均质机中文说明书

- 格式:pdf

- 大小:1005.32 KB

- 文档页数:162

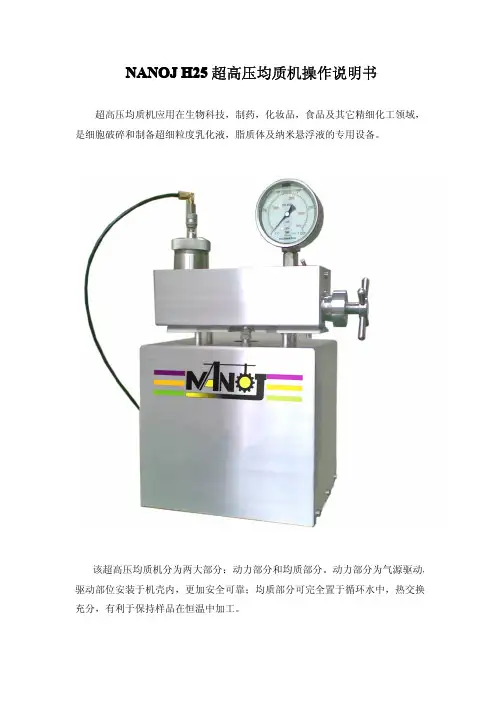

高剪切均质机说明书一、摘要均质机主要用于生物技术领域的组织分散、医药领域的样品准备、食品工业的酶处理, ,食品中农药残留以及兽药残留检测以及在制药工业、化妆品工业、油漆工业和石油化工等方面。

均质机采用不锈钢系统,可有效的分离护体样品表面和被包含在内的微生物均一样品,样品装在一次性无菌均质袋中,不与仪器接触,满足快速、结果准确、重复性好的要求。

目前,高剪切均质机主要具备结构紧凑、操作简便、性能稳定可靠、均质效果显著等优点。

为了更好的满足实际工作要求,设计者们还应努力尝试设计出能应对多种介质、实现最大自动化生产的机械设备。

近年来出现各种功能独特的食品机械,在这方面我国与国外先进水平的差距确实存在,但是正在不断缩小。

国内在设计制造特种食品机械的过程中也积累了大量的实际经验。

本次毕业设计是关于高剪切均质机的设计。

首先对高剪切均质机作了简单的概述;接着分析了各部分元件、零件的选型原则及计算方法;然后根据这些设计准则与计算选型方法按照给定参数要求进行选型设计;接着对所选择的各主要零部件进行了校核。

