector (DB9 pin female to 8-pin DIN)ELC-CBPCELC3Cable to Connect a PC or ELC-GP unit to ELC, 3 meters (DB9 pin female to 8-pin DIN)ELC-CBPCGP3Cable to Connect a PC to an ELC-GP unit, 3 meters (DB9 pin female to DB9 pin female)ELC-GPXFERMOD Program transfer module for ELC-GP unitsELC-ACPGMXFR Program transfer module for ELC controllersELC-ACCOVER Plate mount for specialty modules, qty. 10ELCSTARTKIT1ELC Starter Kit (includes ECL-PA10AADT, ELC-PS01, ELC-GP04, ELC-CBPCELC3,ELC-CBPCGP3, ELCSoft, ELCSoft GP)ELC-COENETM10/100 Ethernet Module, need ELC-PV, ModbusTCP, P-P, for use with ELC-PV onlyELC-CODNETM DeviceNet Module, need ELC-PV, Scanner, Poll, CC, COS, BS, for use with ELC-PV onlyELC-COPBDP Profibus DP Slave ModuleELC-CODNET DeviceNet Slave ModuleELC-485APTR RS-485 Easy Connect Adapter, DB9, RJ-12, 2-Pin Connections to RS-485ELC-MC01Motion Control, 1 Axis Module (Up to 8 Modules per Controller)eaton corporation Programmable Logic Controller7Eaton Corporation Electrical Sector1111 Superior Ave. Cleveland, OH 44114United States877-ETN-CARE (877-386-2273) © 2010 Eaton CorporationAll Rights ReservedPrinted in USAPublication No. BR05003001E / MZ588 March 2010PowerChain Management is a registered trademark of Eaton Corporation.All other trademarks are property of theirrespective owners.Eaton’s Electrical Sectoris a global leader in power distribution, power quality, control and automation, and monitoring products. When combined with Eaton’s full-scale engineering services, these products provide customer-driven PowerChain™ solutions to serve the power system needs of the data center, industrial, institutional, public sector, utility, commercial, residential, IT, mission critical, alternative energy and OEM markets worldwide. PowerChain solutions help enterprises achieve sustainable and competitive advantages through proactive management of the power system as a strategic, integrated asset throughout its life cycle, resulting in enhanced safety, greater reliability and energy efficiency. For more information, visit /electrical.。

12864](https://uimg.taocdn.com/3b7b4f57f01dc281e53af0ac.webp)

