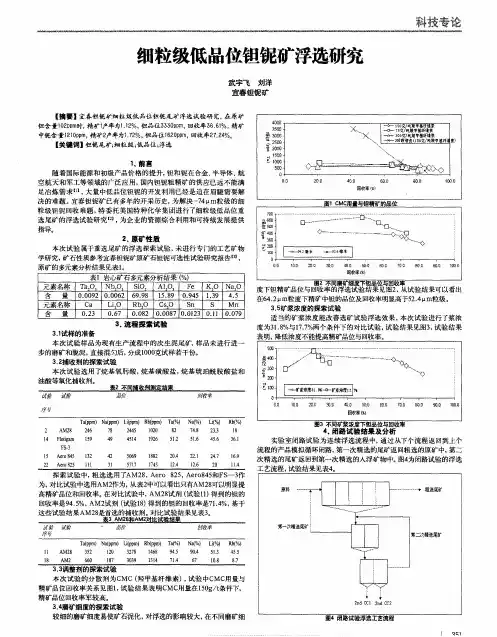

细粒级低品位钽铌稀土矿选矿工艺研究

- 格式:pdf

- 大小:180.60 KB

- 文档页数:3

细粒钽铌矿选矿工艺流程英文回答:Tantalum-niobium ore is a valuable mineral resourcethat is widely used in various industries, including electronics, aerospace, and automotive. The ore istypically found in complex geological formations andrequires a detailed beneficiation process to extract the valuable minerals. In this article, I will discuss the process of beneficiation for fine-grained tantalum-niobium ore.The beneficiation process for fine-grained tantalum-niobium ore typically involves several stages, including crushing, grinding, gravity separation, magnetic separation, and flotation. Let's go through each stage in detail.1. Crushing: The first step in the beneficiationprocess is to crush the ore into small particles. This can be done using jaw crushers or cone crushers. The crushedore is then further ground to a finer size using ball mills or rod mills.2. Grinding: The ground ore is then subjected togrinding to further reduce its size. This is typically done using ball mills or rod mills. The purpose of grinding isto liberate the valuable minerals from the gangue minerals and prepare the ore for the subsequent separation processes.3. Gravity separation: After grinding, the ore is subjected to gravity separation to separate the heavy minerals from the light minerals. Gravity separation is based on the differences in the specific gravity of the minerals. Common gravity separation methods include jigging, shaking table, and spiral chute. The heavy minerals, suchas tantalum and niobium, will settle to the bottom, whilethe light minerals will float to the top.4. Magnetic separation: The next step is magnetic separation, which is used to separate the magnetic minerals from the non-magnetic minerals. This is achieved byapplying a magnetic field to the ore. The magnetic minerals,such as magnetite and ilmenite, will be attracted to the magnetic field and can be easily separated from the non-magnetic minerals.5. Flotation: The final stage in the beneficiation process is flotation, which is used to separate the valuable minerals from the gangue minerals based on their hydrophobicity. In flotation, the ore is mixed with water and chemicals, and air bubbles are introduced. The hydrophobic minerals will attach to the air bubbles andrise to the surface, forming a froth, while the hydrophilic gangue minerals will remain in the water. The froth containing the valuable minerals can then be collected and further processed.Overall, the beneficiation process for fine-grained tantalum-niobium ore involves crushing, grinding, gravity separation, magnetic separation, and flotation. Each stage plays a crucial role in extracting the valuable minerals and preparing the ore for further processing. By optimizing each stage of the process, it is possible to achieve a high recovery rate of tantalum and niobium from the ore.中文回答:钽铌矿是一种有价值的矿产资源,广泛应用于电子、航空航天和汽车等各个行业。

