过渡金属催化活性自由基聚合

- 格式:pdf

- 大小:3.82 MB

- 文档页数:88

文章编号:100128220(2003)0320317208配体在卤化铜催化的原子转移自由基聚合反应中的作用蒋晓慧1,胡星琪2(11西华师范大学化学系,四川南充637002;21西南石油学院化工学院,四川南充637001)摘 要:在原子转移自由基聚合(ATRP )反应中,配体对催化体系的活性是至关重要的,它们可以调节过渡金属的氧化还原性能,并以自身的立体效应供给催化剂以适当的选择性,它们还可以改善催化剂在反应混合物中的溶解性能.研究配体结构和相应催化体系在ATRP 反应中的催化活性之间的关系,对寻找性能优良的ATRP 催化剂有十分重要的指导意义.本文将近几年对Cu +/Cu 2+催化体系中含氮配体的研究进展作一综合评述.关键词:配体;原子转移;自由基聚合;溴化铜;络合物;引发剂中图分类号:O64114 文献标识码:A1 引 言从1995年发现原子转移自由基聚合(简称ATRP )以来,由于过渡金属催化的活性自由基聚合反应条件温和,适用单体广泛如丙烯酸及其酯,丙烯酰胺,苯乙烯及二烯类均可,聚合物分子可控在1000<Mn <200000,可以合成性能特异的聚合物材料如星状、梯度、超支化聚合物等[1-9].所以目前在该领域的研究如火如荼.很多过渡金属对原子转移自由基聚合反应有催化能力[10-12],尤其是后过渡金属具有强的催化活性.而早过渡金属对氢和氧有较强的亲合力,它们易抽取β-H 或和单体中的酯基配位等,催化活性低.在ATRP 反应中,Cu +/Cu 2+体系的催化能力强,研究也较深入.现在大多数研究者公认的催化机理[13-14]如下:引发 R -X +CuX/bpy R ・+Cu 2+/bpy ↓M 链增长 RMX +CuX/bpyRM +Cu 2+/bpy RMnX +CuXMn ・+Cu 2+/bpy(1)或表达为:(2)在CuX -bpy 催化体中,催化活性中心按下式产生:收稿日期:2002-12-09作者简介:蒋晓慧(1958-),女,四川蓬溪人,西华师范大学化学系副教授,西南石油学院化工系博士研究生.主要从事有机化学和精细有机合成等方面的研究工作1 第24卷 第3期西华师范大学学报(自然科学版)2003年9月 Vol 124 No 13Journal of China West Normal University (Natural Sciences )Sep 12003卤代烃引发剂与Cu +产生自由基后,就一直被控制在Cu 2+配位环境中,大量的烯将在铜配位环境中反复反应(如下),最后发生原子转移,生成P -X 和Cu +.根据(2)式,可建立如下的动力学方程: Rp =kp kact kDeact [M][I]0[Cu +][Cu 2+](Ⅰ)M w Mn =1+(kp [I]0kDeact[Cu 2+])(2P -1)(Ⅱ)上式中[Ⅰ]0为引发剂的初始浓度,Rp 为聚合反应速度,P 为单体转化率,kact 为活化速率常数,kDeact 为去活化速率常数,kp 为链增长速率常数,它是单体的特性常数.从动力学方程可见,聚合反应速率受引发剂及单体浓度,活化及去活化速率和链增长速率常数的影响;多分散系数M w/Mn 随转化率增加而下降,kDeact 相对于kp 值愈大,M w/Mn 愈低,催化剂对该聚合反应的活性控制能力愈强.从动力学方程还可以看出,Cu +浓度愈大,聚合速率愈快;Cu 2+浓度愈大,聚合速率下降,但多分散性也下降.而根据历程可知,kact 愈大,Cu 2+浓度愈大,Pn ・浓度愈大,链终止反应愈快,分子量分布愈宽;kDeact 愈大,Cu 2+浓度愈小,分子量分布愈窄.所以一个理想的ATRP 反应催化剂应有较大的kDeact 和适当的kact 值.Cu +和Cu 2+的浓度受各自结构的稳定性影响,而配体对其稳定性起着关键的作用,配体是ATRP 催化剂中最重要的组分[12],配体的电子效应和空间位阻将影响催化剂在活化和去活化步骤中的活性.用于ATRP 反应中的催化剂中的配体种类很多,如含氮配体,含P 的配体(膦和亚磷酸酯),含氧配体(酚氧负离子,酸根阴离子),含碳配体(芳环、碳烯、烷基、环戊二烯基、C O 等),以及一些混配体等,而对于铜催化体系,最常见的配体是含氮配体,因此本文就Cu +/Cu 2+催化体系中含氮配体的作用进行综述和讨论.2 含氮配体的类别按提供电子对的配位N 原子结构特点可以分为:芳环氮原子如吡啶环上的氮,脂肪氮如脂肪胺中的氮,亚胺氮及混合氮配体等.根据配体的几何特征,可将配体分为线性的、环状的、或多分支的配体等.根据配位数,配体可分为单齿,双齿,三齿及多齿配体等;在多齿配体中,配位点之间的空间矩离有C 2,C 3或C 4等,以便造成过渡金属的空间位阻,但是乙撑或C 2最合适,这样N 周围的位阻最小,有利于和中心金属离子配位.此外配体可以是中性的或带电荷的,不同配体与Cu +和Cu 2+的配体能力不同因而活性不同.3 氮配体的结构与活性的关系3.1 配体中含氮结合点的个数3.1.1 联吡啶常见的二齿配体是联吡啶,由于其价廉易得,所以是原子转移自由基聚合反应中应用最广的配体.例如Jinying Y uan 等人[15]用α-溴丙酸乙酯-CuBr -2,2′联吡啶催化BM D0(5,6-苯并-2-甲撑-1,3-二氧环庚烷)的开环聚合,该聚合反应具有如下特点:转化率达70%时,自由基浓度仍然维持恒定,多分散系数为318 西华师范大学学报(自然科学版) 2003年1120,分子量可由聚合反应时间及单体/引发剂的比例控制,引发剂效率随温度升高而增加.吡啶环上的取代基对ATRP 反应有影响,一个好的π电子接受体能有效地稳定金属离子的低价氧化态,使原子转移平衡朝休眠体PnX 方向移动,例如比较2,2′-联吡啶与CuBr 的催化体系和4,4′-甲氧酰基-2,2′-联吡啶与CuBr 催化体系在ATRP 反应中的催化活性,结果表明吸电基如CH 3OC O —将使反应速率显著下降[16].此外氮原子周围的空间位阻将阻碍氮与中心金属成键,催化剂的催化活性下降,例如在N 上有2个位阻大的取代基的脂肪胺以及6,6′—二取代联吡啶无催化活性[16].3.1.2 二齿、三齿和三足配体Me 6TRE N (三-(2-二甲氨乙基)胺),一个三足配体,与铜体系是最活泼催化剂[12],它能有效催化丙烯酸酯类聚合(1h 内转化率达50%,[M]0∶[RK]0∶[CuBr ]∶[MeTRE N ]0=200∶1∶0.1∶0.1),但是它对M M A 体系太活泼,并因平衡常数太大,所以在苯乙烯的聚合中的应用也受到限制.甲基丙烯酸甲脂和丙烯酸正丁酯能过共聚可以形成梯度聚合物,Micheal J.Z iegler 和K rzysztof ,Maty 2jaszewski [17]研究了CuBr/dNbpy (4,4′-二(5-壬基)-2,2′-联吡啶,CuBr/PM DET A (N ,N ,N ′,N ″,N ″一五甲基二乙撑三胺)CuBr/Me 6TRE N 3种不同的催化体系对该反应的催化活性.研究结果表明,在CuBr/dNbpy 催化下,Mn 值随单体转化率增加而增加,但略高于理论值Mn (th ),多分散系数在聚合过程中逐渐下降,最低达M w/Mn -1・2;在CuBr/PM DET A 催化下,Mn 随单体转化率增加而线性增加,Mn 值仍略高于Mn (th ),分子量分布窄M w/Mn <1.3;在CuBr/Me 6TRE N 催化下,Mn 的变化与前二者相同,但分子量分布更窄.研究者认为不论用何种配体,Mn 值略高于理论值的原因是M M A/n -BA 聚合物的力学体积与线性聚苯乙烯不一致,而Mn 值通过G PC 法获得,该方法用线性聚苯乙烯标准物效正.X.S.Wang [18]等人以OEG Br 引发OEG M A (单甲氧端基的低聚乙烯醇甲基丙烯酸酯)在中性水溶液中的聚合反应,考察了CuCl 与3种不同配体的催化体系.3种不同配体的结构如下:从结构中可以看出,BPY 和配体Ⅱ相当于二齿配体,而配体Ⅰ至少可认为是三齿或四齿配体(包括杂环上的氧原子).实验结果是:使用配体Ⅰ的催化体系在20℃时Mn 与单体转化率之间有良好的线性关系,且整个聚合过程中保持低的多分散性M w/Mn <1.18,若温度升高如20-80℃,Mn 与转化率之间线性关系差,M w/Mn 最初大于1.40,但随转化率增加逐渐降至1.25,升高温度,聚合速度加快,1H -NMR 研究证明,在80℃加热0.5h 后,配体1组成的催化体系有些分解.表1 OEG M A 在CuBr/L 催化下的聚合反应结果T able 1 The polymerization of OEG M A by the catalysis of CuBr/L配体L 聚合温度(℃)OEG M A (Wt %)收率%/反应时间(h )Mn/M w Ⅰ201003<5;40Ⅰ205093;4.0 1.18Ⅰ505090;1.0 1.25Ⅰ805090;0.5 1.35Ⅱ205075;5.0 1.45bpy2050>95;0.51.25 3 位阻聚合表1列出了3种不同配体的催化活性比较.从表中数据可以看出,在同样的反应条件下,产率是CuCl/bpy >CuC1/L 1>CuCl/L Ⅱ,由此可见,催化体系的活性是CuCl/bpy >CuCI/L Ⅰ>CuCl/L Ⅱ;多分散性是CuCl/L Ⅱ 第24卷第3期蒋晓慧,等:配体在卤化铜催化的原子转移自由基聚合反应中的作用319>CuCl/bpy >CuCl/L Ⅰ.可能的原因是吡啶N 上的孤对电子的配位能力强于亚胺N 上的孤对电子,能更好地与中心金属离子配位,而亚胺配体在稳定低价氧化态的过渡金属离子的能力比吡啶N 强[14],根据动力学方程,Cu 2+浓度低,则Pn ・浓度也低,故有上述活性顺序.配体Ⅰ可能与中心金属离子形成如下所示的结构:使CuCl/LⅠ和CuCl 2/L Ⅰ的稳定性有所增加,同时中心金属离子的空间位阻也增加,对聚合反应的控制能力增强,聚合物的多分散系数低.从上述研究中可以看出,三足配体对活性聚合的可控能力强于三齿配体,而四齿配体优于三齿配体,后者优于二齿配体.3.2 [14] 上述8个线性三齿配体中有5种不同的N 结合点:烷基胺(如1,6),芳胺(4,8),烷基亚胺(5),芳基亚胺(7)和吡啶型(2,3等).这8个配体分别与CuBr 组成不同的催化体系,催化聚合反应的结果列入表2.3.2.1 氮配体结构对聚合反应的选择性不同的催化体系在不同的单体聚合反应中催化能力不同.CuBr/DOIP 仅对甲基丙烯酸酯的聚合有较强的控制能力;CuBr/PM DET A 和CuBr/BPOA 对丙烯酸酯,甲基丙烯酸酯,苯乙烯及其衍生物类单体均有较好的催化活性[19];CuBr/DOAP 对甲基丙烯酸甲酯的聚合失控,聚合反应所获得的分子量Mn (G PC ),远高于理论值Mn (th ),且分子量分布相当宽(M w/Mn )1.6[20],但是该催化体系能有效地控制苯乙烯的聚合,反应速度快,且分子量分布窄(M w/Mn )1.18;CuBr/DPIP 仅能使甲基丙烯酸甲酯发生氧化还原引发的自由基聚合;而CuBr/DPAP 不能使丙烯酸酯,甲基丙烯酸酯,苯乙烯及其衍生物类单体发生聚合.3.2.2 配体结构对催化活性的影响在ATRP 反应中的高活性的催化剂具有大的活化速率常数kact (见表3).CuBr/烷基胺和CuBr/吡啶类催化剂易被活化,同类型的N 的配体如PM DET A 和TERPY 构成的催化剂将快速活化,而吡啶N 和脂肪胺N 混合的配体如DOAP 和BPOA 次之,从DOAP 到BPOA 到DOIP ,活化速率降低.BPPA 配体形成的催化体系有较低的活化速率常数,原因是该配体和Cu 2+形成的配合物在反应介质中溶解度低[30],使聚合速度慢,反应15.5h ,转化率为73%,若加入10%的DMF ,速率加快,反应3h 后,转化率达50%.N 上有苯环的配体如DPIP 和DPAP 的活化速率常数最低.笔者认为,造成上述现象的原因可能是由于配体中不同配位氮的杂化状态不同以及空间拥挤程度不同所致.脂肪胺中N 是sp 3杂化,而吡啶和亚胺中320 西华师范大学学报(自然科学版) 2003年N 采取sp 2杂化,显然,sp 3杂化轨道的孤对电子易给出,易与中心金属离子络合,反应速率快.