CONTROLEDGE™The ControlEdge HC900 is fully validated to perform its safety tasks, and is certified by TUV for use in a SIL-2 environment. The system isideal for a process/safety environment. Its non-interfering software meansthat the ControlEdge HC900 system iscapable of hosting process control andsafety applications, providing control,monitoring, password protectionfor configuration, alarm processingand data acquisition for processapplications thus adding to reliabledata and information being stored andprotected.TUV Compliance TYPICAL INDUSTRIES• Chemicals (including specialty andfine chemicals, plastics and rubber)• Life sciences and Cosmetics• Power (excluding nuclear)• Cement and Glass• Pulp and Paper• Mining and Metals• Water and Wastewater• Food and Beverage• Heat Treatment• Buildings/ Infrastructure-Metro Rail, HVAC etc.CUSTOMER BENEFITSProven & ReliableMaximizes uptime• Proven track record• Redundancy• G3 conformal coating forharsh environment• RoHS compliant• Actionable informationHigh PerformanceIncreases profitability• Tighter control• Reduced scrap• Higher throughputEasy to Use & EngineerLowers operational costs• Easy engineering• Faster startup• Simple intuitive tools• No additional maintenance feesEnhanced Safetywith SIL2 certification• Common hardware andsoftware for process and safety• Improved plant safetyTYPICAL APPLICATIONSSafety• Burner Management Systems (e.g.furnaces, boilers, ovens, pre-heaters,reactors, calciners, dryers, thermaloxidizers, kilns, melters, incinerators,process heaters, vaporizers)• Combustion Control• Pipeline Monitoring• Spill Prevention• Metro/ Road Transportation-Tunnel Safety, Ventilation• Wastewater Treatment• Terminal Automation• Emergency Shutdown• Fire & Gas Monitoring• Pressure and Flow ControlCritical Control• Electronics & SemiConductor• Cement and Glass• TextilesCertifications• TUV SIL2• CSA-Canada and USA(HazLoc) / FM CL1 / Div2• ATEX• ABS• UL• CE• RoHSsuch as burner management systems (BMS), emergency shutdown systems (ESD), fire & gas monitoring, pipeline monitoring, spill prevention, tunnel ventilation, etc.MUL TIPLE SYSTEMS,MUL TIPLE I/O RACKSControlEdge HC900 Hot Stand-by ArchitectureCPU CapacityControlEdge HC900 Designer Software• Configuration: ControlEdge HC900 Controller – offline with run-mode editing • Operating environment: Windows 7 Pro (32 or 64-Bit), Win 8 and Win 10• PC: Pentium, 1.5 GHz with 1 GB RAM minimum, SVGA or greater screen resolution • English and Mandarin languages supported (switchable after installation)• Cable: RS 485 – three-wire, Ethernet 10/100 base T • Modem support: Monitor, upload, download configuration• New input voting (1oo2 and 2oo3) and outputvalidation function blocks (with feedback verification)• New non-interfering process and safety worksheets in • Change management and Version Control built into the software same configuration• Function Blocks: C70, C75 CPU–15000, C50 CPU–2000, C30 CPU–400• Controller C75 CPU supports redundancy (in common and separate rack). Redundant CPU racks can be placed at least 1km apart • Analog Inputs: Up to 1152 universal analog inputs, 2304 high level, A/D Resolution is ±15 Bits • Accuracy: 0.1% of span(field calibration to ±0.05% of span)• Analog Outputs: Up to 480 withinternal power, 2304 with external power 0 to 20 mA maximum, 0.1% accuracy • Universal SIL IO Module (UIO)- 16 channel, with 1ms SOE, HART, Line Monitoring, Voting & Validation and IO redundancy • HART-IP support for improved device diagnostics and easy maintenance • Digital Inputs / Outputs: Up to 4608, contact DI, 24 Vdc DI / DO, 120VacDI /DO, 240 Vac DI/DO • Total I/O: Up to 4608• I/O Racks per System: One controller and up to 11 remote I/O racks• Control Loops: PID, on/off, cascade, ratio, %C, three-position step• Control Output Types: Current, time -proportioning, position-proportioning, three-position steps • New Input Voting (1oo2 and 2oo3) and outputvalidation function blocks (with feedback verification)• Setpoint Programmers: 50 segments each, 16 event outputs, multiple stored profiles • Setpoint Scheduler: 50 segments, 8 ramp / soak outputs, eight auxiliary outputs, 16 events, multiple schedules• Communications: Ethernet 10 / 100/ base T,Modbus / TCP protocol, up to 10 Ethernet hosts on C50, C70, C75 up to 32 peer-to-peer controllers, Serial Modbus RTU, RS485, slave or master operation (up to 32 slaves), HART-IP for Analog signals • Operating Temp: Rated 32° to 140°F (0° to 60°C)• Humidity: Rated 10% RH to 90% RH, non-condensingControllerMODULAR AND SCALABLE• Available in three rack sizes and three CPU performance levels• Handles a wide range of automation requirements• Analog and digital modules support up to 4608 I/O points • Scalable and expandable• Easy to own, engineer,operate and maintain•Upto 12 racks and 4608 IO’sFUNCTION BLOCKS• Simplify execution of complex control strategies• Over 125 different types of softwarefunction blocks available• Each function block represents a uniquealgorithm for a specific control function• Available CPU options support up to 400,2,000 or 15,000 function blocks• Simply drag and drop, and soft-wire• 1oo2 and 2oo3 Voting Function Blocks.DO-V and AO-V (Digital Output and AnalogOutput Validation Function blocks).SEPARATE PROCESS SAFETY WORKSHEETS• Same type of controller can be used for process andsafety applications thus reducing total cost of ownership• Provisions are provided within programming environmentto program using safety/process worksheetsUNIVERSAL ANALOG INPUTS• Accept both direct and indirect inputs from sensors• Minimize the number of input cardsand spare parts required• Inputs may be mixed on a module and mayinclude multiple thermocouple types, RTDs,ohms, voltage or millivoltage types.SIL UNIVERSAL IO MODULE• 16 channel user configurable to DI, DO, AI or AO• High resolution SOE with 1 ms time stamp• Line Monitoring (Open Wire, Short Circuit Detection)• HART support for Analog signals• In-built Voting & ValidationCONTROL LOOPS• Provide tighter, more accurateprocess control• Include applications ranging from single loop control to interactive cascade, ratio, duplex, feed-forward, three-position-step, or custom controlled strategies • Increase throughput, reduce scrap, and minimize energy costs•Quantity of loops per controller is not limitedFUZZY OVERSHOOT SUPPRESSION• Fuzzy Overshoot Suppression minimizesthe Process Variable (PV) overshootfollowing a Setpoint (SP) change or aprocess disturbance. This is especiallyuseful in processes that experienceload changes or where even a smallovershoot beyond the setpoint mayresult in damage or product loss.• The Fuzzy Logic in the controller observesthe speed and direction of the PV signalas it approaches the setpoint andtemporarily modifies the internal controllerresponse action as necessary to avoidan overshoot. There is no change to thePID algorithm, and the Fuzzy Logic doesnot alter the PID tuning parameters.CARBON POTENTIAL• The carbon potential of the furnaceatmosphere can be controlled bymonitoring the furnace temperature andthe probe output because oxygen potentialdirectly relates to the carbon potential.A combined carbon probe, temperatureprobe and PID algorithm determinecarbon potential of furnace atmospheresbased on a zirconium probe input.• Activates anti-sooting feature thatlimits the working setpoint of thecarbon control loop to a value thatprevents sooting in the furnace.FREE-FORMAT LOGIC• Optimizes design by combining multiple logic functions into one • Simplifies operation and troubleshootingSEQUENCERS• Control the output states ofmultiple digital parameters• Control the sequence of process operation based on time or process events • Each sequencer supports up to 16 digital outputs and may have up to 50 process states • Multiple sequences can be selected on demand from the operator interface oras part of a recipeRECIPES• Stored in the controller memory • Ensure error-free product/process changeovers• Write values into analog and digital variables • Load via Control Station • Load via RCP block • Can be used to:– Write a value to any variable – Load setpoints– Select setpoint programs – Set alarm limits– Activate control valvesSETPOINT PROGRAMMER• Automatically manipulates a setpoint value for use by PID loops • Creates a time / value profile for process batch control• Multiple setpoint programmers, with profiles of up to 50 segments each, may be configured and stored • Any programmer may run any profile separately or simultaneously• Each also has an auxiliary soak output and up to 16 event outputs for integration with sequence control functionsDEW POINT CONTROL• Dew point analysis measures the amount of water vapor present which in turn helps determine the carbon potential of a furnace atmosphere • This application uses the dew point function block to calculate dew point based on using a carbon probe where the input is an O2 sensor • A typical example is control of an endothermic atmosphere generator when the user requires dew point for PVSETPOINT SCHEDULER• Provides up to eight ramp/soak setpoints that operate on a common time base • Supports up to 16event digital outputs 50 segments per schedule; the number of storedschedules is configurable • Auxiliary Scheduler provides an additional 8 Soak Setpoints • Multiple independent setpoint schedulers areavailable in a configurationREDUNDANCY• Maximize process availability by providing backupcontrollers, power supplies and communications for seamless failover under fault conditions • Redundant Switch Module (RSM) is located in the rack between two CPUs and visuallyindicates which CPU is the lead and which is the reserve• Key switch on the RSM allows the user