加速器说明书

- 格式:doc

- 大小:1.30 MB

- 文档页数:37

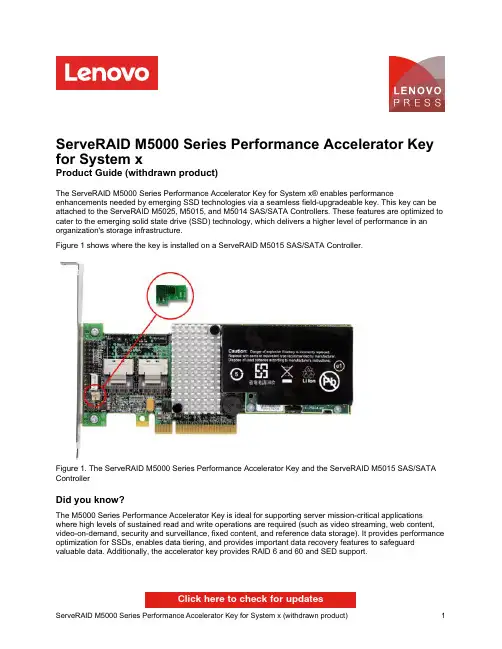

ServeRAID M5000 Series Performance Accelerator Key for System xProduct Guide (withdrawn product)The ServeRAID M5000 Series Performance Accelerator Key for System x® enables performance enhancements needed by emerging SSD technologies via a seamless field-upgradeable key. This key can be attached to the ServeRAID M5025, M5015, and M5014 SAS/SATA Controllers. These features are optimized to cater to the emerging solid state drive (SSD) technology, which delivers a higher level of performance in an organization's storage infrastructure.Figure 1 shows where the key is installed on a ServeRAID M5015 SAS/SATA Controller.Figure 1. The ServeRAID M5000 Series Performance Accelerator Key and the ServeRAID M5015 SAS/SATA ControllerDid you know?The M5000 Series Performance Accelerator Key is ideal for supporting server mission-critical applications where high levels of sustained read and write operations are required (such as video streaming, web content, video-on-demand, security and surveillance, fixed content, and reference data storage). It provides performance optimization for SSDs, enables data tiering, and provides important data recovery features to safeguard valuable data. Additionally, the accelerator key provides RAID 6 and 60 and SED support.Click here to check for updatesFigure 2. Location of the Performance Accelerator Key on the supported adaptersSupported ServeRAID controllersTable 2 lists the ServeRAID SAS/SATA controllers that support the Performance Accelerator Key.Table 2. Supported ServeRAID controllersServeRAID M5000 Series Performance Accelerator Key Y Y Y N N N N N N N N N N N N The minimum firmware level required for the supported adapters to enable the use of the Performance Accelerator Key is v12.7.0-0020. The latest firmware is available from:/support/entry/portal/docdisplay?lndocid=MIGR-5073015The ServeRAID M5000 Series Performance Accelerator Key cannot be installed at the same time as the ServeRAID M5000 Series Advanced Feature Key, 46M0930. The Advanced Feature Key must be removed before the Performance Accelerator Key is installed. The functions of the Advanced Feature Key are provided by the Performance Accelerator Key. No further migration steps are needed.Supported serversThe ServeRAID M5000 Series Performance Accelerator Key is supported on the System x servers listed in Table 2.Table 2. Supported System x servers (part 1)ServeRAID M5000 Series Performance Accelerator Key81Y4426N N Y N Y N N Y Y N N Y Y Table 2. Supported System x servers (part 2)ServeRAID M5000 Series Performance Accelerator Key N Y Y N N N N Y Y N Y N N N N Y See the ServerProven website for the latest information about the adapters supported by each System x server type:/us/en/serverproven/Once the hardware key has been installed on the controller, the Recovery, Safestore, and CacheCade Features can be configured through the WeBIOS or MegaRAID Storage Manager Utilities. Figure 3 shows the LSI MegaRAID Storage Manager Dashboard View.Figure 3. LSI MegaRAID Storage Manager Dashboard ViewMegaRAID RecoveryMegaRAID Recovery enhances the ServeRAID data protection feature set by offering snapshot functionality that allows users to capture source volume data changes and either Restore-from-View or Rollback to a previous point in time (PiT) should accidental or malicious data deletion or infection occur. While traditional overnight backups continue to be the preferred method for creating physical copies of data for offsite or archival purposes, MegaRAID Recovery meets a growing need for more frequent backups and reduced recovery times. By supplementing traditional backup methods with MegaRAID Recovery, IT organizations can greatly enhance their level of business continuity, data protection, and restore capabilities.How MegaRAID Recovery worksMegaRAID Recovery preserves the state of information stored on a virtual drive at a specific point in time using a copy-on-write methodology. This means that when data is written to a designated volume or virtual drive (VD), the original data that was present before being written over is then copied to a snapshot repository. The VD will continue to accept new data while copying original data to the repository. The snapshot repository will then continue to collect the original data that is being written over until a snapshot event takes place. Once a snapshot is taken, all of the new and old data on the VD becomes original data. So the repository never becomes a complete copy of the source VD.Figure 4 shows a server with three VDs and a single snapshot repository.Figure 4: Server with three VDs and a single snapshot repositoryThe Volume Shadow Copy Service (VSS) provides the backup infrastructure for the Microsoft Windows XP and Microsoft Windows Server 2003 operating systems. VSS has native support, using a standard set of application programming interfaces (APIs) for creating consistent point-in-time copies of data, regardless of the snapshot technology or application. As a certified Microsoft VSS Provider, MegaRAID Recovery can be initiated by VSS in order to create PiT volume snapshots on demand. This functionality provides a straight-forward and standard way to produce clean snapshots of a volume while coordinating with different types of business applications,file-system services, backup applications, and storage hardware.MegaRAID FastPathMegaRAID FastPath is a high-performance IO accelerator for solid state drive (SSD) arrays connected to a ServeRAID controller card. This advanced software is an optimized version of ServeRAID technology that can dramatically boost storage subsystem and overall application performance -- particularly those that demonstrate high random read/write operation workloads -- when deployed with a M5000-series controller connected to SSDs.Enabling MegaRAID FastPathEnabling MegaRAID FastPath does not require any special configuration. Simply connect the Performance Accelerator Key to the ServeRAID controller and MegaRAID FastPath will be enabled. As the user implements SSDs into an array, he should see a significant increase in overall application performance. Application workloads that will benefit most from MegaRAID FastPath with SSD volumes are those with small and random I/O patterns requiring high transactional throughput, such as OLTP.RAID 0 random workload performanceWith MegaRAID FastPath enabled, SSD configurations tuned for small, random block-size IO activity — typical of transactional database applications — can sustain over 150,000 I/O reads per second in RAID 0 configurations. This is two times the transactional performance of identical configurations when the MegaRAID FastPath software is disabled. This is particularly evident in 4 K random reads and random writes, as well as 4 K and 8 K OLTP transaction-oriented benchmarks.In Figure 5, note that in the standard mode where MegaRAID FastPath software is not enabled, arrays are able to reach more than 80,000 IOPs. This is due to additional performance tuning optimizations over previous 6 Gbps MegaRAID SATA+SAS generations. However, with the MegaRAID FastPath software enabled, users can experience more than a 70% increase in IOPs throughput.Figure 5. Performance benefits of having MegaRAID FastPath enabled (light green) versus disabled (dark green) - RAID 0 random workloadsRAID 5 random workload performanceIn Figure 6, read performance in RAID 5 configurations demonstrates similar IOP performance as RAID 0. When comparing RAID 5 write performance, MegaRAID FastPath software demonstrates 2.5 times the IOP's performance over an identical configuration with this feature disabled.Figure 6. Performance benefits of having MegaRAID FastPath enabled (lighter color) versus disabled (darker color) - RAID 5 random workloadsRAID 0 application performanceMegaRAID FastPath software significantly boosts server application performance levels for typical workloads as well. MegaRAID controllers with MegaRAID FastPath software disabled are limited to 80,000 IOPs, whereas application performance improves by up to 45% with MegaRAID FastPath software enabled (Figure 7).Figure 7. Typical workloads - RAID 0MegaRAID CacheCadeMegaRAID CacheCade software allows customers to blend inexpensive SATA or SAS hard disk drives (HDDs) with a small amount of solid state storage capacity to provide a substantial performance boost while avoiding complete 1:1 replacement of SATA HDDs with faster SAS HDDs, adding additional SATA HDDs or moving to an all-SSD RAID volume to achieve performance requirements. This combination of HDDs and SSDs as secondary cache helps improve IOPs per dollar, particularly in random read-intensive applications. Simply select an SSD and associate it with one or more virtual drives to configure and use CacheCade software.How CacheCade worksCertain applications access different data sectors more frequently than other data sectors. By determining which data is accessed more frequently, it is possible to move the more frequently accessed data to a faster media, allowing for faster overall READ performance from the controller. CacheCade software allows for frequently read data (hot-spot) to be moved to second-tier SSD cache for much faster retrieval of that data when it is time for it to be re-read. This provides significant performance improvement of 2x to 50x for read-intensive applications such as web, file, SQL, and other transactional server applicationsFigure 8. CacheCade in actionEnabling CacheCadeOnce the Performance Accelerator Key is connected to the M5000 Series Controller, CacheCade can be configured through the MegaRAID Storage Manager Utility. When configuring for CacheCade, it is necessary to make sure that no volume data be stored on the available SSDs prior to creating the SSD cache.Performance impactCacheCade uses SSDs to super-swell the M5000 Series controller cache. As with any other SSD caching implementation, the amount of performance improvement that is achieved differs depending on the application that is running. For this generation, users will see greater performance gains in READ-intensive applications. Supported operating systemsTrademarksLenovo and the Lenovo logo are trademarks or registered trademarks of Lenovo in the United States, other countries, or both. A current list of Lenovo trademarks is available on the Web athttps:///us/en/legal/copytrade/.The following terms are trademarks of Lenovo in the United States, other countries, or both:Lenovo®ServeRAIDServerProven®System x®The following terms are trademarks of other companies:Linux® is the trademark of Linus Torvalds in the U.S. and other countries.Microsoft®, Windows Server®, and Windows® are trademarks of Microsoft Corporation in the United States, other countries, or both.Other company, product, or service names may be trademarks or service marks of others.。

1. Safety ..............................................2 2. Equipment Included (3)Light System Parts for Assembly (3)3. Assembly Instructions/Diagrams ....... 4-5 4. Features & Specification......................6 5. Operation .. (7)Treatment Settings ………………......8-96. Maintenance (9)Warranty (10)Teeth Whitening Accelerator Manufacturer warrants that for a period of one year from the date of purchase this instrument shall be free from defects in material and workmanship and will perform satisfactory under normal use and service. It is the responsibility of the user to comply with all manufacturer assembly, operation, and maintenance instructions provided. This will ensure safe use, consistent results, and maintain rights to warranty.This warranty does not cover damages caused by natural disaster or misuse.Our liability with respect to this product is expressly limited to the specifications set forth above. We shall under no circumstances be liable for incidental or consequential damages.*Manual is subject to change without prior notice.Limited Warranty*Table Of ContentsPLEASE NOTE:Prior to assembly and use of this unit, carefully read the instructions provided herein. As with all technical devices, the proper function and safe operation of this unit depend on the user’s compliance with the safety recommendations.CAUTION: Persons with a history of photosensitivity or who are using photosensitizing drugs should not beexposed to the light from this unit.CAUTION: This equipment is not suitable for use in the presence of flammable anesthetic mixtures with air or nitrous oxide.emitting from this unit when it is in use. Be sure to wear the protective eye glasses provided.by flexible light arm. This will affect the warranty.MaintenanceCleaning Light SystemThe outer case of the light system control panel is madeup of plastic and metal materials. Proper cleaning consists of spraying a soft cloth with mild soapy solution and wiping the outside surface of the unit.Cleaning LED Light IlluminatorLED light Illuminator should always be used with plastic sheath on to protect the light from damage and debris. Replace sheath when needed to maintain sanitary condition3. Pause Treatment: Stop the timer and light by pressing the “PAUSE” button. The remaining time will display on the digital time indicator. Press the button again to continue.do not turn off main power switch.5. Please turn off main power switch at the end of the day.SafetyLight System Parts 17 QTY (1 Box)Remote Control 1 QTYPower Cable (8ft.) 1 QTY Plastic Sheath 20 QTY (1 Box)Safety Glasses 2 QTYUser Manual1 QTYEquipment IncludedLight System Parts for Assembly(1 QTY)(1 QTY)(1 QTY)(1 QTY)(1 QTY)(1 QTY)(1 QTY)(5 QTY)(1 QTY)Light System ControlInfrared Remote ControlTreatment Settings(Applicable for System Control Panel or Remote Control)1. Setting the Timer: Use the “Up” or “Down” button to adjust treatment time to 20 minutes.2. Turn On/Off the light and timer by pressing the “START/STOP” button.(Steps continue on page 9.)Assembly InstructionsStep 1:Insert Part 1 into Part 2 and slide Part 3 over the junction to create the wheel base.Step 2:Slide Part 4 onto Part 5 and slide screw up through the bottom of the wheel base. Screw Part 5 into Part 6 and tighten with wrench provided.(1)(2)(3)(4)(5)(6)3. Once whitening tray is inserted into the patient’s bend the light arm to position the light ½ an inch from the patients treatment tray.1. Plug the power cord into the socket on the back of the system control panel. Confirm wall outlet to assure cord and plug in is suitable to your outlet.2. Turn on the power switch on the back of the control panel.FusePower SwitchP roduct Features♦ High efficiency goose neck arm design, adjustable and convenient. ♦ Combination of high power BLUE led.♦ Programmable bleaching time with microprocessor-controlled timer presets.♦ Digital indicator with audio feedback♦ Smart auto-select power: 100-240V 50/60 Hz for global use. ♦ High speed Multi-Arch teeth whitening system♦ Small base size design, suitable for use in dental offices ♦ Uniformity of light output (see product specifications below). ♦ Infrared remote control setting function♦ Enclosed disposable sheath, prevents cross-infection, clean and convenient.Product Specifications♦ Broad Spectrum: 430nm-490nm♦ Light Output Power: U to 2000 mW/cm2 ♦ 100-240V, 50/60Hz ♦ Weight: 4.7Kg♦ Max. Working Radius: 50cm ♦ Uniform light outputStep 3:Align screw holes on top of Part 7 with the bottom of the light system control panel. Insert 5 screws and tighten with Phillips head screwdriver provided.(Light System Control Panel)。

