附录b锂电池操作中英文标签

- 格式:doc

- 大小:78.00 KB

- 文档页数:2

关于金属锂电池和锂离子电池操作指引(第一版)根据IATA DGR 50版关于锂电池运输的最新规定将从2009年1月1日起生效。

为保证运输安全以及操作顺畅,CX/KA(PVG)根据本公司有关规定,特制定以下操作指引:一, 锂电池运输必须证明符合联合国《试验与标准手册》第III部分38.3的每一项测试规定。

CX/KA(PVG)认可的锂电池运输鉴定机构见附件A. PVG出港必须出具认可的检测机构出具的《货物运输条件鉴定书》二, 锂电池(Lithium Battery)作为非限制性货物运输1. 包装要求请根据所运输锂电池货物的实际运输专用名称, 查阅IATA DGR 50 版运输锂电池相对应的包装说明Part 1(PI965, 966, 967, 968, 969和970), 包装必须满足该锂电池货物所对应的要求.2. 单证要求1)在所附文件, 如货运单上填写以下a-d的所有内容。

运单上的空白处如果无法包含相关内容,请另附声明,此时运单上须注明“Document as per attached ”. 除此之外(a)中提到的内容在任何情况下仍需显示在运单上。

a. 注明包装件内含有锂电池(无论是锂金属电池还是锂离子电池)Lithium ion batteries or cells, NOT RESTRICTED as per PI 9xx Part1; orLithium metal batteries or cells, NOT RESTRICTED as per PI 9xx Part1; orLithium ion and metal batteries or cells, NOT RESTRICTED as per PI 9xx Part1b. 锂电池的包装件,操作时必须注意小心轻放,原因是因为包装件发生破损容易引发起火危险如“The package must be handled with care and a flammability hazard exists, if thepackage is damaged.”c. 根据对应的包装说明,注明当包装件破损情况发生时的处置说明如:“Do not Damage or mishandle this package. If package is damaged, batteriesmust be protected so as to prevent short circuit.”d.填写24小时电话联系人,联系人的电话必须保持畅通, 以便获取更多的货物有关信息。

危险货物鉴定分类国际规章制度和法规已出2011年最新版本危险货物鉴定分类的国际规章制度和法规具有有效期,一般一到两年就会出新的修订版,以下为实验室整理的已在2011年1月1日出了最新版本的危险货物分类的规章制度和法规。

2011年需要采用的新版本为:国际航空运输协会《危险货物规则》第52版(2011年版),国际危险货物内河运输欧洲协定(ADN)2011版,国际危险货物公路运输欧洲协定(ADR)2011版,国际危险货物铁路运输规则(RID)2011版;可选择采用的新版本为:《国际海运危规》2010版(因为《海运危规》2008年版的有效期为2010.1.1-2011.12.31,但由于《国际海运危规》的有效期为两年,还可以提前应用一年,所以2011年可提前应用2010版)。

《危险货物规则》第52版的重要变更及修订(2011)国际航空运输协会(IATA)《危险货物规则》第52版综合了危险货物委员会作出的所有修正,并且包括至付印之日为止的国际民用航空组织(ICAO)对于《技术细则》2011-2012版所作的变更。

以下清单用以帮助使用者更好地辨识本版本中所引入的主要修订,但不得将其视为包览无遗的修正表。

修订内容前面标注出所处章节的编号。

1—适用范围1.2—本规则适用范围。

本节对始发站国家及运营人国家批准的文字表述作了显著修改。

豁免要求也作了阐明,并且新规定允许包含危险品的旅客行李作为“货运逾重行李”进行运输。

1.3—托运人责任。

将一份托运人危险品申报单最少保留三个月现已强制执行。

2—限制2.3—旅客或机组人员携带的危险品。

旅客行李中危险品的规定已修订,变化包括:υ带有保安装置的外交公文箱;禁止携带电震击武器(如泰瑟枪);υ允许携带锂离子电池驱动的助行器;υυ允许携带便携式医疗装置,如锂电池驱动的去纤颤器和雾化器;燃料电池系统的规定修改为允许作为交运行李携带一定量的备用燃料电池罐。

υ2.5—运营人物资中的危险品。

关于符合DGR相关包装说明第II部分要求运输的锂电池的运单说明根据2013DGR的要求,为了保证例外情况锂电池或含锂电池的产品收运顺利,请留意运单注意事项:若是锂离子或含锂离子产品,运单品名栏(Nature and Quantity of Good s)必须注明:Lithium ion batterie s in compliance with Section I I of P I xxx(其中P I965-PI967)运单上还必须含有以下描述:1. the pa ckage contain s lithium ion cells or batte ries (包装件内含锂离子电池芯或锂离子电池)2. the pa ckage m ust be handled w ith care and that a flammability hazard exists i f thepackage is dam aged(一旦包装件破损会存在易燃的危险性,必须小心操作)3. special procedures must be follo wed in the event the pa ckage is dam aged, to includeinspection an d repa cking i f necessary(包装件如发生破损必须采取特殊程序,程序内容包括检查和重新包装)--注:特殊程序是指详细的程序内容。

4. a telephone number for additional information(联系人电话号码)如果运单上没有空白处可填写,代理可以附一张声明书,声明上述内容。

但是必须在handling information(操作注意事项)栏打上D ocuments as per attached(资料附后)的字样。

若是锂金属或含锂金属产品,运单品名栏(Nature and Quantity of Good s)必须注明:Lithium metal batteries in compliance w ith Section II of PI xxx (其中P I968-PI970)运单上还必须含有以下描述:1. the pa ckage contain s lithium metal cells or batte ries (包装件内含锂金属电池芯或锂金属电池)2. the pa ckage m ust be handled w ith care and that a flammability hazard exists i f thepackage is dam aged(一旦包装件破损会存在易燃的危险性,必须小心操作)3.special procedures must be follo wed in the event the pa ckage is dam aged, to includeinspection an d repa cking i f necessary(包装件如发生破损必须采取特殊程序,程序内容包括检查和重新包装)--注:特殊程序是指详细的程序内容。

B6AC充电器中文说明书感谢您选购此款充放电器. 您选购的这款是运用高科技和专业操控软件的快速充电/放电器.在使用此产品之前请认真阅读完此操作手册最佳操作软件当充/ 放电时,它具有自动设定电流的功能. 尤其是锂电池,可以防止因用户失误而造成的充电爆炸事故. 单位内的每个程序,都是相互控制与联系,使每一个可能的误差为最高安全这些可以根据用户的选择来设定.接受, 转接, 启动充电器的特殊充电插口.频繁使用的充电器插口, 比如多功能插头等.高功率和高性能的电路它所使用的电路最大输出功率为50瓦.因此,当最大电流是5.0 安时, 它充电或者放电可以达到15个NiCd/NiMH和6节锂电池并联的效果.此外,制冷系统可以在这样的功率下毫无障碍地运行CPI或操作程序.锂电池内部的单个电压平衡器它里面带有独特锂电池专用的平衡功能. 因此在充锂电(Lilo/LiPo/LiFe) 时, 不需要额外的平衡器来平衡电压.平衡放电的单个电池它在放电时, 还可以监测和平衡锂电池组中的单个电池. 当电池电压出现异常时, 放电就会伴随错误信息而停止.适合各种各样的锂电池它可以接受三种类型的锂电池-Lilo,LiPo 和LiFe. 它们因化学成分的不同而具有不同的特点.你可以选择他们中任一一种来使用,根据它们的规格,参照”警告和安全说明书”.锂电池快速和存储模式你可以充电锂电池作特殊用途。