苯胺中N 虽然采取近sp 3杂化,但是其孤对电子参与苯环共轭而难以给出,所以DPIP 和DPAP 活化速率常数最低.N 上的取代基体积大,将阻碍N 与金属离子的配位,因此DOIP 和DOAP 的活化速率常数较低可能还与辛基体积大有关.此外,不同配体刚性不同,可能影响配合物的稳定性,造成其活性差异.表2 CuBr/配体催化聚合反应的结果T able 2 The results of polymerizations catalyzed by CuBr/L催化剂单体[M]0∶[Ⅰ]0∶[Cat ]0时间(h )/温度(℃)转化率%Mn (th )Mn (G PC )M w/Mn CuBr/P M DET ASTY RE NE96∶1∶12/11090900085001123M A 232∶1∶1215/909218500164001111M M A200∶1∶1815/907615200185001116CuBr/TERPYSTY RE NE 96∶1∶16/90787800110001120M A 96∶1∶16/9079650075001109M M A200∶1∶18/507314500229001118CuBr/BPOASTY RE NE 96∶1∶12/110878700101001113M A232∶1∶13/508216500144001112CuBr/BPPASTY RE NE 96∶1∶13/11067670042001177M A 232∶1∶11515/906412800138001128M M A200∶1∶1315/906813600143001123CuBr/DOIPSTY RE NE 200∶1∶113/1105511400130001174M A 200∶1∶120/9015630063001143M M A200∶1∶17125/706513000240001156CuBr/DOAPSTY RE NE 200∶1∶1513/1107315000220001118M A 200∶1∶115/90621070092001126M M A200∶1∶1氧化还原引发自由基聚合CuBr/DPIPSTY RE NE 200∶1∶1无反应M A 200∶1∶1无反应M M A200∶1∶1无反应CuBr/DPAPSTY RE NE 200∶1∶1无反应M A200∶1∶1无反应表3 不同引发剂作用下CuBr 络和物的活化速率常数(乙腈,35℃)T able 3 Rate constants of activation for different initiators and CuBr com plexes in acetonitriles配合物EbiB[M -1S -1]M BP[M -1S -1]PE Br[M -1S -1]BzBr[M -1S -1]CuBr/P M DET A 11801150110113CuBr/TERPY 1150.4101420138CuBr/BPOA 0170108010501023CuBr/BPPA 013010140.06601066CuBr/DOIP 0110101101014010038CuBr/DOAP 010057010006010014010023CuBr/DPIP 010009010005010004010004CuBr/DPAP≌0.00009≌01000008≌01000002≌0.000002 注:E BiB ———2-甲基-2-溴丙酸乙酯,M BP ———2-溴丙酸乙酯,PE Br ———2-溴乙苯,BzBr ———澳化苄.配体的性质不仅影响催化体系的活化速率常数,还影响其去活化速率常数K deact ,总趋势是易活化者缓慢地去活化,反之亦反.表4的数据说明,中心为脂肪胺N 接合点的配体组成的催化体系(如CuBr 2/PM DET A 和CuBr 2/BPOA )去活化速度显然快于中心是吡啶N 接合点的配体组成的催化体系(如CuBr 2/TERPY 和CuBr 2/DOAP ).二亚胺基吡啶配合物如CuBr 2/DOIP 同样如此.但是,N 上有苯环的胺和亚胺类配体(如CuBr 2/ 第24卷第3期蒋晓慧,等:配体在卤化铜催化的原子转移自由基聚合反应中的作用321DPIP ,CuBr 2/BPPA 和CuBr 2/DPAP )并不遵守上述规律,它们有很高的去活化速率.中心是吡啶N 接合点的配体DPAP 与CuBr 2组成的催化体系的去活化速率是中心为苯代脂肪胺N 接合点的配体BPPA -CuBr 2体系的8倍.所以,配体中心的N 接合点的性质对催化剂的去活化速率影响更为显著,有研究者认为配体中心的N 接合点将产生John -T eller 效应[21],可以调节催化体系的去活化速率.表4 CuBr2/L 与PESG 1作用的去活化速率T able 4 Rate constants of deactivation for different CuBr 2com plexes with PESG 1配合物k Deact [M -1S -1]配合物k Deact [M -1S -1]CuBr 2/TERPY 4.1×105CuBr 2/P M DET A 6.1×106CuBr 2/DOAP 4.2×105CuBr 2/DPIP 7.9×106CuBr 2/DOIP 3.1×106CuBr 2/BPPA 9.1×106CuBr 2/BPOA3.3×106CuBr 2/DPAP7.2×107 注:PESG 1的结构为3.2.3 配体结构对催化活性相关性的唯象分析配体中心的N 接合点还能调节催化剂的还原电位.对于CuBr 2/L 配合物,如配体中有苯环与N 相连,该配合物的还原电位为正(165-200mV )这说明该配合物易被还原为Cu +,而其逆过程Cu +氧化为Cu 2+则难以发生,因此该类配合物在ATRP 反应中的活性低.CuBr 2/PM DET A 和CuBr 2/BPOA 催化体系,由于配体中心的N 接合点为脂肪胺N ,其还原电位比配体中心的N 接合点为吡啶N 的催化体系CuBr 2/DOAP 和CuBr 2/TERPY 更正.CuBr 2/DOAP 和CuBr 2/TERPY 的去活化速率比CuBr 2/PM DET A 和CuBr 2/BPOA 慢10倍,说明前两个络合催化剂比后二者难以还原.CuBr 2/L 的还原电位愈负,活化速率愈大,去活化速率愈小;CuBr 2/L 的还原电位愈小,ln kact/k Deact 愈大,在ATRP 反应中活性愈高.一般,在ATRP 反应中活泼的催化剂应易于氧化,具有较低的氧化电位(-30-100mV )或较低的还原电位(-240--110mV ).PM DET A ,BPOA ,TERPY 和DOAP 与Cu +形成的配合物有较高的活化速率,反应中迅速地生成活化体,但它们的去活化速率不同,前两个配体与Cu 2+形成的配合物在反应中可以快速地去活化,而后两个配体构成的催化剂的去活化速率较慢.根据动力学方程可知,去活化速率影响聚合物的分子量分布,因此在聚合反应中的催化体系应具有足够的去活化速率.PM DET A 和BPOA 与CuBr 组成的催化体系不仅有较高的活化速率,而且还有较快的去活化速率,所以适合许多单体的ATRP 反应.TERPY 和DOAP 与CuBr 组成的催化体系无法满足控制聚合中催化剂应有较高的去活化速率的要求,所以在ATRP 反应中应用范围较窄.3.2.4 配体结构对催化活性相关性的微观分析配体的柔性对CuBr 2/L 和CuBr/L 配合物的稳定性起着重要作用.刚性的TERPY 和DOAP 形成的Cu +/L 是平面正方形,而Cu 2+/L 则为扭曲的三角双锥.柔顺性较好的PM DET A 和BPOA 与Cu +形成四面体,而与Cu 2+形成扭曲的四方锥[22].实际上Cu +易形成四面体配合物,而Cu 2+/L 则以三角双锥占优势.这就不难说明为什么CuBr 2/PM DET A 具有较快的去活化速率,而CuBr 2/TERPY 则缓慢地去活化.配体中的π-电子形成反馈键的能力也将影响催化体系的稳定性.α-二亚胺形成π-反馈键的能力比2,2′-联吡啶强2倍,因为吡啶环上的N 相当于硝基,使环上的电子云密度降低而难以供出.因此,α-二亚胺比,2′-联吡啶能更好地稳定中心金属离子的低价氧化态.将Cu 2+/DOIP (二亚胺基吡啶)和Cu 2+/TERPY (2,2′,2″-联三吡啶)比较便可以说明这点.CuBr 2/DOIP 的还原电位为-110mV ,CuBr 2/TERPY 为-240mV ,这说明DOIP 能更好地稳定Cu +而TERPY 则形成一个更稳定的Cu 2+配合物.因此,DOIP 形成的催化剂具有较322 西华师范大学学报(自然科学版) 2003年低的活化速度和较快的去活化速度,CuBr 2/DOIP 体系对甲基丙烯酸甲酯的聚合有较高的催化活性,而对丙烯酸甲酯和苯乙烯的聚合反应活性很低.综上所述,一个理想的ATRP 催化剂应有很大的K deact 和适当的K act ,而决定这两个速率常数的关键因素是配体,它们可以调节过渡金属的氧化还原性能,通过配体的立体效应提供适当的选择性,而且它们可以确保催化剂在反应混合物中有足够的溶解性能.含氮配体能为ATRP 反应提供十分有效的催化剂,配体结构不同,其催化活性不同,一般有如下活性顺序:烷基胺吡啶>烷基亚胺>芳基胺>芳基亚胺.三足配体对活性聚合的可控能力强于三齿配体,而四齿配体优于三齿配体,后者优于二齿配体.但是,同一配体对不同单体的活性并不一致,因此有必要对特定催化剂在各类单体的聚合反应中的特性进行深入研究,以便研制更有效的催化剂.参考文献:[1]W ANG X S ,ARMES S P.Scope and Limitations of Atomic T rans fer Radical P olymerization in Aqueous Media [J ].P olymer Preprints ,2000,41(1):4131[2]H ADD LET ON D M ,PERRIER S.Atom T rans fer P olymerization of P oly (ethylene G lycol )Methyl E ther Methacrylate Macrom onomer[J ].P olymer Preprints ,2000,41(1):4151[3]MI URA Y,NAK AM URA N ,T ANIG UCHI I.Low -T emperature “Living ”Radical P olymerization of S tyrene in the Presence of Nitroxideswith S piro S tructures Macrom olecules[J ].2000,34(3):4471[4]万应龙,刘燕飞,应圣康.BDE/CuCl 催化体系中高熔融温度聚苯乙烯的合成[J ].中国科学(B 辑),2000,6:5691[5]M OSCH OGI ANNI P ,PISPAS S.Multifunctional ATRP Initiators :Synthesis of F our-Arm S tar H om opolymers of Methyl Methacrylate andG raft C opolymers of P olystyrene and P oly (t-butyl methacrylate )[J ].J.P olymer Science ,Part A :P olymer Chemistry ,2001,39:6501[6]SHE N Y Q ,ZH U S P ,PE LT ON R.Supported Atom T rans fer Radical P olymerization of Methyl Methacrylate Mediated by CuBr-te 2traethyldiethylenetriamine G rafted onto S ilicagel[J ].J.P olymer Science ,Part A :P olymer Chemistry ,2001,391[7]Y U Q ,ZE NG F Q ,ZH U S P.Atom T rans fer Radical P olymerization of P oly (ethylene glycol )Dimethacrylate[J ].Macrom olecules ,2001,34(6):16121[8]郭建华,罗贤安,吴平平,等.