丹麦Oreco公司的成品油罐自动清洗设备Moclean

- 格式:pdf

- 大小:188.25 KB

- 文档页数:2

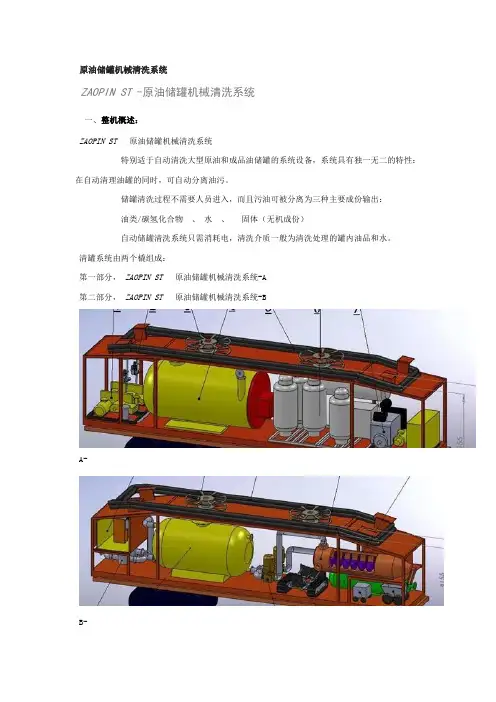

原油储罐机械清洗系统ZAOPIN ST -原油储罐机械清洗系统一、整机概述:ZAOPIN ST 原油储罐机械清洗系统特别适于自动清洗大型原油和成品油储罐的系统设备,系统具有独一无二的特性:在自动清理油罐的同时,可自动分离油污。

储罐清洗过程不需要人员进入,而且污油可被分离为三种主要成份输出:油类/碳氢化合物、水、固体(无机成份)自动储罐清洗系统只需消耗电,清洗介质一般为清洗处理的罐内油品和水。

清罐系统由两个橇组成:第一部分,ZAOPIN ST 原油储罐机械清洗系统-A第二部分,ZAOPIN ST 原油储罐机械清洗系统-BA-B-二、ZAOPIN ST原油储罐清洗系统的组成2.1 ZAOPIN ST原油储罐机械清洗系统-A(1)泵站单元采用柱塞泵作为主清洗泵两个柱塞泵单元组成2套独立运行的清洗系统,可以单独使用清洗5000-10000立方的小原油罐,也可以清洗50000-100000立方的大原油罐。

(2)可视清洗炮清洗炮按照ATEX 94/9/EG防爆设计。

适用于直径至60-80米原油储罐。

ZAOPIN ST公司压力喷射枪系统,通过自动化的工艺过程使用现代化的喷射枪替代以前的高风险和高体力和精神强度的人工清洗方式。

单个喷射枪是由一个喷嘴,1个摄像头和1个光源组成的单元,它从外侧装在油罐的清洗孔(人孔)上。

喷射枪可以水平和垂直180°旋转。

油罐内部由监控和报警系统连续监控,它可探测氧气,可燃和爆炸烟雾。

旋转驱动采用液压传动,高稳定性。

附件:3D人孔清洗器及执行杆专门适用于拱顶原油储罐的水清洗及原油槽车罐的清洗。

随车配置2台。

① 3D清洗器ZAOPIN ST公司3D压力喷射枪系统,通过自动化的工艺过程使用现代化的喷射枪替代以前的高风险和高体力和精神强度的人工清洗方式。

安装方式:从人孔安装。

一个3D喷头,实现全方位清洗。

执行器是安装在人孔内的一个执行杆,方便3D清洗器的作业和固定。

316不锈钢制作,带人孔封闭盘。

PALL CORPORATION操作维护 手 册PHCP100A汽轮机油净化机颇尔过滤器(北京)有限公司北京经济技术开发区宏达南路12号邮编:100176Tel: (010) 67802266 Fax: (010) 67802319前言此手册是本公司按照客户采购单的要求而制造的设备的安装、操作及保养指南。

在安装、操作及保养此设备之前,必须阅读此手册的有关内容。

此设备和选购部件将分别包装,并由客户装配。

拆开包装箱时,要细心谨慎,并按发货单核查所收到的部件。

此设备已按颇尔公司标准程序进行了试验和质量检验,而且也根据合同的要求进行必要的试验。

然而,在试验后,为便于运输,设备可能已打开或解体,并已将其放空和清洗等。

客户应检查并确保运输时,螺母、螺栓、软管或其它任何部件均未松动,必要时将其紧固。

铭牌已固定在设备上,如需要参数、服务或备件时,可查阅铭牌提供的信息。

用户有责任检查实际的操作条件,并确保过滤部件、滤芯、容器及密封材料与实际应用条件相匹配并符合地方安全法规。

手册编号版次日期MAN PHCP100A B 2006/3目录概述 3 选型 4 技术参数 5 报警条件 7 储存与安装 9储存9安装前检验9HCP与用户系统的连接10HCP与电源的连接12操作屏幕 14操作屏幕概述14主菜单15设备启动 19脱水循环19过滤循环20设备排空20维护 22日常维护22滤芯更换22故障诊断23附录 25备件清单25PALL图纸 HCP100AINST 共2张PALL图纸 H0473.E 共5张此设备是颇尔公司专为汽轮机油设计的过滤脱水系统,它集油液的精密过滤及高效脱水于一体,能有效清除油液中的颗粒及乳化水、游离水。

处理完成后油液清洁度可达NAS1638 6级,自由水含量可低于100 PPM。

本设备的功能包括:1.过滤循环:可单独作为颗粒过滤设备使用。

2.脱水循环:可去除汽轮机油中乳化水、游离水。

本设备具备如下特点:1.无人值守运行:经调试合格进入正常运行后,无须值守;2.故障自动报警:运行异常需维护时可自动报警并提示操作方法;3.遇险自动停机:运行中出现危急情况时可自动停机关闭系统;4.系统状态显示:设备操作屏幕可显示设备当前及历史操作数据;5.远程工况监视:预留设备状态信号远传接口,用户可根据需要连接。