快速充电减少了锂电池的充电时间, 而存储模式也使得锂电池的额定电压可以长时间的储存.最大化安全Delta-peaksensitivity:一种自动充电电流关闭程序, 其工作原理是在电池电压上升至最高点而开始回降时, 将充电电流关闭完成充电.(镍镉/ 镍氢)自动充电电流限制:在自动电流模式下充镍镉或镍氢电池, 你可以设置充电电流的上限以避免高充电电流.在’AUT0模式下,在充低阻碍,小容量的镍氢电池时非常有用.容量限制:充电容量以充电电流X充电时间来计算.在设定了最高充电值的情况下,当充电容量超过了最高限额时, 程序将强制结束充电.温度限制:充电时,电池由于内部发生化学反应,温度也将相应增高.如果对充电器设定温度限制,在温度到达最高限额时,程序将强制结束充电.充电时间限制:对充电时间进行限制也可以防止任何可能的错误输入电流检测器:为保护蓄电池在电流输入时不受损坏, 通常可以对其电压进行检测. 当电压下降至最低额时, 程序将自动关闭充电电流.自动制冷风扇: 只有在单个电池的内部温度升高时,电子制冷风扇才自动运转.资料存储/ 下载为方便用户,它最多可以存储5个数据不同的电池. 你可以建立包含了程序设置的数据来持续不断的充电或是放电. 在你需要的任意时候都可以叫出这些数据,并且这个过程在没有设定程序时执行.循环充电或者放电持续不断的运转1-5 周期使电池得以更新和平衡.充电器外观警告和安全提示O任何情况都不要在无人看管的情况下充电.如果有故障出现,请立即结束程序,再查阅程序说明书.o不要放在有灰尘,潮湿,太阳直射或振动的地方,不要摔它.O进入电源只允许10-18DC电源.O充电器和电池在充电或放电时应放置在强抵抗,防易燃和抗导体的表面上.切勿放在汽车坐垫上, 地毯上或类似物体上.确保所有易然易爆物品远离操纵区域.O充电器的冷却口不能被覆盖或关闭,以便提供良好的通风.确保准确地掌握要充电和放电的电池性能. 如果程序设置错误可能损坏电池. 尤其是锂电池, 可能会导致火灾或充电过度导致爆炸.NiCd/NiMH 电压等级:1.2v/cell允许快速充电电流:1C~2C依赖于电池的运转.放电电压切断级别:0.85v/cell (镍镉电池),1.0v/cell(镍氢电池)Lilo 电压等级:3.6V/C最大充电电压:4.1V/cell允许快速充电电流:1C或更少最小放电电压切断级别:2.5V/cell或更高LiPo 电压等级:3.7V/cell最大充电电压:4.2V/cell允许快速充电电流:1C或更少放电电压切断级别:3.0V/cell或更高LiFe 电压等级:3.3V/cell最大充电电压:3.6V/cell允许快速充电电流:4C或更少(例如A123)最大充电电压 246V/cell允许快速充电电流:0.4C 或更少放电电压切断级别:1.50V/cell 或更高O 为避免充电导线之间发生短路,应先将充电导线与充电器连接,然后再连接电池,拆开线路时,步骤相反.-你必须注意核实锂电池组的容量和电压.它可能是串,并联混合组成.并联时,电池组的容量是每个电池的容量乘以电池的个数,而电池组的电压不变.在充电过程中,这种电压不平 衡引起火灾或爆炸,我们建议你串联锂电池组O 放电放电的典型目的是确定电池剩余的容量或是降低电池的电压来界定级别 时,必须和充电时一样注意放电过程.为了避免电池放电过度,一定要正确设定额定放电电 压.锂电池不能低于最低电压,因为这样会导致容量的快速损失或者完全失败 .一般来说,不需要给锂电池放电.-据说一些充电电池有记忆效应。

深圳市聚力电池有限公司SHENZHEN JOOLEE BATTERY CO., LTD磷酸铁锂动力电池组LFP Power Li-ion Rechargeable Battery产品规格承认书Specification For Approval Model: JL-24S4P-72V/200Ah深圳市聚力电池有限公司SHENZHEN JOOLEE BATTERY CO., LTD1. scope of application 适用范围This specification describes the basic performance ,technical requirement ,testing method, warning and caution of the LFP power Li-ion rechargeable battery .The specification only applies to SHENZHEN JOOLEE BA TTERY CO., LTD.本规格书规定了磷酸铁锂动力锂离子可充电电池的基本性能、技术要求、测试方法及注意事项。

本规格书只适用于深圳市聚力电池有限公司所生产的磷酸铁锂动力锂离子电池。

2. Production description产品描述2.1Mode l 型号:JL-24S4P-200Ah2.2Spec. 规格:72V/200Ah2.3Cell model电池型号:47115215(50Ah/3.3V)2.4. Assembly mode组合形式:12串4并*2箱2.5 Cell dimension and Assembly drawing 产品尺寸与装配示意图此图为一个模块电池。

Drawing图例Cell dimension单体电池尺寸Drawin g图示Item 项目Description描述Dimension尺寸T Thickness厚度≤47.5mmW Width宽度≤115.5mmL Length长度≤215.5mmBattery pack one box size电池组尺寸T Hight高度≤260mmW Width宽度≤480mmL Length长度≤580mm 3.Specification 产品规格NO.序号Item项目Unit单位Specifications说明Remark备注3.1 Nominal capacity标称容量Ah 2003.2 Minimum capacity最小容量Ah 2003.3 Rated voltage额定电压V 723.4 Charge Ending V oltage充电截止电压V 87.6Constant current/Constant voltage3.5 Discharge Ending V oltage放电截止电压V 603.6 Standard charging current标准充电电流A 60(0.3C5A)3.7 Max. charging current最大充电电流A 200 (1C5A)LW序号项目测试方法和条件标准7.1 Thermal shock热冲击Put the battery in the oven. The temperature of theoven is to be raised at 5±2℃ per minute to atemperature of 130±2℃ and remains 30 minutes.将电池放进烘箱内,以5±2℃每分钟的速度升高烘箱内温度至130±2℃后,恒温30min。

