混凝土工程中英文(个人整理)

- 格式:doc

- 大小:26.00 KB

- 文档页数:5

混凝土工艺中英文对照外文翻译文献混凝土工艺中英文对照外文翻译文献混凝土工艺中英文对照外文翻译文献(文档含英文原文和中文翻译) Concrete technology and developmentPortland cement concrete has clearly emerged as the material of choice for the construction of a large number and variety of structures in the world today. This is attributed mainly to low cost of materials and construction for concrete structures as well as low cost of maintenance.Therefore, it is not surprising that many advancements in concrete technology have occurred as a result of two driving forces, namely the speed of construction and the durability of concrete.During the period 1940-1970, the availability of high early strength portland cements enabled the use of high water content in concrete mixtures that were easy to handle. This approach, however, led to serious problems with durability of structures, especially those subjected to severe environmental exposures.With us lightweight concrete is a development mainly of the last twenty years.Concrete technology is the making of plentiful good concrete cheaply. It includes the correct choice of the cement and the water, and the right treatment of the aggregates. Those which are dug near by and therefore cheap, must be sized, washed free of clay or silt, and recombined in the correct proportions so as to make a cheap concrete which is workable at a low water/cement ratio, thus easily comoacted to a high density and therefore strong.It hardens with age and the process of hardening continues for a long time after the concrete has attained sufficient strength.Abrams’law, perhaps the oldest law of concrete technology, states that the strength of a concrete varies inversely with its water cement ratio. This means that the sand content (particularly the fine sand which needs much water) must be reduced so far as possible. The fact that the sand “drinks” large quantities of water can easily be established by mixing several batches of x kg of cement with y kg of stone and the same amount of water but increasing amounts of sand. However if there is no sand the concrete will be so stiff that it will be unworkable thereforw porous and weak. The same will be true if the sand is too coarse. Therefore for each set of aggregates, the correct mix must not be changed without good reason. This applied particularly to the water content.Any drinkable and many undrinkable waters can be used for making concrete, including most clear waters from the sea or rivers. It is important that clay should be kept out of the concrete. The cement if fresh can usually be chosen on the basis of the maker’s certificates of tensile or crushing tests, but these are always made with fresh cement. Where strength is important , and the cement at the site is old, it should be tested.This stress , causing breakage,will be a tension since concretes are from 9 to 11times as strong in compression as in tension, This stress, the modulus of rupture, will be roughly double the direct tensile breaking stress obtained in a tensile testing machine,so a very rough guess at the conpressive strength can be made by multiplying the modulus of rupture by 4.5. The method can be used in combination with the strength results of machine-crushed cubes or cylinders or tensile test pieces but cannot otherwise be regarded as reliable. With these comparisons,however, it is suitable for comparing concretes on the same site made from the same aggregates and cement, with beams cast and tested in the same way.Extreme care is necessary for preparation,transport,plating and finish of concrete in construction works.It is important to note that only a bit of care and supervision make a great difference between good and bad concrete.The following factors may be kept in mind in concreting works.MixingThe mixing of ingredients shall be done in a mixer as specified in the contract.Handling and ConveyingThe handling&conveying of concrete from the mixer to the place of final deposit shall be done as rapidly as practicable and without any objectionable separation or loss of ingredients.Whenever the length of haul from the mixing plant to the place of deposit is such that the concrete unduly compacts or segregates,suitable agitators shall be installed in the conveying system.Where concrete is being conveyed on chutes or on belts,the free fall or drop shall be limited to 5ft.(or 150cm.) unless otherwise permitted.The concrete shall be placed in position within 30 minutes of its removal from the mixer.Placing ConcreteNo concrete shall be placed until the place of deposit has been thoroughly inspected and approved,all reinforcement,inserts and embedded metal properly security in position and checked,and forms thoroughly wetted(expect in freezing weather)or oiled.Placing shall be continued without avoidable interruption while the section is completed or satisfactory construction joint made.Within FormsConcrete shall be systematically deposited in shallow layers and at such rate as to maintain,until the completion of the unit,a plastic surface approximately horizontal throughout.Each layer shall be thoroughly compacted before placing the succeeding layer.CompactingMethod. Concrete shall be thoroughly compacted by means of suitable tools during and immediately after depositing.The concrete shall be worked around all reinforcement,embedded fixtures,and into the comers of the forms.Every precaution shall be taken to keep the reinforcement and embedded metal in proper position and to prevent distortion.Vibrating. Wherever practicable,concrete shall be internally vibrated within the forms,or in the mass,in order to increase the plasticity as to compact effectively to improve the surface texture and appearance,and to facilitate placing of the concrete.Vibration shall be continued the entire batch melts to a uniform appearance and the surface just starts to glisten.A minute film of cement paste shall be discernible between the concrete and the form and around the reinforcement.Over vibration causing segregation,unnecessary bleeding or formation of laitance shall be avoided.The effect spent on careful grading, mixing and compaction of concrete will be largely wasted if the concrete is badly cured. Curing means keeping the concretethoroughly damp for some time, usually a week, until it has reached the desired strength. So long as concrete is kept wet it will continue to gain strength, though more slowly as it grows older.Admixtures or additives to concrete are materials arematerials which are added to it or to the cement so as to improve one or more of the properties of the concrete. The main types are:1. Accelerators of set or hardening,2. Retarders of set or hardening,3. Air-entraining agents, including frothing or foaming agents,4. Gassing agents,5. Pozzolanas, blast-furnace slag cement, pulverized coal ash,6. Inhibitors of the chemical reaction between cement and aggregate, which might cause the aggregate to expand7. Agents for damp-proofing a concrete or reducing its permeability to water,8. Workability agents, often called plasticizers,9. Grouting agents and expanding cements.Wherever possible, admixtures should be avouded, particularly those that are added on site. Small variations in the quantity added may greatly affect the concrete properties in an undesiraale way. An accelerator can often be avoided by using a rapid-hardening cement or a richer mix with ordinary cement, or for very rapid gain of strength, high-alumina cement, though this is very much more expensive, in Britain about three times as costly as ordinary Portland cement. But in twenty-four hours its strength is equal to that reached with ordinary Portland cement in thirty days.A retarder may have to be used in warm weather when a large quantity of concrete has to be cast in one piece of formwork, and it is important that the concrete cast early in the day does not set before the last concrete. This occurs with bridges when they are cast in place, and the formwork necessarily bends underthe heavy load of the wet concrete. Some retarders permanently weaken the concrete and should not be used without good technical advice.A somewhat similar effect,milder than that of retarders, is obtained with low-heat cement. These may be sold by the cement maker or mixed by the civil engineering contractor. They give out less heat on setting and hardening, partly because they harden more slowly, and they are used in large casts such as gravity dams, where the concrete may take years to cool down to the temperature of the surrounding air. In countries like Britain or France, where pulverized coal is burnt in the power stations, the ash, which is very fine, has been mixed with cement to reduce its production of heat and its cost without reducing its long-term strength. Up to about 20 per cent ash by weight of the cement has been successfully used, with considerable savings in cement costs.In countries where air-entraining cement cement can be bought from the cement maker, no air-entraining agent needs to be mixed in .When air-entraining agents draw into the wet cement and concrete some 3-8 percent of air in the form of very small bubbles, they plasticize the concrete, making it more easily workable and therefore enable the water |cement ratio to be reduced. They reduce the strength of the concrete slightly but so little that in the United States their use is now standard practice in road-building where heavy frost occur. They greatly improve the frost resistance of the concrete.Pozzolane is a volcanic ash found near the Italian town of Puzzuoli, which is a natural cement. The name has been given to all natural mineral cements, as well as to the ash from coal or the slag from blast furnaces, both of which may become cementswhen ground and mixed with water. Pozzolanas of either the industrial or the mineral type are important to civil engineers because they have been added to oridinary Portland cement in proportions up to about 20 percent without loss of strength in the cement and with great savings in cement cost. Their main interest is in large dams, where they may reduce the heat given out by the cement during hardening. Some pozzolanas have been known to prevent the action between cement and certain aggregates which causes the aggregate to expand, and weaken or burst the concrete.The best way of waterproof a concrete is to reduce its permeability by careful mix design and manufacture of the concrete, with correct placing and tighr compaction in strong formwork ar a low water|cement ratio. Even an air-entraining agent can be used because the minute pores are discontinuous. Slow, careful curing of the concrete improves the hydration of the cement, which helps to block the capillary passages through the concrete mass. An asphalt or other waterproofing means the waterproofing of concrete by any method concerned with the quality of the concrete but not by a waterproof skin.Workability agents, water-reducing agents and plasticizers are three names for the same thing, mentioned under air-entraining agents. Their use can sometimes be avoided by adding more cement or fine sand, or even water, but of course only with great care.The rapid growth from 1945 onwards in the prestressing of concrete shows that there was a real need for this high-quality structural material. The quality must be high because the worst conditions of loading normally occur at the beginning of the life of the member, at the transfer of stress from the steel to theconcrete. Failure is therefore more likely then than later, when the concrete has become stronger and the stress in the steel has decreased because of creep in the steel and concrete, and shrinkage of the concrete. Faulty members are therefore observed and thrown out early, before they enter the structure, or at least before it The main advantages of prestressed concrete in comparison with reinforced concrete are :①The whole concrete cross-section resists load. In reinforced concrete about half the section, the cracked area below the neutral axis, does no useful work. Working deflections are smaller.②High working stresses are possible. In reinforced concrete they are not usually possible because they result in severe cracking which is always ugly and may be dangerous if it causes rusting of the steel.③Cracking is almost completely avoided in prestressed concrete.The main disadvantage of prestressed concrete is that much more care is needed to make it than reinforced concrete and it is therefore more expensive, but because it is of higher quality less of it needs to be needs to be used. It can therefore happen that a solution of a structural problem may be cheaper in prestressed concrete than in reinforced concrete, and it does often happen that a solution is possible with prestressing but impossible without it.Prestressing of the concrete means that it is placed under compression before it carries any working load. This means that the section can be designed so that it takes no tension or very little under the full design load. It therefore has theoretically no cracks and in practice very few. The prestress is usually applied by tensioning the steel before the concrete in which it isembedded has hardened. After the concrete has hardened enough to take the stress from the steel to the concrete. In a bridge with abutments able to resist thrust, the prestress can be applied without steel in the concrete. It is applied by jacks forcing the bridge inwards from the abutments. This methods has the advantage that the jacking force, or prestress, can be varied during the life of the structure as required.In the ten years from 1950 to 1960 prestressed concrete ceased to be an experinmental material and engineers won confidence in its use. With this confidence came an increase in the use of precast prestressed concrete particularly for long-span floors or the decks of motorways. Whereever the quantity to be made was large enough, for example in a motorway bridge 500 m kong , provided that most of the spans could be made the same and not much longer than 18m, it became economical to usefactory-precast prestressed beams, at least in industrial areas near a precasting factory prestressed beams, at least in industrial areas near a precasting factory. Most of these beams are heat-cured so as to free the forms quickly for re-use.In this period also, in the United States, precast prestressed roof beams and floor beams were used in many school buildings, occasionally 32 m long or more. Such long beams over a single span could not possibly be successful in reinforced concrete unless they were cast on site because they would have to be much deeper and much heavier than prestressed concrete beams. They would certainlly be less pleasing to the eye and often more expensive than the prestressed concrete beams. These school buildings have a strong, simple architectural appeal and will be a pleasure to look at for many years.The most important parts of a precast prestressed concrete beam are the tendons and the concrete. The tendons, as the name implies, are the cables, rods or wires of steel which are under tension in the concrete.Before the concrete has hardened (before transfer of stress), the tendons are either unstressed (post-tensioned prestressing) or are stressed and held by abutments outside the concrete ( pre-tensioned prestressing). While the concrete is hardening it grips each tendon more and more tightly by bond along its full length. End anchorages consisting of plates or blocks are placed on the ends of the tendons of post-tensioned prestressed units, and such tendons are stressed up at the time of transfer, when the concrete has hardened sufficiently. In the other type of pretressing, with pre-tensioned tendons, the tendons are released from external abutments at the moment of transfer, and act on the concrete through bond or archorage or both, shortening it by compression, and themselves also shortening and losing some tension.Further shortening of the concrete (and therefore of the steel) takes place with time. The concrete is said to creep. This means that it shortens permanently under load and spreads the stresses more uniformly and thus more safely across its section. Steel also creeps, but rather less. The result of these two effects ( and of the concrete shrinking when it dries ) is that prestressed concrete beams are never more highly stressed than at the moment of transfer.The factory precasting of long prestressed concrete beams is likely to become more and more popular in the future, but one difficulty will be road transport. As the length of the beam increases, the lorry becomes less and less manoeuvrable untileventually the only suitable time for it to travel is in the middle of the night when traffic in the district and the route, whether the roads are straight or curved. Precasting at the site avoids these difficulties; it may be expensive, but it has often been used for large bridge beams.混凝土工艺及发展波特兰水泥混凝土在当今世界已成为建造数量繁多、种类复杂结构的首选材料。