ORACLE APPLICATION TESTING SUITE - TESTING ACCELERATORS FOR ORACLE E-BUSINESS SUITEFEATURES• Automates complex Oracle E-Business Suite transactionsfor both functional testing andload testing• Supports automation of bothWeb and Oracle Formsapplication interfaces andprotocols• Provides custom test cases tovalidate application content• Enables parameterization oftest scripts for data-driventesting• Simulates loads of hundredsto tens of thousands ofconcurrent users whileminimizing hardwarerequirements• Gathers critical infrastructureperformance metrics toidentify bottlenecks underload• Provides an intuitive Web-based console to configureand run load tests and sharereal-time results withdistributed users• EBS Test Starter Kit withsample test scripts providedfor EBS R12 and 11iOracle Application Testing Suite’s Testing Accelerators for Oracle E-Business Suite provide a comprehensive solution for ensuring the quality and performance of Oracle E-Business Suite applications. The Functional Testing Accelerator for Oracle E-Business Suite extends Oracle Functional Testing to enable automated functional and regression testing of Oracle E-Business Suite applications. The Load Testing Accelerator for Oracle E-Business Suite extends Oracle Load Testing to enable load and performance testing of Oracle E-Business Suite applications. The Testing Accelerators for Oracle E-Business Suite are components of Oracle Application Testing Suite, the centerpiece of the Oracle Enterprise Manager solution for comprehensive testing of packaged, Web and service-oriented architecture–based applications. Ensuring Oracle E-Business Suite Application Quality Ensuring the quality of your Oracle E-Business Suite (EBS) applications is critical to your business. But testing EBS applications prior to deployment and keeping up with the pace application updates while maintaining application quality can be a challenge. Oracle Application Testing Suite (ATS) provides a comprehensive quality management solution for Oracle E-Business Suite. Oracle Functional Testing and the Functional Testing Accelerator for Oracle E-Business Suite provides an automated functional and regression testing solution to validate application functionality prior to deployment and reduce the need for manual testing. Oracle Load Testing and the Load Testing Accelerator for Oracle E-Business Suite provide a powerful load testing solution to test and tune application performance under real production workloads and identify bottlenecks. Oracle Test Manager provides an integrated solution for managing the test process including documenting test cases, test requirements and issues identified during testing in a central repository and managing test execution. Together, these products provide a comprehensive solution for ensuring EBS application quality. Functional Testing Accelerator for Oracle E-Business Suite The Functional Testing Accelerator for Oracle E-Business Suite extends Oracle Functional Testing to provide a powerful and easy-to-use solution to automate functional and regression testing of Oracle’s E-Business Suite applications. OracleFunctional Testing allows users to create test scripts that automate complex business transactions within their EBS applications, including both Web and Oracle Forms based application interfaces. Oracle Functional Testing’s OpenScript integrated scripting platform combines an intuitive graphical scripting interface to quickly create complex test scripts and a powerful Java IDE that provides users with the flexibility to extend scripts programmatically. Users can automate business transactions by simply creating a new script and recording as they step through an EBS transaction in a browser. OpenScript captures all actions performed within Web or Forms based applications interfaces which can then be played back to automatically reproduce the recorded transaction. Users can then add test cases to validate specific Web or Forms application content and parameterize their script inputs to perform data-driven testing. Additional transactions can then be recorded to create a comprehensive automated regression test suite.Figure1. Oracle Functional Testing automates Oracle E-Business Suite functional and regression testingLoad Testing Accelerator for Oracle E-Business SuiteThe Load Testing Accelerator for Oracle E-Business Suite extends Oracle Load Testing to enable automated load and performance testing of Oracle E-Business Suite applications. With Oracle Load Testing you can simulate thousands of virtual users accessing the Oracle E-Business Suite application simultaneously to measure the effect of user load on application performance.Users create their EBS load test scripts in Oracle Functional Testing’s OpenScript integrated scripting platform. OpenScript automates both Web and Forms application protocols to generate highly scalable load test scripts for Oracle EBS. The scripts are automatically correlated to handle dynamic session parameters. These scripts can then be configured to run in Oracle Load Testing against any number of virtual users.Oracle Load Testing provides a Web-based console that allows you to configure and run one or multiple scripts across thousands of virtual users to assess performance. Users can specify a number of run time parameters such as the amount of think time each user spends per page and the browser or connection speed to emulate. During the load test, Oracle Load Testing measures end-user response times as well as the performance of the underlying application infrastructure to help identify and resolve application performance bottlenecks.Comprehensive Testing for Oracle E-Business SuiteOracle Application Testing Suite provides a comprehensive testing solution for Oracle E-Business Suite. With Oracle Functional Testing and the Functional Testing Accelerator for Oracle E-Business Suite, users can effectively introduce automation into their functional test process to ensure the quality of their Oracle E-Business Suite applications and reduce testing time. With Oracle Load Testing and the Load Testing Accelerator for Oracle E-Business Suite, users can leverage a powerful solution for ensuring Oracle E-Business Suite application performance. The Oracle E-Business Suite testing accelerator includes a Test Starter Kit with pre-build test automation scripts for Oracle E-Business Suite applications. The Test Starter Kit covers a broad range of applications and user flows for both functional and performance testing based on the VISION demo database.And with Oracle Test Manager users can effectively document and manage their test process from a central location and report on application readiness.Oracle Application Testing Suite provides a powerful integrated scripting platform for automated functional & regression testing and load testing. Oracle Functional Testing’s OpenScript integrated scripting interface provides a unique combination of ease-of-use and flexibility through its intuitive graphical scripting interface and powerful Java IDE for extending scripts at the code-level. Oracle Functional Testing also provides custom capabilities for testing SOA and Oracle packaged applications through its integrated testing accelerators. Oracle Load Testing provides a fully Web-based user interface for configuring and running load tests and an integrated ServerStats module for monitoring application infrastructure during a load test to identify bottlenecks. Oracle Load Testing also enables multi-user collaboration by allowing testers to view and share real-time results during load test execution through their browser. With Oracle Application Testing Suite users can leverage a comprehensive, integrated solution for automated functional and regression testing, load testing and test process management.Contact UsFor more information about Oracle Application Testing Suite Oracle E-Business Suite Accelerators and Oracle Enterprise Manager please visit or call+1.800.ORACLE1 to speak to an Oracle representative.Copyright © 2011, Oracle and/or its affiliates. All rights reserved.This document is provided for information purposes only and the contents hereof are subject to change without notice. This document is not warranted to be error-free, nor subject to any other warranties or conditions, whether expressed orally or implied in law, including implied warranties and conditions of merchantability or fitness for a particular purpose. We specifically disclaim any liability with respect to this document and no contractual obligations are formed either directly or indirectly by this document. This document may not be reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose, without our prior written permission.Oracle and Java are registered trademarks of Oracle and/or its affiliates. Other names may be trademarks of their respective owners.AMD, Opteron, the AMD logo, and the AMD Opteron logo are trademarks or registered trademarks of Advanced Micro Devices. Intel and Intel Xeon are trademarks or registered trademarks of Intel Corporation. All SPARC trademarks are used under license and are trademarks or registered trademarks of SPARC International, Inc. UNIX is a registered trademark licensed through X/Open Company, Ltd. 0110。