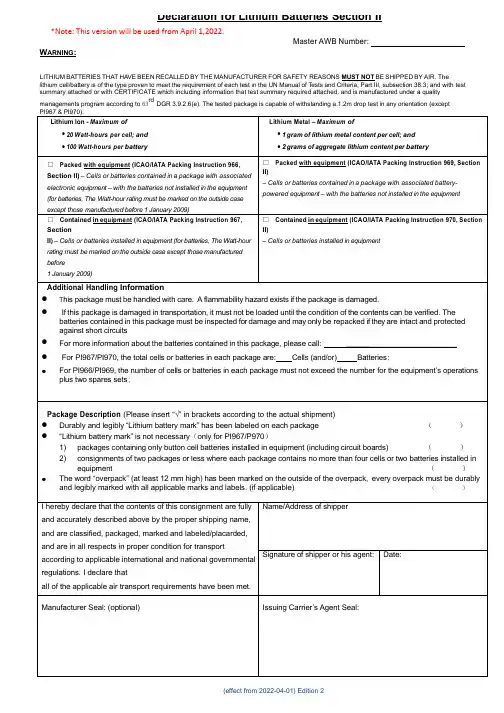

Declaration for Lithium Batteries Section II *Note: This version will be used from April 1,2022.W ARNING:Master AWB Number:LITHIUM BATTERIES THAT HAVE BEEN RECALLED BY THE MANUFACTURER FOR SAFETY REASONS MUST NOT BE SHIPPED BY AIR. The lithium cell/battery is of the type proven to meet the requirement of each test in the UN Manual of T ests and Criteria, Part III, subsection 38.3; and with test summary attached or with CERTIFICATE which including information that test summary required attached, and is manufactured under a qualitymanagements program according to 63rdDGR 3.9.2.6(e). The tested package is capable of withstanding a.1.2m drop test in any orientation (exceptPI967 & PI970).Lithium Ion - Maximum of•20 Watt-hours per cell; and•100 Watt-hours per battery Lithium Metal – Maximum of•1 gram of lithium metal content per cell; and•2 grams of aggregate lithium content per battery□ Packed with equipment (ICAO/IATA Packing Instruction 966, Section II) – Cells or batteries contained in a package with associated electronic equipment – with the batteries not installed in the equipment (for batteries, The Watt-hour rating must be marked on the outside case except those manufactured before 1 January 2009)□ Packed with equipment (ICAO/IATA Packing Instruction 969, Section II)– Cells or batteries contained in a package with associated battery-powered equipment – with the batteries not installed in the equipment□ Contained in equipment (ICAO/IATA Packing Instruction 967, SectionII) – Cells or batteries installed in equipment (for batteries, The Watt-hour rating must be marked on the outside case except those manufactured before1 January 2009)□ Contained in equipment (ICAO/IATA Packing Instruction 970, Section II)– Cells or batteries installed in equipmentAdditional Handling Informationl T his package must be handled with care. A flammability hazard exists if the package is damaged.l If this package is damaged in transportation, it must not be loaded until the condition of the contents can be verified. The batteries contained in this package must be inspected for damage and may only be repacked if they are intact and protected against short circuitsl For more information about the batteries contained in this package, please call: __________________________l For PI967/PI970, the total cells or batteries in each package are: Cells (and/or) Batteries;l For PI966/PI969, the number of cells or batteries in each package must not exceed the number for the equipment’s operations plus two spares sets;Package Description (Please insert “√” in brackets according to the actual shipment)l Durably and legibly “Lithium battery mark” has been labeled on each package ( )l“Lithium battery mark” is not necessary(only for PI967/P970)1) packages containing only button cell batteries installed in equipment (including circuit boards) ()2) consignments of two packages or less where each package contains no more than four cells or two batteries installed inequipment ( )l The word “overpack” (at least 12 mm high) has been marked on the outside of the overpack,every overpack must be durably and legibly marked with all applicable marks and labels. (if applicable)()I hereby declare that the contents of this consignment are fully and accurately described above by the proper shipping name, and are classified, packaged, marked and labeled/placarded, and are in all respects in proper condition for transport according to applicable international and national governmental regulations. I declare thatall of the applicable air transport requirements have been /Address of shipperSignature of shipper or his agent:Date:Manufacturer Seal: (optional)Issuing Carrier’s Agent Seal:(effect from 2022-04-01) Edition 2关于锂电池 Section II 空运声明*提醒:本版本自2022年4月1日起使用。

History of revision 版本更改历史记录Contents 目录1.Scope 适用范围 (4)2.Adopted Standard引用标准 (4)3.Electrical Characteristics电气特性 (4)4.Battery Performances Test Criterion 电池性能测试规范 (5)5.1 Appearance 外观 (5)5.2 Measurement Apparatus 测试设备 (5)5.3 Testing Condition 测试条件 (6)5.4 Reliability Test 可靠性测试 (6)5.Shipment 运输 (8)6.Storage 贮存 (8)7.Package and Marking包装与标志 (8)8.1 Package 包装 (8)8.2 Marking 标志 (8)8.Protection Circuit 保护电路 (9)9.1 Schematic of the PCB 保护板原理图 (9)9.2 PCM BOM....................................................................................................................................9.3 PCM Parameter PCM参数 (9)9.Outline Drawing 外形图纸 (10)10.Appendix 附录 (11)3.7 Instructions and Safety Requirement 使用说明和安全规程 (11)3.7.1 Recommending Usage推荐使用事项 (11)3.7.2 Hazard Warning危险警告 (11)3.7.3 Warning 警告 (12)3.7.4 Cautions 注意事项 (13)10.2 Quality Evaluation Programme 质量评定 (14)10.3 Environment Protection 环保要求 (14)10.4 Others 其他事项 (14)1.Scope 适用范围This description defines the general requirements for the battery’s rating parameter, electrical requirement, safety requirement, environmental compatibility, test and judgment, usage instructions, safety regulation, quality evaluation and packaging, marking, storage, shipment and handling, which cellular phone battery with 523450AR-850mAh rechargeable battery cell, adapted for Digital products.本规格书描述电池之标称参数、电气特性、安全性能、环境适应性及其实验和判定、使用说明和安全规程、质量评定及包装、标志、贮存、运输等。