混凝土及钢筋混凝土施工质量要求(Quality requirements for concrete and reinforced concrete construction)1、基础施工质量(foundation construction quality)(1)坑(槽)结构尺寸满足设计要求;(The size of the pit (groove) meets the design requirements;)(2)建基面无松动岩块、无浮渣,无反坡、倒悬坡、陡坎尖角,无爆破影响裂缝;(There is no loose rock mass, no scum, no anti-slope, overhanging slope, steep Angle, no blasting influence crack;)(3)地表水或地下水妥善引排或封堵;(Proper drainage or sealing of surface water or groundwater;)(4)混凝土施工缝无乳皮、成毛面、微露粗砂,洁净、无积水。

(The concrete construction is sewn without milk skin, hair surface, fine sand, clean, no water.)2、钢筋施工质量(Construction quality of reinforcement)(1)钢筋的材质、数量、规格尺寸、加工制作及安装位置符合产品质量标准和设计要求;(The material, quantity, size, processing and installation of reinforcement are in accordance with the product quality standards and design requirements.)(2)钢筋表面应保持清洁,无锈蚀和油污;(The surface of the steel bar should be kept clean, free from rust and oil.)(3)钢筋长度方向的偏差:±1/2净保护层厚;(Deviation of the length direction of the steel bar: the thickness of the net protective layer of plus or minus 1/2;)(4)保护层厚度的局部偏差:±1/4净保护层厚;(Local deviation of protective layer thickness: 1/4 net protective coating thickness;)(5)依据图纸要求,留置钢筋保护层;(According to the requirements of the drawing, the protective layer of the reinforcement bars;)(6)预埋件结构型式、位置、尺寸、材料的品种、规格、性能符合图纸设计要求。

结构工程常用词汇混凝土:concrete钢筋:reinforcin g steel bar 钢筋混凝土:reinforced concrete (RC)钢筋混凝土结构:reinforced concrete structure 板式楼梯:cranked slab stairs 刚度:rigidity徐变:creep水泥:cement钢筋保护层:cover to reinforce ment梁:beam 柱:column 板:slab 剪力墙:shear wall 基础:foundatio n剪力:shear形:shear deformati on剪切模量:shear modulus 拉力:tension压力:pressure 延伸率:percentag e of elongation 位移:displacem ent应力:stress应变:strain应力集中:concentra tion of stresses 应力松弛:stress relaxation 应力图:stress diagram 应力应变曲线:stress-strain curve应力状态:state of stress 钢丝:steel wirehoop reinforce ment箍筋间距:stirrup spacing加载:loading抗压强度:compressi ve strength 抗弯强度:bending strength 抗扭强度:torsional strength 抗拉强度:tensile strength 裂缝:crack屈服:yield屈服点:yield point 屈服荷载:yield load屈服极限:limit of yielding 屈服强度:yield strength屈服强度下限:lower limit of yield荷载:load横截面:cross section承载力:bearing capacity 承重结构:bearing structure 弹性模量:elastic modulus预应力钢筋混凝土:prestresse d reinforced concrete 预应力钢筋:prestresse d reinforce ment预应力损失:loss of prestress 预制板:precast slab现浇钢筋混凝土结构:cast-in-place reinforced concrete 双向配筋:two-way reinforce ment主梁:main beam次梁:secondary beam弯矩:moment 悬臂梁:cantilever beam延性:ductileity 受弯构件:member in bending 受拉区:tensile region受压区:compressi ve region 塑性:plasticity 轴向压力:axial pressure 轴向拉力:axial tensioncrane beam可靠性:reliability 粘结力:cohesive force外力:external force弯起钢筋:bent-up bar弯曲破坏:bending failure屋架:roof truss 素混凝土:non-reinforced concrete 无梁楼盖:flat slab配筋率:reinforce ment ratio 配箍率:stirrup ratio泊松比:Poisson’s ratio偏心受拉:eccentric tension偏心受压:eccentric compressi oneccentric distance疲劳强度:fatigue strength偏心荷载:eccentric load跨度:span跨高比:span-to-depth ratio跨中荷载:midspan load框架结构:frame structure 集中荷载:concentra ted load 分布荷载:distributio n load分布钢筋:distributio n steel挠度:deflection 设计荷载:design load度:design strength 构造:constructi on简支梁:simple beam截面面积:area of section 浇注:pouring浇注混凝土:concreting 钢筋搭接:bar splicing刚架:rigid frame脆性:brittleness 脆性破坏:brittle failure。