异丙醇铝改进的原子转移自由基聚合催化体系[J ].高分子学报,1999,6:7251[9]袁金颖,王延梅,潘才元.引发剂结构对原子转移自由基聚合反应的影响[J ].功能高分子学报,2001,14(1):571[10]ZH U S M ,Y AN D Y,ZH ANG G S.Reverse Atom T rans fer Radical P olymerization of Methyl Methacrylate with a New Catalytic System ,FeCl 3/is ophthalic Acid[J ].J.P olymer Science ,Part A :P olymer Chemistry ,2001,39:7651[11]ZH U S M ,Y AN D Y,ZH ANG G S.Atom T rans fer Radical P olymerization of S tyrene with FeCl 2/acetic Acid as the Catalyst System[J ].P olymer Bulletin ,2001,45:4571[12]M ATY JASZEWSKI K.T ransition Metal Catalyzed Atom T rans fer Radical P olymerization[J ].P olymer Preprints ,2000,41(1):4111[13]王晓松,罗 宁,应圣康.铜体系催化原子转移自由基聚合机理研究的讨论[J ].高分子通报,1999,1:91[14]M ATY JASZEWSKI K,G ;BE LT B ,PAIK H J.T ridentate Nitrogen-Based Ligands in Cu-Based ATRP :A S tructure-Activity S tudy[J ].Macrom olecules ,2001,34(3):4301[15]Y UAN J Y,PAN C.Y,T ANGB Z.“Living ”Free Radical Ring -Opening P olymerization of 5,6-Benzo-2-methylene-1,3-dioxepane Usingthe Atom T rans fer Radical P olymerization Method[J ].Macrom olecules ,2001,34(2):2111[16]E LY ASHI V -BARAD S ,G REI NERT N ,SE N A.C opolymerization of Methyl Acrylate with N orbornene Derivatives by Atom T rans fer Radi 2cal P olymerization[J ].Macrom olecules ,2002,35(19):7521-75261[17]ZIEG LER M J ,M ATY JASZEWSKI K.Atom T rans fer Radical C opolymerization of Methyl Methacrylate and n-Butyl Acrylate[J ].Macro 2m olecules ,2001,34(3):4151[18]W ANG X S ,M A LET F L G S ,ARMES P.Unexpected Viability of Pyridyl Methanimine-Based Ligands for T ransition-Metal-MediatedLiving Radical P olymerization in Aqueous Media at Ambient T emperature[J ].Macrom olecules ,2001,34(2):1621[19]XI A J ,M ATY JASZEWSKI K.C ontrolled/“Living ”Radical P olymerization.Atom T rans fer Radical P olymerization Catalyzed by C opper(I )and Picolylamine C omplexes[J ].Macrom olecules ,1999,32:24341[20]G ;BE LT B ,M ATY JASZEWSKI K.Diimino-and Diaminopyridine C omplexes of CuBr and FeBr 2as Catalysts in Aton T ransfer Radical P olymerization (ATRP )[J ].Microm ole.Chem.Phys.,2000,201:16191[21]H ATH AW AY B J.In C omprehensive C oordination Chemistry (V ol.5)[M].Wilkins on ,G.,E t.,Pergam on Books Ltd Ox ford ,1987.652, 第24卷第3期蒋晓慧,等:配体在卤化铜催化的原子转移自由基聚合反应中的作用3236971[22]CH UNG I S.M ATY JASZEWSKI K.Synthesis of Degradable P oly (methyl methacrylate )via ATRP :Atom T rans fer Radical Ring -OpeningC opolymerization of 5-Methylene-2-phenyl-1,3-diox olan-4-one and Methyl Methacrylate[J ].Macrom olecules ;(C ommunication );20031[24]M ORI H ,SE NGD C ,LECH NER H.et al.Synthesis and Characterization of Branched P olyelectrolytes. 1.Preparation of Hyper 2branched P oly (acrylic acid )via Self-C ondensing Atom T rans fer Radical C opolymerization [J ].Macrom olecules ,2002,35(25):9270-92811[25]OPST A L T ,C OUCHEZ K,VERPOORT F.Easily Accessible Ring Opening Metathesis and Atom T rans fer Radical P olymerization Cata 2lysts based on Arene ,N orbornadiene and Cyclooctadiene Ruthenium C omplexes Bearing Schiff Base Ligands (V ol.345)[M].Advanced Synthesis &Catalysis ,2003.393-4011[26]ZH ANG H Q ,FI J TE N M W M ,H OOGE NBOOM R ,et al.Application of a Parallel Synthetic Approach in Atom -T rans fer Radical P oly 2merization :Set-Up and Feasibility Dem onstration[J ].Macrom olecular Rapid C ommunications ,2003,24:81-861[27]Cu (S2C NE t2)Cl-Catalyzed Reverse Atom -T rans fer Radical P olymerization of Vinyl M onomers[J ].Macrom olecular Rapid C ommunica 2tions ,2003,23:1124-11291[28]ZE NG F Q ,SHE N Y P ,ZH U S P.Atom -T rans fer Radical P olymerization of 2-(N ,N -Dimethylamino )ethyl Acrylate[J ].Macrom olecularRapid C ommunications ,2003,23:1113-11171[29]LI P ,QI U K Y.Synthesis of Well-Defined P oly (methyl methacrylate )by a N ormal Atom -T rans fer Radical P olymerization Procedure with aNew Catalyst ,Cuprous N ,N -Diethyldithiocarbamate [J ].Macrom olecular Chemistry and Physics ,2002,203:2305-23111[30]BONTE MPO D ,TIRE LLI N ,FE LDM AN K,et al.Atom T rans fer Radical P olymerization as a T ool for Surface Functionalization[J ].Ad 2vanced Materials ,2002,14:1239-12411[31]REYES M ,Y U X ,SHIPP D A.K inetic Analysis of the Atom T rans fer Radical P olymerization of Butyl Acrylate Mediated by Cu (I )Br/N ,N ,N ′,N ′,N ″-Pentamethyldiethylenetriamine[J ].Macrom olecular Chemistry and Physics ,2001,202:3268-32721E ffects of Ligands in ATRP C atalyzed by CuXJ IANG X iao 2hui 1,HU X ing 2qi 2(1.Department of Chemistry ,China West N ormal University ,Nanchong 637002,China ;2.Department of Chemistry &Engineering ,S outh-West Petroleum Institute ,Nanchong 637001,China)Abstract :Ligands play a crucial role in ATRP (atom trans fer radical polymerzation ).They can tune the redox property of transition-metals ,im prove the s olubility of the related catalysts in reaction mixture and offer the related catalysts suitable selectivity.S o a structure-activity study on ligands is helpful in searching g ood catalysts in ATRP.In this paper the latest developments have been reviewed about nitrogen-based ligands in Cu-based ATRP.K ey w ords :ligands ;atom trans fer ;radical polymerization ;copper bromide ;com plex ;initiators324 西华师范大学学报(自然科学版) 2003年。