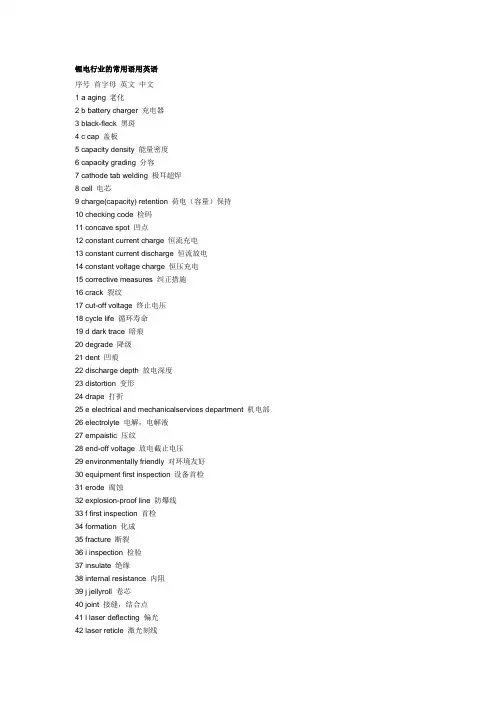

锂电行业的常用语用英语序号首字母英文中文1 a aging 老化2 b battery charger 充电器3 black-fleck 黑斑4 c cap 盖板5 capacity density 能量密度6 capacity grading 分容7 cathode tab welding 极耳超焊8 cell 电芯9 charge(capacity) retention 荷电(容量)保持10 checking code 检码11 concave spot 凹点12 constant current charge 恒流充电13 constant current discharge 恒流放电14 constant voltage charge 恒压充电15 corrective measures 纠正措施16 crack 裂纹17 cut-off voltage 终止电压18 cycle life 循环寿命19 d dark trace 暗痕20 degrade 降级21 dent 凹痕22 discharge depth 放电深度23 distortion 变形24 drape 打折25 e electrical and mechanicalservices department 机电部26 electrolyte 电解,电解液27 empaistic 压纹28 end-off voltage 放电截止电压29 environmentally friendly 对环境友好30 equipment first inspection 设备首检31 erode 腐蚀32 explosion-proof line 防爆线33 f first inspection 首检34 formation 化成35 fracture 断裂36 i inspection 检验37 insulate 绝缘38 internal resistance 内阻39 j jellyroll 卷芯40 joint 接缝,结合点41 l laser deflecting 偏光42 laser reticle 激光刻线43 laser welding-flatwise weld 激光焊接-平焊laser welding-standing weld 激光焊接-立焊44 leakage 漏液45 leak-checking 测漏46 leaving out of welding 漏焊47 limited charge voltage 充电限制电压48 local action 自放电49 m margin turnly 翘边50 measuring the dimension of cells 电芯卡尺寸51 meet requirement 达到要求52 memory effects 记忆效应53 n nick 划痕54 nominal voltage 标称电压55 notice-board confirmation 看板确认56 nugget 硬块57 o obverse 正面58 open circuit voltage 开路电压59 over charge 过充60 over discharge 过放61 over the thickness 超厚62 p particle 颗粒63 pe membrane pe膜64 pit 坑点65 placing cells into the box 电芯装盒66 point inspection 点检67 preventive measures 预防措施68 pricking the tapes 扎孔69 process inspection 制程检验70 put the battery piled up 将电芯叠放在一起71 q qualified products 合格品72 quality assurance 质量保证73 quality control 质量控制74 quality improvement 质量改进75 quality match 品质配对76 quality planning 质量策划77 r rated capacity 额定容量78 recharge 再充电79 refitting the can of cell 电芯壳口整形80 requirment 要求81 reverse 背面,反面82 rework 返工83 ringing cells into pyrocondensation films 套热缩膜84 s safety vent 安全阀85 sand aperture 砂眼86 scar 疤痕87 secondary battery 二次电池88 select appearance 选外观sharp-set 批锋89 short circuit checking 测短路90 smudginess 污物91 spot welding by laser 激光点焊92 spot welding place 点焊位置93 spraying the code 喷码94 spur 毛刺95 sticking the pvc cover boards 贴面垫96 storing 陈化97 storing with high voltage 高压储存98 t tabs deflection 极耳歪斜99 tabs excursion 极耳错位100 technics requiment 工艺要求101 u ultrasonic welding 超声波焊接102 ultrasonic welding strength 超焊强度103 unqualified products 不合格品104 w wave 波浪105 working procedure 工序Voltage:Units of measuring electrical current, all batteries are rated in volts DC. (Direct Current). This determines how much energy is needed to power your equipment.Voltage plateau:(电压平台)A slow decrease in voltage over a long period of time. As a rule, the plateau extends from the first voltage drop at the start of the discharge to the bend of the curve after which the voltage drops rapidly at the end. Nominal Voltage(标称电压)The voltage of a battery, as specified by the manufacturer, discharging at a specified rate and temperature.Working voltage(工作电压)The working voltage of a cell or battery begins at its electrical connections as soon as an electrical consumer is connected to it.Discharging voltage, average voltage (放电电压)The average discharging voltage is the average value of the discharging voltage during the entire discharging process with a related discharging current.Open circuit voltage (OCV开路电压)The voltage of a battery when there is no current flowing.Closed-Circuit Voltage (CCV闭路电压)The potential or voltage of a battery when it is discharging or charging.State of charge:The rate of charge capacity vs. whole capacity.Initial voltage(起始电压)A battery's initial voltage is the working voltage when discharging begins.End-point voltage (End voltage, Cutoff voltage, Final voltage)截止电压Specified closed circuit voltage at which a service output test is terminated.End-of-discharge voltageThe battery voltage when discharge is terminated.End-of-charge voltageThe battery voltage when charge is terminated.Cutoff voltage (V)The battery voltage at which charge or discharge is terminated.1.Self Discharge 自放电2.Uniformity of the Li-ion Batteries 锂离子电池的一致性3.steel strap 钢带4.Burst vent 防爆阀5.Filling port 注液孔6.spirally wound type cylindrical wound type 圆柱形7.foil 箔8.parallel-plate prismatic design 方形叠片式设计Ageing (老化)- Permanent loss of capacity with frequent use orthe passage of time due to unwanted irreversible chemical reactions in the cell.Anode(阳极)- The electrode in an electrochemical cell where oxidation takes place, releasing electrons. During discharge the negative electrode of the cell is the anode.During charge the situation reverses and the positive electrode of the cell is the anode.Cathode(阴极)- The electrode in an electrochemical cell where reduction takes place, gaining electrons. During discharge the positive electrode of the cell is the cathode. During charge the situation reverses andthe negative electrode of the cell is the cathode.Cycle (循环)- A single charge and discharge of a battery.Depth of discharge DOD (放电深度)- The ratio of the quantity of electricity or charge removed from a cell on discharge to its rated capacity.Internal impedance(交流内阻)- Resistance to the flow of AC current within a cell. It takes into account the capacitive effect of the plates forming the electrodes.Internal resistance (直流内阻)- Resistance to the flow of DC electric current within a cell,causing a voltage drop across the cell in closed circuit proportional to the current drain from the cell.A low internal impedance is usually required for a high rate cell.。

