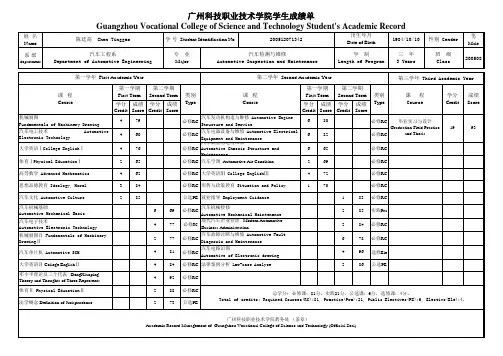

吉林大学汽车发动机专业中英文对照成绩单(大四前)

- 格式:pdf

- 大小:118.03 KB

- 文档页数:2

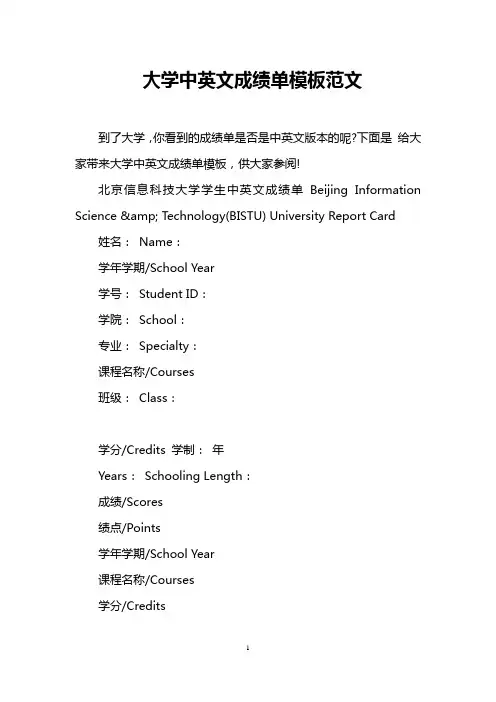

大学中英文成绩单模板范文到了大学,你看到的成绩单是否是中英文版本的呢?下面是给大家带来大学中英文成绩单模板,供大家参阅!北京信息科技大学学生中英文成绩单Beijing Information Science & Technology(BISTU) University Report Card 姓名:Name:学年学期/School Year学号:Student ID:学院:School:专业:Specialty:课程名称/Courses班级:Class:学分/Credits 学制:年Years:Schooling Length:成绩/Scores绩点/Points学年学期/School Year课程名称/Courses学分/Credits成绩/Scores绩点/Points毕业应取得总学分(Total Credits Required for Graduatior)/ 已获得总学分(Total Credits Earned)其中包括(including)必修课(Required)专业选修课(Specialized Elective)公共选修课(Common.Elective)实践课(Practical Course)必修课平均学分绩点(GPA of equired Course)此成绩单仅供出国使用This report is only for going abroad 北京信息科技大学教务处Academic Administration of BISTU 打印日期(PRINT DATE):吉林大学中英文本科成绩单模板Key Comprehensive University Directly Under The Ministry of Education of The People’s Republic of China本科生成绩单Academic Transcript of Undergraduate 姓名:Name:院系:Dept.:学制:Periods of Schooling:学号:专业:入学及毕业时间:吉林大学学生成绩表注释:1. 考试成绩采用优秀、良好、中等、及格、不及格五级记分或百分制记分。

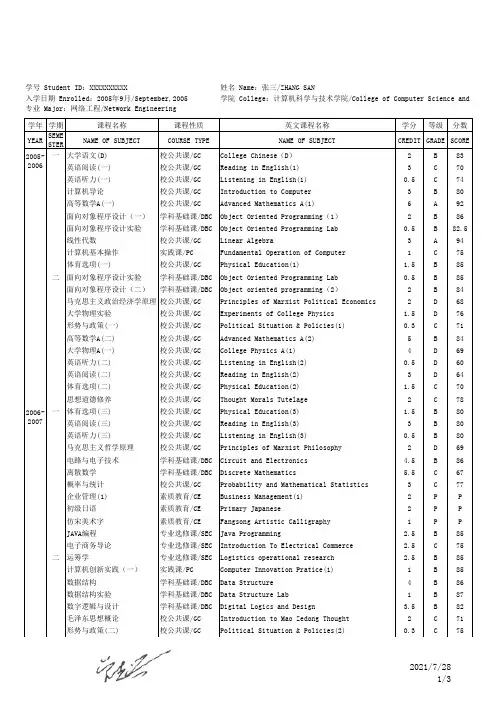

学年学期课程名称课程性质英文课程名称学分等级分数YEAR SEMESTERNAME OF SUBJECT COURSE TYPE NAME OF SUBJECT CREDIT GRADE SCORE 一大学语文(D)校公共课/GC College Chinese(D)2B83英语阅读(一)校公共课/GC Reading in English(1)3C70英语听力(一)校公共课/GC Listening in English(1)0.5C74计算机导论校公共课/GC Introduction to Computer3B80高等数学A(一)校公共课/GC Advanced Mathematics A(1)6A92面向对象程序设计(一)学科基础课/DBC Object Oriented Programming(1)2B86面向对象程序设计实验学科基础课/DBC Object Oriented Programming Lab0.5B82.5线性代数校公共课/GC Linear Algebra3A94计算机基本操作实践课/PC Fundamental Operation of Computer1C75体育选项(一)校公共课/GC Physical Education(1) 1.5B85二面向对象程序设计实验学科基础课/DBC Object Oriented Programming Lab0.5B85面向对象程序设计(二)学科基础课/DBC Object oriented programming(2)2B84马克思主义政治经济学原理校公共课/GC Principles of Marxist Political Economics2D68大学物理实验校公共课/GC Experiments of College Physics 1.5D76形势与政策(一)校公共课/GC Political Situation & Policies(1)0.3C71高等数学A(二)校公共课/GC Advanced Mathematics A(2)5B84大学物理A(一)校公共课/GC College Physics A(1)4D69英语听力(二)校公共课/GC Listening in English(2)0.5D60英语阅读(二)校公共课/GC Reading in English(2)3D64体育选项(二)校公共课/GC Physical Education(2) 1.5C70思想道德修养校公共课/GC Thought Morals Tutelage2C78一体育选项(三)校公共课/GC Physical Education(3) 1.5B80英语阅读(三)校公共课/GC Reading in English(3)3B80英语听力(三)校公共课/GC Listening in English(3)0.5B80马克思主义哲学原理校公共课/GC Principles of Marxist Philosophy2D69电路与电子技术学科基础课/DBC Circuit and Electronics 4.5B86离散数学学科基础课/DBC Discrete Mathematics 5.5C67概率与统计校公共课/GC Probability and Mathematical Statistics3C77企业管理(1)素质教育/CE Business Management(1)2P P 初级日语素质教育/CE Primary Japanese2P P 仿宋美术字素质教育/CE Fangsong Artistic Calligraphy1P P JAVA编程专业选修课/SEC Java Programming 2.5B85电子商务导论专业选修课/SEC Introduction To Electrical Commerce 2.5C75二运筹学专业选修课/SEC Logistics operational research 2.5B85计算机创新实践(一)实践课/PC Computer Innovation Pratice(1)1B85数据结构学科基础课/DBC Data Structure4B86数据结构实验学科基础课/DBC Data Structure Lab1B87数字逻辑与设计学科基础课/DBC Digital Logics and Design 3.5B82毛泽东思想概论校公共课/GC Introduction to Mao Zedong Thought2C71形势与政策(二)校公共课/GC Political Situation & Policies(2)0.3C75学号 