油罐清洗作业操作规程1. 前言在石油化工生产中,油罐作为储存原油、成品油或液化气等化工产品的重要设备,常年处于使用状态。

如果油罐内部不进行定期清洗,将会存在长期积存且无法清洗干净的沉淀物和污渍,对生产安全和产品品质会带来不利影响。

因此,制定一份规范、科学的油罐清洗操作规程,对于保证生产安全、提高生产效率以及产品品质具有重要的意义。

2. 清洗前准备工作2.1 告知作业人员清洗前应当告知相关工作人员,并在油罐周围设置安全警戒标志,避免他人误入工作区域,避免发生意外事故。

2.2 准备清洗工具和设备清洗工具和设备的选择应当符合清洗对象的实际情况。

清洗设备主要包括高压清洗机、输送泵、管道等设备。

2.3 准备清洗液和助剂清洗液和助剂的选择应根据所清洗对象和腐蚀性质、沉淀物特点等实际情况,选择适宜的清洗剂进行。

2.4 提前进行安全检查在清洗前,必须做好检查工作,包括检查清洗设备状态、管路是否连通、电气设备是否完好等。

3. 操作规程3.1 清洗前准备在启动清洗设备之前,首先需要进行检查,确保清洗设备和安全防护设施处于正常工作状态。

3.2 加入清洗剂和助剂在清洗开始之前,应根据所清洗对象的实际情况,选择适宜的清洗剂,以及必要的助剂,倒入清洗机的储罐中。

3.3 连接输送管道清洗机输送管道的选择应根据实际情况进行选择。

连接之前应先进行套接管的安装,并对管道进行检测。

3.4 启动清洗设备将清洗设备进行启动,检查输送泵摆臂的摆动情况,并调整出水口进行操作。

3.5 清洗操作在进行清洗操作时,需要注意以下几点:•清洗时应保证清洗液的温度符合要求。

•在清洗时应及时更换管路泼嘴,并反复冲洗以达到清洗效果。

•在必要时,需要对留有残液区域进行反复冲洗,确保清洗彻底。

3.6 清洗后清理油罐清洗后,应及时将清洗设备和泵进行清洗,清洗后的垃圾需要分类处理,避免对环境影响。

4. 安全注意事项•操作时必须穿戴符合规定的个人防护用品,严格遵守操作规程和安全操作规程;•操作前必须经过安全培训并取得合格证书;•任何时候,都不能不戴安全帽、安全眼镜、手套、安全鞋等个人防护用品。