本次设计主要由动力输出电机、联轴器、主轴、筒体、均质轮、端盖、轴承、密封件、紧固件、底座等部件组成。

最后简单的说明了安装与维护。

本次设计代表了设计的一般过程, 难免存在各种纰漏、失误。

权当一次难得的实践过程,希望对今后的选型设计工作有一定的参考和借鉴价值。

关键词:高剪切均质机;选型设计;主要部件;养护维修。

二、AbstractHomogeneous machine is mainly used for decentralized organization in the field ofbiotechnology and medical field sample preparation, food industry of enzyme treatment, food pesticide residues and detection of veterinary drug residues as well as in the pharmaceutical industry, cosmetics industry, paint industry, petrochemical industry, etc.. Homogeneous machine uses the stainless steel system, which can effectively separation barrier on the surface of the sample and is contained, microbe homogenous samples, samples were packed indisposable sterile homogeneous bag, and instrument contact meet the requirements of fast, accurate and reproducible.At present, the high shear homogenization machine has the advantages of compact structure,simple operation, stable and reliable performance, and homogeneous effect. In order to better meet the actual work requirements, designers should alsotry to design can deal with a variety of media, to achieve maximum automated production machinery and equipment. In recent years, a variety of features unique food machinery, the gap between China and foreign advanced level do exist in this area, but is shrinking. Domestic design and manufacturing of special food machinery in the process has accumulated a lot of practical experience.This graduation design is about the design of high shear homogeneous machine. First of highshearing homogenizer made brief overview; followed by analysis of the components and parts selection principles and calculation methods; then calculated based on these design criteria and selection method in accordance with the given parameters requires selection of design; then to choose the main parts are checked. This design is mainly composed of the power output of the motor, the shaft coupling, the main shaft, the cylinder body, the homogeneous wheel, end cover, bearings, seals, fasteners, base etc. parts. Finally, simply explain the installation and maintenance.This design represents the general design process, there are many flaws, mistakes. Rightwhen a rare practical process, I hope to have a reference value for future design work..Keywords: high shear homogeneous machine; type selection design; main components;maintenance and maintenance.三、目录一、摘要 . ......................................................................... (1)二、Abstract ..................................................................... .. (2)三、目录 . ......................................................................... (3)四、绪论 . ......................................................................... (5)(一)原始参数 . ......................................................................... . (6)(二)设计解决的问题 . ......................................................................... . (6)五、高剪切均质机设计概述 . ......................................................................... . (7)(一)高剪切均质机的工作原理 . ......................................................................... (7)1.动力输出电机 . ......................................................................... (7)2.联轴器 . ......................................................................... (8)3.轴 . ..................................................................... (8)4.筒体 . ......................................................................... . (8)5.均质轮 . ......................................................................... (8)6.端盖 . ......................................................................... . (8)7.轴承 . ......................................................................... . (9)8.密封件 . ......................................................................... (9)9.底座 . ......................................................................... . (9)(二)高剪切均质机的工艺原理 . ......................................................................... (9)六、高剪切均质机的设计计算 . ......................................................................... . (10)(一)已知原始数据及工作条件 . ......................................................................... . (10)(二)初始数据的计算 . ......................................................................... .. (10)1.电动机的确定 . ......................................................................... . (10)2.设备排量的计算 . ......................................................................... (10)3.介质流速的确定 . ......................................................................... (10)4.设备最小通径的计算 . ......................................................................... . (10)5.电机功率初略确定 . ......................................................................... .. (10)6.联轴器的选择 . ......................................................................... . (10)7.主轴轴径初略确定 . ......................................................................... .. (11)8.密封形式的确定 . ......................................................................... (11)9.底座的形式 . ......................................................................... .. (11)(三)具体计算及校核 . ......................................................................... .. (11)1.三相异步电机 . ......................................................................... . (11)2.轴的作用及类型 . ......................................................................... (14)3.轴的计算及校核 . ......................................................................... (18)4.弹性柱销联轴器 . ......................................................................... (23)5.圆锥滚子轴承 . ......................................................................... . (26)6.密封件的选用 . ......................................................................... . (28)7.均质轮的设计计算 . ......................................................................... .. (31)8.筒体的设计 . ......................................................................... .. (33)(四)设备安装、调试与操作 . ......................................................................... .. (34)(五)制动装置 . ......................................................................... .. (34)七、电气及安全保护装置 . ......................................................................... (35)八、结论 . ......................................................................... . (36)九、致谢 . ......................................................................... . (37)十、参考文献 . ......................................................................... .. (38)四、绪论顾名思义,高剪切均质机是在定子和转子相对转动的作用下,在合理狭窄的间隙中形成强烈、往复的液力剪切、摩擦、离心挤压、液流碰撞等综合效应;使物料在容器中循环往复以上工作过程,最终获得产品的机械设备。

无菌均质器的使用说明书均质器技术指标1)无菌均质器电源插头必需插紧到位,显现松动可能影响电脑掌控器造成死机,如显现死机现象,请关闭后侧电源开关,关机3分钟后重新启动。

2)在锤击板工作时请不要任意打开均质器门,以免样品液溢出。

应按开/停建,设备自动停止运行。

当把门关上后,再按开/停建,设备自动完成余下工作。

3)仪器长期不使用应切断电源,拨去插头。

4)均质器门底部为防止均质袋意外分裂,便于清洗溢出物,底部设计为空的,可放置接水盘,所以仪器运转时请勿用手从底部伸入,以免纹伤手指。

5)机器在运转前,请查看均质箱内有无异物,以免工作时发生故障和损伤均质袋。

6)硬块,骨状,冰状物质不宜使用,以免破坏均质袋。

7)无菌均质器和均质袋的存放都应避开阳光的直射,特别是均质袋应存放在无阳光或避开紫外线照射的地方,以免老化。

8)量少时,需加快速度时,均质物纤维韧时,可用后面旋钮调整拍击板与可视窗的间距,来达到更好的均质效果。

仪器故障及排出:(1)在确认箱门关严的条件下仪器不运转时,假如液晶显示屏无任何显示,应检查电源是否正常连接,保险丝是否完好。

(2)无菌均质器运转声音异常,检查各连接螺栓、锤击板有否松动。

长期工作后,若锤击杆、套中润滑干枯时要适时清理并加新的润滑脂JTONE品牌无菌均质器广泛应用于食品微生物分析;动物组织、生物样品、化妆品的均质处理;肉、鱼、蔬菜、水果、饼干;药品的微生物分析等。