acid proof concrete耐酸混凝土acid resisting concrete抗酸acid-resisting concrete抗酸混凝土aerated concrete掺气混凝土; 充气混凝土aerated concrete compressive strength 加气混凝土抗压强度aerated concrete density 加气混凝土容重aerated concrete floor slab 加气混凝土楼板aerated concrete glue-joint block partition 加气混凝土粘胶缝隔墙aerated concrete member 加气混凝土构件aerated concrete panel 加气混凝土板aerated concrete partition 加气混凝土隔墙aerated concrete pipe insulating section 加气混凝土管套age of concrete混凝土令期aggregate for reinforced concrete钢筋混凝土骨料air entraining concrete加气混凝土air-entraining fibrous concrete加气纤维混凝土air-gravel concrete气干砾石混凝土Aliva concrete sprayer 阿里瓦混凝土喷射器alkali resistant cement concrete flooring 耐碱混凝土地面all-haydite concrete全陶粒混凝土allowable bearing stress for concrete foundation 混凝土基础的许用承压应力alunite expansion agent for concrete明矾石混凝土膨胀剂arched concrete dam 混凝土拱坝architectural concrete装饰混凝土armoring concrete block 护面混凝土块体armoured concrete钢筋混凝土armoured concrete slab 钢筋混凝土板as-cast-finish concrete清水面混凝土asbestos concrete石棉混凝土asbestos concrete pipe 石棉混凝土管asbestos concrete slab 石棉混凝土板asphalt concrete沥青混凝土; 地沥青混凝土asphalt concrete flooring 沥青混凝土楼地面asphaltic concrete地沥青混凝土asphaltic concrete road 地沥青混凝土路atractylis concrete苍术硬脂autogenous growth of concrete混凝土自生体积增长ballast concrete石渣混凝土barium concrete含钡混凝土bituminous concrete沥青混凝土bituminous concrete flooring 沥青混凝土楼地面blinding concrete盖面混凝土blown-out concrete充气混凝土bond between concrete and steel 混凝土与钢筋间的结合力boulder concrete卵石混凝土braced reinforced concrete flume 桁架式钢筋混凝土渡槽breeze concrete焦渣混凝土buried concrete地下混凝土carbon fibre reinforced concrete (CFRC) 碳纤维增强混凝土cast concrete模铸混凝土cast-in-concrete reactor 混凝土芯电抗器cast-in-situ concrete原地混凝土cell concrete多孔混凝土cellular concrete泡沫混凝土; 多孔混凝土; 加气混凝土cellular concrete block 格形混凝土块体cement concrete水泥混凝土central concrete membrane 混凝土心墙central mix concrete集中拌合混凝土centrifugally spun concrete pipe 离心制混凝土管ceramsite concrete陶粒混凝土ceramsite concrete wall panel 陶粒混凝土墙板chassis concrete残花浸膏cinder concrete焦渣混凝土; 煤渣混凝土; 矿渣混凝土cinder concrete block 焦渣混凝土砌块cinder concrete brick 煤渣混凝土砖cinder concrete insulating course 焦渣混凝土保温层cinder concrete lintel 焦渣混凝土过梁coarse aggregate concrete粗骨料混凝土coarse asphaltic concrete粗骨料沥青混凝土code for reinforced concrete structure 钢筋混凝土结构规范coke breeze concrete煤渣混凝土cold-mixed asphaltic concrete冷拌沥青混凝土colloidal concrete胶质混凝土combined steel and concrete column 钢骨混凝土柱compacted concrete捣实混凝土composite steel concrete column 劲性混凝土柱concrete固结的; 混凝土concrete accelerator 混凝土速凝剂concrete admixture 混凝土外加剂concrete age 混凝土龄期concrete aggregate 混凝土骨料; 混凝土集料concrete apron 混凝土护坦concrete arch dam 混凝土拱坝concrete backfill 混凝土回填concrete baffle pier 混凝土消力墩concrete bagwork 袋装混凝土护岸工程concrete ballast 混凝土压载concrete base slab 混凝土基础板concrete basin 混凝土水池concrete batch plant 混凝土搅拌设备concrete batcher 混凝土配料器concrete batching plant 混凝土搅拌站concrete beam 混凝土梁concrete bed 混凝土基础concrete bent construction 混凝土构架结构concrete bit 混凝土钻头concrete bleeding 混凝土泌水现象concrete blinding 混凝土模板concrete block 混凝土块concrete block and rock-mound breakwater 混凝土方块堆石防波堤concrete block breakwater 混凝土块防波堤concrete block cutter 混凝土方块切割机concrete block revetment 混凝土块护岸concrete blockyard 混凝土块制造场concrete blower 混凝土风力输送机concrete bottom 混凝土底面concrete box culvert 混凝土箱涵concrete breaker 混凝土捣碎机; 混凝土破碎机concrete brick 混凝土砖concrete bridge 混凝土桥concrete bucket 混凝土吊斗; 混凝土吊罐concrete bucket lock 混凝土料斗闸门concrete buggy 混凝土手推车; 混凝土用二轮车concrete burn 混凝土灼伤concrete caisson breakwater 混凝土沉箱防波堤concrete caisson sinking 混凝土沉箱下沉concrete canal lining 混凝土渠道衬砌concrete cart 混凝土手推车; 混凝土载运车concrete casing 混凝土外壳concrete check 混凝土配水闸concrete check dam 混凝土谷坊; 混凝土拦沙坝concrete chisel 混凝土凿concrete chute 混凝土溜槽concrete column 混凝土柱concrete composition 混凝土成分concrete construction 混凝土建筑; 混凝土结构; 混凝土施工concrete container 混凝土容器concrete core-wall 混凝土心墙concrete cover 混凝土保护层concrete cradle 混凝土管座concrete creep 混凝土蠕变; 混凝土徐变concrete crib breakwater 混凝土木笼防波堤; 混凝土箱格防波堤concrete cribbing 混凝土筐笼; 混凝土箱格concrete cube test 混凝土立方试块试验concrete culvert 混凝土涵洞concrete curing 混凝土养护concrete curing blanket 混凝土保温覆盖concrete curing compound 混凝土养护剂concrete curing mat 混凝土养护盖垫concrete cushion 混凝土垫层concrete cutoff wall 混凝土截水墙concrete cutting machine 混凝土切割机concrete dam 混凝土坝concrete deadman (拉岸壁板桩的) 混凝土锚桩concrete deep-water structure 深水混凝土结构concrete delivery pipe 混凝土输送管concrete delivery truck 混凝土运送车; 运输混凝土的卡车concrete deposit 混凝土浇筑物concrete design 混凝土配合比设计; 混凝土设计concrete diaphragm wall 地下连续墙concrete disintegration 混凝土离析concrete distributing tower 混凝土分配塔concrete distributor 混凝土分布机; 混凝土摊铺机concrete drain tile 混凝土排水管concrete equipment 混凝土设备concrete equivalence 混凝土当量concrete face 混凝土面板concrete face rockfill dam 混凝土面板坝concrete facing 混凝土护面; 混凝土面板concrete fatigue 混凝土疲劳concrete filled caisson 混凝土充填沉箱concrete filler block 混凝土填块concrete fillet 混凝土内补角concrete finish 混凝土表面光洁度concrete finisher 混凝土整修机concrete finishing 混凝土表面磨光concrete finishing machine 混凝土整面机concrete fireproofing 混凝土防火性concrete floor 混凝土底板; 混凝土楼板concrete flowability 混凝土流动性concrete flume 混凝土渡槽concrete footing 混凝土基础; 混凝土基脚concrete form 混凝土模板concrete forming cycle 混凝土模板周转concrete foundation block 混凝土基础块体concrete frame 混凝土排架concrete grade 混凝土等级concrete gravity dam 混凝土重力坝concrete gravity dockwall 混凝土重力式船坞墙concrete gravity platform 混凝土重力式钻井平台concrete grip 混凝土握固力concrete guard wall 混凝土挡墙; 混凝土护墙concrete guide wall 混凝土导墙concrete gun 混凝土喷枪concrete handling 混凝土吊运concrete hardener 混凝土硬化剂concrete hardening 混凝土硬化concrete hauling container 混凝土运送容器concrete high frequency vibrator 混凝土高频振动器concrete hollow block 混凝土空心块concrete hopper 混凝土料斗concrete ingredient 混凝土成分concrete inspection 混凝土检验concrete intelligence 具体智能; 具体智能concrete interface treating agent 混凝土界面处理剂concrete iron 钢筋concrete jacket 混凝土套; 混凝土外皮concrete key trench 混凝土截水槽concrete labor 具体劳动; 具体劳动concrete lead-lined cell 铅衬混凝土电解槽concrete lift 混凝土浇筑层; 混凝土升高层concrete lifting bucket 混凝土吊斗concrete lintel 混凝土过梁concrete lock 混凝土船闸concrete lock floor 混凝土船闸底板concrete masonry 混凝土圬工concrete mattress 混凝土沉排concrete mattress roll 混凝土排辊concrete membrane 混凝土薄层concrete mixer 混凝土混合器; 混凝土搅拌车; 混凝土搅拌机concrete mixer truck 混凝土拌和汽车concrete mixing machine 混凝土搅拌机concrete mixing plant 混凝土拌和设备concrete mixing truck 混凝土搅拌车concrete mixing vehicle 混凝土搅拌车concrete mobility 混凝土流动性concrete model 具体模型; 具体模型concrete moist room 混凝土湿养护间concrete nail 混凝土钉; 水泥钉concrete number 名数concrete of jasmine 茉莉浸膏concrete of low porosity 密实混凝土concrete of Michelia 白兰浸膏concrete of rose crimson glory 墨红花浸膏concrete orifice turnout 孔口式混凝土斗门; 孔口式混凝土分水闸concrete overflow dam 混凝土溢流坝concrete pavement 混凝土护面; 混凝土路面concrete pavement vibrator 混凝土铺路振动器concrete paver 混凝土铺路机concrete paving 混凝土护面concrete pedestal 混凝土基座concrete penetrometer 混凝土渗透仪concrete pier 混凝土墩concrete pile 混凝土桩concrete piling 混凝土桩concrete pillar 混凝土标石; 混凝土支柱concrete pipe 混凝土管concrete pipe rack 混凝土管架concrete piping 混凝土管道输送concrete placeability 混凝土的可浇置性concrete placement 混凝土浇筑concrete placer 混凝土浇注机; 混凝土铺注机; 混凝土摊铺机concrete placing installation 混凝土浇筑设备concrete placing plant 混凝土浇筑设备concrete placing skip 混凝土浇注斗concrete placing trestle 混凝土施工栈桥concrete plant 混凝土厂concrete plug 混凝土塞concrete pond 混凝土贮槽concrete pontoon 混凝土浮船; 混凝土平底船concrete pouring 混凝土浇筑concrete pouring machine 混凝土浇注机concrete power saw 混凝土动力锯; 混凝土动力锯缝机concrete product 混凝土制品concrete proportioning 混凝土配合concrete pump 混凝土泵; 混凝土输送泵concrete quay 混凝土码头concrete rammer 混凝土夯实器concrete reactor 混凝土芯电抗器concrete reinforced bar 钢筋concrete reinforced pipe 钢筋混凝土管concrete reinforcement 混凝土配筋concrete reinforcing bars 钢筋concrete retarder 混凝土缓凝剂; 混凝土绶凝剂concrete retempering 混凝土重塑concrete revetment 混凝土护岸concrete road finisher 混凝土修平路面机concrete road paver 混凝土路面铺设机concrete roof 混凝土顶板concrete saddle 混凝土鞍座concrete sample 混凝土试件concrete saw 混凝土锯concrete scaling 混凝土剥落concrete scraper 混凝土铲运机concrete setting 混凝土凝固concrete sheet-piling 混凝土板桩concrete sheetpile breakwater 混凝土板桩防波堤concrete shell 混凝土薄壳concrete shell pile 混凝土薄壳桩concrete shrinkage 混凝土干缩; 混凝土收缩concrete signal 具体信号; 具体信号concrete sinker 混凝土沉锤concrete siphon 混凝土虹吸管concrete skeleton 混凝土骨架concrete slab 混凝土板; 混凝土面板concrete slab pavement 混凝土板护面concrete slab revetment 混凝土板护坡concrete sleeper 混凝土轨枕concrete sluice 混凝土节制闸concrete snow 固结雪concrete specification 混凝土规范concrete specimen 混凝土试件concrete spiral casing 混凝土蜗壳concrete splitter 混凝土分离器; 混凝土劈裂器concrete sprayer 混凝土喷射机concrete spreader 混凝土平铺机; 混凝土撒布机; 混凝土摊铺机concrete spreading 混凝土平仓concrete spreading plant 混凝土散布机concrete steel 钢筋钢; 劲性钢筋concrete structure 混凝土结构concrete surface joint cutter 混凝土路面接缝切削机concrete tank 混凝土水箱; 混凝土油罐; 混凝土贮水池concrete terrazzo 混凝土水磨石concrete tetrapod 混凝土四脚体concrete tower 混凝土升运塔concrete transfer car 混凝土转运车concrete transporting equipment 混凝土运输设备concrete tribar 混凝土三棱体块concrete tubular pile 混凝土管桩concrete unit 具体单位; 具体单位concrete vault 混凝土穹顶concrete vibrating machine 混凝土夯实机concrete vibrator 混凝土捣实器; 混凝土振捣器concrete vibratory machine 混凝土夯实机; 混凝土振捣机concrete waterproofing 混凝土防火性concrete waterproofing oil 混凝土防水油concrete workability 混凝土和易性concrete-bar bending machine 钢筋弯曲机concrete-bar drawer 钢筋拉伸机concrete-bar straightening-cutting machine 钢筋调直切断机concrete-consistency meter 混凝土粘度计concrete-filled tube column 混凝土充填管柱; 混凝土填塞管柱concrete-lined 混凝土衬砌的concrete-lined canal 混凝土衬砌渠道concrete-lined channel 混凝土衬砌渠道concrete-lined tunnel 混凝土衬砌隧洞concrete-mattress revetment 混凝土沉排护岸concrete-reinforcing steel 混凝土加固用钢筋concrete-spouting plant 混凝土灌注设备concrete-timber pile 混凝土木桩concrete-vibrating compactor 混凝土振动压实机confined concrete侧限混凝土continuous concrete wall 地下连续墙contraction of mass concrete大体积混凝土体积收缩cooperation of concrete and steel 混凝土与钢筋的联合作用corrugated concrete slab 波纹混凝土板; 波形混凝土板covered reinforced-concrete flume 封闭式钢筋混凝土渡槽crushed stone concrete碎石混凝土cyclopeam concrete毛石混凝土cyclopean concrete蛮石混凝土; 大块石混凝土cylindrical concrete shell 筒形混凝土壳de-aired concrete去气混凝土deaerated concrete去气混凝土deformed ore-stressed concrete steel wire 预应力混凝土异形钢丝dense concrete密实混凝土dense-graded asphalt concrete密级配沥青混凝土dense-graded bituminous concrete密级配沥青混凝土depositing concrete浇注混凝土diatomaceous concrete硅藻土混凝土diesel concrete mixer 柴油混凝土搅拌机double reinforced concrete双重配筋混凝土double-sided reinforced concrete jetty (靠船的) 二边钢筋混凝土突码头drum type concrete mixer 鼓形混凝土拌合机dry batched concrete干拌合混凝土dry concrete干硬性混凝土dry lean concrete干贫混凝土dry mixed concrete干拌合混凝土dry-packed concrete干填混凝土dry-tamped concrete干捣实混凝土earth concrete掺土混凝土effective area of concrete混凝土有效面积electric curing of concrete混凝土电热养护epoxy asphalt concrete环氧沥青混凝土expanded aggregate concrete膨胀性集料混凝土expanded slag concrete膨胀矿渣混凝土external concrete vibrators with motor 带电动机的混凝土振动器facing concrete面层混凝土fair-faced concrete清水面混凝土fast hardening concrete快硬混凝土fat concrete富混凝土; 肥混凝土fiber concrete纤维增强混凝土fibre concrete纤维性混凝土fibre reinforced concrete纤维加强混凝土; 玻璃纤维混凝土fibrous concrete纤维性混凝土fill concrete填充混凝土; 回填混凝土fill-up concrete block 填充式混凝土砌块fine concrete细骨料混凝土fine-graded bituminous concrete细级配沥青混凝土finished concrete饰面混凝土fire-resisting concrete耐火混凝土fireproof concrete耐火混凝土floated concrete抹面混凝土floating concrete mixer 混凝土搅拌船fly-ash-cement concrete烟灰水泥混凝土flyash concrete粉煤灰混凝土foam concrete泡沫混凝土foamed concrete泡沫混凝土form-vibrated concrete模板振捣混凝土fresh concrete新拌混凝土freshly mixed concrete新拌混凝土frost-resistant concrete防冻混凝土; 抗冻混凝土gap-graded