储油罐清洗方案储油罐清洗方案广州创蓝环保科技有限公司是一家专业的油罐清洁公司,专业从事油罐机械清洁服务和防腐业务,拥有一支专业性强的油罐清洁队伍作业人员无需进入灌内,用同种油清洗或自配的去油剂施工,作业安全清罐清洗时间短,没有污染,罐底沉淀物及废渣全部清除,经济效益显著几年来,清洗技术和服务水平始终走在市场前列,用一流的设备、一流的技术和一流的服务在市场上赢得了良好的商誉,也受到中国石油,中国石化两大集团公司的信赖发展空间越来越宽到目前为止,清洗公司已拥有从国外引进的具有先进水平的清罐设备3套,掌握国际清洗技术的工程技术人员10人,专业清洗技术工人数百名,为用户创造了巨大的经济效益我们的清洗服务不仅保证了石油储罐内部的清洁、完全满足更换油品标准,从成本上也为客户节约了大量的经费在安全的角度,我们做到无懈可击,全部防爆设备、防暴工具,作业人员必须要配备专业的防护用具,作业全过程对储罐保持强制通风和罐内气体的实时监测曾先后为中石油、中石化加油站、油库提供清洗服务,得到顾客的好评同时承接批量的油桶清洗业务,管道清洗及酸洗钝化业务1、储罐内外防腐无论地上地下的石油储罐,传统的防腐技术已经远远的落后于国外同期水平采用先进的防腐工艺,更能长效的保护储罐的金属本体,增加储罐的维修周期,延长储罐的使用寿命,同时也保证了油品品质的纯正和洁净,这一点对于汽油储罐尤为重要值得注意的是,发达国家油品储罐已经 % 的利用专门的防腐材料进行储罐内壁防腐处理,不仅保护了储罐金属内壁免受介质侵蚀,而且由于没有了金属锈蚀生成物的产生,保证了油品品质,我们竭诚为您提供各种介质储罐的防腐技术与服务2、专业储罐检测由于过去的储罐制造,安装技术层次不齐,在用储罐已经发现有很多内壁腐蚀严重、罐底板严重变形、储罐地基下陷等现象再加没有周期性的全面地储罐检测,对于现役储罐的安全状况没有准确地把握,这种安全隐患一旦发生,后果不可想象本公司与中国石化北京某权威无损检验机构常年合作,为广大用户提供储罐无损检验工作根据客户要求,由专职检验技术人员上门查看储罐,制定有针对性的检验各个储罐的方案,并实施,向您提供权威的检验报告让您准确把握每一个储罐的实际使用情况3、高压水射流清洗服务高压水射流清洗技术是利用经设备增压系统加压的水由喷头射出形成具有很高的冲击和剥削能力的高速水射流,可将内外壁上的结垢、金属氧化物和其他附着物清除,清洗质量好,无污染配备专用喷头,可使水生产多束、多角度、强度各异的高压水射流,对被清洗设备内结垢和附着物以及堵塞物进行彻底地切削、破碎、挤压、冲刷达到完全清洗的目的根据设备内壁结垢的性质和特点,配以相应的工业清洗剂,可使高压清洗效果更好现如今随着供需燃油体系的完善,风云唤起的燃油市场激烈竞争,随之而来的工业设备油罐问题有待于我们引起注意科学考证,加油站的所有储油罐经过一段时间的使用,因冷热温差的变化,冷凝水顺罐流入罐底,加快燃油的乳化,罐壁腐蚀,黑油泥会逐渐增加,影响油的质量,不仅使油质量下降,同时也影响了企业信誉和经济效益,还存在着储油罐许多不良的隐患,给车辆造成不应有的损失,因此储油罐必须定期定时做好清洗工作公司坚持以“诚信为本,服务为先”的宗旨,本着“质量第一,服务最好”的标准,对待每一个客户和每一件作业经我们清洗过的加油站,客户反映油质纯多了,因油质引起的燃油机故障减少了,同时加油站也大大增加了经济效益,引来更多的新客户一、总则:为了保证加油站油罐清洗工程施工安全和质量,防止意外事故发生,特制定本规范本规范适用于汽车加油站,汽车运输用轻质燃油和液化石油气容器的工程施工油罐清洗工程施工处应遵守本规范外,尚应符合国家现行有关标准和规范规定二、一般规定:1、施工人员必须具备本岗位的施工技能,并经安全知识培训和考核,合格后方可上岗工作2、施工人员必须了解或掌握施工过程中可能存在和产生的危险和有害因素,并能根据其危害性采取防范措施3、施工过程中所使用的各类工具,应满足施工现场防爆要求4、施工过程中所使用的各类设备、设施、应具有相应的防爆性能,并配备静电接地装置5、施工过程中所使用的各类设备、施设,应摆放在远离储罐的安全位置6、施工现场严禁烟火7、施工人员应穿戴防静电工作服、鞋帽、手套等8、施工人员严禁携带手机、香烟、火柴、打火机和金属物品进入现场 9、非施工人员严禁进入施工现场,如遇特殊情况必须要进入时,应停止施工 10、施工现场应配备专职的安全监督员和质量检查员三、施工前的准备1、为保证施工顺利进行,施工前应对施工现场进行详细的勘察,划分施工材料、施工设备及工具的摆放场地;了解是否具备充足的水源及安全可靠的电源,是否具备必要的消防设施2、施工前应对各类施工设备在施工现场以外的场地进行调试,达到使用状态3、被改造单位应在施工前24h停止营业,并抽空储罐内介质4、施工现场应采取安全隔离措施并设置明显的警示标志5、施工现场应按规定摆放消防器材四、拆卸人孔盖及管路1、施工工具应轻拿轻放,避免磕碰撞击;使用工具时不得用力过猛,防止工具滑脱2、拆卸完毕后,采用专用吊装工具将人孔盖吊出五、抽空罐内残液1、操作前应检查抽空设备,确保严格接地2、抽出的残液应盛装在专用的密闭容器内3、应避免抽出的残液洒落在场地上六、清洗1、清洗前应检查清洗设备,确保严格接地2、应确保罐壁各处得到充分清洗3、清洗完毕,应使用专用仪器测量罐内油气浓度,达到安全要求后方可进行下一步操作七、安装人孔盖1、采用专用吊装工具进行安装2、人孔盖法兰及各管路连接处的密封垫应重新制作并涂抹密封胶3、应保证个连接处的紧固件扭力均衡,防止泄露事故发生4、应确保各静电接地线及跨接线连接正确,不得有遗漏八、检查、测试和验收1、施工完成后,用户应按规定对各部位进行检查2、用户在第一次使用时,应检查各管路的连接处有无渗漏现象清洗标准1、清洗后的油罐要求达到无铁锈、无杂质、无水份、无油垢2、油罐清洗完毕后,应由双方负责人员共同对清罐工作质量进行验收,并签署验收报告3、验收合格后的油罐,应立即进行人孔封闭、管线连接,恢复至原始状态4、油罐清理作业结束后,应按规定彻底清理现场,并做好清罐记录切实做到安