Student ID:XXXXXXXXXX姓名 Name:张三/ZHANG SAN入学日期 Enrolled:2005年9月/September,2005学院 College:计算机科学与技术学院/College of Computer Science and2005-20062006-2007专业 Major:网络工程/Network Engineering学年学期课程名称课程性质英文课程名称学分等级分数YEARSEME STERNAME OF SUBJECT COURSE TYPE NAME OF SUBJECTCREDIT GRADE SCORE 学号 Student ID:XXXXXXXXXX姓名 Name:张三/ZHANG SAN入学日期 Enrolled:2005年9月/September,2005学院 College:计算机科学与技术学院/College of Computer Science and专业 Major:网络工程/Network Engineering 英语听力(四)校公共课/GC Listening in English(4)0.5D 67英语阅读(四)校公共课/GC Reading in English(4)3C 72体育选项(四)校公共课/GCPhysical Education(4)1.5A 90法律基础校公共课/GC Fundamentals of Law2D 65一邓小平理论与“三个代表”重要思想概论校公共课/GC Introduction to Deng Xiaoping Theory and the Major Thoughts of “the Three Represents” 2.5C 71计算机组成原理学科基础课/DBCPrinciple of Computer Organization 3C 77计算机组成原理实验学科基础课/DBC Principle of Computer Organization Lab 1C 75汇编语言程序设计学科基础课/DBC Assembly Language Program Design 2B 89汇编语言程序设计实验学科基础课/DBC Assemlby Language Program Design Lab 1A 95数据通信与计算机网络学科基础课/DBC Digital Communication and Computer Network 4B 86.5数据通信与计算机网络实验学科基础课/DBCDigital Communication and Computer Network Lab1C 75数据库系统原理学科基础课/DBC Principle of Database System 3.5B 81计算方法专业选修课/SEC Computational Methods2.5B 80电子商务平台构建实践课/PC E-Commerce Platform Development 0.5C 75计算机创新实践(二)实践课/PC Computer Innovation Pratice(2)1B 85二计算机创新实践(三)实践课/PC Computer Innovation Pratice(3)1A 95网络互连技术专业选修课/SEC Network Connection Techniques 2.5A 95软件工程专业选修课/SEC Software Engineer2.5C 70计算机网络管理实践实践课/PC Commputer Network Management Practice 1C 75网络安全实践实践课/PCNetwork Security Practice0.5C 75TCP/IP协议与网络编程实验专业课/SC TCP/IP Protocols and Network Programming Lab 1A 95网络工程与系统集成技术专业课/SCNetwork Engineering and System Assembly Techniques2A 90网络工程与系统集成技术实验专业课/SCNetwork Engineering and System Assembly Techniques Lab1C 70接口与通信技术实验专业课/SC Interface and Communication Techniques Lab 1B 85TCP/IP协议与网络编程专业课/SC TCP/IP Protocols and Network Programming 2A 94计算机网络管理专业课/SC Computer Network Management 3A 90计算机网络管理实验专业课/SC Computer Network Management Lab 1C 75接口与通信技术专业课/SC Interface and Communication Techniques 3B 81.5形势与政策(三)校公共课/GC Political Situation & Policies(3)0.4C 75网络编程实践实践课/PC Practice for Network Programming 0.5A 95一计算机网络综合实践实践课/PC Computer Network Integrative Practice 1B 85计算机网络安全专业课/SC Computer Network Security 2B 80操作系统学科基础课/DBC Operating System3.5A 93计算机网络安全实验专业课/SC Computer Network Security Lab 1B 85软件开发实践实践课/PC Software Development Practice 1A 95二毕业实践实践课/PC Graduation Practice 3C 75毕业设计实践课/PCGraduation Design12A952007-20082008-2009学年学期课程名称课程性质英文课程名称学分等级分数YEAR SEMESTERNAME OF SUBJECT COURSE TYPE NAME OF SUBJECT CREDIT GRADE SCORE学号 Student ID:XXXXXXXXXX姓名 Name:张三/ZHANG SAN入学日期 Enrolled:2005年9月/September,2005学院 College:计算机科学与技术学院/College of Computer Science and 专业 Major:网络工程/Network Engineering1.成绩 A(优秀)90-100%,B(良好)80-89%,C(中等) 70-79%,D(及格)60-69%,E(不及格)<60%;华侨大学学生成绩单说明:2.课外创新实践、素质教育课及跨学科校选修课程成绩记载为“P(合格)”或“F(不合格)”,该类课程为我校学生课外拓展考查课程,成绩不计入平均绩点及平均分;3.课程性质说明:“校公共课”表示为“GC”,“学科基础课”表示为“DBC”,“实践课”表示为“PC”,“课外创新实践”表示为“EIP”,“素质教育”表示为“CE”,“专业选修课”表示为“SEC”,“专业课”表示为“SC”,“跨学科校选修课”表示为“CEC ”。

