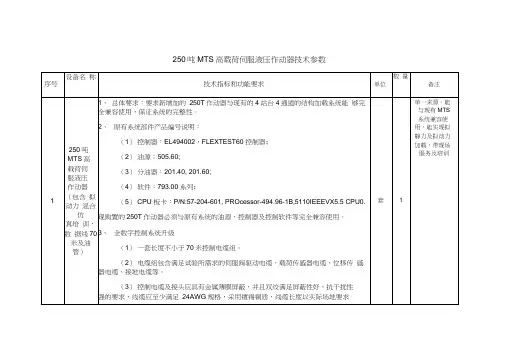

德国FORM+TEST公司常规-特殊涂层-静压支撑电液伺服作动器

- 格式:pdf

- 大小:1.64 MB

- 文档页数:6

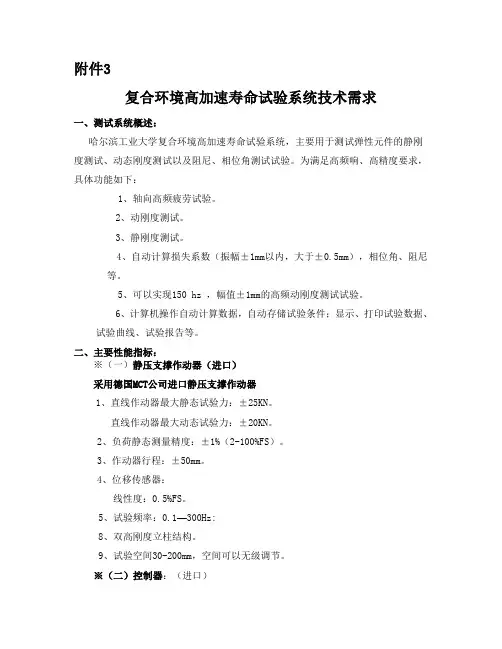

附件3复合环境高加速寿命试验系统技术需求一、测试系统概述:哈尔滨工业大学复合环境高加速寿命试验系统,主要用于测试弹性元件的静刚度测试、动态刚度测试以及阻尼、相位角测试试验。

为满足高频响、高精度要求,具体功能如下:1、轴向高频疲劳试验。

2、动刚度测试。

3、静刚度测试。

4、自动计算损失系数(振幅±1mm以内,大于±0.5mm),相位角、阻尼等。

5、可以实现150 hz ,幅值±1mm的高频动刚度测试试验。

6、计算机操作自动计算数据,自动存储试验条件;显示、打印试验数据、试验曲线、试验报告等。

二、主要性能指标:※(一)静压支撑作动器(进口)采用德国MCT公司进口静压支撑作动器1、直线作动器最大静态试验力:±25KN。

直线作动器最大动态试验力:±20KN。

2、负荷静态测量精度:±1%(2-100%FS)。

3、作动器行程:±50mm。

4、位移传感器:线性度:0.5%FS。

5、试验频率:0.1—300Hz:8、双高刚度立柱结构。

9、试验空间30-200mm,空间可以无级调节。

※(二)控制器:(进口)1、采用德国原装进口EDC580伺服控制器,CPU采用AMD520、133Hz处理器2、控制处理器采用32位DSP芯片,软件操作系统运行于WIN DOWSXP平台。

3、函数发生器频率:0.01~300Hz。

4、试验频率:0.1~120Hz。

5、控制方式:位移、负荷二种控制方式,并可平滑切换。

6、函数发生器波形:正弦波、三角波、方波、锯齿波、扫频波、随机波以及外部输入波形等。

(三)、液压系统:1、额定流量100L/min,额定压力21MPa,工作介质为N46汽轮机油,油液过滤精度:5 μm。

2、设备总功率约37KW,电源采用三相四线制380ACV±5%,50Hz。

3、冷却水流量:常温下6吨/小时,压力0.2-0.4MPa。

(四)、环境系统1)温度范围:-196~﹢350℃2)均热带:100mm3)温度梯度:2℃4)温度波动度:±1℃5)Pt100铂电阻热电偶测温(五) 、断裂分析系统可对断裂后试样的断口及裂纹进行成像与分析三、其他1)根据使用方提供的实验室平面布局示意图进行总体设计(见实验室平面布局示意图)。