全施工、文明施工油罐使用中容易忽视的3点,油罐使用误区,油罐使用技巧面对油罐近来发生的一场场灾难,不得不引起我们的重视,油罐的安全操作已经成了刻不容缓的事情油罐很多操作不符合使用规定,这是导致油罐事故的一大原因所在油罐使用地点严禁在高压电线附近及其危险场所附近作业油罐保养汽油滤清器时,不提倡用汽油烧滤清器芯子有些司机朋友在保养汽油滤清器时,喜欢用汽油烧陶瓷滤芯的办法来清除滤芯上的杂质这样做容易引起失火,同时对于滤芯的使用寿命有影响油罐车在油库内,不许用短路划火的办法来检查蓄电池存电状况在通风不好的小油库内,往往还放置轮胎、蓄电池、篷布等器材,地面上还有洒落的汽油,划火时产生的火花很可能将空气中的油分子引燃油罐车发动机运转时或摇车时,严禁往化油器口倒汽油有些司机朋友为了提高缸内混合气的浓度向化油器内加注汽油,这样做虽然在发生油不进缸故障时有利于启动,而且这样做也可能造成回火,很危险无人进罐清洗设备→功能设备A、超高压自动桶罐清洗器这是一款专门为超高压清洗附着有顽固污垢的容器而设计的在高压水的驱动下,自动旋转,水射流的轨迹可形成完整的球面适用于清除油罐或箱体内的重型油脂、油污和油垢,也用于清除结焦、高温或烘烤后的聚合物和非常难以去除的乳胶残留物;同样适用于清洗反应釜、离析器、热交换器头,以及用于其它加工处理操作的无开口容器无需精确定位或移动即可彻底清洗!用于食品加工、饮料、化工、制药等行业的大罐和各类罐车清洗 B、行走伸缩自动清洗系这是早期我公司技术部自行研发设计并在工程操作中加以改进试用的一套清洗装置它是在大型罐体内利用伸缩链自由伸缩的特性,把高压水射流喷头安装其上,对被污染或需要清洗的罐体部位进行清洗但与自动清洗器相比,在水射流路线上没有很规范的目标性操作,所以需要配合红外射线摄像设备对内部的情况进行实时监测,以便达到更好的施工效果→其它外设为了配合无人进罐清洗系统,将和外置特种摄像头经过有线传输或无线蓝牙传输,和笔记本显示器AV-端口相连一则可以对清洗前欲清洗罐体进行拍照,以便与清洗后的效果对比;其二,对罐体内的少数死角部分进行侦测,以便补偿清洗从而在确保工程质量的同时也减少了人工进罐的次数,从某种意义上大大减少了人身安全方面的隐患清洗工程业绩展示典型工程:项目名称清洗工程描述立方米苯乙烯储罐6台同舟化工20立方米聚醚储罐5台长佶化工立方米树脂罐1台货品污染清罐清XX年8月化学清洗;高质量、高效率洗XX年6月化学清洗;高质量、高效率施工时间清洗方法,技术关键词广州市远洋船舶物立方米重油储罐 3台资供应有限公司建滔(番禺南沙)石立方米浓硫酸储罐化有限公司建滔(番禺南沙)石立方米重油储罐化有限公司米左右管线建滔(番禺南沙)石换热器及反应釜清洗化有限公司XX年5月化学清洗;高质量、高效率XX年9月化学清洗;高质量、高效率XX年10月化学清洗;高质量、高效率XX年11月高压水清洗节能、环保广州发展碧辟油品立方米,立方米,XX年4月有限公司立方米,立方米~XX年10月化学清洗;高质量、高效率广州宏昌塑料制品换热器及反应釜清洗有限公司高压水清洗;节能、环保化学清洗;高质量、高效率份有限公司清洗广东省生益科技服立方米新罐6台使用前的XX年5月XX年3月化学清洗;高质量、高效率增城市丽高雅涂料50立方米溶剂储罐12台有限公司广州本田汽车有限30立方米汽油储罐10台公司储罐清洗、储罐压力测试,焊缝抛光广州广船国际股份30立方米柴油储罐,1台,有限公司30立方米汽油储罐,1台储罐清洗,储罐压力测试东莞寮步大岭山裕25立方米汽油储罐,4台兴油站XX年7月化学清洗;高质量、高效率XX年9月化学清洗;高质量、高效率XX年10月化学清洗;高质量、高效率XX年3月化学清洗;高质量、高效率储罐清洗,管线清洗,压力测试东莞彩杨塑料制品立方米储罐,1台有限公司XX年3月化学清洗;高质量、高效率广州石化集团换热器清洗平方米 XX年5月高压水清洗,高效、安全、环保南沙建滔南沙建滔反应釜清洗 XX年6月高压水清洗,高效、安全、环保南沙建滔换热器清洗 XX年6月高压水清洗,高效、安全、建滔反应釜清洗 XX年11月化学清洗,高质理、高效率石化有限公司珠海华丰纸业有限纸浆塔清洗公司XX年12月化学清洗,高质量、高效率 2日至XX年x月x日 14日惠州惠菱番禺昶联炼油设备清洗XX年3月高压清洗,高效、安全、环10日至3月保, 29日XX年3月连续炉脱脂段清洗31日至年x月x日喷砂清洗,高效、安全、环保广州科力特柴油储罐清洗 XX年4月1化学清洗,高质量,高效率日至XX年x月x 日东莞玖龙纸业糊化装置清洗 XX年4月6化学清洗,高质理,高效率日藤顺化工聚胺酯反应釜清洗 XX年4月高压清洗,高效、安全、环16至XX年保 x月x日亨斯曼冷却水管道清洗 XX年5月1高压清洗,高效、安全、环日保珠海华丰纸业纸浆塔,管线清洗 XX年5月高压清洗,高效、安全、环21日至保年x月x日化学清洗,高质量、高效率亨斯曼蒸发器清洗 XX年6月1高压清洗,高效、安全、环日南沙建滔反应釜清洗 XX年6月9高压清洗,高效、安全、环日保珠海澳圣合成材料开车前清洗有限公司XX年3月化学清洗,高质量、高效率珠海华丰纸业广州科力特转产清洗船舱清洗XX年11月化学清洗,高质量、高效率 XX年1月化学清洗,高质量、高效率 XX年2月-高压清洗,高效、安全、环4月保中山色料有限反应釜清洗公司广东大鹏天然气有管道清洗米限公司佛山市三市顺通聚聚酯反应釜ΦX 酯切片有限公司上海方有实业有限传送带清洗公司中山多美化工厂管道设备清洗广东生益科技股份储罐及管道清洗有限公司XX年5月化学清洗,高质量、高效率XX年5月化学清洗,高质量、高效率XX年6月化学清洗,高质量、高效率XX年6月化学清洗,高质量、高效率 XX年6月化学清洗,高质量、高效率尊敬的客户:您好!现在将广州创蓝环保科技有限公司针对贵单位储油罐系统清洗简介书呈上,感谢您在百忙之中查阅本公司的简介书,更感谢贵处给本公司创造了“为您服务”的机会,如有进一步需求,随时至电本公司此致敬礼广州创蓝环保科技有限公司联系人:罗保明手机:传真:-。