固体样品中提取细菌的过程变得操作简单,只需将样品和稀释液加入到无菌的样品袋中,然后将样品袋放入拍打式均质器中即可完成样品的处理。

削减了样品的处理和准备时间,处理后的样品溶液可以直接进行取样和分析,没有样品的变化和交叉污染的不安全。

随着生物医药、石油化工、食品工业等领域的进展,越来越多的运用到均质器。

而试验仪器行业的进展,也为上述行业的试验室供应了多种多样不同功能的均质器。

试验室常用的均质器的原理:将试验样本和溶液或溶剂混合均匀,达到试验所要求的标准溶液。

ATS Engineering Inc.OWNER’S MANUAL AH100DAttention1. To avoid the particles of impurities (such as iron, glass, etc.) into the homogenizer to wear inlet valve and homogenizing valve, every materiel should be filtered by filter screen of 60-100 mu before it is put into homogenizer to homogenized.2. It is forbidden to operate machine long time when there is no material3. Do not turn on homogenizer under handle was tightly, for sudden overload capacity will damage motor.4. AH08-100 homogenizer is designed for production. The machine can work for a long time.5. Solid ceramic plunger used for homogenizer. So the temperature changes of product contact pieces couldn’t over 70℃, or the plunger may rupture. The range of temperature changes shouldn’t over 5℃, especially under cleaning operation.1 The theory of Homogenization1.1 What is homogenizationHomogenization is finished by homogenizing valve and piston which can refine the material occurred in the homogeneous valve and mix them.1.2 The theory of homogenizationMaterial is inhaled through the piston. With the help of the plunger, it can enter the gap. Also, the size of the gap is changing with different pressures. Releasing the pressure, the material eject with the speed of one thousand to one thousand and five hundred meters per second. Three effects produced after the material hit the impact ring which is one of the valve components .Hole effectThe material accumulated high energy after pressed by the plunger. When passing the limiting gap, it can release high energy after the sudden decreasing of pressure. Through it , the material can be smashed and refined .This is called Hole effect.Impact effectWhen passing the limiting gap, the material smashed and refined after hitting the special impact ring.Shear effectThe high speeding material produce strong shearing when crossing the valve chamber channel and limiting gap.1.3 Function diagram of plunger pump1.4 Function diagram of homogeneous valve1.5 Function diagram of two stages homogeneous valves2Introduction of equipment structure2.1Pressure block1- stainless inlet cup 6- inlet pipe2- inlet valve plunger 7- outlet pipe3- outlet valve plunger 8- pressure block4- pressure gauge 9- the first stage valve 5- the second stage valve2.2ceramic plunger1- solid ceramic plunger 2- locknut3- tension ring 4- spacer ring- plunger seal2.3inlet valve1.fixed nut2.fixed plug3.gasket4.o-ring5.spring6.ceramicball7.inlet valveseatPressure block was made of two-phase alloys stainless steel. To ensure equipment work well under high pressure and easily removal and installation. The internal pipe size of pressure block is 12ml. At least 50ml material can be operated circularly with the special feeder.Installation with pressure block:√A solid ceramic plunger, which has smooth surface and high corrosion-resistant that self-lubricating.√Special material of plunger seal. It can be used with no water lubrication.√Unidirectional inlet valve and outlet valve. A valve support was be installed under inlet valve which can be removal. Inlet valve is made of alloys with high hardness STELLITE√A digtal gauge of high precision which adopted sanitary design and with battery.2.4homogeneous valve group1-homogenous valve body2-O-ring3-Inside O-ring4-Outside O-ring5-Mandril O-ring6-Mandril7-HandleA set valve was installed in valve body by rotating handle to push mandril to change pressure. They formed a standard homogenous valve group.2.5homogeneous valveWe supplied two sets of homogeneous valves for AH100D. One set emulsion valve and one set rupture valve.Emulsion valve is formed by one ceramic ball, one stainless collision ring and one tungsten carbide valve seat. Both sides of valve seat can be used, so it can be used for a more time.Emulsion valve usually used for preparation of emulsion, for example, Chemical and pharmaceutical : vitamin emulsion, vein emulsionFood and beverage: essence,juice,vegetable protein beverageDairy products: milk, ice cream, cream, yogurtRupture valve is formed by one impact head, one valve seat and one impact ring. They are made of tungsten carbide.2.6Technical parameters of the equipment Model: AH100DCapacity: 8-15L/HMaximum operating pressure: 1800barStroke of equipment: 98-184 times/min Maximum viscosity: 2000CpMaximum temperature of the product: 90℃Maximum temperature of the steam: 121℃3. Equipment Operation3.1. Check before start1. ATS high-pressured homogenizer is designed to reach very high pressure,therefore, good operational habit can prevent and avoid injuries & harm to device itself.2. In order to use this equipment accurately and safely, operators are asked to make regular and necessary inspection, make sure that the equipment works in ideal condition and prevent any possible problems.Note: Make sure no metal particles in homogenizing or broken material fluid.3. Make sure that bolts on the Flan, different connecting and pressure mass are totally tightened.4. Put up the power line and turn on the main power.5. Check the rotational direction of motor. Make sure that fan rotates in the direction of the arrow.Note: If the direction of motor is not consistent with the direction of the arrow, please adjust the connection on the electric plug.6. Check manifolds assemble correct or not, manifolds washers well or not, if they are correct and well, then you can reconfigure manifolds.7. Make sure that two stages homogenizing valve hand wheels are totallyloosened, but not too loosen.8. Press the switch of pressure gauge and confirm the value is zero.9.Check the ring & piston seal periodically to make it leak-off.3.2 Turn on the equipment1. Add some water into the inlet cup.2. Make sure handle is loose and pressure gauge shows there is no pressure.3. Rotate the switch, and then the equipment can begin to work. According to the required