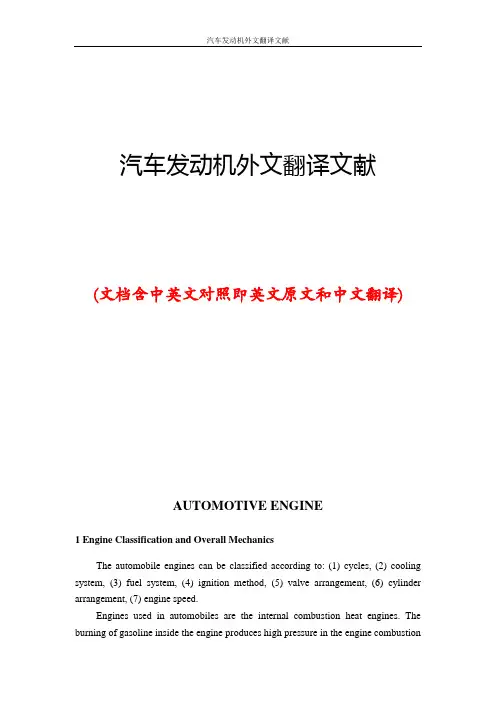

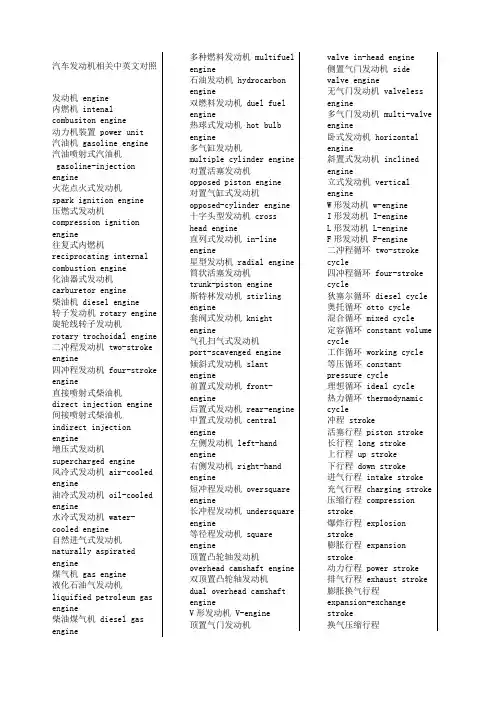

汽车发动机外文文献翻译(含:英文原文及中文译文)文献出处:Talom M. AUTOMOTIVE ENGINE[J]. Applied Thermal Engineering, 2013, 2(3):39-45.英文原文AUTOMOTIVE ENGINETalom M1 Engine Classification and Overall MechanicsThe automobile engines can be classified according to: (1) cycles, (2) cooling system, (3) fuel system, (4) ignition method, (5) valve arrangement, (6) cylinder arrangement, (7) engine speed.Engines used in automobiles are the internal combustion heat engines. The burning of gasoline inside the engine produces high pressure in the engine combustion chamber. This high pressure force piston to move, the movement is carried by connecting rods to the engine crankshaft. The crankshaft is thus made to rotate: the rotary motion is carried through the power train to the car wheels so that they rotate and the car moves.The engine requires four basic systems to run (Fig. 2-1). Diesel engines require three of these systems. They are fuel system, ignition system (except diesel), lubricating system andcooling system. However, three other related systems are also necessary. These are the exhaust system, the emission-control system, and the starting system. Each performs a basic job in making the engine run.2 Engine Operating PrinciplesThe term “stroke” is used to describe the movem ent of the piston within the cylinder. The movement of the piston from its uppermost position (TDC, top dead center) to its lowest position (BDC, bottom dead center) is called a stroke. The operating cycle may require either two or four strokes to complete. Most automobile engines operate on the four stroke cycle.In four-stroke engine, four strokes of the piston in the cylinder are required to complete one full operating cycle. Each stroke is named after the action. It performs intake, compression, power, and exhaust in that order.The intake strokeThe intake stroke begins with the piston near the top of its travel. As the piston begins its descent, the exhaust valve closes fully, the intake valve opens and the volume of the combustion chamber begins to increase, creating a vacuum. As the piston descends, an air/fuel mixture is drawn from the carburetor into the cylinder through the intake manifold. The intake stroke endswith the intake valve close just after the piston has begun its upstroke.Compression strokeAs the piston is moved up by the crankshaft from BDC, the intake valve closes. The air/fuel mixture is trapped in the cylinder above the piston. Future piston travel compresses the air/fuel mixture to approximately one-eighth of its original volume (approximately 8:1 compression ratio) when the piston has reached TDC. This completes the compression stroke. Power strokeAs the piston reaches TDC on the compression stroke, an electric spark is produced at the spark plug. The ignition system delivers a high-voltage surge of electricity to the spark plug to produce the spark. The spark ignites, or sets fire to, the air/fuel mixture. It now begins to burn very rapidly, and the cylinder pressure increases to as much as 3-5MPa or even more. This terrific push against the piston forces it downward, and a powerful impulse is transmitted through the connecting rod to the crankpin on the crankshaft. The crankshaft is rotated as the piston is pushed down by the pressure above it.Exhaust strokeAt the end of the power stroke the camshaft opens theexhaust valve, and the exhaust stroke begins. Remaining pressure in the cylinder, and upward movement of the piston, force the exhaust gases out of the cylinder. At the end of the exhaust stroke, the exhaust valve closes and the intake valve opens, repeating the entire cycle of events over and over again.3 Engine Block and Cylinder HeadEngine BlockThe engine block is the basic frame of the engine. All other engine parts either fit inside it or fasten to it. It holds the cylinders, water jackets and oil galleries (Fig. 2-4). The engine block also holds the crankshaft, which fastens to the bottom of the block. The camshaft also fits in the block, except on overhead-cam engines. In most cars, this block is made of gray iron, or an alloy (mixture) of gray iron and other metals, such as nickel or chromium. Engine blocks are castings.Some engine blocks, especially those in smaller cars, are made of cast aluminum. This metal is much lighter than iron. However, iron wears better than aluminum. Therefore, the cylinders in most aluminum engines are lined with iron or steel sleeves. These sleeves are called cylinder sleeves. Some engine blocks are made entirely of aluminum.Cylinder SleevesCylinder sleeves are used in engine blocks to provide a hard wearing material for pistons and piston rings. The block can be made of one kind of iron that is light and easy to cast while the sleeves uses another that is better able to stand up wear and tear.There are two main types of sleeves: dry and wet (Fig. 2-5).Dry sleeve Wet sleeveCylinder HeadThe cylinder head fastens to the top of the block, just as a roof fits over a house. The underside forms the combustion chamber with the top of the piston. In-line engine of light vehicles have just one cylinder head for all cylinders; larger in-line engines can have two or more. Just as with engine blocks, cylinder heads can be made of cast iron or aluminum alloy. The cylinder head carries the valves, valve springs and the rockers on the rocker shaft, this part of valve gear being worked by the pushrods. Sometimes the camshaft is fitted directly into the cylinder head and operates on the valves without rockers. This is called an overhead camshaft arrangement.GasketThe cylinder head is attached to the block with high-tensile steel studs. The joint between the block and the head must begas-tight so that none of the burning mixture can escape. This is achieved by using cylinder head gasket. Gaskets are also used to seal joins between the other parts, such as between the oil pan, manifolds, or water pump and the blocks.Oil PanThe oil pan is usually formed of pressed steel. The oil pan and the lower part of cylinder block together are called the crankcase; they enclose, or encase, the crankshaft. The oil pump in the lubricating system draws oil from the oil pan and sends it to all working parts in the engine. The oil drains off and run down into the pan. Thus, there is a constant circulation of oil between the pan and the working parts of the engine.4 Piston Assembly, piston rings, The piston pin ,Connecting Rods, Crankshafts And FlywheelPistonPiston rings and the piston pin are together called the piston assembly.The piston is an important part of a four-stroke cycle engine. Most pistons are made from cast aluminum. The piston, through the connecting rod, transfers to the crankshaft the force created by the burning fuel mixture. This force turns the crankshaft.To withstand the heat of the combustion chamber, the piston must be strong. It also must be light, since it travels at high speeds as it moves up and down inside the cylinder. The piston is hollow. It is thick at the top where it takes the brunt of the heat and the expansion force. It is thin at the bottom, where there is less heat. The top part of the piston is the head, or crown. The thin part is the skirt. Most pistons have three ring grooves at the top. The sections between the ring grooves are called ring lands.piston ringsPiston rings fit into ring grooves near the top of the piston. In simplest terms, piston rings are thin, circular pieces of metal that fit into grooves in the tops of the pistons. In modern engines, each piston has three rings. (Piston in older engines sometimes had four rings, or even five.) The inside surface of the ring fits in the groove on the piston. The ring's outside surface presses against the cylinder walls. Rings provide the needed seal between the piston and the cylinder walls. That is, only the rings contact the cylinder walls. The top two rings are to keep the gases in the cylinder and are called compression rings. The lower one prevents the oil splashed onto the cylinder bore fro m entering the combustion chamber, and is called an oil ring.The piston pinThe piston pin holds together the piston and the connecting rod. This pin fits into th e piston pin holes and into a hole in the top end of the connecting rod. The top end of t he rod is much smaller than the end that fits on the crankshaft. This small end fits inside the bottom of the piston. The piston pin fits through one side of the piston, through the small end of the rod, and then through the other side of the piston. It holds the rod firmly in place in the center of the piston. Pins are made of high-strength steel and have a hollow center. Many pins are chrome-plated to help them wear better. A piston pin fits into a round hole in the piston. The piston pin joins the piston to the connecting rod. The thick part of the piston that holds the piston pin is the pin boss. Connecting RodsThe connecting rod little end is connected to the piston pin.A bush made from a soft metal, such as bronze, is used for this joint. The lower end of the connecting rod f its the crankshaft journal. This is called the big end. For this big-end bearing, steel-backed lead or tin shell bearings are used. These are the same as those used for the main bearings. The split of the big end is sometimes at an angle, so that it is small enough t o be withdrawn through the cylinder bore. The connecting rod ismade from forged alloy steel.CrankshaftsThe crankshaft is regarded as the “backbone” of the engine (Fig. 2-7). The crankshaft, in conjunction with the connecting rod, converts the reciprocating motion of the piston to the rotary motion needed to drive the vehicle. It is usually made from car-bon steel which is alloyed with a small proportion of nickel. The main bearing journals fit into the cylinder block and the big end journals align with the connecting rods. At the rear end of the crankshaft is attached the flywheel, and at the front end are the driving wheels for the timing gears, fan, cooling water and alternator. The throw of the crankshaft, . the distance between the main journal and the big end centers, controls the length of the stroke. The stroke is double the throw, and the stroke length is the distance that the piston travels from TDC to BDC and vice versa.中文译文汽车发动机Talom M1发动机分类和一般力学(1)循环,(2)冷却系统,(3)燃料系统,(4)点火方法,(5)阀门布置,(6)气缸布置,(7)发动机速度。

