应用行星式球磨机进行机械合金化的研究

- 格式:pdf

- 大小:229.20 KB

- 文档页数:9

冷喷涂制备cBN NiCrAl金属陶瓷涂层Fabrication of cBN N iCrA l Cermet Coating by Cold Spray雒晓涛,杨冠军,李长久(西安交通大学材料科学与工程学院,金属材料强度国家重点实验室,西安710049)LU O Xiao Tao,YANG Guan Jun,LI Chang jiu(State Key Labo rato ry for M echanical Behavior of M aterials, Scho ol o f Materials Science and Eng ineer ing,Xi an Jiaotong University,Xi an710049,China)摘要:采用机械合金化制备40v ol%cBN N iCrA l金属陶瓷复合结构粉末,采用冷喷涂制备了40%cBN N iCrA l(体积分数)金属陶瓷复合结构涂层。

研究了机械合金化过程对粉末的相组成、晶粒尺寸以及显微组织的影响。

采用扫描电子显微镜和X射线衍射分别表征不同球磨时间下粉末以及冷喷涂涂层的显微组织和相结构。

采用Scher rer公式估算不同球磨时间下粉末以及冷喷涂涂层中合金基体相的晶粒尺寸。

结果表明,40v ol%cBN N iCrA l金属陶瓷粉末球磨40h后,基体的平均晶粒尺寸达到~50nm;复合结构涂层组织致密,硬质颗粒在合金基体中分布均匀。

喷涂过程中,粉末相结构未发生变化,晶粒尺寸也未发生明显的长大。

测试表明涂层的显微硬度约为1170H V0 3。

关键词:cBN N iCr Al;机械合金化;冷喷涂;涂层;显微组织中图分类号:T B333 文献标识码:A 文章编号:1001 4381(2009)Suppl1 0032 04Abstract:40%cBN NiCrAl pow der w as prepared by mechanical alloying(MA)metho d to investig ate the effect of MA process o n the gr ain size,phase structure and microstr ucture of the pow der.40vol% cBN NiCrAl coating(1170H V0 3)w as successfully deposited by cold spray.Scanning electron micros copy(SEM)and X ray diffr actio n(XRD)w ere carr ied out to characterize its microstructure and phase structure,respectively.Scherrer for mula w as used to estim ate the mean grain size fo r the pow der and the coating.T he results show that a dense and cBN particles unifo rmly distributed coating has been obtained.No phase transfor mation occur s during the spray pro cess.The m ean g rain size of the alloy in the pow der is abo ut50nm after40hours ball milling.M oreov er,there is no ev ident grain grow th during the spray pro cess.Key words:cBN NiCrAl;Mechanical allo ying;cold spray;hardness;micr ostructure立方氮化硼(cBN)是除金刚石以外,硬度(70GPa)和热导率(13W/cm K)最高的材料,此外,与金刚石不同,cBN在熔融有色金属中具有比较高的稳定性[1-2]。

行星式球磨机毕业论文行星式球磨机是一种新型磨削设备,能够广泛应用于金属、非金属、化学、医药、食品等行业的颗粒物体粉碎和分散过程中。

本文将会对行星式球磨机所涉及到的基本原理、特点、优点以及在工业应用上所具有的优势进行介绍。

1. 基本原理及特点行星式球磨机是一种多功能的磨床设备,它的磨削过程采用了滚瓜石的原理。

行星式球磨机由磨料罐、磨料装置、主轴、摆轮等几个组成部分。

其磨料罐在装有一定数量的磨球后,与主轴、摆轮产生高速旋转。

因为磨球向着一定方向滚动而不断地为磨罐内的物料互相碰撞、互相磨擦,以期达到研磨和混合的目的。

由于行星式球磨机的磨削过程采用滚瓜石的原理,因此与其他磨削设备相比,具有以下几个特点:(1)磨削时间短:在相同的磨削条件下,行星式球磨机所需要的磨削时间短于其他磨削设备。

(2)磨削效果好:磨球的摆动轨迹为弧形,其向与离心力方向相反的方向偏移一定角度,使得磨球中的磨料得以不断地撞击和磨合,从而达到更好的磨削效果。

(3)安全性好:行星式球磨机在磨削过程中不会产生任何脱落情况,因此其安全性得到了更好的保障。

2. 优点行星式球磨机在工业应用中具有如下优势:(1)广泛的适用范围:行星式球磨机能够适用于各种颗粒物体的磨削和混合过程,具有广泛的适用范围。

(2)高效能的磨削:行星式球磨机具有高效能的磨削水平,其磨削效率一般高于传统的磨床设备。

(3)优秀的研磨效果:行星式球磨机不仅能够研磨物料,同时还能对颗粒物体进行分散效果,具有优秀的研磨效果。

(4)低能耗:与传统的磨床设备相比,使用行星式球磨机的能耗要低于其他磨床设备。

3. 工业应用行星式球磨机在众多领域中都有广泛的应用,例如:(1)化工行业:行星式球磨机能够将块状物料研磨成细粉末,在化学和冶金行业中有很广泛的应用。

(2)生物医药行业:在生物医药领域,行星式球磨机被广泛用于分散混合药物,制造新型药物。

(3)纳米材料制备:在纳米材料制备领域中,行星式球磨机被广泛应用于制造纳米颗粒。

陶瓷/Mg2Si纳米复合材料制备及力学性能研究王墨林;王莉【摘要】以纳米陶瓷颗粒Si3N、AlN和常规Mg、Si粉为原料,采用机械合金化和真空热压相结合的方法制备Si3N/Mg2Si和AlN/Mg2Si纳米复合材料,并对样品的微结构和力学性能进行了表征。

结果表明:随着纳米陶瓷颗粒体积分数由0%增加到20%,金属间化合物M g2Si的硬度得到了很大的提高,Si3N/M g2Si纳米复合材料的断裂韧性由0.59 MPa· m -1/2增加到1.38 MPa· m-1/2,而AlN/Mg2Si的断裂韧性却基本不随AIN的含量增加而改变。

%Bulkceramic/Mg2Si nanocomposites are prepared by mechanical alloying and hot-pressing in vacuum , and the microstructures and the mechanical properties are analyzed .The results indicate that the hardness of Mg2Si nanocomposites is improved by the addition of ceramic nanoparticles ,and the fracture toughness of Si3N/Mg2Si nanocomposites increases from0 .59MPa · m-1/2 to 1 .38MPa · m-1/2 with the increase of the Si3N content from 0(vol .)% to 20(vol .)% ,while that of the AlN/Mg2Si nanocomposites changes little .【期刊名称】《实验技术与管理》【年(卷),期】2013(000)010【总页数】5页(P47-50,54)【关键词】纳米复合材料;Mg2Si;陶瓷颗粒;机械合金化【作者】王墨林;王莉【作者单位】合肥工业大学电子科学与应用物理学院,安徽合肥 230009;合肥工业大学电子科学与应用物理学院,安徽合肥 230009【正文语种】中文【中图分类】TB33金属间化合物的长程有序超点阵结构,使其具有许多特殊的物理化学和力学性能,比如比重小、熔点高、硬度高等。