capacity to adjust converter knob slowly, until it reach a appropriate frequency and the discharge is well-distributed and continuous, without abnormal noise.4. When the value of pressure is zero, you can switch off the equipment. Note: If there’s no material fluid discharged from the outlet after you turn on the equipment for 60 seconds, it indicates that air blocking existed in the pressure mass. If so, you should switch off the equipment firstly, turn on the charging valve and divert material fluid into pressure mass, then turn on equipment again3.3 Pressure adjustmentThe second-stage pressureadjustment.Rotate handle clockwise toincrease pressure, and rotatewiddershins to decrease.First-stage adjustmentRotate handle clockwise toincrease pressure, and rotatewiddershins to decrease.Max pressure is 1800bar.Pressure increased:1)Adjust the pressure of second-stage valve: rotate handle widdershins andslowly to increase the pressure to requirement.2)Adjust the pressure of first-stage: rotate handle clockwise and slowly toincrease the pressure to the total pressure.Remarks: it is a normal condition that the noise is increased by the increased pressure.Pressure discharged:1)discharge pressure of the first-stage homogeneous valve: Rotate handlewiddershins and slowly to decrease the pressure to the pressure of the second-stage, then stop rotating.2)Discharge pressure of the second-stage homogeneous valve: Rotate handlewiddershins and slowly until the pressure was decreased to zero, then stop rotating.Attention: stop rotating until the pressure is zero, do not rotate too loose.3.4 Operational procedure1. Put some water into the inlet cup, turn on equipment.2. Adjust the pressure to the requirement.3. Don’t put material into the inlet cup until water flowed to the bottom of the cup.4. At the process of homogenous, operator should pay attention to the material in the inlet cup.5. when finished operating, please discharge material in equipment. Put some water into inlet cup.6. Adjust the pressure to zero, then clean equipment as your requirement.7. Rotate switch widdershins, turn off.3.5 Cleaning1.Put clear water into inlet cup immediately when the operating material is flowing in the bottom of the cup. Then use 60℃water to clean.2.200bar pressure can be used when cleaning the equipment.3.Suited detergent:NaOH : Maximum consistency 3% Max temperature 90℃HNO3 :Maximum consistency 0.5% Max temperature 70℃H3PO4 : Maximum consistency 3% Max temperature 85℃Hot water: Max temperature 95℃Steam : Max temperature 130℃Attention: Detergent is prohibit to include the element of chlorine and iodine.3.6 Sterilization operationAH100D homogenizer was designed to sterilize by pure steam. The maximum temperature of the pure steam is 121℃. The longest time of sterilization is 30min. The highest pressure of sterilization is 3.8bar.1.Open the inlet clamp, remove the inlet cup.2.Steam producer and inlet flange is connected by clamp.3.Time of sterilization should not over 30min. Do not turn on equipment onthe process of sterilization.4.Nature cooling after sterilization. Do not cooling by cool water.5.Disconnect the connection of inlet flange after the pressure block is cooltotally.4 Maintained4.1 To disassemble and assemble valves of Inlet/ OutletTo disassemblee spanner to remove the fixed bolt 1&2e extractor to remove fixation device 3&4e tweezers to remove spring and ceramic ball of 5&6To assemble1.Put ceramic ball 5 on opening of outlet valve by tweezers, and put ceramicball 6 on inlet valve seat. Make sure they are in middle position.2.To fix spring on fixation device 3&4. To tighten fixed blot 1&2 by spanner.4.2 To disassemble and assemble the pressure gaugeTo disassembleLoosen bolts and remove the pressure gauge 1. Do not pull the head of the gauge. Please hold the body of the gauge.To assemble1.Put gasket 2 below pressure gauge, then install o-ring 3.2.Put the gauge into hole, then fix bolts.4.3 To disassemble and assemble homogeneous valveTo disassemble and inspect1.Loosen bolt of valve, remove the whole valve.2.Press valve seat and rotate handle clockwise to push out valve group andmandril 7.3.Check the surface of homogeneous valve seat and impact head or ring.To assemble1.Lubricate all O-rings by food grade grease before assemble all products.2.To put handle 8 into valve 4 by rotating clockwise.3.Put impact head into valve, then put impact ring, at last put valve seat intovalve.4.Put wetting gasket 2 attached to the surface of valve seat.5.Check out if there is gasket in the hole of the first-stage valve, then put itinto valve body and fix the bolts.6.To assemble the second-stage valve is the same progress as the first-stage.4.4 To disassemble and assemble the pressure blockTo disassemble1.Remove the fixed bolt 1 by spanner of 24#2.Hold pressure block 2 to pull it out gently, then remove pressure block. Theweight of pressure block is 20KG.3.Remove oriented ring 4 and support block 6 in turn. Do not touch plunger.4.Check out if the ceramic plunger is loosed.To assemble1.To assemble support block 6, vent side down. Mounted on four bolts.2.Set oriented ring 4 into plunger. Put them into support block.3.Ceramic plunger and plunger seal are wetted by water. It is good forlubrication.4.Push pressure block 2 gently until it contact with support block 6.5.Lock fixed bolts tightly.ATS ENG INC.215 Common errors and solutionsCondition Reason SolutionMotor is not working No powerCheck electrical connectionMotor is working but nothing out fromoutlet Air plug in pressure block so material can not flow Plunger is rupture Open inlet valve to discharge air Change another plunger No pressureInlet valve seat is wear outPressure gauge is damagedChange another valve seator pressure gauge Unstable pressureGauge is damagedImpurity is in material Air is in materialChange another gauge Pretreatment again Discharge airNo material out orreduction afterincreased pressureInlet valve or valve seat iswear outCheck out and change a newoneNo display on gaugePressure gauge is damagedor no powerChange gauge or battery。