concrete间断级配混凝土gas concrete产气轻质混凝土glass concrete玻璃纤维混凝土; 玻璃纤维增强混凝土glass fibre concrete玻璃纤维混凝土glass reinforced concrete glass 玻璃纤维混凝土glass-concrete construction 嵌玻璃砖混凝土构造granolithic concrete花岗石混凝土; 仿石混凝土; 假石混凝土gravel concrete砾石混凝土grip between concrete and steel 钢筋混凝土握裹力grouted-aggregate concrete骨料灌浆混凝土; 灌浆混凝土gunited concrete喷射浇灌的混凝土gunning concrete喷涂混凝土gypsum concrete石膏混凝土gypsum fiber concrete石膏纤维混凝土hand-compacted concrete人工捣实混凝土hand-placed concrete人工浇筑混凝土handy concrete mixer 手动混凝土搅拌机hard rock concrete硬石混凝土hardened concrete硬化混凝土; 硬结混凝土haydite concrete陶粒混凝土haydite concrete wall panel 陶粒混凝土墙板heat insulating concrete隔热混凝土heat rise in mass concrete大体积混凝土内热量升高heat-insulating concrete绝热混凝土; 绝热混凝土heat-resistant concrete抗热性混凝土heavy aggregate concrete shield 重混凝土防护层heavy concrete重混凝土heavy concrete (通常用于防辐射) 高密度混凝土heavy-aggregate concrete重混凝土high drying shrinkage concrete高干缩率混凝土high-density concrete高密度混凝土high-grade concrete高标号混凝土high-lift concrete construction method 混凝土高块浇筑法high-strength concrete高强混凝土hollow concrete蜂窝混凝土homogeneous concrete均质混凝土; 均质混凝土honeycomb concrete蜂窝混凝土horizontal axis concrete mixer 水平轴混凝土拌和机hot asphaltic concrete pavement 热铺地沥青混凝土路面hot-laid asphaltic concrete热铺沥青混凝土hot-mixed asphaltic concrete热拌沥青混凝土ice concrete冰混凝体ilmenite loaded concrete钛铁混凝土; 钛铁混凝土immature concrete未凝结混凝土immersible concrete vibrator 插入式混凝土振捣器in situ concrete原地混凝土insulating concrete隔热混凝土iron aggregate concrete铁混凝土iron plated concrete包铁混凝土iron-aggregate concrete铁屑混凝土iron-loaded concrete铁混凝土jasmine concrete茉莉浸膏Jasminum grandiflorum concrete大花茉莉浸膏lean concrete贫混凝土lean mix concrete贫混凝土light aggregate concrete轻集料混凝土light concrete轻混凝土light concrete wall panel 轻混凝土墙板light weight concrete低密度混凝土light-concrete structure 轻混凝土结构; 轻质混凝土结构lightweight aggregate concrete轻骨料混凝土lightweight concrete轻混凝土; 轻质混凝土lightweight lime concrete轻三合土ligno-concrete木筋混凝土lime concrete石灰混凝土; 石灰三和土lime-cement-flyash concrete石灰水泥粉煤灰三合混凝土lime-earth-broken brick concrete碎砖三合土limestone coarse aggregate concrete石灰石粗骨料混凝土linear-type concrete hinge-bearing 线式混凝土铰支座liquid concrete液体混凝土; 液状混凝土loaded concrete重混凝土low shrinkage concrete低缩性混凝土low-grade concrete低标号混凝土low-lift construction for mass concrete大体积混凝土薄层施工low-porosity concrete低孔率混凝土low-shrinkage concrete低缩性混凝土low-slump concrete低坍落度混凝土low-strength concrete低强混凝土machine-mixed concrete机拌混凝土mass concrete大体积混凝土; 大块混凝土mass concrete dam 大体积混凝土坝mass concrete invert (干船坞的) 大体积混凝土底板mass-concrete wall 大体积混凝土岸壁Michelia alba concrete白兰浸膏Michelia concrete白兰花浸膏mixed concrete拌好的混凝土moist-cured concrete湿养护混凝土; 湿治混凝土moulded concrete模制混凝土mushy concrete浆状混凝土mushy consistency of concrete混凝土流态稠度nailable concrete受钉混凝土newly-laid concrete新浇混凝土no-fines concrete无细骨料混凝土; 无细料混凝士no-slump concrete无坍落度混凝土; 不坍落混凝土non-air-entrained concrete非加气混凝土non-destructive testing of concrete混凝土非破坏性试验non-load-bearing concrete非承重混凝土non-reinforced concrete无筋混凝土non-shrinking concrete不收缩混凝土nonfines concrete无砂混凝土nonslip concrete防滑混凝土nonvoided concrete beam 实心混凝土梁normal heavy concrete普通重混凝土normal-weight concrete常规重量混凝土old concrete旧混凝土; 旧混凝土one-course concrete pavement 单层混凝土铺面open-end concrete block 敞口混凝土浇筑块oversite concrete地基混凝土板层; 满堂混凝土垫层packaged concrete (按水灰比加水即可使用) 干配料混凝土packing concrete in forms 模内捣实混凝土partially reinforced concrete masonry 局部配筋混凝土砌体; 局部配筋混凝土砌体pavement concrete路面混凝土pea gravel concrete豆石混凝土pea stone concrete豆石混凝土penetration concrete灌入混凝土; 贯入混凝土perforated concrete tube 多孔混凝土管placing concrete浇注混凝土placing concrete against natural ground 地模混凝土浇筑plain concrete素混凝土; 无筋混凝土plain concrete pier 素混凝土墩plant-mixed concrete厂拌混凝土plaster concrete石膏混凝土plastic concrete塑性混凝土plastic theory of reinforced concrete钢筋混凝土塑性理论plasto-concrete塑料混凝土pneumatic concrete breaker 风动混凝土破碎机pneumatic concrete placer 气动混凝土浇筑机; 气压混凝土浇灌机pneumatically placed concrete喷射浇灌的混凝土polished concrete pavement 磨光的混凝土路面polyester concrete聚酯混凝土; 聚酯混凝土polymer impregnated concrete (P.I.C) 聚合物注入混凝土; 聚合物注入混凝土polystyrene-impregnated concrete聚苯乙烯注入混凝土; 聚苯乙烯注入混凝土ponding method of curing concrete混凝土泡水养护法; 混凝土养生池养护法poor concrete劣质混凝土poor-quality concrete劣质混凝土porous concrete drain 多孔混凝土排水管porous concrete pipe 多孔混凝土管Portland cement concrete (PCC) 硅酸盐水泥混凝土post-stressed concrete后张法混凝土post-tensioned concrete后张混凝土post-tensioned concrete pile 后张混凝土桩powder ash air-entrained concrete粉煤灰加气混凝土precast aerated concrete预制加气混凝土precast ceramsite concrete预制陶粒混凝土precast concrete预制混凝土; 预制混凝土构件precast concrete block flue 预制混凝土块烟道precast concrete cladding 预制混凝土饰面precast concrete cover 预制混凝土盖板precast concrete floor 预制混凝土楼盖precast concrete house 预制混凝土房屋precast concrete lintel 预制混凝土过梁precast concrete pavement 预制混凝土路面precast concrete pile 预制混凝土桩precast concrete plank 预制混凝土板precast concrete slab 预制混凝土板precast concrete unit 预制混凝土构件precast concrete wall panel 预制混凝土墙板precast foam concrete预制泡沫混凝土precast hollow concrete block 预制空心混凝土块precast reinforced concrete framed support 钢筋混凝土支架precast vermiculite concrete预制蛭石混凝土precast-concrete sheet-pile 预制混凝土板桩premixed concrete预拌混凝土prepacked aggregate concrete预填骨料灌浆混凝土prepacked concrete预填集料混凝土prepakt concrete压浆混凝土preplaced-aggregate concrete灌浆混凝土pressed concrete压制混凝土prestressed concrete预应力混凝土prestressed concrete bar 预应力混凝土芯棒prestressed concrete beam 预应力混凝土梁prestressed concrete bridge 预应力混凝土桥prestressed concrete drilled caisson 预应力管柱prestressed concrete pavement 预应力混凝土路面prestressed concrete pipe 预应力混凝土管prestressed concrete reactor vessel(PCRV) 预应力混凝土反应堆容器prestressed concrete steel wire strand 预应力混凝土结构用钢绞线prestressed concrete tank 预应力混凝土蓄液池prestressed concrete tower 预应力混凝土塔prestressed concrete wire(P.C.wire) 预应力钢丝prestressed reinforced concrete预应力钢筋混凝土prestressed reinforced concrete tie 预应力混凝土轨枕prestressed-concrete cylinder 预应力混凝土管柱prestressed-concrete pile 预应力混凝土桩pretensioned concrete先张法混凝土pumice concrete浮石混凝土pumiceous concrete浮石混凝土pump concrete泵浇混凝土; 泵送混凝土quaking concrete软混凝土; 塑性混凝土quality concrete优质混凝土quality concrete production 优质混凝土生产radiation-shielding concrete防射线混凝土rammed concrete夯实混凝土rate of concrete placement 混凝土浇筑速率Raymond concrete pile 雷蒙德混凝土桩; 雷蒙式桩ready-mixed concrete预拌混凝土refractory concrete耐火混凝土refractory concrete block 耐火混凝土砌块refractory insulating concrete耐火隔热混凝土reinforced aerated concrete lintel 钢筋加气混凝土过梁reinforced concrete钢筋混凝土; 钢筋水泥reinforced concrete arch 钢筋混凝土拱reinforced concrete beam 钢筋混凝土梁reinforced concrete bolt 钢筋砂浆锚杆reinforced concrete bridge 钢筋混凝土桥reinforced concrete buttressed dam 钢筋混凝土支墩坝reinforced concrete chimney 钢筋混凝土烟囱reinforced concrete column 钢筋混凝土柱reinforced concrete construction 钢筋混凝土构造; 钢筋混凝土建筑reinforced concrete dam 钢筋混凝土坝reinforced concrete dock 钢筋混凝土船坞reinforced concrete draught tube 钢筋混凝土尾水管reinforced concrete drill 钢筋混凝土钻reinforced concrete flat slab floor 钢筋混凝土无梁楼盖reinforced concrete floor 钢筋混凝土楼盖reinforced concrete flume 钢筋混凝土渡槽; 钢筋砼渡槽reinforced concrete foundation 钢筋混凝土基础reinforced concrete frame 钢筋混凝土构架reinforced concrete frame structure 钢筋混凝土框架结构reinforced concrete gate 钢筋混凝土闸门reinforced concrete girder 钢筋混凝土梁reinforced concrete grill 钢筋混凝土格子reinforced concrete member 钢筋混凝土构件reinforced concrete pavement 钢筋混凝土路面reinforced concrete penstock 钢筋混凝土压力水管reinforced concrete pier 钢筋混凝土闸墩reinforced concrete pile 钢筋混凝土桩reinforced concrete pipe 钢筋水泥管reinforced concrete pipe (RCP) 钢筋混凝土管reinforced concrete pole 钢筋混凝土电杆reinforced concrete pressure pipe 钢筋混凝土压力水管reinforced concrete radial gate 钢筋混凝土弧形闸门reinforced concrete retaining wall 钢筋混凝土挡土墙reinforced concrete road 钢筋混凝土路reinforced concrete sector gate 钢筋混凝土扇形闸门reinforced concrete sewer pipe 钢筋混凝土排水管reinforced concrete shear wall 钢筋混凝土剪力墙reinforced concrete sheet pile 钢筋混凝土板桩reinforced concrete skeleton frame 钢筋混凝土骨架reinforced concrete slab 钢筋混凝土板reinforced concrete sleeper 钢筋混凝土轨枕reinforced concrete spiral casing 钢筋混凝土蜗壳reinforced concrete stairs 钢筋混凝土楼梯reinforced concrete storage 钢筋混凝土油罐reinforced concrete structure 钢筋混凝土结构reinforced concrete structure regulations 钢筋混凝土结构规范reinforced concrete surge tank 钢筋混凝土调压塔reinforced concrete tie rod 钢筋混凝土拉杆reinforced concrete wall panel 钢筋混凝土墙板reinforced concrete works 钢筋混凝土工程remixed concrete复拌混凝土; 二次搅拌的混凝土revolving-drum concrete mixer 转筒式混凝土搅拌机ribbed concrete floor 肋形混凝土楼盖rich concrete富混凝土; 水泥含量高的混凝土; 多水泥混凝土rockfill dam with concrete facing 混凝土斜墙堆石坝rolled concrete碾实混凝土rose concrete玫瑰凝结物rotary drum concrete mixer 转筒式混凝土搅拌机rough concrete未修整混凝土roughening concrete surface 混凝土毛面round concrete bar 混凝土用圆钢rubbed concrete磨面混凝土rubble concrete毛石混凝土; 块石混凝土sacked concrete revetment 袋装水下混凝土护岸sand and gravel concrete砂砾石混凝土sawdust concrete锯末混凝土; 锯末混凝土; 木屑混凝土sealing concrete封混凝土self-stressing concrete自应力混凝土shielding concrete防护用混凝土shock concrete振捣混凝土shrink-mixed concrete缩拌混凝土simplex concrete pile 单纯混凝土桩slag concrete矿渣混凝土; 炉渣混凝土slag concrete block 矿渣混凝土彻块slip-form concrete paver 滑模混凝土摊铺机sodium silicate concrete水玻璃混凝土soil concrete掺土混凝土solid concrete beam 实心混凝土梁sound-insulating concrete隔音混凝土sound-proof concrete隔音混凝土sprayed concrete喷射混凝土stamped concrete捣固混凝土stationary concrete pump 固定式混凝土泵steam curing of concrete蒸汽养护混凝土steel concrete钢筋混凝土steel concrete composite girder 钢筋混凝土合成梁steel concrete sleeper 钢筋混凝土轨枕steel cone concrete column 钢心混凝土柱steel fiber reinforced concrete钢纤维混凝土steel framed reinforced concrete column 钢骨钢筋混凝土柱steel-concrete composite girder 钢材混凝土组合梁steel-lined concrete pipe 钢板衬砌混凝土管steel-shelled concrete pile 钢壳混凝土桩steel-troweled concrete钢镘抹面混凝土stiff concrete稠混凝土stiff consistency concrete干硬性混凝土stone concrete块石混凝土stone pockets of concrete混凝土蜂窝状气孔string-wire concrete钢弦混凝土strong concrete高强度混凝土; 高强混凝土structural concrete结构混凝土structural light-weight concrete轻质结构混凝土structural lightweight concrete轻结构混凝土subaqueous concrete水底混凝土sulphur concrete硫磺混凝土Syringa amurensis concrete白丁香浸膏tamped concrete捣实混凝土tank concrete pad 油罐混凝土基座tar concrete柏油混凝土theoretical mix of concrete混凝土理论配合比tied concrete column 混凝土系柱tilting drum concrete mixer 倾卸式滚筒混凝土搅拌机trass concrete火山灰混凝土truck-concrete mixer 混凝土搅拌车truck-mixed concrete拌和车拌制的混凝土two-course concrete pavement 双层混凝土路面two-way concrete slab 双向钢筋; 双向钢筋混凝土板two-way reinforced concrete双向配筋混凝土two-way reinforced concrete slab 双向钢筋混凝土板ultrasonic concrete tester (UCT) 超声波混凝土测试仪under-water concrete mix 水下混凝土混合料undercured concrete欠养护混凝土underwater concrete水下混凝土unhardened concrete未硬结混凝土unprotected concrete pad 无防护的混凝土发射坪unrammed concrete未捣实混凝土; 未夯实混凝土unreinforced concrete无筋混凝土unsaturated polyester concrete equipment 不饱和聚酯混凝土设备unset concrete未凝结混凝土unsteamed concrete非蒸养混凝土unworkable concrete不易浇筑的混凝土vacuum concrete真空吸水处理混凝土vacuum processed concrete真空处理混凝土vacuum-concrete process 真空混凝土法vacuum-treated concrete真空处理的混凝土vermex concrete隔音混凝土vibrated concrete振捣过的混凝土; 振捣混凝土vibrating concrete float 混凝土表面振捣; 混凝土振平器vibrocast concrete振捣混凝土volume method of concrete mix design 混凝土体积比设计法water cured concrete湿养护混凝土water-cured concrete水养护混凝土water-tight concrete防水混凝土; 抗渗混凝土waterproof concrete防水混凝土wet concrete塑性混凝土wet consistency of concrete混凝土塑性稠度wet-mix concrete湿拌混凝土winterized concrete plant 防寒混凝土拌合厂wire mesh concrete plate 钢丝网混凝土板wire-reinforced concrete钢丝加劲混凝土wood-cement concrete slab 木屑砂浆板wooden concrete composite beam 木材混凝土混合梁wooden concrete form 木制混凝土模板。