Sun Microsystems, Inc.4150 Network CircleSanta Clara, CA 95054 U.S.A.650-960-1300请访问以下网址来提交您对本文档的意见/hwdocs/feedbackSun Fire™ V880z 服务器和Sun™ XVR-4000图形加速器安装与用户指南部件号 817-2636-102003 年 5月修订版 A请回收版权所有 2003 Sun Microsystems, Inc., 4150 Network Circle, Santa Clara, California 95054, U.S.A. 保留所有权利Sun Microsystems, Inc. 拥有与本文档所述产品包含的技术有关的知识产权重点来讲但不限于此这些知识产权包括/patents网站列出的一个或多个美国专利以及一个或多个在美国或其它国家/地区注册的其它专利或正在申请中的专利本文档及其所述产品的发行受限制其使用复制发行和反编译的许可证的制约未经 Sun 及其许可证发行者如果有事先书面授权不得以任何形式任何方式复制本产品或文档的任何部分第三方软件包括字体技术均已从 Sun 供应商处取得版权和使用许可产品的部分部件可能源于 Berkeley BSD 系统Sun 已从 University of California 获得使用许可UNIX 是在美国及其它国家/地区的注册商标Sun 已从 X/Open Company , Ltd. 获得独家使用授权SunSun Microsystems Sun 徽标Sun FireJava3DJavaOpenBoot 和 Solaris 是 Sun Microsystems,Inc. 在美国及其它国家/地区的商标或注册商标所有 SPARC 商标都是 SPARC International, Inc. 在美国以及其它国家/地区的商标或注册商标必须根据许可证条款使用带有 SPARC 商标的产品以 Sun Microsystems, Inc.开发的体系结构为基础OPEN LOOK 和 Sun™ Graphical User Interface 是 Sun Microsystems, Inc. 专门为其用户和许可证获得者开发的Sun 感谢 Xerox 在用户界面形象化和图形化研发方面为计算机行业所做的先导性贡献Sun 已从 Xerox 获得对 Xerox 图形用户界面 (GUI) 的非独占使用许可该许可也涵盖实施 OPEN LOOK GUI 的 Sun 许可获得者而其它情况则应符合 Sun 的书面许可协议OpenGL 是 Silicon Graphics, Inc. 的注册商标文档以原样提供除非有关的免责声明在法律上无效否则 Sun 拒绝承担任何明确或暗示的条件表示和担保包括任何对适销性特定用途的适用性或非侵犯性作出的暗示担保目录ኔዔxi1.Sun XVR-4000 ᅄተଝႥڔᓤগၤ1安装过程概述1软件补丁程序22.Sun XVR-4000 ᅄተଝႥগၤ3安装工具包3Sun XVR-4000 图形加速器概述4屏幕分辨率8查看现场可更换件信息11技术支持123.ڔᓤ Sun XVR-4000 ᅄተଝႥྟୈ13软件要求13Sun XVR-4000 图形加速器软件包14安装软件16iii4.ڔᓤ Sun XVR-4000 ᅄተଝႥ፮ୈ17安装准备工作17在 Sun Fire V880z 服务器中安装硬件18从 Sun Fire V880z 服务器中卸下硬件27Sun XVR-4000 图形加速器电缆30更改显示器屏幕分辨率305.ᒙࣶৈᑷદߡ31通过Xservers文件配置多个帧缓冲器31Xinerama336.ဧ Sun XVR-4000 ᅄተଝႥถ35联机资料35-outputs端口映射36流传送方法38设置流传送方法40多板设置42多次采样抗锯齿43控制抖动和过滤47检查设备配置497.Sun XVR-4000 ᅄተଝႥᑷჄࢾ51Sun XVR-4000 图形加速器帧锁定系统51缓冲器交换同步52创建多屏幕应用53连接帧锁定电缆54在图形加速器上启用帧锁定56禁用帧锁定57帧锁定电缆58iv Sun Fire V880z 服务器和 Sun XVR-4000 图形加速器安装与用户指南•2003 年 5 月8.Sun XVR-4000 ᅄተଝႥᄴݛჄࢾ59Sun XVR-4000 图形加速器同步锁定59连接同步锁定电缆60为图形加速器启用同步锁定62禁用同步锁定67A.ᒙ෦ཱྀࡼ఼ᒜგመာᓤᒙ69B.ᒙ S-Video73C.ڔᓤ OpenBoot PROM ဍۈ81D.Sun Fire V880z ॲᇗဍ83E.Ᏼ Sun Fire V880z ॲᇗᒦڔᓤ Solaris 8 2/02 ྟୈ89F.Sun XVR-4000 ᅄተଝႥ I/O ࣡ాਖৃ99Ⴣ105目录vvi Sun Fire V880z 服务器和 Sun XVR-4000 图形加速器安装与用户指南•2003 年 5 月图图 2-1Sun Fire V880z 服务器4图 2-2装有空气导流盖的 Sun XVR-4000 图形加速器5图 2-3未装有空气导流盖的 Sun XVR-4000 图形加速器5图 4-1Sun Fire V880z 服务器后面板上用于插槽 B 和 C 的盖板18图 4-2打开 Sun Fire V880z 服务器机壳挡门19图 4-3确定 Sun Fire V880z 服务器插槽 B 和 C 的位置20图 4-4从插槽 B 中卸下 Sun Fire V880z 主板总线插槽盖板21图 4-5将 Sun XVR-4000 图形加速器装入插槽 B 连接器22图 4-6在服务器后面板 I/O 插槽 B 上安装后面板 EMI 适配器23图 4-7Sun XVR-4000 图形加速器电源和温度 LED 指示灯24图 4-8Sun XVR-4000 图形加速器 LED 指示灯25图 4-9卸下 Sun XVR-4000 图形加速器28图 4-10装回 Sun Fire V880z 主板总线插槽盖板29图 6-1Sun XVR-4000 图形加速器后面板36图 6-2输出端口映射 (-outputs)37图 6-3多板设置示例43图 7-1Sun XVR-4000 图形加速器立体/帧锁定连接器54图 7-2Sun XVR-4000 图形加速器和帧锁定电缆55图 7-3帧锁定电缆58vii图 8-1Sun XVR-4000 图形加速器 13W3 和同步锁定连接器60图 8-2Sun XVR-4000 图形加速器同步锁定连接61图 8-3Sun XVR-4000 图形加速器同步锁定 LED 指示灯67图 B-1Sun XVR-4000 图形加速器 S-Video DIN4 连接器74图 D-1卸下 Sun Fire V880 服务器前挡板85图 D-2安装 Sun Fire V880z 服务器前挡板86图 F-1Sun XVR-4000 图形加速器后面板 I/O 端口99图 F-2Sun XVR-4000 图形加速器后面板 13W3 连接器100图 F-3Sun XVR-4000 图形加速器后面板立体/帧锁定 DIN7 连接器101图 F-4Sun XVR-4000 图形加速器后面板 S-Video 连接器102图 F-5Sun XVR-4000 图形加速器后面板 BNC 连接器103viii Sun Fire V880z 服务器和 Sun XVR-4000 图形加速器安装与用户指南•2003 年 5 月表表 2-1Sun XVR-4000 图形加速器屏幕分辨率8表 3-1Sun XVR-4000 图形加速器 CD 目录14表 3-2Sun XVR-4000 图形加速器软件包的位置14表 3-3Sun XVR-4000 图形加速器软件包名称15表 3-4Sun XVR-4000 图形加速器补丁程序目录15表 3-5Sun XVR-4000 图形加速器补丁程序15表 6-1多次采样选项说明44表 6-2典型多次采样支持44表 6-3-jitter选项47表 6-4-filter选项48表 7-1帧锁定电缆连接58表 8-1屏幕分辨率同步属性65表 F-1Sun XVR-4000 图形加速器 13W3 连接器插针100表 F-2Sun XVR-4000 图形加速器立体/帧锁定连接器插针101表 F-3Sun XVR-4000 图形加速器 S-Video 连接器插针102表 F-4Sun XVR-4000 图形加速器 BNC 连接器插针103ixx Sun Fire V880z 服务器和 Sun XVR-4000 图形加速器安装与用户指南•2003 年 5 月xi序言本手册讲述如何在 Sun Fire ™ V880z 服务器中安装 Sun ™ XVR-4000 图形加速器及相关软件此外它还介绍了将 Sun Fire V880 服务器升级至 Sun Fire V880z 服务器的过程ᓖ – Sun Fire XVR-4000 图形加速器和 Sun Fire V880z 服务器必须 由合格的服务人员管理和维修本书的内容编排第 1 章概述 Sun XVR-4000图形加速器的安装过程第 2 章简要介绍 Sun XVR-4000 图形加速器包括产品功能和支持的视频格式第 3 章说明如何安装 Sun XVR-4000图形加速器软件第 4 章说明如何安装 Sun XVR-4000图形加速器硬件第 5 章介绍如何修改 Xservers 配置文件从而运行多个帧缓冲器第 6 章提供有关使用 Sun XVR-4000图形加速器功能的信息包括通过 fbconfig配置加速器多次采样和多次采样抗锯齿功能第 7 章介绍如何对多个 Sun XVR-4000图形加速器进行帧锁定第 8 章说明如何对多个 Sun XVR-4000图形加速器进行同步锁定附录 A 说明如何将 Sun XVR-4000图形加速器设置为默认的显示器控制台显示装置附录 B 介绍如何在 Sun XVR-4000 图形加速器上设置 S-video NTSC 和 PAL 视频格式xii Sun Fire V880z 服务器和 Sun XVR-4000 图形加速器安装与用户指南•2003 年 5 月附录 C 说明如何安装 OpenBoot PROM 4.7.0升级版附录 D 介绍如何将 Sun Fire V880 服务器升级至配有 Sun XVR-4000 图形加速器的 Sun Fire V880z服务器附录 E 提供有关使用 Sun Fire V880z Operating Environment Installation DVD 的信息附录 F 提供 Sun XVR-4000 图形加速器的 I/O端口规格使用 UNIX 命令本文档没有介绍基本 UNIX ® 命令和操作过程的有关信息如关闭系统启动系统和配置设备等有关此类信息的详细说明请参阅以下文档I Solaris Handbook for Sun PeripheralsI 用于 Solaris ™ 软件环境的 AnswerBook2™ 联机文档I系统附带的其它软件文档印刷约定ᔊዹ९ፃာಿAaBbCc123命令文件和目录的名称计算机的屏幕输出编辑您的 .login文件使用 ls -a列出所有文件% You have mail.AaBbCc123键入的内容相对于屏幕上的计算机输出% suPassword:AaBbCc123书的标题新词或术语需要强调的词需用真名或实际值替换命令行变量阅读用户指南 中的第 6章这些选项称为 class 选项要删除文件请键入 rm文件名序言xiiishell 提示相关文档访问 Sun 文档用户可从以下网站查看打印或订购 Sun 提供的各类文档包括本地化版本/documentationshellᄋာ९C shell计算机名%C shell 超级用户计算机名#Bourne shell 和 Korn shell$Bourne shell 和 Korn shell 超级用户#።ၗݝୈ维修Sun Fire V880 Server Service Manual 806-6597系统选项Sun Fire V880 服务器用户指南816-0756xiv Sun Fire V880z 服务器和 Sun XVR-4000 图形加速器安装与用户指南•2003 年 5 月联系 Sun 技术支持人员如果遇到本文档不能解决的产品技术问题请访问以下网址/service/contactingSun 欢迎您提出意见Sun十分注重改进自身文档的质量并欢迎您提出宝贵的意见和建议您可通过访问以下网址来提交您的意见/hwdocs/feedback请在反馈意见中注明本文档的书名和部件号Sun Fire V880z 服务器和 Sun XVR-4000图形加速器安装与用户指南部件号 817-2636-101第章1Sun XVR-4000 图形加速器安装概述本章介绍 Sun XVR-4000 图形加速器的安装过程有关 Sun XVR-4000图形加速器Sun Fire V880z 服务器和安装工具包内容的概述请参阅第 2 章ᓖ – Sun Fire XVR-4000 图形加速器和 Sun Fire V880z 服务器必须由合格的服务人员管理和维修I 第 1页的安装过程概述I第 2页的软件补丁程序安装过程概述共有三种不同的安装情况请选用其中一个适用的安装过程在 Sun Fire V880z 服务器上安装 Sun XVR-4000 图形加速器软件Sun XVR-4000 图形加速器 DVD 和 Solaris CD 只适用于 Solaris 8 2/02操作环境1. 放入 Sun Fire V880z Operating Environment Installation DVD然后从中引导系统第 3章2. 安装 Solaris 8 2/02软件第 3章3.出现提示时放入 Solaris CD安装 Solaris之后系统会重新引导继续步骤4如果您安装的是 Solaris 9 4/03操作环境则在安装之后无需进一步安装软件因为该 Solaris 版本或更高版本已包含了配有 Sun XVR-4000 图形加速器的 Sun Fire V880z 服务器所需的软件否则请继续步骤4以从 Sun XVR-1000 图形加速器 CD 中安装 OpenGL 1.3Sun XVR-4000图形加速器补丁程序以及额外的值软件2Sun Fire V880z 服务器和 Sun XVR-4000 图形加速器安装与用户指南•2003 年 5 月4. 将 Sun XVR-4000 图形加速器 CD 放入 DVD驱动器第 3章然后键入5. 根据需要安装第二个 Sun XVR-4000 图形加速器硬件第 4章Sun Fire V880z已安装了一个 Sun XVR-4000 图形加速器6. 通过 Xservers文件配置软件第 5章如有必要也可通过 fbconfig 配置软件第 6章从一个 Sun XVR-4000 图形加速器升级至两个1.编辑两个 Sun XVR-4000 图形加速器的 Xservers配置文件第 5章2. 安装第二个 Sun XVR-4000图形加速器硬件第 4章将 Sun Fire V880 服务器升级至 Sun Fire V880z 服务器此升级过程包括硬件软件前门和前挡板的安装步骤1.系统要求使用 OpenBoot PROM 4.7.0 或更高版本如果 OpenBoot PROM 版本低于4.7.0请安装 OpenBoot PROM升级版本附录C 2. 执行 Sun Fire V880z服务器升级附录D 3. 通过 Xservers文件配置软件第 5章如有必要也可通过 fbconfig 配置软件第 6章软件补丁程序确保您安装了正确的的补丁程序 第 3章列出了产品软件包和补丁程序有关最新的软件补丁程序请随时访问 / 网站# cd /cdrom/cdrom0# ./install3第章2Sun XVR-4000 图形加速器概述本章简要介绍了 Sun Fire V880z 服务器的 Sun XVR-4000 图形加速器I 第 3页的安装工具包I 第 4页的Sun XVR-4000 图形加速器概述I 第 8页的屏幕分辨率I 第 11 页的查看现场可更换件信息I第 12 页的技术支持有关 Sun Fire V880z服务器的详细信息请参阅 Sun Fire V880服务器文档I Sun Fire V880 Server Service Manual (806-6597)ISun Fire V880 服务器用户指南 (816-0756)安装工具包Sun XVR-4000图形加速器安装工具包包括I Sun XVR-4000 图形加速器I Sun XVR-4000 图形加速器软件 CDI Sun Fire V880z Operating Environment Installation DVD I 13W3 到 HD15 显示器电缆适配器I 防静电腕带ISun Fire V880z Server and Sun XVR-4000 Graphics Accelerator Installation and User's Guide 即本文档有关其它电缆信息请参阅第 30 页的Sun XVR-4000图形加速器电缆4Sun Fire V880z 服务器和 Sun XVR-4000 图形加速器安装与用户指南•2003 年 5 月Sun XVR-4000 图形加速器概述Sun XVR-4000图形加速器是一款高性能可实现相片质量的 3D图形加速器它在Sun Fire V880z 服务器的 Sun ™ Fireplane互连总线上运行图2-1应用程序界面包括 Sun OpenGL ® 1.3 for Solaris 和 Java3D ™通过 Java ™ Advanced Imaging API可以支持成像Sun XVR-4000图形加速器通过提供极高性能的渲染并提供每时每刻的全景抗锯齿在视觉上产生了栩栩如生的效果从而实现预期的高质量抗锯齿渲染ᅄ 2-1Sun Fire V880z 服务器第 2 章Sun XVR-4000 图形加速器概述5图 2-2 和图 2-3 分别显示了装有和未装有空气导流盖的 Sun XVR-4000图形加速器 附录 F介绍了后面板上的 I/O端口ᅄ 2-2装有空气导流盖的 Sun XVR-4000 图形加速器ᅄ 2-3未装有空气导流盖的 Sun XVR-4000图形加速器6Sun Fire V880z 服务器和 Sun XVR-4000 图形加速器安装与用户指南•2003 年 5 月Sun XVR-4000 图形加速器功能质量I 通过视频速率达 5 × 5 的像素处理阵列实现行业领先的抗锯齿质量I 支持 30位颜色精度提供更广更精确的色域I 12 位有效线性光预灰度系数颜色精度I26 位浮点 Z缓冲实现比 32 位整数 Z 缓冲更有效的深度分辨率性能I 几何处理速率高达每秒 65M 个硬件纹理三角形I全几何速率时达 256 MB的纹理内存或在几何速率降低时达 1 GB的纹理内存使用目标纹理 OpenGL扩展I在 Sun Fireplane 互连总线上的高性能 DMA灵活性I 通过能够同时运行不同分辨率的两个 10 位视频 DAC 和 13W3输出端口支持两个异步视频流I经优化用于超取样的 144 MB高分辨率样本缓冲器保持高达 10 M 的图像样本值而不是像素值允许用户在屏幕分辨率与每像素样本数之间折衷选择由 32 3DRAM64 帧缓冲器内存芯片实现I 在帧缓冲器容量和 Convolve 带宽限制范围内可持续设定分辨率I在具有已过滤的抗锯齿像素的相同屏幕上支持非过滤的 X-Windows 像素扩展性I使用四个平行图形处理引擎四个 Cafe 处理器和四个FBC3 ASIC 的硬件几何加速第 2 章Sun XVR-4000 图形加速器概述7标准X-WindowsOpenGLI 视频端口剪辑I 窗口 ID (WID) 剪辑用于超过八个交叠窗口的辅助剪辑硬件I 64 个主 X Windows 窗口 ID 15 个重叠窗口 IDI 每个视频流中有四个 3 × 256 10 位彩色图伪颜色或调配色I每个视频流有一个 3 × 4096 10 位可调整灰度系数校正表用于真彩色单独的红色绿色和蓝色灰度系数视频操作Sun XVR-4000 图形加速器支持以下视频输出和功能默认视频端口可以是 13W3A 视频端口也可以是 13W3B 视频端口具体通过 fbconfig选定参阅第 6章视频输出Sun XVR-4000图形加速器支持两个同步视频流这些视频流可用于多种用途例如在两个高分辨率的显示器或投影仪上分别显示共享的帧缓冲器区域在两个显示设备上显示两个不同高分辨率的 X-window 系统屏幕或者在显示器上显示高分辨率的图像并在高分辨率显示器上同步显示 NTSC分辨率的内容ᓖ –如果情景内容在两个视频流之间共享即内容来源于共享帧缓冲器而不是独立的帧缓冲器垂直速率必须一致才能在两个视频输出上获得正确的显示S-Video 功能对于 S-video 输出NTSC 或PAL 主显示屏的任何子区域最大到整个显示屏均可重新调整至 NTSC 或 PAL以便进行录像等操作I从主视频桌面的一部分到 TV/VCR视频输出端口可为 NTSC视频格式刷新率60 Hz 分辨率 640 ×480和 PAL视频格式刷新率50Hz 分辨率 640 ×480提供次视频输出流I TV/VCR 视频输出是S-video采用适当的机械连接I如果未使用 S-video 输出则可使用第二个 13W3输出以实现高分辨率显示8Sun Fire V880z 服务器和 Sun XVR-4000 图形加速器安装与用户指南•2003 年 5 月屏幕分辨率Sun XVR-4000 图形加速器能够以支持的所有分辨率显示全部 30 位3D 双/z 缓冲图形 表 2-1 列出了 Sun XVR-4000图形加速器支持的屏幕分辨率GገࡻჅᎌᅄተ۸ࡼܭ༿ྜྷG ገࡻመာ۸ࡼభॊܦൈܭ༿ྜྷhost% fbconfig -listhost% fbconfig -dev zulu0 -res \?