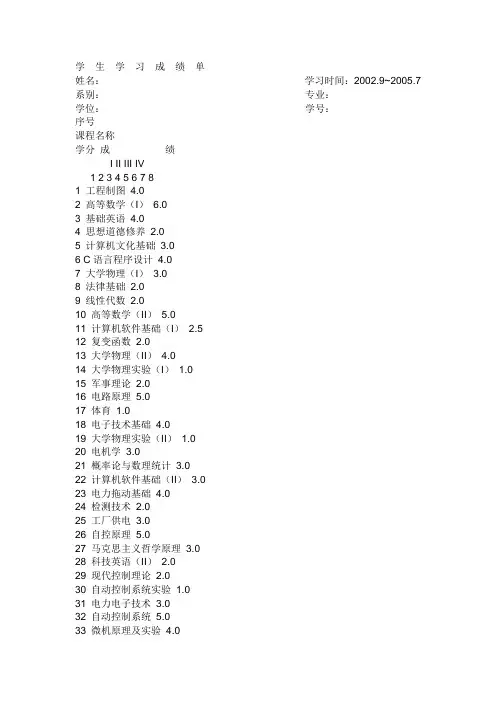

学生学习成绩单姓名:学习时间:2002.9~2005.7 系别:专业:学位:学号:序号课程名称学分成绩I II III IV1 2 3 4 5 6 7 81 工程制图4.02 高等数学(I)6.03 基础英语4.04 思想道德修养2.05 计算机文化基础3.06 C语言程序设计4.07 大学物理(I)3.08 法律基础2.09 线性代数2.010 高等数学(II)5.011 计算机软件基础(I)2.512 复变函数2.013 大学物理(II)4.014 大学物理实验(I)1.015 军事理论2.016 电路原理5.017 体育1.018 电子技术基础4.019 大学物理实验(II)1.020 电机学3.021 概率论与数理统计3.022 计算机软件基础(II)3.023 电力拖动基础4.024 检测技术2.025 工厂供电3.026 自控原理5.027 马克思主义哲学原理3.028 科技英语(II)2.029 现代控制理论2.030 自动控制系统实验1.031 电力电子技术3.032 自动控制系统5.033 微机原理及实验4.0学生学习成绩单姓名:学习时间:2002.9~2005.7 系别:专业:学位:学号:序号课程名称学分成绩I II III IV1 2 3 4 5 6 7 81 工程制图4.02 高等数学(I)6.03 基础英语4.04 思想道德修养2.05 计算机文化基础3.06 C语言程序设计4.07 大学物理(I)3.08 法律基础2.09 线性代数2.010 高等数学(II)5.011 计算机软件基础(I)2.512 复变函数2.013 大学物理(II)4.014 大学物理实验(I)1.015 军事理论2.016 电路原理5.017 体育1.018 电子技术基础4.019 大学物理实验(II)1.020 电机学3.021 概率论与数理统计3.022 计算机软件基础(II)3.023 电力拖动基础4.024 检测技术2.025 工厂供电3.026 自控原理5.027 马克思主义哲学原理3.028 科技英语(II)2.029 现代控制理论2.030 自动控制系统实验1.031 电力电子技术3.032 自动控制系统5.0STUDENT ACADEMIC RECORD (TRANSTATION)NAME: PERIOD: 2002.9~2005.7 DEPARTMENT: SPECITALITY: DEGREE: STUDENT No.:No.COURSE TITLECREDIT RECORDI II III IV1 2 3 4 5 6 7 81 Graphing of Engineering 4.02 Advanced Mathematics(I)6.03 College English 4.04 Thought & Moral Training 2.05 Fundamentals of Computer Science 3.06 C Language 4.07 College Physics(I)3.08 Fundamentals of Law 2.09 Linear Algebra 2.010 Advanced Mathematics(II)5.011 Fundamentals of Computer Software(I)2.512 Functions of Complex Variables 2.013 College Physics(II)4.014 Experiment of College Physics(I)1.015 Military Theory 2.016 Theory of Circuit 5.017 Physical Education 1.018 Basic Electronic Technology 4.019 Electrical Motor 3.019 Experiment of College Physic(II)1.021 Probability & Mathematical Statistics 3.022 Fundamentals of Computer Software(II)3.023 Electrical Machinery & Towage 4.024 Automatic Measurement Technique 2.025 Factory Electricity Supply 3.026 Automatic Control Theory 5.027 Principle of Marxim Philosophy 3.028 Specialty English(II)2.029 Contemporary Control Theory 2.030 Experiment of Automatic Control System 1.031 Power Electronics 3.032 Automatic Control System 5.033 Principle of Single Chip Computer 4.090-100 4.0 A85-89 3.7 A-82-84 3.3 B+78-81 3.0 B75-77 2.7 B-72-74 2.3 C+68-71 2.0 C64-67 1.5 C-60-63 1.0 DCERTIFICATE FOR GRADUATION********** UNIVERSITYCertificate No: 0000000000000This is to certify that LEI FENG, male, born on June 10, 198*, majoring in Mechanical Design, Manufacturing & Automation of this university from September 2001 to June 2005, has successfully fulfilled all curriculums of the four-year undergraduate program of study, and passed the examinations. Hereby he is allowed to graduate.President: DONG CUN RUI************ UniversityJune 30,2005CERTIFICATE FOR THE BACHELOR'S DEGREECertificate No: 0000000000000 This is to certify that LEI FENG, male, born in June 198*, majoring in Mechanical Design, Manufacturing & Automation in the Department of Mechanical Engineering of this university from September 2001 to June 2005, has successfully fulfilled all curriculums of the four-year undergraduate program of study, and has graduated.Upon the examination and verification in conformity with the Regulations of Academic Degrees of the People's Republic of China, he is thereby granted the Degree of Bachelor of Engineering.President of ***** University: DONG CUN RUI Chairman of the Degree Senate: DONG CUN RUIJune 30,2005******大学本科学生学籍成绩表中华人民共和国湖北武汉姓名: 雷锋系部: 机械工程学院专业: 机械设计制造及其自动化学制: 4 年入学日期:2001.9 学号:0000000000制表日期:2007/06/13序号课程学分第一学年第二学年第三学年第四学年第一学期第二学期第三学期第四学期第五学期第六学期第七学期第八学期1 体育4.5 73 75 75 772 工程图学6 85 883 思想道德修养2 814 军训5 845 计算机基础6 90 866 高等数学10 86 907 大学英语16 82 85 87 888 金工实习4 889 毛泽东思想概论1.5 8210 政治经济学2 7711 大学物理7 81 7812 理论力学4 8313 法律基础1.5 8114 电路理论3 8515 线性代数2 9116 概率论与数理统计3 8017 物理实验3.5 88 8318 机械原理3.5 9419 材料力学4.5 8420 工程图学课程设计2 9221 模拟电子技术3.5 8722 哲学2.5 7823 复变函数与积分变换2.5 8724 控制工程基础3 8625 工程材料学3 8926 互换性及技术测量2.5 8227 质量控制技术3 8128 机械设计课程设计3 9129 机械设计4 9230 数字电子技术3.5 8531 邓小平理论概论3 8232 机电传动与控制4 9233 微机原理3 9034 液压与气压传动3.5 8635 测试技术3 8336 计算机软件基础3 8137 专业英语2 8738 机械制造基础4.5 9239 微机接口及应用2.5 8340 数控技术2.5 8841 计算机控制系统3.5 9042 机电一体化系统设计3 8743 CAD/CAM技术2.5 9544 工业机器人2.5 8445 特种加工2 8546 虚拟设计2 9047 液压与气动课程设计2 8748 专业课课程设计3 8849 综合实验1 9050 毕业设计(论文)13 8551 毕业实习4 9052 数控实训2 83UNDERGRADUATE ACADEMIC RECORD OF ********* UNIVERSITY WUHAN, HUBEI, THE PEOPLE' S REPUBLIC OF CHINAName: Lei Feng STUDENT' S NUMBER: 000000000Department: Mechanical Engineering Major: Mechanical Design, Manufacturing & AutomationLength of schooling: 4 years Date of Entrance: September 2001Date of Tabling: 06/13/2007NO. Course Credit 1st AcademicYear 2nd Academic Year 3rd Academic Year 4th Academic Year1st Term 2nd Term 1st Term 2nd Term 1st Term 2nd Term 1st Term 2nd Term1 Physical Education 4.5 73 75 75 772 Engineering Graphics 6 85 883 Cultivation of Ethic Thought 2 814 Military Training5 845 Basis of Computer Engineering6 90 866 Advanced Mathematics 10 86 907 College English 16 82 85 87 888 Metalworking Practice 4 889 Introduction to Mao Zedong Thought 1.5 8210 Political Economics 2 7711 College Physics 7 81 7812 Theoretical Mechanics 4 8313 Fundamentals of Law 1.5 8114 Theory of Circuitry 3 8515 Linear Algebra 2 9116 Probability and Mathematical Statistics 3 8017 Experiment of College Physics 3.5 88 8318 Principle of Mechanics 3.5 9419 Material Mechanics 4.5 8420 Course Design of Engineering Graphics 2 9221 Analogue Electronic Technique 3.5 8722 Philosophy 2.5 7823 Complex Function & Integral Transformation 2.5 8724 Basis of Control Engineering 3 8625 Engineering Materials 3 8926 Interchangeability & Technica 2.5 8227 Quality Control Technique 3 8128 Course Design of Mechanical Design 3 9129 Mechanical Designing 4 9230 Digital Electronic Technique 3.5 8531 Introduction to Deng Xiao-ping theory 3 8232 Electromechanical Drive & Control 4 9233 Principle of Micro-computer 3 9034 Hydraulic & Pneumatic Transmission 3.5 8635 Testing Technology 3 8336 Computer Software 3 8137 Specialty English 2 8738 Machine Building 4.5 9239 Microcomputer Interface and Application 2.5 8340 Digit Control Technique 2.5 8841 Computer Control System 3.5 9042 Opto-electronic-mechanical System Design 3 8743 CAD/CAM Technology 2.5 9544 Industrial Robot 2.5 8445 Specialty Manufacturing 2 8546 Virtual Design 2 9047 Hydraulic and Air Pressure Driven Project Design 2 8748 Professional Course Project 3 8849 Comprehensive Experiment 1 9050 Graduation Project(Thesis) 13 8551 Graduation Practice 4 9052 Digit Control Training 2 83。