A rounded approach to tank cleaning At Alfa Laval we take a panoramic view of tank cleaning. That’s to say rather than simply seeing it as a maintenance issue, experience has taught us tank cleaning holds far-reaching benefits for the entire production cycle. This know-how is clearly reflected in the cleaning machines and services we supply.Let’s face it, for most companies tank cleaning is a necessary evil, a constant hindrance to maximum throughput. However, at Alfa Laval we take a slightly different view.We believe tank cleaning has an important role to play in the drive for efficiency. You see we don’t look at tank cleaning in isolation, but rather as an integral link in the production line. By optimizing every stage of the cleaning process, it’s possible to have a significant impact on overall plant output.Our ability to dramatically streamline tank cleaning – and plant efficiency – hinges on two vital proprietary resources: cutting-edge cleaning heads and an unparalleled knowledge base. To be more explicit, an intimate knowledge of process engineering lets us assess customer needs and weigh up system variations quickly. Then our exhaustive range of cleaning heads and implementation expertise allows us to select and configure a suitable cleaning system in a cost-effective, timely manner.360º coverageIntegral to our broader view of tank cleaning are the cleaning machines themselves. Including our respected Toftejorg brand, we supply a complete range of rotary spray and jet cleaning heads as well as fixed spray heads.We also supply verification systems that let you electronically certify each stage of a CIP cycle has been carried out as expected. Rotary spray and jet heads are designedto make sure every square inch of a tank’sinternal surfaces are covered by detergentduring a cleaning cycle. The physicalimpact of cleaning media combined withthe rotary motion is highly effective inremoving residual material.As a result the heads have the obviouseffect of improving tank cleanliness.But their effectiveness also has a widerimpact on time and costs. Rotary cleaningheads significantly cut the amount oftime, chemicals, water and energy usedduring cleaning. This means the volumeof waste generated is reduced too. Allthis adds up to increased efficiency atlower cost, and the effect on throughputis often striking.In other words, when you invest in anautomated cleaning system from Alfa Laval,the impact is not only felt in your tanks,it resonates throughout your business.Toftejorg rotary jet headsclean tanks by castingjets of cleaning mediaagainst tank walls. Theflow of detergent throughthe head’s turbine andgears causes the nozzlesto perform rotationsaround the vertical andhorizontal axes, generat-ing a criss-cross spraypattern inside the tank.Benefits of rotary cleaning heads•Improved tank hygiene•Increased plant efficiency andreduced cleaning time•Considerable savings in water,energy and chemical consumption•Enhanced employee safety•Significant reduction in waste•Verification of cleaning processAlfa Laval Tank Equipment 3This background translates into meaning-ful benefits for our customers in that our cleaning heads display a profound under-standing of industry and regulatory needs, with many designed to cope with specific applications.Industry knowledge is also an invaluable guide in product development. We con-stantly refine and update our cleaning head range in response to customer feedback, changes in production techniques and new regulations.Here are some key benefits our Toftejorg cleaning heads hold for specific industries. Beyond the sectors covered here, our products also cater to many other process cleaning applications.Beverage applicationsOur T oftejorg range represents the cleaning benchmark for breweries, and the rotary cleaning machines streamline every stage of the process: from yeast propagation and fermentation to bright beer. A 30% saving in cleaning time and chemical con-sumption is quite normal when switching from conventional cleaning techniques to rotary jet heads.Our proprietary knowledge of the industry means we can optimize CIP performance for all types of brewery vessels extremely quickly. And for added peace of mind, a Rotacheck verification system lets you confirm that each stage of a CIP cycle is carried out as expected. All these benefits also hold true for the bev-erage industry at large, and rotary heads are ideal for streamlining cleaning opera-tions in the wine and soft drink sectors.Food applicationsOur cleaning machines for the food industry are designed to meet all manner of cleaning challenges common in food production, including the removal of burnt residue and biofilm, elimination of cross-contamination, and cleaning tanks and mixers with agitators or baffles. Our tech-nology complies with industry hygiene requirements, and many of the heads are self-cleaning and self-draining. In addition, products come in FDA-compliant materi-als, and adding a Rotacheck verification system lets you document that your tanks are being consistently cleaned to the required standards.Dairy applicationsConsistent with EHEDG design require-ments, our rotary heads can significantly improve tank cleanliness in dairies, while minimizing time, water and chemical con-sumption. The scrubbing action that rotaryWith over a century’sexperience of workingwith industrial compo-nents and processes,few companies matchAlfa Laval’s depth ofknowledge and range oftank cleaning products.An insider’s understanding of industry4 Alfa Laval Tank EquipmentAlfa Laval Tank Equipment 5technology delivers is ideal for removing stubborn residues such as fermented products, eg, yogurt or fresh cheese.Rotary heads heat up tanks faster during a CIP cycle, thereby reducing total turn-around time. For powder applications or where internal components or geometry complicate installing permanent cleaning machines, our self-actuated retractable systems represent an extremely effective and reliable solution.Pharmaceutical applicationsAs well as delivering highly effective tank cleaning, our machines for the pharma-ceutical sector are self-cleaning and self-draining and some have integrated self-cleaning down-pipes (patent pending).Using automated CIP systems severely reduces employee exposure to hazardous materials, and including a Rotacheck verification system lets you certify elec-tronically that tanks are being consistently cleaned to validated standards.Our sanitary product line conforms with the strictest guidelines laid down byindustry regulators (e.g. FDA, cGMP , ICH Q7A, EHEDG). As such we can provideall required documentation and data onToftejorg SaniMidget •Full coverage•Effective cleaning at low flow rate •Sanitary designToftejorg SaniMidget Retractor •Retractable•Suited to tanks with internal components •Self cleaning andself drainingToftejorg SaniJet 20•Totally self cleaning •Follows EHEDG guidelines•FDA compliant •High-impactcleaningToftejorg TJ 20G•360°impact cleaning and coverage•Award-winninghygienic design Toftejorg TZ-74•360°impact cleaning and coverage•Effective cleaningat low flow ratemachines, application analyses, or both.Product documentation includes surface roughness data, material traceability, FDA material conformance, factory test reports,manuals and validation support.Personal care applicationsThe complete coverage, rotary action and impact afforded by rotary jet heads makes them particularly effective in cleaning vis-cous, foaming or thixotropic products of the type commonly produced in the per-sonal care industry. The efficient removal of such residue also grants significant savings in terms of time and water consumption.8000 Series Spray Balls •3A compliant •Custom optionsincluding laser drilling •A variety of surfacefinishes including EPA scientific route to implementation, a human path to customer service Purchasing a tank cleaning system from Alfa Laval is also an investment in peace of mind. That’s because our wealth of experience in selecting, configuring and maintaining tank cleaning machines leaves nothing to chance.We’re quite aware tank cleaning isn’t the foremost thought in your mind. On the contrary, it’s probably something you’d rather forget in your daily life. Our senti-ments exactly.By taking the care and attention up front to ensure all equipment is correctly implemented, and by delivering responsive post-sales support, customers can spend their energy on issues other than tank cleaning. T o help in this endeavor, we have several unique resources at our disposal.TRAX®simulationOn each rotary jet head within a tank cleaning system, all variables are carefully selected and adjusted for best results. Then our proprietary TRAX®simulation soft-ware is used to recreate how a machine would perform in a customer’s tank. The simulation gives information on wetting intensity, pattern mesh width and cleaning jet velocity. Using this information it’s not only possible to determine an appropriate jet head and its placement, but also the correct combination of flow, time and pressure to implement in a CIP program.Test facilityCustomers have access to Alfa Laval’s world-class tank cleaning test facilities. Here it’s possible to recreate a huge variety of specific tank cleaning operations under carefully controlled conditions. The facility has two full-scale production tanks, each connected to a CIP unit. The test facility allows customers to compare the cleaning performance of different machines and multiple CIP programs under varying conditions of temperature and detergent concentration.Among other things, the test facility aids in determining suitable machines, the placement and configuration of each machine, and CIP program steps.Global customer supportOur tank cleaning machines are guaran-teed to deliver high performance and complete coverage. The same is true for our sales companies and global distribu-tion network. That’s to say our offices around the world are always ready to provide you with the parts, advice and service you may need at any time.Known as “Nonstop Performance”, our service commitment gives customers total confi-dence they won’t be left high and dry should a tank cleaning system fail.6 Alfa Laval Tank Equipment。