FB-110Q高压均质机说明书FB注意事项1.任何物料在进入均质机进行均质之前,必须经过60— 100目的滤网过滤,避免颗粒的杂质(如铁屑、玻璃碎片等)进入均质机,磨损机器的进料阀座和均质阀。

2.均质机禁止在无物料的情况下长时间运行。

3.均质机严禁在两级均质阀手柄旋紧的情况下开机,突然的过载负荷严重损害马达。

4. FB-110Q均质机为实验型设备,机器设计为短时间的实验使用。

5.均质机使用固体陶瓷柱塞,与柱塞接触的物料温差变化不得超过70℃,否则可能造成柱塞断裂。

物料的温度增加或降低的幅度不得大于每分钟5℃(特别在机器灭菌操作时)。

6.高压均质机是精密设备,需专人维护和管理,并严格按照如下步骤进行操作7. 任何物料在高压下对密封部件的都有磨损性。

磨损性随着压力的升高而增加。

硬质的颗粒状物料如金属氧化物微粉,纳米颗粒,不溶性结晶颗粒等磨损性极强,建议工作压力不要超过600barFB1 8.对于金属或者陶瓷表面有粘附性的物料如成膜剂,油漆,金属防腐剂尽量不要使用超过600bar的压力。

使用后必须立即用溶剂清洗。

9.均质机在超过800bar压力情况,连续操作不得超过1小时否则电机过热影像电机使用寿命。

10.电源采用380V50Hz三相四线制2.5平方电缆线,必须要有可靠的安全接地装置。

________________________________________________________________________________FB1均质原理1.1何为均质均质是由柱塞泵和均质阀共同作用使物料在均质阀区发生细化和均匀混合的过程。

1.2均质原理物料通过柱塞泵吸入并加压,在柱塞作用下进入压力大小可调节的阀组中,经过特定宽度的限流缝隙(工作区)后,瞬间失压的物料以极高的流速(1000 至1500 米/秒)喷出,碰撞在阀组件之一的碰撞环上,产生了三种效应:1、空穴效应被柱塞压缩的物料内积聚了极高的能量,通过限流缝隙时瞬间失压,造成高能释放引起空穴爆炸,致使物料强烈粉碎细化。