混凝土工程 concrete works 一、材料袋装水泥 bagged cement散装水泥 bulk cement砂 sand骨料 aggregate商品混凝土 commercial concrete现浇混凝土 concrete-in-situ预制混凝土 precast concrete预埋件 embedment(fit 安装)外加剂 admixtures抗渗混凝土 waterproofing concrete 石场 aggregate quarry垫块 spacer二、施工机械及工具搅拌机 mixer振动器vibrator电动振动器 electrical vibrator振动棒vibrator bar抹子(steel wood) trowel磨光机 glasser混凝土泵送机 concrete pump橡胶圈 rubber ring夹子 clip混凝土运输车 mixer truck自动搅拌站 auto-batching plant输送机 conveyor塔吊 tower crane汽车式吊车 motor crane铲子 shovel水枪 jetting water橡胶轮胎 rubber tires布袋 cloth-bags塑料水管 plastic tubes喷水雾 spray water fog三、构件及其他专业名称截面尺寸 section size(section dimension)混凝土梁 concrete girder简支梁 simple supported beam挑梁 cantilever beam悬挑板 cantilevered slab檐板eaves board封口梁 joint girder翻梁 upstand beam楼板floor slab空调板 AC board飘窗 bay window(suspending window)振捣 vibration串筒 a chain of funnels混凝土施工缝 concrete joint水灰比ratio of water and cement砂率 sand ratio大体积混凝土 large quantity of pouring混凝土配合比 concrete mixture rate混凝土硬化 hardening of concrete(in a hardening process 硬化中)规定时间 regulated period质保文件 quality assurance program设计强度 design strength永久工程 permanent works临时工程 temporary works四、质量控制及检测不符合规格的 non-standard有机物 organic matters粘土 clay含水率 moisture content(water content)中心线 central line安定性 soundness (good soundness 优良的安定性)坍落度 slump (the concrete with 18mm±20mm slump)混凝土养护 concrete curing标养混凝土试件 standard curing concrete test sample同条件混凝土试件 field-cure specimen收缩 shrinkage初凝时间 initial setting time终凝时间 final setting time成品保护 finished product protection混凝土试件 concrete cube偏心受压 eccentric pressing保护层 concrete cover孔洞 hole裂缝 crack蜂窝 honeycomb五、句子1,Usually we control the cement within 2% 我们将水泥的误差控制在2%2,Are there any pipe clogging happened during the concreting?浇筑混凝土中有堵管现象吗?3,Will the pipe be worn out very fast?管道磨损很快吗?4,This embedment is fixed at 1500mm from the floor and 350mm from the left edge of the column. Would you measure the dimension by this meter?预埋件的位置在地面上1500mm,离柱边350mm。

