电磁加热器使用说明书

- 格式:doc

- 大小:715.50 KB

- 文档页数:10

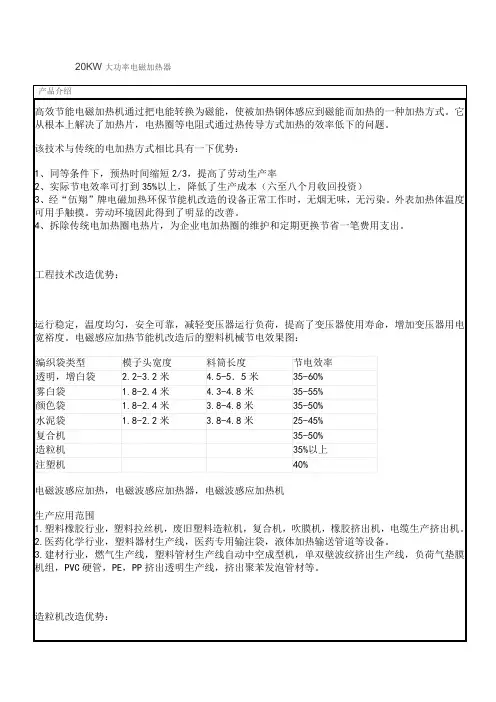

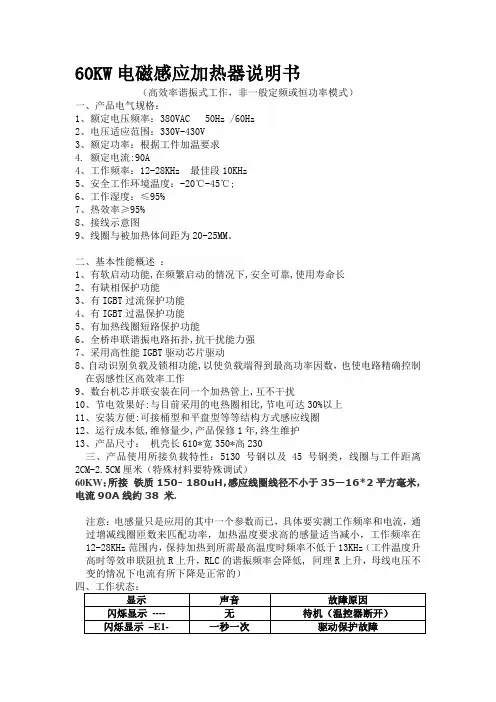

60KW电磁感应加热器说明书(高效率谐振式工作,非一般定频或恒功率模式)一、产品电气规格:1、额定电压频率:380VAC 50Hz /60Hz2、电压适应范围:330V-430V3、额定功率:根据工件加温要求4. 额定电流:90A4、工作频率:12-28KHz 最佳段10KHz5、安全工作环境温度:-20℃-45℃;6、工作湿度:≤95%7、热效率≥95%8、接线示意图9、线圈与被加热体间距为20-25MM。

二、基本性能概述:1、有软启动功能,在频繁启动的情况下,安全可靠,使用寿命长2、有缺相保护功能3、有IGBT过流保护功能4、有IGBT过温保护功能5、有加热线圈短路保护功能6、全桥串联谐振电路拓扑,抗干扰能力强7、采用高性能IGBT驱动芯片驱动8、自动识别负载及锁相功能,以使负载端得到最高功率因数,也使电路精确控制在弱感性区高效率工作9、数台机芯并联安装在同一个加热管上,互不干扰10、节电效果好:与目前采用的电热圈相比,节电可达30%以上11、安装方便:可接桶型和平盘型等等结构方式感应线圈12、运行成本低,维修量少,产品保修1年,终生维护13、产品尺寸:机壳长610*宽350*高230三、产品使用所接负载特性:5130号钢以及45号钢类,线圈与工件距离2CM-2.5CM厘米(特殊材料要特殊调试)60KW:所接铁质150- 180uH,感应线圈线径不小于35—16*2平方毫米,电流90A线约38米.注意:电感量只是应用的其中一个参数而已,具体要实测工作频率和电流,通过增减线圈匝数来匹配功率,加热温度要求高的感量适当减小,工作频率在12-28KHz范围内,保持加热到所需最高温度时频率不低于13KHz(工件温度升高时等效串联阻抗R上升,RLC的谐振频率会降低, 同理R上升,母线电压不变的情况下电流有所下降是正常的)五、产品主要应用领域:工业加热设备如塑胶机械注塑机、造粒机、吹膜机、拉丝机,锅炉等等的节能改造中; 民用加热产品如电磁热水器,电磁热水瓶,电磁炉等高效加热电器中。