本科生毕业设计(论文)翻译资料中文题目:配合新一代液力变矩器的柴油动力线的一些特性英文题目:some properties of a diesel driveline with hydrodynamic torque converters of thelastest generation学生姓名:学号:班级:专业:机械工程及自动化指导教师:吉林大学机械科学与工程学院Some properties of a diesel drive line withhydrodynamic torque converters of the latestgenerationAbstractDynamic properties of a drive line with a controlled Diesel engine, hydrodynamic transmission mechanism, additional gearing and a loading-working machine producing common monoharmonic loading are investigated. Solution of the dynamic problem is based on phenomenological experimental data: drivingtorque-speed characteristic in the part of the prime mover and so-called external static characteristic in the hydrotransmission part. The non-linear task is solved by a modified harmonic balance method that was described in preceding publications by the author.Keywords: Machine drive line; Controlled Diesel drive; Hydrodynamic torque converter; Working machine; Periodic loading; Stationary dynamic stateNomenclature and abbreviationsa, b --- ------Coulomb and viscous non-dimensional friction lossesA i,B i --- ----coefficients in mathematical expression of torque-speed characteristic i, i m ----------kinematic transmission, supplementary gearing transmission ratio -------mean reduced moment of inertia in driving and loading partI, I, k K ---------tangent slopes of λ(i) and K(i) curves respectivelykλK -------------moment transmissionM ------------Diesel-engine momentM D(ω, z) ----controlled torque-speed driving characteristicM Dmax(ω), M Dmin(ω) ---torque-speed characteristic for maximal and minimal fuel supplyM1, (), M2, () ---pump loading moment and turbine driving momentM T1, M T2 ----friction loss moment in driving and loading partM z, M za ----mean value and amplitude of loading moment-------------hydrodynamic converter characteristic radius吉林大学本科毕业论文外文翻译t -------------timeT, T D------------Watt regulator and Diesel-engine time constantu, z ---------gas lever and regulator displacementw -----------common dynamic variableε -----------regulator structural parameterζ -----------regulator damping ratioλ -----------coefficient of rotation momentν -----------loading angular velocity, π-------index denoting mean value and periodical component---------hydraulic medium density----------rotation angleω1, (), ω2 ---pump and turbine angular velocityDM ------Diesel-engineG, G D ---additional and Watt-regulator gearingHdPT ---hydrodynamic power transmissionIJ --------InjectorLM ------loading mechanism (working machine)P, R, T---pump, reactor, turbineArticle OutlineNomenclature1. Introduction2. Mathematical model of the system3. Stationary dynamic solution at monoharmonic loading4. Results evaluation and concluding remarks1. IntroductionDynamic properties of a drive line (actuating unit) consisting of a controlled Diesel engine (DM), hydrodynamic power transmission system (HdPT), additional gearing (G) and a loading mechanism (LM) or working machine are investigated. The working machine loads the prime mover and the transmissions with a prescribed moment. A simple idealised schematic layout of the complete system is given in Fig.1. The considered Diesel engine is a standard production: ZETOR 8002.1 controlled by a mechanical (Watt’s) or electronic regulator R D governing fuel injector IJ. In the place of the hydrodynamic power transmission there are gradually applied hydrodynamic torque converters of the latest generation that have been projected吉林大学机械科学与工程学院and tested in WUSAM (Research and Projecting Institute of Machines and Mechanisms), j.s.c. Zvolen, Slovakia. These converters represent a three component assembly composed of a rotational pump (P), turbine (T) and a reactor (R) that may revolve in one direction as a free wheel. Advantage of these converters is the fact that their external dimensions and the dimensions of their individual components are identical and they may be mutually changed and arbitrarily combined in order to reach demanded properties. They differ only by internal configuration and blade geometry. According to [1] up to now more than 70 various types have been experimentally tested and from them the ones have been chosen that optimally fulfilled required properties. The mechanical system under consideration represents a sophisticated energy transfer chain from a source––prime mover to working mechanism. Because every real drive is of finite power, any periodic loading always evokes vibrations of all the dynamic variables even though we suppose all the connecting shafts and gearings rigid and backlash free. The influence of dynamic loading on the prime mover may be just controlled by a suitable choice of the torque converter.Fig. 1. Schematic layout of the Diesel drive line.In the paper influence of constant and periodic loading on time course of all the dynamic variables of the system (and particularly on the variables of the prime mover) is investigated at application of some selected types of hydrodynamic torque converters of the latest generation. For fulfilling this task it is necessary to create a suitable mathematical model of the whole combined system and then find its stationary solution corresponding to a required loading.2. Mathematical model of the system吉林大学本科毕业论文外文翻译At the beginning it is necessary to emphasize that mathematical modelling of the drive line in question is based, in our approach, on knowledge of the published phenomenological data: stationary torque-speed characteristic of the prime mover and so-called external static characteristic of the applied hydrodynamic torque converter. It is a much simpler process than modelling based on thermodynamic equations of burning fuel mixture in the Diesel engine and on hydrodynamic equations of real streaming working medium in very complicated cavities of the torque converter. The characteristics are usually given by manufacturer of the individual system components. This is different and simpler approach to solution of the problem than one may find e.g. at Ishihara [2], Hrovat and Tobler [3], Kesy and Kesy [4], Laptev [5] and some others. The derived dimensional and non-dimensional mathematical models of the mechanical system are introduced in [6]. Thenon-dimensional, reduced, so-called single-shaft model (in the driving and loading part), was derived in the form of combined system of the following differential and algebraic equations:(1)(2)(3)(4)M2=KM1, (5)λ=λ(i), (6)K=K(i), (7)(8)吉林大学机械科学与工程学院(9) where the meaning of the individual symbols is explained in nomenclature. In the non-dimensional model all the dynamic variables and parameters are expressed by means of properly chosen relative standard quantities so that the model of the system might be the most simple. Transformation of the original equations system to the non-dimensional form Figs. (1), (2), (3), (4), (5), (6), (7), (8) and (9) is described in detail in [6]. As for this cited paper, it is necessary to say that the relative standard value of loading angular frequency has been settled according to the relation, where in denominator is relative standard value of time. For this value,the time constant of the regulator has been just chosen, i.e. , where therelated dimensional dynamic variables are distinguished by upper bars. The introduced mathematical model has nine variables: M, M1, ω1, z, λ, K, i, M2, ω2 and their meaning is explained in nomenclature. The first three equations represent mathematic model of the prime mover where in inertia moment I there is includedinertia moment of the pump and equivalent part of the working medium because driving and pump shafts are connected by a rigid clutch. The right side of Eq. (3) represents the controlled stationary torque-speed characteristic for which it holds: M D(ω1,z)=M Dmax(ω1)-[M Dmax(ω1)-M Dmin(ω1)]z, (10) where M Dmax(ω1), M Dmin(ω1) represent its non-dimensional extreme branches for maximal and minimal fuel supply and z is the non-dimensional regulator deviation.If the experimentally measured dependences M Dmax(ω1), M Dmin(ω1) are expressed by second degree polynomials then the controlled non-dimensional torque-speed characteristic has the form:(11) From the introduced model it is evident that at chosen parameter value u driving speed growth causes regulator displacement to increase and fuel supply to decrease. The idealised controlled torque-speed characteristic for a chosen parameter value u (gas lever displacement) is schematically depicted in Fig. 2. From Eq. (2) it is evident that the structural parameter ε must be chosen in such away that regulator self-oscillations should not occur. Eqs. Figs. (4), (5), (6), (7) and (8), in the sense of considerations in [6], represent the dynamic equations of the torque converter. Eq. (9) represents simplified motion equation of the loading mechanism under assumptiondoes not depend on rotation angle . In thisthat the reduced inertia moment Ireduced inertia moment there is involved inertia moment of the turbine with吉林大学本科毕业论文外文翻译equivalent part of the working medium too. It is obvious that in this inertia moment and in all moments of the loading mechanism there is considered gear ratio i m of the supplementary gearing of the originally non-reduced system. Eqs. Figs. (6) and (7) represent the external static characteristic of the hydrodynamic transmission, i.e. formal dependences of λ and K on the kinematic ratio i and the dependences are given for every converter type in graphical form. The dynamic variables λ and K are defined in non-dimensional form very simply by non-linear relations Figs. (4) and (5). In a general way these non-dimensional variables are defined by means of dimensional values (distinguished by upper bars) as follows:(12) where individual symbol meaning may be found in nomenclature. As we have chosen (according to Fig. 2) for the relative standard value of angular velocity the idle motion angular velocity of the Diesel engine at maximal fuel supply, i.e. at z = 0, then from Figs. (4) and (12) it is evident that the relative standard moment value is(13)It means that if for the applied drive s−1 and all the applied convertertypes have equal characteristic radius m and if we consider mean valuekg m−3 at stationary thermic regime then the relative standard value of themoment is N m for all the considered converter types. The external static characteristics of the applied converters with internal labelling: M350.222,M350.623M, M350.675, M350.72M3M, are (according to the measuring records [7]) successively introduced in Fig. 3(a)–(d). When the torque-speed characteristic is known and the measured dependences Figs. (6) and (7) are at disposal, it is possible to solve the combined system of differential and algebraic equations Figs. (1), (2), (3), (4), (5), (6), (7), (8) and (9). This is a little complicated task because the differential and algebraic equations in the accepted mathematical model arenon-linear. Stationary dynamic state of the system was calculated by a modified harmonic balance method that is fully described in [8].吉林大学机械科学与工程学院Fig. 