行星式球磨机的使用流程一、行星式球磨机简介行星式球磨机是一种常用的实验室设备,用于研磨材料并获得细粉末。

该设备具有多个工作站,每个工作站都有一个磨杯进行高速旋转和球磨。

行星式球磨机通常用于制备粉体材料、合金的混合和机械合金化等实验研究。

二、行星式球磨机的使用流程使用行星式球磨机前,需要确保已经做好以下准备工作:1.检查行星式球磨机的外观是否完好,并确保电源接线正常。

2.准备好所需的磨杯、球磨介质和待磨样品。

3.确保操作者已经了解行星式球磨机的各部件的名称和功能。

接下来,我们来介绍行星式球磨机的使用流程:1. 打开行星式球磨机•将电源线插入插座,并打开电源开关。

•按下控制面板上的电源按钮,行星式球磨机即可打开。

2. 加载磨杯和球磨介质•打开行星式球磨机的磨机门,将磨杯放入工作站。

•确保磨杯的盖子已经打开,将适量的球磨介质倒入磨杯中。

球磨介质的种类和数量要根据实验需求确定。

3. 加入待磨样品•将待磨样品加入到已经加入球磨介质的磨杯中。

注意加入的样品量不要超过磨杯的容量。

4. 关闭磨机门并设置运行参数•关闭磨机门,并确保磨杯盖子已经盖好。

•使用控制面板上的按钮设置所需的运行参数,如旋转速度、运行时间等。

5. 开始球磨•按下控制面板上的开始按钮,行星式球磨机即开始工作。

•在球磨的过程中,可以通过控制面板上的显示屏实时监测磨机的运行状态。

6. 完成球磨•当设定的运行时间到达时,行星式球磨机会自动停止工作。

•打开磨机门,取出已经球磨完成的样品。

7. 清洁和维护•清洁磨杯和球磨介质,并妥善保管。

•将行星式球磨机的各部件进行清洁和维护,保持设备的正常运行。

三、行星式球磨机使用注意事项使用行星式球磨机时,需要注意以下事项:•在操作行星式球磨机前,确保已经阅读并理解相关的操作说明和安全注意事项。

•注意操作中的安全问题,如避免手指接触旋转部件、防止磨机门意外打开等。

•设置合适的运行参数,以确保样品的研磨过程具有可重复性和准确性。

机械合金化的研究及进展一、简述随着科学技术的不断发展,机械合金化作为一种新型的材料加工技术,已经引起了广泛的关注。

机械合金化是指通过机械手段使金属基体与合金元素发生反应,从而实现对金属材料性能的调控。

这种方法具有工艺简便、成本低、生产效率高等优点,因此在航空、航天、汽车、能源等领域具有广泛的应用前景。

自20世纪初以来,机械合金化的研究取得了显著的进展。

首先研究人员通过对合金元素的选择和添加方式的优化,实现了对金属材料性能的有效调控。

例如通过控制合金元素的比例和分布,可以实现对金属硬度、强度、韧性等性能的精确控制。

此外还可以通过改变合金化过程中的温度、压力等条件,进一步提高材料的性能。

其次机械合金化技术在实际生产中的应用也取得了显著的成果。

许多国家和地区的企业和研究机构都在积极开展机械合金化技术的研究与应用,如美国的GE公司、德国的西门子公司等。

这些企业在航空航天、汽车制造等领域成功地将机械合金化技术应用于实际生产中,为提高产品质量和降低生产成本做出了重要贡献。

随着人们对新材料的需求不断增加,机械合金化技术的研究也在不断深入。

目前研究人员正致力于开发新型的合金元素和合金体系,以满足不同领域对高性能金属材料的需求。

同时还将加强对机械合金化过程的理论研究,以期为实际应用提供更有效的指导。

机械合金化作为一种具有广泛应用前景的新型材料加工技术,其研究与发展将继续受到人们的关注和重视。

A. 研究背景和意义机械合金化技术可以有效地改善金属材料的力学性能、耐磨性、耐腐蚀性等综合性能。

通过对金属基体的改性,可以使其具有更高的强度、硬度、韧性等性能指标,从而满足不同工程领域对材料的高性能要求。

机械合金化技术可以通过控制合金元素的含量、分布和形态,实现对金属材料组织结构的优化。

例如通过控制合金元素的添加量,可以使金属基体中出现一定程度的相变现象,从而形成具有特定性能的相,如马氏体、贝氏体等。

这些相具有优异的力学性能和耐腐蚀性能,可以提高金属材料的整体性能。

《AlCoCrFeNi高熵合金颗粒增强Al基复合材料制备及界面行为研究》篇一摘要:本文研究了AlCoCrFeNi高熵合金颗粒增强Al基复合材料的制备过程,探讨了制备过程中的各项参数对材料性能的影响,并对复合材料中的界面行为进行了详细的分析。

本研究的目的是通过深入理解这一新型复合材料的微观结构和性能,为制备具有更高强度和优异性能的金属基复合材料提供理论依据和实验支持。

一、引言随着现代工业的快速发展,金属基复合材料因其优异的力学性能和良好的综合性能而受到广泛关注。

其中,高熵合金因其多主元结构在材料科学中显示出独特的性能。

本研究采用AlCoCrFeNi高熵合金颗粒作为增强相,与Al基体复合,旨在制备出具有优异力学性能的复合材料。

二、制备方法及实验材料本实验采用粉末冶金法,通过机械合金化与热压烧结相结合的方式制备AlCoCrFeNi高熵合金颗粒增强Al基复合材料。

实验材料包括纯铝粉末、高熵合金粉末及其他必要的添加剂。

三、制备过程及参数影响(一)机械合金化将纯铝粉末与高熵合金粉末按照一定比例混合后,在行星式球磨机中进行机械合金化处理。

处理时间、球磨速度等参数对合金化效果有着显著影响。

适当延长球磨时间和提高球磨速度可以增强合金元素的扩散与固溶,从而提高复合材料的力学性能。

(二)热压烧结机械合金化后的粉末经过热压烧结处理,通过控制烧结温度、压力和时间等参数,可以获得致密且组织均匀的复合材料。

其中,烧结温度对材料的晶粒尺寸和相组成具有重要影响。

四、界面行为研究(一)界面结构分析通过扫描电子显微镜(SEM)和高分辨透射电子显微镜(HRTEM)对复合材料的界面结构进行观察,发现高熵合金颗粒与Al基体之间形成了良好的界面结合,没有明显的界面反应和孔洞。