活性自由基聚合摘要:阐述了活性自由基聚合的产生背景和基本概念,介绍了活性自由基聚合的分类,描述了原子转移自由基聚合的研究进展。

关键词:活性自由基聚合1.活性自由基聚合的基本思想活性自由基聚合的核心思想是抑制增长自由基浓度,减少双基终止的发生。

由高分子化学知识可知,链终止速率与链增长速率之比可用下式表示:[1]通常kt/kp为104~105,假定体系中单体浓度为1mol/L,则:当然,自由基活性种浓度不可能无限制地降低,一般来说,[P*]在10-8mol/L左右,聚合反应的速率仍很可观。

在这样的自由基浓度下,Rt /Rp≈10-4~10-3,Rt相对于Rp就可忽略不计,所谓的活性自由基聚合的“活性”就在这里。

自由基浓度的下降必然降低聚合反应速度,但由于链增长反应活化能高于链终止反应活化能,因此提高聚合反应温度不仅能提高聚合速率(因为能提高kp ),而且能有效降低kt/kp比值,从而抑制链终止反应的进行。

这里需要解决两个问题:一是如何从聚合反应开始直到反应结束始终控制如此低的反应活性种浓度;二是在如此低的反应活性种浓度下,如何避免聚合物的聚合度过大(DPn =[M]/[P*]=1/10-8=108)。

解决这两个问题的方法是在聚合体系中加入数量可人为控制的反应物X,此反应物X不能引发单体聚合,但可与自由基P*迅速作用而发生钝化反应,生成一种不会引发单体聚合的“休眠种”P-X。

而此休眠种在聚合反应条件下又可均裂成增长自由基P*及X,如下式表示:[2]这样体系中存在的自由基活性种的浓度将取决于3个参数:反应物X的浓度、钝化速率常数kd 和活化速率常数ka,其中反应物X的浓度是人为可控的,所谓的可控活性自由基聚合的“可控”就在这里。

另外研究表明,如果钝化反应和活化反应的转化速率足够快(不小于链增长速率),则在活性种浓度很低的情况下,聚合物的分子量将不由P*而由P-X的浓度决定。

其中d为单体转化率,[P-X]可控。

“活性”/可控自由基聚合熊鹏鹏2010214110 摘要: 自由基聚合是生产高分子量聚合物的重要方法, “活性”/ 可控自由基聚合综合了自由基聚合和离子聚合的优点, 使自由基聚合具有可控性。

本文对目前可以实现“活性”/ 可控自由基聚合的途径和各自机理进行介绍, 指出应该重视对“活性”/可控自由基聚合的研究。

关键词: “活性”/可控自由基聚合; 稳定自由基; 可逆加成-裂解链转移; 原子转移; 引发转移终止剂;退化转移。

自由基聚合是工业上和实验室中生产高分子量聚合物的重要方法, 该法具有可聚合的单体种类多、反应条件宽松、以水为介质、容易实现工业化生产等优点, 但也存在着缺陷, 如自由基聚合的本质( 慢引发, 快速链增长, 易发生链终止和链转移等) 决定了聚合反应的失控行为,其结果常常导致聚合产物呈现宽分布, 分子量和结构不可控, 有时甚至会发生支化、交联等,从而严重影响聚合物的性能, 此外, 传统的自由基聚合也不能用于合成指定结构的规整聚合物。

鉴于离子聚合和配位聚合可以很好地控制聚合物结构, 而能不能控制自由基聚合体系则成为当前的研究热点, 但近年来从离子聚合和可控有机自由基反应的研究进展来看, 答案是肯定的。

就聚合反应而言, 要合成具有确定结构的聚合物, 则要求所有的链应同时引发, 增长相似, 这就需要快速引发, 在聚合结束前增长链应保持活性, 链转移和链终止的效应可以忽略, 而自由基聚合的本质( 慢引发, 快终止) 与之正好相反。

所以实现可控自由基聚合要基于以下三个原则:1) 自由基体系中的增长反应应对自由基敏感, 终止反应对自由基浓度的敏感度次之。

这样, 在自由基浓度很低时, 链增长反应与终止反应的速率比才足够高, 才能合成出分子量很大的聚合物。

2) 增长链的浓度必须比初始游离自由基的浓度高得多, 在整个反应过程中所有的链均需保持活性, 且游离自由基与高浓度休眠链处于动态平衡之中, 这种持续自由基效应对任何控制自由基反应来说都是最重要的。

原子转移自由基聚合催化剂一、引言随着科技的飞速发展,高分子材料在我们的日常生活和工业生产中发挥着越来越重要的作用。

作为高分子合成中的关键技术之一,聚合反应对于高分子材料的发展具有至关重要的影响。

其中,原子转移自由基聚合(Atom Transfer Radical Polymerization,简称ATRP)是一种高效、环保的聚合方法,其催化剂的研究与应用受到了广泛关注。