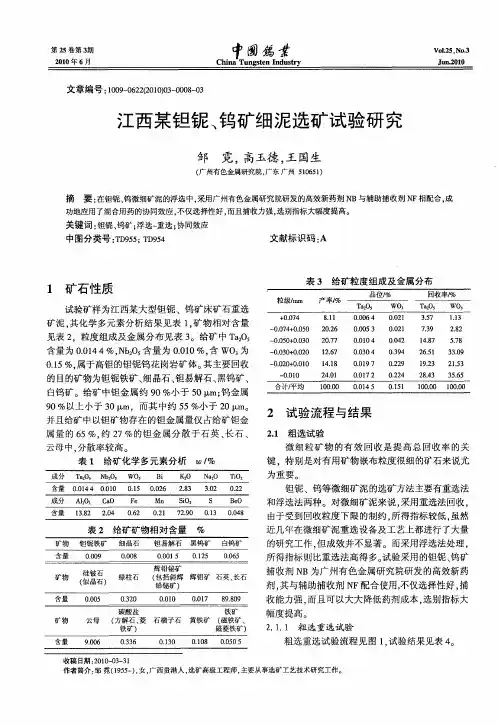

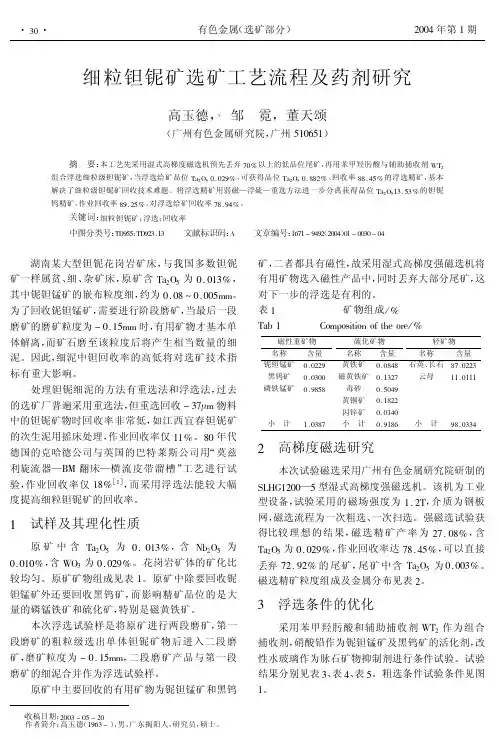

细粒钽铌矿选矿工艺流程及药剂研究

高玉德;邹霓;董天颂

【期刊名称】《有色金属(选矿部分)》

【年(卷),期】2004(000)001

【摘要】本工艺先采用湿式高梯度磁选机预先丢弃70%以上的低品位尾矿,再用苯甲羟肟酸与辅助捕收剂WT2组合浮选细粒级钽铌矿,当浮选给矿品位Ta2O5

0.029%,可获得品位Ta2O5 0.882%、回收率88.45%的浮选精矿,基本解决了细粒级钽铌矿回收技术难题.将浮选精矿用弱磁-浮硫-重选方法进一步分离获得品位Ta2O5 13.53%的钽铌钨精矿,作业回收率89.25%,对浮选给矿回收率78.94%.【总页数】4页(P30-33)