SST & QSTSplit Sheath Insertion HeatersUser’s Guidee-mail:**************For latest product manuals:/en-us/pdf-manualsShop online at NOTICE: Carefully remove heater(s) from shipping containers and check for shipping damage. Any damage claims should be entered immediately with the carrier.GENERALe Chromalox electric cartridge heaters are ruggedly constructed and if properly installed, operated and maintained, will provide long life and dependable, trouble-free service.Since excess temperatures may permanently damage the heaters, temperature regulating and limiting controls are recommended.If cartridge heater is to be used in platen, dies, mold, etc. the hole should be drilled and reamed to allow as close a t as is possible. is is especially important when installing high watt density heaters. Good surface contact between the heater surface and the heated metal is essential to good heat transfer and for longer heater life. A loose t, resulting in poor contact willcause the heater to “run hot” and could cause premature heater failure. Table A gives the di erence between nominal and actual diameters. If further information regarding t or watt density is required, contact your Chromalox representative or ask for a copy of Curve G-235 from Chromalox Cartridge Graphite and other lubricants to help insert the cartridge heater into the hole are not recommended. ey areelectrically conductive and can contaminate the heater and shorten heater life.1.5.6. A. 2.Do not twist or braid wire leads. Where leads are subject to exing, support the leadwires to prevent them from twisting or breaking o at the terminal end.3.Avoid the use of tape on leads where they emerge from the cartridge heater. e adhesive on some tapes can contaminate the heater and shorten heater life.4.WARNING: Users should install adequate back-up controls and safety devices with their electric heating equipment. Where the consequences of failure may be severe, back-up controls are essential. Although thesafety of the installation is the responsibility of the user, Chromalox will assist in identifying equipment options.INSTALLATIONWARNING: Hazard of Shock. Disconnect all power before installing heater.WARNING: The suitability of these heaters for any particular application is solely the responsibility of the user. Please check Chromalox factory or representative for guidance if needed.WARNING: Never hammer the heater ends when installing.Electric wiring to heating elements must be installed in accordance with National Electrical Codes and Local Electrical Codes by a quali ed person as de ned in the e high-temperature manganese nickel leadwire or alloy busbar for electrical connections at the heater itself. Insulated copper leadwire may be used up to 350°F.2.Do not operate heaters at voltages in excess of that stamped on the heater since excess voltage will shorten heater life.1.Do not operate heaters under conditions that result in temperatures higher than the recommended maximum since excess temperatures can cause premature heater failure.e maximum recommended temperature on sheath materials normally supplied is:2.Cartridge heaters of 5/8” diameter and larger and of equal wattage and voltage can be series-connected across 480 volts maximum power supply. Smaller diameter units of equal rating can be series-connected across 250 volts maximum. An extra layer of high temperature Fiberglass sleeving is recommended for the leadwire to increase electrical insulation.3.Protection with properly sized fuses/breakers is required to minimize hazards.4.WIRINGWARNING: Hazard of Shock. Any installation involving electric heaters must be effectively grounded in accordance with the National Electrical Code to eliminate shock hazard.Make certain that the terminals or leads and heater sheath are free from contact with oil, liquids or other foreign matter.1.Note: Chromalox cannot be responsible for failures or damage caused by organic contamination in cartridge heaters. Make certain that the heaters are not exposed to organic contaminants.Check electrical connections and tighten if necessary. is will help avoid hot terminals that may destroy wire insulation or heater terminals.2.Check overheat operation to insure heater protection.3.REPAIR — For In-Warranty repair please follow instructions4.MAINTENANCEWARNING: Hazard of Shock. Disconnect all power to heaters before servicing or replacing heaters.Electrical terminals should be protected from spillage ofplastics, water, oil, and their vapors which can create electrical hazards and/or heater failure.3.OPERATIONLeadwires must not enter the hole containing the heater. e lead end of the heater should be ush with the surface of the part being heated. Make sure that the leads are in an ambient temperature which does not exceed the maximum temperature rating of the lead insulation and end seal material.DANGER: Hazard of Fire. Since cartridge heaters are capable of developing high temperatures, extreme care should be taken to:Avoid mounting heaters in an atmosphere containing combustible gases and vapors.B.Avoid contact between heaters and combustible materials.C.Keep combustible materials far enough away to be free of the e ects of high temperatures.Stainless Steel — 1200°F— 1600°F AlloyWARRANTYTolerances and LimitationsNominal Sheath DiameterActual Sheath Diameter (±.003)Minimum Sheath LengthMaximum Sheath Length – SST Maximum Sheath Length – QST Minimum Ohms/inch of EHL*SST QSTSSTQSTSST QSTMaximum Ohms/inch of EHL*Maximum Standard Voltage Maximum Amperage Wattage Resistance Sheath Length3/8”.370”5”60”N/A-11-24015-.2781/2”495”5”60”36”.59321382403030.3085/8”.620”5”60”36”36”.593.59321382404030.296.29611/16”.682”5”60”213848040303/4”.745”5”60”36”.59326384804030.3501”.995”5”60”N/A -26-48040-.350+5% – 10%+10% – 5%±3% up to 20”, ±2% over 20”Fig. 04CFig. 13CFig. 15CFig. 10CFig. 17C* QST (QUAD) N/A in 3/8” Diameter ** Not applicable to Fig. 13C or Fig. 17CQST Quad Sheath Insertion HeaterSST Split Sheath Insertion HeaterUnenergized SST Energized SSTUnenergized QST Energized QSTO MEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This a ords our customers the latest in technology and engineering.OMEGA is a trademark of OMEGA ENGINEERING, INC.© Copyright 2019 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, withoutthe prior written consent of OMEGA ENGINEERING, INC.***********************Servicing North America:Omega Engineering, Inc.Toll-Free: 1-800-826-6342 (USA & Canada only) Customer Service: 1-S00-622-2378 (USA & Canada only)Engineering Service: 1-800-872-9436 (USA & Canada only) Tel: (203) 359-1660 Fax: (203) 359-7700 e-mail:**************For Other Locations Visit /worldwideU.S.A.Headquarters:。