本篇文章将对原子转移自由基聚合催化剂的特性、发展历程、在合成高分子材料中的应用以及未来展望进行深入探讨。

二、原子转移自由基聚合催化剂的特性原子转移自由基聚合催化剂主要由过渡金属和配位基组成。

这些催化剂可以在温和的条件下高效地引发和传播自由基聚合反应,从而实现高分子材料的可控制备。

催化剂的活性中心通常为过渡金属,如铜、铁、钴等,它们能够与配位基形成稳定的络合物,进一步催化自由基聚合反应。

原子转移自由基聚合催化剂的主要特性包括:催化活性高、适用范围广、聚合过程可控制等。

首先,催化剂能够高效地引发和催化聚合反应,使得聚合反应能够在较短的时间内完成,并获得较高分子量的聚合物。

其次,催化剂对不同的单体具有良好的适应性,能够用于合成多种不同结构的高分子材料。

最后,通过调整催化剂的浓度、反应温度等参数,可以实现对聚合过程的精确控制,进而获得具有特定性能的高分子材料。

三、原子转移自由基聚合催化剂的发展历程自20世纪90年代初原子转移自由基聚合被发现以来,该领域的研究经历了漫长的发展历程。

从最初的铜催化体系到如今多样化的催化剂体系,原子转移自由基聚合技术在不断完善和进步。

以下简要回顾了原子转移自由基聚合催化剂的发展历程:1.铜催化体系:铜是最早被用于原子转移自由基聚合的金属元素之一。

在铜催化剂的作用下,可以在较低的温度下引发和催化自由基聚合反应,合成出具有优异性能的高分子材料。

尽管铜催化体系具有较高的催化活性和广泛的单体适应性,但其对水和氧的敏感性限制了其在某些特定条件下的应用。

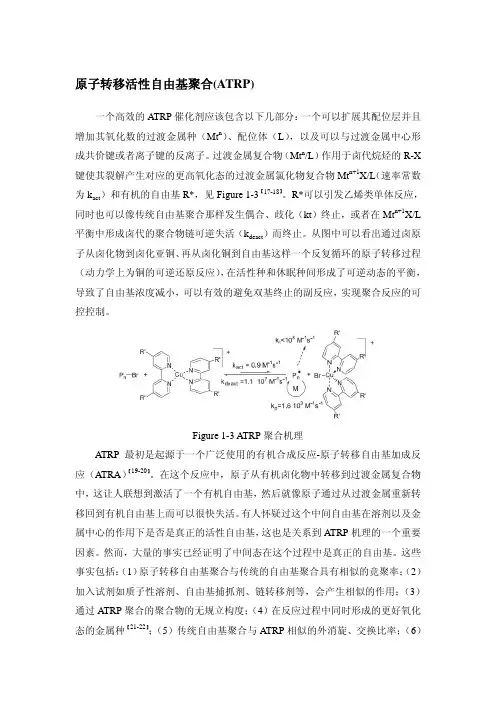

原子转移活性自由基聚合(ATRP)一个高效的ATRP催化剂应该包含以下几部分:一个可以扩展其配位层并且增加其氧化数的过渡金属种(Mt n)、配位体(L),以及可以与过渡金属中心形成共价键或者离子键的反离子。

过渡金属复合物(Mt n/L)作用于卤代烷烃的R-X 键使其裂解产生对应的更高氧化态的过渡金属氯化物复合物Mt n+1X/L(速率常数为k act)和有机的自由基R*,见Figure 1-3【17-18】。

R*可以引发乙烯类单体反应,同时也可以像传统自由基聚合那样发生偶合、歧化(kt)终止,或者在Mt n+1X/L 平衡中形成卤代的聚合物链可逆失活(k deact)而终止。

从图中可以看出通过卤原子从卤化物到卤化亚铜、再从卤化铜到自由基这样一个反复循环的原子转移过程(动力学上为铜的可逆还原反应),在活性种和休眠种间形成了可逆动态的平衡,导致了自由基浓度减小,可以有效的避免双基终止的副反应,实现聚合反应的可控控制。

Figure 1-3 ATRP聚合机理ATRP最初是起源于一个广泛使用的有机合成反应-原子转移自由基加成反应(ATRA)【19-20】。

在这个反应中,原子从有机卤化物中转移到过渡金属复合物中,这让人联想到激活了一个有机自由基,然后就像原子通过从过渡金属重新转移回到有机自由基上而可以很快失活。

有人怀疑过这个中间自由基在溶剂以及金属中心的作用下是否是真正的活性自由基,这也是关系到ATRP机理的一个重要因素。

然而,大量的事实已经证明了中间态在这个过程中是真正的自由基。

这些事实包括:(1)原子转移自由基聚合与传统的自由基聚合具有相似的竞聚率;(2)加入试剂如质子性溶剂、自由基捕抓剂、链转移剂等,会产生相似的作用;(3)通过ATRP聚合的聚合物的无规立构度;(4)在反应过程中同时形成的更好氧化态的金属种【21-22】;(5)传统自由基聚合与ATRP相似的外消旋、交换比率;(6)传统自由基聚合与ATRP之间不可辨别的13C动力学同位素效应。

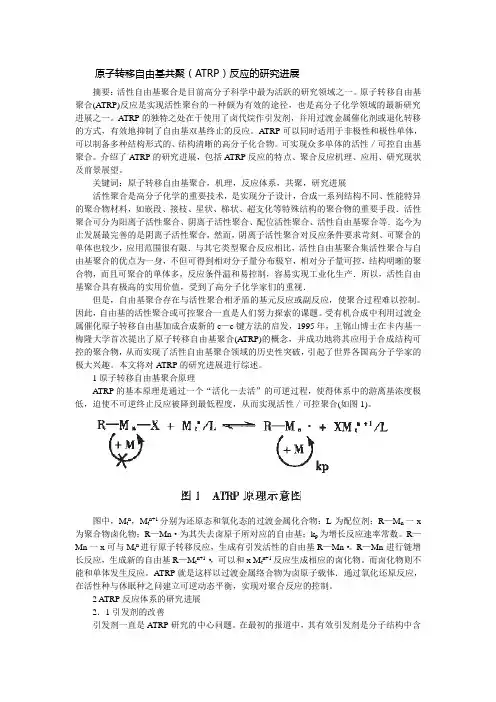

原子转移自由基共聚(ATRP)反应的研究进展摘要:活性自由基聚合是目前高分子科学中最为活跃的研究领域之一。

原子转移自由基聚合(A TRP)反应是实现活性聚台的一种颇为有效的途径,也是高分子化学领域的最新研究进展之一。

ATRP的独特之处在于使用了卤代烷作引发剂,并用过渡金属催化剂或退化转移的方式,有效地抑制了自由基双基终止的反应。

ATRP可以同时适用于非极性和极性单体,可以制备多种结构形式的、结构清晰的高分子化合物。

可实现众多单体的活性/可控自由基聚合。

介绍了ATRP的研究进展,包括ATRP反应的特点、聚合反应机理、应用、研究现状及前景展望。

关键词:原子转移自由基聚合,机理,反应体系,共聚,研究进展活性聚合是高分子化学的重要技术,是实现分子设计,合成一系列结构不同、性能特异的聚合物材料,如嵌段、接枝、星状、梯状、超支化等特殊结构的聚合物的重要手段.活性聚合可分为阳离子活性聚合、阴离子活性聚合、配位活性聚合、活性自由基聚合等.迄今为止发展最完善的是阴离子活性聚合,然而,阴离子活性聚合对反应条件要求苛刻、可聚合的单体也较少,应用范围很有限.与其它类型聚合反应相比,活性自由基聚合集活性聚合与自由基聚合的优点为一身,不但可得到相对分子量分布极窄,相对分子量可控,结构明晰的聚合物,而且可聚合的单体多,反应条件温和易控制,容易实现工业化生产.所以,活性自由基聚合具有极高的实用价值,受到了高分子化学家们的重视.但是,自由基聚合存在与活性聚合相矛盾的基元反应或副反应,使聚合过程难以控制。

因此,自由基的活性聚合或可控聚合一直是人们努力探索的课题。

受有机合成中利用过渡金属催化原子转移自由基加成合成新的c—c键方法的启发,1995年,王锦山博士在卡内基一梅隆大学首次提出了原子转移自由基聚合(ATRP)的概念,并成功地将其应用于合成结构可控的聚合物,从而实现了活性自由基聚合领域的历史性突破,引起了世界各国高分子学家的极大兴趣。

ATRP 在嵌段共聚物合成中的应用进展摘要:段共聚物作为一种新型的高分子材料越来越受到人们的关注,原子转移自由基聚合(ATRP)作为一种“活性/可控”聚合方法,在嵌段共聚物合成领域发挥着重要的作用。

文中主要介绍了近年来采用ATRP 合成的不同性能的嵌段高分子聚合物,并对ATRP 在嵌段共聚物中的应用前景进行了展望。

关键词:原子转移自由基聚合;合成;嵌段共聚物0 引言原子转移自由基聚合(Atom Transfer Radical Polymerization, ATRP)现在作为“活性/可控”自由基聚合技术,具有聚合条件温和(甚至可以在少量氧存在下进行),使用单体范围广范,分子设计能力强等特点,正逐渐成为合成功能高分子材料的有力手段而备受关注[1~4]。

是现在其他活性聚合方法所无法比拟的。

1 ATRP 的反应机理1.1 ATRP 简介原子转移自由基聚合(ATRP)是以低价态过渡金属配合物作为催化剂的“活性/可控”聚合,是制备具有预期分子量、精确末端官能团和预期链结构聚合物的新技术。

早在1995 年王锦山和Matyjaszewski 等人首先报道了一种新型自由基聚合方法[ 5,6 ],它是以卤代化合物为引发剂,过渡金属化合物以适当的配体为催化剂,使可进行自由基聚合的单体进行具有活性特征的聚合。