to change the operating mode of the lead and reserve CPUs • Ethernet network ports are continuously active on the leadcontroller, each on a different subnet • Transfer of communicationsfrom one port to another port on the same CPU is handled by the host application • A secondary power supply can also be added to eachControlEdge 900 Platform I/O rack for standby redundancy • Supports redundant I/Oconfiguration in Universal ModuleAMS COMPLIANCE• The ControlEdge HC900 meets AMS 2750E, the key requirement for controlling, monitoring and recording instruments, which is acalibrated accuracy (± 2° F/1.1°C)FLEXIBLECONNECTIVITY SUITS YOUR PROCESSENVIRONMENTOPEN ETHERNET CONNECTIVITY• Enables ControlEdge HC900 controllers to communicate with their host interfaces and each other • Open Modbus / TCP protocol allows interfacing to most popular HMI, data acquisition and OPC software • Up to 10 device connections are supported on the host Ethernet port • ControlEdge HC900 network of controllers and operator interfaces are partitioned into segments on the network to maximize communication performanceSERIAL ETHERNET CONNECTIVITY• Allows two RS485 ports to be configured as Modbusslaves, while one of the ports is selected as a Modbus master • Wide variety of devices (touch panel operator interfaces, I/O devices, etc.) can be connected to the controller • Provides greater flexibility in system designCONNECTIVITY AND COMMUNICATIONS• Adapts to existing process-line infrastructure • Satisfies specific control requirements• Accommodates specialtyapplicationsPEER-TO-PEER COMMUNICATIONS• The improved ControlEdge HC900 controllers provide peer-to-peer interface between a maximum of 32 units for process/safetyequipment applications that require sharing data between controllers.• Up to 2,240 parameters per controller may be exchanged • Standard Ethernet communication port supports concurrent peer-to-peer communications andconnectivity to supervisory systems• Peer-peer between safety systems is done using the new Safety-peer protocol that can exchange safety critical data between peersINTEGRATION WITH EXPERION• ControlEdge HC900 controllers can be integrated with the Honeywell Experion DCS system for supervisory control and data acquisition• Can be integrated with Experion PKS, LX and HS systems Configured using Quick Builder application • Uses Universal Modbus Driver for communication • Redundant controllers can also be integrated with ExperionCONTROLEDGE HC900 OPC SERVER FROM MATRIKONOPC• Provides secure and reliable real-time data access between the ControlEdge HC900 Controller and any OPC-enabled applications such as Historians, HMIs, SCADA etc.• Enables 3rd party connectivity for successful phased migration and integration • Enables easy and cost-efficient management of openly connected systemsBUILDING-BLOCK CONFIGURATION SIMPLIFIES CONTROLIMPLEMENTATIONCONTROLEDGE HC900 DESIGNER SOFTWARE• Enables system configuration with a Windows 7 (32 or 64-bit), Win 8 and Win 10 based PC • English and Mandarin languages supported (switchable after installation) • Uses drag-and-drop placement techniques for graphic icons and soft-wiring connections between function blocks • Automatically calculates memory usage and processor scan time as function blocks are configured • User-friendly graphic development allows partitioning of the control strategy into multiple worksheets• Ease of record-keeping, faster access to functional areas during programming • Better support for user-specified process function identificationsCONFIGURATION DEBUG TOOLS• Simplify troubleshooting Include online monitoring of multiplefunction blocks on a single display, on/off identification of digital signal flow connections, and output forcing capability for most block outputs • Selectable user-defined Watch Windows and Signal Trace-back provide a clear view of the configuration operation and quick identification of potential errorsPRINTABLE PRESENTATION FORMATS• Simplify configuration documentation• Include a summary of controller I/O, the graphic configuration diagram, function block properties, recipe groups, setpoint profile groups, operator display and point selectionRUN-MODECONFIGURATION EDITING• Standard feature that cansignificantly reduce start-up time and avoid costly process shutdowns• History Backfill: If Experion HS loses communication with ControlEdge HC900 the History backfill functionality will backfill data to the HMI once communication is restored. This feature is very important for food and beverage, pharmaceutical and other data critical applications and is not often provided by other general purpose PLC’s• Paired with Experion HS,ControlEdge HC900 can meet FDA 21 CFR part 11 requirements for pharmaceuticals, food and beverage industry that need a proven and reliable solution capable of change management, automated electronic recordkeeping, and advanced controller security and protection methods • Seamless integration with FDM for HART signalsSYSTEMCONFIGURATION AND OPERATION ADAPT TO YOUR NEEDSThe 900 Control Station operator interfaceStandard displays provided inControlEdge HC900 Control Station• NEMA Type 4X operator interface screen withstands harsh operating environments • Easy-to-operate 10” and 15” touch screen display • Standard and custom graphic elements can be assembled into specific displays, for fast and easy start-up• Custom graphics tools let you select from 4,000+ pre-built objects for animation support, math, formulas, scripting• Function block widgets accelerate configuration development • Controller status displays verify system integrity, with no configuration required• Recipe selection makesproduct/process changeovers simple and accurate • Trending and data logging is provided via SD card storage • Multi-level log-on security feature prevents unauthorized access • Alarm/Event logging withe-mail notification of impending problems tracks process upsets and validates performance • Ethernet or serial connectivity enhance installation flexibility, includes Modbus and Modbus\TCP protocol support • Embedded web serverfeature allows access to your application from anywhere• Multiple interfaces on each controller enableprocess management from up to three locations• Multilingual: English, French, Italian, German, Spanish. Other languages may be added by expanding its lexicon library• The software also supportsaccessing the translation libraries of Microsoft® and / or Google® for any untranslatable text strings used in the product during configuration • Setpoint Programmer Pre-PlotDisplay: Pre-plot display is a Widget that gets bound to a Setpoint Programmer function block • Concurrent Batch Reports: Schedules multiple batch reports to run concurrentlyOPERATOR INTERFACE FEATURESStandard displays in station designer 4 - WidgetsGraphic symbols provided in Station Designer software tosimplify configuration. Hundreds of icons availableincluding pumps, valves, and tanks icons shown.CONTROL STATION OPERATOR INTERFACE• The 900 Control Station is available with either a 10.4 inch (254 mm) or 15 inch (381mm) display size • LCD Display: 10” (800 x 600), 15” (1024 x 768) pixels, color active matrix thin film transistor (TFT), 16M colors • Touch Screen: Resistive analog• Backlight: 50,000 hr typical lifetime at room temperature (field replaceable in non-hazardous locations)• Distance from Controller: Ethernet-328 ft (100 m), RS485 - 2000ft (600 m) RS232 - 50ft (15.24 m)• Power Supply 10 inch: 24 Vdc, 16 Watts maximum 15 inch 22 Watts maximum without options • Operating Temperature: 14 to 122 °F, (-10 to 50 °C)• Humidity: Rated 0 to 85%, non-condensing from 14 to 122 °F, (-10 to 50 °C)• Panel Rating: Type 4X / IP66• Memory: 512MB onboard non-volatile flash, optional SD card• Communication Ports: 10 inch (254 mm) 1 x Ethernet RJ45 10/100 base T, 15 inch (381mm) 2 x Ethernet 10/100 base T, 2 x RS-485, 2 x RS232 Serial • USB Ports: 2 x USB specification 2.0 host port, type A, 1 x USB specification 2.0 device port type B900 STATION DESIGNER SOFTWARE• Configuration: 900 control station CR interface – offline • Operating environment: Windows 7 (32, 64-bit), Windows 8, Windows 10• PC: Pentium class processor and RAM as required by the chosen operating system plus 50MB for software installation, 800 by 600 pixels minimum, 256 or more colors. RS-232 or USB port•Cable: USB Host, RS232 Serial, Ethernet 10/100 base TEASY ENGINEERING AND FLEXIBILITY THROUGH USER FRIENDL Y TOOLSCONFIGURATION COMPARISON• Change management • Save engineering hours in finding previous changesBULK EDIT• Reduces engineering hoursVERSION CONTROL• Easy tracking, de-bugging • Revert to earlier versions • Save dollars for a separate version control offeringPASTE SPECIAL• Saves 15-20% of engineering effortsCHANGEMANAGEMENT• Manage versions, track and compare configurations • Easier troubleshooting thereby reducing maintenance costsPASSWORD PROTECTION• Controllers are password protected and thus prevents any intrusion through the network • Any changes to thecontroller are monitored and validated with credentialsRE-USABLE CUSTOM LIBRARIES• Save engineeringtime, create logic once and avoid errorsControlEdge™ is a trademark and Experion® is a registered trademark of Honeywell International Inc.BR -20-42-ENG | 10/2020© 2020 Honeywell International Inc.For more informationTo learn more about Honeywell’s ControlEdge HC900, visit or contact your Honeywell account manager.Honeywell Process Solutions2101 CityWest Blvd, Houston TX 77042Honeywell House, Skimped Hill Lane Bracknell, Berkshire, England RG12 1EB UK Building #1, 555 Huanke Road, Zhangjiang Hi-Tech Industrial Park, Pudong New Area, Shanghai 。