【作者】高玉德;邹霓;董天颂

【作者单位】广州有色金属研究院,广州,510651;广州有色金属研究院,广

州,510651;广州有色金属研究院,广州,510651

【正文语种】中文

【中图分类】TD955;TD923.13

【相关文献】

1.南平钽铌矿选矿工艺流程设计研究 [J], 卢道刚

2.宜春钽铌矿扩建工程选矿工艺流程方案设计研究 [J], 卢道刚

3.细粒级低品位钽铌稀土矿选矿工艺研究 [J], 高玉德;邱显扬;韩兆元;万丽

4.细粒钽铌矿选矿新工艺的研究 [J], 董天颂;邹霓;高玉德

5.细粒钽铌矿选矿新工艺的研究 [J], 董天颂;邹霓;等

因版权原因,仅展示原文概要,查看原文内容请购买。

细粒钽铌矿选矿工艺流程英文回答:Tantalum-niobium ore is a valuable mineral resourcethat is widely used in various industries. The ore is typically found in the form of fine-grained tantalum-niobium minerals, such as tantalite and columbite. Extracting tantalum and niobium from the ore requires a complex process known as mineral beneficiation.The beneficiation process for tantalum-niobium ore typically involves several stages, including crushing, grinding, gravity separation, magnetic separation, and flotation. Each stage is designed to remove impurities and increase the concentration of tantalum and niobium minerals in the ore.Firstly, the ore is crushed into small particles using a jaw crusher or a cone crusher. This helps to break down the ore and release the tantalum and niobium minerals. Thecrushed ore is then ground into a fine powder using a ball mill or a rod mill. This grinding process helps to further liberate the minerals and increase their surface area for subsequent separation.Next, gravity separation is employed to separate the heavier tantalum and niobium minerals from the lighter gangue minerals. This is done using techniques such as spiral concentrators, shaking tables, or centrifugal concentrators. The principle behind gravity separation is that the denser minerals will settle to the bottom, while the lighter minerals will rise to the top. By adjusting the parameters of the gravity separation equipment, such as the angle of inclination or the water flow rate, the desired separation can be achieved.After gravity separation, magnetic separation is used to remove any remaining magnetic minerals from thetantalum-niobium concentrate. This is done using high-intensity magnetic separators, which generate a strong magnetic field to attract and separate the magnetic minerals. The non-magnetic minerals are discarded as waste,while the magnetic minerals are collected as a magnetic concentrate.Finally, flotation is employed to further increase the concentration of tantalum and niobium minerals in the concentrate. Flotation involves the use of chemicals, such as collectors and frothers, to selectively separate the valuable minerals from the gangue minerals. The froth flotation process relies on the differences in the surface properties of the minerals, allowing the valuable minerals to attach to air bubbles and float to the surface, while the gangue minerals sink.Overall, the beneficiation process for tantalum-niobium ore is a complex and multi-stage process. It requires careful optimization and control to achieve the desired separation and concentration of tantalum and niobium minerals. However, with the right combination of equipment and process parameters, it is possible to produce a high-quality tantalum-niobium concentrate that can be further processed into valuable products.中文回答:英文回答:钽铌矿是一种有价值的矿产资源,广泛应用于各个行业。

钽铌矿选矿工艺流程

钽铌矿通常通过以下工艺流程进行选矿:

1. 矿石破碎:将原始的钽铌矿石经过破碎过程,使其颗粒度变得更细。

2. 矿石磨矿:将破碎后的矿石通过磨矿设备进行进一步细磨,以提高矿石中有用矿物的释放率。

3. 重选:采用重选设备,如重力选矿机、螺旋选矿机等,通过重力作用将磨矿后的矿石分离成浓缩矿和尾矿。

重选可以去除部分杂质及非有用矿物。

4. 浮选:浮选是一种常用的选矿方法,通过调整药剂、气体和搅拌条件来使有用矿物粒子与气泡相互吸附,使其浮起。

经浮选后,可以得到富含钽铌的浮选精矿。

5. 精选:通过精选设备,如震动筛、离心选矿机等,对浮选精矿进行进一步的筛分和分离,以提高钽铌的品位和回收率。

6. 尾矿处理:处理尾矿中的有害元素和无用矿物,以提高资源利用率和环境保护效果。

以上是钽铌矿选矿工艺流程的一般步骤,具体的选矿方法根据矿石的性质和矿山的实际情况可以有所不同。

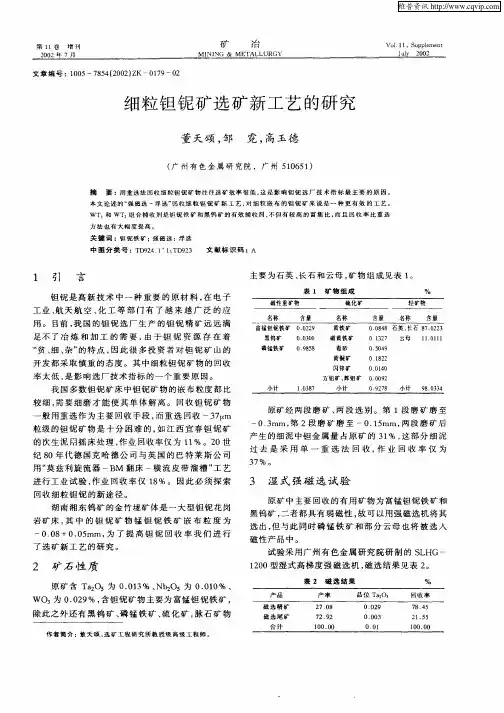

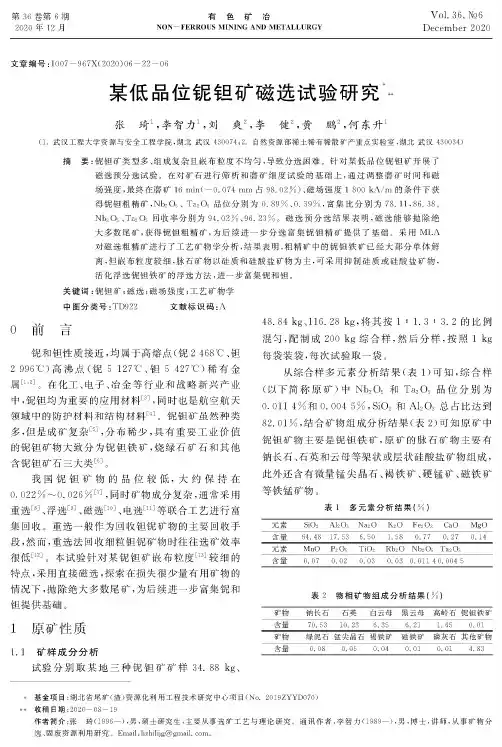

Vol36 N6December2020第36卷第6期2020年12月有 色 矿 冶NON —FERROUS MINING AND METALLURGY文章编号:1007 — 967X (2020)06 — 22 — 06某低品位铌钽矿磁选试验研究张 琦1,李智力1,刘 爽2,李 健2,黄 鹏2,何东升1(1.武汉工程大学资源与安全工程学院,湖北武汉430074;.自然资源部稀土稀有稀散矿产重点实验室,湖北武汉430034)摘要:铌钽矿类型多、组成复杂且嵌布粒度不均匀,导致分选困难。

针对某低品位铌钽矿开展了磁选预分选试验。

在对矿石进行筛析和磨矿细度试验的基础上,通过调整磨矿时间和磁 场强度,最终在磨矿16 min ( — 0. 074 mm 占98 02%)、磁场强度1 800 kA/m 的条件下获得铌钽粗精矿,Nb 2O 5、Ta 2O 5品位分别为0. 89%、0. 39%,富集比分别为78 11,86. 38。

Nb 2O 5、Ta 2O 5回收率分别为94.02%、96. 23%。

磁选预分选结果表明,磁选能够抛除绝大多数尾矿,获得铌钽粗精矿,为后续进一步分选富集铌钽精矿提供了基础。

采用MLA对磁选粗精矿进行了工艺矿物学分析,结果表明,粗精矿中的铌钽铁矿已经大部分单体解离,但嵌布粒度较细,脉石矿物以硅质和硅酸盐矿物为主,可采用抑制硅质或硅酸盐矿物, 活化浮选铌钽铁矿的浮选方法,进一步富集铌和钽。

关键词:铌钽矿;磁选;磁场强度;工艺矿物学 中图分类号:TD922文献标识码:A0 前言铌和钽性质接近,均属于高熔点(铌2 468C 、钽2 996 D 高沸点(铌5 127C 、钽5 427 D 稀有金属[12]。

在化工、电子、冶金等行业和战略新兴产业 中,铌钽均为重要的应用材料同时也是航空航天领域中的防护材料和结构材料4。

铌钽矿虽然种类多,但是成矿复杂旧,分布稀少,具有重要工业价值 的铌钽矿物大致分为铌钽铁矿,烧绿石矿石和其他 含铌钽矿石三大类6。

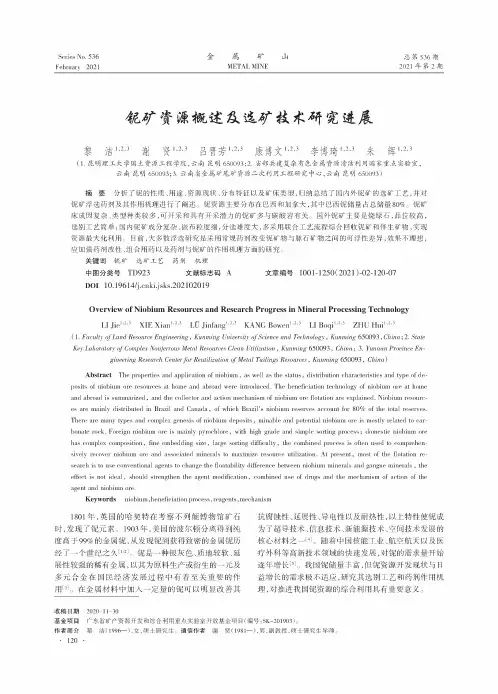

金属矿山METAL MINE总第536期2021年第2期Series No.536February2021铌矿资源概述及选矿技术研究进展黎洁3谢贤3吕晋芳3康博文3李博琦3朱辉3(1.昆明理工大学国土资源工程学院,云南昆明650093;2.省部共建复杂有色金属资源清洁利用国家重点实验室,云南昆明650093;3.云南省金属矿尾矿资源二次利用工程研究中心,云南昆明650093)摘要分析了铌的性质、用途、资源现状、分布特征以及矿床类型,归纳总结了国内外铌矿的选矿工艺,并对铌矿浮选药剂及其作用机理进行了阐述。