ܭ 2-1 Sun XVR-4000 图形加速器屏幕分辨率መာॊܦൈၮቤൈ (Hz)ܪᓰᔑ੯܈ၒ߲࣡ా၁ຫৃါ1920 × 120060d Sun 16:1013W3SUNW_DIG_1920x1200x601920 × 12007075Sun 16:1013W3SUNW_STD_1920x1200x70SUNW_STD_1920x1200x751920 × 108060d Sun 16:913W3SUNW_DIG_1920x1080x601920 × 108072Sun 16:913W3SUNW_STD_1920x1080x721792 × 134460VESA 4:313W3VESA_STD_1792x1344x601600 × 128076Sun 5:413W3SUNW_STD_1600x1280x761600 × 120060d Sun 4:313W3SUNW_DIG_1600x1200x601600 × 12006075VESA 4:313W3VESA_STD_1600x1200x60VESA_STD_1600x1200x751600 × 102460Sun 16:1013W3SUNW_DIG_1600x1024x60 或SUNW_STD_1600x1024x601600 × 10006676Sun 16:1013W3SUNW_STD_1600x1000x66SUNW_STD_1600x1000x761440 × 90076Sun 16:1013W3SUNW_STD_1440x900x761280 × 102496112Sun stereo 5:413W3SUNW_STEREO_1280x1024x96SUNW_STEREO_1280x1024x1121280 × 1024108dSun stereo5:413W3SUNW_STEREO-DIG_1280x1024x1081280 × 1024607585VESA5:413W3VESA_STD_1280x1024x60VESA_STD_1280x1024x75VESA_STD_1280x1024x851280 × 10246776Sun5:413W3SUNW_STD_1280x1024x67SUNW_STD_1280x1024x761280 × 800112Sun stereo16:1013W3SUNW_STEREO_1280x800x112 1280 × 80076Sun16:1013W3SUNW_STD_1280x800x76 1280 × 76856Sun5:313W3SUNW_STD_1280x768x56 1152 × 900120Sun stereo5:413W3SUNW_STEREO_1152x900x1201152 × 9006676Sun5:413W3SUNW_STD_1152x900x66SUNW_STD_1152x900x761024 × 692100Sun stereo4:313W3SUNW_STEREO_1024x692x100 1024 × 80084Sun4:313W3SUNW_STD_1024x800x84 1024 × 76896Sun stereo4:313W3SUNW_STEREO_1024x768x96 1024 × 76877Sun4:313W3SUNW_STD_1024x768x771024 × 768607075VESA4:313W3VESA_STD_1024x768x60VESA_STD_1024x768x70VESA_STD_1024x768x75960 × 680108112Sun stereo14:1013W3SUNW_STEREO_960x680x108SUNW_STEREO_960x680x112800 × 60075VESA4:313W3VESA_STD_800x600x75 768 × 57550i PAL (RGB)4:313W3SUNW_PAL_768x575x50 768 × 57550i Sun4:313W3SUNW_INT_768x575x50 640 × 48060fsc Sun4:313W3SUNW_FSC_640x480x60640 × 480607275VESA4:313W3VESA_STD_640x480x60VESA_STD_640x480x72VESA_STD_640x480x75640 × 48060i SunNTSC (RGB)4:313W3SUNW_INT_640x480x60640 × 48060i NTSC(Composite)4:3S-video SUNW_NTSC_640x480x60640 × 48050i PAL(Composite)4:3S-video SUNW_PAL_640x480x50ܭ 2-1 Sun XVR-4000 图形加速器屏幕分辨率续መာॊܦൈၮቤൈ(Hz)ܪᓰᔑ੯܈ၒ߲࣡ా၁ຫৃါ第 2 章Sun XVR-4000 图形加速器概述910Sun Fire V880z 服务器和 Sun XVR-4000 图形加速器安装与用户指南•2003 年 5 月ᓖ – 刷新率标记为d 的视频格式只适用于 LCD和其它数字设备这些刷新率缩短了不适用于 CRT和其它模拟设备的间隔时间刷新率标记为i的视频格式是隔行扫描方式刷新率标记为fsc的视频格式仅用于特定的场序彩色显示NTSC 和 PAL 复合视频格式仅使用 S-video输出端口虽然 Sun XVR-4000图形加速器支持有线立体眼镜和无线立体眼镜但不 支持那些无外部电源的无线立体眼镜有关说明请参阅第 54页的连接帧锁定电缆第 2 章Sun XVR-4000 图形加速器概述11查看现场可更换件信息您可以使用 fbconfig 命令获得 Sun XVR-4000 图形加速器子部件的版本号和其它数据G ገࡻFRU IDሚޝభৎધୈܪဤ९ቧᇦ༿ྜྷጲሆෘഎhost% fbconfig -dev zulu0 -prconf--- Hardware Configuration for /dev/fbs/zulu0 ---Type: XVR-4000 Graphics Accelerator Part: 501-5588Memory:MAJC: 128MBTexture: 1GB total3DRAM64: 10.0M samplesVersions:Fcode 1.18 MCode 1.4 MAJC 2.1 FBC3 3.0 Master 1.0 Convolve 0.0 Sched 1.0 I/O 0.0 FPGA 1.0 Power Level:Monitor Power: On Board Power: OnVideo Streams: Stream A:Current resolution setting: Flags: Default Primary Monitor/EDID data (13W3)Monitor Manufacturer: SUN EDID: Version 1, Revision 3Stream B:Current resolution setting: Flags: NoneMonitor/EDID data (13W3)EDID Data: Not Available12Sun Fire V880z 服务器和 Sun XVR-4000 图形加速器安装与用户指南•2003 年 5 月技术支持欲了解本文档中未介绍的 Sun XVR-4000图形加速器的帮助和其它信息请访问网站 /service/online 上的Support Services支持服务要获得安装与用户指南的最新版本请访问 /documentation网站13第章3安装 Sun XVR-4000 图形加速器软件本章介绍如何安装 Sun XVR-4000图形加速器软件I 第 13 页的软件要求I 第 14 页的Sun XVR-4000图形加速器软件包I第 16 页的安装软件软件要求ISolaris 8 2/02 操作环境或以后的兼容版本对于 Solaris 8 2/02操作环境您必须 首先安装 Sun XVR-4000 图形加速器安装工具包中附带的 Operating Environment Installation DVD有关此过程的说明请参阅附录EISolaris 9 4/03 操作环境或以后的兼容版本如果您安装的是 Solaris 9 4/03操作环境则在安装之后无需进一步安装软件因为该 Solaris 版本或更高版本已包含了配有 Sun XVR-4000 图形加速器的 Sun Fire V880z 服务器所需的软件有关补丁程序的列表请参见表 3-5有关最新的软件补丁程序信息请随时访问以下网站 /您可从以下网址获取 Sun OpenGL ® for Solaris的更新版本 /software/graphics/OpenGL/14Sun Fire V880z 服务器和 Sun XVR-4000 图形加速器安装与用户指南•2003 年 5 月Sun XVR-4000 图形加速器软件包表 3-1 列出了 Sun XVR-4000 图形加速器 CD 的目录软件包位于目录路径/cdrom/cdrom0/下软件包位置Sun XVR-4000 图形加速器软件包位于表 3-2列出的目录中ܭ 3-1 Sun XVR-4000 图形加速器 CD 目录ഺႁීLicense二进制代码许可证XVR-4000/Solaris_8/Packages/ Solaris 8 图形加速器软件包XVR-4000/Solaris_9/Packages/ Solaris 9 图形加速器软件包Docs/ Sun XVR-4000 图形加速器文档Copyright 美国版权版本FR_Copyright 法国版权版本install 产品安装脚本remove产品删除脚本OpenGL/1.3/Packages/ OpenGL 1.3 软件包OBP/ OpenBoot PROM 更新实用程序README包含重要安装信息的文件ܭ 3-2Sun XVR-4000 图形加速器软件包的位置ྟୈ۞ഺᆡᒙSolaris 8 软件/cdrom/cdrom0/XVR-4000/Solaris_8/Packages Solaris 9 软件/cdrom/cdrom0/XVR-4000/Solaris_9/Packages第 3 章安装 Sun XVR-4000 图形加速器软件15软件包表 3-3 列出了 Sun XVR-4000图形加速器软件包的名称和说明软件补丁程序表 3-4 列出了包含 Solaris操作环境适用的补丁程序的目录表 3-5列出了软件安装所需的补丁程序ܭ 3-3Sun XVR-4000 图形加速器软件包名称ྟୈ۞߂ႁීSUNWzuluc Sun XVR-4000 图形加速器的配置实用程序SUNWzulur Sun XVR-4000 图形加速器引导期间的设备初始化支持SUNWzuluwSun XVR-4000 图形加速器的 X Windows 系统可加载模块SUNWzulux.u Sun XVR-4000图形加速器64位的设备驱动程序SUNWzulum Sun XVR-4000 图形加速器联机资料SUNWvid 一般视频计时信息SUNWgldp Sun OpenGL 1.3 for Solaris 设备管道SUNWgldpxSun OpenGL 1.3 for Solaris设备管道64 位ܭ 3-4Sun XVR-4000 图形加速器补丁程序目录Solaris ۈ۾ᆡᒙSolaris 8 软件/cdrom/cdrom0/XVR-4000/Solaris_8/Patches Solaris 9 软件/cdrom/cdrom0/XVR-4000/Solaris_9/Patchesܭ 3-5 Sun XVR-4000 图形加速器补丁程序ݗࢷ߈ኔܠႁී114469Solaris 8 中的 Sun XVR-4000 图形加速器软件114470Solaris 9 中的 Sun XVR-4000 图形加速器软件113886OpenGL 1.3 32位库任何 Solaris 版本113887OpenGL 1.3 64位库任何 Solaris 版本16Sun Fire V880z 服务器和 Sun XVR-4000 图形加速器安装与用户指南•2003 年 5 月安装软件ᓖ – 对于 Solaris 8 2/02操作环境您必须 首先安装名称为Operating EnvironmentInstallation DVD 的 DVD 有关此过程的说明请参阅附录E如果您安装的是 Solaris 9 4/03操作环境则在安装之后无需进一步安装软件因为该 Solaris 版本或更高版本已包含了配有 Sun XVR-4000 图形加速器的 Sun Fire V880z 服务器所需的软件安装 Solaris 版本或更新版本后从 Sun XVR-4000 Graphics Accelerator CD 中安装 OpenGL 1.3, XVR-4000补丁程序和额外的值软件 下面简要介绍了适于 Solaris 8 2/02操作环境的软件安装过程1.ږᑍএഺE Ᏼ Sun Fire V880z ᒦڔᓤ Solaris 8 2/02ྟୈᒦࡼႁීઁ Sun Fire V880z Operating Environment Installation DVD हྜྷ DVD-ROM དࣅઁ࠭ᒦࡴᇹᄻ2.߲ሚᄋာဟहྜྷSolaris DVD安装 Solaris之后系统会重新引导3. Sun XVR-4000 ᅄተଝႥ CD हྜྷ DVD-ROMདࣅ߅ᆐިઓઁྜྷጲሆഺ4.ࣅ install୭۾ྜྷጲሆෘഎ回应安装提示问题5.ྙਫᆚڔᓤ Sun XVR-4000ᅄተଝႥ፮ୈ༿ڔᓤ6.ᄰਭ Xserversᆪୈᒙྟୈ 5ᐺྙᎌܘገጐభᄰਭ fbconfigᒙྟୈ 6ᐺ若要删除软件请使用 ./remove 命令然后回应 remove 提示问题# cd /cdrom/cdrom0/# ./install17第章4安装 Sun XVR-4000 图形加速器硬件本章介绍如何为 Sun Fire V880z 服务器安装 Sun XVR-4000图形加速器硬件I第 17 页的安装准备工作I第 18页的在 Sun Fire V880z服务器中安装硬件I第 27页的从 Sun Fire V880z服务器中卸下硬件I第 30 页的Sun XVR-4000图形加速器电缆I 第 30 页的更改显示器屏幕分辨率安装准备工作有关如何在安装或拆卸任何内部插件板之前安全关闭系统以及如何在安装之后重新引导系统的正确过程请参阅Sun Fire V880 服务器用户指南网站 /documentation上提供了全套的文档有关 Sun Fire V880z 服务器的详细维修信息请参阅以下硬件文档ISun Fire V880 Server Service Manual (806-6597)I Sun Fire V880 服务器用户指南 (816-0756)18Sun Fire V880z 服务器和 Sun XVR-4000 图形加速器安装与用户指南•2003 年 5 月在 Sun Fire V880z 服务器中安装硬件Sun Fire V880z 服务器最多支持两个 Sun XVR-4000图形加速器装有两个 Sun XVR-4000 图形加速器时系统可以支持四个视频显示设备Sun XVR-4000 图形加速器安装在 Sun Fire V880z CPU 插槽 B 和 C内因此装有一个 Sun XVR-4000 图形加速器的 Sun Fire V880z 系统最多可安装六个 CPU 装有两个 Sun XVR-4000 图形加速器的 Sun Fire V880z 系统最多可安装四个CPUᓖፀ – Sun XVR-4000 图形加速器不是热交换设备1.ਈܕᇹᄻ࢟Ꮞ2.࠭ᇹᄻઁෂۇڰሆመာ࢟಄ރᄿᓖፀ –机箱的交流电源线必须保持连接以确保正确的接地至少保留一条电源线的连接3.Ᏼᇹᄻઁෂۇᑊࡵ᎖ڔᓤ Sun XVR-4000 ᅄተଝႥࡼރݹઁቘሆᑚቋރݹࡼঙۇ图4-1后面板上的填充插槽盖板由四颗十字螺丝固定拧下螺丝并妥善保管以备后用ᅄ 4-1 Sun Fire V880z 服务器后面板上用于插槽 B 和 C的盖板插槽 C 盖板盖板第 4 章安装 Sun XVR-4000 图形加速器硬件194.ࡌఎ Sun Fire V880zॲᇗ૦ఫࡪඡ图4-2a.ဧᇹᄻᏙߓࡌఎݾࡪඡࡼჄb.ኟఎݾࡪඡc.ገ࠭૦ረቘሆࡪඡ༿ࡪඡࡌఎᒗ 90 ࣞઁሶᄋࡪඡᒇᒗৼࢾၴᅙಭ۳ෂۇࡼᑽଦᅄ 4-2 打开 Sun Fire V880z服务器机壳挡门20Sun Fire V880z 服务器和 Sun XVR-4000 图形加速器安装与用户指南•2003 年 5 月5.ཀྵࢾރݹ B ਜ਼ C ࡼᆡᒙ图4-3如果您只安装一个 Sun XVR-4000 图形加速器则可以使用插槽 B 或插槽CSun Fire V880z 服务器主板插槽从下到上依次标识为 A 到Dᅄ 4-3 确定 Sun Fire V880z 服务器插槽 B 和 C的位置插槽 B插槽 C第 4 章安装 Sun XVR-4000 图形加速器硬件216.࠭ CPUᑽଦቘሆഗۇ݀࠭ᓍۇ VHDMೌᒦቘሆऴঙۇރݹ B ᎖图ᅄ 4-4 从插槽 B 中卸下 Sun Fire V880z 主板总线插槽盖板7.ഗۇઘࣅࡵ૦ఫดݝࢻۇࡼၢࡀݹሆऱࡀഗۇጲ۸ઁ气流隔板与存储槽正确对齐时气流隔板的黑色插栓可以轻松插入金属槽孔以将隔板锁定到位要将气流隔板装回机箱的图形加速器插槽请将插槽与气流隔板正确对齐黑色插栓将很容易地插入孔中并将气流隔板锁定到位8.ཀྵۣࡑڔᓤ۞ᒦএࡒࡼऴஸ࢟ᅻࡒ参阅Sun Fire V880 服务器用户指南 中的如何避免静电放电一节9. Sun XVR-4000 ᅄተଝႥहྜྷኡࢾރݹB C ࡼ૦ረࡴਜ22Sun Fire V880z 服务器和 Sun XVR-4000 图形加速器安装与用户指南•2003 年 5 月10.ཀྵۣጯ Sun XVR-4000 ᅄተଝႥࡼࡧ߲ঝሶᅪኟᓞᒗ 90ࣞ图4-511.ᆻᓕᅄተۇࡼೝ࣡ Sun XVR-4000ᅄተଝႥઘྜྷఌࡴਜଦ若要安装一个 Sun XVR-4000 图形加速器请使用插槽B若要安装两个图形加速器请使用插槽 B 和 C Sun XVR-4000图形加速器的弹出杆触到导轨架时停止滑入ᓖ – 如果弹出杆无法触到卡导轨架请勿尝试强行装入图形加速器这可能会损坏 Sun XVR-4000图形加速器或主板ᅄ 4-5 将 Sun XVR-4000 图形加速器装入插槽 B 连接器导轨第 4 章安装 Sun XVR-4000 图形加速器硬件2312.ᓙᓕೝৈࡧ߲ঝᄴဟሶดᓞࣅ不要在卡导轨架中摇晃图形加速器当从 CPU 模块/Sun XVR-4000 图形加速器侧面观看时Sun XVR-4000图形加速器朝向机箱的左前侧安装应顺利平稳13.ྙਫࡧ߲ঝጯᅲཝᓞࣅࡵᆡ༿၄ูஜೝၴᇹ൛ႋᓖ –请先用手拧紧然后再使用扭矩仪14.ဧ 2 လᔊ൛ႋጥูஜᎎݾࡼၴᇹ൛ႋઁูஜᔧݾࡼၴᇹ൛ႋ如果使用扭矩仪请先用 8 英寸-磅0.90 米-牛顿的扭矩将右侧的栓系螺丝固定到位然后对左侧的栓系螺丝重复同样的操作15.ઁෂۇ I/O ރݹ EMI းৼࢾࡵሚጯڔᓤ Sun XVR-4000ᅄተଝႥࡼރݹ图4-6使用用于固定后面板填充盖板的四颗十字螺丝固定 EMI适配器ᅄ 4-6 在服务器后面板 I/O 插槽 B 上安装后面板 EMI 适配器后面板EMI适配器24Sun Fire V880z 服务器和 Sun XVR-4000 图形加速器安装与用户指南•2003 年 5 月16.ሤ።ࡼመာ࢟಄ೌᒗᇹᄻઁෂۇࡼ Sun XVR-4000ᅄተଝႥઁෂۇ17.ૄ࢟Ꮞሣ18.ࡌఎᇹᄻ࢟Ꮞ19.ڔᓤ Sun XVR-4000ᅄተଝႥ݀ᄰᇹᄻ࢟Ꮞᒄઁ༿އఘ Sun XVR-4000 ᅄተଝႥࡼൊྻ LED ᒎာࡾਜ਼ሤ።ࡼᒦቦۇ CPU ރݹᒎာࡾ图4-7每个 Sun XVR-4000 图形加速器上的绿色电源 LED 指示灯可以确切地表示每个 Sun XVR-4000图形加速器的电源状态Sun XVR-4000 图形加速器有两个 LED 指示灯左侧的 LED指示灯是绿色电源指示灯右侧的 LED指示灯是琥珀色温度指示灯图4-7当琥珀色 LED指示灯亮起时表示由于温度过高而导致 Sun XVR-4000图形加速器模块断电正常情况下Sun FireV880z 服务器软件会在琥珀色 LED 指示灯指示紧急断电保护之前采取纠正措施以断开温度过高的插槽的电源因此很少会看到琥珀色 LED指示灯亮起ᅄ 4-7 Sun XVR-4000 图形加速器电源和温度 LED 指示灯安装 Sun XVR-4000 图形加速器并打开系统电源之后请通过验证电源 LED 指示灯是否亮起来确定 Sun XVR-4000 图形加速器安装的正确性即每一个 Sun XVR-4000 图形加速器上的绿色电源 LED 指示灯和机箱中心板 CPU插槽指示灯。