锂电池安全操作指南1. 简介锂电池作为一种高效、环保的能源存储设备,广泛应用于便携式电子设备、电动工具、电动汽车等领域。

为确保锂电池的安全使用,减少意外事故的发生,本文档提供了详细的安全操作指南。

2. 锂电池特性2.1 优点- 高能量密度:锂电池具有较高的能量密度,可满足各类设备的能源需求。

- 长寿命:锂电池具有较长的循环寿命,降低了更换电池的频率。

- 低自放电率:锂电池的自放电率较低,有利于延长存储时间。

- 环保:锂电池不含铅、镉等有害物质,对环境友好。

2.2 缺点- 安全性:锂电池在过充、过放、短路等极端条件下可能发生热失控,导致火灾或爆炸。

- 温度敏感性:锂电池在高温或低温环境下,性能可能受到影响。

3. 安全操作规范3.1 存储1. 存放环境:应选择干燥、通风、避光的环境进行存储。

2. 温度范围:建议在-20℃至45℃的温度范围内存放锂电池。

3. 避免静电:存放时应避免与带有静电的物体接触。

3.2 充电1. 使用正规充电器:使用与锂电池兼容的、具有过充、过放、短路保护功能的充电器。

2. 充电环境:建议在干燥、通风的环境中进行充电。

3. 避免过充:充电时应控制在 0%-100% 的充电范围内,避免长时间充电。

4. 充电时间:避免在电池充满后继续充电,以防止过充。

3.3 使用1. 正确连接:确保电池与设备正确连接,避免反向插入。

2. 避免过放:使用过程中,应避免电池电量低于 20%。

3. 避免高温:避免将锂电池暴露在高温环境下,以免影响性能。

4. 避免短路:避免将电池短路、拆解或改装,以免引发安全事故。

3.4 运输1. 包装:确保电池在运输过程中处于稳定、固定的状态。

2. 标识:将锂电池作为危险品进行标识,遵守相关运输规定。

3. 避免碰撞:避免在运输过程中发生剧烈碰撞或震动。

4. 故障处理1. 若电池出现鼓包、变形、渗液等异常现象,应立即停止使用。

2. 若电池发生燃烧或爆炸,请迅速采取灭火措施,并拨打紧急电话求助。

锂离子电池英文资料锂离子电池技术英文词句2.3 assembly line process(5/15)流水线工艺film loading-vacuum on-film folding-sliding jig backward-top cutting-sliding jig forward-vacuum off-film unloading放上包装膜—抽真空—包装膜折叠-分切夹心的后端-剪掉顶部-分切夹心的前段-释放真空-拿下包装膜station 岗位two station 两个岗位folding 折叠guide type 指导方式top cutting 顶部剪切knife 刀片2.3 assembly line process(6/15)流水线工艺j/r loading-vacuum on-j/r jig backward-bottom former up-upper former down-放极组-抽真空-极组夹具放在后端-模板末端在上面-顶端在下面- heating forming-former up,down-j/r jig forward-vacuum off-j/r unloading加热模板-模板上下翻转-极组夹具朝前-释放真空-取下极组station two station岗位两个岗位heating forming pressing time,preset timer加热模板施压时间施压次数temperature thermocouple温度热电耦time:mmin,2~max.3sec时间:press force :40~50kg压力temperature:150℃温度2.3 assembly line process(7/15)流水线工艺film loading-fim clamp-sliding jig backward-edge pushing-tab clamp-tab unclamp-放上包装膜-包装夹具-分切极组末端-整边-放极耳夹具-卸下极耳夹具sliding jig forward-cell unloading分切极耳前端station two stationheat sealing top热封sealing thickness control(micrometer)热封厚度控制(毫米)sealing control pressing time,preset timer热封控制施压时间施压次数precision regulator精度校准temperature, thermocouple温度热电耦time :min.2~max.3sec时间press force:250kg压力temperature:180~250℃温度2.3 assembly line process(9/15)流水线工艺cell loading-vacuum on-sliding jig backward-side cutting-feeding-tab cutting-放上电芯-抽真空-滑动夹心后端-裁边-流入下工序-剪极耳sliding jig forward-cacuum off-cell unloaing滑动夹心前端-释放真空-取下电芯station two stationside cutting knifeside cutting force 100kgtab cutting knifetab cutting force 100kg2.3 assembly line process(10/15)流水线工艺cell loading-sliding jig backward-vacuum pad down-open-needle down-e/l filling(e/l-needle up-needle up-vacuum pad up-sliding jig forward-cell unloadingstation two statione/l supply 3kuter sub-tank on equipmentmetering pump hi -bar pump,hbd-2bc-17accuracy; under 3.0;±0.1gocer 3.0; ±3.5g2.3 assembly line process(11/15)流水线工艺cell loading-sliding jig backward-jig backward-jig up-vacuum(vacuum chamber)-放上电芯-滑动夹心后端-夹心向后-再向上-抽真空-sealing block forward-sealing热封前端- 密封--sealing block backward-jig down-silding jig forward-cell loading-formation热封后端- 夹心翻转向下-滑动夹心前端-取下电芯-成型station two stationvacuum source 740mmhg max.vacuum pumpsealing control pressing time preset tiomerpressing force, precision regulatortemperature, thermocouple热电偶time:min.3~max4secpress force:250kgtemperatrure:180~250℃2.3 assembly line process(12/15)流水线工艺cell loading-conveyor drive-numbering-numbering-head down-vacuum on-放上电芯- 启动传送带- 编号码-编号码-电芯朝下-抽真空head up-head forwward-head down-vacuum purge-head up-cell unloading电芯朝上- 电芯朝前- 电芯朝下-真空净化- 电芯朝上-取下电芯speed controller motor 25Wnumbering ink jet printercell unloading magacine2.3 assembly line process(13/15)流水线工艺piercing-cell loading-sliding jig backward-jig up-vacuum°assing-穿透??- 放电芯-滑动夹心后端-夹心向上- 抽真空&脱气sealing block forward-sealing-sealing block backward-jig down-sliding jig forward-cell loading热封前端- 热封–热封后端-滑动夹心前端–取电芯station two stationpiercing ∮6holevacuum source 750mmhg max.vacuum pumpsealing comtrol pressing time ,preset timerpressing force,preision regulator调整压力temperature,thermocouple(温度热电偶)time: min.3~max.4sec时间press force:250kg(压力)temperature:180~250℃(温度)2.3 assembly line process(14/15)流水线工艺cell loading-vacuum on-sliding jig backward-cutter down-cutting-cutter up-放电芯-抽真空-滑动夹心后端-切割刀具向下-切割-切割刀具向上sliding jig forward-vacuum off-cell loading滑动夹心前端- 释放真空-取下电芯电池封口--cutting(切断) knife(刀)2.3 assembly line process(15/15)流水线工艺cell loading-ist folding-2nd folding-heat pressing-3nd folding-4th folding(sicing)放电芯- 第一次折叠-第二次折叠-热压-第三次折叠-第四次折叠cell unloading取下电芯manual-loading-2st foliding-heat pressing-3nd folding-4th folding手工–放上- 第二次折叠- 热压- 第三次折叠- 第四次折叠cell transfer linear transferfolding actuator pneumatic actuatorheat pressing pressing time,preset timerpressing forceprecision regulatortemperature, thermocoupletime:min.2~max.3 secpress force:40kgtemperatrure:80~100℃2.3 assembly line process(1/6)流水线工艺jelly roll supply-jelly roll loading-cell alignment-tab straightening-提供极组-放上极组-电芯排列好-将极耳伸直sealant sealing(sealant film supply)-sealant sealing(sealant film supply)-final sealing- 密封胶密封(密封膜供给)-密封胶密封(密封膜供给)-最终的密封sealant film check-tab forming-jelly roll unloading(ng unloading)检验密封膜-极耳成型-取下极组2.3 assembly line process(2/6)流水线工艺al-foil supply-pre heating(contact)-pouch forming---pouch punch out-—供应箔(铝塑膜)-预热(连接)-成型成袋状- 袋状膜冲压打孔pouch loading(pouch pin hole check)-pouch loading-ist folding-lst folding-2nd folding- 放上袋状膜(检验针孔)-放上袋状膜- 第一次折叠-第二次折叠top cutting(ng unloading)-jelly roll insertion(jelly roll alignment-jelly roll loading)—剪掉顶部—插入极组(调整极组-放上极组)3nd folding-pre heat sealing-package unloading第三次折叠-预热密封—取下包好的电芯2.3 assembly line process(3/6)流水线工艺cell loading-lst top sealing--2nd top sealing-top cooling-side sealing-side cooling-放上电芯-第一次顶部密封-第二次顶部密封-顶部冷却—封边—两边冷却side cutting-short check-cell unloading-ng unloading裁边- 测短路—取下电芯—ng是什么啊package loading-pre weighing-package opening-e/l filling(e/l dispensing e/l supply tank) 放上包装好的电芯—预称重—打开电芯--- 注液(分配电解液电解液供给罐)--lst vacuum-2nd vacuum --lst sealing-2nd sealing-plst-weighing-package unloading-第一次抽真空---第二次真空---第一次密封---第二次密封------称重---取下电芯package loading-package aging--formation 放上电芯---电芯老化-----化成cell loader-cell-loading-piercing-vacuum°assing heat sealing-2nd sealing-装电芯设备-电芯-装上电芯—穿透(??)-抽真空& 脱气热封—第二次密封side trimming-cell unloading修边--- 取下电芯cell loading-lst folding-2nd folding-3rd folding-4th folding-5th folding(sizing)-放电芯---第一次折叠---第二次折叠---第三次折叠---第四次折叠---第五次折叠(量尺寸)5th folding(sizing)-tab cutting-height&vision check-final weighging-final weighting- 第五次折叠(量尺寸)---剪极耳---检验高度&视觉---最后称重ng rejection-cell unloading-cell unloading-cell palleticing挑选,排除---取下电芯--- (用托盘)搬运电芯1.1 assembly line specification –products流水线特殊产品can type(壳体类型) aluminum can(A3003) 铝壳(材质A3003)conventional prismatic type ,not oval type 传统的方型,不是椭圆型model of cell电池型号basic design model:xx-yy—zz基本设计型号:XX-YY-ZZ range 范围w:30~34mm t:4.0 ~10mm h:40~67mm宽:厚:高:cathode tab正极耳AL,t0.08~0.12mm,w3/4mm铝带,厚度0.08~0.12mm宽度3/4mm welding to top cap with ultrasonic welder 用超声波焊接机超焊在极片头部anode tab负极耳ni,t0.08~0.12mm,w3/4mm镍带,厚度0.08~0.12mm宽度3/4mm welding to top cap with resistance spot welder用阻抗点焊机焊在极片头部can seam welding壳盖的缝隙焊接side welding侧面焊接top insulator 顶部绝缘片injection molded注液模具bottom tape wrapping底部贴胶纸pp-tape,same as j/r wrapping tape, roll,w:28~32mmt:0.05~0.10mm o.d:200mm core id:3inchesfor xx30zz width 28mm,for xx34zz width 32mmfill port welding 补焊砂眼AL Ball (Al050,∮1.37±0.03mm),laser seam welding 激光焊接e/l filling accuracy 精确注液量under 3.0g; ±0.1gover 3.0g ±3.5g r/l filling volume:1~7g 注液量范围1~7gmodel change exchange tool,jig, carrier&tray搬运工具,夹具,搬运盒&托盘option:only carrier&tray (others:sutomatically adiusted其它:适当调整)tray托盘jr极组(256pcs),can壳(300pcs),cap盖帽(100pcs),(rivet) all trays are prepared user1.2 assembly line specification –equipment流水线特殊设备line tact time 流水线标准工时 2.0(30ppm)Drive mechanism 发动装置cam,ac servo drive&air actuatorelectrical power 电源286kva,3p-380v±10%,50hz±1hzpneumatic source 气源13300l/min,0.6mpa (include welding jig cooling包括焊接模具冷却)nitrogen gas 氮气285 l/min, 0.6mpa(for laser welding shield gas激光焊接防护气)laser cooling water激光焊冷却水320 l/min,below25℃fume collector 烟、气收集罐400cfm,explosion-proof type for al-fume,outdoor typefume suction main piping 抽气主管道系统 4 inchexhaust piping排气管道系统5inchdry air piping干燥气管道系统5inchdry chamber(total) 干燥室20.78m3total weight总重量14.8ton(approx大概),(not include laser welder不包括激光焊接机)floor load 场地负荷1500kg/m2dry room height干燥室高度2500mm(min)can seam welding壳盖的缝隙焊接side welding侧面焊接,welding speed 焊接速率10~15mm/sec.