________________________________________________________________________________________1清達光電技術有限公司TSINGTEK DISPLAY CO.,LTDLCD CONTROLLER & DRIVERST7920 OR EQUIVALENT公司地址:杭州市文三路569号康新花园A座703公司电话:0571-******** 85121742 85121304(f)(总公司)62000662 62366871(f)(北京分部)门市地址:杭州市登云路639号杭州电子市场2A095/K31 门市电话:0571-******** 89902095(f)网址:目录使用须知 3 第一章液晶模块汇总 6 第二章液晶模块的结构特点7 第三章液晶模块供电说明9 第四章液晶模块控制器介绍10 第五章液晶模块指令系统24 第六章液晶模块接口技术及测试程序31 第七章液晶模块调试经验41 附录一清达光电配套产品42 附录二清达光电维修服务规范42 附录三液晶模块内部字符集432________________________________________________________________________________________3使用须知十分感谢您购买我公司的产品,因为液晶模块属于精密器件,结构复杂、工艺精细,所以在使用前请您首先仔细阅读以下注意事项,以免给您造成不必要的损失。

您在使用过程中遇到困难时,请拨打我们的技术服务电话,我们将竭诚为您提供服务和帮助。

一、处理保护膜在装好的模块成品表面贴有一层保护膜,以防在装配时沾污显示屏表面,在整机装配结束前不得揭去,以免弄脏或划商显示屏表面。

二、加装衬垫在模块与前面板之间最好加装一块约0.1毫米左右的衬垫。

面板还应保持平整,以免在装配后产生扭曲,并可提高其抗振性能。

试验台、通风柜柜技术指标技术规定:技术参数规定中带▲符号旳为本次台柜设备配套项目重要技术参数规定,必须提供有关汇报或者证明文献证明设备符合规定。

(一)试验家俱材质规定1.试验台、中央台---(钢木构造)1.1、试验台台面参照品牌:上海榕德(roadlab)、费亚泰克(friatec)和德国赛试验台台面主材阐明:采用20mm厚试验室工业陶瓷板台面。

采用高温一体烧制成型,耐1550℃极限高温,耐强酸、强碱、强有机溶剂、染色剂等多种化学试剂,耐刮磨,耐高温,抗明火,抗污染,抗菌,抗变形,经久耐用,无需维护,安全环境保护,其中所有水池台台面采用碟形工艺,操作面部分整体下凹5mm 翘边,总厚度25mm,配置同品牌试验室专用570*470*350mm陶瓷水槽,防止有害液体外溢,有效保持台面美观。

投标时需提供如下相对应检测汇报及资质文献:▲环境保护性能:需提供辐射限量检测汇报,参照GB6566《建筑材料放射性核素限量》原则,检测成果必须符合:内照射指数≤0.4。

▲化学性能:需提供及持续2年SGS机构出具旳耐腐蚀检测汇报:参照SEFA3-科学设备及家俱协会-试验室工作台面条款2.1台面检测原则,台面至少抗“47”种以上化学品且检测成果为0级(表面无变化)旳检测汇报。

▲物理性能:台面旳耐污染性能:需提供提供国家建筑材料测试中心出具旳GB/T4100-检测汇报出具旳测试项目为“吸水率”检测汇报,测试成果最大值不得不小于0.03%。

▲高温性能:需提供耐极限高温到达1500度以上旳国家级检测汇报。

1.2、▲柜体:柜体:采用≥15mm厚优质高密度中纤板面贴三聚氰胺板,所有断面经优质2mm厚度pvc封边防水处理,中纤板静曲强度≥15.0mpa,甲醛释放量≤0.5mpa,吸水厚度膨胀率≤0.5%。

(投标供应商须提供以上参数旳CMA或CAL机构出具旳检测汇报,检测汇报中须附产品旳实物照片)1.3、铰链:采用110°铰链,弹性好,使用过程中无噪音,耐酸碱、耐腐蚀,使用寿命长。