COW原油储罐机械清洗系统的主要优点烟台杰瑞集团大型COTWS 浮顶罐清洗系统简介COTWS(原油储油罐机械清洗)装置,本公司油罐清洗设备是基于多年来大型油罐的清洗经验,参考了日本、瑞士等国外设备改进装置.本装置从清洗油罐中回收油类,采用抽吸系统,通过将清洗所用主要机器实现组件化,不仅减少了临时设置作业,还使主要机器装置的集中管理成为可能,在丰富的实际操作和运行中发现和从结构上改进了国外设备许多的不足,使目前国际上在使用的比较先进的设备,同时我们还在不断的努力,常年跟踪维护改进我们客户的设备。

BJATL 储油罐机械清洗的优点:1. 缩短清洗期大容量罐含有大量沉积的淤渣,有些方法是利用人力,需6 个月至1 年清洗期。

这意味着长时间里无法使用油罐,存储设备的利用率很低。

因此要求无论油罐的大小和沉积物多少,清洗工程都应在短时期内完成。

2. 高效率清洗清洗法必须是具备信赖度和高效率且不受油罐大小,沉积物多少和其他因素影响。

3. 安全性掌握好工作中的安全性,这样应该可以避免因人为疏忽,和类似火灾和爆炸等灾难性因素带来的后果。

4. 资源再利用沉积物中有用的部分应该复原并作为资源再使用。

5. 复原油应完好地复原而不使其再腐化。

6. 减少大量沉积物的损失。

7. 环境保护。

8. 节省人力的机械化方法油罐中的工作是最脏和最危险的工作之一。

工作人员显然不愿意长时间在如此坏的环境里工作,火灾随时可能发生,此外在恶劣工作环境中容易因疲劳而造成工作效率低下。

应避免完全依赖人力的工作法,采用能最大限度减少油罐中肮脏工作量的方法,这意味着应该推进机械化和节省劳力。

9. 不受油罐位置影响的方法完成清洗工作可以不受蒸汽,电力,水,污水罐和废液处理设备等条件制约。

10. 经济性的方法清洗法应在各种投资方面是经济的,例如,公益费(蒸汽,水和电力),化学物质,沉积物处理,污水处理,还原油,复原油量,工作期,油罐使用停止期,机器,原材料和人力等方面的投资。

国产大型储油罐机械清洗设备的应用国产化大型储油罐机械清洗设备是北京华油惠博普科技有限公司和我公司联合研制开发的。

研制开发过程中,参考了日本和丹麦的同类设备,并结合了我公司多年施工积累的经验,充分考虑了我国油品的特性。

使设备具有适合我国油品“三高”性质的特点,从而也更适合国外油品。

该设备于2006年4月至11月间,先后在铁岭、大庆和任丘进行了现场试验,截止到现在已成功的清洗了6座原油储罐,其中10万m31座,5万m31座,1万m34座。

在清洗现场试验过程中,遇上了前所未有的来自油品、储罐结构和罐内淤积等方面的困难,但是设备运行良好,表现出了较高的能力,各项功能经受住了严峻的考验。

这标志着大型储油罐机械清洗设备国产化的成功。

该设备在日本大凤和丹麦宝罗同类设备的基础上有多处改进,经现场验收证明,多项性能优于同类设备。

结构紧凑,使用方便,抽吸能力增强,自动化程度、安全性和施工效率均有提高。

系统的组成系统由A、B、C三个撬块和相应的管路、管件、阀门、可燃气体监测系统等组成。

A撬是用于过滤、抽吸和升压的装置;B撬是用于清洗介质换热、离心泵冷却、系统配电、过滤和喷射装置旋转动力供给的装置;C撬是用于热水清洗阶段漂油、最终清洗用含油污水达标处理的装置;可燃气体监测系统是用于清洗施工过程中对罐内的可燃气体和氧气浓度进行不间断或即时监测的装置;管件、阀门等是用于清洗过程中的临时工艺管线的器材。

清洗工艺流程采用该系统对储油罐进行机械清洗时按下述工艺顺序进行。

换油搅拌→油移送→注入氮气→油洗油→残油回收移送→热水清洗→油水分离排放→通风换气→进罐最终处理换油搅拌边接受其他油罐所供给的清洗油,边用清洗机喷射被清洗罐内的淤渣,使淤渣溶解、分散,并将流动化了的淤渣移送到其他油罐。

