DuPontTedlar薄膜手册-杜邦

- 格式:pdf

- 大小:2.01 MB

- 文档页数:9

桥梁缆索防腐与维护-Tedlar®聚氟乙烯胶带[摘要] 结合桥梁缆索防腐蚀保护系统,介绍了一种具有优良耐候性能的Tedlar®聚氟乙烯缆索保护胶带,同时列举了部分国内外的实际使用案例。

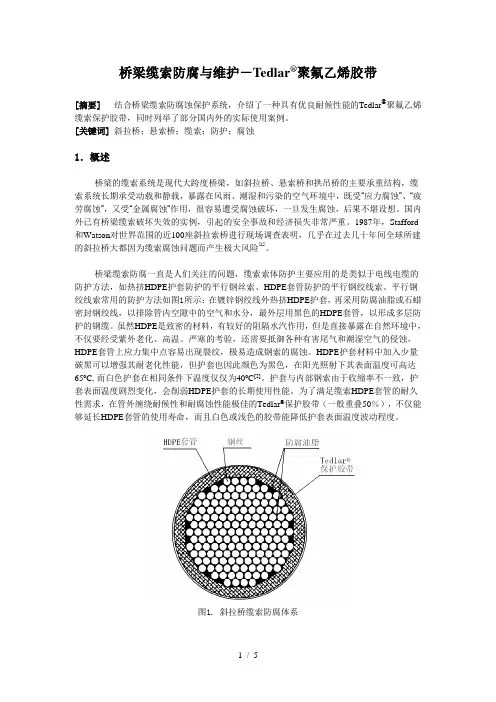

[关键词] 斜拉桥;悬索桥;缆索;防护;腐蚀1.概述桥梁的缆索系统是现代大跨度桥梁,如斜拉桥、悬索桥和拱吊桥的主要承重结构,缆索系统长期承受动载和静载,暴露在风雨、潮湿和污染的空气环境中,既受“应力腐蚀”、“疲劳腐蚀”,又受“金属腐蚀”作用,很容易遭受腐蚀破坏,一旦发生腐蚀,后果不堪设想。

国内外已有桥梁缆索破坏失效的实例,引起的安全事故和经济损失非常严重。

1987年,Stafford 和Watson对世界范围的近100座斜拉索桥进行现场调查表明,几乎在过去几十年间全球所建的斜拉桥大都因为缆索腐蚀问题而产生极大风险[1]。

桥梁缆索防腐一直是人们关注的问题,缆索索体防护主要应用的是类似于电线电缆的防护方法,如热挤HDPE护套防护的平行钢丝索、HDPE套管防护的平行钢绞线索。

平行钢绞线索常用的防护方法如图1所示:在镀锌钢绞线外热挤HDPE护套,再采用防腐油脂或石蜡密封钢绞线,以排除管内空隙中的空气和水分,最外层用黑色的HDPE套管,以形成多层防护的钢缆。

虽然HDPE是致密的材料,有较好的阻隔水汽作用,但是直接暴露在自然环境中,不仅要经受紫外老化、高温、严寒的考验,还需要抵御各种有害尾气和潮湿空气的侵蚀,HDPE套管上应力集中点容易出现裂纹,极易造成钢索的腐蚀。

HDPE护套材料中加入少量碳黑可以增强其耐老化性能,但护套也因此颜色为黑色,在阳光照射下其表面温度可高达65o C,而白色护套在相同条件下温度仅仅为40o C[2]。

护套与内部钢索由于收缩率不一致,护套表面温度剧烈变化,会削弱HDPE护套的长期使用性能。

为了满足缆索HDPE套管的耐久性需求,在管外缠绕耐候性和耐腐蚀性能极佳的Tedlar®保护胶带(一般重叠50%),不仅能够延长HDPE套管的使用寿命,而且白色或浅色的胶带能降低护套表面温度波动程度。