U S e aloja en una carcasade metal resistente para uso en campoU I nterfaz de ordenadorRS232 para la transferencia de datos y programas o el control en tiempo realU A lta precisión yestabilidad para la certificación de los sensores de temperatura y los termostatos hidráulicosU G ran formato deinserción intercambiable para la flexibilidad de usoU T iempos de calentamientoy enfriamiento rápidos U U niformidad yestabilidad del control de la zona de la temperatura mejoradasU R esolución de pantalla:0,01U I ncluye certificado decalibración rastreable por NISTLos modelos de la serie CL-700A se envían listos para su uso inmediato y vienen completos de serie con inserción para pozos múltiples, cable de corriente CA, herramienta de extracción de inserción, calibración rastreable por NIST e interfaz RS232. El rango de la serie CL-700A está protegido por una garantía de piezas y mano de obra de 3 años. Los modelos de la serie CL-700A utilizan las mismas inserciones que los modelos anteriores para poder actualizarlos fácilmente sin necesidad de sustituir las inserciones personalizadas que usted Serie CL-780ACalibradores de bloque seco El calibrador de bloque de OMEGA cuenta con una carcasa más resistente y ligeraK-37pueda tener. Vea la serie CL-700A en /cl-700a para obtener un listado de las inserciones. Para quienes deseen poner en marcha una unidad desde un ordenador, ofrecemos elsoftware Calsoft que puede descargarse gratuitamente en /cl-780a.El modelo CL-780A se muestra en un tamaño inferior al real.El modelo CL-780A se muestra en un tamaño inferior al real.K-381 inserción para pozos múltiples (1⁄8, 3⁄16, 1⁄4, 5⁄16, 3⁄8"), calibración rastreable por NIST , interfaz RS232C y manual del operador.Ejemplos de pedidos: CL-770A, calibrador de bloque de 120 V , 900 W, 50/60 Hz y CL7A-CASE, estuche portátil blando.CL780A, calibrador de bloque de 120 V , 900 W, 50/60 Hz. OCW-2, OMEGACARE SM extiendela garantía estándar de 3 años a un total de 5 años. Especificaciones CL-770A Temperatura mínima:45 °C (113 °F) inferior a ambiente Temperatura máxima:140 °C (284 °F)Precisión de temperatura:±0,3 °C (32,5 °F)Uniformidad de temperatura (radial): ±0,2 °C (32,3 °F)Estabilidad de temperatura (después de 10 minutos): ±0,05 °C (32,09 °F)Resolución de pantalla:0,01 °C o 0,1 °F Resolución del punto de referencia: 0,1 °C o 0,1 °F Velocidad de calentamiento, 20 a 100 °C (68 a 212 °F):5 minutos Velocidad de enfriamiento, 100 a 0 °C (212 a 32 °F): 9 minutosInserciones para pozos grandes:38 x 114,3 mm (1,5 x 4,5")Dimensiones:267 de alto x 206 de ancho x 290 mm de profundidad (10,7 x 8,1 x 11,4")Peso: 12,7 kg (28 lb))Interfaz RS232: IncluidaCL-780A Temperatura mínima:20 °C (68 °F) superior a ambiente Temperatura máxima:425 °C (797 °F)Precisión de temperatura:±0,3 °C (32,5 °F)Uniformidad de temperatura (radial): ±0,2 °C (32,3 °F)Estabilidad de temperatura (después de 10 minutos): 200 °C (392 °F): ±0,03 °C425 °C (797 °F): ±0,05 °CResolución de pantalla:0,01 °C o 0,1 °F Resolución del punto de referencia: 0,1 °C o 0,1 °F Velocidad de calentamiento, 20 a 400 °C: 12 minutos Velocidad de enfriamiento, 400 a 100 °C: 21 minutos Inserciones para pozos grandes:38 x 114,3 mm (1,5 x 4,5")Dimensiones:269 de alto x 170 de ancho x 254 mm de profundidad (10,6 x 6,7 x 10,0")Peso: 6,3 kg (14 lb)Interfaz RS232: IncluidaCL-790A Temperatura mínima: 25 °C (77 °F) superior a ambiente Temperatura máxima: 650 °C (1.202 °F)Precisión de temperatura:±0,4 °C (32,7 °F)Uniformidad de temperatura (radial): ±1,0 °C (33,8 °F)Estabilidad de temperatura (después de 10 minutos):±0,09 °C (32,2 °F)Resolución de pantalla: 0,01 °C o 0,1 °F Resolución del punto de referencia: 0,1 °C o 0,1 °F Velocidad de calentamiento, 20 a 600 °C: 24 minutosVelocidad de enfriamiento, 600 a 200 °C: 21 minutosInserciones para pozos grandes: 38 x 152 mm (1,5 x 6,0")Dimensiones: 277 de alto x 170 de ancho x 300 mm de profundidad (10,9 x 6,7 x 11,8")Peso: 10,8 kg (24 lb)Interfaz RS232: Incluida。

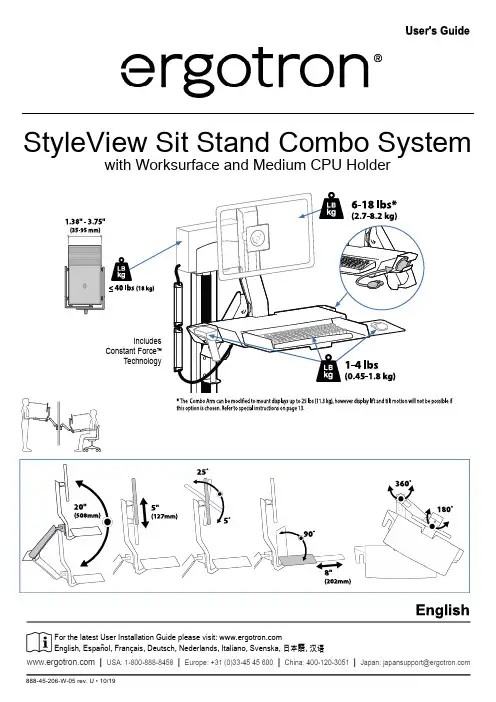

English, Español, Français, Deutsch, Nederlands, Italiano, Svenska, 日本語, 汉语For the latest User Installation Guide please visit: Important! You will need to adjust this product after installation is complete. Make sure all your equipment is properlyinstalled on the product before attempting adjustments. This product should move smoothly and easily through thefull range of motion and stay where you set it. If movements are too easy or diffi cult or if product does not stay indesired positions, follow the adjustment instructions to create smooth and easy movements. Depending on yourproduct and the adjustment, it may take many turns to notice a diff erence. Any time equipment is added or removedfrom this product, resulting in a change in the weight of the mounted load, you should repeat these adjustment stepsto ensure safe and optimum operation.Tools NeededComponentsAdjustment StepImportant! You will need to adjust this product after installation is complete. Make sure all your equipment is properly installed on the product before attempting adjustments. This product should move smoothly and easily through the full range of motion and stay where you set it. If movements are too easy or diffi cult or if product does not stay in desired positions, follow the adjustment instructions to create smooth and easy movements. Depending on your product and the adjustment, it may take many turns to notice a diff erence. Any time equipment is added or removed from this product, resulting in a change in the weight of the mounted load, you should repeat these adjustment steps to ensure safe and optimum operation.Increase Lift StrengthIf the mounted weight is too heavy or this product does not stay up whenraised, then you'll need to increase Lift Strength:Decrease Lift StrengthIf the mounted weight is too light orthis product does not stay down when lowered, then you'll need to decreaseLift Strength:Increase Lift StrengthIf the mounted weight is too heavy orthis product does not stay up whenraised, then you'll need to increaseLift Strength:Decrease Lift StrengthIf the mounted weight is too light or this product does not stay down when lowered, then you'll need to decreaseLift Strength:© 2014 Ergotron, Inc. All rights reserved. For local customer care phone numbers visit: For Service visit: For Warranty visit: /warrantyLearn more about ergonomic computer use at:Set Your Workstation to Work For YOU!Height Position top of screen slightly below eye level.Position keyboard at about elbow height with wrists fl at. Distance Position screen an arm's length from face—at least 20” (508mm).Position keyboard close enough to create a 90˚ angle in elbow.Angle Tilt screen to eliminate glare. Tilt the keyboard back 10° so that your wrists remain fl at.To Reduce FatigueBreathe - Breathe deeply through your nose.Blink - Blink often to avoid dry eyes.Break • 2 to 3 minutes every 20 minutes • 15 to 20 minutes every 2 hours.。

毕业设计(论文)课题名称常减压装置减压塔工段自动控制工程设计姓名XXXXX学号XXXXXXXX系(分院) 自动化系专业生产过程自动化技术班级自动化XXXX指导教师XXXXX企业指导教师2017年5月日XXXXXXXXXXXXXXXXXXXXXX毕业论文声明本人郑重声明:毕业论文及毕业设计工作是由本人在指导教师的指导下独立完成,尽我所知,在完成论文时利用的一切资料均已在参考文献中列出。