逐步减少被清洗罐内的淤渣量,使浮顶支柱能够着底、淤渣量最大限度的减少后结束。

油移送浮顶支柱着底、淤渣量最少后,将被清洗油罐中有流动性的油,移送到其他油罐。

TECHNOLOGYCleaning Technology for beverage industriesCLEANING TECHNOLOGYAt the forefront of GEA Flow ComponentsAggressive robust cleaning, together with reliability and economic efficiency are key characteristics of the state-of-the-art cleaners in the GEA Flow Components range.GEA Flow ComponentsThe Flow Components portfolio comprises hygienic pumps, valves and Cleaning Technology. Our prod-ucts comply with the highest hygiene standards, such as EHEDG and 3-A.Our customers’ success depends on the quality and profitability of their products. That is why they rely on advanced technology and on our decades of experience in ensuring smooth processing of liquid products. Our sophisticated process compo-nents and service offers for everything that flows are available worldwide from the international GEA sales networkState-of-the-art Cleaning Technology, made to our customers’ preferencesAt the GEA Cleaning Technology Technical Center we develop innovative cleaning products and solu-tions together with our customers. Our decades of up close experience with operations and systems at our customers’ production sites ensure optimum selection and configuration of the tank cleaners for every application.Maximum efficiencyMultiple product types within the GEA Cleaning Technology range enable our customers to choose the correct style and performance to match their cleaning requirements. This enables the precise selection with a multitude of smart adaption options to achieve faster CIP operation, increasing produc-tion availability, and reduced consumption of valuable resources. Robust construction features of all our cleaners provide for exceptionally per-formance while delivering top-quality products to consumers.Maximum reliabilityOur customers rely on the safe, continuous opera-tion of their production systems without unplanned breaks or disturbances. That is why GEA cleaners are optimized for uncompromising reliability in all applications. Thanks to their robust design and long service life, they are known as “workhorses” for their ease of maintenance and outstanding ser-vice, proven over decades, and for the great number of cleaners currently in operation. Of course, GEA cleaner also comply with all relevant hygiene stan-dards and norms, with continuous documentation and up-to-date certifications safely ensuring judicial security.Always delivering performance. 2GEA Cleaning TechnologySOILINGCLASSIFICATIONSThe right solution –Soiling classifications determine the mechanical cleaning power required for effective vessel cleaning.Soiling Classification IWater-soluble products or products that have little or no adhesion to the vessel walls with a good sur-face finish.Soiling Classification IIWater-soluble solutions with low adhesion to the surface of the vessel.Soiling Classification IIIStubborn residues with a stronger adhesion to the vessel walls. Ideally the product is still wet and cleaning can be carried out before any drying takes place.Soiling Classification IVEncrusted or dry products with a higher adhesion to the vessel wall.Soiling Classification IVSoiling Classification III Soiling Classification IISoiling Classification I As a general guide, the higher the soiling classification the greater the mechanical clean-ing power that is necessary to achieve an acceptable andeconomical clean.3CLEANING TECHNOLOGY PORTFOLIOGEA Cleaning TechnologyWide model range of Cleaning Technology products. Optimisation to specific vessel requirements. Static CleanersThe cleaning of vessels withinsoiling classification I requires aliquid distribution which deliverslarge volumes of fluid simultane-ously over the complete vessel.Static spray balls offer very littlemechanical force so they rely onthe liquid running down the vesselwalls to create surface friction orto dissolve the residues.Free Rotating CleanersFree rotating cleaners are char-acterized by their fast rotationaround a single axis. This rotationis driven by the liquid flow whichcreates a range of small to me-dium-sized fast moving dropletsto produce a mechanical force onthe vessel walls.Spray ballsIS 25 RetractorTorus / ChemitorusTurbodisc / ChemidiscClipdisc4GEA Cleaning TechnologyGEA is a full-line supplier of premium cleaning solutions. Our range has a variety of models suited to different stages of the industrial process. We can outfit your entire application requirements with specialised cleaner types capable of cleaning your process vessels with care and precision. Optimising the use of water and chemicals to help you maintain the strictest hygienic criteria.Slow Rotating CleanersGEA’s slow rotating cleaners use targeted flat or round jets to project the cleaning solution onto the vessel walls. These units operate at higher liquid pressures than free rotating units but, because of their design, maintain slower rotation speeds. This enables these devices to impact greater cleaning forces onto the vessel walls than the free rotating units.Orbital CleanersThe extensive range of orbital and index cleaners from GEA offers high impact cleaning solutions for the most difficult to clean applications. The orbital cleaners work on two rotating axes, both horizontal and vertical, along a predetermined path creating a tight 3D matrix.Index CleanersThe extensive range of orbital and index cleaners from GEA offers high impact cleaning solutions for the most difficult to clean applications. The index cleaners provide highly effective cleaning performance through their piston operated index mechanism. The advantage of this type of cleaner is that large amounts of energy can be applied by this slow moving operation, directly onto the vessel walls.Tank Safety SystemThe tank safety system VARITOP ® is a modular system based on stan-dardized components. VARITOP ® is used for tank cleaning, to protect tanks against inadmissible over-pressure and vacuum and forcontrolled gassing and degassing. Every customer can select alter-native functional components. In addition, the configuration can be designed largely individually. The result is a functional unit adapted to customer desires.Turbo SSB Sanitor Troll Ball Rotating Jet Cleaner Cyclone / Twister Typhoon / Tempest / Tornado OC 200Fury 404Fury602 / TankmasterFury TWBVARITOP®Jumbo 65GEA AND THE BEVERAGE INDUSTRY 6GEA Cleaning TechnologyFor every conceivable cleaning applicationin beverage production, the full GEA cleanerrange gives you peace of mind and optimalcleaning capabilities.All over the world, our unique,hygienic cleaning solutions are installed in:BreweriesAll GEA cleaning technology cleaners are self cleaning which prevents contamination of the beer and ensures product characteristics are maintained.WineriesThis venerable tradition requires a high degree of environmental control with rigid hygiene standards: GEA hygienic cleaning solutions ensure the finished product lives up to its label.Juice productionOur wide range of cleaner catersfor the highly varying cleaningrequirements of juice manufacturers,maintaining the desired hygieniclevels and product integrity.DistilleriesHere the emphasis is on safe handlingin hazardous environments. In orderto meet the needs of this industry,we offer cleaners that comply with theATEX requirements.Soft drinksOur Cleaning in Place (CIP) andSterilization in Place (SIP) capablecleaners are ideal for maintaining thehygienic standards of the carbonizingprocesses in this industry. Residue invessels are reliably cleaned away intime for the next batch.7QUALITY PRODUCTS REQUIREQUALITY CLEANERSStandardisationClearly defined list of models with industry stan-dardised connections. GEA Cleaning Technology provides smart solutions for standard applications with uncompromising hygiene and quality. The GEA OC200 , for instance, offers a clearly defined list of interchangeable options to tailor the cleaning performance.CustomisationCustomised to perform. With the GEA OC200, you always get a perfect match to your needs. The OC200 offers a choice of numerous connections, rotors, sealing materials, nozzle carriers and nozzle sizes. One cleaner many options.Quality materialsOnly the highest grades of stainless steel are used to ensure reliability. Machined to the highest stan-dard and quality checked before assemble. That’s why all GEA Cleaning Technology products provide a robust, homogenous and pore-free surface. These surfaces can then be electropolished – which means a completely smooth surface down to the molecular level.Unique modular designThe modular concept of the OC200 allows the performance of the cleaner to be adjusted using a number of standard key components that can tailor the performance to suit the individual application. This allows you to optimise the use of valued resources such as water, chemical, energy and time-ensuringsustainability of supply for future generations.8GEA Cleaning TechnologyIn such a diverse and competitive industry the selection of cleaners directly contribute to the quality of your product. GEA Cleaning Technology does this simply by providing reliable and repeatable cleaning of tanks and production vessels protecting product quality and brand image. And this is why:1 I nterchangeable rotors and stators for rotational speed control2 S election of nozzle diameters and length3 D ifferent nozzle carriers for 2, 3 &4 nozzle options2139CLEANER & PUMP FIELDS OF APPLICATIONProcedure in a brewery A Malt B Water C MashD Lauter wortE Hopping rateF Hot wortG Wort H Yeast I Sterile airJ Process water K CO 21 Malt silo2 Malt cleaning3 Scale4 Malt-mill5 Grist case6 Mash pan7 P roduct pump (centrifugal pump)8 Lauter tun 9 Wort kettle 10 Heat recovery 11 Whirlpool 12Wort cooler10GEA Cleaning Technology13 Yeast tanks14 Fermenting tanks 15P roduct pump(rotary lobe pump)16 Yeast dosage17 Wort aeration18 Green beer cooling 19 Beer cooling20 Filter21 Stabilizer22 Storage tanks23 Yeast production24 Yeast beer cooling25 Deaerator26 Cooling27 Blender28 Carbonizer29 Pressure tank30 Bottling31 Keg filling32 Orbital cleaner33 Rotating jet cleaner34 Slow rotating cleaner35 Index cleanerPleaseNote:Cleanerselectionwilldependonvesselsizeandsoilingclassification.11CLEANING TECHNOLOGY THAT SAFEGUARDS YOUR PRODUCTIn a competitive industry you need premium cleaners that safeguard the quality of your product. GEA hygienic cleaners are manufactured and certified to the highest industry standards. With our solutions, you know your product’s integrity is guaranteed and its level of quality reproduced every time. In bever-age industries all vessels are cleaned reliable. Our cleaners are designed for quick and effective CIP (Cleaning In Place) applications so reducing the chance of residue tainting the next batch. And like all GEA Cleaning Technology products our sanitary solutions are designed to be highly user-friendly.CIPAll GEA Cleaning Technology products have been designed and developed to be compatible with all standard CIP detergents and solutions. We do offer alternative materials where special process solutions are required.Applications large and smallWe at GEA have products to cater for all requirements from the smallest of process vessels to the largest storage vessels. Our experts are always on hand to assist you in assessing the application where size and soiling classification is vitally important.12GEA Cleaning Technology13。