Bulletin No. 5600PD9601July 1996Oxford, OH, USAProduct Data BulletinMYLAR ® BUS BAR INSULATION—A THIRTY YEAR TRACK RECORDFor more than 30 years, Square D has used Mylar ® to insulate bus bars in I-Line ®and I-Line II Busway. The purpose of this paper is to provide information demonstrating that Mylar is both a proven and reliable insulation system.QUESTIONS AND ANSWERSWhat is Mylar ®?Mylar is a polyester film made from polyethylene terephthalate, the polymer formed by the condensation reaction of ethylene glycol and terephthalic acid.Mylar has an average dielectric strength of 7,000 volts for 1 mil film, a tensile strength of 23,000 psi, and an excellent resistance to most chemicals andmoisture. Mylar also remains flexible throughout temperature extremes from –60° to 150°C and does not become brittle with age.Does Mylar ® meet To meet to Underwriters Laboratory (UL) requirements, UL Listed busways UL requirements?cannot exceed a total operating temperature of 95°C in an ambient temperature of 40°C at full load. This requirement applies to the complete busway system, not just a single busway component. At loads up to and including the full load rating and at 40°C ambient temperature, I-Line and I-Line II Busway will not exceed a total operating temperature of 95°C. Actual supplier testing (DuPont #EL-63-2)has proven Mylar to have a conservative Class B, 130°C thermal rating, which is 35°C above the approved operating temperature of UL Listed busways.What about reliability?I-Line and I-Line II bus bars are insulated with two layers of 7.5 mil Mylar. Once assembled, every busway length and fitting must pass a 7,000Vdc (4,950Vac)hi-potential test before shipment from the factory. The factory test is conducted at eight times greater than the maximum operating voltage to ensure the highest quality insulation with every section of busway delivered.Mylar has many electrical applications in addition to insulating bus bars. Many manufacturers also use Mylar as insulation in transformers and electric motors.In fact, one of the largest electric motor manufacturers in the United States has used Mylar as a stand-alone insulator in Class B motors for over 35 years.Laminates containing Mylar are commonly used in Class F motors with ratings of 115°C and higher.ELECTRICAL PROPERTIES With an excellent balance of chemical, thermal, and physical properties, the OF MYLAR ®electrical properties of Mylar offer unique design capabilities to the electrical industry.Film ThicknessThe average dielectric strength for 1 mil film is 7,000 volts. For 7.5 mil film, the dielectric strength is approximately 2,700 volts/mil for an excellent dielectric strength of 20,250 volts. I-Line and I-Line II Busway use two layers of 7.5 mil film for a total insulation thickness of 15 mil. As with most materials, the ac dielectric strength of Mylar film in volts/mil decreases as film thickness increases. This is illustrated in Figure 1, page 2. After being tested at a 500volts/second rate of rise, corona occurs within seconds and the film begins to melt before the actual breakdown occurs.Bulletin No. 5600PD9601July 1996Mylar ® Bus Bar Insulation—A Thirty Year Track Record2Figure 2: Dielectric strength vs. temperatureFigure 1: Dielectric strength vs. thicknessInsulation ResistanceAnother outstanding property of Mylar is its high insulation resistance over a wide temperature range. As shown in Figure 2, the dielectric strength remains constant over a temperature range from 25°C up to 150°C.Bulletin No. 5600PD9601 Mylar® Bus Bar Insulation—A Thirty Year Track RecordJuly 1996Bulletin No. 5600PD9601July 1996Mylar ® Bus Bar Insulation—A Thirty Year Track RecordPHYSICAL AND THERMAL Mylar polyester film retains good physical properties over a wide temperature PROPERTIES OF MYLAR ®range from –60° to 150°C. Its shear strength is significantly higher than published data for other polymeric insulating materials. Mylar is also resistant to electrical creepage.Shear StrengthShear strength was measured by a punch-type test according to ASTM D-732.This measurement is reported in pounds of force required to shear divided by the product of the circumference and the thickness. These tests showed that 5and 10 mil Mylar films have shear strengths of 15.0 (21.5) and 13.6 (19.5) kg/mm 2(kpsi), respectively.Heat Aging and Service LifeThe film manufacturer’s maximum service temperature usually recommended for Mylar polyester film is 150°C. UL Listed busways are designed not to exceed a total operating temperature of 95°C. Where extensive exposure, severeenvironmental conditions, or unusual physical requirements such as severe flexing are involved, reducing the service life of Mylar may be necessary.Because the Mylar in I-Line and I-Line II Busway is totally enclosed within the housing, the Mylar is protected against extensive exposure, severeenvironmental conditions, and flexing. As a result of this protection and when subjected to normal operating conditions, long life can be expected.CHEMICAL PROPERTIES Mylar polyester film exhibits good resistance to the action of many chemical OF MYLAR ®reagents, solvents, varnishes, and other contaminants and is virtuallyimpermeable to the liquid phase of most chemicals and reagents. Oils and greases such as penetrating oil, lard, cottonseed oil, and motor oil will notpenetrate through 1mil film even after two months of constant exposure at room temperature. Mylar is relatively insensitive to moisture absorption, absorbing less than 0.8% moisture when totally immersed in water over a 24-hour period (ASTM D-570-63).SUMMARYMany types of bus bar insulation systems can exceed the maximum allowable operating temperature as required by UL. It is important to understand that UL Listed busways are designed not to exceed a total operating temperature of 95°C, which falls into Class A limits . Thus, high quality busway designs, like I-Line and I-Line II Busway, will never reach operating temperatures of 130°C under normal operating conditions. Unlike our competitors, Square D usesfull-size bus bars in I-Line and I-Line II Busway. Full-size bus bars contribute to cooler operation of the busway system, lower voltage drop, and higher electrical efficiency. This equates to a lower operating cost and long life .Today, I-Line and I-Line II Busway installations are in operation throughout the world, dating back to the early 1960s. Test data for new insulation systems is generated in laboratory conditions. Historical data generated from actualapplications is the most relevant and valuable data available. With more than 30years of both laboratory and historical data along with proven performance,Square D Busway with Mylar insulation has proven reliability in the industry.Source: DuPont Films EnterpriseI-LINE, SQUARE D, and are Registered Trademarks of Square D Company.Mylar is a Registered Trademark of E. I. DuPont.© 1996 Square D, all rights reserved. This bulletin may not be copied in whole or in part, ortransferred to any other media, without the written permission of Square D Company.Square D Company5735 College Corner Road Oxford, OH, 45056 USA。

投资光伏电站请先了解材料清单光伏电池组件来源:世纪新能源网作者:肖蓓2014/8/25 9:20:56我要投稿关键词: 光伏电站投资光伏背板杜邦北极星太阳能光伏网讯:频发的质量问题、高衰减率组件正在中国西部光伏电站蔓延,可能会将过去三年积累的光伏电站成绩打入尘埃。

“部分多晶硅电池组件2-3年功率衰减3.8%-7.0%,非晶硅3年功率衰减达20%。

”中科院电工所在对青海省太阳能光伏电站后评估检测后得出令人惊讶的结果。

根据鉴衡认证中心调查,425座太阳能电站中,30%建成的3年以上电站都不同程度出现了问题;由于组件的质量问题,有些建成三年的电站设备衰减率甚至高达68%。

如果组件一年衰减超过5%,照此速度,五年后这个电站就报废了。

随着“婴儿期”(运行一年)失效率组件的出现,建设1年的电站成本、收益都出现了较大波动。

这样的电站如何保证投资回报率?如何获得银行贷款?如何让投资者、业主放心?以国内现有的招标交易及竞争环境,单独的太阳能电站组件供应商没有力量挽回这一局面,有些事情,需要电站业主、投资商自己把关。

未经实绩验证的材料损害组件根本组件是太阳能电站最重要的组成设备,电站的质量、发电量、收益率、价值都与它息息相关。

它主要由太阳电池、封装材料、背板、玻璃、边框、接线盒等组成,这些材料都对组件性能、质量产生影响,电池片是核心,外面的封装材料都是为了保护它,其中一个关键的保护材料是处于最外层的背板,一旦背板失效,里面的封装材料、电池片就如失去蔽护的花朵,随环境凋零。

背板是光伏组件背面的一层复合结构材料,将电池片和组件封装材料与大气环境隔离,为组件提供绝缘保护,它需要长期耐受各种环境应力作用,对组件在户外的可靠性、功率衰减和使用寿命都至关重要。

随着国内电站装机的不断攀升,市场上出现了采?不同材料和结构类型的背板,目前比较常见的背板外层保护材料有杜邦™特能®(Tedlar®)PVF薄膜、PVDF薄膜、FEVE涂料、PET聚酯/耐水解PET、PA聚酰胺。