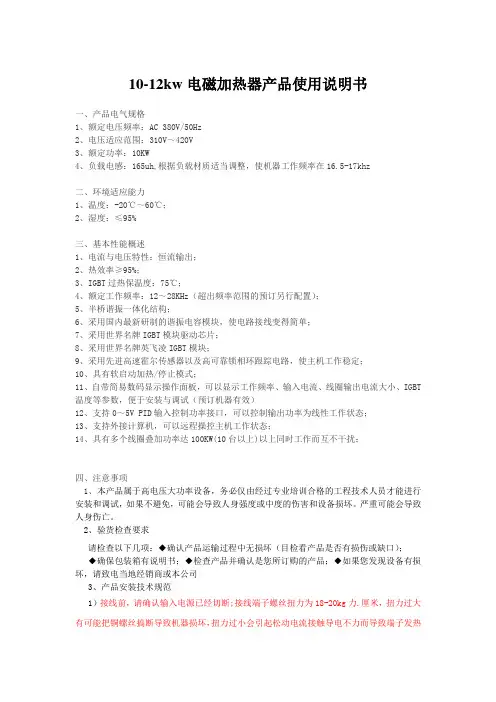

10-12kw电磁加热器产品使用说明书一、产品电气规格1、额定电压频率:AC 380V/50Hz2、电压适应范围:310V~420V3、额定功率:10KW4、负载电感:165uh,根据负载材质适当调整,使机器工作频率在16.5-17khz二、环境适应能力1、温度:-20℃~60℃;2、湿度:≤95%三、基本性能概述1、电流与电压特性:恒流输出;2、热效率≥95%;3、IGBT过热保温度:75℃;4、额定工作频率:12~28KHz(超出频率范围的预订另行配置);5、半桥谐振一体化结构;6、采用国内最新研制的谐振电容模块,使电路接线变得简单;7、采用世界名牌IGBT模块驱动芯片;8、采用世界名牌英飞凌IGBT模块;9、采用先进高速霍尔传感器以及高可靠锁相环跟踪电路,使主机工作稳定;10、具有软启动加热/停止模式;11、自带简易数码显示操作面板,可以显示工作频率、输入电流、线圈输出电流大小、IGBT 温度等参数,便于安装与调试(预订机器有效)12、支持0~5V PID输入控制功率接口,可以控制输出功率为线性工作状态;13、支持外接计算机,可以远程操控主机工作状态;14、具有多个线圈叠加功率达100KW(10台以上)以上同时工作而互不干扰;四、注意事项1、本产品属于高电压大功率设备,务必仅由经过专业培训合格的工程技术人员才能进行安装和调试,如果不避免,可能会导致人身强度或中度的伤害和设备损坏。