油罐清洗流程Tank cleaning process:1. Liquid drainage: Before cleaning the tank, all the liquid must be drained out. This requires workers to fully understand the structure of the pipeline system and tank to avoid safety issues caused by residual liquid.2. Ultrasonic inspection of the tank: Ultrasonic inspection can accurately measure the wall thickness inside and outside the tank.3. Preparation of cleaning solution: According to the type of tank, type, quantity and hardness of dirt, the concentration of cleaning chemicals should be reasonably configured. These chemicals may include cleaning agents, acid cleaning agents, alkali cleaning agents and enhancers.4. Dust suction and sediment removal: After draining the liquid, dust suction is carried out to clean up debris and sediments on the tank bottom and wall surface, ensuring that the inside of the tank is clean and tidy.5. Start cleaning: Steam cleaning is one of the commonly used cleaning methods. The high temperature and pressure of steam can effectively clean the tank. Steam is sprayed onto the inner wall and floor of the tank to loosen the dirt.6. Inspection after cleaning: After cleaning, the tank should be inspected again to ensure that all dirt and sediments have been removed, and the inside of the tank is clean and tidy.In addition, according to the actual situation of the tank and the cleaning requirements, dry cleaning or chemical cleaning can also be selected. Dry cleaning mainly uses sawdust and other materials for dry cleaning, while chemical cleaning uses chemical cleaning agents such as acid cleaning agents. Regardless of which method is chosen, safety requirements and procedures must be strictly followed to ensure the safety and effectiveness of the cleaning process.油罐清洗流程:1. 排放液体:在清洗油罐之前,必须将所有液体排放出来。

Oreco’s MoClean® system Automated cleaning of oil product tanks

Automated cleaning of tanks

for oil products and petrochemicals

The MoClean® system is a mobile, fully integrated process system offering internal cleaning of tanks for oil products like gasoline, diesel oil, kerosene, chemicals and petrochemicals. The system is auto-mated meaning that there is no need for humans to enter tanks during the cleaning process.

A versatile solution

Today, service providers most often use high-pres-sure jetting equipment and simple manual sludge removing procedures to clean tanks. If the entire inner surface has to be thoroughly cleaned, scaf-folding must be erected. Consequently, the tank may be out of operation for weeks at a time. Now the Oreco MoClean® system has combined tradi-tional vacuum truck facilities with tank cleaning and separation processes, delivering an entirely new, mobile solution to tank cleaning.

The answer to escalating pressure

While MoClean® answers the need for faster, better cleaning of tanks, our engineers also has taken into account the demands presently being formulated by authorities around the world for less hydrocar-bon emission and less or no involvement of person-nel inside the tank during cleaning. At the same time, MoClean® enables more frequent inspection of the tanks – warding off another fast-approaching problem for tank farm managers.

Easy operation

The MoClean® system is an advanced, highly effec-tive mobile tank cleaning solution for oil product

tanks. No personnel needs to enter the tank during

Oreco’s MoClean ® system

Automated cleaning of oil product tanks

Moclean-process-uk-0512© Copyright Oreco A/S. All rights reserved.

The MoClean ® system is a non-man entry tank cleaning system for oil product tanks combining

ef fi cient and fast tank cleaning with simultaneously recovery of valuable hydrocarbons.

cleaning and thanks to the user-friendly design of

the truck, it is possible for only one person to oper-ate the cleaning process within few hours. Effective cleaning process The process is very simple. As seen in the diagram below, one or more specially designed tank clean-

ing nozzles are installed via openings in the tank to be cleaned. Once connected to the MoClean ® truck, the cleaned-out sludge is separated so that the cleaning liquid can be re-circulated back into the tank through the nozzles. This enables more sludge to be fl uidised and pumped out for separation. Once the tank is emptied of sludge, it may undergo a last hot-water wash.After ventilation, the tank is now opened for in-

spection and is ready for hot-work if needed.

Safe operation During the cleaning process, the tank’s atmos-pheric condition is constantly monitored to ensure that the overall operation remains within speci fi ed safety limits. The entire process is carefully moni-

tored, to comply with the strictest international

safety regulations.

Unique technology

The tank cleaning nozzles are a key element in

the cleaning process. They ensure that all internal

surfaces on the bottom, walls and roof are cleaned, thus optimising the cleaning result. The nozzles produce far-reaching, low pressure, high-impact rotating jets, which provide ef fi cient cleaning of all internal surfaces in a precise indexed pattern, making use of re-circulated cleaning liquid. Tank cleaning nozzles operating at low pressures have proved far more ef fi cient in terms of time and water usage compared with traditional high pres-sure methods.。