(二)界面反应及元素扩散通过对界面进行元素分析,发现高熵合金元素在Al基体中发生了明显的扩散现象,形成了连续的固溶体层。

这种扩散现象有助于提高两相之间的结合强度,从而提高复合材料的整体性能。

Zr-Al-Ni-Cu合金非晶形成范围的Miedema模型预测刘衡;尹洪波;周仁杰;张怀亮;龙卧云【摘要】运用扩展Miedema模型及Toop几何模型,计算了Zr-Al-Ni-Cu四元系中各三元合金及四元合金的形成焓与系统组成间的分布关系.利用对应三元合金焓值的加权计算,获得了Zr-Al-Ni-Cu四元合金的最佳非晶形成组分.与现有实验结果相对比,计算结果及机械合金化实验均表明,利用合金的形成焓值可以较好地预测系统的非晶形成范围.【期刊名称】《广西师范学院学报(自然科学版)》【年(卷),期】2018(035)001【总页数】6页(P41-46)【关键词】Miedema模型;非晶合金;形成焓;加权计算【作者】刘衡;尹洪波;周仁杰;张怀亮;龙卧云【作者单位】湖南农业大学东方科技学院 ,湖南长沙 410128;湖南农业大学东方科技学院 ,湖南长沙 410128;湖南农业大学东方科技学院 ,湖南长沙 410128;湖南农业大学东方科技学院 ,湖南长沙 410128;湖南农业大学东方科技学院 ,湖南长沙 410128【正文语种】中文【中图分类】TG139+.80 引言非晶合金因其具有独特的优异性能,在众多领域都具有重要应用价值,已成为材料科学与工程领域中的一个重要发展方向.虽然人们已在非晶合金的制备技术、理化性能及应用开发等方面取得了大量的研究进展,但在如何合理确定适宜非晶合金形成的组成范围(AFCR)方面一直未有重大突破,多是采用试错法(try-and-error)[1]来确定,效率较低.因此,寻找实用而有效的非晶成分设计方法,发现新的具有强非晶形成能力的合金体系,仍是非晶合金研究领域的主要研究方向之一.由于熔体快速凝固法成本过高,加之相关热力学参数难以获取,探寻非晶组成范围的预测更多地利用固相非晶化反应(SSAR)来实现.SSAR模型指出,非晶化的机理是组元间大的负形成焓和元素与非晶合金间大的扩散系数差的作用结果[2].大的负形成焓为固相扩散提供大的驱动力,是固相非晶化反应的热力学条件.形成焓是描述物相形成能力和稳定性的重要参数,对预测非晶形成范围具有重要的参考价值.在众多的预测模型中,Miedema模型相对更为成熟,应用更为普遍.经不断完善,Miedema模型已成为预测合金热力学性质的众多理论模型中最成功的一个.由于模型本身针对的是二元合金系统,多元系统的形成焓值需要借助于几何模型及外推方法来得到.本文以Miedema模型为基础,结合Toop几何模型,以形成焓值为标准,在各三元系的基础上,拟对Zr-Al-Ni-Cu四元系的非晶形成范围进行预测,以期为非晶合金的制备提供一定的理论参考.1 模型计算所用公式根据Miedema理论[3],二元i-j合金体系的形成焓ΔH可表示为(1)有关Miedema模型中各参数的物理意义及其使用可参考文献[4].根据Toop模型,三元合金系统的形成焓值可由对应的二元系形成焓值通过几何模型外推得到,而四元系的则可由对应的三元系的外推得到,其计算公式可分别表示为[5](2)(3)式中,a,b,c和d表示四元系统的四个组元,Hab,Habc则分别表示对应二元、三元系的形成焓值.本文中计算形成焓时所用到的各热力学参数如表1所示[6].表1 计算所需的热力学参数元素ZrAlNiCuφ*(V)3.684.25.264.45nws(d.u.)2.82.75.363.18V(cm3/mol)14106.67. 12B(GPa)83.33572.18186131G(GPa)34.1426.5975.145.13Tm(K)2127.85933.6 17261356.62 计算结果利用文献[4]的结论,根据式(1)及式(2)计算了Zr-Al-Cu,Zr-Al-Ni,Zr-Ni-Cu和Al-Ni-Cu三元系的形成焓值,其各自的形成焓值与组分间的关系如图1所示.根据计算结果可得各三元系的最低形成焓值及其所对应的组分分别为:Zr40.52Al24.92Cu34.56(-16.76 kJ/mol),Zr36.56Al25.89Ni37.55(-22.50 kJ/mol),Zr39.91Cu0Ni60.09(-17.85 kJ/mol),Al45.58Ni54.02Cu0(-7.94 kJ/mol),分别用A,B,C及D来进行标记,四组分的形成焓值之和为-65.05 kJ/mol.为减小计算工作量,探索利用加权平均法,来获得Zr-Al-Ni-Cu四元系的基本组成,即:Zr-Al-Ni-Cu=A×16.76/65.05+B×22.50/65.05+C×17.85/65.05+D×7.94/65.05.(4)通过式(4)获取了四元非晶相组成为Zr34.9Al19.8Ni37.4Cu7.9.同时,利用式(1)、式(2)和式(3),直接计算了Zr-Al-Ni-Cu四元系各成分所对应的形成焓值(ΔHAmor)与焓差值(ΔHAmor-ΔHSol),以便与加权平均法所得结果进行对比.将所有的理论计算结果均与实验已确定能形成非晶合金的成分进行对比,所得ΔHAmor及ΔHAmor-ΔHSol与系统组分间的关系如图2所示.图中还标出了已实验确定能形成非晶合金的具体成分点,其中,a表示实验已确定的非晶形成组分[7~29],b表示利用式(3)计算所得的最低形成焓值组分,c表示Inoue的经典组分Zr55Al10Ni5Cu30[30],d表示Zr34.9Al19.8Ni37.4Cu7.9组分.显然,利用加权平均法所获得组分与Zr55Al10Ni5Cu30组分相差较远,但与式(3)计算所得的最低形成焓值组分相对一致.当然,Inoue的经典组分也并非系统的深共晶点成分. 图1 三元Zr-Al-Cu,Zr-Al-Ni,Zr-Ni-Cu和Al-Ni-Cu系的形成焓(kJ/mol)-成分曲线图2 四元Zr-Al-Ni-Cu系的形成焓(ΔHAmor,kJ/mol),焓差值(ΔHAmor-ΔHSol,kJ/mol)与实验确定的AFCR的对比为了验证计算结果的合理性,本文选取了成分Zr50Al15Ni10Cu25(记为A)与Zr34.9Al19.8Ni37.4Cu7.9(记为B)进行对比实验验证.以市售粒径为200目,纯度为99%的商业Zr,Al,Ni和Cu粉末为原料,按成分要求配料,在YXQM型行星式高能球磨机上进行机械合金化实验.实验所获粉末的X射线衍射图如图3所示,其中C代表成分A以前在不同球磨机上进行的实验的结果[31].随着球磨时间的延长,原来峰比较尖锐的元素Zr,Ni及ZrH2峰强度显著降低,逐渐转变为非晶态所对应馒头峰.虽然两个成分的样品均未能实现完全非晶化,但通过对比发现,可以完全非晶化的成分A相比于成分B,在相同的球磨条件下,成分B的非晶化效果显然要好于成分A.这也说明了利用Miedema模型及几何外推模型在预测系统的AFCR方面的合理性.同时,对于较为复杂的多元系统,我们可以采用相对较为简单的加权平均法来获取系统的最佳成分点,以减少计算工作量.由图3可知,在该球磨条件下,系统形成非晶的最佳球磨时间应在30~50h之间.图3 不同球磨时间下Zr50Al15Ni10Cu25与Zr34.9Al19.8Ni37.4Cu7.9粉末的XRD3 结果讨论Schwarz和Johnson[32]提出通过机械合金化形成非晶合金相的必要条件,即非晶合金中存在大的负混合热.基于Miedema理论,一般用下列两个判据来确定体系中非晶相的稳定性:Hamor<0和Hamor Hss<0 [33].大多数研究者倾向于应用后一个判据来确定体系的AFCR.通过与现有实验数据(图2A)相对比可发现,用前一判据所得并没有与现有的实验结果相一致,而根据计算结果,应将其修改为Hamor<24.20 kJ/mol才与实验结果较为吻合;而利用Hamor Hss<0判据所得(图2B),则可较好地反映已有的实验结果.机械合金化实验从一个侧面进一步验证了Miedema模型与Toop模型的组合可以成功地预测Zr-Al-Ni-Cu四元系的AFCR.通过模型计算,可以定量获得形成焓与系统组成间的分布关系,从而确定驱动固相扩散反应进行的成分区间,为非晶化反应提供必要的热力学条件.4 结论基于扩展的Miedema模型与几何外推模型,计算了Zr-Al-Ni-Cu四元系及其各成分间三元系的形成焓与系统组成间的分布关系.通过与现有的实验数据相对比,利用Hamor<24.20 kJ/mol或Hamor Hss<0可较为成功地预测四元Zr-Al-Ni-Cu合金的非晶形成范围.针对预测结果,进行了对应的机械合金化实验,实验结果也与理论预测相一致.这为后续寻求不同体系的非晶组成提供了一定的理论依据,可用于指导实验开展,节约人力物力,进一步提高探索效率.参考文献:[1]EGAMI T. Atomistic mechanism of bulk metallic glass formation[J]. Journal of Non-Crystalline Solids, 2003, 317(1-2): 30-33.[2]SCHWARZ R B, JOHNSON W L. Formation of an amorphous alloy by solid-state reaction of the pure polycrystalline metals[J]. Physical Review Letters, 1983, 51(5): 415-418.