ATRP 方法进行聚合反应的单体,一般都是一端含有一个卤素端基,另一端含有功能化引发端基;或者两端皆为卤素端基。

这些端基很容易进一步的功能化,合成出相对分子量分布较窄的聚合物。

1.2 ATRP 反应机理过渡金属化合物Mtn 从有机卤化物“提取”出卤原子,产生氧化物种Mtn+1X 和初级自由基R· ;随后自由基R·和烯烃M 反应,生成单体自由基R-M· (即活性种);R-M·与40 Mtn+1X 反应,得到目标物种R-M-X;同时过渡金属被还原为Mtn,可再次引发新一轮的氧化还原反应。

Transition Metal-Catalyzed Living Radical Polymerization:Toward Perfection in Catalysis and Precision Polymer SynthesisMakoto Ouchi,Takaya Terashima,and Mitsuo Sawamoto*Department of Polymer Chemistry,Graduate School of Engineering,Kyoto University,Katsura,Nishikyo-ku,Kyoto615-8510,JapanReceived July1,2009 Contents1.Introduction49642.Design of the Initiating Systems49652.1.Required Initiating Systems49652.1.1.Synthesis of Controlled Polymers Freefrom Catalyst Residues49662.1.2.Environmentally Friendly and InexpensiveCatalysts49662.1.3.Suppression of Side Reactions for HighMolecular Weight Polymers and PerfectBlock Copolymerization49662.1.4.Application to Nonprotected FunctionalMonomers49662.1.5.Biopolymers and Inorganic Molecules:Interdisciplinary Extension49662.1.6.Tacticity and Sequence:Advanced Control49672.2.Transition Metal Catalysts49672.2.1.Overviews of Catalysts49672.2.2.Ruthenium49672.2.3.Copper49712.2.4.Iron49712.2.5.Nickel49752.2.6.Molybdenum49752.2.7.Manganese49762.2.8.Osmium49762.2.9.Cobalt49762.2.10.Other Metals49762.3.Cocatalysts(Additives)49772.3.1.Overview of Cocatalysts49772.3.2.Reducing Agents49772.3.3.Free Radical Initiators49772.3.4.Metal Alkoxides49772.3.5.Amines49782.3.6.Halogen Source49782.4.Initiators49782.4.1.Overview of Initiators:Scope and Design49782.4.2.Alkyl Halides49782.4.3.Arenesulfonyl Halides49792.4.4.N-Chloro Compounds49792.4.5.Halogen-Free Initiators49792.5.Solvents49802.5.1.Overview of Solvents49802.5.2.Catalyst Solubility and Coordination ofSolvent 49812.5.3.Environmentally Friendly Solvents49812.5.4.Water49812.5.5.Catalytic Solvents:CatalystDisproportionation49812.6.Monomers49822.6.1.Overview of Monomers49822.6.2.Conjugated Monomers49822.6.3.Nonconjugated Monomers49823.Precision Polymer Synthesis49833.1.Overview of Precision Polymer Synthesis49833.2.Pendant-Functionalized Polymers49833.2.1.Non-Protected Functional Monomers49843.2.2.Protected Functional Monomers andReactive Monomers49853.2.3.Ionic Monomers and or Styrenic FunctionalMonomers49863.2.4.Designer Functional Monomers49863.3.End-Functionalized Polymers49873.3.1.R-End Functionalization via FunctionalInitiators49883.3.2.ω-End Functionalization via TerminalTransformation49923.3.3.R,ω-Telechelics via Polymer Reaction49943.4.Block Copolymers49943.4.1.System Design49953.4.2.Functionalized Block Copolymers49963.4.3.System Combination50003.4.4.Polymer Reaction50083.5.Random Copolymers50093.5.1.Conjugated Monomers50103.5.2.Non-Conjugated Monomers50133.5.3.Cyclic Monomers50153.6.Alternating Copolymers50153.7.Gradient Copolymers50153.7.1.Monomer Reactivity50153.7.2.Monomer Addition50163.8.Star Polymers50163.8.1.Multifunctional Initiators50163.8.2.Cross-Linked Microgel Cores50213.8.3.Polymer Reaction50263.9.Graft Copolymers50273.9.1.Grafting From50273.9.2.Grafting Through50323.9.3.Grafting Onto50343.10.Hyperbranched and Dendritic Polymers50353.10.1.Inimers50353.10.2.Divinyl Compounds5036*To whom correspondence should be addressed.Phone:+81-75-383-2600.Fax:+81-75-383-2601.E-mail:sawamoto@star.polym.kyoto-u.ac.jp.Chem.Rev.2009,109,4963–5050496310.1021/cr900234b CCC:$71.50 2009American Chemical SocietyPublished on Web09/29/20093.10.3.Iterative Divergent Approach50363.11.Advanced Designer Materials50363.11.1.Protein-Conjugated Polymers50363.11.2.Surface-Graft Polymers50374.Abbreviations50385.References5039 1.IntroductionPrecision control of radical polymerization,or living radical polymerization,has been among the most important and long-waited subjects in polymer chemistry and macro-molecular synthesis.Given the inherent nature of“free”radical species that tend to undergo bimolecular termination and disproportionation,along with their poor chemo-and regioselectivity in organic reactions,pessimistic views have prevailed for a long time.Since the1980s and the1990s, however,first gradually and then very rapidly,promising methods began to emerge,and in2009,polymer chemists are certainly confident that one can now possess a variety of methodologies for precisely controlled and often living radical polymerizations.For these methods,numerous re-views and accounts are available(see below).1-9In general,almost all of the current methods for living radical polymerization are based on a seemingly common concept,the reversible and dynamic equilibrium of a radical growing species with a dormant species(Scheme1).1The dormant species in this context is defined as a covalent species(with an appropriate leaving group)that is stable enough to elude side reactions and thereby incapable of propagation but is capable of generating a true growth-active intermediate(propagating or growing species)by dissociating the leaving group upon chemical catalysis or physical stimuli (heat or light).In the authors’view,a considerable number of living or controlled polymerizations via ionic and other related mechanisms also rely on this concept.1Typical dormant species for radical polymerization include alkyl halides with a conjugating and radical-stabilizing R-substituents such as2-bromo-2-methylpropionates(bro-moisobutyrates)[(CH3)2CBrCO2R;R)alkyl,etc.],which is considered as a precursor of methacrylate radicals via dissociation of the bromine as a leaving group in the presence of a catalyst.Under selected conditions,a dormant species thus generates a growth-active radical species to initiate radical propagation,and a key to precision reaction control is the reversibility and dynamic equilibrium in this process assisted by catalysis or physical stimulus,namely,sooner or later the radical intermediates are,and should be,“capped”with the bromine and other leaving groups,to regenerate the dormant species.Equally important,the dormant-active species equilibrium is shifted to the former,retaining a low instantaneous concentration of the latter,while the exchange between the two is faster than the concurrent propagation.Combination of these conditions leads tofine control of radical polymerization to give macromolecules of well-defined molecular weights,main-chain structure,terminal groups,along with very narrow molecular weight distribu-tions,though the mechanistic implication of the equilibrium stays outside of the scope of this article.As will be discussed in the following sections,the reversible generation of radicals involve metal catalysis,1-6stable radicals(as leaving groups),7addition-fragmentationchaintransfer,8metal-carbon bonds,9among many others.In the period of1994-95,we found that a class of organometallic complexes of late transition metals,typically divalent ruthenium[Ru(II)],are excellent catalysts for such a dormant-active radical equilibria and thereby catalyze what we now call“transition metal-catalyzed living radical po-lymerization”,which meets virtually all the phenomenologi-cal criteria for living polymerization.1-3Nearly the same time Wang and Matyjaszewski reported a similar process with copper catalysis and coined it as atom transfer radical polymerization or ATRP.4-6To summarize the discoveryand Makoto Ouchi,born in Osaka,Japan(1973),received his B.S.(1996), M.S.(1998),and Ph.D.degrees(2001)from Kyoto University.His doctoral study was on stereo-and regiospecific cationic polymerizations via designed Lewis acids and counteranions under the direction of Professor Mitsuo Sawamoto,during which he received a Research Fellowship for Young Scientist of the Japan Society for the Promotion of Scientists (1998-2001).In2001-2004,he worked in Toyota Central R&D Laboratories,Inc.,as a researcher to develop poly(lactic acid)-based materials for automobile parts.In2004,he moved to the Graduate School of Engineering of Kyoto University as an Assistant Professor of the Department of Polymer Chemistry.He was a visiting associate at California Institute of Technology working with Professor David A.Tirrell(2007-2008). His current research interests include precision sequence control in chain-growth polymerizations through design of monomers,catalysts,and polymerizationfields.Takaya Terashima,born in Shiga,Japan(1978),received his B.S.(2002), M.S.(2004),and Ph.D.degrees(2007)from Kyoto University.His doctoral study was on development of multifunctional designer catalysts via living radical polymerization,especially focused on star polymer catalysis and tandem catalysis,under the direction of Professor Mitsuo Sawamoto,where he received a Research Fellowship for Young Scientist of the Japan Society for the Promotion of Scientists(2004-2007).He received Student Poster Board Award in SAS2006Kyoto.He joined the faculty of Department of Polymer Chemistry,Graduate School of Engineering,Kyoto University in2007as an assistant professor.His research interests include functionalized catalysts toward precision polymer synthesis and organic reaction.4964Chemical Reviews,2009,Vol.109,No.11Ouchi et al.the early development of these metal-catalyzed polymeriza-tions,in 2001,we published our first comprehensive review in this journal,and the current review may be considered as a sequel that covers the latest progress in the field after 2001.Chronologically,the first review covers the period of 1994-2000,while the second covers 2001-2008.If we arbitrarily call these periods phase I and phase II,respec-tively,a comparison of our two reviews shows some notable and interesting trends in the metal-catalyzed living radical polymerizations:First,our phase I review involved 460references,while the phase II article now comprises over 970publications,indicating a fast and steady growth and extension of the field on going from phase I to phase II (the references herein do not include a considerable number of papers for copper-based catalysis).Second,in our view,research interest has also been shifting during the two periods.The major discovery and developments in these phases may be summarized as follows:Phase I (1995-2001)Discovery of metal-catalyzed living radical polymerization Establishment of