(approx) cartesian robot stageelectrolyte filling process注电解液工序40station-80 jig index unit,vacuum真空&pressurize加压elctrolyte filling range注液范围depend on internal dead space of cell design根据电池设计内部的绝对空间hbd-2bc series of hibar pum, japan hibarleak check 测漏differential pressure check system,100pa max.不同压力测试系统,最大为100pa accuracy:+/-0.5%精确度need test actual work 需要通过实际操作测量2.1 assembly parts name&compositionball-top cap assembly盖板流水线(t/c)--top insulator顶部绝缘片(t/l)-cathode正极耳(al-tab铝带)-anode负极耳(ni-tab镍带)- bottom tape底部胶纸(b/t)-jelly roll极芯(j/r)-aluminum can铝壳2.2 assembly process basic specification装配过程概述3.1 prismatic lib assembly processbottom tape底部胶纸-jelly roll insertion极芯入壳-top insulator顶部绝缘片-tab forming极耳修整-top-cap welding顶部极耳焊接-top cap folding极耳折叠-top cap setting卡极耳-seam welding焊缝焊接-leak check测漏-electrolyte filling注液- ball insertion压钢珠-fill port welding补焊砂眼()3.2 assembly line process(1/8)can supply供应壳non dust paper tray无尘的纸盘can tray size装壳的盘子尺寸270*212*22/32htray capacity盘子容量423048-450can/tray343450-496can/tray(suppiled by user)stack volume堆叠范围48/50h:8tray65/67h:6traycan supply供应壳体-can loading放上壳体-can check检验壳体-jelly roll loading放上极芯(ng reject-bottomtape check检验底部胶纸-bottom tape wrapping贴底部胶纸-jelly roll supply供应极芯-from winder从卷绕机)-jelly roll centering 极芯放在正中央-jelly roll insertion插入极芯-insertion height check检验极芯入壳高度-ng rejectj/r supply 极芯供应tray from winder来自卷绕机的盘子j/r tray size放极芯盘子的尺寸540*540*50hj/r capacity 容纳极芯的数量48/50h:40*8=320/tray65/67h:40*6=240/tray supplied by userstack volume堆叠范围8 traytray handling盘子搬运using manual cart用手推车bottom tape底部胶纸pp tape,rollcore size标准尺寸 3 inch paper coreb/t color 底部胶纸颜色blue or green兰色或绿色b/t check 检验底部胶纸color sensor颜色传感器3.2 assembly line process(2/8)tab straightening拉直极耳—tab position check检查极耳位置—top insulator insertion插入绝缘片(t/I escapement镊子??—top insulator supply供应绝缘片)—T/I presence check检查绝缘片—tab forming极耳修整—j/r final insertion极芯入壳—t/c welding 盖板焊接(ni tab镍带)—(t/c direction check检查盖板方向—top cap supply盖板供应)—al tab welding铝带超焊—cap/tab welding check检验焊接是否牢固—tab folding极耳折叠—t/csetting&check固定、检验盖板—ng rejecttop cap supply盖板供应tray from cap ass’y m/ccap tray size 装盖板盘子的尺寸340*240*18hcap capacity能装盖板的数量18*6=108 cap/traystack volume 堆叠范围24 tray(2592 cap)j/r final insertion极芯入壳include j/r insertion height check 包括检验极芯入壳高度ni-tab welding焊接镍带resistance spot welding,2points阻抗点焊机,2点include welding current monitor包括焊接电流监控器al-tab welding铝带超焊ultrasonic welding超声波焊接40khx/800w/branson brandtop insulator顶部绝缘片pull check拉力测试cap height check盖板高度检验t/c setting check 检验盖板牢固性setting height check检验固定的高度3.2 assembly line process(3/8)height check#1高度检验1#—pre spot welding预点焊—height check#2高度检验2#—ng reject排除不合格品??—seam welding#1焊缝焊接1#—seam welding#2焊缝焊接2#—seam welding#3焊缝焊接3#—seam welding#4焊缝焊接4# (jig cooling模具冷却)—short check 测短路—ng reject排除不合格品pre spot welding预点焊laser spot welder激光点焊机,3-points 50w/2-fiber,1system(supplied by user)height check#1 高度检验1# check the top cap setting height 检查盖板固定的高度height check#2 高度检验2# check the top cap welded height 检查盖板焊接高度seam welding缝隙焊接laser welder激光焊接机,10~15mm/sec,700w/2-fiber,4systemsrequire speed down for 34xxyy 对于34xxyy需减速models (prevent against overheat预防过热)supplied by user jig cooling 模具冷却vortex tube,using compressed air热交换管道,采用压缩气体air pressure 0.65mpa (minimum)气压shield gas supply保护气供应nitrogen gas,0.65mpa18/min氮气with digital flow meter数显流动仪表fume collector烟气收集罐400 cfm,1.5kw,amanl/japanexplosion proof,outdoor type户外气体排放装置short check测短路lcr meter3.2 assembly line process(4/8)vacuum out释放真空—equilibrium平衡状态—leak detection 测漏—vent排除气体—ng reject排除不合格品leak check procedure 测漏程序atmosphere气体—vacuum抽真空—equilibrium平衡状态—detection测漏—leaked cell漏气电芯—normal cell 正常电芯leak check测漏differential pressure,100pa max.. 不同压力测试系统,最大为100pavacuum out-100kpa max.释放真空leak detection time 8.0sec.max.测漏时间using master cell采用好的电芯accuracy:+-0.5%精确度cell handling搬运电芯8 cells,simultaneously check 8只电芯,同时检查3.2 assembly line process(5/8)pre weighing预称重—cell loading放上电芯—e/l dispensing 电解液分配—vacuum/vent抽真空/排气—vacuum 抽真空—pressurize加压—vent排气—cell unloading取下电芯—post weighting快速称重—ng rejectelectrolyte supply供应电解液drum桶,200 literusing nitrogen gas使用氮气, 0.02~0.04mpasub-tank in equipment装置内的储槽,3 litermetering pump 抽吸仪表hibar pump,japan hibarhbd-2bc series*2vacuum抽真空-700mmhg,(max.-740mmhg)suction capacity抽吸泵容量310/min.r5c 0040e*02,busch/germany德国??Pressurize加压nitrogen gas氮气,0.15~0.2mpaWeighing称重load-cell,6digits,nmb/japan日本Display显示;000.00gnozzle cleaning 清洗喷嘴nitrogen gas blow out用氮气吹,0.15~0.2mpafor blow out the remained e/l 把剩余的电解液吹出来process time 工序工时128sec (max)filling accuracy 注液精确度under 3.0g;±0.1g 小于3.0g,±0.1g over 3.0g; ±3.5% 大于3.0g; ±3.5%3.2 assembly line process(8/8),al ball typecleaning paper supply供应纸巾-cap face cleaning清洁盖帽表面-cleaning paper supply供应纸巾-cap face wet cleaning盖帽表面除湿-solvent dispenser溶剂给料器-fill port cleaning清洁注液孔-cleaning paper supply供应纸巾-ball insertion钢珠插入-ball supply钢珠供应-ball press压钢珠-ball height check检验压钢珠的高度--ball seam welding钢珠缝隙焊接-welding check焊接检验-uv glue dispensing UV胶水给料-ng reject-uv curing紫外光固化-cell unloading取下电芯cleaning paper清洁纸巾non-dust paper,roll,width 14mm无尘纸巾,卷,14mm宽3 inch paper coreballsupply钢珠供应bowl feeder钢珠进料器requies testing by the actual sample目前测试样版ball press force压力35~40kgfseam welding定位焊接方法laser seam welder,6.5mm/sec激光焊接工作350w/-fiber,1 system焊接系统(supplied by user)适当调整6.1 model change time 型号变化时间manual conversion type 46-30-48 vs 46-30-xx:6 hours approx.(only different'heieght)xx-xx-xx vs yy-yy-yy:3days6.2 delivery交货manual conversion type 7months to shipping,after l/c open6.3 customer scope 客户范围primary main power wiring to control panel of the each equipment,with main power panel.主要的电源线控制每一个设备的主电路板Primary main pneumatic piping to beside the each equipment, with main air-filter unit.主要的气管道系统装在每个设备的旁边,主要的气体过滤器Primary main nitrogen gas piping to beside the each equipment, with main gas -line filter unit.主要的氮气管道系统装在每个设备的旁边,主要的气体过滤器/All duct piping for suction &exhaust from equipment's inlet/outlet to main duct.所以用于从设备上的进口/出口抽气或排气的输送管道Installation &piping/wiring/wiring for fume collector(outdoor type)给烟气收集器(户外类型)安装管道系统/配线系统Inlet/drain water piping of the washing machine,with waterstrainer.清洗设备的进水/排水管道,水过滤器Laser welding system &laser welder welder import/export fee激光焊接系统&激光输入/输出Cooling water piping for each laser system,below 25℃.(it requires a water filter (strainer)用于激光系统的冷却水,25℃以下(需要一个水过滤器)Cooler or chiller for laser cooling water.激光冷却水的冷却器Dry pneumatic piping for laser shutter operation to each laser system.用于每一个激光系统的激光开关操作的干燥气管道Installation&wiring/cabling for laser fiber and laser control cable.给激光光纤和激光控制电缆安装配线/电缆Installation &wiring/cabling for laser control pendant.给激光控制的悬吊物安装配线/电缆6.4 laser system location outdoor of the dry room. It requires air-conditioning or sufficient ventilation.激光系统位于干燥间的外面。