[3] MIEDEMA A R, CHATEL P F d, BOER F R d. Cohesion in alloys -fundamentals of a semi-empirical model[J]. Physica B+C, 1980, 100(1): 1-28.[4] 龙卧云,袁神佑,曹哥尽,等. 基于扩展Miedema模型预测Zr-Al-Cu合金的非晶形成范围[J]. 内江师范学院学报, 2009, 29(12): 19-22,26.[5] 黄福祥, 尹平, 李司山, 等. 计算合金热力学性质的Miedema理论[J]. 重庆理工大学学报(自然科学版), 2010, 24(1): 92-98.[6]LIDE D R. CRC handbook of chemistry and physics[M].89th ed.The Chemica l Rubber Company Press,2008.[7] CAI A H, XIONG X, LIU Y, et al. Design of new Zr-Al-Ni-Cu bulk metallic glasses[J]. Alloys Compd,2009,468(1-2):432-437.[8] 陈伟荣, 王英敏, 羌建兵, 等. Zr-Al-Ni-Cu块体非晶合金的成分设计与微结构表征[J]. 金属学报,2002, 38(4): 421-426.[9] 王鸿婧. ZrCuNiAl非晶合金成分设计与玻璃形成能力[J].金属功能材料,2011,18(1):1-5.[10] 王鸿婧. ZrCuNiAl块体非晶合金玻璃形成能力及力学行为研究[D].哈尔滨:哈尔滨工业大学, 2007.[11] MI S J, JIN K L. Crystallization behavior of Zr62Al8Ni13Cu17 metallic gl ass[J]. Arch Metall Mater, 2017, 62(2):1023-1026.[12] SUN Y J, QU D D, HUANG Y J, et al. Zr-Cu-Ni-Al bulk metallic glasses with superhigh glass-forming ability[J].Acta Materialia,2009,57(4):1290-1299.[13] ZHANG T, INOUE A, MASUMOTO T. Amorphous Zr-Al-TM (TM=Co,Ni,Cu) alloys with significant supercooled liquid region of over 100 K[J]. Mater Trans, JIM, 2007, 32(11): 1005-1010.[14] WU J, GROSDIDIER T, ALLAIN-BONASSO N,et al. On the mechanically induced crystallization of FCC phas es by mechanical milling in ZrAlNiCu bulk metallic glasses[J]. J Alloys Comp d, 2010, 504(S1):S264-S266.[15] YOKOYAMA Y, FUJITA K, YAVARI A R, et al. Malleable hypoeutectic Zr-Ni-Cu-Al bulk glassy alloys with tensile plastic elongation at room temperature[J]. Philos Mag Lett, 2009, 89(5):322-334.[16] ZHANG Y, PAN M X, ZHAO D Q, et al. Formation of Zr-based bulk metallic glasses from low purity of materials by yttrium additio n[J]. Mater Trans, JIM, 2000, 41(11):1410-1414.[17] WANG W H. The elastic properties, elastic models and elastic perspecti ves of metallic glasses[J]. Prog Mater Sci, 2012, 57(3):487-656.[18] 吴洁. Zr-Al-Ni-Cu块体非晶合金的成分优化 [D]. 大连:大连理工大学, 2004.[19] SPASSOV T, GYUROV S, STEFANOV G, et al. Thermo-mechanical study of bulk glass forming Zr-Cu-Ni-Al alloys[J]. J Non-Cryst Solids, 2016, 443:103-107.[20] 刘金民,袁晓光.冷却速度对ZrAlNiCu合金组织与力学性能的影响[J]. 特种铸造及有色合金, 2010, 30(10):883-886.[21] 宋旼,李杳奇,贺跃辉.三种ZrAlNiCu大块金属玻璃的力学性能[J].稀有金属材料与工程, 2011, 40(10):1836-1839.[22] YANG Y W, HUA N B, LI R, et al. High-zirconium bulk metallic glasses with high strength and large ductility enha ncement of plasticity in Zr-based bulk metallic glasses[J]. Sci China(G), 2013, 56(3): 540-544.[23] IQBAL M, AKHTER J I, ZHANG H F,et al.Effect of minor alloying on cryst allization behavior and thermal properties of Zr64.5Ni15.5Al11.5Cu8.5 bulk amorphous alloy [J]. J Mater Sci Technol, 2011, 27(6):534-538.[24] TAO P J, YANG Y Z, BAI X J. Vickers indentation tests in a Zr62.55Cu17. 55Ni9.9Al10 bulk amorphous alloy[J]. Mater Lett, 2010, 64(9):1102-1104.[25] ZHOU W, ZHANG C W, SHENG M Q, et al. Glass forming ability and co rrosion resistance of Zr-Cu-Ni-Al-Ag bulk metallic glass[J]. Metals,2016, 6(10):230.[26] LI Y H, ZHANG W, DONG C, et al.Effects of Ni addition on the glass-forming ability,mechanical properties and corrosion resistance of Zr-Cu-Al bulk metallic glasses[J]. Mater Sci Eng(A), 2011, 528(29):8551-8556. [27] KÖSTER U, MEINHARDT, ROOS S, et al. Formation of quasicrystals in b ulk glass forming Zr-Cu-Ni-Al alloys[J]. Mater Sci Eng(A),1996,1(2):25-30.[28] XING L Q, HUFNAGEL T C, ECKERT J, et al. Relation between short-range order and crystallization behavior in Zr-based amorphous alloys[J]. Appl Phys Lett, 2000, 77(13):1970-1972. [29] SUN Y J, QU D D, HUANG Y J, et al. Zr-Cu-Ni-Al bulk metallic glasses with superhigh glass-forming ability[J]. Acta Mater, 2009, 57(4):1290-1299.[30] INOUE A, ZHANG T. Fabrication of bulk glassy Zr55Al10Ni5Cu30 alloy of 30 mm in diameter by a suction casting method[J]. Materials Transactio ns, JIM, 1996, 37(2):185-187.[31] 龙卧云.机械合金化制备Zr-Al-Ni-Cu-Y非晶合金粉末及其低压烧结工艺探索[D].长沙:中南大学,2012.[32] 刘浏,贾兴旺,付勇,等.分子动力学模拟Ti-Al合金非晶的形成与晶化[J].西华大学学报(自然科学版), 2007, 26(3): 6-8.[33] SHINDO T, WASEDA Y, INOUE A. Prediction of glass-forming composition ranges in Zr-Ni-Al alloys[J]. Materials Transactions, JIM, 2002, 43(10): 2502-2508.。