the dormant-active species concept Systematic development of metal catalysts Systematic development of initiatorsLiving radical polymerization of common conjugated mono-mersPrecision polymer synthesis for block,end-functionalized,star,and other polymersAqueous-phase systems such as dispersion and emulsion living polymerizationsPhase II (2001-2008)Extension of catalysis into iron-based catalysts (abundant and safer)Extremely active catalysts (reduction of catalyst concentra-tion)Removal,recovery,and recycling of metal catalystsLiving radical polymerizations of functionalized monomers Precision synthesis of (multi)functional polymersBidirectional interaction with organic and organometallic chemistry particularly in catalyst developmentExtended application in multidisciplinary areas notably in biology,biochemisty,medicine,and nanotechnologyCombination with other controlled systems (polymerizations/reactions)These trend shifts would not necessarily be specific for metal-catalyzed living radical polymerizations but certainly for living and controlled radical polymerizations in general;however,for the former one can see that the shifts have certainly been driven by a few specific factors that include the following:(a)A fast extension to the metal-catalyzed living radical polymerization of a wide variety of (nonprotected)func-tionalized monomers,while retaining the advantages inher-ited from free radical polymerization such as simplicity and versatility(b)Establishment of reliable,reproducible,and robust living radical polymerizations via metal catalysis,now recognized as common “synthetic tools”,so simple,versatile,and user-friendly as to prompt many researchers in disciplines outside polymer chemistry to use for their own purposes(c)A fast expansion of interest and applications in biochem-istry,chemical biology,biology,and medicinal science,along with nanotechnology,as seen in “bioconjugation”or “hy-bridization”of synthetic functional polymers with enzymes,proteins,etc.,for medicine and diagnosis.It is particularly of importance,as implicated in item c,that these trends will encourage and promote new vistas and direction of future polymer chemistry and science,beyond its traditional disciplinary boundary for further development and deepening.2.Design of the Initiating Systems 2.1.Required Initiating SystemsBy around 2000,when we submitted a comprehensive review 1about metal-catalyzed living radical polymerization to Chemical Re V iews ,the targeted subjects had been directed to fundamental ones,for example,improvement in control over molecular weight and its distribution,quantitative polymerization,block copolymerization,versatility of con-trollable monomer,clarification of the mechanism,etc.Although these are now still important and should be examined,interest or demands for living radical polymeri-zation have shifted to more applicable and advanced ones,along with evolution of catalytic systems,Figure 1sum-marizes general features required for the initiating systems of metal-catalyzed living radical polymerization from such viewpoints and the predicted strategies for these subjects.Before going into details,we will refer to theseaspects.Mitsuo Sawamoto,born in Kyoto,Japan (1951),received his B.S.(1974),M.S.(1976),and Ph.D.degrees (1979)in polymer chemistry from Kyoto University.After a postdoctoral research at theInstitute of Polymer Science,The University of Akron,Akron,OH (1980-81),he joined the faculty of Department of Polymer Chemistry,Kyoto University in 1981as a research instructor and is currently Professor of Department of Polymer Chemistry,Graduate School of Engineering,Kyoto University since 1994.He serves as an executive member of the Science Council of Japan,a titular member of IUPAC Polymer Division,President of the Society of Polymer Science,Japan,and one of the Editors of the Journal of Polymer Science,Part A,Polymer Chemistry .He received,among others,Award of the Society of Polymer Science,Japan (1992),Divisional Research Award of the Chemical Society of Japan (1999),and Arthur K.Doolittle Award of PMSE Division,the American Chemical Society (2002).Scheme 1.Metal-Catalyzed Living RadicalPolymerizationLiving Radical Polymerization Chemical Reviews,2009,Vol.109,No.1149652.1.1.Synthesis of Controlled Polymers Free from Catalyst ResiduesThe synthesis of controlled polymer without catalyst contamination would be an important issue to be resolved toward actual applications of metal-catalyzed living radical polymerization,since metal residues are sometimes toxic and affect polymer functions.This problem would be more severe for biomedical and precision mechanical applications.Im-mobilization of catalysts could be a promising strategy as with polyolefins and in catalyst recycling.However,the heterogeneity of these catalysts might be disadvantageous in control over molecular weight,because such an im-mobilized catalyst causes difficulty in equal catalysis for generating polymer chains under dynamic catalysis.Phase-transfer catalysts would be also interesting for catalyst removal and recycling,though rather impractical in applica-tions.Behind these trends,highly efficient catalytic systems have been focused,where the polymerization is controlled even with extremely small amount of catalyst (e.g.,less than 10ppm),because such a system possibly does not require catalyst removal if the catalyst concentration is low enough to be negligible for toxicity and polymer functions.For this,the catalytic cycle or the so-called turnover frequency should be fast (high)efficiently accelerated and rotated.2.1.2.Environmentally Friendly and Inexpensive CatalystsEnvironmentally friendly and less expensive systems are required in actual applications.For this issue,a decrease in catalyst amount or recycling without loss of catalytic functions would be desired,because metal catalysts are often expensive.Choice of the central metal is also significant for global environment:a precious or rare metal should be preferably replaced with an abundant one if similar perfor-mance is obtained.Among metals used in metal-catalyzed living radical polymerization,iron (Fe)would be ideal from this viewpoint.Polymerization at ambient temperature would be favorable if activity is not lost seriously,because it contributes to saving energy costs.For solution polymeri-zation,use of low volatility solvent might be favored from environmentally consideration.2.1.3.Suppression of Side Reactions for High Molecular Weight Polymers and Perfect Block CopolymerizationIn living radical polymerizations,complete elimination of side reactions is difficult,distinguished from living anionic polymerizations,and it gets more severe for polymerization with lower concentration of initiator or at high monomer conversions in polymerization.This in turn causes difficulty in syntheses of high molecular-weight polymer (MW >106)with low polydispersity and quantitative sequential block copolymerization.To overcome the difficulty,an efficient and fast catalytic cycle between dormant and active species is required,and therefore two antithetical processes,that is,“activation”to radical species and “deactivation”to dormant species,need to be catalytically promoted.Lowering the temperature would be useful for suppression of side reactions,if the catalytic activity is not seriously lowered.2.1.4.Application to Nonprotected Functional MonomersRadical species are inherently tolerance to functional groups,in contrast to ionic intermediates,and thus functional monomers can be directly polymerized,which is advanta-geous to living radical polymerization toward precision syntheses of functional polymers.However,in metal-catalyzed systems,functional groups are poisonous for some catalysts,and therefore polymerization control is sometimes difficult for functional monomers.This subject is rather specific to the metal-catalyzed system,relative to metal-free systems including nitroxide-mediated (NMP),7,10reversible addition -fragmentation chain transfer (RAFT),8,11and ogra-notellurium-mediated (TERP)9,12polymerizations.The toler-ance to functional groups is partly dependent on the central metal,while to be improved by ligand design.2.1.5.Biopolymers and Inorganic Molecules:Interdisciplinary ExtensionIn living polymerization,all polymer chains carry an initiator moiety at the R -end because chain transfer is absent,thus lead to end-functionalized polymers from functionalized initiators.Due to tolerance against functional groups,living radical polymerization is now a powerful “tool”for incor-porating controlled polymers into biomoleules andinorganicFigure 1.Requirements for initiating systems.4966Chemical Reviews,2009,Vol.109,No.11Ouchi et al.molecules,as seen in“bioconjugation”13,14or“organic/ inorganic hybridization”.15Metal-catalyzed living radical polymerization is mostly initiated from a ubiquitous carbon-halogen bond adjacent to a conjugating substituent, and its introduction is more facile than the initiating functionalities for other living radical polymerizations. Furthermore,the initiating efficiency is relatively high,and thus suitable for quantitative connection.This should be one of the reasons why the metal-catalyzed systems have been employed for variety of interdisciplinary applications.Ef-ficient and quantitative incorporation of the initiating site without breaking the target molecule is essential for this purpose.2.1.6.Tacticity and Sequence:Advanced ControlAs reviewed by Kamigaito and Satoh in this issue,16 stereospecific and living radical polymerization has received considerable attention over the years toward development of more advanced polymers of well-defined structures.As stereospecificity is usually drawn at lower temperature,active living polymerization systems even at low temperature are required for simultaneous control of molecular weight and tacticity.Inspired by perfectly controlled structures seen in natural polymers,advanced control over another class of selectivity is also getting targeted for polymerization: monomer sequence or the controlled sequence of repeat units, and thereby of functional groups along the main