严重可能会导致人身伤亡。

2、验货检查要求请检查以下几项:◆确认产品运输过程中无损坏(目检看产品是否有损伤或缺口);◆确保包装箱有说明书;◆检查产品并确认是您所订购的产品;◆如果您发现设备有损坏,请致电当地经销商或本公司3、产品安装技术规范1)接线前,请确认输入电源已经切断;接线端子螺丝扭力为18-20kg力.厘米,扭力过大有可能把铜螺丝搞断导致机器损坏,扭力过小会引起松动电流接触导电不力而导致端子发热出现故障。

2)请确保设备进出口风道通畅;3)必须将感应加热设备接地端子可靠接地,接地电阻小于10欧姆,否则会有触电和火灾的危险;4)请勿将输入电源线接到输出端子OUT1、OUT2上,否则会损坏感应加热设备;5)请勿直接触摸电源输入端子ABC和电源输出端子OUT1、OUT2,同时OUT1、OUT2输出端子切勿与外壳连接,输出端子切勿短接;6)通电时请务必安装好端子外罩,拆卸外罩时,一定要切断电源。

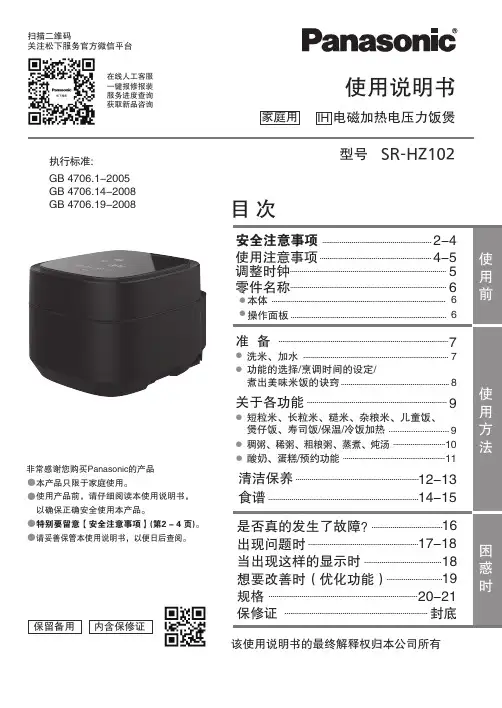

使用说明书目 次●●●●保留备用内含保修证家庭用IH 电磁加热电压力饭煲该使用说明书的最终解释权归本公司所有非常感谢您购买Panasonic的产品本产品只限于家庭使用。

使用产品前,请仔细阅读本使用说明书, 以确保正确安全使用本产品。

特别要留意【安全注意事项】(第2 - 4 页)。

请妥善保管本使用说明书,以便日后查阅。

型号执行标准:GB 4706.1-2005GB 4706.14-2008GB 4706.19-2008扫描二维码关注松下服务官方微信平台在线人工客服一键报修报装服务进度查询获取新品咨询安全注意事项为防止造成人身伤害、财产损失,请务必遵守以下安全注意事项。