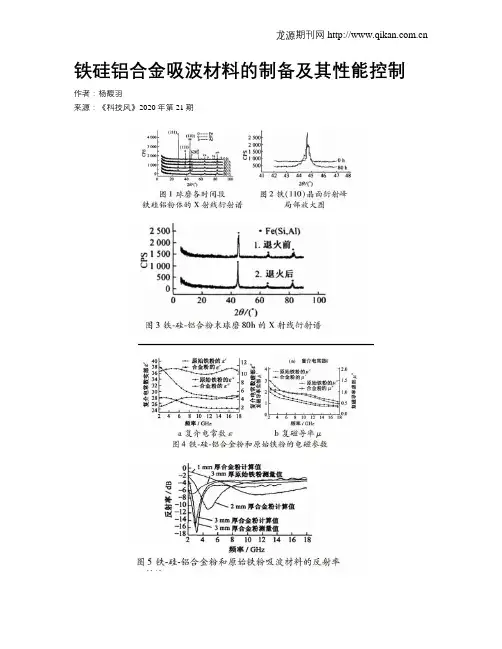

铁硅铝合金吸波材料的制备及其性能控制作者:杨馥羽来源:《科技风》2020年第21期摘要:由于电子技术的不断发展,大量电子设备如手机、电脑等的工作频率上升到了兆赫兹级,在为人民提供便利的同时,对人们的身体健康与环保等方面造成了不良影响。

为了能够处理电磁波造成的危害,世界各个国家投入了大量的人力、物力来开展这一方面的研究工作,在此其中,利用吸波材料来限制电磁波的辐射与干扰,获得了良好的效果。

文章针对铁硅铝合金吸波材料的制备以及对其性能的控制开展了相关研讨。

关键词:铁硅铝合金;吸波材料;制备;性能文章主要将高纯铁硅铝粉作为原料,使用机械合金化(MA)工艺制备出了铁硅铝合金粉。

利用XRD与矢量网络分析仪,对各种球磨次数下粉末的相组成和铁硅铝合金吸波材料在1—18GHz频率中的电磁性能开展了相关的研讨。

一、试样制备和实验方式(一)试样制备在实验中采取铁、硅、铝三种粉末作为原料,其纯度都高达99.5%以上,粒径均为48μm。

实验过程中,把铁粉、硅粉、铝粉根据质量比例85∶9.6∶5.4进行配料以后,添加到100mm的不锈钢球磨罐内。

不锈钢球和粉末的质量比例为20∶1,可对球磨罐进行真空处理,填充氲气进行保护。

合金化环节是在XQM22l型行星球磨机上开展的,其公转速度为225r·min-1,自转速度为360r·min-1。

在球磨的时候,间隔一段实际就去除少量粉末实行分析。

在球磨进行80h以后,把合金粉体与原始铁粉根据自身体积分数的43%和三元乙丙橡胶进行均匀混合,制备出外径为70mm、内径为3.04mm、厚度为3mm的同轴环形吸波材料样品。

(二)试验方式采用瑞士ARLXTRA x射线衍射仪(XRD)对粉末开展了物相分析,参数是铜靶x射线,管电压为40kV,管电流100mA;并且使用HP8722ET型矢量网络分析仪,按照透射/反射法对吸波材料的电磁的参数进行相关测量,并且使用同轴反射法测试吸波性能,扫描频率范围都是1~18GHz。

第21卷第3期贵州大学学报(自然科学版)V ol.21N o.3 2004年 8月Jour nal of Guizhou U niversit y(N atural Sciences)Aug.2004文章编号 1000-5269(2004)03-0255-03Mg Al二元系的机械合金化研究*郭德博,覃善华,欧阳义芳,钟夏平,吴伟明(广西大学物理学院,广西南宁 530004)摘 要 用X射线衍射和DSC对成分为Mg1-x Al x (x=0 1,0 4,0 6,0 8)的纯元素混合粉末的机械合金化过程进行了研究。

结果表明成分为Mg0 9Al0 1和Mg0 6Al0 4的混合粉末经球磨后都有Mg17Al12相生成;而球磨成分为M g0 4Al0 6的混合粉末,没有得到预想的Mg2Al3相,但经热处理后得到M g2Al3相;对于成分为M g0 2Al0 8的混合粉末经球磨后只得到固溶体结构。

关键词 机械合金化;铝镁合金;金属间化合物中图分类号 O641 文献标识码 A1 引言M g Al合金由于其高强度、低密度、易焊接等特点而备受关注。

Zhang等人[1]对M g1-x Al x(x=0 2, 0 4,0 6)进行了机械合金化,得到了 相和固溶体;Lu等人[2]对Al-37w t%M g机械合金化得到 相。

Bououdina等人[3]对Al10Mg90机械合金化得到 相。

而Singh等人[4]对含10~50at %M g的机械合金化则认为在很宽的成分范围内形成Al12Mg17。

本文对不同成分配比的M g1-x Al x(x=0 1,0 4,0 6,0 8)混合粉末进行机械合金化,系统地研究Mg Al系在球磨中合金化过程的特点。

2 实验方法将纯Mg粉(150m,99%)和纯Al粉(150m,99%)按原子比配成M g1-x Al x(x=0 1,0 4,0 6,0 8)的混合粉末,然后放入QM 1SP型行星式高能球磨机上进行球磨。

134材料导报2008年8月第22卷专辑Ⅺ纳米T i C粉末的制备研究李世鹏,刘志勇,周辽奇,刘忠侠,王明星(郑州大学物理工程学院材料物理教育部重点实验室,郑州450052)摘要分别以T i和T i O z粉为钛源,石墨为碳源,结合机械合金化及高温烧结制备出T i C微粉。