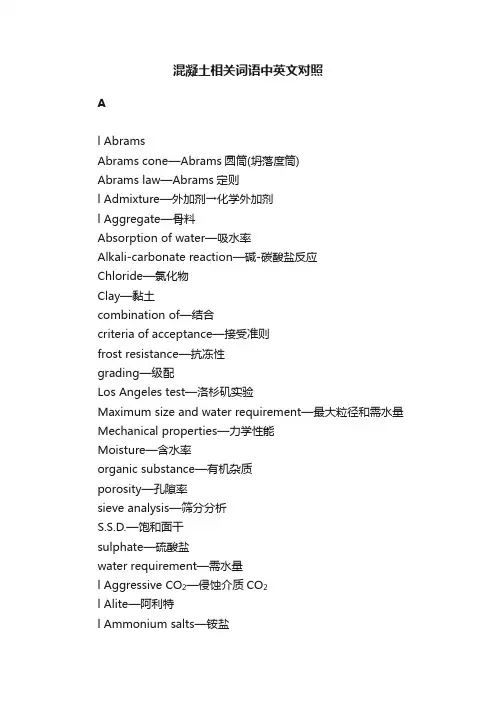

混凝土相关词语中英文对照Al AbramsAbrams cone—Abrams圆筒(坍落度筒)Abrams law—Abrams定则l Admixture—外加剂→化学外加剂l Aggregate—骨料Absorption of water—吸水率Alkali-carbonate reaction—碱-碳酸盐反应Chloride—氯化物Clay—黏土combination of—结合criteria of acceptance—接受准则frost resistance—抗冻性grading—级配Los Angeles test—洛杉矶实验Maximum size and water requirement—最大粒径和需水量Mechanical properties—力学性能Moisture—含水率organic substance—有机杂质porosity—孔隙率sieve analysis—筛分分析S.S.D.—饱和面干sulphate—硫酸盐water requirement—需水量l Aggressive CO2—侵蚀介质CO2l Alite—阿利特l Ammonium salts—铵盐l Amorphous silica—无定形二氧化硅l ASR Alkali-silica-reaction in aggregate—骨料中的碱-硅反应: Bl Belite—贝利特l Blast furnace cement—矿渣水泥l Bleeding—泌水concrete in floor—地板混凝土grout—水泥浆influence of steel bond—钢筋粘结的影响influence of transition zone—过渡区的影响mortar—砂浆l BolomeyCl Capillary porosity—毛细管孔隙率l Capillary pressure—毛细管压力l Carbonation—碳化l Characteristic strength—特征强度l Chemical admixtures一化学外加剂Air entraining agents(AEA)—引气剂use in shotcrete—在喷射混凝土中的应用ASR inhibitor—碱-硅反应抑制剂Corrosion inhibitors—防腐剂Classification—分类Hardening accelerators—促硬剂Hydrophobic admixtures—防水剂High-range water reducers superplasticizers—高效减水剂(超塑化剂)Retarders—缓凝剂Setting accelerators—促凝剂Use in shotcrete—用于喷射混凝土中Silanes—硅烷Shrinkage-reducing admixtures—减缩剂SRA→Shrinkage-reducing admixturesSuperplasticizers—高效减水剂(超塑化剂)Mechanism of action of—作用机理Slump loss/retention—坍落度损失/保持Multifunctional—多功能的Use in shotcrete—用于喷射混凝土中Use to increase strength/durability—用于提高强度/耐久性Use to reduce cement—用于减少水泥Use to increase workability—用于提高工作性Viscosity modifying agents—黏度调节剂VMA→Viscosity modifying agentsWater-reducers—减水剂l Cement—水泥Norms—标准Set regulator—调凝剂Setting—凝结Strength—强度l Chloride—氯化物Diffusion—扩散l Compactability—密实性l Compacting factor—密实系数l Composite cement—复合水泥l Composite Portland cement—复合硅酸盐水泥l Concrete—混凝土Deterioration—劣化Manufacture—生产Placing—浇筑Prestressed—预应力Reinforced—增强l Corrosion of reinforcement—钢筋的腐蚀Promoted by carbonation—碳化引起Promoted by chloride—氯化物引起l Cracking—开裂l Creep—徐变Basic—基本Drying—干燥Influence of creep on drying shrinkage—徐变对干缩的影响Prediction of creep in concrete structures—混凝土结构的徐变预测l Cored concrete—混凝土芯样l Curing—养护Influence of curing on durability—养护对耐久性的影响Influence of curing on concrete strength—养护对混凝土强度的影响Membrane—薄膜Wet curing—湿养l C3A—铝酸三钙l C4AF—铁铝酸四钙l C3S—硅酸三钙l C2S—硅酸二钙l C-S-H—水化硅酸钙Dl Damage→deterioration—损伤→劣化l DEF—延迟钙矾石形成l Degree of compaction—密实度In shotcrete—喷射混凝土l Degree of consolidation—密实度l Degree of hydration—水化程度l Depassivation—去钝化l Deterioration—劣化l Drying shrinkage→shrinkage—干缩→收缩l DSP一致密小颗粒混凝土l Durability—耐久性Capillary porosity—毛细管孔隙率Concrete cover—混凝土保护层Exposure classes—暴露等级Long term durability—长期耐久性El Entrained air一引气Influence on freezing—对抗冻性的影响Influence on strength—对强度的影响l Entrapped air—夹杂气体l Ettringite—钙矾石Primary—一次Secondary—二次l Expansive agents→Shrinkage compensating concrete—膨胀剂→收缩补偿混凝土Fl Fibre-inforced concrete ( FRC )—纤维增强混凝土Application of FRC一纤维增强混凝土的应用Crack-free concrete一无裂缝混凝土Toughness of concrete—混凝土的韧性Impact strength—冲击强度In shotcrete—喷射混凝土Metallic fibre—金属纤维Polymer mini-fibre—聚合物微纤维Polymer macro-fibre—聚合物大纤维Polymer structure PVA fibres—聚合物结构聚乙烯醇纤维l Fictitious thickness一虚拟厚度l Fire endurance of concrete一混凝土的耐火性Behavior of concrete during fire一混凝土在火中的行为Behavior of high-strength concrete during fire—高强混凝土在火中的行为Influence of the aggregate—骨料的影响Influence of the concrete cover—混凝土保护层的影响Influence of the metallic fibres一金属纤维的影响Influence of the loading in service一服役荷载的影响Influence of the polymeric fibres—聚合物纤维的影响l Fly ash—粉煤灰Beneficiation—选矿l Freezing and thawing一冻融l Füllerl Füller&Thompson→FüllerGl GGBFS→slag—磨细粒化高炉矿渣→矿渣l Gluconate—葡萄糖酸盐l Glucose—葡萄糖l Grout—浆体l Gypsum—石膏Hl Heat—热Cracking due to thermal gradients—温度梯度诱发开裂Of hydration—水化热l Hydration—水化Of aluminates—铝酸盐的水化Of silicates—硅酸盐的水化l High-Performance Concrete—高性能混凝土l High Strength Concrete—高强混凝土l Hooke law—Hooke定律Kl Kiln一烧窑Ll Leaching—析浆l Lightweight concrete—轻混凝土Glassification—分类Expanded clay—陶粒Lightweight aggregate—轻骨料In the Rome Pantheon—罗马万神殿Natural lightweight aggregate(pumice)—天然轻骨料(浮石) Shrinkage—收缩Structural—结构的Precast L. C—预制轻混凝土SCC L. C—自密实轻混凝土Structural L. C for ready-mixed concrete—预拌结构轻混凝土l Lignosulphonate—木素磺酸盐l Lime—石灰l Limestone—石灰石Blended cement一混合水泥l Lyse rule—Lyse准则Ml Magnesium salts—镁盐l Mass concrete—大体积混凝土l Mix design—配合比设计l Modulus—模数Of elasticity—弹性模量Of fineness一细度模数l Mill一磨机l Municipal Solid Waste Incinerator一市政固体废物焚烧炉Pl Passivation—钝化l Permeability—渗透性l Pop-out一凸起l Porosity—孔隙率Capillary—毛细管孔隙Capillary porosity and strength—毛细管孔隙率与强度Capillary porosity and elastic modulus—毛细管孔隙率与弹性模量Capillary porosity and permeability—毛细管孔隙率与渗透性Capillary porosity and durability—毛细管孔隙率与耐久性Gel—凝胶Macroporosity—大孔孔隙率l Portland cement—硅酸盐水泥Blended cements一混合水泥European norm—欧洲标准Ferric一铁相Manufacture—生产White—白色l Powers—能源l Pozzolan一火山灰Activity—活性Industrial—工业的l Pozzolanic cement一火山灰水泥l Precast concrete—预制混凝土Steam curing—蒸养l Prescriptions on concrete structures—混凝土结构的质量要求Concrete composition prescriptions—混凝土组成的质量要求Concrete performance prescriptions—混凝土性能的质量要求Contractor prescriptions一对承包商的要求Rl Reactive Powder Concrete一活性粉末混凝土l Recycled concrete一再生混凝土Process of manufacturing recycled aggregate (RA)一再生骨料的加工工艺Properties of RA一再生骨料的性能Contaminant products—污染物Density of RA一再生骨料的密度Water absorption—吸水率Properties of concrete with RA—含有再生骨料混凝土的性能l Relaxation—松弛l Retempering—重拌合Sl Segregation—离析l SCC→Self-Compacting Concrete—自密实混凝土l Self-Compacting Concrete—自密实混凝土Architectural一装饰High strength—高强Mass concrete—大体积混凝土Lightweight concrete—轻混凝土Shrinkage-compensating—收缩补偿l Setting—凝结l Shrinkage—收缩Drying shrinkage—干缩Influence of aggregate on drying shrinkage一骨料对干缩的影响Influence of high range water reducers on drying shrinkage—高效减水剂对干缩的影响Influence of workability on drying shrinkage一工作性对干缩的影响Prediction of drying shrinkage in concrete structures—混凝土结构干缩的预测Plastic shrinkage—塑性收缩Standard shrinkage—标准收缩l Shrinkage-compensating concrete—收缩补偿混凝土Expansive agents—膨胀剂Combined use of SRA and expansive agents—减缩剂和膨胀剂的结合应用Lime-based expansive agents—石灰基膨胀剂Sulphoaluminate-based expansive agents—硫铝酸盐基膨胀剂Application of shrinkage compensating concrete—补偿收缩混凝土的应用Joint-free architectural buildings—无缝装饰建筑Joint-free industrial floor一无缝工业地板Repair of damaged concrete structures—损坏混凝土结构的修补Expansion of specimen vs. that of structure—试件的膨胀与结构的膨胀Restrained expansion—约束膨胀SCC shrinkage-compensating concrete—自密实收缩补偿混凝土l Shotcrete—喷射混凝土ACI recommendations—ACI建议Bond of shotcrete. to substrate—喷射混凝土与基层的粘结Chemical admixtures in—喷射混凝土的化学外加剂Alkali-free accelerators—无碱促进剂Sodium silicate accelerators—硅酸钠促进剂Composition of一喷射混凝土组成Fibres in—喷射混凝土的纤维High performance—高性能喷射混凝土Influence of steel bars on—配筋的影响Mineral additions in—矿物掺合料Nozzelman喷枪操作工Rebound—回弹l Sieve analysis—筛分l Silica fume—硅灰Silica fume in high strength concrete—高强混凝土中的硅灰l Slag—矿渣Cement—矿渣水泥l Slump—坍落度Slump loss—坍落度损失l SRA→Shrinkage Reducing Admixture in Chemical Admixtures-一化学外加剂中的减缩剂l Standard deviation一标准差l Steam curing—蒸养l Steel-concrete bond—钢筋-混凝土的粘结l Strength—强度Characteristic一特征强度Class of cement—水泥的强度等级Class of concrete一混凝土的强度等级Compressive—抗压强度DSP concrete—细颗粒密实混凝土Flexural—抗折强度High-strength concrete—高强混凝土Influence of compaction on一密实性对强度的影响Influence of cement on concrete一水泥对混凝土强度的影响Influence of temperature on concrete—温度对混凝土强度的影响Influence of transition zone on—过渡区对强度的影响Of cement paste—水泥浆的强度Of cored samples一芯样的强度Of specimens—试件的强度Standard deviation—标准差Tensile—抗拉强度l Stress—应力Compressive—压应力Flexural—弯曲应力Tensile一拉应力l Sulphate attack—硫酸盐侵蚀l Superplsticizer→Chemical. admixtures—超塑化剂(高效减水剂)→化学外加剂Tl Temperature—温度Influence of temperature on concrete strength—温度对强度的影响Influence of temperature on site organization—温度对现场浇筑的影响Placing in summer time一夏季浇筑Placing in winter time一冬季浇筑l Thaumasite—硅灰石膏l Thermal gradients—温度梯度l Transition zone—过渡区Vl Vebe—维勃l Vibration—振动Wl Water—水And workability—水与工作性And strength.一水与强度Addition on job site一水的现场添加l Water-cement ratio—水灰比l Workability—工作性And consolidation—工作性与密实性。