■以下图标表示错误操作可导致的危害程度。

■符号的分类及解释如下。

请务必遵守!2● 如电源线或电源插头已损坏或电源插座与电源插头的接口松脱,请勿使用产品。

(以免导致触电或因短路导致火灾。

)→如果电源线损坏,必须用从Panasonic认定 服务店购买的专用组件来更换。

● 请勿损坏电源线或电源插头。

·绝对禁止进行以下操作:损伤、加工、使其接触或靠近高温部、 强行 弯曲、扭转、拉拔、挂在角上、 在其上放置 重物、扎成束、夹入、拉动 电源线移动。

(以免因电源线和电源插头破损而触电,或因短路导致火灾。

)● 请勿以湿手插入或拔掉电源插头。

·接触电源插头或产品前请务必确保手是干燥的。

(以免导致触电或受伤。

)● 请勿将水或其它液体溅到本体插头上。

(以免导致触电或因短路导致火灾)● 请勿让任何人舔本体插头。

(以免导致触电或受伤。

)·特别要留意婴幼儿。

● 务必要单独使用规格为AC 220 V/10 A 的交流电的电源插座。

(以免与其他电器并用,因发热而引起火灾。

)·务必使用规格至少为10 A的接线板。

● 务必要将本体插头、电源插头切实插到底。

(以免导致冒烟、火灾或触电。

)● 本产品应使用单向两极带接地的电源插座, 并保证其可靠接地。

ELECTRIC PATIO HEATERModel No.:9711026ASSEMBLE & OPERATION INSTRUCTIONPlease read carefully and save this instructionWARNINGTHESE INSTRUCTIONS SHOULD BE READ CAREFULLY AND RETAINED FOR FUTURE REFERENCE. The supplier is not liable for any damages caused by failure to follow these instructions.IMPORTANT SAFETY INSTRUCTIONSPLEASE READ CAREFULLY - The infrared heater is designed for safe operation. Nevertheless, installation, maintenance and operation of the heater can be dangerous. Observing the following procedures will keep installation time to a minimum and reduce the risk of fire, electric shock, injury to persons. Save these instructions for future use.1.Read all instructions before using this heater. The manufacturer will not be liable forany damage caused by noncompliance with these instructions or any other improperuse or mishandling.e this heater only as described in this manual. Any use not recommended by themanufacturer may cause fire, electric shock, or injury to persons.3.Remove the unit from its packaging and check to make sure it is in good conditionbefore using. Do not let children play with any of the parts or packaging, includingplastic bags.4.Check your household voltage to ensure it matches the heater’s rated specifications.5.Check the power cord and plug carefully before use to make sure that they are notdamaged in any way.6.Connect to properly grounded outlets only. Always plug heaters directly into a walloutlet/receptacle. Never use with an extension cord or power strip.7.Do not allow cord to overhang a counter top or other area where it can be easily pulledby children or pets.8.Do not run cord under carpeting. Do not cover cord with throw rugs, runners, or similarcoverings. Do not route cord under furniture or appliances. Arrange cord away fromtraffic areas and only place it where it will not be tripped over.9.To disconnect the heater, turn the controls to off; then remove the plug from outlet.10.Whenever operating or handling the unit, be sure your hands are dry to prevent electricshock.11.To prevent overheating of this appliance, keep the air inlets and outlets clean and freeof anything that may cause blockage. Check all inlets and outlets from time to time toensure it is clear of any dirt or dust accumulation. DO NOT COVER THIS UNIT.12.Do not insert or allow foreign objects to enter any ventilation or exhaust opening, as thismay cause an electric shock, fire or damage to the heater. Do not put fingers or foreign objects into the grill while in operation.13.This heater is very hot when in use. Keep combustible materials, such as furniture,pillows, bedding, paper, clothes, and curtains at least 3 feet (1m) from the front sides and rear of the heater.14.A heater has hot and arcing or sparking parts inside. Do not use it in areas wheregasoline, paint, or flammable liquids are used or stored.15.Parts of the heater may exceed 392°F (200°C). Contact with the heating tube, reflector,or mental parts near the heating tube, may cause severe BURNS. To avoid burns, do not let bare skin touch any hot surface. If provided, use handles when moving this heater.16.ALWAYS allow heating element to cool at least 10 minutes before touching any part ofthe heater.17.Do not use near or in the immediate vicinity of a bath or swimming pool or any sourceof water. Never immerse unit, cord or plug in water or any other liquid.18.This heater is not intended for use in bathrooms, laundry rooms and similar indoorlocations; never locate the heater where it may fall into a bathtub, sink or other water container.19.Do not leave the appliance unattended when in use. Always unplug the heater whennot in use.e extreme caution when any heater is used by or near children or people withreduced physical, sensory or mental capabilities. This appliance is not intended for use by children or people with reduced physical, sensory or mental capabilities or lack of experience and knowledge. Children and vulnerable people should be supervised to ensure they do not misuse or play with the appliance.21.Do not operate any heater with a damaged cord or plug or after the heatermalfunctions, or has been dropped or damaged in any manner. Disconnect power at service panel and have the heater inspected by a licensed electrician before reusing. If the supply cord is damaged in any way, it must be replaced by the manufacturer or its service agent or a similarly qualified person in order to avoid a hazard.22.Please recycle. This product contains recyclable materials. Do not dispose this productas municipal waste. Please contact your local municipality for the nearest collection point.SAVE THESE INSTRUCTIONSINTRODUCTIONThese halogen lamp heaters produce instant and comfortable heat like the sun. These heaters are designed for domestic heating applications. This model does not come with a remote.Model 9711026Voltage 120 VACWattage 1500 WBTU 5118Dimensions W X H X D 31.5 X 7.9 X 7.9 inchesWeight 9.48 lbsOPERATINGPress ON/OFF button to turn the appliance ON/OFFCAUTION1.This heater should only be installed by an experienced adult or a qualified electrician.2.Always disconnected the heater from the electricity supply and allow it to cool beforeinstallation.3.Keep the supply cord away from the body of the heater which will get hot during use.4.When the appliance is not in use for an extended period of time, the heater should beturned OFF and unplugged from the electrical connection.5.Do not touch the heating element with bare fingers, as residue from your hand couldaffect the life of the lamp. If it is accidentally touched, remove the finger marks with asoft cloth moistened with mentholated spirit or alcohol while the unit is OFF and COOL.6.The heater contains no user-serviceable parts. If the product is damaged or otherwisemalfunctioning, it must be returned to the manufacturer or its service agent or it must be properly disposed of. Do not attempt to repair or adjust any electrical ormechanical functions on this heater.7.Damaged supply cords must be replaced by a service agent or similarly qualified personin order to avoid hazard.MAINTENANCEPeriodic inspection and removal of dirt and contaminants will ensure that the heater can be operated safely. Always perform maintenance and cleaning before operating the heater if it has not been used in a long period of time.1.Check the Reflector and IR-Filament at least once a month for dirt and dust. If cleaning isnecessary, follow the cleaning and maintenance instructions.2.Inspect more frequently if the environment is prone to unusual amounts of dirt or dust.3.Visually inspect the heater (wire, frame, and lamp), power cord and plug for any damageor wear at least once per month. If damaged or worn, consult with a technical service.NOTE: Proper and regular maintenance is easy and important for the long and efficient operation of your heater.CLEANINGRegular and careful cleaning helps your infrared heater operate efficiently for many trouble-free years. To clean your heater, follow the steps below:1.Unplug the power cord for your safety before cleaning your appliance.2.Make sure the heater is cool before continuing.3.Clean the outer shell with a soft, damp cloth. You may use a mild detergent if necessary.After cleaning, dry the unit with a soft cloth. CAUTION: DO NOT let liquids enter theheater.4.DO NOT use alcohol, gasoline, abrasive powders, furniture polish or rough brushes toclean the heater. This may cause damage or deterioration to the surface of the heater.e an air blower to remove any loose dust, dirt or debris from the unit.6.DO NOT immerse the heater in water7.Wait until the heater is completely dry before use.NOTE: If the heater has collected dust or dirt inside the unit or around the heating element, have the unit cleaned by a qualified service agent. Do not operate the heater in this condition. The only maintenance required is cleaning of the external surfaces of the heater.STORAGEStore the heater in a cool, dry location when not in use to prevent dust and dirt build-up. Heater covers are available for protection when appliance is not un use.If not using a cover, use packaging cartons to store.RECYCLINGAt the end of the electrical products useful life it should not be disposed of with household waste. Please recycle where facilities exist. Check with your Local Authority or retailer for recycling advice in your country.。