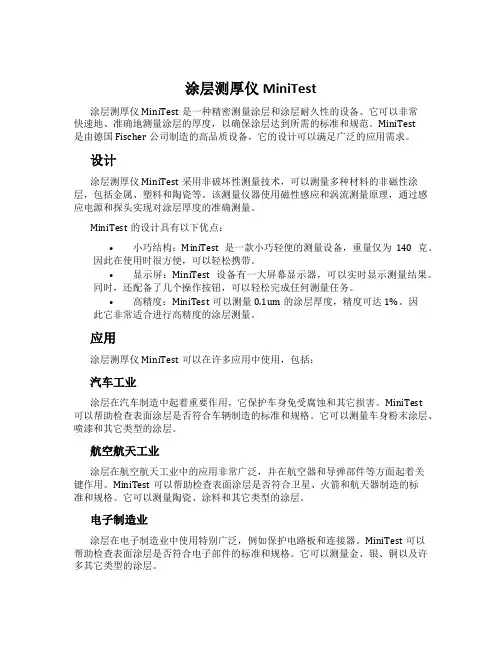

涂层测厚仪MiniTest涂层测厚仪MiniTest是一种精密测量涂层和涂层耐久性的设备。

它可以非常快速地、准确地测量涂层的厚度,以确保涂层达到所需的标准和规范。

MiniTest是由德国Fischer公司制造的高品质设备,它的设计可以满足广泛的应用需求。

设计涂层测厚仪MiniTest采用非破坏性测量技术,可以测量多种材料的非磁性涂层,包括金属、塑料和陶瓷等。

该测量仪器使用磁性感应和涡流测量原理,通过感应电源和探头实现对涂层厚度的准确测量。

MiniTest的设计具有以下优点:•小巧结构:MiniTest是一款小巧轻便的测量设备,重量仅为140克。

因此在使用时很方便,可以轻松携带。

•显示屏:MiniTest设备有一大屏幕显示器,可以实时显示测量结果。

同时,还配备了几个操作按钮,可以轻松完成任何测量任务。

•高精度:MiniTest可以测量0.1um的涂层厚度,精度可达1%。

因此它非常适合进行高精度的涂层测量。

应用涂层测厚仪MiniTest可以在许多应用中使用,包括:汽车工业涂层在汽车制造中起着重要作用,它保护车身免受腐蚀和其它损害。

MiniTest可以帮助检查表面涂层是否符合车辆制造的标准和规格。

它可以测量车身粉末涂层、喷漆和其它类型的涂层。

航空航天工业涂层在航空航天工业中的应用非常广泛,并在航空器和导弹部件等方面起着关键作用。

MiniTest可以帮助检查表面涂层是否符合卫星、火箭和航天器制造的标准和规格。

它可以测量陶瓷、涂料和其它类型的涂层。

电子制造业涂层在电子制造业中使用特别广泛,例如保护电路板和连接器。

MiniTest可以帮助检查表面涂层是否符合电子部件的标准和规格。

它可以测量金、银、铜以及许多其它类型的涂层。

操作涂层测厚仪MiniTest的操作非常简单,如下所示:1.打开MiniTest设备,并按下电源按钮。

2.将探头放在要测量的表面上。

3.从屏幕上读取测量结果,并记录校准值。

重要的是要确保MiniTest设备在每次测量前都被正确校准,以获得准确的结果。

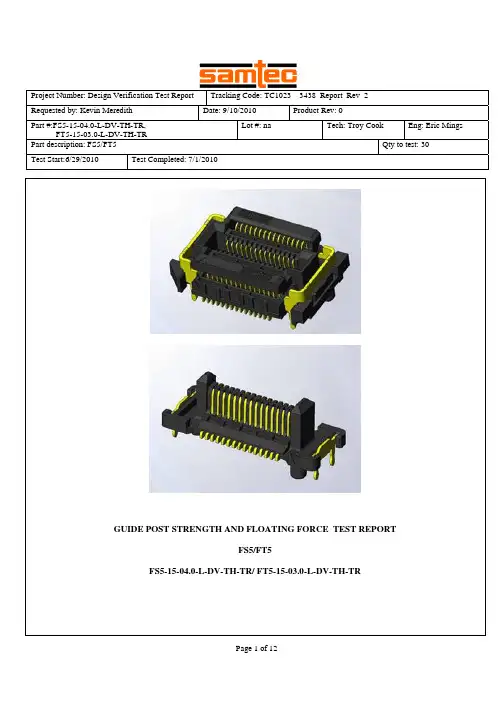

Project Number: Design Verification Test ReportTracking Code: TC1023—3438_Report_Rev_2 Requested by: Kevin Meredith Date: 9/10/2010Product Rev: 0Part #:FS5-15-04.0-L-DV-TH-TR,FT5-15-03.0-L-DV-TH-TR Lot #: naTech: Troy CookEng: Eric MingsPart description: FS5/FT5 Qty to test: 30Test Start:6/29/2010 Test Completed: 7/1/2010GUIDE POST STRENGTH AND FLOATING FORCE TEST REPORTFS5/FT5FS5-15-04.0-L-DV-TH-TR/ FT5-15-03.0-L-DV-TH-TRPart description: FS5/FT5CERTIFICATIONAll instruments and measuring equipment were calibrated to National Institute for Standards and Technology (NIST) traceable standards according to IS0 10012-l and ANSI/NCSL 2540-1, as applicable.All contents contained herein are the property of Samtec. No portion of this report, in part or in full shall be reproduced without prior written approval of Samtec.SCOPETo determine the force required to fail the guide features and the force required to displace the floating portion of the connector system .5mm in the X and Y direction.APPLICABLE DOCUMENTSStandards: EIA Publication 364TEST SAMPLES AND PREPARATION1)All materials were manufactured in accordance with the applicable product specification.2)All test samples were identified and encoded to maintain traceability throughout the test sequences.3)Any additional preparation will be