中英文对照外文翻译(文档含英文原文和中文翻译)Reinforced ConcreteConcrete and reinforced concrete are used as building materials in every country. In many, including the United States and Canada, reinforced concrete is a dominant structural material in engineered construction. The universal nature of reinforced concrete construction stems from the wide availability of reinforcing bars and the constituents of concrete, gravel, sand, and cement, the relatively simple skills required in concrete construction, and the economy of reinforced concrete compared to other forms of construction. Concrete and reinforced concrete are used in bridges, buildings of all sorts underground structures, water tanks, television towers, offshore oil exploration and production structures, dams, and even in ships.Reinforced concrete structures may be cast-in-place concrete, constructed in their final location, or they may be precast concreteproduced in a factory and erected at the construction site. Concrete structures may be severe and functional in design, or the shape and layout and be whimsical and artistic. Few other building materials off the architect and engineer such versatility and scope.Concrete is strong in compression but weak in tension. As a result, cracks develop whenever loads, or restrained shrinkage of temperature changes, give rise to tensile stresses in excess of the tensile strength of the concrete. In a plain concrete beam, the moments about the neutral axis due to applied loads are resisted by an internal tension-compression couple involving tension in the concrete. Such a beam fails very suddenly and completely when the first crack forms. In a reinforced concrete beam, steel bars are embedded in the concrete in such a way that the tension forces needed for moment equilibrium after the concrete cracks can be developed in the bars.The construction of a reinforced concrete member involves building a from of mold in the shape of the member being built. The form must be strong enough to support both the weight and hydrostatic pressure of the wet concrete, and any forces applied to it by workers, concrete buggies, wind, and so on. The reinforcement is placed in this form and held in place during the concreting operation. After the concrete has hardened, the forms are removed. As the forms are removed, props of shores are installed to support the weight of the concrete until it has reached sufficient strength to support the loads by itself.The designer must proportion a concrete member for adequate strength to resist the loads and adequate stiffness to prevent excessive deflections. In beam must be proportioned so that it can be constructed. For example, the reinforcement must be detailed so that it can be assembled in the field, and since the concrete is placed in the form after the reinforcement is in place, the concrete must be able to flow around, between, and past the reinforcement to fill all parts of the form completely.The choice of whether a structure should be built of concrete, steel, masonry, or timber depends on the availability of materials and on a number of value decisions. The choice of structural system is made by the architect of engineer early in the design, based on the following considerations:1. Economy. Frequently, the foremost consideration is the overall const of the structure. This is, of course, a function of the costs of the materials and the labor necessary to erect them. Frequently, however, the overall cost is affected as much or more by the overall construction time since the contractor and owner must borrow or otherwise allocate money to carry out the construction and will not receive a return on this investment until the building is ready for occupancy. In a typical large apartment of commercial project, the cost of construction financing will be a significant fraction of the total cost. As a result, financial savings due to rapid construction may more than offset increased material costs. For this reason, any measures the designer can take to standardize the design and forming will generally pay off in reduced overall costs.In many cases the long-term economy of the structure may be more important than the first cost. As a result, maintenance and durability are important consideration.2. Suitability of material for architectural and structural function.A reinforced concrete system frequently allows the designer to combine the architectural and structural functions. Concrete has the advantage that it is placed in a plastic condition and is given the desired shape and texture by means of the forms and the finishing techniques. This allows such elements ad flat plates or other types of slabs to serve as load-bearing elements while providing the finished floor and / or ceiling surfaces. Similarly, reinforced concrete walls can provide architecturally attractive surfaces in addition to having the ability to resist gravity, wind, or seismic loads. Finally, the choice of size of shape is governed by the designer and not by the availability of standard manufactured members.3. Fire resistance. The structure in a building must withstand the effects of a fire and remain standing while the building is evacuated and the fire is extinguished. A concrete building inherently has a 1- to 3-hour fire rating without special fireproofing or other details. Structural steel or timber buildings must be fireproofed to attain similar fire ratings.4. Low maintenance.Concrete members inherently require less maintenance than do structural steel or timber members. This is particularly true if dense, air-entrained concrete has been used forsurfaces exposed to the atmosphere, and if care has been taken in the design to provide adequate drainage off and away from the structure. Special precautions must be taken for concrete exposed to salts such as deicing chemicals.5. Availability of materials. Sand, gravel, cement, and concrete mixing facilities are very widely available, and reinforcing steel can be transported to most job sites more easily than can structural steel. As a result, reinforced concrete is frequently used in remote areas.On the other hand, there are a number of factors that may cause one to select a material other than reinforced concrete. These include:1. Low tensile strength.The tensile strength concrete is much lower than its compressive strength ( about 1/10 ), and hence concrete is subject to cracking. In structural uses this is overcome by using reinforcement to carry tensile forces and limit crack widths to within acceptable values. Unless care is taken in design and construction, however, these cracks may be unsightly or may allow penetration of water. When this occurs, water or chemicals such as road deicing salts may cause deterioration or staining of the concrete. Special design details are required in such cases. In the case of water-retaining structures, special details and / of prestressing are required to prevent leakage.2. Forms and shoring. The construction of a cast-in-place structure involves three steps not encountered in the construction of steel or timber structures. These are ( a ) the construction of the forms, ( b ) the removal of these forms, and (c) propping or shoring the new concrete to support its weight until its strength is adequate. Each of these steps involves labor and / or materials, which are not necessary with other forms of construction.3. Relatively low strength per unit of weight for volume.The compressive strength of concrete is roughly 5 to 10% that of steel, while its unit density is roughly 30% that of steel. As a result, a concrete structure requires a larger volume and a greater weight of material than does a comparable steel structure. As a result, long-span structures are often built from steel.4. Time-dependent volume changes. Both concrete and steel undergo-approximately the same amount of thermal expansion and contraction. Because there is less mass of steel to be heated or cooled,and because steel is a better concrete, a steel structure is generally affected by temperature changes to a greater extent than is a concrete structure. On the other hand, concrete undergoes frying shrinkage, which, if restrained, may cause deflections or cracking. Furthermore, deflections will tend to increase with time, possibly doubling, due to creep of the concrete under sustained loads.In almost every branch of civil engineering and architecture extensive use is made of reinforced concrete for structures and foundations. Engineers and architects requires basic knowledge of reinforced concrete design throughout their professional careers. Much of this text is directly concerned with the behavior and proportioning of components that make up typical reinforced concrete structures-beams, columns, and slabs. Once the behavior of these individual elements is understood, the designer will have the background to analyze and design a wide range of complex structures, such as foundations, buildings, and bridges, composed of these elements.Since reinforced concrete is a no homogeneous material that creeps, shrinks, and cracks, its stresses cannot be accurately predicted by the traditional equations derived in a course in strength of materials for homogeneous elastic materials. Much of reinforced concrete design in therefore empirical, i.e., design equations and design methods are based on experimental and time-proved results instead of being derived exclusively from theoretical formulations.A thorough understanding of the behavior of reinforced concrete will allow the designer to convert an otherwise brittle material into tough ductile structural elements and thereby take advantage of concrete’s desirable characteristics, its high compressive strength, its fire resistance, and its durability.Concrete, a stone like material, is made by mixing cement, water, fine aggregate ( often sand ), coarse aggregate, and frequently other additives ( that modify properties ) into a workable mixture. In its unhardened or plastic state, concrete can be placed in forms to produce a large variety of structural elements. Although the hardened concrete by itself, i.e., without any reinforcement, is strong in compression, it lacks tensile strength and therefore cracks easily. Because unreinforced concrete is brittle, it cannot undergo large deformations under load and failssuddenly-without warning. The addition fo steel reinforcement to the concrete reduces the negative effects of its two principal inherent weaknesses, its susceptibility to cracking and its brittleness. When the reinforcement is strongly bonded to the concrete, a strong, stiff, and ductile construction material is produced. This material, called reinforced concrete, is used extensively to construct foundations, structural frames, storage takes, shell roofs, highways, walls, dams, canals, and innumerable other structures and building products. Two other characteristics of concrete that are present even when concrete is reinforced are shrinkage and creep, but the negative effects of these properties can be mitigated by careful design.A code is a set technical specifications and standards that control important details of design and construction. The purpose of codes it produce structures so that the public will be protected from poor of inadequate and construction.Two types f coeds exist. One type, called a structural code, is originated and controlled by specialists who are concerned with the proper use of a specific material or who are involved with the safe design of a particular class of structures.The second type of code, called a building code, is established to cover construction in a given region, often a city or a state. The objective of a building code is also to protect the public by accounting for the influence of the local environmental conditions on construction. For example, local authorities may specify additional provisions to account for such regional conditions as earthquake, heavy snow, or tornados. National structural codes genrally are incorporated into local building codes.The American Concrete Institute ( ACI ) Building Code covering the design of reinforced concrete buildings. It contains provisions covering all aspects of reinforced concrete manufacture, design, and construction. It includes specifications on quality of materials, details on mixing and placing concrete, design assumptions for the analysis of continuous structures, and equations for proportioning members for design forces.All structures must be proportioned so they will not fail or deform excessively under any possible condition of service. Therefore it is important that an engineer use great care in anticipating all the probableloads to which a structure will be subjected during its lifetime.Although the design of most members is controlled typically by dead and live load acting simultaneously, consideration must also be given to the forces produced by wind, impact, shrinkage, temperature change, creep and support settlements, earthquake, and so forth.The load associated with the weight of the structure itself and its permanent components is called the dead load. The dead load of concrete members, which is substantial, should never be neglected in design computations. The exact magnitude of the dead load is not known accurately until members have been sized. Since some figure for the dead load must be used in computations to size the members, its magnitude must be estimated at first. After a structure has been analyzed, the members sized, and architectural details completed, the dead load can be computed more accurately. If the computed dead load is approximately equal to the initial estimate of its value ( or slightly less ), the design is complete, but if a significant difference exists between the computed and estimated values of dead weight, the computations should be revised using an improved value of dead load. An accurate estimate of dead load is particularly important when spans are long, say over 75 ft ( 22.9 m ), because dead load constitutes a major portion of the design load.Live loads associated with building use are specific items of equipment and occupants in a certain area of a building, building codes specify values of uniform live for which members are to be designed.After the structure has been sized for vertical load, it is checked for wind in combination with dead and live load as specified in the code. Wind loads do not usually control the size of members in building less than 16 to 18 stories, but for tall buildings wind loads become significant and cause large forces to develop in the structures. Under these conditions economy can be achieved only by selecting a structural system that is able to transfer horizontal loads into the ground efficiently.钢筋混凝土在每一个国家,混凝土及钢筋混凝土都被用来作为建筑材料。