为了正确使用本产品,请认真细读使用说明书一、产品的部件名称和接线12345689710121113141617181920212423152825222726德国英飞凌原厂驱动:磁隔离技术全进口高性能、多级电感虑波电源,贴片制造工艺编号接线和用途1接散热风扇的电源电压,当风扇为220V时就接220V电源,当风扇为380V 电压时,就接380V电源2接散热风扇220V或380V(随用户定,一般为380V)3当外接散热风扇为直流24V时,此接口为开关,控制24V风扇工作或停止。

此两端接口实际上就是主板上继电器输出常闭接触点4双交流24V电源(做半桥时4或5选1个)5双交流24V电源(做半桥时4或5选1个)6单交流16V电源7电源指示灯(红色)8工作指示灯,待机时,闪亮,工作时,一直亮(绿色)9外接指示灯,引接到机箱外面的LED接口上10软启动接口,引到外机箱中的R/S接口上(可通过F-02设置断开工作或闭合工作,出厂默认闭合工作、断开停止状态)11微调节功率电位器,当功率出现较大的偏差时,这个电位器可适当调整1232位高速DSP处理器13外接可编程操作显示器14隔离型RS485通讯接口15外部负载温度检测接口1,精度达±1℃(最高150℃)单路时,默认1用来测量外部工作温度16外部负载温度检测接口2,精度达±1℃(最高150℃)17多功能输入接口(通过F-20来设置):1、做外接电位器10K输入,可以调节功率大小20%-100%范围2、做外接PID输入(0-5V)输入做红外测温仪或热电偶转换电压0-5V输入,实现显示温度和控制功率大小(最高可以测量显示1000℃)18接高频互感器,注意方向。