若有不实之处,一切后果均由本人承担(包括接受毕业论文成绩不及格,不能按时获得毕业证书等),与毕业论文指导老师无关。

论文题目:专业班级:作者签名:日期:目录毕业论文声明 (I)摘要 (VI)1常减压装置减压塔工段工艺流程简介 (1)1.1装置概况 (1)1.2工艺原理 (1)2 常减压装置减压塔工段主要设备及控制指标 (4)2.1 主要设备列表 (4)2.2主要调节器 (4)2.3仪表显示 (5)3 常减压装置减压塔工段DCS图 (6)4 常减压减压塔自动控制工程设计 (8)4.1设备EH-501 TIC-501(A)控制系统设计 (8)4.1.1测量仪表的选择 (8)4.1.2控制器的选择 (8)4.1.3安全栅的选择 (8)4.1.4执行器的选择 (9)4.1.5设备EH-501 TIC-501(A)控制系统设计的常规仪表回路 (9)4.2设备EH-502 TIC-502(A)控制系统设计 (1)4.2.1测量仪表的选择 (1)4.2.2控制器的选择 (1)4.2.3安全栅的选择 (1)4.2.4执行器的选择 (2)4.2.5设备EH-501 TIC-502(A)控制系统设计的常规仪表回路 (2)4.3设备N8 FIC-507(M)控制系统设计 (4)4.3.1测量仪表的选择 (4)4.3.2控制器的选择 (4)4.3.3安全栅的选择 (4)4.3.4执行器的选择 (4)4.3.5设备N8 FIC-507(M)控制系统设计的常规仪表回路 (5)4.4设备N9 FIC-508(M)控制系统设计 (7)4.4.1测量仪表的选择 (7)4.4.2控制器的选择 (7)4.4.3安全栅的选择 (7)4.4.4执行器的选择 (7)4.4.5设备N9 FIC-508(M)控制系统设计的常规仪表回路 (7)4.5设备N10 FIC-509(M)控制系统设计 (9)4.5.1测量仪表的选择 (9)4.5.2控制器选用 (9)4.5.4执行器的选择 (10)4.5.5设备N10 FIC-509(M)控制系统设计的常规仪表回路图 (10)4.6设备N11 FIC-510(M)控制系统设计 (12)4.6.1测量仪表的选择 (12)4.6.2控制器的选择 (12)4.6.3安全栅的选择 (12)4.6.4执行器的选择 (13)4.6.5设备N11 FIC-510(M)控制系统设计的常规仪表回路图 (13)4.7设备V A LIC-501(A)控制系统设计 (15)4.7.1测量仪表的选择 (15)4.7.2控制器的选择 (15)4.7.3安全栅的选择 (16)4.7.4执行器的选择 (16)4.7.5设备V A LIC-501(A)控制系统设计的常规仪表回路图 (16)4.8 设备T5 LIC-502(A)控制系统设计 (18)4.8.1测量仪表的选择 (18)4.8.2控制器的选择 (18)4.8.3安全栅的选择 (19)4.8.4执行器的选择 (19)4.8.5设备T5 LIC-502(A)控制系统设计的常规仪表回路图 (19)4.9设备T5 LIC-503(A)控制系统设计 (21)4.9.1测量仪表的选择 (21)图4-27 数显压力变送器产AKT-3815智能型差压变送器外观 (21)4.9.2控制器的选择 (21)4.9.4执行器的选择 (22)4.9.5设备T5 LIC-503(A)控制系统设计的常规仪表回路图 (22)4.10设备T5 LIC-504(A)控制系统设计 (24)4.10.1测量仪表的选择 (24)4.10.2控制器的选择 (24)4.10.3安全栅的选择 (24)4.10.4执行器的选择 (24)4.10.5设备T5 LIC-504(A)控制系统设计的常规仪表回路图 (25)4.11设备T5 FIC-506(M)控制系统设计 (26)4.11.1测量仪表的选择 (26)4.11.2控制器的选择 (26)4.11.5设备T5 FIC-506(M)控制系统设计的常规仪表回路图 (27)4.12设备T4 FIC-501(M)控制系统设计 (29)4.12.1测量仪表的选择 (29)4.12.2控制器的选择 (29)4.12.3安全栅的选择 (29)4.12.5设备T4 FIC-501(M)控制系统设计的常规仪表回路图 (29)4.13设备T4 FIC-502(M)控制系统设计 (31)4.13.1测量仪表的选择 (31)4.13.2控制器的选择 (31)4.13.3安全栅的选择 (31)4.13.4执行器的选择 (32)4.13.5设备T4 FIC-502(M)控制系统设计的常规仪表回路图 (32)4.14 设备T4 FIC-503(M)控制系统设计 (34)4.14.1测量仪表的选择 (34)4.14.2控制器的选择 (34)4.14.3安全栅的选择 (34)4.14.4执行器的选择 (35)4.14.5设备T4 FIC-503(M)控制系统设计的常规仪表回路图 (35)4.15设备T4 TIC-503(A)和FIC-504(C)串级控制系统设计 (37)4.15.1测量仪表的选择 (37)4.15.2控制器的选择 (37)4.15.3安全栅的选择 (37)4.15.4执行器的选择 (38)4.15.5设备T4 TIC-503(A)和FIC-504(C)串级控制系统设计的常规仪表回路图 (38)4.16设备T4 LIC-505(A)和FIC-505(C)串级控制系统设计 (40)4.16.1测量仪表的选择 (40)4.16.2控制器的选择 (40)4.16.3安全栅的选择 (41)4.16.4执行器的选择 (41)4.16.5设备T4 LIC-505(A)和FIC-505(C)串级控制系统设计的常规仪表回路图 (41)4.17设备F2 FIC-401(M)控制系统设计 (43)4.17.1测量仪表的选择 (43)4.17.2控制器的选择 (43)4.17.3安全栅的选择 (43)4.17.4执行器的选择 (43)4.17.5设备F2 FIC-401(M)控制系统设计的常规仪表回路图 (44)4.18设备F2 FIC-402(M)控制系统设计 (46)4.18.1测量仪表的选择 (46)4.18.2控制器的选择 (46)4.18.3安全栅的选择 (46)4.18.4执行器的选择 (47)4.18.5设备F2 FIC-402(M)控制系统设计的常规仪表回路图 (47)4.19设备F2 FIC-403(M)控制系统设计 (49)4.19.3安全栅的选择 (49)4.19.4执行器的选择 (49)4.19.5设备F2 FIC-403(M)控制系统设计的常规仪表回路图 (49)4.20设备F2 FIC-404(M)控制系统设计 (51)4.20.1测量仪表的选择 (51)4.20.2控制器的选择 (51)4.20.3安全栅的选择 (51)4.20.4执行器的选择 (51)4.20.5设备F2 FIC-404(M)控制系统设计的常规仪表回路图 (52)4.21设备F2 PIC-401(M)控制系统设计 (54)4.21.1测量仪表的选择 (54)4.21.2控制器的选择 (54)4.21.3安全栅的选择 (54)4.21.4执行器的选择 (55)4.21.5设备F2 PIC-401(M)控制系统设计的常规仪表回路图 (55)4.22设备F2 TIC-402(A)和TIC-401(C)串级控制系统设计 (57)4.22.1测量仪表的选择 (57)4.22.2控制器的选择 (57)4.22.3执行器的选择 (57)4.22.4执行器的选择 (57)4.22.5设备F2 TIC-402(A)和TIC-401(C)串级控制系统设计的常规仪表回路图 (57)结论 (59)参考文献 (60)致谢 (61)摘要本设计针对常减压装置减压塔工段自动控制工程设计。