2. Idealised diagram of the driving torque-speed characteristic.Fig. 3. External static characteristics of the hydrodynamic power transmissions: M350.222,M350.623M, M350.675, M350.72M3M.3. Stationary dynamic solution at monoharmonicloadingIn this section stationary solution of the system Figs. (1), (2), (3), (4), (5), (6), (7), (8) and (9) will be looked for always with the same prime mover and successively considering all the converters types whose external static characteristics are introduced in Fig. 3(a)–(d). If each of the nine dynamic variables is denoted by a common symbol w≡M, M1, ω1, z, λ, K, i, M2, ω2 then, in accordance with applied method, every dynamic variable may be formally expressed as a sum of its mean and its centred periodic component, i.e.:w=w+w π. (14) Following the mentioned method, on restrictive presumption that it holds:MM z→wπw, (15)吉林大学本科毕业论文外文翻译the system Figs. (1), (2), (3), (4), (5), (6), (7), (8) and (9) splits into twoindependent systems of equations: a system of non-linear algebraic equations for calculationw and a combined system of linearised differential and algebraic equations for calculation w π. If one considers that friction losses in the driving part are implicitly expressed already in the torque-speed characteristic of the drive and in the external static characteristic of the applied hydrodynamic torque converter and friction losses in the loading part are supposed as a combination of Coulomb and viscous friction, i.e.:M T 2=a +bω2, (16)then the non-linear algebraic system has the form:(17)The combined system of the linearised differential and algebraic equations is(18)where for writing abbreviation it is denoted:吉林大学机械科学与工程学院(19) The solution process of both equation systems Figs. (17) and (18) is introduced in [8]. The system of non-linear equations (17) was calculated for three parameter levels u (u = 0.3, 0.4, 0.6) that respond to 30%, 40%, and 60% of the maximal gas lever displacement. To each chosen parameter value u, a certain driving angular velocity interval responds. From Fig. 2 and from Eq. (2) it is evident that for a chosen value u the corresponding mean driving angular velocity value must lie in interval:ω1ω1b, (20)ωwhere for border values of the interval it holds:(21) For the chosen parameter value u = 0.3 and for different mean values M z, the calculated mean values w(for the drive line with given drive and all the consideredconverter types) are introduced in diagrams in Fig. 4(a)–(d). Analogical mean values w of the same variables corresponding with the parameter u = 0.4 are in Fig.5(a)–(d). Finally, the calculated mean values w corresponding with parameteru = 0.6 and identical torque converter types are depicted in Fig. 6(a)–(d). Here it is important to remind that x-coordinates in Fig. 4, Fig. 5 and Fig. 6 represent the mean angular velocity interval (20) gradually for parameters u = 0.3, 0.4, 0.6 and the decimal fractions on this section denote only its decimal division. From the calculated mean values w in Fig. 4, Fig. 5 and Fig. 6 and from the introducedexternal static characteristics in Fig. 3a complete nine of the mean values w can be determined for any mean loading value Mand estimated loss moment value M T2in the loading part. When this complete nine w is known then it is possible, in the sense of the applied method, to construct all the constant coefficients of the combined differential and algebraic system (18) for calculation wπ. This system is already linear and may be solved by known classical methods. First of all, we take interest in stationary dynamic solution. In sense of the procedure one may express the centred periodic component of every dynamic variable in the form:wπ=M za(W c cosνt+W s sinνt), (22) where notations W c, W s represent cosine and sine components of the dynamic factor (transmissibility) of corresponding dynamic variable. Detailed computing procedure is introduced in [8]. For transmissibility of the centred periodic component of every dynamic variable it holds:(23)As an example in Fig. 7, Fig. 8, Fig. 9, Fig. 10 and Fig. 11 there are successively introduced dynamic characteristics of the centred periodic components of dynamic variables: moment (M) and angular velocity of the drive (ω1), loading moment of the pump (M1), moment (M2) and angular velocity of the turbine (ω2) for the system with hydrodynamic converter M350.222 and for chosen parameter value u = 0.4. Results are given in two forms of dynamic characteristics, namely as classic frequency response functions (upper parts) and as Nyquist diagrams (lower parts). Both types of dynamic characteristics are calculated for four values of the loadingmechanism inertia moment: kg m2 and for supplementary gear ratio i m = 1. Equal sections of loading angular velocity Δν with value π corresponding to equal sections on frequency response function x-coordinates are in the Nyquist diagrams separated by bold points as well. In dynamic calculations, theDiesel-engine time constant s, regulator time constant s and the regulator damping ratio ζ = 0.55 were considered. The left parts of the dynamic characteristics in Fig. 7, Fig. 8, Fig. 9, Fig. 10 and Fig. 11 correspond to the dynamic regime with mean values: λ = 0.111, K = 3.12, i = 0.127, which are quantified bybold points on the left thin vertical in the external static characteristic in Fig. 3(a), when the converter works in so-called friction clutch regime. Mean values of dynamic variables, corresponding to this dynamic regime, are: M = 0.0506,= 0.158, ω1 = 0.673, ω2 = 0.0855, M z = 0.152, z = 0.0849. These values areMalso accentuated in Fig. 5(a) by bold points on thin vertical line. In this dynamic regime the converter works with mean transfer energy efficiency η≈ 0.405. Theright parts of the dynamic characteristics introduced in Fig. 7, Fig. 8, Fig. 9, Fig. 10 and Fig. 11 correspond to dynamic regime with mean values: λ = 0.111, K = 1.1,i = 0.74, represented by bold points on the right thin vertical on the external staticcharacteristic in Fig. 3(a) when the converter works in so-called moment converter regime with mean energy transfer efficiency higher than 0.8. The mean values of dynamic variables corresponding to this dynamic state are: M = 0.0506,M= 0.0557, ω1 = 0.673, ω2 = 0.4986, M z = 0.0466, z = 0.0849 and aremarked out in Fig. 5(a) as well on thin vertical line by bold points. Non-dimensional friction losses at dynamic calculation were considered according to (16) as follows:, , where is dimensional relative moment standard value (13).Fig. 4. Mean values of the chosen dynamic variables w of the system with converters: M350.222,M350.623M, M350.675, M350.72M3M for optional parameter u = 0.3.Fig. 5. Mean values of the chosen dynamic variables w of the system with converters: M350.222,M350.623M, M350.675, M350.72M3M for optional parameter u = 0.4.Fig. 6. Mean values of the chosen dynamic variables w of the system with converters: M350.222,M350.623M, M350.675, M350.72M3M for optional parameter u = 0.6.Fig. 7. Dynamic factor (transmissibility) of the centred periodic component of the system driving moment with the converter M350.222 in fretting clutch and moment converter regime for optionalparameter u = 0.4Fig. 8. Dynamic factor (transmissibility) of centred periodic component of the driving angular velocity of the system with the converter M350.222 in fretting clutch and moment converter regimefor optional parameter u = 0.4Fig. 9. Dynamic factor (transmissibility) of centred periodic component of the pump moment of the converter M350.222 in fretting clutch and moment converter regime for parameter u = 0.4.Fig. 10. Dynamic factor (transmissibility) of centred periodic component of the turbine moment of the converter M350.222 in fretting clutch and moment converter regime for parameter u = 0.4.Fig. 11. Dynamic factor (transmissibility) of centred periodic component of the turbine angular velocity of the system converter M350.222 at fretting clutch and moment converter regime forparameter u = 0.4.4. Results evaluation and concluding remarksIn the paper some dynamic properties of a Diesel drive line with some the latest generation torque converter types were inquired and stationary response to common monoharmonic loading was calculated. Mean values of all dynamic variables were calculated for the system with the same controlled drive and successively four chosen torque converter types. In order to save space, complete dynamic calculations are performed only for the system with converter M350.222 and results are introduced in form of frequency response functions and Nyquist diagrams.Already from the calculated mean values in Fig. 4, Fig. 5 and Fig. 6 one may judge technical possibilities and collaboration aptness of the applied drive with the considered converter type. Even from these diagrams it is evident that at application M350.222 this converter can work in arbitrary hydrodynamic regime when optional parameter value u 0.6. Working regime of the system adjusts automatically and depends only on external loading and parameter values u. At maximal loading and lower values u all the considered hydrodynamic converter work in hydrodynamic friction clutch regime when turbine rotation may even extremely decrease to zero value. At mean loading the converter works in the system as hydrodynamic moment converter with average energy transfer efficiency above 0.8. At low system loading and higher values u, the converter behaves as quasi-hydrodynamic fix clutch when relative working medium velocity is low and creates impression of stiffened substance. In this working regime angular velocities of all the converter rotating components are close to each other and mean energy transfer efficiency approaches theoretically to 1. From calculated mean values in Fig. 5 and Fig. 6 it is evident that the torque converters: M350.623M, M350.675, M350.72M3M can at optional parameter u 0.4 cooperate with given drive only in moment converter andhydrodynamic fix clutch regime respectively. The dynamical responses of the drive line with the torque converter M350.222 are depicted in Fig. 7, Fig. 8, Fig. 9, Fig. 10 and Fig. 11. In Fig. 7 and Fig. 8 dynamic factors (transmissibility) of moment and angular velocity of the drive are introduced. It is evident that at chosen value of damping ratio ζ = 0.55 only one significant resonance of these variables occurswhich lies always in loading frequency interval (), regardless of the fact in what regime the applied converter works. Resonance values of moment and angular velocity of the drive are significantly influenced by total inertia moment ofvalue is, the lower resonant values are. Verythe loading mechanism. The higher Isimply one can inquire influence of the supplementary gearing ratio i m because reduced inertia moment I z changes with its second power. It is interesting that change of the loading mechanism inertia moment does not shift resonant peak of dynamic characteristics that remain practically at the same loading angular frequency ν. Remarkable results may be observed in Fig. 9(a) and (b) where the dynamic factors of the pump loading moment corresponding to resonant values of moment and angular velocity of the drive are minimal and express small sensibility to I z magnitude in both inquired converter regimes. In Fig. 10 and Fig. 11, the dynamic factors of driving moment and angular velocity of the turbine are drawn for the case when the applied converter works in friction clutch and moment converter regime. Whole range of dynamic calculations has been made for different values of the time constant and regulator damping ratio ζ. It turned out that the drive linewith all the applied converter types has small sensibility to time constant magnitudeof the Watt regulator. Time constant changes in range (0.01–0.1 s) did not visibly reveal in calculated dynamic factors what is certain difference in comparison with hydrostatic transmission mechanisms (see e.g. [9]). On the other part, dynamic calculations prove that damping ratio ζ influences noticeably resonant values of all dynamic variables. The resonant transmissibility peaks of the driving moment M r and angular velocity ωr in dependence on damping ratio ζ, for the system with converter M350.222 and for four different loading inertia moment values areintroduced in Fig. 12(a) and (b). The thin dash lines always denote stationary resonant dynamic factor values of appertaining variable corresponding to zero-value loading frequency. Equally, as in previous cases, left parts of the Fig. 12(a) represent resonant values of moment and angular driving velocity when the applied converter works in hydrodynamic friction clutch regime. Analogically the right parts of the Fig. 12(b) represent resonant values of the same variable when the converter works in hydrodynamic moment converter regime. From the introduced diagrams it is evident that disturbance transmissibility from the loading mechanism to the drive grows with increasing damping ratio ζ. On the other part, dynamic calculations showed that for low damping ratio values (ζ 0.1) indication of a secondary resonance ofchosen variables appears in loading frequency band but the values of this secondary resonance are essentially lower than corresponding stationary values.Fig. 12. Transmissibility resonant values dependences of moment and driving angular velocity on damping ratio and on reduced inertia moment of the loading for the system with the at hydrodynamicclutch and moment converter regime at u = 0.4.配合新一代液力变矩器的柴油动力线的一些特性摘要:带有控制柴油机的车的动态特性,液力传导机制,还有传动装置和进行普通装卸工作的装载机的调查。