利用Ⅺm、SE M对T i C的成分和形貌进行了观察分析。

通过对比发现,以T i02作为钛源可得到纯度较高且粒度为纳米级的Ti C粉末。

球磨过程中原料粉末不断细化,有助于相互扩散并加速烧结过程中Ti C的生成。

关键词T i C纳米机械合金化烧结中图分类号:TB383文献标识码:AR es e ar ch on P r epa r a t i on of N anocr ys t al l i ne T i C Pow er sL I Shi peng,L I U Z hi yong,Z H O U L i aoqi,L I U Zhongxi a,W A N G M i ngxi ng(Physi c s D epar t m e nt,K ey Labor a t ory of M at er i a l s Phy si cs,M i ni st r y of E ducat i on,Z he ngzhou U ni ver si t y,Zhengz hou450052)A bs t ract Taki ng Ti a nd Ti02as t he t i t ani um s o ur c e r espec t i vel y,an d gr a phi t e as t he ca r bon sour ce,t he n an opow de r sof T i C ar e pr epa r e d by m echa ni ca l al l oy i ng and hi gh-t em per at ur e si nt er i ng.X RD and SE M ar e used t o ana l yze and obs er ve t he po w der s.I t i s f ound t hat t he na no-s i ze d T i C pow des i n hi ghe r pur i t y ca n be easi l y obt ai n ed w hen T i02i s t aken as t he t i t ani um so ur ce.D ur i n g t he bal l m i l l i ng pr oces s,t he par t icl e s i ze of r a w pow des i s de cr eas ed cont i n uous—l Y。