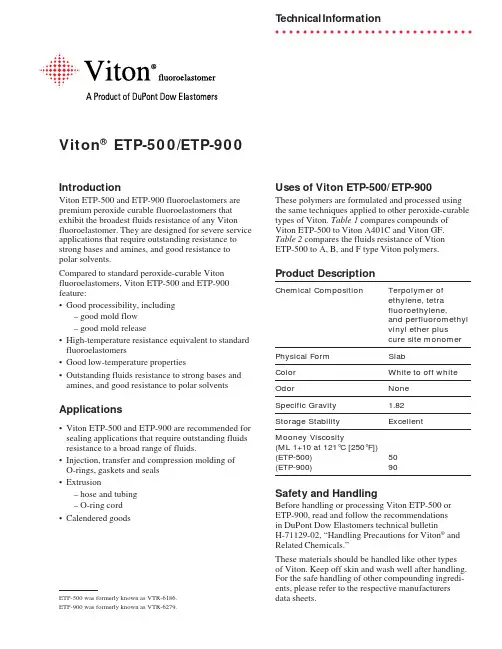

Viton® ETP-500/ETP-900T echnical Information○○○○○○○○○○○○○○○○○○○○○○○○○○○○○IntroductionViton ETP-500 and ETP-900 fluoroelastomers are premium peroxide curable fluoroelastomers that exhibit the broadest fluids resistance of any Viton fluoroelastomer. They are designed for severe service applications that require outstanding resistance to strong bases and amines, and good resistance to polar solvents.Compared to standard peroxide-curable Viton fluoroelastomers, Viton ETP-500 and ETP-900 feature:•Good processibility, including– good mold flow– good mold release•High-temperature resistance equivalent to standard fluoroelastomers•Good low-temperature properties •Outstanding fluids resistance to strong bases and amines, and good resistance to polar solvents Applications•Viton ETP-500 and ETP-900 are recommended for sealing applications that require outstanding fluids resistance to a broad range of fluids.•Injection, transfer and compression molding ofO-rings, gaskets and seals•Extrusion– hose and tubing– O-ring cord•Calendered goods Uses of Viton ETP-500/ETP-900These polymers are formulated and processed using the same techniques applied to other peroxide-curable types of Viton. Table 1 compares compounds of Viton ETP-500 to Viton A401C and Viton GF. Table 2 compares the fluids resistance of VtionETP-500 to A, B, and F type Viton polymers. Product DescriptionChemical Composition Terpolymer ofethylene, tetrafluoroethylene,and perfluoromethylvinyl ether pluscure site monomer Physical Form SlabColor White to off white Odor NoneSpecific Gravity 1.82Storage Stability ExcellentMooney Viscosity(ML 1+10 at 121°C [250°F])(ETP-500)50(ETP-900)90Safety and HandlingBefore handling or processing Viton ETP-500 or ETP-900, read and follow the recommendationsin DuPont Dow Elastomers technical bulletinH-71129-02, “Handling Precautions for Viton® and Related Chemicals.”These materials should be handled like other typesof Viton. Keep off skin and wash well after handling. For the safe handling of other compounding ingredi-ents, please refer to the respective manufacturers data sheets.ETP-500 was formerly known as VTR-6186. ETP-900 was formerly known as VTR-6279.Table 1The Performance of Viton® ETP-500 in Typical CompoundsViton Viton VitonETP-500A401C GFViton ETP-500100——Viton A401C—100—Viton GF——100Zinc Oxide 1.5—3High-Activity MgO—3—Calcium Hydroxide—6—N990 Carbon Black303030Carnauba Wax0.50.50.5Armeen®* 18D0.5—0.5Diak™ No. 73—3Luperco®** 101XL3—3Stock PropertiesMooney Scorch, MS at 121°C (250°F)Minimum, in·lb4340282-unit rise, min18.815.818.25-unit rise, min24.8>3023.4ODR at 177°C (350°F), Microdie, 3° Arc, 12 minM L, in·lb191313T s2, min 1.1 1.9 1.2T c90, min 6.1 3.6 6.9M H, in·lb7410276 Vulcanizate PropertiesSlabs Cured: 10 min at 177°C (350°F)Post-Cured: 16 hr at 232°C (450°F)Stress/Strain at 23°C (73°F)—Original, Post-Cured100% Modulus, MPa (psi)7.4 (1,080)7.6 (1,100)7.4 (1,080) Tensile Strength, MPa (psi)15.4 (2,235)16.3 (2,360)19.8 (2,870) Elongation at Break, %205190215 Hardness, Durometer A, pts827779Stress/Strain at 23°C (73°F)—After aging 70 hr at 250°C (428°F)100% Modulus, MPa 6.87.68.1% change–8.10.09.5Tensile Strength, MPa15.515.720.7% change0.6–3.7 4.5 Elongation at Break, %240185215% change17.1–2.60.0 Hardness, Durometer A, pts827880Stress/Strain at 23°C (73°F)—After aging 168 hr at 150°C (302°F)/80W-90 EP Gear Lubricant100% Modulus, MPa 5.9—% change–20.3——Tensile Strength, MPa14.510.39.3% change–5.8–36.8–53.0 Elongation at Break, %2358095% change14.6–57.9–55.8 Hardness, Durometer A, pts.818481Volume change, %313(continued) *Akzo Chemicals**Elf Atochem2Table 1(continued)The Performance of Viton® ETP-500 in Typical CompoundsViton Viton VitonETP-500A401C GF Stress/Strain at 23°C (73°F)—After aging 168 hr at 40°C (104°F)/Toulene100% Modulus, MPa 4.6 5.8 4.7 % change–37.8–23.7–36.5 Tensile Strength, MPa12.29.714.5 % change–20.8–40.5–26.8 Elongation at Break, %220150210 % change7.3–21.1–2.3 Hardness, Durometer A, pts746769 Volume change, %92311 Stress/Strain at 23°C (73°F)—After aging 168 hr at 23°C (73°F)/MTBE (92%) Toluene (8%)100% Modulus, MPa 3.8— 4.7 % change–48.8—–36.5 Tensile Strength, MPa9.3 4.9 5.6 % change–39.6–69.9–71.7 Elongation at Break, %19070110 % change–7.3–63.2–48.8 Hardness, Durometer A, pts676353 Volume change, %2012167 Stress/Strain at 23°C (73°F)—After aging 168 hr at 23°C (73°F)/Methyl Ethyl Ketone100% Modulus, MPa 3.6——% change–51.4——Tensile Strength, MPa10.2 1.4 2.7 % change–33.8–91.4–86.4 Elongation at Break, %2154050 % change 4.9–78.9–76.7 Hardness, Durometer A, pts653541 Volume change, %19222183 Stress/Strain at 23°C (73°F)—After aging 168 hr at 100°C (212°F)/30% Potassium Hydroxide100% Modulus, MPa 6.0— 1.0 % change–18.9—–86.5 Tensile Strength, MPa14.20.9 1.4 % change–7.8–94.5–92.9 Elongation at Break, %26580120 % change29.3–57.9–44.2 Hardness, Durometer A, pts793030 Volume change, %6132*12* Low-Temperature PropertiesDSC (glass transition temperature)Inflection, °C (°F)–11 (12)–15 (5)–7 (19) TR-10, °C (°F)–11 (12)–17 (1)–7 (19) *Samples were dissolvingNote: 1 MPa is equal to 145 psi3Table 2Comparative Fluids ResistanceViton Viton Viton VitonETP-500A-type B-type GF Fluid Resistance, Volume Swell, %Acids and BasesAcetic Acid, Glacial, 70 hr at 118°C (244°F)27110n.t.26 Nitric Acid (60%), 70 hr at 86°C (187°F)1150n.t.19 Potassium Hydroxide (sat.)7 days at 100°C (212°F)3dissolved n.t.n.t. Potassium Hydroxide (30%),70 hr at 150°C (302°F)12n.t.n.t.dissolved Sodium Hydroxide (30%)70 hr at 100°C (212°F)0n.t.n.t.cracked Sulfuric Acid (90%)7 days at 95°C (203°F)312n.t.n.t.SolventsAcetone7 days at 20°C (68°F)25181n.t.n.t. Butyl Acetate70 hr at 125°C (257°F)31300+n.t.70 Ethyl Acetate70 hr at 20°C (68°F)25280n.t.n.t. Methylene Chloride7 days at 20°C (68°F)12252016 Methy Ethyl Ketone7 days at 20°C (68°F)25458313n.t. Methyl t-Butyl Ether70 hr at 23°C (73°F)2612210074 MEK/Toluene (50/50)70 hr at 23°C (73°F)1616612787 Tetrahydrofuran7 days at 20°C (68°F)40380281n.t. Toluene70 hr at 23°C (73°F)41152Hydraulic Fluids and LubricantsSkydrol® 500B70 hr at 125°C (257°F)10n.t.n.t.25 Skydrol 500B7 days at 125°C (257°F)2017115145 Skydrol LD70 hr at 121°C (250°F)1119614980Other Aggressive FluidsDimethyl Formamide7 days at 20°C (68°F)8250+n.t.n.t. Ethylenediamine70 hr at 90°C (194°F)60n.t.n.t.dissolved Water/Nalcool 2000/PotassiumHydroxide (80/10/10)70 hr at 70°C (158°F)1761 (Sample Appearance)no cracks cracks cracks slight(v. hard)cracksn.t. (not tested)4Test ProceduresProperty Measured Test ProcedureHardness ASTM D2240-91, Durometer AMoooney Scorch ASTM D1646-95, using small rotor. Minimum viscosity andtime to a 1-, 2-, 5-, and 10-unit rise are reported.Mooney Viscosity ASTM D1646-95, ten pass 121°C (250°F)ODR (vulcanization characteristics ASTM D2084-93measured with an oscillating disk cure meter)Property Change After Oven Heat-Aging ASTM D573-88Stress/Strain Properties100% Modulus ASTM D412-92, pulled at 8.5 mm/sTensile Strength(20 in/min)Elongation at BreakVolume Change in Fluids ASTM D471-95Temperature Retraction ASTM D1329-88Test measured is 24°C (75°F) except where specified otherwiseProprietary MaterialsSources of compounding ingredients used in developing the information in this technical bulletin are listed below. This is not to imply that comparable ingedients from other sources might not be equally usable.Material Composition SupplierArmeen® 18D Octadecyl amine Akzo ChemicalsChicago, IL 60606Skydrol®Hydraulic fluid/lubricant Monsanto ChemicalsSt. Louis, MODiak™ No. 7 Curing Agent Organic trizine (TAIC)DuPont Dow Elastomers L.L.C.Wilmington, DE 19809Luperco® 101-XL2,5-dimethyl-2,5-bis (t-butyl Atochem North America Inc. Organic Peroxide peroxyul hexane, 45% active Buffalo, NY 14240ingredient on inert carrier5(12/98)301743A Printed in U.S.A. [Replaces: H-77662]Reorder No.: H-77662-01Viton Business Center DuPont Dow Elastomers L.L.C. P.O. Box 306Elkton, MD 21922-0306Tel. 410-392-2500Fax. 410-392-2540For more information on Viton®(800) 853-5515 (U.S. & Canada) or other elastomers:(302) 792-4000Global Headquarters DuPont Dow Elastomers L.L.C. 300 Bellevue Parkway, Suite 300 Wilmington, DE 19809 USA Tel. 302-792-4000Fax. 302-892-7390European RegionalHeadquartersDuPont Dow Elastomers S.A.2, chemin du PavillonCH-1218 Le Grand-SaconnexGeneva, SwitzerlandTel. +41-22-717-4000Fax. +41-22-717-4001Asia Pacific RegionalHeadquartersDuPont Dow Elastomers Pte Ltd.1 Maritime Square #10-54World Trade CentreSingapore 099253Tel. +65-275-9383Fax. +65-275-9395South & Central AmericaRegional HeadquartersDuPont Dow Elastomers Ltda.Rua Henrique Monteiro, 905: andar – Pinheiros05423-912São Paulo – SPBrazilTel. +55-11-816-0256Fax. +55-11-814-6845The information set forth herein is furnished free of charge and is based on technical data that DuPont Dow Elastomers believes to be reliable. It is intended for use by persons having technical skill, at their own discretion and risk. The handling precaution information contained herein is given with the understanding that those using it will satisfy themselves that their particular conditions of use present no health or safety hazards. Because conditions of product use and disposal are outside our control, we make no warranties, express or implied, and assume no liability in connection with any use of this information. As with any material, evaluation of any compound under end-use conditions prior to specification is essential. Nothing herein is to be taken as a license to operate under or a recommendation to infringe on any patents.CAUTION: Do not use in medical applications involving permanent implantation in the human body. For other medical applications, discuss with your DuPont Dow Elastomers customer service representative, and read Medical Caution Statement, H69237.Viton® is a registered trademark of DuPont Dow Elastomers.Copyright ©1997, 1998 DuPont Dow Elastomers.All Rights Reserved.。