高压均质机操作说明1.准备工作:(1)检查高压均质机的整体结构是否完好无损,各部件是否牢固;(2)检查电源插座是否正常,接地是否良好;(3)检查水源和冷却系统是否正常;(4)准备好需要均质的原料,确保原料浓度和温度达到要求。

2.开启高压均质机:(1)先将电源插头插入插座,确保电源开关处于关闭状态;(2)打开工作台上的电源开关;(3)打开水源,使冷却系统能正常工作;(4)打开均质机本体的电源开关;(5)调整均质机的操作参数,如调节工作压力、流量等。

3.进料过程:(1)打开料液进料阀门;(2)调整进料阀门的开度,使得进料速度适中;(3)将预处理好的原料缓慢地注入均质机的料液进料口;(4)观察进料情况,确保原料能顺利进入均质机。

4.运行过程:(1)观察压力表和流量表的读数,确保均质机的工作参数在合理范围内;(2)根据需要,调节均质机的工作压力和流量,达到所需的均质效果;(3)观察均质机本体的工作状态,如有异常情况及时停机检查;(4)根据实际情况,酌情调整均质机的工作时间和温度。

5.停机过程:(1)关闭料液进料阀门,使原料不再进入均质机;(2)停止给水,关闭冷却系统;(3)关闭均质机本体的电源开关;(4)关闭工作台上的电源开关;(5)拔出电源插头。

6.清洗和保养:(1)停机后,拆卸均质机的各个部件,如均质头、转子等,进行彻底清洗;(2)用干净的布擦拭均质机本体,确保无水和残留物;(3)定期检查和更换均质机的易损件,如密封圈、轴承等;(4)定期对均质机进行润滑和保养,确保其正常运行。

以上就是高压均质机的操作说明。

在操作过程中,要严格遵守安全操作规程,确保个人和设备的安全。

同时,根据具体的生产需求和原料特性,可以对操作参数进行适当的调整和优化,以达到最佳的均质效果。

均质机使用方法说明书使用方法说明书一、产品概述均质机是一种常用的实验室设备,主要用于将液体悬浮液或乳浊液高速剪切、撞击和遭受剪切力以实现均质、乳化、分散和混合等目的。