© 2008 Advanced Study Center Co. Ltd.Corresponding author: Galina G. Chernik, e-mail: galgeorg@yandex.ru MECHANICAL ALLOYING IN PLANETARY MILLS OFHIGH ACCELERATIONSMarco Hüller 1, Galina G. Chernik 2, Elena L. Fokina 2 and Nadezda I. Budim 21Corporate Research Centre Germany, EADS Deutschland GmbH, 81663 Munich, Germany2Institute of Chemistry, St. Petersburg State University, Universitetski pr. 26, Petrodvorets, 198504 St. Petersburg,RussiaReceived: March 29, 2008Abstract. Mechanical activation effects were studied for metal matrix composites (MMC). Plan-etary mills of high accelerations were applied in super-high energy milling with the aim of obtaining an Aluminium alloy AA6061 containing a finely dispersed hard phase of NiTi or Al 2O 3. During separate milling of the components it was possible to diminish the particle size and obtain a nar-row particle size distribution. The crystallite size attained for Al alloy can be as low as 40 nm. The time of milling in the planetary mills of 28 and 50 g accelerations is much lower than that in the milling devices of lower energy density. During the process of mechanical alloying in the planetary mill further reduction of the crystallite size took place, yielding nanoscale crystallite size for all components. A high degree of coverage of the reinforcement particles by aluminium was achieved.A sample of NiTi mechanically alloyed with AA6061 showed excellent matrix/particle interface and low porosity in the MMC powder. Fine dispersion of NiTi particles was obtained, and the reinforce-ment particles were well distributed in the matrix. The use of planetary mills of high accelerations can significantly accelerate mechanical alloying.1. INTRODUCTIONThe quest for new aluminium alloys of better per-formance has been in progress at least since the discovery of practical methods for producing alu-minium itself. Almost from the beginning, the use-fulness of such alloys in high performance aero-space structures was recognized, and research aimed at identifying alloys and processes produc-ing unique combinations of mechanical and physi-cal properties has been ongoing since that time [1]. In this work the following two approaches, us-ing mechanical activation, are investigated to im-prove the performance of commercially used Al alloys.1. Nanocrystalline materials with grain sizes of the order of 100 nm and below are known to be high-strength materials, with the yield strength ofabout an order of magnitude higher than that for their coarse-grained counterparts [2]. It has been shown recently that nanocrystalline metals and al-loys can be produced by mechanical treatment.This method introduces large deformations into the material and produces nanocrystalline structure by creating randomly orientated high-angle grain boundaries within conventional polycrystals [3]. Our motivation was to obtain nanocrystalline commer-cial Al alloys by ball milling without using liquid ni-trogen for cooling.2. Metal matrix composites possess the metal-lic properties of ductility, toughness and environ-mental resistance in combination with the ceramic properties of high strength and high modulus. The widely used commercial particulates generally have a size ranging from a few micrometers to several367Mechanical alloying in planetary mills of high accelerationsaFig. 1. Particle size distribution for Al alloy AA6061: a) initial; b) milled in Pulverisette 6 mill in Ar at 6.5 g for 4 h; c) milled in MPP-1 mill in air at 28 g for 30 min; d) milled in MPP-1-1 mill in Ar at 50 g for 20 min. hundred micrometers. Some investigations haveindicated that the strength of the composites tendsto increase with decreasing particulate size. There-fore nanometric particulates have attracted con-siderable attention for their special properties [4].High energy ball milling was successfully employedto fabricate metal matrix composites (MMCs) [5].Liquid phase processes result in the lower valuesof the mechanical properties because of bad wet-ting of the particles [6].It is known that planetary mills possess higherenergy density and provide stronger mechanicalimpact on materials than other milling devices.Planetary mills are characterized by higher pres-sure on particles and higher energy density thanattritors, vibro-mills, jet mills and disintegrators [7].Earlier only laboratory planetary mills were in use,and at present industrial planetary mills are com-mercially available [8]. Industrial planetary mills ofperiodic action characterized by acceleration of 20g (1 g is gravitational acceleration) and productiv-ity up to 20-40 kg/h are promising for applicationsin powder metallurgy. The aim of the present workwas to perform comminution and mechanical al-loying and study possibilities of the laboratory plan-etary mills of high accelerations having in mind thatscaling up of the processes is possible.368M. H üller, G. G. Chernik, E. L. Fokina and N. I. BudimFig. 2. Comparison of X-ray diffraction [111] maximum of Al alloy AA6061 samples - powder milled atacceleration 28 g for 90 min (a), powder milled for 40 min (b) and initial powder (c).2. EXPERIMENTAL MaterialsAluminium powder AA6061 was produced by intergas spray-atomization at ECKART-WERKE (Fürth, Germany). ASM specifications allow the following content of elements: Al – balance, Mg 0.8-1.2%, Si 0.4-0.8%, Cu 0.15-1.4%, Cr 0.04-0.35%, Fe 0.7%. The particle size of the initial pow-der was reported to be 50-100 µm. Al 2O 3 micro-powder, particle size 100-400 µm, was manufac-tured by Abler (Germany) and NiTi powder was supplied by NANOVAL (Berlin, Germany), Ni:Ti ratio = 50:50, particle size 45 - 350 mm.Milling conditionsMechanical milling was performed at the Corpo-rate Research Centre of the European Aeronautic Defence and Space Company (EADS) in the fol-lowing milling device: planetary ball mill Pulverisette 6 (Fritsch, Germany). The vial and the balls (10mm diameter) are made up of hardened steel. The ball-to-powder ratio was 5:1. A rotational speed of 250 rpm results in an acceleration of about 6.5 ling with the use of Pulverisette 6 planetary mill was accomplished inside an Ar filled glove box. To avoid temperatures >60 °C the process was stopped for 45 min after 15 min milling. Milling was performed for 1, 4, 8, 16, and 64 h.The possibilities of the planetary ball mills [8]produced by Technics and Technology of Disinte-gration Ltd. (TTD, Russia) were investigated. The planetary mills of periodic action (MPP) of this manufacturer are characterized by high accelera-tion of 25 g and higher [9]. Laboratory planetary mills MPP-1 (at acceleration 28 g) and MPP-1-1(acceleration 50 g) with steel jars and milling bod-ies were exploited. Milling experiments at high ac-celerations were performed at the TTD company.369Mechanical alloying in planetary mills of high accelerations Fig. 3. Dependence of the degree of amorphisation (a) and structural factor (dw ) calculated from X-raydata for AA6061 upon time of milling in air at acceleration 28 g.The technical specifications of MPP-1 mill are given in Table 1. The milling of NiTi was performed at 50g, with removing of the finest fraction and adding of the initial powder after 5 min milling. The total time of the milling experiments was 88 min for mill-ing in air and 160 min for milling in jars filled with argon. Al 2O 3 was milled in air at 50 g for 5 min.MethodsScanning electron microscope (SEM) observations were performed by means of JEOL JSM-6320F.X-ray diffraction analysis was performed at St.Petersburg State University using DRON 4 M (Burevestnik, Russia) X-ray diffractometer, Cu K αradiation, Ni filter. Emission spectroscopy analysis was done by means of a DFS-13 spectrophotom-eter (Russia) in order to estimate the contents of elements in the subject matter. TEM observations were carried out with a Philips CM20 microscope operated at 200 kV at the University of Erlangen.The determination of the particle size was carried out by means of laser diffraction using “Analysette 22” (Fritsch, Germany).3. RESULTS AND DISCUSSION Milling of Al alloy AA6061Milling of AA6061 in planetary mills of different ac-celerations was undertaken with the aim to dimin-ish the crystallite size. Particle size distribution for the initial and milled powders is reproduced in Fig.1. Milling at acceleration of 6.5 g induced particle growth because of strong cold welding tendencies (Fig. 1b). The particle size increased from 50 µm to about 1500 µm in the milling time of more than 4h. Particles milled for a duration longer than 4 h exhibited an almost spherical morphology. The average crystallite size was found to be less than 100 nm.After milling in TTD planetary mill MPP-1 at an acceleration of 28 g the diminishing of the particle size was achieved. The average particle size d 50observed after 30 min milling was 7.5 µm. The size distribution curve of a sample ground for 30 min was rather narrow (Fig. 1c). For that sample 10%of the particles had sizes less than 2 µm. Contami-nation as a result of grinding was rather small370M. Hüller, G. G. Chernik, E. L. Fokina and N. I. Budim PARAMETERS MODELMPP-1Number of jars 4Jar diameter, mm Changeable jars80, 100, 120, 150Jar height, mm 48Single jar volume, without lining, ml variable240; 370; 540; 850 Loaded batch volume per jar, ml variable40; 70; 100; 170Weight of the loaded material of density 3 g/cm3, g variable- per jar 120; 210; 300; 510- per all jars 480; 840; 1200; 2040Maximum particle size of feed material, mm 2Milling time, min- till 90% less than 10 µm5÷ 10- till 90% less than 1 µm20 ÷ 40Centrifugal factor, G (gravitational acceleration) Variable, up to 25Electric motor, asynchronic 3-phasicNominal power, kW 3.0Weight, kg130Dimensions, L x B x H, m 0.7 x 0.5 x 0.4Table 1. Technical specifications of MPP-1 planetary mill of periodic action (TTD, Russia) [13].