chains.For the untrodden control,some additional mechanisms might be combined with living polymerization,where polymeri-zation would be performed at lower temperature to draw the selectivity for the next coming monomer.As shown here,recent interests for metal-catalyzed living radical polymerizations have been certainly directed to more advanced control and practical applications.In focus on these aspects,initiating systems for the polymerization,mainly developed for the past8years from2001-2008,will be reviewed below.2.2.Transition Metal Catalysts2.2.1.Overviews of CatalystsAs already established,1-6a catalyst in metal-catalyzed living radical polymerization contributes to catalysis for two antithetical processes(Scheme1),that is,activation and deactivation of a dormant and a growing polymer terminal respectively,via a one-electron redox.A metal complex with a lower oxidation statefirst activates the carbon-halogen bond in an initiator,or the corresponding dormant terminal to generate a growth-active radical species.In the activation process,the catalyst is oxidized to a one-electron higher valence state upon abstracting the halogen,to form a new metal-halogen bond.While the catalyst remains the higher valence state of the catalyst,the radical species can propagate by repeating radical-addition to monomers.After propagation with some monomers,the oxidized catalyst returns the halogen to a radical intermediate by capping or giving a dormant species,in which it is reduced by one electron to regenerate the original complex of the lower oxidation state. The metal complex repeats such a one-electron redox catalytic cycle to mediate controlled polymerization,and because of the reversible and dynamic equilibrium between the dormant(carbon-halogen)and the active(carbon radical species),the concentration of the active growing species is consequently kept low(probably two orders magnitude lower than in a conventional radical polymerizations),leading to suppression of side reactions(e.g.,coupling and dispropor-tionation),as generalized for other living or controlled polymerizations.Importantly,this catalytic cycle in the metal-catalyzed radical polymerization consists of a“one-electron”transfer,distinguished from other oxidation/reduction ca-talysis via two-electrons transfer,typically as seen in some palladium-catalyzed coupling reactions involving an oxida-tive addition and subsequent reductive elimination.17There-fore,the central metal needs to take at least two states of valence with one electron difference,even though either state is unstable to be isolated,and also carry moderate a halogen-affinity to accept and release a halogen atom.From these requirements,most likely,late transition metals of group 8-11have been employed for the metal-catalyzed living radical polymerization;most typically,these metals include iron,nickel,ruthenium,and copper.2.2.2.RutheniumRuthenium complexes are thefirst class of catalysts for metal-catalyzed living radical polymerization,asfirst reported in1995.18The ruthenium catalyst employed therein is a divalent Ru(II)complex,typically carrying two anionic ligands,such as halogens,conjugated carbanions,and phenoxy anions,as well as some neutral ones as phosphines, amines,cymene,and carbenes.The large capacity of the coordination space and the inherent tolerance(low oxo-philicity)to functional groups of the Ru(II)complexes allow coordination of various ligands,leading to a broad scope in catalyst design for the modulation of electron density and the steric environment in the ruthenium center.It is note-worthy that some ruthenium complexes allow the formation of ruthenium-carbon bonds,which enables the direct “communication”of the metal center with substituents and a wider range of“organic”design than other metal complexes mainly consisting of metal-heteroatom bonds. Dichlorides.RuCl2(PPh3)3(Ru-1)is thefirst example of ruthenium complexes catalyzing living radical polymeriza-tion,18which was originally proved to catalyze Kharasch addition reactions,19a model of the polymerization(Figure 2).It certainly gives well-controlled polymers for some monomers in conjunction with cocatalysts(additives),such as aluminum isopropoxide and amines,18,20-31but usually a little higher amount is needed([Ru]0/[Initiator]0)1/2)for sufficient catalytic activity than the later generation of Ru(II) complexes,for example,half-metallocene derivatives(see below).An ionic complex(Ru-2)was developed as a hydrophilic catalyst evolving from Ru-1,where one phenyl of the PPh3in Ru-1is replaced with that carrying a sulufonic acid sodium salt at the meta-position.32It is effective for catalyst removal in the polymerization of methyl methacry-late(MMA),as well as those of hydrophilic monomers,for example,2-hydroxyethyl methacrylate(HEMA)in methanol. The triazol-5-ylidene complex(Ru-3)showed a high activity for MMA with the assistance of amine additive(n-Bu2NH) to give narrow molecular weight distributions(M w/M n<1.3) within24h.33Half-Metallocenes.Half-metallocene-type ruthenium com-plexes with indenyl(Ru-4)34-36and pentamethylcyclopen-tadiene(Cp*,Ru-5)35,37ligands are representative of active catalysts for living radical polymerization giving quite narrow molecular weight distributions and well-defined block co-polymers.Their superior catalysis supposedly originates fromLiving Radical Polymerization Chemical Reviews,2009,Vol.109,No.114967a fast halogen-exchange reaction,as supported by model reactions with an initiator or a model compound for the growing chain (dormant species),analyzed by 1H NMR along with the low redox potential by cyclic voltammetry (CV).35Toward further enhancement of the catalytic activity for Ru-4,an electron-donating dimethylamino group was introduced onto the indenyl ring (Ru-6),and indeed this complex induced a faster polymerization (10vs 16h for >90%conversion)to give narrower molecular weight distributions (M w /M n ) 1.07vs 1.13)than does the nonsubstituted derivative (Ru-4).38Similarly,the introduction of other electron-donating groups,for example,phenyl (Ru-7)and aza-crown (Ru-8),was also effective to improve catalytic activity.3The position of these substituents seems to be important for polymerization control,as indicated by a poorer control with Ru-9with a pyrrolidinnyl group at the 1-position (M w /M n >1.30).3A cationic complex with ethylene-ligand (Ru-10)is more active than Ru-4since the former easily gives a vacant site for acceptance of a transferred halogen by releasing the labile ethylene ligand.39The Cp*complex Ru-5is potentially active enough to achieve fine control for three kinds of signature monomers,MMA,methyl acrylate (MA),and styrene (St)under the same conditions.37However,it had a drawback to take a long time for high conversion in the polymerizations,most likely because this complex is coodinatively saturated (an 18-electron complex),and so it would need to release at least one ligand to accept a halogen from the dormant terminal upon activation.So efforts have been addressed to accelerate polymerization without losing the fine control-ability.Thus,coordinatively unsaturated with a Cp*ligand were examined so as to achieve a more frequent activation.Ru(Cp*)Cl(PCy 3)(Ru-11),a 16-electron complex,induced a faster polymer-ization of MMA without a serious loss of the fine control ability as for Ru-4.37However,the control becomes worse for the polymerizations of MA and St.Similarly,coordina-tively unsaturated dimers with amidinate (Ru-12)40and alkoxide (Ru-13)41were reported to induce controlled polymerization of MMA,but their activity were not suf-ficient,resulting in limited conversions (conv <∼50%).A P -N chelate complex (Ru-14)was developed from the finding that an amine compound works as a cocatalyst/additive for ruthenium complexes.39Also,nitrogen coordina-tion is more labile than the phosphine counterpart for ruthenium,and thus such a hetero chelation is expected to promote the catalysis via a dynamic elimination/plex Ru-14exactly catalyzes a faster polymeriza-tion than Ru-5without loss of fine control,and the higher activity is supported by the lower redox potential (0.26vs 0.46V for Ag/AgCl).Comprehensive study on steric/electronic effects of phos-phine ligands for polymerization of MMA with a useful tetramer precursor ([RuCp*(µ3-Cl)]4)revealed that bulkiness is more critical for polymerization control than the electron-donating ability.42Within some range of bulkiness (cone angle,θ),the bulkier a ligand is,the narrower the molecular weight distribution of the produced polymers;thus,tri(m -tolyl)phosphine (Ru-15,θ)165°)gave narrower molecular weight distributions than triphenylphosphine derivative (Ru-5,θ)145°)under the same conditions (M w /M n ,1.07vs 1.20).Combination of a primary mono-or diamine cocatalyst with Ru-15enhanced catalytic activity so as to decrease in catalyst concentration without loss of control ([catalyst]0/[initiator]0)1/40,M w /M n )1.11,conversion )∼90%,in 4h).According to 31P NMR analysis,the added amine was exchanged with one of the phosphine,to form in situ a presumably reactive phosphine/amine-coordinated complex.The more labile and dynamic character of amine coordination would promote both activation and deactivation steps (see section 2.3.5).Hydrophilic aminoalcohols are also available as cocatalysts to enhance catalytic activity,and in this case the ruthenium residue was almost quantitatively removed (>97%removal)after the polymerization just by washing with water,since a hydrophilic catalyst carrying the alcohol is generated in situ via the ligand-exchange.A Cp*-ruthenium complex with π-coordinated acetonitrile (Ru-16)was employed for styrene polymerization,where combination with Et 2NH gave polystyrene fast with narrow MWDs (M w /M n ≈1.1-1.2).43The Cp*-based complex with poly(ethylene glycol)(PEG)phophine (Ru-17)shows an interesting thermosensitive and phase-transfer catalysis in suspension polymerization of MMA in toluene/water (∼1/1v/v).44Because of the ther-mosensitive character of PEG,the catalyst exists intheFigure 2.Ruthenium catalysts 1.4968Chemical Reviews,2009,Vol.109,No.11Ouchi et al.。