noted in the individual test sequences.Part description: FS5/FT5Part description: FS5/FT5YXFigure 1: the photo to test the post strengthPart description: FS5/FT5SUPPLEMENTAL TESTS Shift force:1) Measure force to shift connector .5mm in X and Y directionFigure 2: the photo to test shift forcePart description: FS5/FT5RESULTSGuide Post strength Forces∙X direction:o Fat align pin▪Min--------------------------------------23.068 Lbs▪Max--------------------------------------30.232 Lbso Thin align pin▪Min--------------------------------------20.524 Lbs▪Max--------------------------------------32.077 Lbs∙X direction-Oppositeo Fat align pin▪Min---------------------------------------4.932 Lbs▪Max---------------------------------------6.157 Lbso Thin align pin▪Min---------------------------------------4.261 Lbs▪Max---------------------------------------4.630 Lbs∙Y direction:o Fat align pin▪Min----------------------------------- 10.603 Lbs▪Max--------------------------------------16.290 Lbso Thin align pin▪Min---------------------------------------8.271 Lbs▪Max---------------------------------------9.429 LbsShift forceFS5-15-04.0-L-DV-TH-TR/FT5-15-03.0-L-DV-TH-TR∙X direction:o Min--------------------------------------------------2.456 Lbs Displacement at: 0.0195 incho Max-------------------------------------------------2.617 Lbs Displacement at: 0.0237 inch ∙Y direction:o Min--------------------------------------------------6.320 Lbs Displacement at: 0.0225 incho Max------------------------------------------------12.275 Lbs Displacement at: 0.0520 inch FS5-30-04.0-L-DV-TH-TR/FT5-30-03.0-L-DV-TH-TR∙X direction:o Min--------------------------------------------------4.697 Lbs Displacement at: 0.0250 incho Max-------------------------------------------------5.267 Lbs Displacement at: 0.0259 inch ∙Y direction:o Min--------------------------------------------------6.308 Lbs Displacement at: 0.0200 incho Max-------------------------------------------------8.052 Lbs Displacement at: 0.0200 inchPart description: FS5/FT5DATA SUMMARIES Guide Post strength Forces∙X direction:Side#1 (FAT)Side#2 (THIN)Force (lbs) Force (lbs)Minimum 23.068 20.524Maximum 30.232 32.077Average 26.443 25.280 ∙X direction-OppositeSide#1(FAT)Side#2(THIN)Force (lbs)Force (lbs)Minimum 4.932 