外文文献原稿和译文原稿A New Type Car -- Hybrid Electric VehicleWith skyrocketing fuel prices and changes in weather patterns, many car manufacturers claimed to develop the kind of vehicles that will increase the mileage and reduce the emissions. Hybrid car is a kind of vehicle which can meet above requirements. A hybrid car features a small fuel-efficient gas engine combined with an electric motor that assists the engine.The reasons of building such a complicated machine are twofold: to reduce tailpipe emissions and to improve mileage. Firstly, hybrid cars are good for the environment. They can reduce smog by 90 percent and they use far less gasoline than conventional cars. Meanwhile, hybrid cars burn less gasoline per mile, so they release fewer greenhouse gases. Secondly, hybrid cars are economical. Hybrid cars, which run on gas and electricity, can get up to 55 to 60 miles per gallon in city driving, while a typical SUV might use three times as much gas for the same distance! There are three reasons can mainly account for that: 1) Hybrid engines are much smaller than those on conventional cars. A hybrid car engine is to accommodate the 99% of driving time when a car is not going up hills or accelerating quickly. When extra acceleration power is needed, it relies on the battery to provide additional force. 2) Hybrid gasoline engine can shut off when the car is stopped and run off their electric motor and battery.3) Hybrid cars often recover braking energy. Electric motors could take the lost kinetic energy in braking and use it to charge the battery. Furthermore, hybrids are better than all-electric cars because hybrid car batteries recharge as you drive so there is no need to plug in. Most electric cars need to be recharged every 50-100miles. Also, most electric cars cannot go faster than 50-60 mph, while hybrids can.Hybrid cars bridge the gap between electric and gasoline-powered cars by traveling further and driving faster and hybrid gas-electric cars are proving to be a feasible alternative at a time of high gas prices. So, in my opinion, hybrid cars will have a bright future.How Does Hybrid Electric Vehicle Work?You probably own a gasoline or diesel-engine car. You may have heard of electric vehicles too. A hybrid vehicle or hybrid electric vehicle (HEV) is a combination of both. Hybrid vehicles utilize two or more sources of energy for propulsion. In the case of HEVs, a combustion engine and an electric motor are used.How it works depends on the type of drive train it has. A hybrid vehicle can either have a parallel or series or parallel-series drive train.Parallel HybridThe parallel hybrid car has a gas tank, a combustion engine, transmission,electric motor, and batteries.A parallel hybrid is designed to run directly from either the combustion engine or the electric motor. It can run using both the engine and the motor. As a conventional vehicle, the parallel hybrid draws its power from the combustion engine which will then drive the transmission that turns the wheels. If it is using the electric motor, the car draws its power from the batteries. The energy from the batteries will then power the electric motor that drives the transmission and turns the wheel.Both the combustion engine and the electric motor are used at the same time during quick acceleration, on steep ascend, or when either the engine or the motor needs additional boost.Since the engine is directly connected to the wheels in a parallel drive train, it eliminates the inefficiency of converting mechanical energy into electrical energy and back. This makes a very effective vehicle to drive on the highway.Series HybridThe series hybrid car also has a gas tank, a combustion engine, transmission, electric motor, and batteries with the addition of the generator. The generator can be the electric motor or it can be another separate component.The series configuration is the simplest among the 3. The engine is not connected to the transmission rather it is connected to the electric motor. This means that the transmission can be driven only by the electric motor which draws its energy from the battery pack, the engine or the generator.A hybrid car with a series drive train is more suited for city driving conditions since the engine will not be subjected to the varying speed demands (stop, go, and idle) that contributes to fuel consumption.Series-Parallel HybridThe series-parallel configuration solves the individual problems of the parallel and series hybrid. By combining the 2 designs, the transmission can be directly connected to the engine or can be separated for optimum fuel consumption. The Toyota Prius and the Ford Escape Hybrid use this technology.Honda’s hybridFor those of you who have toyed with the idea of buying a hybrid but were discouraged by the price, you are not alone. In fact, despite the growing concern for the environment, not to mention the skyrocketing price of gas, hybrid cars still only represent a small percentage of global car sales, and a major reason for this is the cost.Hybrids are considered the wave of the future because they not only reduce emissions, addressing the issue of climate change, but they get great gas mileage, an important consideration with the current price of oil. It should be noted that hybrids can also improve the power of the engine, which compromises any advantages in fuel efficiency and emissions. Whatever the application, however, the technology makes the cars more expensive.Because of this, they are the vehicle of choice for only a small niche of people who can afford them, and they currently enjoy a special status amongst the image conscious celebrity-set. For most average consumers, however, they are not an option.That may soon change.Honda Motor Corporation, one of the largest car manufacturers in the world and a leader in fuel efficient technology, has unveiled it’s plan to introduce a low-cost hybrid by 2009. If they can pull it off, they hope to make the hybrid a more mainstream car that will be more appealing to the general public, with the ultimate goal of achieving greater sales and broader appeal than their current incarnation.This, of course, is making Detroit nervous, and may signal a need for American car makers to start making greener and more fuel efficient vehicles, something they could afford to ignore in the past because hybrid cars weren’t worth their attention (due to such a small market share) while gas-guzzling SUVs have such high profit margins.Honda, meanwhile, has had to confront a growing need to compete with Toyota, which has not only grown to be the world’s largest automaker, but makes the car that has become synonymous with the hybrid movement, the Prius. Honda is therefore faced with the seemingly insurmountable task of challenging Toyota’s dominance in the market.Concurrently, Toyota is racing to lower production costs on the Prius, as well, which would hopefully result in a lower cost to the consumer. All eyes are on a potentially favorable car buyers market in 2009.In the meantime, with even adamant global warming naysayers warming up (no pun intended) to the possibilities of an ecological disaster on the horizon, maybe it’s time that we got over our need to drive huge SUVs and start moderating our fuel consumption.Then again, as gas prices hovering around $4.00 and with no ceiling in sight, we may have little choice in the matter.Engine Operating PrinciplesMost automobile dngines are internal combustion, reciprocating 4-stroke gasoline engines, but other types have been used, including the diesel, the rotary ( Wankel ) , the 2-srtoke, and stratified charge.Reciprocating means up and down or banck and forth, It is the up and down action of a piston in the cylinder blick, or engine block. The blick is an iron or aluminum casting that contains engine cylinders and passges called water jackets for coolant circulation. The top of the block is covered with the cylinder head. Which forms the combustion chanber. The bottom of the block is covered with an oil pan or oil sump.Power is produced by the linear motion of a piston in a cylinder. However, this linear motion must be changed into rotary motion to turn the wheels of cars of trucks. The piston is attached to the top of a connecting rod by a pin, called a piston pin or wrist pin. The bottom of the connecting rod is attached to the crankshaft. The connecting rod transmits the up-and-down motion of the piston to the crankshaft, which changes it into rotary motion.The connecting rod is mounted on the crankshaft with large beaings called rodbearings. Similar bearings, called main bearings, are used to mount the crankshaft in the block. Shown in Fig. 1-1The diameter of the cylinder is called the engine bore. Displacement and compression ratio are two frequently used engine specifications. Displacement indicates engine size, and compression ratio compares the total cylinder volume to compression chamber volume.The term stroke is used to describe the movement of the iston within the cylinder, as well as the distance of piston travel. Depending on the type of engine the operating cycle may require either two or four strokes to complete. The 4-stroke engine is also called Otto cycle engine, in honor of the German engineer, Dr. Nikolaus Otto, who first applied the principle in 1876. In the 4-stroke engine, four strokes of the piston in the cylinder are required to complete one full operating cycle. Each stroke is named after the action it performs intake, compression, power, and exhaust in that order, shown in Fig1-2.1、Intake strokeAs the piston moves down, the vaporized mixture of fuel and air enters the cylinder through open intake valve. To obtain the maximum filling of the cylinder the intake valve opens about 10°before t.b.c., giving 20°overlap. The inlet valve remains open until some 50°after b.d.c. to take advantage of incoming mixture.2、 Compression strokeThe piston turns up, the intake valve closes, the mixture is compressed within the combustion chamber, while the pressure rise to about 1Mpa, depending on various factors including the compression ratio, throttle opening and engine speed. Near the top of the stroke the mixture is ignited by a spark which bridges the gap of the spark plug.3、 Power strokeThe expanding gases of combustion produces a rise in pressure of the gas to some 3.5Mpa, and the piston is forced down in the cylinder. The exhaust valve opens near the bottom of the stroke.4、Exhust strokeThe piston moves back up with the exhaust valve open some 50°before b.d.d., allowing the pressure within the cylinder to fall and to reduce ‘back’pressure on the piston during the exhaust stroke, and the burned gases are pushed out to prepare for the next intake stroke.The intake valve usually opens just before the exhaust stroke. This 4-stroke cycle is continuously repeared in every as long as the engineremains running.A 2-stroke engine also goes through four actions to complete one operating cycle.However, the intake and the compression actions are combined in one seroke, and the power and exhaust actions are combined in the other stroke. The term2-stroke cycle or 2-stroke is preferred to the term 2-cycle, which is really not accurate.In automobile engines, all pistons are attached to a single crankshaft. The more cylinders an engine has, the more power strokes produced for cach revolution. This means that an 8-cylinder engine runs more smoothly bdcause the power atrokes arecloser together in time and in degrees of engine rotation.The cylinders of multi-cylinder automotive engines arranged in one of three ways. 1、Inline engines use a single block of cylinder.Most 4-cylinder and any 6-cylinder engines are of this design. The cylinders do not have to be vertical. They can be inclined either side.2、V-type engines use two equal bands of cylinders, usually inclined 60degrees or 90degrees from the cach other. Most V-type engines have 6 or 8 cylinders, although V-4 and V-12 engines have been built.3、Horizontally opposed or pancake engines have two equal banks of cylinders 180degreeas apart. These space saving engine designs are often air-cooled, and are found in the Chevrolet Carvair, Porsches, Subaus, and V olkswagens. Subaus design is liquid cooled.Late-model V olkswagen vans use a liquid-cooled version of the air cooled VWhorizontally opposed engine.译文新型汽车----混合动力汽车在油价飞涨的今天,汽车制造商被要求发展一种排放低,行驶里程长的汽车。