Alveo U200 和 U250 数据中心加速器卡用户指南UG1289 (v1.0) 2019 年 2 月 15 日条款中英文版本如有歧义,概以英文本为准。

修订历史修订历史下表列出了本文档的修订历史。

目录修订历史 (2)第 1 章: 引言 (4)原理图 (4)卡功能 (5)卡规格 (6)设计流程 (7)第 2 章: 卡建立与配置 (11)静电放电提示 (11)在服务器机箱中安装 Alveo 数据中心加速器卡 (11)FPGA 配置 (11)第 3 章: 卡组件描述 (13)Virtex UltraScale+ FPGA (13)DDR4 DIMM 存储器 (13)Quad SPI 闪存 (13)USB JTAG 接口 (14)FT4232HQ USB-UART 接口 (14)PCI Express 端点 (14)QSFP28 模块连接器 (14)I2C 总线 (15)状态 LED (15)卡电源系统 (15)附录 A: 赛灵思的约束文件 (16)附录 B: 法规合规信息 (17)CE 指令 (17)CE 标准 (17)合规标识 (18)附录 C: 附加资源与法律提示 (19)赛灵思资源 (19)Documentation Navigator 与设计中心 (19)参考资料 (19)请阅读:重要法律提示 (20)第 1 章引言重要提示! 除非另行说明,本用户指南适用于有源与无源版本的 U200 和 U250 卡。

赛灵思 Alveo™ U200/U250 数据中心加速器卡符合外围部件互联 (PCIe®) Gen3 x16 要求,并采用了赛灵思 Virtex®UltraScale+™技术。

这些卡可加速计算密集型应用,如机器学习、数据分析、视频处理等。

Alveo U200/U250 数据中心加速器卡支持被动散热和主动散热配備。

下图展示的是被动散热型 Alveo U200 ES1 加速器卡。

Electrical PropertiesUSB port supplies power, 5V, <30mA required. Pedal current ~1mA.Status LEDs: green and red. Green LED indicates normal operation, flashes during re-programming. Green+red indicates a pedal is pressed. Red-only indicates operational fault. Environmental PropertiesOperating temperature: 40 to 105°F (4 to 41°C).Non-operating temperature: -10 to 120°F (-23 to 49°C). Operating relative humidity: 5% to 90% non-condensing. Non-operating relative humidity: 0% to 95% non-condensing. Flame resistance rating (electronics enclosure): UL94V-0.Physical PropertiesProduct net weight, FP10J: 1.7 lbs. (0.77kg). Shipping gross weight, FP10J: 2.1lbs. (0.96kg). Control module (available separately at FSMJ2): Color: black.Dimensions: 2.0” (5.1cm) deep x 5.5” (14cm) wide x 0.75” (1.9cm) tall. Cable: ~9ft (~2.7m), black, USB connector (type A). Color: black.Dimensions: 2.7” (6.9cm) wide x 3.7” (9.4cm) long, 1.1” (2.8cm) tall.Two years, parts & labor (see details at , click on SpecificationsKinesis ®™Programmable USB Foot Pedal FamilySingle Pedal & Control Module, Model FP10JModel FP10J i ncludes control module with dual input jacks (FPMJ2) and single foot pedal (FS007MP) FP10JOptional Accessories#∙ Extra pedal (FS007MP): 10ft black cable, mini-phono plug, IPX1 rated.∙ Extra waterproof pedal (FS007MP-IPX8): IPX8 rated, 10ft black cable, mini-phono plug (note: mini -phono connection to control module is not waterproof).∙ Optional hand trigger (FS002HT8): 8 ft beige cable, mini-phono plug, IPX1 rated.∙ Pedal extension cables, mini-phono: Inquire (long lengths are possible).#Extra pedals and hand trigger require jack-equipped model.。