本说明书将为您详细介绍均质机的使用方法,确保您正确、安全地操作设备。

二、安全注意事项1.在使用均质机之前,请仔细阅读设备的使用手册和操作规范,了解并熟悉每一项安全注意事项。

2.确保均质机放置在稳固、平坦的台面上,避免设备晃动或滑动。

3.使用符合要求的电源和插座,确保配电线路能够满足设备的功率需求。

4.在使用均质机时,请佩戴安全手套、护目镜等个人防护装备,避免发生意外伤害。

5.在操作过程中,严禁将手或其它物件伸入设备内部,以免被均质刀片伤到。

三、设备操作步骤1. 准备工作a. 检查设备:检查均质机是否有损坏、松动的部件,如有异常情况,请及时维修。

b. 准备液体样品:根据实验要求制备好液体样品,保证样品准确、完整。

c. 确保环境安全:确保操作环境无明火、易燃物品等,保证工作区域安全。

2. 连接电源a. 将均质机插头与电源插座连接,并确保电源开关处于关闭状态。

b. 确认电源线连接牢固,无损坏情况。

3. 调整均质机参数a. 根据实验要求,选择合适的转速和运行时间。

b. 调整工作台面的高度,使均质机的浸入深度适合实验需求。

c. 确保所有参数调整正确,避免因操作错误导致实验失败。

4. 加样和操作a. 打开均质机顶部的进料夹管,将液体样品缓慢加入。

b. 根据实验要求,选择自动或手动模式,开始运行均质机。

c. 在操作过程中,可以适度调整进料速度和均质机的运行时间,以达到最佳效果。

d. 注意观察实验过程中的变化,如有异常情况,及时停止操作并进行检查。

5. 实验结束a. 当实验时间到达设定值时,关闭均质机。

b. 等待设备停止运行后,打开出料夹管进行液体样品收集。

c. 关闭电源开关,并拔掉电源插头。

四、设备维护及保养1. 清洁设备a. 在使用完均质机后,必须对设备进行及时的清洁。

均质机作业指导书

1 目的

正确操作均质机。

2 适用范围

前处理均质机机台。

3 职责

3.1 操作员负责机器的操作保养。

4 操作规程

4.1 卫生工作。

4.1.1 每次开闭机清洁设备卫生,表面做到无污渍、无油渍。

清理冷却水槽,保持排水通畅。

4.2 CIP

4.2.1 疏通CIP管路,确保通路手动阀门打开,自动阀状态正常。

4.2.2 CIP时不要加压清洗。

4.3 开机。

4.3.1 均质机为自动运行,手动加压,设备运行后检查活塞杆冷却水是否开启。

4.3.1确认生产工艺,先升一段压力(低压段),一段达到后在升二段(高压段)压力,完全按工艺执行。

4.4 停机

4.4.1 生产结束后,在出料完成后水顶料过程中进行泄压,先降二段压力,完成后在降一段。

注意将压力降到0。

4.4.2 注意加压与降压的开停顺序,升压先升低压(一段),到位后在升高压(二段)。

降压时先降高压,到位后在降低压。

5 安全

5.1 高压设备做到专人操作。

5.2 维护及设备清洁必须在设备停止时进行。

一、用途JJ系列均质机是流体混合物料(液一液相或液—固相)均质,乳化设备。

该机可广泛用于食品、乳品、饮料、制药、精细化工和生物技术等领域的生产,科研和技术开发。

对牛奶、豆乳等各类乳品的物料,在高压下进行均质,能使乳品液中的脂肪球显著细化,使其制品食用后易于消化吸收,提高食用价值。

用于冰淇淋等制品的生产,能提高料液的细度和疏松度,使其内在品质明显提高。

用于乳剂、胶剂、果汁等物料的生产,能起到防止或减少料液的分层,改善料液外观作用,使其色泽更为鲜明,香味更浓,口感更醇。

料液经该设备细化后,通过喷雾干燥设备制成粉剂。

也是粉剂生产中的主要设备。

二、主要技术参数三、结构原理及特点本机主要由箱体部件、泵体部件、均质部件,压力显示等部件组成。

通过电动机采用三角带带动传动轴、经连杆滑块,带动柱塞作往复运动,使泵体的料液不断吸入和压出,因此,物料则产生了强大压力,使料液在挤研,强力冲击与失压,膨胀等多种复合力作用下被有效的进行细化混合。

该机具有结构新颖,操作简单、维修方便,安全可靠等特点。

四、安装与使用1、安装(1)本机底部有四件调整螺杆及垫块支撑,不需作其它固定,若在垫块下面铺放橡胶防震垫,则能进一步减少工作时的噪音及提高平稳性。

(2)就位后,应用水平尺对阀体校平,以保证使用时工作平稳。

(3)需接用清洁的冷却水。

(4)料液缸应高于本机进料口。

(5)本机出料口管道上不准安装阀门,以免产生闷车事故。

2、使用(1)启动前,应全面检查各坚固件及管道等接合是否坚固可靠。

(2)往动力箱注入清洁的机械油油位线。

一般情况下采用HJ40机械油,在高温场所工作应选用HJ50机械油。

(3)核对皮带轮转向(面对大皮带轮逆时针转动),工作中严禁反向转动。

(4)将调节手柄旋至放松位置。

(5)接通冷却水。

(6)启动后,应逐步调整到所需压力,避免压力突变引起冲击,为保证产品质量启动阶段出来的料液应将其回至料缸,待压力稳定后再将其送出。

(7)启动后如压力表剧烈跳动或压力上不去,则应松开放气装置螺钉,直至无气泡溢出,再将螺钉旋紧。

上海昂尼仪器仪表有限公司ShangHai Angni Instrumen ts & Met ers Co.,Ltd.请保持说明书的完整性以供将来使用时之参考请在产品组装前按说明书中的装箱清单核对零部件使用说明书Operation manual系列AD200/300L 实验室分散均质机Laboratory homogeneous dispersing machine内附保修单上海昂尼仪器仪表有限公司ShangHai Angni Ins trum ents & Meters Co.,Ltd.公司地址/ADD:上海市民星路201号37幢邮编/P.C:200433电话/TEL:021-******** 55086046传真/FAX:021-******** 55086046E-mail:***************全国服务热线:400-0185-099http://w 产品装箱清单:序号名 称单位数量1 2 3 4 56台1均 质 主 机机 座立 柱件根12序号名 称单位数量789电刷(备件)产品合格证使用说明书付份本211工 作 头件111支 柱件支撑固定架套10件立 柱 扳 手1感谢您采用“AN 昂尼仪器 ”液体介质混合实验仪器设备。