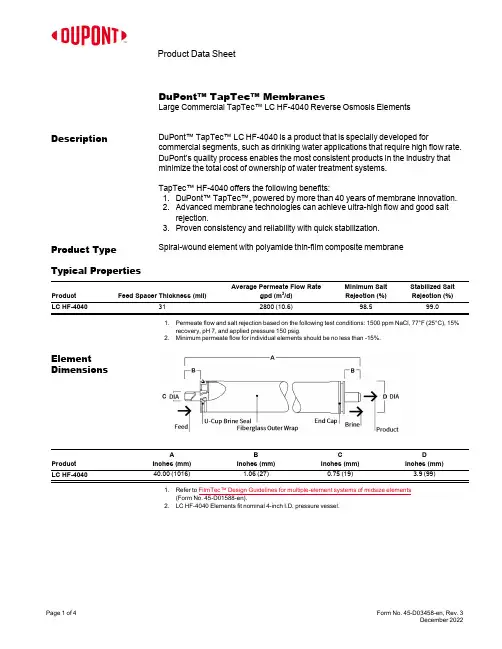

Product Data SheetDuPont™TapTec™MembranesLarge Commercial TapTec™LC HF-4040Reverse Osmosis ElementsDescription DuPont™TapTec™LC HF-4040is a product that is specially developed forcommercial segments,such as drinking water applications that require high flow rate.DuPont’s quality process enables the most consistent products in the industry thatminimize the total cost of ownership of water treatment systems.TapTec™HF-4040offers the following benefits:1.DuPont™TapTec™,powered by more than 40years of membrane innovation.2.Advanced membrane technologies can achieve ultra-high flow and good saltrejection.3.Proven consistency and reliability with quick stabilization.Product TypeSpiral-wound element with polyamide thin-film composite membrane Typical PropertiesProductFeed Spacer Thickness (mil)Average Permeate Flow Rate gpd (m 3/d)Minimum Salt Rejection (%)Stabilized Salt Rejection (%)312800(10.6)98.599.01.Permeate flow and salt rejection based on the following test conditions:1500ppm NaCl,77°F (25°C),15%recovery,pH 7,and applied pressure 150psig.2.Minimum permeate flow for individual elements should be no less than -15%.ElementDimensionsProductA Inches (mm)B Inches (mm)C Inches (mm)D Inches (mm)LC HF-404040.00(1016)1.06(27)0.75(19) 3.9(99)1.Refer to FilmTec™Design Guidelines for multiple-element systems of midsize elements (Form No. 45-D01588-en).2.LC HF-4040Elements fit nominal 4-inch I.D.pressure vessel.Operating and Cleaning Limits Membrane type Polyamide Thin-Film CompositeMaximum operating temperature95°F(35°C)Maximum operating pressure a600psi(41bar)Maximum pressure drop15psi(1.0bar)Maximum feed flow rate,gpm(m3/h)16gpm(3.6m3/h)pH rangeContinuous operation3-10Cleaning2-12Maximum Feed Silt Density Index5ba.This element is optimized to operate below300psi.However,exposure to feed water pressures of600psi willnot negatively impact the long-term performance.b.Under certain conditions,the presence of free chlorine and other oxidizing agents will cause prematuremembrane failure.Since oxidation damage is not covered under warranty,DuPont recommends removing residual free chlorine and other oxidants by pretreatment prior to membrane exposure.Please refer toDechlorinating Feedwater(Form No. 45-D01569-en)for more information.General Information Proper start-up of reverse osmosis water treatment systems is essential to prepare the membranes for operating service and to prevent membrane damage due to overfeeding or hydraulic shock.Following the proper start-up sequence also helps ensure that system operating parameters conform to design specifications so that system water quality and productivity goals can be achieved.Before initiating system start-up procedures,membrane pretreatment,loading of the membrane elements,instrument calibration and other system checks should be completed.Please refer to the application information literature entitled Start-Up Sequence (Form No. 45-D01609-en)for more information.Operation Guidelines Avoid any abrupt pressure or cross-flow variations on the spiral elements during start-up,shutdown,cleaning or other sequences to prevent possible membrane damage. During start-up,a gradual change from a standstill to operating state is recommended as follows:l Feed pressure should be increased gradually over a30–60second time frame.l Cross-flow velocity at set operating point should be achieved gradually over15 – 20seconds.Important Information Keep elements moist at all times after initial wetting.For successful operation of Reverse Osmosis(RO)and Nanofiltration(NF)membrane systems,the operation must follow the guidelines provided in the FilmTec™Reverse Osmosis/Nanofiltration Elements Operation Excellence and Limiting Conditions Tech Fact(Form No. 45-D04388-en).To prevent biological growth during prolonged system shutdowns,it is recommended that membrane elements be immersed in a storage solution.The customer is fully responsible for the effects of incompatible chemicals and lubricants on elements.Maximum pressure drop across an entire pressure vessel(housing)is50psi(3.4bar). Avoid static permeate-side backpressure at all times.Product Stewardship DuPont has a fundamental concern for all who make,distribute,and use its products,and for the environment in which we live.This concern is the basis for our product stewardship philosophy by which we assess the safety,health,and environmental information on our products and then take appropriate steps to protect employee and public health and our environment.The success of our product stewardship program rests with each and every individual involved with DuPont products—from the initial concept and research,to manufacture,use,sale,disposal,and recycle of each product.Customer Notice DuPont strongly encourages its customers to review both their manufacturing processesand their applications of DuPont products from the standpoint of human health andenvironmental quality to ensure that DuPont products are not used in ways for which theyare not intended or tested.DuPont personnel are available to answer your questions and toprovide reasonable technical support.DuPont product literature,including safety datasheets,should be consulted prior to use of DuPont products.Current safety data sheets areavailable from DuPont.Please be aware of the following:l The use of this product in and of itself does not necessarily guarantee the removal ofcysts and pathogens from water.Effective cyst and pathogen reduction isdependent on the complete system design and on the operation and maintenanceof the system.l Permeate obtained from the first hour of operation should be discarded.Regulatory Note This product may be subject to drinking water application restrictions in somecountries;please check the application status before use and sale.Have a question?Contact us at: /water/contact-us All information set forth herein is for informational purposes only.This information is general information and may differ from that based on actual conditions.Customer is responsible for determining whether products and the information in this document are appropriate for Customer's use and for ensuring that Customer's workplace and disposal practices are in compliance with applicable laws and other government enactments.The product shown in this literature may not be available for sale and/or available in all geographies where DuPont is represented.The claims made may not have been approved for use in all countries.Please note that physical properties may vary depending on certain conditions and while operating conditions stated in this document are intended to lengthen product lifespan and/or improve product performance,it will ultimately depend on actual circumstances and is in no event a guarantee of achieving any specific results.DuPont assumes no obligation or liability for the information in this document.References to“DuPont”or the“Company”mean the DuPont legal entity selling the products to Customer unless otherwise expressly noted.NO WARRANTIES ARE GIVEN;ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.No freedom from infringement of any patent or trademark owned by DuPont or others is to be inferred.© 2022 DuPont.DuPont™,the DuPont Oval Logo,and all trademarks and service marks denoted with™,℠or®are owned by affiliates of DuPont de Nemours Inc.,unless otherwise noted.。