4.261Maximum 6.157 4.630Average 5.515 4.411 ∙Y direction:Side#1 (FAT)Side#2 (THIN)Force (lbs) Force (lbs)Minimum 10.603 8.271Maximum 16.290 9.429Average 13.317 8.861 Shift force:FS5-15-04.0-L-DV-TH-TR/FT5-15-03.0-L-DV-TH-TR∙X direction:Force(lbs) DisplacementMinimum 2.456 0.0195Maximum 2.617 0.0237Average 2.551 0.0213 ∙Y direction:Force(lbs) DisplacementMinimum 6.320 0.0225 Maximum 12.275 0.0520 Average 8.746 0.0344Part description: FS5/FT5Shift force:FS5-30-04.0-L-DV-TH-TR/FT5-30-03.0-L-DV-TH-TR∙X direction:Force (lbs)DisplacementMinimum 4.697 0.0250Maximum 5.267 0.0260Average 4.982 0.0250∙Y direction:Force (lbs)DisplacementMinimum 6.308 0.0200Maximum 8.052 0.0200Average 7.392 0.0200Part description: FS5/FT5DATA Guide Post strength Forces∙X direction:Side#1 (FAT)Side#2 (THIN)Sample# Force (lbs) Force (lbs)1 23.068 21.4742 25.987 24.9643 30.232 32.0774 24.628 20.5245 28.302 27.363 ∙X direction-Opposite:Side#1 (FAT)Side#2 (THIN)Sample# Force (lbs) Force (lbs)1 6.157 4.3122 5.735 4.6303 4.932 4.3724 5.236 4.4795 4.261 ∙Y direction:Side#1 (FAT)Side#2 (THIN)Sample# Force (lbs) Force (lbs)1 16.290 8.5652 10.603 9.1773 12.683 9.4294 13.690 8.271Part description: FS5/FT5DATA Continued Shift force:FS5-15-04.0-L-DV-TH-TR/FT5-15-03.0-L-DV-TH-TR∙X direction:Sample# Force(lbs) Displacement1 2.456 0.01952 2.537 0.02063 2.596 0.02144 2.595 0.02205 2.499 0.01976 2.589 0.02377 2.486 0.02148 2.592 0.02069 2.617 0.022810 2.547 0.0212 ∙Y direction:Sample# Force(lbs) Displacement1 10.440 0.03362 6.320 0.02253 8.521 0.02944 7.438 0.03875 7.876 0.02306 8.078 0.03977 12.275 0.02988 8.838 0.04849 9.223 0.052010 8.448 0.0264 FS5-30-04.0-L-DV-TH-TR/FT5-30-03.0-L-DV-TH-TR∙X direction:Sample# Force(lbs) Displacement1 5.267 0.02592 4.996 0.02503 5.129 0.02454 4.821 0.02405 4.697 0.0250Part description: FS5/FT5 FS5-30-04.0-L-DV-TH-TR/FT5-30-03.0-L-DV-TH-TRY direction:Sample# Force(lbs) Displacement1 6.308 0.02002 7.440 0.02003 8.016 0.02004 7.144 0.02005 8.052 0.0200Part description: FS5/FT5EQUIPMENT AND CALIBRATION SCHEDULES Equipment #: TCT-04Description: Dillon Quantrol TC2 Test StandManufacturer: Dillon QuantrolModel: TC2Serial #:Accuracy: Speed Accuracy: +/- 5% of indicated speed; Displacement: +/- 5 micrometers. … Last Cal: 05/07/2009, Next Cal: 05/07/2010。