为了本产品更好地为您服务,在使用本产品前,请详细地阅读使用说明书,并妥善保存以备查用。

请特别注意带此符号的警示事项为避免人身伤害,请特别注意说明书中带此符号的内容1. 产品概述高粘度液体的搅拌混合,在液体介质中分散均质颗粒物料、组织细胞破碎等。

该机由高速电机、分散均质工作头及调速控制器等组成。

驱动主机采用压铸铝合金为机体,运行状态稳定;工作头采用优质不锈钢精制,实验应用面域广;运行转速由微处理器保障实验长时间满负荷连续运行的安全;转速的无级调节,满足实验中对搅拌转速随时修正运行定时控制功能,确保实验的时间性有效可控。

AD200/300L 系列实验室分散均质机采用结构紧凑的串激式微型高速电机驱动,适用于实验室低至中、控制,能即时有效补偿因负载变化和电源电压波动而引起的转速变化,恒速可靠;内置软起动、自动过载保护,。

高压均质机操作使用说明技术支持:上海红礼生物科技有限公司开机前检查1、保证机器的进料管清洁,需要均质的料液要确保不含杂质。

注意:要确保待均质或破碎的料液中无金属颗粒;在料液中有金属颗粒存在,会严重损伤进料阀和均质阀,造成机器无法使用。

2、确定两级均质阀的手轮完全松开,但需注意不可过松。

3、按下压力表上的开关,确认压力表显示的数值为零。

开机准备1、往料斗中加入请清水,并打开排气阀进行排气。

2、打开电源电源开关,运行机器,出料均匀连续,无异常噪音。

3、可先调节压力,先加二级阀,至需要压力的10%-15%然后在加一级阀至需要的压力。

均质完成后需要先卸掉一级阀压力,然后在卸掉二级压力至压力表显示0后,方可进行关机操作。

注意:如果开机30秒后,出料口无料液排出,说明压力块内有气堵现象。

应该关闭设备,打开进料阀,把料液引入压力块,然后重新安装进料阀,再进行开机操作。

操作步骤1.料斗中加入清水,开机。

2.调节均质压力到所需工作压力,工作加压时,当加压手柄感觉加不动时,要立刻把压力减到0Bar,重新加压,如果还是加不上去,要打开均质阀看一下。

3.当清水流到料斗底部时,往料斗中加入物料。

4.在机器均质过程中,操作人员要随时关注料斗中的存料量,及时补料、循环或准备降压停机(工作时不能走空物料)。

5.完成均质后,排放设备内部的物料,在料斗中的物料将尽时加入清水。

6.调节压力为零,根据需要进行清洗。

7.将开关转动到“0”位置,关机。

注意:进料斗中的料液不得全部排空后再停机,否则进入空气会造成气堵。

清洗1.在料液将尽时,立即向料斗里进清水进行清洗,防止料液在机器内部形成料膜或残留。

最好使用60℃的热水清洗。

2.在清洗时可以加压力至100bar,清洗机器。

3.该设备可以使用以下清洁剂4,清洗时间为10-15分钟(清洗水不能循环)NaOH类:最大浓度3%最高温度90℃HNO3类:最大浓度0.5%最高温度70℃H3PO4类:最大浓度3%最高温度85℃热水:最高温度95℃蒸汽:最高温度130℃注意:该设备不得使用含氯和碘的洗洁剂。

均质机中文操作手册一.目录---------------------------------------------------第01页二.安装前的前置作业---------------------------------第02页三.安装时的注意要项---------------------------------第03页四.主机润滑油兼容油品------------------------------第05页五.主机液压油兼容油品------------------------------第06页六.主机差速箱油兼容油品---------------------------第07页七.冷却水流量需求------------------------------------第08页八.启动程序---------------------------------------------第09页九.日常操作注意要点---------------------------------第10页十.故障排除---------------------------------------------第12页十一.保养程序--------------------------------------------第13页十二.清絜与保养-----------------------------------------第14页十一. 如何订购APV原厂需件-------------------------第17页十二. 附件本机器分解图----------------------------------第18页十三. 试机安装测试报告---------------------------------第19页APV 均质机安装前的前置作业在安装均质机前, 必须了解及准备下列条件:1. 安装及操作保养的空间需求.2. 机器的电力需求.3. 控制盘的设置位置.4. 二个冷却水的供给水量.5. 相关配管大小, 例如进出料管径, 二个冷却水管径.6. 机器重量.7. 安装搬运工具, 如堆高机, 板车等8. 机器的油品准备.安装设备时注意要项:一.机器拆箱:机器的拆箱,请配合APV人员或代理商协同拆箱,并小心操作。