汽车发动机外文翻译文献(文档含中英文对照即英文原文和中文翻译)AUTOMOTIVE ENGINE1 Engine Classification and Overall MechanicsThe automobile engines can be classified according to: (1) cycles, (2) cooling system, (3) fuel system, (4) ignition method, (5) valve arrangement, (6) cylinder arrangement, (7) engine speed.Engines used in automobiles are the internal combustion heat engines. The burning of gasoline inside the engine produces high pressure in the engine combustionchamber. This high pressure force piston to move, the movement is carried by connecting rods to the engine crankshaft. The crankshaft is thus made to rotate: the rotary motion is carried through the power train to the car wheels so that they rotate and the car moves.The engine requires four basic systems to run (Fig. 2-1). Diesel engines require three of these systems. They are fuel system, ignition system (except diesel), lubricating system and cooling system. However, three other related systems are also necessary. These are the exhaust system, the emission-control system, and the starting system. Each performs a basic job in making the engine run.Fig. 2-1 The engine construction2 Engine Operating PrinciplesFig. 2-2 Engine termsThe term “stroke” is used to describe the movement of the piston within the cylinder. The movement of the piston from its uppermost position (TDC, top dead center) to its lowest position (BDC, bottom dead center) is called a stroke. The operating cycle may require either two or four strokes to complete. Most automobile engines operate on the four stroke cycle (Fig. 2-2).In four-stroke engine, four strokes of the piston in the cylinder are required tocomplete one full operating cycle. Each stroke is named after the action. It performs intake, compression, power, and exhaust in that order (Fig. 2-3).Intake stroke Compression stroke Power stroke Exhaust strokeFig. 2-3 Four-stroke-cycle gasoline engine1. The intake strokeThe intake stroke begins with the piston near the top of its travel. As the piston begins its descent, the exhaust valve closes fully, the intake valve opens and the volume of the combustion chamber begins to increase, creating a vacuum. As the piston descends, an air/fuel mixture is drawn from the carburetor into the cylinder through the intake manifold. The intake stroke ends with the intake valve close just after the piston has begun its upstroke.2. Compression strokeAs the piston is moved up by the crankshaft from BDC, the intake valve closes. The air/fuel mixture is trapped in the cylinder above the piston. Future piston travel compresses the air/fuel mixture to approximately one-eighth of its original volume (approximately 8:1 compression ratio) when the piston has reached TDC. This completes the compression stroke.3. Power strokeAs the piston reaches TDC on the compression stroke, an electric spark is produced at the spark plug. The ignition system delivers a high-voltage surge of electricity to the spark plug to produce the spark. The spark ignites, or sets fire to, the air/fuel mixture. It now begins to burn very rapidly, and the cylinder pressure increases to as much as 3-5MPa or even more. This terrific push against the piston forces it downward, and a powerful impulse is transmitted through the connecting rod to the crankpin on the crankshaft. The crankshaft is rotated as the piston is pushed down by the pressure above it.4. Exhaust strokeAt the end of the power stroke the camshaft opens the exhaust valve, and the exhaust stroke begins. Remaining pressure in the cylinder, and upward movement of the piston, force the exhaust gases out of the cylinder. At the end of the exhaust stroke, the exhaust valve closes and the intake valve opens, repeating the entire cycle of events over and over again.3 Engine Block and Cylinder Head3.1 Engine BlockThe engine block is the basic frame of the engine. All other engine parts either fit inside it or fasten to it. It holds the cylinders, water jackets and oil galleries (Fig. 2-4). The engine block also holds the crankshaft, which fastens to the bottom of the block. The camshaft also fits in the block, except on overhead-cam engines. In most cars, this block is made of gray iron, or an alloy (mixture) of gray iron and other metals, such as nickel or chromium. Engine blocks are castings.Fig. 2-4 V6 engine blockSome engine blocks, especially those in smaller cars, are made of cast aluminum. This metal is much lighter than iron. However, iron wears better than aluminum. Therefore, the cylinders in most aluminum engines are lined with iron or steel sleeves. These sleeves are called cylinder sleeves. Some engine blocks are made entirely of aluminum.3.2 Cylinder SleevesCylinder sleeves are used in engine blocks to provide a hard wearing material for pistons and piston rings. The block can be made of one kind of iron that is light and easy to cast while the sleeves uses another that is better able to stand up wear and tear. There are two main types of sleeves: dry and wet (Fig. 2-5).Dry sleeve Wet sleeveFig. 2-5 Cylinder sleeve3.3 Cylinder HeadThe cylinder head fastens to the top of the block, just as a roof fits over a house. The underside forms the combustion chamber with the top of the piston. In-line engine of light vehicles have just one cylinder head for all cylinders; larger in-line engines can have two or more. Just as with engine blocks, cylinder heads can be made of cast iron or aluminum alloy. The cylinder head carries the valves, valve springs and the rockers on the rocker shaft, this part of valve gear being worked by the pushrods. Sometimes the camshaft is fitted directly into the cylinder head and operates on the valves without rockers. This is called an overhead camshaft arrangement.3.4 GasketThe cylinder head is attached to the block with high-tensile steel studs. The joint between the block and the head must be gas-tight so that none of the burning mixture can escape. This is achieved by using cylinder head gasket. Gaskets are also used to seal joins between the other parts, such as between the oil pan, manifolds, or water pump and the blocks.3.5 Oil PanThe oil pan is usually formed of pressed steel. The oil pan and the lower part of cylinder block together are called the crankcase; they enclose, or encase, thecrankshaft. The oil pump in the lubricating system draws oil from the oil pan and sends it to all working parts in the engine. The oil drains off and run down into the pan. Thus, there is a constant circulation of oil between the pan and the working parts of the engine.4 Piston Assembly, piston rings , The piston pin ,Connecting Rods, Crankshafts And Flywheel4.1 PistonPiston rings and the piston pin are together called the piston assembly (Fig. 2-6).Fig. 2-6 Piston, piston rings and connecting rodThe piston is an important part of a four-stroke cycle engine. Most pistons are made fr om cast aluminum. The piston, through the connecting rod, transfers to the crankshaft the force created by the burning fuel mixture. This force turns the crankshaft.To withstand the heat of the combustion chamber, the piston must be strong. It also must be light, since it travels at high speeds as it moves up and down inside the cylind er. The piston is hollow. It is thick at the top where it takes the brunt of the heat and th e expansion force. It is thin at the bottom, where there is less heat. The top part of the piston is the head, or crown. The thin part is the skirt. Most pistons have three ring gro oves at the top. The sections between the ring grooves are called ring lands.4.2 piston ringspiston rings fit into ring grooves near the top of the piston. In simplest terms, pisto n rings are thin, circular pieces of metal that fit into grooves in the tops of the pistons. In modern engines, each piston has three rings. (Piston in older engines sometimeshad four rings, or even five.) The inside surface of the ring fits in the groove on the pi ston. The ring's outside surface presses against the cylinder walls. Rings provide the n eeded seal between the piston and the cylinder walls. That is, only the rings contact th e cylinder walls. The top two rings are to keep the gases in the cylinder and are called compression rings. The lower one prevents the oil splashed onto the cylinder bore fro m entering the combustion chamber, and is called an oil ring.4.3 The piston pinThe piston pin holds together the piston and the connecting rod. This pin fits into th e piston pin holes and into a hole in the top end of the connecting rod. The top end of t he rod is much smaller than the end that fits on the crankshaft. This small end fits insi de the bottom of the piston. The piston pin fits through one side of the piston, through the small end of the rod, and then through the other side of the piston. It holds the rod firmly in place in the center of the piston. Pins are made of high-strength steel and hav e a hollow center. Many pins are chrome-plated to help them wear better.A piston pin fits into a round hole in the piston. The piston pin joins the piston to the connecting ro d. The thick part of the piston that holds the piston pin is the pin boss.4.4 Connecting RodsThe connecting rod little end is connected to the piston pin. A bush made from a soft metal, such as bronze, is used for this joint. The lower end of the connecting rod f its the crankshaft journal. This is called the big end. For this big-end bearing, steel-ba cked lead or tin shell bearings are used. These are the same as those used for the main bearings. The split of the big end is sometimes at an angle, so that it is small enough t o be withdrawn through the cylinder bore. The connecting rod is made from forged all oy steel.4.5 CrankshaftsThe crankshaft is regarded as the “backbone” of the engine (Fig. 2-7). The crankshaft, in conjunction with the connecting rod, converts the reciprocating mo tion of the piston to the rotary motion needed to drive the vehicle. It is usually made fr om car-bon steel which is alloyed with a small proportion of nickel. The main bearing journals fit into the cylinder block and the big end journals align with the connecting rods. At the rear end of the crankshaft is attached the flywheel, and at the front end ar e the driving wheels for the timing gears, fan, cooling water and alternator. The throw of the crankshaft, i.e. the distance between the main journal and the big end centers, controls the length of the stroke. The stroke is double the throw, and the strokelength is the distance that the piston travels from TDC to BDC and vice versa.Fig. 2-7 The crankshaft4.6 FlywheelThe flywheel is made from carbon steel. It fits onto the rear of the crankshaft. As well as keeping the engine rotating between power strokes it also carries the clutch, w hich transmits the drive to the gearbox, and has the starter ring gear around its circumf erence. There is only one working stroke in four so a flywheel is needed to drive the c rankshaft during the time that the engine is performing the non-power strokes.5 Valve SystemFig. 2-8 Parts of the valve trainThe valve operating assembly includes the lifters or cam followers, pushrods, rocker arms and shafts or pivot, valve and springs etc. The purpose of this to open and close the intake and exhaust ports that lead to the combustion chambers as required (Fig. 2-8). Valve mechanisms vary depending on the camshaft location. When the camshaft is positioned in the engine block, valve lifters are mounted in the openings above the camshaft. Pushrods are connected from each valve lifter to a pivoted rocker arm mounted above each valve. A lobe on the camshaft is positioned directly below each valve lifter. A typical camshaft drive has a sprocket bolted to the end of the camshaft, and a matching sprocket is attached to the end of the crankshaft. Those two sprockets may be meshed together or surrounded a steel chain to have the camshaft drive. When the lower part of the camshaft lobe is rotating under the valve lifter, the valve spring holds the valve closed.汽车发动机1发动机的分类和整体力学汽车发动机可根据如下因素进行分类:(1)循环系统,(2)冷却系统,(3)燃油系统,(4)点火方式,(5)气门布置,(6)气缸排列,(7)发动机转速。