若方向接反时,功率很小19IGBT模块驱动(做半桥时,选择19、20或23、24即可)20IGBT模块驱动(做半桥时,选择19、20或23、24即可)21接直流母线高压22IGBT温度传感器接口23IGBT模块驱动(做半桥时,选择19、20或23、24即可)24IGBT模块驱动(做半桥时,选择19、20或23、24即可)25接直流母线高压26RS485通讯接口,接A、B27外接K型热电偶28外接12V继电器带动其它需要的负载,与本机的风扇启动/停止同步二、产品的外观尺寸(1)、JS1000-020 (三相全/半桥20KW/380V )(2)、JS1000-030 (三相全/半桥30KW/380V)390250240450250240(3)、JS1000-040、JS1000-050三相全桥40KW/380V 、三相全桥50KW/380V ,60KW (水冷)(4)、JS1000-060(三相全桥60KW/380V风冷)510290260600310250(5)、JS1000-080(三相全桥80KW/380V风冷)(6)、20KW-80KW电磁加热控制柜外观尺寸(风冷、水冷通用)电磁加热器、温控器、线圈示意图接线说明:1、控制器R/S 接口是启动接口,当这两端子短接时就启动,当断开时就停止。

产品名称深圳信辉源8Kw电磁加热器产品用途:工业大功率加热节能设备适用负载范围:加热含磁性金属材料线圈接出端软开关控制指示灯变压器输出变压器输入电源C相电源B相电源A相电风扇电路板接线端子图示(电路更新与现货为准)一、产品电气规格1、额定电压频率:AC 380V / 50Hz2、电压适应范围:350V~450V3、额定功率:5KW-8KW- (12A×220V×3)4、采用方案:硬锁相半桥串联谐振方案5、电磁感应线圈规格:≥6平方毫米(工业用10平方毫米)6、负载匹配电感量:5KW 240±5UH8KW195±5UH 线圈高度1.0-1.5(平盘式)。

28-30M 线圈高2.0-2.5(缠绕式)二、环境适应能力1、温度:-20℃~60℃;2、湿度:≤95%三、基本性能概述1、电压与功率特性:350~420V恒定功率输出;2、热效率≥90%;3、IGBT正常工作温升:△F≤15℃(过热保护温度:95℃);4、工作频率:16-22KHz;5、半桥式串联谐振;6、具有软启动加热/停止模式;7、具有加热线圈短路保护功能;8、具有多个线圈叠加功率达120KW以上工作而互不干扰;9、可连机工作;四、运行工作操作方法:1:按上图加热器的外接端口图示正确连接好2:通电检查加热器待机是否正常,此时电源指示灯(红灯)长亮,风扇不转,机器处在待机状态。

3:软开关线接到带有隔离的温度控制器上,当温控器处在接通加热状态时加热器即开始运行加热工作,数码管显示8:00,工作批示灯亮.此时留意加热情况是否正常(正常输入电流为38A)。

并未听到异常的声音。

4:机器工作一定时间后等料管或炮筒发热到350度以上后输入电流备有下降,一般都在10A 到12A每相左右。

个别高温区可能降到10A左右,用功能键查询工作频率大概为16Khz-18Khz此属正常现象。

如加热料管到450度后工作电流在10A以下或查询工作频率小于14Khz时可以判断缠绕感应加热线圈电感量略偏大.但不会影响机器基本加热工作5:如有需要设置工作输出功率大小时可按功能键进入设置功率大小,.如软开关处于接通加热工作中可随时按开关键停止或加热工作.五、故障排除:1、有按要求正确接线上,开通电源而无任何显示,加热器不通电时解决方法如下:(1)用测电压器测试输入各相电源电压是否正常,(2)确定输入电源跟变压器没接错和未损坏(3)测试供芯片工作电源是否正常2、待机正常但软开关接通并未正常加热工作:(1)无故障灯亮无故障智能报误码:确认软开关连接温控器线路有没接触不良;(2 ) 冷机显示E3 确认电磁线圈电感量偏大已超出可基本工作范围.测试电感量方法:数字电桥按电感参数1KHZ频率串联模式在冷机情况下直接测试(注意其它同料管的机器禁止工作中测试)。

企业简介

大庆科丰石油技术开发有限公司总部位于大庆市高新开发区服务外包园区,下设两个产品加工基地,两个协作企业,员工总数129人,其中专业技术人员22人,教授级高级工程师5人,高级工程师9人。