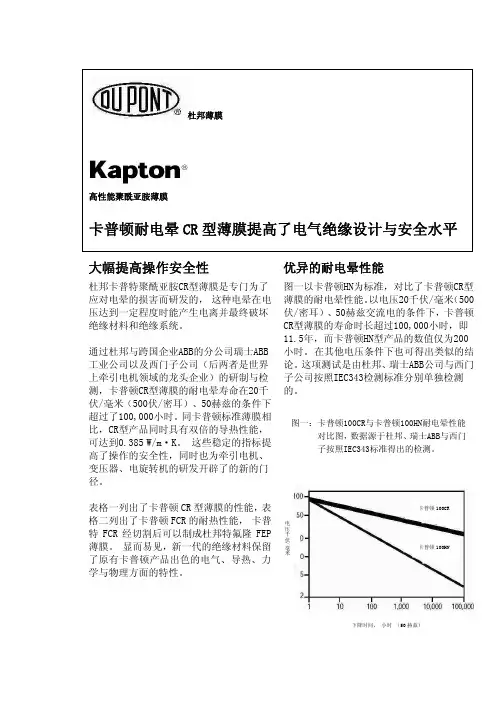

杜邦薄膜高性能聚酰亚胺薄膜卡普顿100CR卡普顿100HN下降时间, 小时 (50赫兹)表一卡普顿100CR聚酰亚胺薄膜的特性,25微米(1密耳)检测项目 23°C (73°F) 的数值 检测方法 电气方面耐电晕 20千伏/毫米;50赫兹 >100,000 小时 IEC-343 绝缘强度 千伏/毫米(伏/密耳) 291 (7,400) ASTM D-149-81 电容率 3.9 ASTM D-150-81 耗散因数 0.003 ASTM D-150-81 体积电阻率 欧姆·厘米 2.3 × 1016 ASTM D-257-78表面电阻率 欧姆/平方米 3.6 × 1016 ASTM D-257-78力学方面极限抗拉强度 兆帕 (磅/英寸) 152 (22,100) ASTM D-882-91 3%拉伸的屈服点 兆帕 (磅/英寸) 66 (9,500) ASTM D-882-91产生5%拉伸的压力 兆帕 (磅/英寸) 86 (12,500) ASTM D-882-91断裂伸长率% 40 ASTM D-882-91拉伸模量兆帕 (磅/英寸) 3.2 (463,000) ASTM D-882-91传导中撕裂强度 牛顿(千克力) 0.03 (0.007) ASTM D-1922原始撕裂强度 牛顿(千克力) 11 (2.5) ASTM D-1004-90 密度 克/立方厘米 1.54 ASTM D-1505-90 屈服应力 平方/千克 (平方英寸/磅) 25.5 (125) —导热方面导热系数 W/m·K 0.385 特拉华州大学检测法 可燃性 94 V-0 UL-94 (杜邦检测) 热收缩率 % 150°C (302°F) 0.2 ASTM D-5214-91 400°C (752°F) 0.6表二卡普顿150FCR聚酰亚胺薄膜019的特性,37.5微米(1.5密耳)检测项目 23°C (73°F) 的数值 检测方法 电气方面耐电晕 20千伏/毫米;50赫兹 >100,000 小时 IEC-343绝缘强度 千伏/毫米(伏/密耳) 173 (4,400) ASTM D-149-81 电容率 2.9 ASTM D-150-81 耗散因数 0.001 ASTM D-150-81 体积电阻率 欧姆·厘米 5.3 × 1016 ASTM D-257-78 表面电阻率 欧姆/平方米 1.6 × 1016 ASTM D-257-78 力学方面极限抗拉强度 兆帕 (磅/英寸) 117 (17,000) ASTM D-882-91 3%拉伸的屈服点 兆帕 (磅/英寸) 48 (7,000) ASTM D-882-91 产生5%拉伸的压力 兆帕 (磅/英寸) 62 (9,000) ASTM D-882-91 断裂伸长率% 43 ASTM D-882-91 拉伸模量兆帕 (磅/英寸) 2.4 (348,000) ASTM D-882-91 传导中撕裂强度 牛顿(千克力) 0.05 (0.012) ASTM D-1922原始撕裂强度 牛顿(千克力) 5.3 (1.2) ASTM D-1004-90密度 克/立方厘米 1.72 ASTM D-1505-90屈服应力 平方/千克 (平方英寸/磅) 15.79 (77.4) —剥离力 牛顿/厘米 (磅/英寸)特氟隆FEP 与卡普顿 CR 7.7 (4.4) 杜邦测试 特氟隆FEP 与铜 7.9 (4.5) 杜邦测试粘合膜 1.2 (0.7) 杜邦测试卡普顿150FCR卡普顿150FN下降时间, 小时 (50赫兹)表三卡普顿150FCR019与卡普顿FN019的耐电晕性能对比Kapton® Kapton® Kapton® Kapton®检测性能 150 FN 019 150 FCR 019 150 FN 019 150 FCR 019包裹层数 1 1 1 1重叠% 50 50 53 53绝缘增强 毫米 0.15 0.15 0.21 0.21绝缘击穿电压;连续的IEC 851-5, 千伏最低值 4.5 4.0 6.0 6.0平均值 6.0 5.5 7.0 7.0弯曲实验 IEC 851-32倍边缘宽度 千伏最低值 4.5 4.0 5.0 5.0平均值 5.5 5.0 6.0 6.02倍平面厚度 千伏最低值 4.5 4.0 5.0 5.0平均值 5.5 5.0 6.0 6.0热震后弯曲实验(220°C [428°F];30分钟)IEC 851-6, 千伏最低值 4.5 4.0 5.0 4.5 平均值 5.5 5.0 6.0 5.5*以上数据源于瑞士绝缘工程公司优良的耐击穿电压性能西门子公司采用了瑞士绝缘工程公司提供的磁线,按照IEC251-3标准要求的射击浴法,对卡普顿FCR薄膜与卡普顿FN薄膜的耐击穿电压性能进行了对比。