YJQ型液压加速器使用说明书INSTRUCTION MANUAL贵州高峰机械厂GUIZHOU GAOFENG MACHINERY FACTORYYJQ型液压加速器使用说明书1 概述和用途YJQ型液压加速器是为液压上击器增加震击功能而设计的井下打捞震击工具。

因此它必须和CSJ型超级震击器或YSJ型液压上击器联合使用。

工作时能对接在其下方的钻铤和上击器上部起加速作用,以获得对卡点更强大的震击力,同时可以减少震击之后钻柱回弹时的震动。

2 基本结构YJQ型液压加速器基本结构如图1所示。

心轴与缸套之间充满了具有高压缩指数的二甲基硅油。

心轴有花键与上缸套下端的花键相嵌合,这样不论是在打开,还是撞击位置都可以传递扭矩。

密封总成包括盘根和盘根压圈。

它安装于震击垫与导向杆之间,形成一个滑动密封副,工作时能使缸内产生高压。

3 工作原理钻具上提,钻具伸长,加速器的密封总成向上移动,硅油被压缩,象弹簧被压缩一样,硅油中贮存了能量(图2a)时,尤如一根上下二端拉紧的橡皮筋,下端突然释放,橡皮筋会迅速地弹上去一样,伸长的钻具回复使加速器下部以及接在其下方的钻铤和上击器上部就一起向上运动,与此同时加速器内腔的硅油贮存的能量也被突然释放,给运动着的钻铤和上击器的上部一个极大的加速度(图2b)。

当上击器到达冲程终点时,一个向上的巨大撞击力直接打击在落鱼上,此时加速器处于关闭状态(图2c)。

一次震击就告结束。

4 操作参照CSJ型超级震击器和YSJ型液压上击器使用说明书。

5 拆卸和装配加速器经多次使用或在恶劣条件下使用后,应送管子站全部拆开、清洗、检查。

拆卸和装配加速器应在井下工具液压拆装工作台上进行。

5.1 拆卸1)拆卸前要清除加速器内外表面上的泥沙和尘土。

2)用液压拆装工作台的钳口夹住中缸套(注意不要损坏油堵孔),拧松并卸下下接头。

流出的硅油盛入事先准备好的干净容器里。

3)用管钳夹紧导向杆末端的扳手位置,拧松导向杆。

4)用液压拆装工作台的钳口夹紧上缸套,拧松并旋转卸下中缸套。

CM4NANO用户手册上海晶珩电子科技有限公司2023-01-04版权声明CM4 Nano及其相关知识产权为上海晶珩电子科技有限公司所有。

上海晶珩电子科技有限公司拥有本文件的版权并保留所有权利。

未经上海晶珩电子科技有限公司的书面许可,不得以任何方式和形式修改、分发或复制本文件的任何部分。

免责声明上海晶珩电子科技有限公司不保证本硬件手册中的信息是最新的、正确的、完整的或高质量的。

上海晶珩电子科技有限公司也不对这些信息的进一步使用作出保证。

如果由于使用或不使用本硬件手册中的信息,或由于使用错误或不完整的信息而造成的物质或非物质相关损失,只要没有证明是上海晶珩电子科技有限公司的故意或过失,就可以免除对上海晶珩电子科技有限公司的责任索赔。

上海晶珩电子科技有限公司明确保留对本硬件手册的内容或部分内容进行修改或补充的权利,无需特别通知。

修订记录目录1产品概述 (6)1.1目标应用 (6)1.2规格参数 (6)1.3系统框图 (7)1.4功能布局 (8)1.5包装清单 (8)1.6订购编码 (8)2快速启动 (9)2.1设备清单 (9)2.2硬件连接 (9)2.3首次启动 (9)2.3.1Raspberry Pi OS (Desktop) (9)2.3.2Raspberry Pi OS (Lite) (12)2.3.3使能SSH功能 (14)2.3.4查找设备IP (14)3接线指南 (14)3.1Panel I/O (15)3.1.1BOOT (15)3.1.2micro-SD Card (15)3.2Internal I/O (15)3.2.1HDMI FPC (15)3.2.2MIPI DSI (16)4软件操作指引 (17)4.1USB 2.0 (17)4.1.1查看USB设备信息 (17)4.1.2USB存储设备挂载 (17)4.2以太网配置 (19)4.2.1千兆以太网 (19)4.2.2使用Network Manager工具配置 (19)4.2.3使用dhcpcd工具配置 (21)4.3WiFi (21)4.3.1使能WiFi功能 (21)4.3.2外置天线/内置PCB天线 (22)4.3.3AP及桥接模式 (22)4.4蓝牙 (22)4.4.1基本用法 (22)4.4.2示例 (23)4.5RTC (24)4.6LED指示 (25)4.7Buzzer (25)4.8串口通信 (25)4.8.1安装picocom工具 (25)4.8.2Debug UART (26)5操作系统安装 (27)5.1镜像下载 (27)5.2eMMC烧录 (28)5.2.1工具下载 (28)5.2.2烧录 (28)5.3基于原版Raspberry Pi OS在线安装BSP (29)6故障排除 (29)7FAQ (29)7.1.1默认用户名密码 (29)8关于我们 (30)8.1关于EDATEC (30)8.2联系方式 (30)1CM4 Nano是一款基于树莓派CM4的面向工业应用场景的计算机。

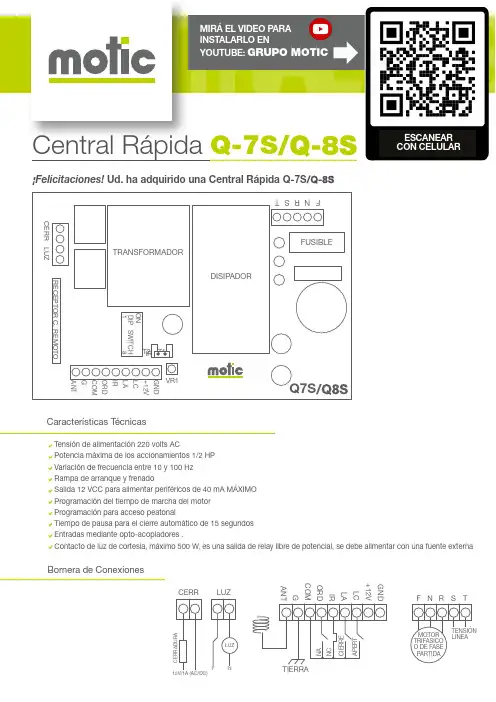

Central Rápida Q-7S¡Felicitaciones! Ud. ha adquirido una Central Rápida Q-7SESCANEAR CON CELULAR Características TécnicasTensión de alimentación 220 volts ACPotencia máxima de los accionamientos 1/2 HPVariación de frecuencia entre 10 y 100 HzRampa de arranque y frenadoSalida 12 VCC para alimentar periféricos de 40 mA MÁXIMOProgramación del tiempo de marcha del motorProgramación para acceso peatonalTiempo de pausa para el cierre automático de 15 segundosEntradas mediante opto-acopladores .Contacto de luz de cortesía, máximo 500 W, es una salida de relay libre de potencial, se debe alimentar con una fuente externa Bornera de ConexionesGND +12V LC LA IR ORD COM GANT CERR LUZ MIRÁ EL VIDEO PARAINSTALARLO ENYOUTUBE: GRUPO MOTICPaso 1 Conexión del Motor y Central Paso 2 Conexión de Accesorios OpcionalesFinales de Carrera (Recomendado)Para ello, liberar el eje del motor y abrir y cerrar manualmente el portón, con lo cual:*Se debe encender LdC cuando el portón está cerrado y apagarse cuando se empieza a abrir.** Se debe encender LdA cuando el portón está abierto y apagarse cuando se empieza a cerrar.En el caso en que se enciendan invertidos, invertir los cables LA y LC en la bornera.En caso de que LdA o LdC no enciendan o lo hagan intermitentemente, revise las conexiones y el Barrera Infrarroja (Opcional)Si no se emplea barrera infrarroja, dejar el Jumper "IR"colocado en la placa.Si se emplea barrera infrarroja, retirar el Jumper "IR" dela placa. Si la barrera infrarroja se activa durante el cierre,el motor se detiene y se vuelve a abrir.Electrocerradura (Opcional)Tener en cuenta que la central no permite alimentar unaelectrocerradura, es solo una salida de relay, por lo quese debe alimentar con fuente externa .Dejar el portón entreabierto y cortar la energía. Al habilitar laenergía nuevamente, al dar una orden con el pulsador o control,debe ABRIR. En caso de que CIERRE, invertir el sentido de girodel motor para corregirlo:Motor Trifásico: En caso de sentido de giro incorrecto,intercambiar los cables de motor S y T.Motor Fase Partida: En este caso, R es el común del motor.EN ESTA CENTRAL,¡LOS MOTORES JAMÁS DEBEN LLEVAR CAPACITOR!En caso de sentido de giro incorrecto, intercambiar los cables Sy T T G S M R NF 220VACTIERRA (JABALINA)T G S M R COMÚN N F 220VACTIERRA(JABALINA)GND +12V LC IR LA ORDCOM G ANT LdA LdC GND +12V LC IR LA ORDCOMCERR FUENTE EXTERNA 12V 1ARxProgramación de funciones mediante los dip switchLuz (Opcional)Botón de Orden (Opcional)LUZ LUZ 220V NF+12GND LUZLUZConexión de Led 12VccConexión de Lámpara 220 VAC pulsador NA GND+12V ORD LC LAProgramación de la apertura vehicularEsto le permitirá abrir el portón parcialmente para el paso peatonal por un tiempo de 10 segundos, tras lo cual se cerrará automáticamente, excepto que la barrera infrarroja esté interrumpida.Programación de los Controles Remotos para el Paso Peatonal1.Pulsar el botón T2, se encenderá el led Ld1.Programación de los Tiempos de Recorrido para apertura vehicularProgramación de apertura peatonal1/ BORRAR todos los controles.Mantener pulsar el botón T2por 6 segundos.El LED pr1 destellarávarias veces dando por T1T2LEDPR12/ GRABADO de los controles.Pulsar el botón T2 El LED pr1 quedaráencendido Si quiere grabarmás controlessiga pulsandolos botones delos controles Si terminó vuelva a pulsar el botón T2. El led pr1 se apagaráRecuerde que la electrónica sólo guarda en su memoria 60 electrónica no permite eliminar sólo un botón (eliminaratodos los controles).Pulsar el botón que quieragrabar T1T2T1T2LEDPR1El led PR1destellaráindicando el grabado del boton deseadoa/ Programación del tiempo del recorrido (sin decelere DIP Nº5 ON).Dejar el portón amitad del recorrido El LED pr1 se va a encender y al soltarlo, el portóncomenzará a cerrar Mantener pulsado elbotón T1 por 6”El portón cerraráy comenzará a abrir solo El portón volverá a cerrar dando porel programado T1T2nalizado el procedimiento 1Programación de los Tiempos de Recorrido para el Paso Peatonal CON FINALES DE CARRERAMOTIC Recomienda elegir los siguientes botones en cada control:Paso Total Paso Peatonal6.Ajuste de la velocidad del motorCon esta función, puede ajustar la velocidad del motor a gusto.Para aumentar la velocidad girar VR1 en sentido horario.Para disminuir la velocidad girar VR1 en sentido anti-horario.GND+12V LC LA IR ORD COM G ANT VR1IRPulsar el botón T2 El LED pr1 quedaráencendido Si quiere grabar más controles siga pulsandolos botones delos controles Si terminó suelte el boton T1,y pulse el boton T2.El led Ld1 se apagaráRecuerde que la electrónica sólo guarda en su memoria 60 electrónica no permite eliminar sólo un botón (eliminara todos los controles).Mantener pulsadoel botón T1 T1T2T1T2LED PR1El led PR1destellaráindicando elgrabado delboton deseado T1T2Pulsar el botón que quiera grabar Dejar el portón amitad del recorrido El portón se cierraautomáticamentey naliza la programaciónEl LED pr1 se va a encender y al soltarlo, el portón comenzará a cerrar hasta pisar el límite de cierre, luego abriráMantener pulsar el Antes de que el portón abra por completo,dar una orden con el botón del control remoto grabado donde se quiera iniciar el paso peatonalbotón T1 por 6”T1T2/ Mantenga alejados los controles y cables del alcance de niños y mascotas. El portón podría accionarse accidentalmente o sufrir lesiones./ Siempre corte el suministro eléctrico antes de operar manualmente el portón o realizar tareas de limpieza./ Evite aproximarse o caminar a través del portón. Su activación puede ocasionar accidentes./ Examine con frecuencia la instalación en busca de signos de desgaste o daño en los cables. Póngase en contacto con perso-nal autorizado en caso necesario.La garantía de los elementos o servicios vendidos por Grupo Motic SRL , (en adelante Motic ) aplica solo a los productos La garantía se reduce al reemplazo del producto defectuoso o a la reparación del mismo, dentro de un plazo de 10 días (dependiendo de la existencia de repuestos), a elección de Motic y a su solo criterio, no cubriendo las conse-cuencias ni costos ni daños emergentes ni daños contingentes que hubiera podido provocar o serles atribuidas a la falla.La garantía abarca única y explícitamente desperfectos de fabricación del equipo que no se encuentren relaciona-dos a errores en su aplicación, instalación, su uso en condiciones anormales o condiciones ambientales o meteo-rológicas extremas.La garantía se brinda en las instalaciones técnicas de Motic (su Domicilio Comercial) por lo que los equipos deben-dos o autorizados.Esta Garantía es Limitada y está sujeta a las condiciones y legislación vigente en la República Argentina,Para cualquier solicitud de cobertura de la Garantía, Reparaciones o Repuestos o cuestiones técnicas comunicar-se con Motic en Agüero 449, Teléfono (011) 4730-3222 en Villa Martelli (1603) Buenos Aires, Argentina. Este equipo está diseñado para uso residencial y no comercial, industrial o de alta demanda.Modelo de Equipo:Fecha de Compra: Lugar de Compra:Número de Factura de Compra:Número de Serie:garantíaPlazo de la Garantía para los motorreductores es de 2 (Dos) años a partir de la fecha de la factura. Las Controladoras electrónicas tienen 1 (Uno) año de garantía, los controles remotos 6 (Seis) meses, las pilas y otros consumibles no tienen garantía.。