REGULATIONSCOMMISSION REGULATION (EU) No 1103/2010of 29 November 2010establishing, pursuant to Directive 2006/66/EC of the European Parliament and of the Council, rules as regards capacity labelling of portable secondary (rechargeable) and automotive batteries and accumulators(Text with EEA relevance)法规欧盟委员会法规第1103/2010号于2010年11月29日根据欧盟议会和理事会第2006/66/EC号指令,建立可携带二次电池(可充电)和汽车电池与蓄电池的容量标签的法规THE EUROPEAN COMMISSION,Having regard to the Treaty on the Functioning of the European Union, Having regard to Directive 2006/66/EC of the European Parliament and of the Council of 6 September 2006 on batteries and accumulators and waste batteries and accumulators and repealing Directive 91/157/EEC ( 1 ), and in particular Article 21(2) and 21(7) thereof,欧盟理事会考虑到欧盟运作的协定考虑到欧盟议会和理事会于2006年9月6日颁布的2006/66/EC号关于电池和蓄电池、废弃电池及蓄电池以及废止91/157/EEC的指令,尤其是第21(2)和21(7)条款。

编写说明

针对可充电锂电池和电池系统在民用航空器上应用的增多,2015年6月,民航局发布了CTSOT79a《永久安装的可充电锂电池、电池组和电池系统》。

CTSO-179a主要参考了RTCAD0-311《可充电锂蓄电池和电池系统最低性能标准》(2008年3月13日发布)中第2节和第3节的最低性能标准和资料要求。

随着对航空锂电池用应用的增加和对其安全性认知的深入,RTCA于2017年12月19日发布D0-31IA《可充电锂蓄电池和电池系统最低运行性能标准》,用以替代上述D0-311标准。

RTCAD0-311A所适用的电池产品更加广泛,内容也更加完备和详尽,并将对设备的技术要求和具体测试方法分开来单独阐述。

最显著的是,RTCADO-31IA新增了一系列安全性要求和测试方法,此外环境性能测试内容也有了较大调整。

为更好支持航空可充电锂电池和电池系统发展,确保民用航空安全,我司启动了CTSOT79a修订工作。

修订后的标准编号为CTSOT79b,名称更改为《可充电锂电池和电池系统》。

CTSO-179b 主要参考了RTCAD0-311A《可充电锂蓄电

池和电池系统最低运行性能标准》中第1节和第2节中的最低性能标准和资料要求,

两个版本的标准内容差别参见表1对比说明。

乘务人员DGR单项选择题(26)1、按法规规定,乘务人员应在前一次培训后多长时间内进行复训?BA.12个日历月B.24个日历月C.36个日历月D.48个日历月2、国际航协(IATA)出版的危险品运输文件是:BA.《TI》(技术细则) B.《DGR》(危险品规则)C.公司《危险品手册》 D.《TI》(技术细则);《DGR》(危险品规则);公司《危险品手册》都是3、民航总局《中国民用航空危险品运输管理规定》(CCAR—276)生效的时间为:AA.2004年9月1日B.2005年9月1日C.2005年3月31日D.2004年7月12日4、下列哪项物品在航空运输中不属于第三类易燃液体危险品:AA.4度的啤酒B.油漆C.香水D.72度的白酒5、每位旅客用来包装易腐物品所需的干冰数量最多不超过____KG,并且该种包装能使二氧化碳气体得以释放时,不受客舱行李运输规定的限制。