Technical BulletinGeneralThis guide is intended to assist the manufacturer in the selection of adhesives for laminating DuPont ™ Tedlar ® polyvinyl fluoride (PVF) film to a variety of substrates. Lamination and quality control guidelines are also included for laminating Tedlar ® PVF film to:• Aluminum• Galvanized steel • Vinyl fabric• Thermoplastic sheet • Vinyl wall coveringThis information is believed to be the best currently available and is offered to help with your own experimentation and evaluations. This information will be revised as additional information becomes available.Adhesive StorageTedlar ® adhesives are best used within two years from date ofmanufacture. Best used dates are guidelines to insure the material maintains its viscosity and appearance. In the event material has exceeded two years from date of manufacture, it may be assessed for use in the following manner:1. Insure the material is at room temperature2. Insure the material is mixed (10 – 15 minutes gentle agitation on drum roller is suitable)3. Collect a small sample of adhesive in a clear vessel to inspect visually for presence of non-soluble gel particles (do not use adhesive if non-soluble gel particles are visible)4. Adhesive may be adjusted to the desired viscosity by thinningwith tolueneProtect the adhesives from temperature and humidity extremes. If adhesives are exposed to temperatures below 4°C (40°F), they must be brought to room temperature, 22°C (70°F), andthoroughly mixed as separate units. Additional mixing is required when blending the compounds.DuPont ™ Tedlar ® Polyvinyl Fluoride FilmsAdhesive and Lamination GuideFlexible Product AdhesivesOver the last 25 years DuPont has developed a family ofadhesives used for laminating Tedlar ® PVF film to a wide range of substrates. These adhesives are characterized by excellent resistance to moisture and UV radiation.DuPont flexible product adhesives are versatile acrylic adhesives developed specifically for laminating Tedlar ® PVF film to a variety of substrates. With these adhesives, high-quality, long-lasting bonds can be achieved to meet demanding quality control specifications of manufacturers.A blend of acrylic adhesive 68070 and Epon ™ 828 is used to bond Tedlar ® PVF film to aluminum and galvanized steel in various gauges.Acrylic adhesive 68080 is a liquid that can be pre-applied to Tedlar ® PVF film to facilitate lamination of products for interiors, such as vinyl wall coverings, and for exteriors, such as architectural siding, awnings, flexible sign faces, and fabric structures.Adhesive CharacteristicsDuPont flexible product adhesives have varying degrees of activation temperature, amine reactivity, and hardness.Key characteristics of these adhesives are shown below:Increasing hardness Increasing amine reactivity Increasing activation temperatureLamination temperature149 – 210°C 300 – 410°F135 – 210°C275 – 410°FToluene, %5570Isopropanol, %4530Solvent CompositionProduct AdvantagesThese flexible product adhesives have superior durability that resists light, moisture degradation and discoloration. These adhesives are used in a wide variety of substrates and broad range of conditions over many years of service.Product LimitationsTedlar® adhesives are best used within two years from date of manufacture. See guidance on Adhesive Storage.68070 has been observed to interact with some components in a flame-retardant vinyl causing yellowing.68070/Epon™ 828 mixtures only have an 8-hour pot life. 68080 is incompatible with 68070.Ketone solvents should be avoided in diluting the adhesives as yellow discoloration will result.Caution: DuPont does not warrant the “lamination.” The performance of the “system” is the sole responsibility of the applicator. DuPont will provide consultation and our best information in assisting the customer to achieve satisfactory lamination.Safety PrecautionsThese products are FLAMMABLE AND CONTAIN HARMFUL VAPORS. Store containers away from heat, sparks, and open flames. Keep containers closed when not in use. Before usingthese products, read the Safety Data Sheet.Polycarbonate68080 or 68070ABS68080 or 68070PVC Film68070/Epoxy, 68080Vinyl Siding68080Vinyl Wall Covering68080Laminate Adhesive Selection GuideFlexible Adhesive ApplicationHeat the adhesive to room temperature and mix accordingto instructions. Dilute with toluene to desired viscosity. Apply adhesive using spray gun, brush, dipping, extrusion, rollers, doctor blade/wire wound rod, reverse roller coater, roller coater or gravure coating. Lamination can proceed as soon as the adhesive is dry. Toluene and/or methyl ethyl ketone (for cleanup only) may be used to clean up equipment.Note: Trial laminations should be made to test adhesive suitability. Adhesives, especially non-DuPont, must be tested for the specific application. Some epoxies may not bond well to the Tedlar® PVF film. The harder polyester adhesives do not bond well to Tedlar® PVF film. Isocyanate curing agents generally enhance adhesion. Some phenolic materials or curing agents may cause staining of the Tedlar® PVF film.Lamination GuidelinesAdhesives, thinned to a desired viscosity with toluene, can be applied to the film using a variety of coating methods. The coated film is normally passed through an oven where the solvent is evaporated to obtain a non-blocking adhesive coating. Thorough drying is essential as residual solvent may cause blocking in the roll. Drying temperatures of 77–104°C (170–220°F) coordinated with proper film web speed and tension are presently being used with success. Excessive machine direction (MD) film stretching and transverse direction (TD) film shrinkage can result from improperly controlled oven temperature and film web tension. Laminating DuPont™ Tedlar® PVF Film to Aluminum Lamination is accomplished by cleaning the metal, depositinga controlled conversion coating on the metal, coating the metal with a solvent-based adhesive, evaporating the solvent, heating the metal to 195–205°C (383–401°F) to activate the adhesive, combining with Tedlar® PVF film in nip rolls and quenchingthe laminate.MaterialsFilm – Tedlar® PVF film type TWH15BL3 and colorsAdhesive – DuPont™ 68070, Epon™ 828Metal – AluminumAdhesive Mixing and ApplicationThe adhesive is prepared by the following formula by weight: While stirring the 68070, slowly add Epon™ 828. Blend the mixture for approximately 5 minutes with a suitable mechanical mixer. Adjust adhesive coater to lay down 37–50 µm (1.5 to2.0 mil) wet adhesive equivalent to 6–7.5 µm (0.23 to 0.30 mil)of dry adhesive. Adjust viscosity by diluting with toluene.During normal operation, the rate of solvent evaporation is slight enough to have no effect on the percent solids. If prolonged halts in coating occur, the viscosity must be checked and adjusted with toluene to the original value. Pot life of the mixed adhesive is8 hours.The solvent is removed and adhesive activated in an oven of such length that the metal is in the oven from 30 to 90 seconds. The metal temperature must be 195–205°C (383–401°F) at the end of the oven followed by immediate lamination.LaminationThe laminating equipment consists of a pair of combining or “nip” rolls that are unaffected by the operating temperature of 175°C (347°F). A nip pressure of 87–175 N/cm (50–100 lb/in) of width must be used. A film wrap of at least 90° on the uppernip roll must be used to prevent wrinkling.Adhesive 6807029Epon™ 8281Laminating DuPont™ Tedlar® PVF Film to Galvanized Steel Lamination is accomplished by cleaning the metal, depositinga