电液伺服疲乏试验机:料子耐久性的“耐力测试者”在料子科学和工程领域,对料子和结构在反复载荷作用下的耐久性进行评估是一项紧要的技术任务。

电液伺服疲乏试验机作为一种先进的料子耐久性测试设备,以其优化的试验原理、高精度和强大的试验本领,在料子和结构耐久性研究中发挥侧紧要作用。

本文将介绍该产品的原理、用途及其在料子科学中的应用。

电液伺服疲乏试验机紧要用于对料子和结构进行反复载荷作用下的耐久性测试。

它的工作原理基于电液伺服掌控技术。

试验机通过电液伺服掌控系统,精准明确掌控试验过程中的载荷、位移和频率等参数。

在测试过程中,试样受到周期性的载荷作用,模拟实际工作环境中的疲乏载荷。

通过监测试样的响应,如应变、位移和裂纹扩展等,可以评估料子和结构的耐久性。

该产品具有以下特点:1.高精度:该产品采用高精度的电液伺服掌控系统,能够精准明确掌控试验过程中的载荷、位移和频率等参数,满足各种耐久性测试的需求。

2.强大的试验本领:该产品通常具有较大的载荷范围和试验频率范围,能够模拟各种多而杂的工作环境,满足不同料子和结构的耐久性测试需求。

3.多种试验模式:该产品可以进行各种疲乏试验,如正弦波疲乏试验、三角波疲乏试验、随机载荷疲乏试验等,满足不同试验需求。

4.数据手记和分析:该产品通常配备有数据手记和分析系统,能够实时监测试样的响应,并进行数据分析和处理,供应认真的试验结果。

5.易于操作和维护:该产品操作界面友好,操作简便,便于非专业人员使用。

同时,结构紧凑,便于安装和维护。

总之,电液伺服疲乏试验机作为一种先进的料子耐久性测试设备,具有高精度、强大的试验本领、多种试验模式、数据手记和分析以及易于操作维护等优点。

它为料子科学和工程领域供应了一种可靠的耐久性测试手段,有助于评估料子和结构的耐久性,优化设计和提高工程安全性。

随着科技的不绝进步和料子科学的需求日益增长,该产品的应用将越来越广泛,为料子研究和工程发展供应强大的支持。

摘要阻尼器是一种能够吸收、衰减冲击与振动的控制装置,随着设计和制造技术的不断提高,其应用越来越广泛.鉴于阻尼器如此广泛的使用,且其对系统的安全性起着至关重要的作用,必须确保阻尼器具备合格的性能指标和制造质量。

因此,研制阻尼器振动试验台对测试阻尼器性能,保证产品质量具有重要意义。

本文调研了阻尼器振动试验台的发展现状,在分析了各类振动试验台性能特点的基础上,提出使用液压振动试验台检测阻尼器的方法,并针对国内外液压振动试验台研究中存在的不足,研究开发了一套具备高精度、大载荷、宽频响等特点的百吨级液压振动试验台系统,并完成了系统具体设计。

对液压振动试验台的系统原理进行阐述,根据试验台的技术指标,对试验台液压系统主要元件和试验台机架进行设计,并针对试验台设计中的技术难点进行分析。

关键词:阻尼器;液压试验台;性能检测;伺服控制AbstractDamper as an absorption and attenuation of shock and vibration control device, as the design and manufacturing technology The continuous improvement of operation, its application is more and more widely. In view of the damper is so widely used, and the system Security plays an important role, must ensure that the damping apparatus for manufacturing quality and qualified performance indicators. Therefore, the development to test the tester damper vibration damper performance, ensure the quality of products is of great significance. In this paper, the research of vibration damper test bench development present situation, the analysis of the various characteristics of vibration table Based on the analysis of using hydraulic method to detect damper vibration test rig, and in view of the hydraulic vibration test at home and abroad Test platform of the insufficiency in research, the research developed a high precision, large load, bandwidth, etc The tonnage hydraulic vibration test system, and completed the system design. On the system principle of hydraulic vibration test bench, according to the technical index of the test bench, main components and hydraulic system on test bench test bed frame design, and in view of the technical difficulties in the design of test bed are analyzed. Based on the above research results, the tonnage hydraulic vibration damper test rig is developed, and in jiangsu electric power Run the installation for co., LTD The damper test showed that this paper developed test rig, Load control accurate, reliable test data, fully meet the needs of enterprises on the damper performance test.Key words: damper; Hydraulic test bench; Performance testing; Servo control目录绪论 (1)第一章液压振动试验台的现状和发展趋势分析 (2)1.1 国外液压振动试验台的发展现状 (2)1.2阻尼器性能检测方法 (4)第二章液压振动试验台的功能分析 (7)1.1 液压振动试验台研制方案的提出 (7)1.2 本文的主要研究内容 (8)1.3 论文组织架构 (9)1.4液压振动试验台的设计 (9)第三章拟定动静态液压试验台的液压原理图 (10)3.1 试验台架功能和组成 (10)3.2 液压系统 (10)3.3 效率问题 (10)3.4 动静态试验问题 (11)第四章选择液压元件 (13)4.1分类 (15)4.2 用途 (16)4.3分类功能 (17)第五章液压系统性能的验算 (18)5.1 系统冲击问题 (18)5.2 主机设计 (19)第六章伺服液压缸机械部分设计 (22)6.1 试验台的技术指标 (22)6.2 供油压力的选择 (22)6.3 机架的设计说明 (26)总结 (29)参考文献 (29)致谢 (30)沈阳化工大学科亚学院学士学位论文绪论绪论阻尼器是一种对速度反应灵敏的振动控制装置,它能够吸收、冲击能量与衰减振动,减少结构的动力反应,控制冲击性的流体振动(如主汽门快速关闭、安全阀排放、水锤、破管等冲击激扰)和地震激扰的管系振动,主要适用于核电厂、火电厂、化工厂、钢铁厂等的管道及设备的减振。