NVIDIA L4 GPU Accelerator Product BriefDocument HistoryPB-11316-001_v01Version Date Authors Description of Change 01 March 9, 2023 AV, SM Initial releaseTable of ContentsOverview (1)Specifications (2)Product Specifications (2)Environmental and Reliability Specifications (4)Airflow Direction Support (5)Product Features (6)PCI Express Interface Specifications (6)PCIe Support (6)Single Root I/O Virtualization Support (6)Interrupt Messaging (6)Polarity Inversion and Lane Reversal Support (7)Root of Trust (7)Form Factor (7)Hockey Stick Board Retention (9)Support Information (10)Certifications (10)Agencies (10)Languages (11)List of FiguresFigure 1.NVIDIA L4 NVFF 5.5 HHHL with Full Height Bracket (1)Figure 2.NVIDIA L4 Airflow Direction (5)Figure 3.NVIDIA L4 PCIe Card Dimensions with Full Height Bracket (8)Figure 4.NVIDIA L4 PCIe Card Dimensions with Low Profile Bracket (8)Figure 5.NVIDIA L4 Hockey Stick Tab (9)List of TablesTable 1.Product Specifications (2)Table 2.Memory Specifications (3)Table 3.Software Specifications (3)Table 4.Board Environmental and Reliability Specifications (4)Table nguages Supported (11)OverviewThe NVIDIA L4 Tensor Core GPU delivers a versatile platform to accelerate Deep Learning, Graphics and Video processing applications in the Cloud and at the Edge. It is a half-height (low profile), half-length, single slot card featuring 24 GB of GDDR6 memory, x16 PCIe Gen4 connectivity at a 72 W maximum power envelope. It is a passively cooled card with a superior thermal design-requiring system airflow to operate and handles challenging ambient environments with ease (NEBS-3 capable).Powered by the NVIDIA Ada Lovelace architecture, L4 provides revolutionary multi-precision performance to accelerate deep learning and machine learning training and inference, video transcoding, AI audio (AU) and video effects, rendering, data analytics, virtual workstations, virtual desktop, and many other workloads.As part of NVIDIA AI, the L4 supports all AI frameworks and neural network models, delivering dramatic performance and efficiency that maximizes the utility of at-scale deployments.Figure 1. NVIDIA L4 NVFF 5.5 HHHL with Full Height BracketSpecificationsProduct SpecificationsTable 1 through Table 3 the product, memory, and software specifications for the NVIDIA L4 PCIe card.Table 1. Product SpecificationsSpecification NVIDIA L4Product SKU PG193 SKU 200NVPN: 699-2G193-0200-xxxTotal board power 72 W default72 W maximum40 W minimumThermal solution PassiveMechanical form factor HHHL-SS (half-height, half-length, single-slot) PCI Device IDs Device ID: 0x27B8Vendor ID: 0x10DESub-Vendor ID: 0x10DESub-System ID: 0x16CAFour-part ID (VID:DEVID:SVID:SSID)110DE:27B8:10DE:16CAGPU clocks Base: 795 MHzBoost: 2,040 MHzVBIOS EEPROM size: 16 MbitUEFI: SupportedDrivers Linux: R525 or laterWindows: R525 or laterPCI Express interface Physical x16 PCIe lanesPCIe Gen4 x16, x8; Gen3 x16Lane and polarity reversal supported Performance states P0, P8Zero Power Not supportedSpecification NVIDIA L4Weight Board: 270 Grams (excluding bracket)Bracket (Full height) with screws: 14 GramsBracket (Half height) with screws: 9 GramsNote:1The NVIDIA L4 is uniquely identified by its complete four-part ID.Table 2. Memory SpecificationsSpecification DescriptionMemory clock 6,251 MHzMemory type GDDR6Memory size 24 GBMemory bus width 192 bitsPeak memory bandwidth 300 GB/secTable 3. Software SpecificationsSpecification NVIDIA L4SR-IOV support Supported: 32 VF (virtual functions)BAR address (physical function) BAR0: 16 MiB1BAR1: 32 GiB1BAR3: 32 MiB1BAR address (virtual function) BAR0: 8 MiB (256 KiB per VF)1BAR1: 64 GiB, 64-bit (2 GiB per VF)1BAR3: 1 GiB, 64-bit (32 MiB per VF)1Message signaled interrupts MSI-X: SupportedMSI: Not supportedARI Forwarding SupportedSecure Boot Supported (See “Root of Trust” section)NVIDIA® CUDA® support CUDA 12.0 or laterVirtual GPU software support Supports vGPU 15.2 or laterPCI class code 0x03 – Display controllerPCI sub-class code 0x02 – 3D controllerECC support Enabled (by default); can be disabled using software SMBus (8-bit address) 0x9E (write), 0x9F (read)IPMI FRU EEPROM I2C address 0x50 (7-bit), 0xA0 (8-bit)Reserved I2C addresses 0xA0, 0xAA, 0xACSMBus direct access SupportedSpecification NVIDIA L4SMBPBI (SMBus Post-Box Interface) SupportedNote:1The KiB, MiB, and GiB notations emphasize the “power of two” nature of the values. Thus,>256 KiB = 256 × 1024>16 MiB = 16 × 10242>64 GiB = 64 × 10243Environmental and Reliability Specifications Table 4 provides the environment conditions specifications for the L4 PCIe card.Table 4. Board Environmental and Reliability SpecificationsSpecification DescriptionAmbient operating temperature 0°C to 50°CAmbient operating temperature (short term)1-5°C to 55°CStorage temperature -40°C to 75°COperating humidity (short term)15% to 93% relative humidityOperating humidity 5% to 85% relative humidityStorage humidity 5% to 95% relative humidityMean time between failures (MTBF) Uncontrolled environment:2 2,147,604 hours at 35°CControlled environment:3 2,785,669 hours at 35°C Notes: Specifications in this table are applicable up to 6,000 feet.1A period not more than 96 hours consecutive, not to exceed 15 days per year.2Some environmental stress with limited maintenance (GF35).3No environmental stress with optimum operation and maintenance (GB35).Airflow Direction SupportThe NVIDIA L4 PCIe card employs a bidirectional heat sink, which accepts airflow either left-to-right or right-to-left directions.Figure 2. NVIDIA L4 Airflow DirectionProduct FeaturesPCI Express Interface SpecificationsThe following subsections describe the PCIe interface specifications for the L4 PCIe card.PCIe SupportThe L4 card supports PCIe Gen4. Gen4 x16 interface should be used when connecting to the L4 PCIe card.Single Root I/O Virtualization SupportSingle Root I/O (SR-IOV) Virtualization is a PCIe specification that allows a physical PCIe device to appear as multiple physical PCIe devices. Per PCIe specification, each device can have up to a maximum of 256 virtual functions (VFs). The actual number can depend on the device. SR-IOV is enabled in L4 PCIe card. The number of VFs supported is given in Table 3.For each device, SR-IOV identifies two function classes:>Physical functions (PFs) constitute full-featured functionality. They are fully configurable, and their configuration can control the entire device. Naturally, a PF also has full ability to move data in and out of the device.>Virtual functions (VFs), which lack configuration resources. VFs exist on an underlying PF, which may support many such VFs. VFs can only move data in and out of the device; they cannot be configured and cannot be treated like a full PCIe device.The OS or hypervisor instance must be aware that they are not full PCIe devices. The L4 requires that SBIOS and software support in the OS instance or hypervisor is configured to enable support SR-IOV. The OS instance or hypervisor must be able to detect and initialize PFs and VFs.Interrupt MessagingThe L4 PCIe card only supports the MSI-X interrupt messaging protocol. The MSI interrupt protocol is not supported.Polarity Inversion and Lane Reversal SupportLane Polarity Inversion, as defined in the PCIe specification, is supported on the L4 PCIe card.Lane Reversal, as defined in the PCIe specification, is supported on the L4 PCIe card. When reversing the order of the PCIe lanes, the order of both the Rx lanes and the Tx lanes must be reversed.Root of TrustThe NVIDIA L4 provides a primary root of trust within the GPU that provides the following:>Secure boot>Secure firmware upgrade>Firmware rollback protection>Support for in-band firmware update disable (established after each GPU reset)>Secure application processor recoveryForm FactorThe NVIDIA L4 PCIe card conforms to NVIDIA Form Factor 5.5 specification for a half-height (low profile) half-length (HHHL) single slot PCIe card. For details refer to the NVIDIA Form Factor 5.5 for Enterprise PCIe Products Specification (NVOnline reference number 106337).In this product brief, nominal dimensions are shown.Figure 3. NVIDIA L4 PCIe Card Dimensions with Full Height BracketFigure 4. NVIDIA L4 PCIe Card Dimensions with Low Profile BracketHockey Stick Board RetentionThe NVDIA L4 enables south edge board retention using a “hockey stick” tab located to the east of the PCIe card fingers, as shown in Figure 5.Figure 5. NVIDIA L4 Hockey Stick TabSupport InformationCertifications>Windows Hardware Quality Lab (WHQL):•Windows 10, Windows 11•Windows Server 2019, Windows Server 2022>Ergonomic requirements for office work W/VDTs (ISO 9241)>EU Reduction of Hazardous Substances (EU RoHS)>Joint Industry guide (J-STD) / Registration, Evaluation, Authorization, and Restriction of Chemical Substance (EU) – (JIG / REACH)>Halogen Free (HF)>EU Waste Electrical and Electronic Equipment (WEEE)Agencies>Australian Communications and Media Authority and New Zealand Radio Spectrum Management (RCM)>Bureau of Standards, Metrology, and Inspection (BSMI)>Conformité Européenne (CE)>Federal Communications Commission (FCC)>Industry Canada - Interference-Causing Equipment Standard (ICES)>Korean Communications Commission (KCC)>Underwriters Laboratories (cUL, UL)>Voluntary Control Council for Interference (VCCI)Support Information LanguagesTable 5. Languages SupportedLanguages Windows1LinuxEnglish (US) Yes YesEnglish (UK) Yes YesArabic YesChinese, Simplified YesChinese, Traditional YesCzech YesDanish YesDutch YesFinnish YesFrench (European) YesGerman YesGreek YesHebrew YesHungarian YesItalian YesJapanese YesKorean YesNorwegian YesPolish YesPortuguese (Brazil) YesPortuguese (European/Iberian) YesRussian YesSlovak YesSlovenian YesSpanish (European) YesSpanish (Latin America) YesSwedish YesThai YesTurkish YesNote:1Microsoft Windows 10, Windows 11, Windows Server 2019, and Windows Server 2022 Windowsare supported.NVIDIA Corporation | 2788 San Tomas Expressway, Santa Clara, CA 95051NoticeThis document is provided for information purposes only and shall not be regarded as a warranty of a certain functionality, condition, or quality of a product. NVIDIA Corporation (“NVIDIA”) makes no representations or warranties, expressed or implied, as to the accuracy or completeness of the information contained in this document and assumes no responsibility for any errors contained herein. NVIDIA shall have no liability for the consequences or use of such information or for any infringement of patents or other rights of third parties that may result from its use. This document is not a commitment to develop, release, or deliver any Material (defined below), code, or functionality.NVIDIA reserves the right to make corrections, modifications, enhancements, improvements, and any other changes to this document, at any time without notice.Customer should obtain the latest relevant information before placing orders and should verify that such information is current and complete. NVIDIA products are sold subject to the NVIDIA standard terms and conditions of sale supplied at the time of order acknowledgement, unless otherwise agreed in an individual sales agreement signed by authorized representatives of NVIDIA and customer (“Terms of Sale”). NVIDIA hereby expressly objects to applying any customer general terms and conditions with regards to the purchase of the NVIDIA product referenced in this document. No contractual obligations are formed either directly or indirectly by this document.NVIDIA products are not designed, authorized, or warranted to be suitable for use in medical, military, aircraft, space, or life support equipment, nor in applications where failure or malfunction of the NVIDIA product can reasonably be expected to result in personal injury, death, or property or environmental damage. NVIDIA accepts no liability for inclusion and/or use of NVIDIA products in such equipment or applications and therefore such inclusion and/or use is at customer’s own risk.NVIDIA makes no representation or warranty that products based on this document will be suitable for any specified use. Testing of all parameters of each product is not necessarily performed by NVIDIA. It is customer’s sole responsibility to evaluate and determine the applicability of any information contained in this document, ensure the product is suitable and fit for the application planned by customer, and perform the necessary testing for the application in order to avoid a default of the application or the product. Weaknesses in customer’s product designs may affect the quality and reliability of the NVIDIA product and may result in additional or different conditions and/or requirements beyond those contained in this document. NVIDIA accepts no liability related to any default, damage, costs, or problem which may be based on or attributable to: (i) the use of the NVIDIA product in any manner that is contrary to this document or (ii) customer product designs.No license, either expressed or implied, is granted under any NVIDIA patent right, copyright, or other NVIDIA intellectual property right under this document. Information published by NVIDIA regarding third-party products or services does not constitute a license from NVIDIA to use such products or services or a warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property rights of the third party, or a license from NVIDIA under the patents or other intellectual property rights of NVIDIA.Reproduction of information in this document is permissible only if approved in advance by NVIDIA in writing, reproduced without alteration and in full compliance with all applicable export laws and regulations, and accompanied by all associated conditions, limitations, and notices. THIS DOCUMENT AND ALL NVIDIA DESIGN SPECIFICATIONS, REFERENCE BOARDS, FILES, DRAWINGS, DIAGNOSTICS, LISTS, AND OTHER DOCUMENTS (TOGETHER AND SEPARATELY, “MATERIALS”) ARE BEING PROVIDED “AS IS.” NVIDIA MAKES NO WARRANTIES, EXPRESSED, IMPLIED, STATUTORY, OR OTHERWISE WITH RESPECT TO THE MATERIALS, AND EXPRESSLY DISCLAIMS ALL IMPLIED WARRANTIES OF NONINFRINGEMENT, MERCHANTABILITY, AND FITNESS FOR A PARTICULAR PURPOSE. TO THE EXTENT NOT PROHIBITED BY LAW, IN NO EVENT WILL NVIDIA BE LIABLE FOR ANY DAMAGES, INCLUDING WITHOUT LIMITATION ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, PUNITIVE, OR CONSEQUENTIAL DAMAGES, HOWEVER CAUSED AND REGARDLESS OF THE THEORY OF LIABILITY, ARISING OUT OF ANY USE OF THIS DOCUMENT, EVEN IF NVIDIA HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Notwithstanding any damages that customer might incur for any reason whatsoever, NVIDIA’s aggregate and cumulative liability towards customer for the products described herein shall be limited in accordance with the Terms of Sale for the product.TrademarksNVIDIA, the NVIDIA logo, CUDA, NVIDIA-Certified System, and NVIDIA GPU Boost are trademarks and/or registered trademarks of NVIDIA Corporation in the U.S. and other countries. Other company and product names may be trademarks of the respective companies with which they are associated.Copyright© 2023 NVIDIA Corporation. All rights reserved.。