controlled conversion coating on the metal, coating the metal with a solvent-based adhesive, evaporating the solvent, heating the metal to activate the adhesive, combining with Tedlar® PVF film in nip rolls and quenching the laminate.MaterialsFilm – Tedlar® PVF film type TWH15BL3 and colorsAdhesive – DuPont™ 68070, Epon™ 828Metal – Hot dipped galvanized steel, generally G-90, is used.The steel must have good forming quality and preferably minimum spangle, temper rolled, lock forming quality or extra smooth spangle. The metal must be free of white rust to enable proper surface treatment and adhesion. Prior to lamination the metal being used must have all mill oils removed.The optimum thickness metal to be laminated is 18 gauge(0.0516”).Laminates on metal, 22 gauge (0.0366”) or lighter, may be made on any standard type of galvanized, including commercial quality, regular spangle. Better forming quality is preferred.Metals heavier than 22 (0.0366”) gauge must be minimum spangle or spangle-free surface. Commercial quality, regular spangle steel is not acceptable in gauges heavier than 22 gauge (0.0366”). Care should be taken when laminating metal heavier than 22 gauge (0.0366”) and formed to a radius of less than3 mm (1/8”) to prevent splitting.Adhesive Mixing and ApplicationThe adhesive is prepared by the following formula by weight Adhesive 6807029Adhesive Epon™ 8281While stirring the 68070, slowly add Epon™ 828. Blend the mixture for approximately 5 minutes with a suitable mechanical mixer. Adjust the coater to lay down 37–50 µm (1.5–2.0 mil) wet adhesive equivalent to 6–7.5 µm (0.23–0.30 mil) of dry adhesive.During normal operation, the rate of solvent evaporation is slight enough to have no effect on the percent solids. If prolonged halts in coating occur, the viscosity must be checked and adjusted with toluene to the original value. The pot life of the mixed adhesive is 8 hours.The solvent is removed and adhesive melted in an oven of such length that the metal is in the oven from 30 to 90 seconds. The metal temperature must be 195–205°C (383–401°F) at the end of the oven followed by immediate minationThe lamination equipment consists of a pair of combining or “nip” rolls that are unaffected by the operating temperature of 175°C (347°F). A nip pressure of 10–20 kg/cm (50–100 lb/in) of width must be used. A film wrap of at least 90° on the upper nip roll must be used to prevent wrinkling.Laminating DuPont™ Tedlar® PVF Film to PVC for Outdoor ApplicationsSince there are many formulations of PVC, optimum laminating conditions may vary with the PVC formulation. The following is given as a suggested starting point for lamination studies and has given good results with a number of PVC films.MaterialsFor opaque laminates, pigmented Tedlar® PVF film, such as TWH15BL3 white film, can be used. Under the pigmented films, a higher proportion of epoxy can be used, and a 68070/ Epon™ 828 ratio of 18/1 by volume (14/1 by weight) can be used. Adhesive ApplicationApply 7.5–12.7 µm (0.3 to 0.5 mil) (measured on dry resin) of adhesive to the DuPont™ Tedlar® PVF film or PVC. Dry the adhesive at 66–71°C (150–160°F), film temperature. After drying, the adhesive will appear practically dry to touch and only slightly tacky. If the PVC is coated, note that the adhesive solvent contains toluene, which attacks vinyl, but under the above conditions it will probably be flashed off so fast that this will not cause trouble. Note also that ketones should not be used for dilution as they can cause yellowing of the 68070 adhesive. LaminationCombine the Tedlar® PVF film and PVC in a nip roll, with a glue line temperature of at least 79°C (175°F) but preferably not over 121°C (250°F). Some people have accomplished such laminations with roll temperatures of about 121°C (250°F).Laminating DuPont™ Tedlar® PVF Film to Thermoplastic SheetMaterialsFilm – Any Tedlar® PVF filmAdhesive – DuPont™ 68070 or 68080Plastic – Polystyrene, Polymethacrylate, Polycarbonate,Acrylonitrilebutadiene-styrene (ABS)6807034460(0.2–0.3 dry mil) 68080303706–7.5 dry µm(0.2–0.3 dry mil) Adhesive ApplicationApply the adhesive, thinned with toluene to a desired viscosity, to the film using adhesive coating equipment. Pass the coated film through an oven evaporating the solvent obtaining anon-blocking adhesive coating.The information provided in this technical bulletin corresponds to our knowledge on the subject at the date of its publication. It may be subject to revision as new knowledge and experience becomes available. This information is not intended to substitute for any testing you may need to conduct to determine for yourself the suitability of our products for your particular purposes. Since we cannot anticipate all variations in end-use and disposal conditions, DuPont makes no warranties and assumes no liability in connection with any use of this information. It is intended for use by persons having technical skill, at their own discretion and risk. Nothing in this publication is to be considered as a license to operate under or a recommendation to infringe any patent right. CAUTION: Do not use in medical applications involving permanent implantation in the human body. For other medical applications, see “DuPont Medical Caution Statement,” H-50102-5 and “DuPont Policy Regarding Medical Applications” H-50103-5.DuPont ™, the DuPont Oval Logo, and all trademarks and service marks denoted with ™, SM or ® areowned by affiliates of DuPont de Nemours, Inc. unless otherwise noted. © 2020 DuPont. Form No. H-56696-5 920 CDP For more information visit: Thorough drying is essential as residual solvent may causeblocking in the roll. Drying temperatures of 77–104°C (170–220°F) coordinated with proper film web speed and tension arepresently being used with success. Excessive MD film stretching and TD film shrinkage can result from improperly controlled oven temperature and film web tension.LaminationLaminating adhesive-coated Tedlar ® PVF film to thermoplastic sheet is easily accomplished at the extruder. The operation consists of combining the film with the hot sheet at the first nip of the take-off stack. Stack temperatures of 149°C (300°F) or higher are necessary to heat activate the adhesive and adequately bond the film. The unwind roll of Tedlar ® PVF film should be positioned so that the film wraps the top roll 30° or more and tension across the sheet is uniform. Press Operations: 1-1/2 minutes, minimum lamination temperatures: 135–149°C (275–300°F), 100–150 psi; cool to 38°C (100°F) before removing from press.Laminating DuPont ™ Tedlar ® PVF Film to Vinyl Wall CoveringWall covering having excellent stain resistance and cleanability is possible with Tedlar ® SP PVF film. Lamination is accomplished by combining adhesive coated Tedlar ® SP PVF film with preheated vinyl in heated nip rolls. The finished product is recommended for interior applications only.Film TypesTedlar ® type TTR5JAM8 and TTR10AM8 coated with 6–7.5 µm (0.2–0.3 mil) dry 68080 acrylic adhesive from DuPont. CTRWCAM919 is available and is already adhesive minationLaminating adhesive-coated Tedlar ® PVF film to vinyl has been successfully demonstrated on various types of equipmentfamiliar to the wall covering industry. The operation consists of combining the film with the vinyl in hot nip rolls, heating the composite to 149–177°C (300–350°F) and embossing. The unwind roll of Tedlar ® PVF film should be positioned so that the film wraps the top nip roll at least 90° and tension across the sheet is uniform.。