产品介绍版本:V1.0日期:2023年02月18日深圳市米尔电子有限公司版本历史版本作者参与者日期备注V1.0 产品部20230218 初版说明:本文档及涉及到的产品相关参数仍存在潜在变动可能,最终产品以最终发布时版本为准目录1. 产品介绍 (4)2. RZ/G2L系列芯片介绍 (5)3. MYC-YG2LX核心板介绍 (6)3.1.核心板外观图 (6)3.2.核心板系统框图 (7)3.3.核心板资源及参数 (8)3.4.核心板扩展信号 (9)3.5.核心板机械结构图 (10)4. MYB-YG2LX底板介绍 (11)4.1.开发板系统框图 (12)4.2.底板外设接口资源 (13)4.3.底板机械尺寸图 (14)5. 软件资源 (15)5.1.多套操作系统镜像文件 (15)5.2.丰富的Linux系统软件资源 (15)5.3.基于QT5的HMI V2.0系统 (16)6. 产品配置及选配 (18)6.1.核心板配置型号 (18)6.2.开发板配置型号 (18)6.3.开发板包装清单 (19)6.4.选配模块 (19)1.产品介绍瑞萨RZ/G2L系列处理器是一款工业级应用芯片,集成了ARM Cortex-A55高性能CPU和ARM Cortex-M33实时CPU,含Mali-G31 3D GPU,VPU支持H.264 1920*1080@30FPS视频编解码,具有丰富多媒体接口MIPI-DSI/RGB/MIPI-CSI/Parallel CSI,支持1080P高清显示。

处理器还支持2个千兆以太网接口、2个CAN FD接口、2个USB2.0接口、7个UART功能接口,适用于工业HMI、医疗、工业自动化、电力、显控终端等场景。

米尔电子基于瑞萨RZ/G2L系列处理器推出了开发套件MYD-YG2LX,套件由核心板MYC-YG2LX和底板MYB-YG2LX组成,核心板与底板采用邮票孔焊接方式。

随同开发套件MYIR提供了丰富的软件资源以及文档资料。

空气动力机械智能制造公共实训基地设备预算清单模块一工业机器人基础工作室一、工业机器人基本技能工作室总体概述工业机器人基本技能实训方案以6轴机器人工作站为核心,配套装配了操作对象承载平台、工具墙、零件箱、学习讨论区、资讯区、机器人安全工作围栏等设施设备及基础教材、仿真软件、工学结合工作页等教学配套。

为工业机器人基本技能实训提供了综合的、完整的、工学结合的解决方案。

针对工业机器人应用维护专业基础技能训练与实习,该阶属于机电工学结合类技能向工业机器人过渡的关键环节,通过简单易操作的机器人本体操作的学习,加强安全意识与规范意识的培养,让学生掌握如何与工业机器人“打交道”。

工业机器人基本技能工作室案例照片(仅供参考)(图片仅供参考、以实际二、工业机器人基本技能工作室配置清单个;高强度铝合金手电筒(3节7号电池)6LED 1个;专业级手动黄油枪400cc 1个;手用黄油枪尖嘴头 1个;手用黄油枪软管12" 1个;德式轴用直口卡簧钳7" 1把;活动扳手10" 1把;木柄安装锤45MM 1把;T 系列双头螺丝批#1&5MM×150MM 1个;2.5MM系列钢柄快脱棘轮扳手 1把;预置式扭力扳手3件套;9件套公制长球头内六角扳手 1套;塑料工具箱19" 1把;吊带1条;卸扣 2个;工业听诊器 1把10、护栏①范围:2980mm×2980mm×920mm②材质:铝型材★含工业机器人拆装与调试课程资源包1、《工业机器人拆装与调试》教材配套教学ppt一套,试题3套、课程标准1套(现场演示)2、★《工业机器人拆装与调试》跨终端网络课程1门:★基于html5开发,课程栏目满足自适应,功能栏目为首页、课程简介、课程学习、★模拟考试(可进行在线考试)、拓展资源;(现场演示)3、《工业机器人拆装与调试》网络课程符合scorm封装标准4、★7个机器人拆装重难点微课;(现场演示)5、批量六关节机器人拆装素材库、视频素材库、教材配套素材库6、提供资源能学辅教,设备与网络课程及资源库能够完整对应。

12Connect the power cable and press the power buttonConecte o cabo de alimentação e pressione o botão liga/desligaOTE: The system will not power-on while the side cover is off. Also, the system will shutdown if OTA: o sistema não liga enquanto a tampa lateral estiver fora do lugar. Além disso, o sistema será Quick Resource LocatorProduct support and manuals Suporte ao produto e manuais/support/support/manuals /support/windowsContact DellEntre em contato com a Dell /contactdellRegulatory and safety Normas e segurança /regulatory_compliance Regulatory model Modelo regulamentarD04X Regulatory type Tipo regulamentar D04X001Computer modelModelo do computadorPrecision 7920 Tower© 2017 Dell Inc. or its subsidiaries.2017-08Connect the displayConecte a tela1. Botão/luz de alimentação2. Luz de atividade da unidade3. Slot de cartão SD4. Portas USB 3.1 de 1ª geração5. Porta USB 3.1 Type-C de 1ª geraçãocom PowerShare 6. Porta USB 3.1 Type-C de 1ª geração 7. Porta para headset8. Trava de liberação da unidade 9. Slots da placa de expansão 10. Compartimento de 5,25 polegadas(opcional)11. Unidade óptica12. Conector do cabo de alimentação 13. Portas USB 3.1 de 1ª geração 14. Portadoras da unidade15. Slot da placa gráfica dedicada(opcional)16. Encaixe do cabo de segurança 17. Anel de cadeado 18. Porta de saída de linha19. Porta do microfone/entrada de linha 20. Porta serial21. Porta do mouse PS/222. Porta do teclado PS/223. Porta de rede (gerenciadaopcionalmente)24. Porta de rede25. Porta USB 3.1 de 1ª geração(compatível com Smart Power On, ativação inteligente)26. Slots da placa de expansão 27. Tampa lateral28. Trava de liberação da tampa lateralFeaturesRecursos1. Power button/Power light2. Drive activity light3. SD card slot4. USB 3.1 Gen 1 ports5. USB 3.1 Gen 1 Type-C port withPowerShare 6. USB 3.1 Gen 1 Type-C port 7. Headset port8. Drive access release latch 9. Expansion card slots 10. 5.25 inch bay (optional)11. Optical drive12. Power cable connector 13. USB 3.1 Gen 1 ports 14. Drive carriers15. Discrete graphics card slot (optional)16. Security cable slot 17. Padlock ring 18. Line-out port19. Microphone/Line-in port 20. Serial port 21. PS/2 Mouse port 22. PS/2 Keyboard port23. Network port (managed optionally)24. Network port25. USB 3.1 Gen 1 port (supportssmart Power-On)26. Expansion card slots 27. Side cover28.Side cover release latch。