铌资源主要分布在巴西和加拿大,其中巴西铌储量占总储量80%o铌矿床成因复杂、类型种类较多,可开采和具有开采潜力的铌矿多与碳酸岩有关。

国外铌矿主要是烧绿石,品位较高,选别工艺简单;国内铌矿成分复杂、嵌布粒度细,分选难度大,多采用联合工艺流程综合回收铌矿和伴生矿物,实现资源最大化利用。

目前,大多数浮选研究是采用常规药剂改变铌矿物与脉石矿物之间的可浮性差异,效果不理想,应加强药剂改性、组合用药以及药剂与铌矿的作用机理方面的研究。

关键词铌矿选矿工艺药剂机理中图分类号TD923文献标志码A文章编号1001-1250(2021)-02-120-07DOI10.19614/ki.jsks.202102019Overview of Niobium Resources and Research Progress in Mineral Processing Technology LI Jie1'2'3XIE Xian1'2'3LU Jinfang1'2'3KANG Bowen1'2'3LI Boqi1'2'3ZHU Hui1'2'3(1.Faculty of L and Resource Engineering,Kunming University of S cience and Technology,Kunming650093,China;2.StateKey Laboratory of Complex Nonferrous Metal Resources Clean Utilization,Kunming650093,China;3.Yunnan Province Engineering Research Center f or Reutilization of Metal Tailings Resources,Kunming650093,China) Abstract The properties and application of niobium as well as the status distribution characteristics and type of deposits of niobium ore resources at home and abroad were introduced.The beneficiation technology of niobium ore at home and abroad is summarized and the collector and action mechanism of niobium ore flotation are explained.Niobium resources are mainly distributed in Brazil and Canada,of which Brazil's niobium reserves account for80%of the total reserves.There are many types and complex genesis of niobium deposits minable and potential niobium ore is mostly related to carbonate rock.Foreign niobium ore is mainly pyrochlore with high grade and simple sorting process;domestic niobium ore has complex composition fine embedding size large sorting difficulty the combined process is often used to comprehensively recover niobium ore and associated minerals to maximize resource utilization.At present most of the flotation research is to use conventional agents to change the floatability difference between niobium minerals and gangue minerals the effect is not ideal should strengthen the agent modification combined use of drugs and the mechanism of action of the agent and niobium ore.Keywords niobium,beneficiation process,reagents?mechanism1801年,英国的哈契特在考察不列颠博物馆矿石时,发现了铌元素。

低品位离子型稀土矿提取过程优化研究低品位离子型稀土矿的提取过程是稀土矿开采和加工领域中的关键问

题之一。

为了实现高效稀土资源的开发利用,需要对低品位离子型稀土矿

提取过程进行优化研究。

具体来说,优化研究需要从以下几个方面入手:

1.选择合适的提取方法:常见的稀土矿提取方法包括浮选、盐酸浸出、氧化焙烧、萃取等。

根据低品位离子型稀土矿的特点选择合适的提取方法,能够提高提取效率和经济效益。

2.优化提取工艺:在选定的提取方法基础上,需要进一步优化提取工艺。

这包括减少杂质含量、提高浸出效率、控制溶液pH值、优化萃取剂

使用量等。

3.引入高效节能技术:高效节能技术是指在提高稀土矿提取效率的同时,减少能源消耗和环境污染。

例如引入微波辐射技术、超声波技术、化

学反应器等。

4.优化设备结构:设备结构的合理设计可以提高设备的稳定性,避免

设备损坏,减少生产过程中的停机时间。

优化设备结构可以从设备选型、

设备制造工艺、设备维护等方面进行,实现设备的高效稳定运转。

综上所述,低品位离子型稀土矿提取过程的优化研究需要在提取方法、提取工艺、高效节能技术和设备结构等方面进行深入研究,以实现高效稀

土资源的开发利用。

一种碱法分解低品位钽铌资源并提取钽铌的方法摘要:一、背景及意义二、碱法分解低品位钽铌资源原理三、提取钽铌的具体方法四、实验结果与分析五、结论与展望正文:一、背景及意义随着现代科技的飞速发展,钽铌等稀有金属在我国高科技产业中的应用越来越广泛。