光伏应用杜邦™的Tedlar®聚氟乙烯薄膜符合耐紫外线和耐候性光伏组件背板的行业标准。

所有的Tedlar®薄膜是由聚氟乙烯制成,使它们有着出色的韧性,耐久性和25年以上的耐候性。

太阳能背板的主要职能包括水蒸气阻隔,物理保护接线和其他敏感元件,电气绝缘性能和降低电池的工作温度。

最流行的背板制作方式是一种三层“三明治”薄膜及在两层的T edlar®薄膜之间层压一层聚酯纤维薄膜。

这就是通常所说的TPT™。

Tedlar®属性工业上更倾向于将T edlar®作为背板材料,因为它独特的性能,能提供各种条件下长期卓越的保护:•抗紫外线•防潮•耐候性•机械性能•强度和耐久性•电气绝缘•UL认证•对大量化学品,溶剂,和染色剂的惰性Tedlar®作为背板的重要组成部分已使用多年。

试验表明,它仍然完好,继续保护太阳能电池组件,现实生活中暴露超过25年以上。

Tedlar®产品类型杜邦™的Tedlar®提供两种产品类型:PV2000系列和PV2100系列薄膜。

这两种类型的市售,目前正在整个市场和跨区域使用。

每个产品提供高的性能和的T edlar®是行业内公认的标准。

Tedlar® PV2100系列薄膜的Tedlar® PV2100系列光伏薄膜光伏组件的附加功能。

PV2111的设计是尺寸稳定,比PV2001反射。

TPT™PV2100系列薄膜制成的背板将在真空层压不容易起皱。

与PV2111太阳能电池组件,可以提供更多的输出功率,因为背板促进更高的内部反射。

的Tedlar® PV2100系列薄膜具有光滑,光泽的外观,领先的有吸引力的层压板。

PV2100系列电影,电影制作技术,导致整个电影的最低厚度变化。

图1.Tedlar®光伏薄膜的尺寸稳定性Tedlar® PV2111薄膜显示示几乎没有收缩,结果改善了TPT™背板的尺寸稳定性。