HEUFT SYSTEMTECHNIK GMBHAmWind1·56659Burgbrohl·Germany··**************Perfect PET!CUSTOMER CENTERviSiT US in OURself of the superior performance of our inspection and quality assurance systems – even with live tests using products from your own portfolio upon request.***************+49 2636 56 0HEUFT system sustainably in the HEUFT Training Center – not only theoretically but also directly at the device!****************** +49 2636 56 2671TeleService , the HEUFT PhoneService up to HEUFT DirectService visits – for a worldwide 24/7 support.************************+49 2636 56 278and events – including a tour of the premises, specialist lectures and practical presentations!*****************+49 2636 56 0Washing machineinfeed check based on the HEUFT InLine ISEmpty bottle inspectionpET inSpECTiOnHEUFT safeguards quality during the filling of returnable pET from the beginning to the end. non-brand, severely misshapen, contaminated and defective empty bottles are reliably detected and removed even before they canput downstream machines out of action. The emptybottle inspector only allows pET containers through afterthe cleaning process which can be safely filled. an inspec-tion is carried out as soon as the drink is inside that the quantity is correct and the bottle does not leak. Finally a detailed examination of all the closure elements ensures the integrity of the packaging and the unadulterated purity of the end product.From bottom to top, from inside to outside, from empty to full, from open to sealed, from bad to good, from con- taminated to pure, from holey to tight, from defective to perfect and from premium to standard. Indeed from A to Z:Cleaning machinepERFECT qUaliTyFROM THE bEginning TO THE EndpET inSpECTiOnHEUFT InLine ISEmpty PET bottle inspection with servo technology.Full coverageContinuous complete inspection of empty pET bottles for the reliable identification of residual liquid, contamination, mould, foreign objects, stress cracks, defective neck rings as well as finish and thread faults including soiled and damaged vent slots.Intelligent assessmentHEUFT reflexx² image processing system and smart algorithm in order to combine the results of a precise scuffing, crack and base wear detection for the reliable iden-tification and evaluation of returnable pET bottles which are too old and no longer useful.Exact adjustmentServo-controlled fine bottle alignment for even more precision during the all-around inspection and automatic adaptation of the transport and detection units for straightforward brand and format changes.Space-saving and cleanCompact construction (actual area < 1 m²) in accordance with the hygiene-optimised HEUFT CleanDesign .HEUFT squeezer IIQSHighly automated leakage check based on the HEUFT SPECTRUM II .Leakproof packaging and pure contents Reliable detection of minute leaks in filled bottles made of pET and other plastics for the sustainable safeguarding of packaging and product integrity.Full stabilityprecise measurement of the internal pressure of the container for stable full containers which can be optimally transported and stored.Outstanding detection reliability Comparative fill level detection in a non-compressed and compressed condition for maximum precision when identifying leaks.reliable and easy operationMaximally automated HEUFT SPECTRUM II system with self-explanatory audio- visual HEUFT NaVi user guidance.Label inspectionSidewall inspectionFinish inspectionReal-time image processingwith individual teach-inClosure defect MisshapenForeign objectMicroleakMicrocrackLeaking closureBase inspectionTorn labelDefective tamper evident ringN on -b r a n d M i s a l i g n m e n tIncorrect alignmentLeaking closureMicroleakFill management MicrocrackClosure inspectionClosurepET inSpECTiOnWashing machine infeed check based on theHEUFT SPECTRUMIIAll-around inspection of returnable PET bottles even before cleaning.Full line efficiency and full productivityEffective protection against productivity thwarting standstills to the bottle washing machine and other downstream devices due to the timely sorting out of unsuitable pET bottles.Maximum packaging and product safetyReliable identification and early rejection of empty bottles which are non-brand, oversized, misshapen, closed, extremely soiled and contain dangerous residual liquids or foreign objects not removed during cleaning.Maximum detection reliabilitypowerful sensor technologies, high-resolution optics and real-time image proces-sing system. innovative camera technology especially for the specific detection of non-brand label remains, imprints and embossing as well as the reliable determi-nation of the colouration and exact quantity of residual liquid on the base of the bottle.Simply automaticMaximally automated HEUFT HEUFT SPECTRUM II system with automatic verticaland guide rail adjustment as well as the self-explanatory audiovisual HEUFT NaVi user guidance.HEUFT FinalView IICAPDetailed closure inspection based on the HEUFT SPECTRUM II .Full closure safety and maximum product integrityContinuous all-around inspection of closures and their safety elements.Superior detection accuracyReliable identification of non-brand, canted, defective, leaking and incorrectly positioned closures as well as the clear detection of thread faults and damaged tamper evident and neck rings.Individual and flexibledifferent detection modules for specific tasks from inspecting colour logos to checking the closure alignment with millimetre precision.Highly automated and self-explanatorybrand changes at the push of a button and audiovisual step-by-step assistance for utmost operational reliability.。