然而,低品位的钽铌资源储量丰富,但其开发利用难度较大。

传统的提取方法往往成本高昂,且对环境造成较大污染。

为了降低提取成本、提高资源利用率并减轻环境负担,研究一种碱法分解低品位钽铌资源并提取钽铌的方法具有重要意义。

二、碱法分解低品位钽铌资源原理低品位的钽铌资源中,钽铌通常以氧化物形式存在,且杂质含量较高。

碱法分解利用了钽铌氧化物与碱性物质发生化学反应的特性,将钽铌氧化物转化为可溶性盐,从而实现钽铌与杂质的分离。

三、提取钽铌的具体方法1.样品处理:将低品位钽铌资源进行粉碎、研磨,使其达到一定的细度,提高反应速率。

2.配制碱溶液:根据实验需求,配制一定浓度和pH值的碱溶液。

3.反应:将处理后的样品与碱溶液混合,置于一定的温度和压力条件下,进行反应。

4.过滤:反应完成后,通过过滤装置将钽铌溶液与固体废物分离。

5.酸化:将过滤得到的钽铌溶液进行酸化处理,使钽铌沉淀。

6.沉淀物洗涤、干燥:对沉淀物进行洗涤,去除杂质,然后进行干燥,得到纯度较高的钽铌。

四、实验结果与分析实验表明,采用碱法分解低品位钽铌资源,钽铌提取率可达到80%以上,且成本较低。

与其他提取方法相比,该方法具有较高的经济效益和环保效益。

同时,通过优化实验条件,可进一步提高钽铌的提取率。

五、结论与展望本文提出了一种碱法分解低品位钽铌资源并提取钽铌的方法,实验结果表明,该方法具有较高的提取率和经济效益。

在今后的研究中,可进一步优化实验条件,提高钽铌的提取率,为低品位钽铌资源的高效利用提供技术支持。

细粒钽铌矿选矿工艺流程英文回答:Tantalum-niobium ore is a valuable mineral resourcethat is widely used in various industries, such as electronics, aerospace, and automotive. The beneficiation process of fine-grained tantalum-niobium ore involves several stages to extract and separate the valuable minerals from the gangue.1. Crushing and grinding: The first step in the beneficiation process is to crush the raw ore into smaller particles and then grind it into a fine powder. This is usually done using crushers and ball mills. The purpose of crushing and grinding is to liberate the valuable minerals from the gangue and prepare the ore for further processing.2. Gravity separation: After the ore is ground into a fine powder, it is subjected to gravity separation to separate the valuable minerals from the gangue. Gravityseparation is based on the difference in density betweenthe minerals. For example, tantalum and niobium minerals have a higher density than most gangue minerals, so theycan be separated using techniques such as jigging, shaking table, or spiral concentrator.3. Magnetic separation: In some cases, magnetic separation is used to remove magnetic minerals from the ore. This is particularly useful for removing magneticimpurities that can affect the quality of the final product. Magnetic separation can be done using magnetic separatorsor high-intensity magnetic separators.4. Flotation: Flotation is a widely used technique in mineral processing to separate minerals based on their differences in surface properties. In the case of tantalum-niobium ore, flotation can be used to separate the valuable minerals from the gangue. This is achieved by adding reagents to the ore slurry that selectively adsorb onto the surface of the valuable minerals, making them hydrophobic and allowing them to attach to air bubbles. The air bubbles carrying the valuable minerals then rise to the surface andform a froth, which is collected and further processed.5. Drying and smelting: After the minerals areseparated from the ore, they are usually dried and then smelted to obtain the final product. Smelting involves heating the minerals at high temperatures to remove impurities and obtain a pure tantalum-niobium alloy.中文回答:英文回答:钽铌矿是一种有价值的矿产资源,在电子、航天航空和汽车等各个行业广泛应用。