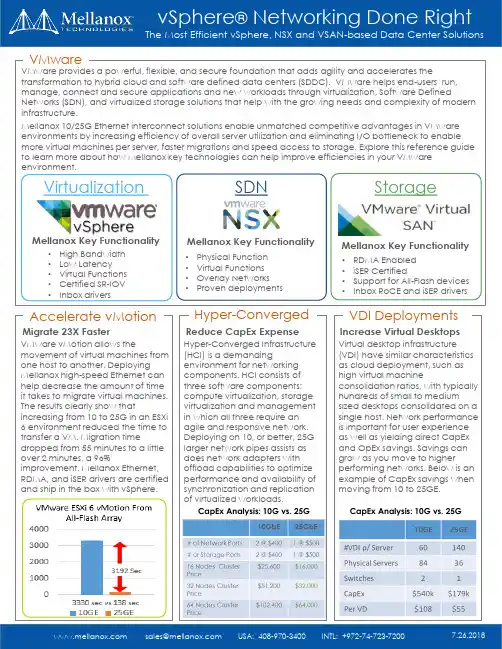

Accelerate vMotionMigrate 23X FasterHyper-ConvergedvSphere ®Networking Done RightThe Most Efficient vSphere, NSX and VSAN-based Data Center Solutionsz VirtualizationSDNStorageMellanox Key FunctionalityMellanox Key FunctionalityMellanox Key Functionality•High Bandwidth •Low Latency •Virtual Functions •Certified SR-IOV •Inbox drivers•Physical Function •Virtual Functions •Overlay Networks •Proven deployments•RDMA Enabled •iSER Certified•Support for All-Flash devices •Inbox RoCE and iSER driversVMwareVMware provides a powerful, flexible, and secure foundation that adds agility and accelerates thetransformation to hybrid cloud and software defined data centers (SDDC). VMware helps end-users run, manage, connect and secure applications and new workloads through virtualization, Software DefinedNetworks (SDN), and virtualized storage solutions that help with the growing needs and complexity of modern infrastructure.Mellanox 10/25G Ethernet interconnect solutions enable unmatched competitive advantages in VMware environments by increasing efficiency of overall server utilization and eliminating I/O bottleneck to enable more virtual machines per server, faster migrations and speed access to storage. Explore this reference guide to learn more about how Mellanox key technologies can help improve efficiencies in your VMware environment.VMware vMotion allows themovement of virtual machines from one host to another. Deploying Mellanox high-speed Ethernet can help decrease the amount of time it takes to migrate virtual machines. The results clearly show thatincreasing from 10 to 25G in an ESXi 6 environment reduced the time to transfer a VM. Migration timedropped from 55 minutes to a little over 2 minutes, a 96%improvement. Mellanox Ethernet, RDMA, and iSER drivers are certified and ship in the box with vSphere.Reduce CapEx ExpenseVDI DeploymentsIncrease Virtual DesktopsVirtual desktop infrastructure (VDI) have similar characteristics as cloud deployment, such as high virtual machineconsolidation ratios, with typically hundreds of small to mediumsized desktops consolidated on a single host. Network performance is important for user experience as well as yielding direct CapEx and OpEx savings. Savings can grow as you move to higherperforming networks. Below is an example of CapEx savings when moving from 10 to 25GE.Hyper-Converged Infrastructure (HCI) is a demandingenvironment for networking components. HCI consists of three software components: compute virtualization, storage virtualization and management in which all three require an agile and responsive network. Deploying on 10, or better, 25G larger network pipes assists as does network adapters with offload capabilities to optimize performance and availability of synchronization and replication of virtualized workloads.CapEx Analysis: 10G vs. 25GCapEx Analysis: 10G vs. 25GScalable from a half rack to multiple racksHalf Rack 12 nodesFull Rack 24 nodesPay As You Grow10 Racks up to 240 nodesDeployment Config134411GbE link: 1GbE Transceiver125/10GbE link: QSFP to SFP+324100GbE link: QSFP to QSFP 100/40GbE link: QSFP to QSFP Why Spectrum▪ 2 switches in 1U▪Ideal storage/HCI port counts▪Zero packet loss ▪Low latency▪RoCE optimized (NVMe-oF, Spark, SMB Direct, etc.)▪NEO for network automation/visibility▪Native SDK for containers ▪Cost optimized▪Network OS alternativesProvisioning & Orchestration▪Zero-touch provisioning ▪VLAN auto-provisioning▪Migrate VMs without manual configuration▪VXLAN/DCI support for VM migration across multiple datacenters for DRMonitoring▪Performance monitoring ▪Health monitoring ▪Detailed telemetry▪Alerts and notificationsAutomated Network▪½ 19” width, 1U height ▪18x10/25GbE + 4x40/100GbE ▪57W typical (ATIS)2Spectrum SwitchesProven Higher EfficiencyIncreasing VMware EfficiencyNSX services enable east-west routing between the SDDC and north-south routing for external networks and require VXLAN segmentation which can consume CPU processes and diminish overall server efficiency. Mellanox supports VXLAN offloads to handle this processing resulting in higher throughput and over 50% reduction in CPU utilization.Accelerate NSXStorage virtualization requires an agile and responsive network. iSER accelerates workloads by using an iSCSI extensions for RDMA. Using the iSER extension lowers latencies and CPU utilization to help keep pace with I/O requirements and provides a 70% improvement in throughput and 70% reduction in latencies.VMware EVO SDDC provides a validated suite of interoperable, tested components to deliver a completely Integrated System. This comprises fully qualifiedhardware components including Mellanox switches and adapters that are pre-built and pre-racked, providing an appliance-likeexperience that makes it easy for customers to deploy, operate and support. Mellanox leverages our relationship with Cumulus Linux to extend access from Layer 2 across Layer 3 networks topologies,Deliver 3X Efficiency with iSERFully Certified with EVOAverage CPU% per 1GbE VXLAN Traffic。

创新智造引领生命科技快速上手指南Quick Start Guide M G I T e c h C o ., L t d .仅供科研使用深圳华大智造科技有限公司Main Building and Second floor of No.11 Building, Beishan Industrial Zone, Yantian District, Shenzhen, 518083, Guangdong, China 中国深圳市盐田区北山工业区综合楼及11栋2楼网址/Website:***********************邮箱/E-mail:地址/Address:Research Use Only关于本指南本指南适用于MegaBOLT生信分析加速器,指南版本1.0,软件版本V2.1.0。

本指南及其包含的信息为深圳华大智造科技有限公司(以下简称深圳华大智造)的专有保密信息,未经深圳华大智造的书面许可,任何个人或组织不得全部或部分地对本指南进行重印、复制、修改、传播或公布给他人。

本指南的读者为终端用户,其作为设备的一部分,由深圳华大智造授权终端用户予以使用。

严禁未授权的个人使用本指南。

深圳华大智造对本指南不做任何种类的保证,包括(但不限于)用于特定目的的商业性和合理性的隐含保证。

深圳华大智造已经采取措施,确保本指南的准确性。

但是,深圳华大智造对错误或遗漏不承担责任,并保留任何对本指南和设备进行改进以提高其可靠性、功能或设计的权利。

本指南中的所有图片均为示意图,图片内容可能与实物有细微差异,请以购买的设备为准。

©2019 深圳华大智造科技有限公司版权所有。

发布日期:2019年11月8日制造商信息版本记录About this guideThis guide is applicable to MegaBOLT Bioinformatics Analysis Accelerator.The edition is 1.0 and the software version is V2.1.0.This guide and the information contained within are proprietary to MGI TechCo., Ltd. (hereinafter called MGI), and are intended solely for the contractualuse of its customer in connection with the use of the product described hereinand for no other purpose. Any person or organization can not entirely orpartially reprint, copy, revise, distribute or disclose to others the guide withoutthe prior written consent of MGI. Any unauthorized person should not use thisguide.MGI does not make any promise of this guide, including (but not limited to)any commercial of special purpose and any reasonable implied guarantee.MGI has taken measures to guarantee the correctness of this guide. However,MGI is not responsible for any mistakes or missing parts in the guide, andreserves the right to revise the guide and the software, so as to improve thereliability, performance or design.Figures in this guide are all illustrations. The contents might be slightlydifferent from the software, please refer to the software purchased.©2019 MGI Tech Co., Ltd. All rights reserved.Release date: November 8, 2019Manufacturer informationRevision history目录1快速开始 (1)硬件安装 (1)进入操作系统 (1)进入命令行终端 (2)查看帮助文档 (3)投递任务 (3)1使用ZLIMS (5)1MegaBOLT文档导航 (6)文档简介 (6)获取文档 (7)C o n t e n t s Contents1Quick start (9)Assembling the device �������������������������������������������������������������������������9Logging into the system ����������������������������������������������������������������������9Starting the terminal ���������������������������������������������������������������������������10Viewing Help ����������������������������������������������������������������������������������������11Submitting a task ��������������������������������������������������������������������������������11 1Working with ZLIMS ....................................................13 1MegaBOLT documents (14)Brief introduction ��������������������������������������������������������������������������������14Accessing the documents �����������������������������������������������������������������15快速开始1 快速开始硬件安装连接主机、显示器、键盘与鼠标,将加密锁插入任意USB 接口,接通电源,即可开机。