PA-200型电液伺服动静试验机一、概述PA系列电液伺服动静试验机是长春科新试验仪器有限公司开发制造的新产品。

广泛用于金属和非金属、特别是新材料如超强度钢、钛合金和增强合成纤维等材料进行拉伸、压缩、疲劳、低周疲劳、裂纹扩展、断裂力学、实物试验以及模拟试验等。

主机采用双立柱可移动横梁结构,加载作动器筒下置式。

整机刚性好、结构紧凑、加工精细、外形简洁大方。

该设备系统主要由主机部分、电液伺服液压部分,计算机及电控部分组成。

主作动器具有低摩擦、低阻尼及良好的抗侧向力能力,内部同轴安装高响应的线性差动变压器传感器。

主机上装有动、静态双向高精度的力传感器,可测试工作最大200kN力值。

电液伺服液压系统采用国内高质量元件器件,切换自如,液压平稳,系统循环无泄渗油现象,使系统工作节时节能。

PA200电液伺服动静试验机主机结构紧凑、试验机采用双立柱结构、油缸下置、横梁升降自如、机架刚度高、夹头夹持可靠、对中性好、无滑动现象、装夹方便。

油源压力稳定、流量大油温恒定。

电控系统采用长春科新试验仪器有限公司生产的全数字控制器GTC350,计算机系统具有人机界面,使操作直观方便,灵巧。

该机可由计算机操作控制,计算机具有单独数据管理、存档功能。

并可以根据用户需要设计。

PA-200电液伺服动静试验机是长春科新试验仪器有限公司开发制造的新产品。

本产品采用自行设计的主机、液压源,动态控制器,主要元器件均采用进口产品。

是一种功能强、精度高、可靠性好、应用范围广、性价比好,用于材料和零部件动态、静态力学性能试验的系统,可用于拉伸、压缩、低周和高周疲劳、疲劳裂纹扩展、断裂力学及模拟实际工况的力学试验。

二、特点1、主机1.1综合我公司多年经验优化设计的主机,采用当代动态电液伺服试验机流行双柱门形框架结构,刚性好、结构紧凑、外形简洁、加工精细。

光杠采用表面镀铬抛光工艺,使光杠表面硬度高,耐磨、耐腐蚀;1.2整体安装于工作台面下的伺服作动器低摩擦、高响应。