DA.1 B.2 C.1.5 D.2.56、下面哪种爆炸品可由客机承运?BA、1.1AB、1.4SC、1.4FD、1.6S7、如果人或衣服上粘上泄漏的危险品,可以AA用大量的水冲洗身体B抽支烟缓解紧张的情绪C喝大量的水D将衣物脱掉,扔弃8、一名旅客可以随身携带几个750ml的发胶罐?DA.1个B.2个C.4个D.不可以携带9、经承运人同意,仅作为手提行李运输的危险品有?AA.官方机构代表携带的水银气压计B.烟花爆炸物C.电动轮椅D.保密型设备10、第一类爆炸品分为几个项别和几个配装组?BA.4 ;13 B.6;13 C.5;13 D.4;1411、《DGR》(危险品规则)几年更新一次?AA.1年B.2年C.3年D.4年12、《TI》(技术细则)几年更新一次? BA.1年B.2年C.3年D.4年13、航空公司承运危险品必须取得?BA.航空公司同意 B.民航局危险品运输许可C.机场许可D.特殊物品运输许可14、《DGR》(危险品规则)将危险品分成()个不同的类别(CLASS)。

低温电池注意事项-低温锂电池安全守则-超低温锂电池中英文说明书Lithium-Ion rechargeable batteries subject to abusive conditions can cause damage to the cell and/or personal injury. Please read and observe the standard cell precautions below before using utilization.滥用锂离子充电电芯可能会造成电芯的损害或人身的伤害,在使用锂离子充电电芯以前,请仔细阅读以下的。

安全守则:Note 1:The customer is required to contact HUANAI in advance, if and when the customer needs other applications or operating conditions than those described in this document.注释1:如果客户需要将电池在该文件之外的条件下操作或应用,请先咨询华耐公司相关事宜。

Note 2:HUANAI will take no responsibility for any accident when the lithium ion battery is used under other conditions than those described in this Document.注释2:在该文件说明的条件之外使用该电芯而产生的事故,华耐公司不承担任何责任。

11.1 Standard lithium ion battery Precaution 电池防范措施a)Do not expose the lithium ion battery to extreme heat or flame.不要将电池暴露在极热或有火星的环境中.b)Do not short circuit, over-charge or over-discharge the lithium ion battery.不要将电池短路,过充或过放。

业务相关知识点(1)DGR(危品规则)引言1.DGR(Dangerous Goods Regulations )是由IATA(国际航空协会)委员会制定的, 旨在向托运人和运营人在所有航空运输方面安全地空运具有危险性物质和制品提供各种程序,并附加了操作要求,为安全有效地接受和运输危品提供了统一和谐的秩序。

联合国专家委员会制定了除放射性物质以外的各类危险品运输的推荐程序;国际原子能机构(IAEA)制定放射性物质安全运输的推荐程序;国际民航组织(ICAO)在这些建议的基础上制定了危险品航空安全运输规则,该规则编入了《国际民用航空公约》的“危险品安全航空运输技术细则”;IATA(DGR)包括了《技术细则》的所有要求,并增加了比《技术细则》更具约束力的规定要求。

第一章适用性2.托运人具体责任:(c)必须依据本规则之规定对运输的物品或物质正确地进行识别,分类,包装,加标记,贴标签,备好文件,并符合本规则的航空运输条件。

1.3.4 托运人应保证至少一份与空运危品相对应的文件(申报单)保留至少3个月。

3.运营人责任:收运;存储;检查;提供信息,包括应急反应信息;报告;保存记录;培训第二章限制4. 2.2 隐含危品:汽车及部件:安全气囊,电瓶,等含爆炸,磁性物质,湿电池野营用具:易燃气体,易燃液体牙科器械:易燃固体(树脂或溶剂),放射性物质(X光机)潜水设备:含压缩气体的钢瓶电器:含磁性物质家庭用品,修理箱:易燃液体(油漆,气溶胶),清洗剂(腐蚀性物质)医疗用品及药品:氧化剂,有机过氧化物,毒性或腐蚀性物质工具箱:含爆炸(射钉枪),压缩气体,易燃气体,油漆,腐蚀性物质疫苗:含固体二氧化碳诊断标本:传染性物质5. 2.6 例外数量危品包装数量极少的危险品,标记Figure 2.6.B6. 2.8.1 国家差异2.8.3 承运人差异第三章分类7. 第一类爆炸品1.1;1.2;1.3;1.4;1.5;1.6第二类2.1 易燃气体(RFG)2.2 非易燃无毒气体(RNG 或RCL)2.3 毒性气体(RPG)第三类易燃液体(RFL)第四类4.1 易燃固体(RFS)4.2 易自然物质(RSC)4.3 遇水释放易燃物质(RFW)第五类5.1 氧化剂(ROX)5.2 有机过氧化物(ROP)第六类6.1 毒性物质(RPB)6.2传染性物质(RIS)第七类放射性物质白色I级(RRW); 黄色II,III级(RRY)裂变物质第八类腐蚀性物质(RCM)第九类杂项(RMD): ICE:干冰;RLI: 锂离子电池RLM: 锂金属电池第四章识别8.* 4.2 表A栏:UN编号;ID8000(B栏:运输专用名称(Proper Shipping Name)*指附加技术或化学名称C栏:类别,项别栏(3,7,8,9类只有类别,没有项别)D栏:危险性标签栏, 有些含次要危险标签E栏:包装等级栏:I,II,III; 有些空着如UN1950;有些同时具有三个等级,如UN1133 F栏:例外数量栏:EO,E1,E2,E3,E4,E5; 见2.6.A表;有些是空着的,说明不允许该危品以例外数量运输;G-J栏:客货机运输对数量的规定G,H栏是客货机对限制数量危品(Ltd Qty)的数量规定G (Pkg Inst): 包装细则(Y…可查具体规定)H(Max Qty/Pkg): 外包装件允许的最大净重I, J栏适用于非限制数量的其它一切危品I栏(Pkg Inst): 包装细则(后有具体规定)J栏(Max Qty/Pkg):联合国规格包装,外包装允许的最大净重K-L栏:货机运输对数量的规定K栏(Pkg Inst): 包装细则(后有具体规定)L栏(Max Qty/Pkg):联合国规格包装,外包装允许的最大净重No Limit 不限量如UN3166M栏: 特殊规定栏(S。

附录B:锂电池操作标签(中英文)

警告!

如果破损

锂电池种类:

不得装载或运输破损的包装件

应急电话:

中文标签

注:

1、标签的边必须有红色斜阴影线,符号和文字使用与背景形成鲜明

对比的黑色。

2、如果标签和包装材料的颜色对比足够明显,锂电池操作标签也可

以直接印刷在外包装上。

3、标签的最小尺寸应为120毫米×110毫米。

4、标签上须按要求填写锂电池的种类和应急电话;

5、对于锂电池安装在设备中运输的情况,当单个包装件中不超过四

个电池芯或二个电池时,可不贴此标签。

英文标签。