KU20控制器诺瓦COEX控制器嵌入式软件V1.1(内嵌在KU20中)规格书更新记录简介KU20是西安诺瓦星云科技股份有限公司(以下简称“诺瓦星云”)全新控制系统COEX系列下的一款6网口控制器,具有1路HDMI输入接口,6路输出网口,以及1路光纤输出接口,支持全新的视觉管理平台VMP,为用户提供更好的操控体验。

认证CCC、CE、FCC、IC、UL、CB、PSE、RCM、KC。

若该产品无所销往国家或地区的相关认证,请第一时间联系诺瓦星云确认或处理,否则,如造成相关法律风险,客户需自行承担或诺瓦星云有权进行追偿。

特性输入输出●HDMI输入接口1×HDMI 1.3(带环路输出)。

●10bit/8bit视频源输入●网口输出6路网口,最大带载390万像素。

●光纤输出1路10G光纤接口。

高级特性●画面缩放支持2种画面缩放模式,包括自定义和点对点。

●全灰阶校正配合诺瓦星云高精度校正系统和C3200科学级相机为每一级灰阶生成其专属的校正系数,保障每一级灰阶的均匀性,显著提升显示屏画质。

●逐点亮色度校正配合诺瓦星云高精度校正系统,对每个灯点的亮度和色度进行校正,有效消除亮度差异和色度差异,使整屏的亮色度达到高度一致。

●延迟−支持低延迟,控制器端0帧延迟(小于1ms),并可实现低延迟不减带载。

−支持额外帧延迟,控制器端可增加0~2帧延迟。

●无矩形框限制异形屏搭建时无矩形框限制,留空不算带载,网口带载计算为所有配屏箱体的分辨率叠加总和。

●帧频自适应自适应各种视频输入帧频,包括小数帧频。

支持用户自定义帧频,并支持0.01Hz步进的精细帧频调节。

●显示系统监测支持设备状态监测和显示屏状态监测,并自动上报故障和告警信息。

●两种设备工作模式支持视频控制器和独立主控两种工作模式。

视频控制器模式下,可使用图层及缩放功能。

操作控制●VMP软件控制使用VMP软件连接设备,易用便捷,并且支持智能化管理。

●支持SNMP协议、Art-Net协议●以太网级联控制千兆以太网控制网口,支持TCP/IP协议,支持星型连接。

LEC-7920桌面型嵌入式工业控制器

Intel Core CPU,带2×LAN,2×COM,DVI-D/DVI-I显示

特点

支持intel 酷睿i7-620M/i5-520M CPU

内置2G DDR3内存,2×DDR3 SO-DIMM,最大支持

到8GB

DVI-I和DVI-D双显示

2×Intel GbE,1×RS-232,1×RS-232/422/485

4×USB 2.0,4×DI/O,1×Mic in/Audio out

Mini-PCIe扩展及SIM读卡器插槽

支持9~30VDC宽电源输入,A TX开关控制

电源及IDE指示灯状态显示

支持Linux,XPE/WES2009,XP PRO,FES,WS7E,

WS7P,WIN 7 PRO-E操作系统

概述

LEC-7920是一款高性能嵌入式工控机,支持Intel i7/i5 Socket CPU。

英特尔i5/i7处理器使得LEC-7920具有超高的数据处理能力和硬件视频解码能力,英特尔高清显卡通过DVI-I和DVI-D端口为机器提供了高清晰的播放能力,千兆以太网确保了顶尖的网络功能。

此外,LEC-7920还提供了多种插槽支持,增加了更多扩展机会。

硬件规格

数字I/O

DI/O 4×DI/O (DB9 Female ) 4路DI 逻辑0:0 ~2VDC 逻辑1:5 VDC 4路DO

逻辑0:0 VDC 逻辑1:5 VDC/50mA 显示

图形控制芯片 Intel GMA HD Graphics 显示 DVI-I+DVI-D

分辨率

DVI-I:2536×1920 DVI-D:2536×1920 机械特性

尺寸 277(W )×54(H )×194(D )mm 净重

3.1kg 工作环境

工作温度 -20~55℃ 工作湿度 5~95%,无凝结 存储温度

-40~80°C 电源需求

输入电压 +9~30VDC ,A TX 电源适配器 75W ,+19V@3.95A 接头 DC Jack /Lock 典型功耗

50W 安规认证

EMC CE,FCC 环境

RoHS

可靠性

报警工具 内建凤鸣器和RTC (实时时钟) 看门狗

内建WTD (看门狗时钟)

保修期

2年内免费维修,终身维护

订购信息

系统

CPU Intel i7-620M 双核2.66GHz Intel i5-520M 双核2.4GHz 芯片组 HM55

DRAM 内置2G DDR3,2×SODIMM (最大8GB ) 操作系统 Linux , XPE/WES2009, XP PRO FES, WS7E, WS7P , WIN 7 PRO-E

存储扩展 1×2.5’’ HDD/SSD, 1×SA TA-DOM 扩展总线 1×Mini-PCIe with SIM card reader 其它接口

6×USB2.0(2个在内部) LAN 口

LAN

2×Intel 82547L ,RJ45接口 数据传输率

10/100/1000Mbps 串口

串口数量 2个 接头 DB9 Female

串口通讯参数

串口标准 1×RS-232/422/485,1×RS-232 数据位 5,6,7,8 停止位 1,1.5,2

奇偶校验 None ,Even ,odd ,Space ,Mark 流量控制 RTS/CTS ,XON/XOFF ,RS-485自动流控 通信速率

RS-232:50bps~115.2Kbps RS-485:50bps~921.6Kbps

串口信号 RS-232 TxD,RxD,DTR,DSR,RTS,CTS,DCD,GND RS-422

TxD+, TxD-, RxD+, RxD-, GND 2-wire RS-485

Data+, Data-, GND 声音

Mic in 1×Phone jack Audio out

1×Phone jack

LEC-7920:2×千兆LAN ,2×COM ,DVI-D/DVI-I 双显示,SATA ,Mic in/Audio Out ,4×USB ,Mini-PCIe 扩展,SIM 读卡器。