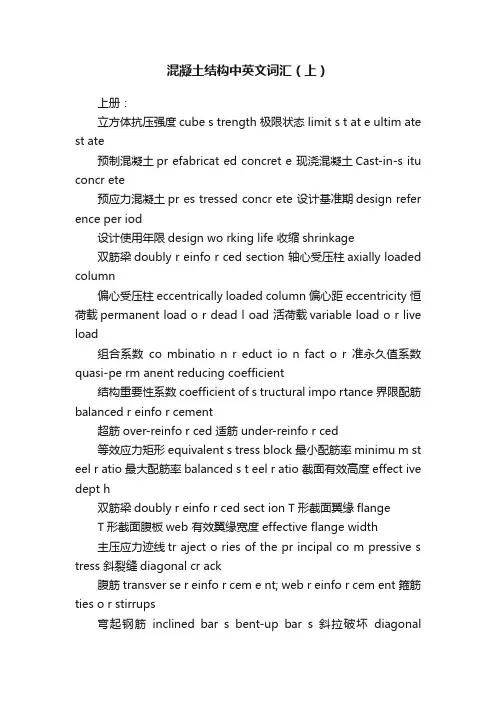

混凝土结构中英文词汇(上)上册:立方体抗压强度cube s trength 极限状态limit s t at e ultim ate st ate预制混凝土pr efabricat ed concret e 现浇混凝土Cast-in-s itu concr ete预应力混凝土pr es tressed concr ete 设计基准期design refer ence per iod设计使用年限design wo rking life 收缩shrinkage双筋梁doubly r einfo r ced section 轴心受压柱axially loaded column偏心受压柱eccentrically loaded column 偏心距eccentricity 恒荷载permanent load o r dead l oad 活荷载variable load o r live load组合系数co mbinatio n r educt io n fact o r准永久值系数quasi-pe rm anent reducing coefficient结构重要性系数coefficient of s tructural impo rtance 界限配筋balanced r einfo r cement超筋over-reinfo r ced 适筋under-reinfo r ced等效应力矩形equivalent s tress block 最小配筋率minimu m st eel r atio 最大配筋率balanced s t eel r atio 截面有效高度effect ive dept h双筋梁doubly r einfo r ced sect ion T形截面翼缘flangeT形截面腹板web 有效翼缘宽度effective flange width主压应力迹线tr aject o ries of the pr incipal co m pressive s tress 斜裂缝diagonal cr ack腹筋transver se r einfo r cem e nt; web r einfo r cem ent 箍筋ties o r stirrups弯起钢筋inclined bar s bent-up bar s 斜拉破坏diagonalsplitting剪压破坏shear co mpr ession 斜压破坏diagonal co m pression 剪跨比shear span r atio 名义剪跨比gener alized shear span配箍率transver se tie r atio 材料弯矩抵抗图diagr am of bending resis t ance不需要面cut-o ff sect io n 充分利用面fully-developed section 充分利用点fully usable point of bar理论截断点t heo r etical cutting point of bar实际截断点r eal cutting point of bar锚固长度ancho r age length 绑扎搭接binding lapped splice 钢筋表bar schedule 连接区段connection sect o r肋梁楼板结构girder-beam-s lab structural sys t em现浇楼板cas t-in-place slab 预应力楼板pr e-cast slab刚度r igidity 弯矩包络图m o m ent envelope diagr am;ultimat e m o m ent diagram剪力包络图shear envelope diagr am塑性铰plas t ic hinge无梁楼盖flat slab塑性内力重分布法plas t ic r edis tribution of s tresses analysis m et hod弯矩调幅法t he m ethod of amplitude m odulation fo r bending m o m ent CHAPTER 1Plain Concr ete 素混凝土,Reinfo r ced Concr ete 钢筋混凝土,Pr estr essed Concr ete 预应力混凝土,r einfo r cement s t eel bar钢筋(也有人直接用bar,fiber),Po rtland cem ent波特兰水泥Light-weight concr ete 轻质混凝土,high-s trength concret e 高强混凝土,Fiber r einfo r cedconcr ete(FRC)纤维混凝土load 荷载,span 跨径,s tr ain 应变,str ess 应力,co m pression 压力,t ension 拉力,m o m ent弯矩,t o r sion 扭矩,扭转thermal expansion coefficient s 热膨胀系数,co rrosion pr o t ection 防腐蚀,Fir e r esis t ance耐火,hollow floo r空心楼板,wall 墙面,girder主梁,beam横梁,column 柱,foo ting 基础allowable s tress design m et hod 允许应力法,ultimat e s trength design method 极限强度设计法,limit s t at e design m et hod 极限状态设计法,co m posit e s truct ure 混合结构CHAPTER 2sm oo t h bar光圆钢筋,defo rm ed bar螺纹钢筋,ho t r olled bar热轧钢筋,cold dr awn bar冷拉钢筋,st eel wires 钢绞线,heat tr eat ed s t eel bar热处理钢筋stress-s train curve 应力应变曲线,yield plat eau 屈服平台defo rmation 变形,deflection 挠度,yield s tr ength 屈服强度,ultimat e strength 极限强度,ductility 韧性,har dening 强化,cold dr awn 冷拉,t empering treatm ent 回火,quenching tr eatment淬火fatigue 疲劳,shrinkage 收缩,cr eep 徐变,cr ack 开裂,cr ush 压溃wat er-cem ent ratio 水灰比cubic co mpr essive s tr ength 立方体抗压强度,pris m atic co m pressive strength 棱柱体抗压强度elas ticity m odulus 弹性模量(杨氏模量),secant m odulus 割线模量,t angent m odulus 切线模量,shear m odulus 剪切模量,poisso n’s r atio 泊松比uniaxial t ension 单轴拉伸,biaxial loading 双轴加载,triaxial loading 三轴加载CHAPTER 3bond 粘结,ancho r age 锚固,bar splicing 钢筋搭接,splitting 撕裂,cr ush 压溃,pull-o ut failure 刮出式破坏splice length 搭接长度,em bedded length 埋置长度,developm ent length 锚固长度shape coefficient外形系数ribs 钢筋肋CHAPTER 4axial load 轴向加载,axial t ension 轴向拉伸,axial co mpr ession 轴向压力elas ticity 弹性,plas t icity 塑性longitudinal bar s 主筋(纵向钢筋),s t irrup 箍筋,hanger bar架立筋,bent bar弯起钢筋brittle failure 脆性破坏,load carrying capacity 承载能力sho rt column 短柱,slender colu mn 长柱,s t ability coefficient稳定系数cr oss section 截面,cr oss-sectional dimension 截面尺寸spiral stirrup 螺旋箍筋CHAPTER 5box sect ion 箱形截面,hollow slab 空心板,T-sect io n T 形截面over-reinfo r ced beam超筋梁,under-reinfo r ced beam少筋梁,balanced-reinfo r ced beam适筋梁brittle failure 脆性破坏concr ete cover混凝土保护层minimum r einfo r cem ent ratio 最小配筋率flexure theo ry 弯曲理论,plane sect io n assumption 平截面假定neutr al axis 中性轴,coefficient系数,par amet er参数,cons t ant常数stress dis tributio n 应力分布,shear span r atio 剪跨比stress block dept h 应力区高度(受压区高度),r elative s tr ess block dept h 相对应力区高度(相对受压区高度),n o minal str ess block dept h 名义应力区高度(名义受压区高度),flexural capacity 抗弯承载能力symm etry reinfo r cement对称配筋effect ive flange width 有效翼缘宽度,flange 翼缘,web 腹板shear-lag effect剪力滞效应sim ple-suppo rted beam简支梁,continuous beam连续梁deep-bending m ember深受弯构件,deep beam深梁,tr ansfer girder转换梁,tie-reinfo r cem ent拉结筋,ho rizontal dis tributing r einfo r cem ent水平分布钢筋spacing 间距CHAPTER 6eccentricity 偏心率,second-o r der effect二阶效应ultim ate limit st at e 使用极限状态additio nal eccentricity 附加偏心距eccentricity magnifying coefficient偏心距放大系数t ensile failur e 受拉破坏,co mpr essive failur e 受压破坏larger eccentricity 大偏心,s m all eccentricity 小偏心out-plane s trength 片面外强度geo m etric centr al axis 几何中心轴CHAPTER 7shear failu r e 剪切破坏diagonal t ension 斜向拉应力shear flow 剪力流diagonal cr acks 斜裂缝,flexural cr ack 弯曲裂缝,co m pression s trut受压杆web r einfo r cem ent腹筋(抗剪钢筋)truss m odel 桁架模型sl ope angle 倾角upper end of t he cr ack 裂缝上端maximu m spacing of s tirrup 箍筋最大间距concentrat ed load 集中荷载,unifo rm load 均布荷载det ailing r equirement构造要求m o m ent envelope 弯矩包络图,m o m ent diagram弯矩图em bedded length 锚固长度point s of bend 弯起点CHAPTER 8equilibrium t o r s ion 均衡扭转,co m patibility t o r s ion 协调扭转st atic equilibrium静力平衡principal s tr ess 主应力cr acking t o rque 开裂弯曲transver se r einfo r cement横向钢筋elas t o-plas t ic m ode 弹塑性模型Plas t ic space truss design m ethod 塑性空间桁架设计方法,Skew bending design m ethod斜弯设计方法hollow sect io n 空心截面per im eter周长hook 弯钩minimum s t irrup r atio 最小配箍率dis tributio n of r einfo r cem ent钢筋分布CHAPTER 9punching shear冲切,local co m pression 局部受压two way shear双向剪切slab-column joint板柱交接点column cap 柱帽,dr op panel 托板linear interpolatio n 线形内插effect ive dept h 有效高度cr itical width 临界宽度punching shear cone 冲压椎体polar m o m ent of inertia 极惯性矩net ar ea 净面积spiral stirrup 螺旋箍筋,m at r einfo r cement钢筋网splitting 劈裂,chipping 崩裂CHAPTER 10pr es tressed concr ete 预应力混凝土pr et ensioning sys t em先张法,pos t-tensioning sys t em后张法wire 钢丝,s trand 钢绞线,t endon 钢束bo tt o m台座,cas t ing-yard 预制场duct孔道,jack 张拉,gr out灌浆,bond 粘结,unbond 无粘结frictio n 摩擦full pr es tr essing 全预应力,partial pr es tressing 部分预应力cr eep 徐变,shrinkage 收缩stress loss 应力损失gripper s 夹具,ancho r age 锚具permissible s tress 容许应力,s tret ching s tr ess 拉伸应力,effectivepr es tress 有效预应力loss of pr es tress 预应力损失,loss due t o friction 摩擦损失,ancho r age-sect io ns 锚具滑移,elas t ic sho rt ening of concret e 混凝土塑性回缩,s t eel s tress r elaxation 钢筋应力松弛,cr eep loss 徐变损失,shrinkageloss 收缩损失t endo n pr o file 钢束形状,deviation fo r ce 偏向力,curvature effect曲率效应,wobbleeffect抖动效应fixed end 固定端,t ension end 张拉端over s tret ching 超张拉curvat u r e frictio n coefficient曲率摩擦系数transfer length 传递长度,bond s tr ess 粘结应力concr ete depositing 混凝土浇注service st age 使用阶段,cons truction s t age 施工阶段Transfo rm ed ar ea 换算面积,m o m ent of inertia 惯性矩hois ting 吊装,tr anspo rting 运输dynamic fact o r动力系数or dinary r einfo r ced s t eel 普通钢筋no rm al section 正截面,oblique section 斜截面CHAPTER 11serviceability 使用性能reliability 可靠性:safety 安全,applicability 实用,dur ability 耐久deflection 挠度,cr ack width 裂缝宽度transver se cr ack 横向裂缝,plas t ic cr ack 塑性裂缝,t emper ature cr ack 温度裂缝,shrinkage cr ack 收缩裂缝,cr acks due t o r us t锈蚀引起的裂缝,cr acks due t o differ ential settle m ent 不均匀沉降引起的裂缝,l oad-induced cr ack 荷载引起的裂缝freezing-thawing 冻容,alkali-aggr egat e r eact io n 碱骨料反应st andar d value 标准值,frequent value 频遇值,quasi-permanent value 准永久值maximu m cr ack width 最大裂缝宽度cr ack co ntr o l 开裂控制bond-s lip t heo ry 粘结滑移理论,no n-s lipping t heo ry 无滑移理论flexural s t iffness 弯曲刚度__。

4 Where fresh concrete is placed on hardened concrete, a good bond must be developed.5 The temperature of fresh concrete must be controlled from the time of mixing through final placement, and protected after placement.。