主要产品有油田环保作业装置、天然气综合处理装置、天然气电磁加热装置、油田油泥处理装置、油田输油伴热装置、BDR电磁管道加热器、盘式电机驱动节能抽油机、井上工具等12系列65项产品,年创产值五千万元。

公司经营机制科学,运行体系流畅,管理思想现代,文化理念先进,多年来坚持“打造一流队伍,创造一流技术,塑造一流品牌,铸造一流企业”的宗旨,努力为新老客户提供优质高效的产品和技术服务。

目前产品和技术服务领域已遍及大庆油田、吉林油田、辽河油田、海拉尔油田、江苏油田、河北油田等地区。

我们愿与各界朋友真诚合作,共谋发展,互信双赢,共创未来。

-1-

BDR电磁管道加热器产品简介

利用电热和电磁感应原理对介质进行双重加热处理是非常成熟的实用技术 ,但该技术在油田输油管线上的应用却是我公司的首创.我公司经过多年的研究和实验,证明了该技术在油田上的应用是较为理想的. 对管道内油温的提升速度快,加热效率高,自动控温,安装简单,维护方便, 使用寿命长,占地面积小,节能环保,防爆性能强,安全可靠.经专家评定具有广泛的推广价值.

一.产品外观

二.技术特性

项目单位指标

加热功率KW 2~28

使用电压V 220/380

设定出口温度℃20~75可调

最大流量L/H 800

最大压力MPa 5

质量kg 45~95

-2- 三.产品系列

型号

功率

(KW)

使用电压

(V)

加热管规格

DN×L(mm)

充液重量

(kg)

BDR380-02 2 220 DN38-50×1650 74 BDR380-03 3 220 DN38-50×1650 74 BDR380-04 4 220 DN38-50×1650 74 BDR380-05 5 220 DN38-50×1650 74 BDR380-06 6 380 DN38-50×1650 122 BDR380-08 8 380 DN38-50×1650 122 BDR380-10 10 380 DN38-50×1650 122 BDR380-12 12 380 DN38-50×1650 122 BDR380-15 15 380 DN38-50×1650 122 BDR380-18 18 380 DN38-50×1650 122 BDR380-20 20 380 DN38-50×1650 122 BDR380-21~28 21~28 380 DN38-50×1875 125

四.安装

电磁管道加热器安装示意图

注:1.加热器入口端距井口距离不得小于3米。

2.加热器须避开井口放气口。

3.加热器底面距地面0.8米。

-3-

五.操作流程

六.操作指南

1.注意事项

▲在使用机器之前,仔细阅读所有条款。

▲不要让未经许可的人操作

▲操作者应穿带合适的防护服装以防伤害。

▲不要把任何材料靠在加热器上。

▲送电前必须完全打开加热器两端阀门.

▲在设备维修之前必须切断电源.

2.温度设定

参数设定

(1)按设置键不放,三秒钟后仪表进入参数设置状态。

参数符号在上排显示器显示,参数数值在下排显示。

这时可以通过增加、

减少键对参数进行修改。

修改后按设置键存储此参数并进行下

一个参数的设置,最后回到测量状态。

(2)仪表通电后即进入工作状态,如要重新设定值,请按上面操作说明进行操作。

3.设备维护

●每周进行1~2次巡检

●每月或根据天气温度变化情况进行温度设定

-5-

单管加热器接线图

-6-

三管加热器接线图

-7-

八.保修说明

一.保修期内双方责任

1.本公司销售的BDR管道电磁加热器自供货日起免费保修期为12个月。

2.我公司将不定期派员对用户使用的设备进行检测,保证设备正常运行。

3.为保证维修及时,我公司派员赴现场检修时,用户应派人协助。

4.由下列原因造成的设备损坏,我公司不承担设备的免费保修义务:

A. 由于非本加热器引起的火灾等造成的事故

B. 由于非产品质量原因而造成的故障,不属于我公司责任。

但我公

司可负责维修,费用由甲方支付;

C. 因用户人为因素引起的故障;

D. 由不可抗力导致的设备故障。

5.设备保修期满之次日以后,如用户需要继续为其进行维修服务,须签订维修合同,所有维修费用由用户承担。

二.商业机密

用户应本着谨慎、诚实的态度,采取必要、合理的措施,协助我公司维护该产品的知识产权和技术秘密,不向其它方提供该产品的样品和技术资料。

-8- 维修记录:

售后服务

公司名称:大庆科丰石油技术开发有限公司

公司地址:大庆市高新区服务外包园D-3座4搂

联系电话:

传真:

Email:。