(0.05% of Fe for 30 min milling), and the accept-able values of Fe content were not exceeded.The diminished height and broadening of the peaks in the X-ray diffraction data for Al alloy pow-der that was activated for 40 and 90 min at 28 g revealed a remarkably strong amorphisation of the structure (Fig. 2). The amorphisation degree (a), the size of the regions of coherent scattering (crys-tallite size) and the structural factor (dw) were cal-culated according to the technique described ear-lier [10]. The structural factor reflects the accumu-lation of various types of defects of the crystalline structure in the state that is pre-transitional to the X-ray-amorphous structure. The crystallite size re-duces to 38 nm after 90 min milling (T able 2). Both the amorphisation degree and the structural factor grow drastically with the milling duration (Fig. 3). The values of the crystallite size of ground AA6061 powder determined by electron microscopy were consistent with the data calculated from X-ray dif-fraction patterns.Summarizing these findings, in the TTD mill MPP-1, with an acceleration four times higher (28 g) than in the reference planetary ball mill, a smaller grain size of 38 nm was achieved almost 5 times faster. It has been made clear that the milling time for grain size refinement could be drastically re-duced when the acceleration of the mill is en-hanced.Al alloy AA6061 was milled in a TTD planetary mill MPP-1-1 at an acceleration of 50 g for 22.5 min (in 2.5 min increments) with metal balls in air and for 20 min in Ar atmosphere. The particle size distribution given in Fig. 1, d reveals significant amounts of small particles. The crystallite sizes for these samples were found to be 73 nm and 70-80 nm, respectively (Table 2). The alloy particles ex-hibited flake-like shape, which was found to be an advantage for further processing. The element content of AA6061 samples obtained by milling at an acceleration of 50 g showed that the content of Fe and Cr stayed within the limits defined by ASM specifications.Milling of reinforcementsNiTi powder was milled at an acceleration of 50 g in small increments, removing (-40) µm fraction and371Mechanical alloying in planetary mills of high accelerations Milling equipmentAcceleration, atmosphereTime of milling Crystallite sizeAA6061TTD planetary mill MPP-1 28 g, air 40 min 130 nm TTD planetary mill MPP-1 28 g, air 90 min 38 nmTTD planetary mill MPP-1-1 50 g, air 22.5 min 73 nmTTD planetary mill MPP-1-1 50 g, Ar 20 min 70-80 nm Fritsch planetary mill 6.5 g, Ar8 h<100 nmPulverisette 6AlAl - Attritor [11] liquid N 2 16 h 26 nm Al - SPEX 8000 [12]Ar24 h22 nmNiTiTTD planetary mill MPP-1-1 50 g, Ar160 min < 50 nmAl 2O 3TTD planetary mill MPP-1-150 g, air 5 min 100 nmTable 2. Crystallite size calculated from X-ray diffraction data for Al alloy AA6061 and reinforcements milled in planetary mills. Comparison with literature data for Al milled in attritor and in SPEX 8000 mill.Mechanical alloying Al crystallite Al 2O 3 crystallite Al 2O 3 coverage time, minsize, nm size, nm degree, %0 70 100 10 60 80 97 15508097.5Table 3. Crystallite sizes and coverage degree of reinforcement calculated from X-ray data for Al alloy AA6061 and Al 2O 3 mechanically alloyed at acceleration 28 g for 10 and 15 min.adding raw powder, in total for 88 min in air and another sample for 160 min in Ar. The crystallite size after milling for 160 min was found to be less than 50 nm. The particles were found to have flat shape. Al 2O 3 was milled at TTD at 50 g for 5 min with metal balls in air atmosphere, with 100 nm crystallite size obtained.4. PREPARATION OF METAL MATRIX COMPOSITES Al alloy AA6061/Al 2O 3 compositeAlloy AA6061 pre-milled at 50 g for 20 min and Al 2O 3 pre-milled in air at 50 g for 5 min were usedfor the preparation of metal matrix composite. Me-chanical alloying was performed in Ar atmosphere for the batch containing 10 vol.% Al 2O 3 at an accel-eration of 28 g during 5, 10, and 15 min. It can be seen from the X-ray diffraction pattern that peaks corresponding to Al 2O 3 have almost completely dis-appeared in the X-ray pattern for the AA6061/Al 2O 3composite (Fig. 4). These results indicate a high degree of coverage of Al 2O 3 particles by the Alu-minium alloy. Crystallite size values were calculated basing on the X-ray structural analysis results (see T able 2).As described above, the diminishing of the crys-tallite sizes of Al and Al 2O 3 takes place when they372M. H üller, G. G. Chernik, E. L. Fokina and N. I. BudimFig. 4. X-ray diffraction pattern for Al 2O 3 milled in air at 50 g for 5 min (curve 1) and composite AA6061/Al 2O 3 mechanically alloyed in Ar atmosphere at acceleration 28 g for 15 min (curve 2).are milled separately (at 50 g). Furthermore, dur-ing the process of mechanical alloying in the plan-etary mill at an acceleration of 28 g further reduc-tion of crystallite size is going on, as well as the encapsulation of Al 2O 3 particles with Al alloy. The coverage degree of Al 2O 3particles was determinedFig. 5. X-ray diffraction pattern for AA6061/NiTi composite (components pre-milled separately at accel-eration 50 g) mechanically alloyed in Ar at acceleration 28 g for 10 min.373Mechanical alloying in planetary mills of high accelerations Fig. 6. Image of AA6061+NiTi composite, with com-ponents pre-milled separately at 50 g, mechani-cally alloyed at 28 g for 15 min and additionally mechanically alloyed with initial AA6061 at 6.5 g for 4 h.according to E. L. Fokina’s technique based on the determination of the optical path depth of X-rays in various materials; the data are presented in Table 3. A high degree of coverage of the reinforcement particles by Aluminium (97.5 %) was observed.Al alloy AA6061/ NiTi compositeAluminium alloy AA6061 pre-milled at 50 g for 20min in Ar atmosphere and NiTi pre-milled at 50 g during 88 min were used. A batch containing 10vol.% NiTi was mechanically alloyed in the TTD planetary mill MPP-1 at 28 g during 5, 10 and 15min. In Fig. 5 a fragment of an X-ray pattern taken for the composite AA6061/NiTi mechanically al-loyed for 10 min is reproduced. A strong amorphization of NiTi can be observed. Both pow-ders show crystallite size in the nanoscale range.As a result of mechanical alloying at an accelera-tion of 28 g reinforcement particles are coated with Al alloy, which is beneficial for the good distribu-tion in the metal matrix.This pre-alloyed at 28 g for 15 min NiTi+AA6061powder was used for further mechanical alloying for 4 h with the initial AA6061 by means of conven-tional milling at low acceleration (Pulverisette 6,acceleration 6.5 g). It seems that the Al alloy coat-ing on the surface of the NiTi particles improved the adhesion of the initial AA6061 powder (Fig. 6).The micrographs show that the particle-matrix in-terface is very good irrespective of the size of the reinforcement particles. As the layers of the matrix material on the surface of the NiTi particles are rather thin, these particles could easily be distrib-uted in the initial AA6061 powder by a subsequent milling process. This indicates that pre-alloying at high accelerations activated the powders and pro-vided a second phase that could easily be intro-duced into the metal matrix.5. CONCLUSIONSThe influence of the centrifugal factor was studied for the process of metal matrix composite prepa-ration. The separate milling of the powders of the Aluminium alloy AA6061 and reinforcements NiTi and Al 2O 3 and the mechanical alloying of these components were performed in the planetary mills of different accelerations.It was demonstrated that during milling of Al alloy in the TTD planetary mill at an acceleration of 28 g for only 30 min it was possible to diminish particle size down to 8 mm and to obtain a narrow particle size distribution. The milling time in the planetarymill of 28 g acceleration is much lower than in mill-ing devices of lower energy density. The crystallite374M. Hüller, G. G. Chernik, E. L. Fokina and N. I. Budim size attained can be as low as 40 nm. The millingtime needed to achieve a crystallite size of the na-nometer scale in planetary mills of high accelera-tions is significantly lower compared to the valuesreported in the literature for milling in an attritor andin a SPEX mill (Table 2).The milling of Al alloy in the TTD planetary millof 50 g acceleration in Ar atmosphere resulted inobtaining a crystallite size in the nanoscale regionin only 20 min. The milling of reinforcement par-ticles of NiTi required 88-160 min; flat flake-likeshape of the particles was beneficial for embed-ding of the reinforcements in the metal matrix.The mechanical alloying of AA6061/NiTi andAA6061/Al2O3metal matrix composites (with pre-milled components) was performed in the planetary mill at 28 g for only 15 min. During the process of mechanical alloying the further reduction of crys-tallite size took place, yielding nanoscale crystal-lite size for all the components. The encapsulation of reinforcement particles with Al alloy was re-vealed. A high degree of coverage (97.5%) of the reinforcement particles by the Aluminium alloy was achieved. Subsequent mechanical alloying at low acceleration (6.5 g) for 4 h resulted in homoge-neous distribution of NiTi reinforcements in the matrix and in a good connection to the matrix.Thus, fast mechanical alloying at an accelera-tion of 28 g of the components activated at a higher acceleration provided metal-coated particles which could be easily distributed in the metal matrix by a subsequent milling process. Therefore, planetary mills of high accelerations can substantially reduce the time of production of nanocrystalline metal matrix composites. ACKNOWLEDGEMENTSThe grant of the 6th Framework Program NMP2-CT-2004-505885 is gratefully acknowledged. We are indebted to Dr. V.G. Kochnev and his co-work-ers at the TTD company (T echnics and Technol-ogy of Disintegration, Russia) for milling of the samples in the TTD planetary mills. REFERENCES[1] R. R. Sawtell and C.L. Jensen // MetallurgicalTransactions. A21A (1990) 421.[2] E. Hellstern, H.J. Fecht, Z. Fu and W.L.Johnson // J.Appl Phys.65 (1989) 305. [3] H.J. Fecht, E. Hellstern, Z. Fu and W.L.Johnson // Adv. Powder Metall. 1 (1989) 11.[4] Z.Y. Ma, Y.L. Li, Y. Liang, F. Zheng, J. Bi andS.C. Tjong // Mater. Sci.Engineering A 219(1996) 229.[5] M.S. El-Eskandarany // J. Alloys Compounds279 (1998) 263.[6] A. Malchere, M. Grosbras, D.L. Demenet,L. Bresson and E. Gaffet // Materials Science Forum225-227 (1996) 763.[7] M.V. Chaikina, Mechanochemistry of Naturaland Synthetic Apatites (Novosibirsk, 2002), In Russian.[8] V.G. Kochnev, Planetary mill, RU Patent1358990 (1992).[9] E.L. Fokina, N.I. Budim, V.G. Kochnev andG.G. Chernik // J. Mater. Sci.39 (2004) 5217.[10] A.N. Streletskii, V.I. Lapshin and E.L. Fokina// Kinetika i kataliz30 (1989) 1064, InRussian.[11] F. Zhou, J. Lee, S. Dallek and E.J. Lavernia// J. Mater. Res.16 (2001) 3451.[12] J. Eckert, J.C. Holzer, C.E. Krill and W.L.Johnson // Materials Science Forum88-90(1992) 505.[13] www.ttd.spb.ru。